Romac Industries RG-PVC Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

3

5

7

6

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the restrainer to ensure you have the proper size.

Style RG-PVC Mechanical Joint Retainer

FOR PVC PIPE 3" - 12" DO NOT USE ON HDPE, DUCTILE IRON OR STEEL PIPE.

Document #5-9-0009 05/06/2009

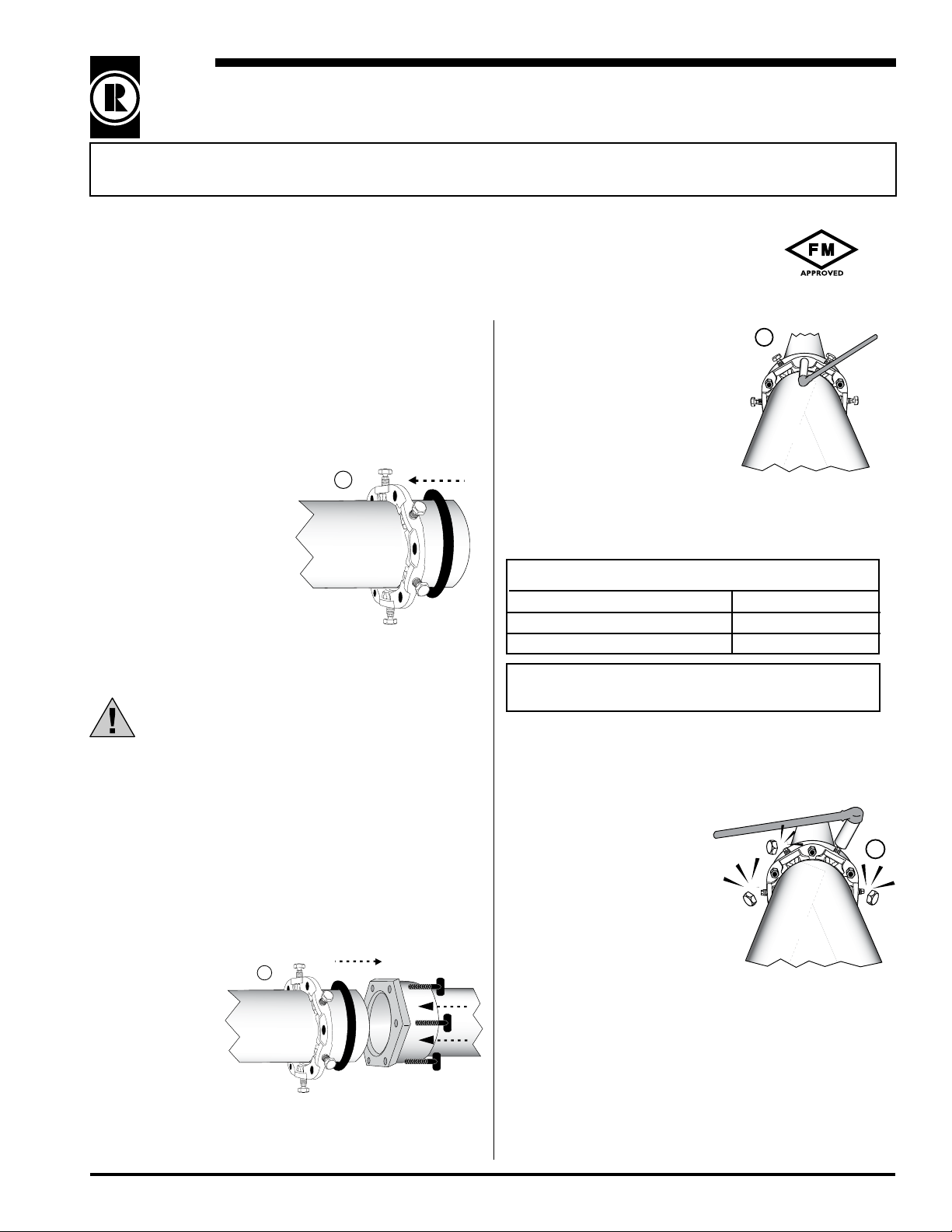

Step 1 • Identify the pipe. The RG-PVC is for use with

C-900 and IPS PVC pipe. Check the compatibility chart on

the back to make sure the pipe you are using is listed.

Step 2 • Check the parts to insure that no damage has

occurred in transit and that no parts are missing.

Step 3 • Clean and lubricate the pipe end and gasket

with soapy water or other

approved pipe lubricant per

ANSI/AWWA C111/A21.11.

Place the RG-PVC on the

pipe with the nose extension

towards the plain end. Place

the gasket over the pipe so

the at side is toward the

RG-PVC.

Note: Make sure the correct gasket is being

used. The Romac DI/IPS combination gasket can

be used on both C-900 and IPS pipe.

A standard MJ gasket can be used on C-900 pipe

and an MJ x IPS transition gasket on IPS pipe

.

Step 4 • Insert the pipe into the mechanical joint tting

and press the gasket rmly into the gasket recess. Keep the

joint straight during assembly.

Step 5 • Slide the gland toward the joint until the nose

of the gland touches the gasket. Insert the T-bolts and hand

tighten the nuts.

Make any deecti on after hand

tightening the Tbolt nuts but before

tightening them to

the proper torque

specications (5º

maximum).

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

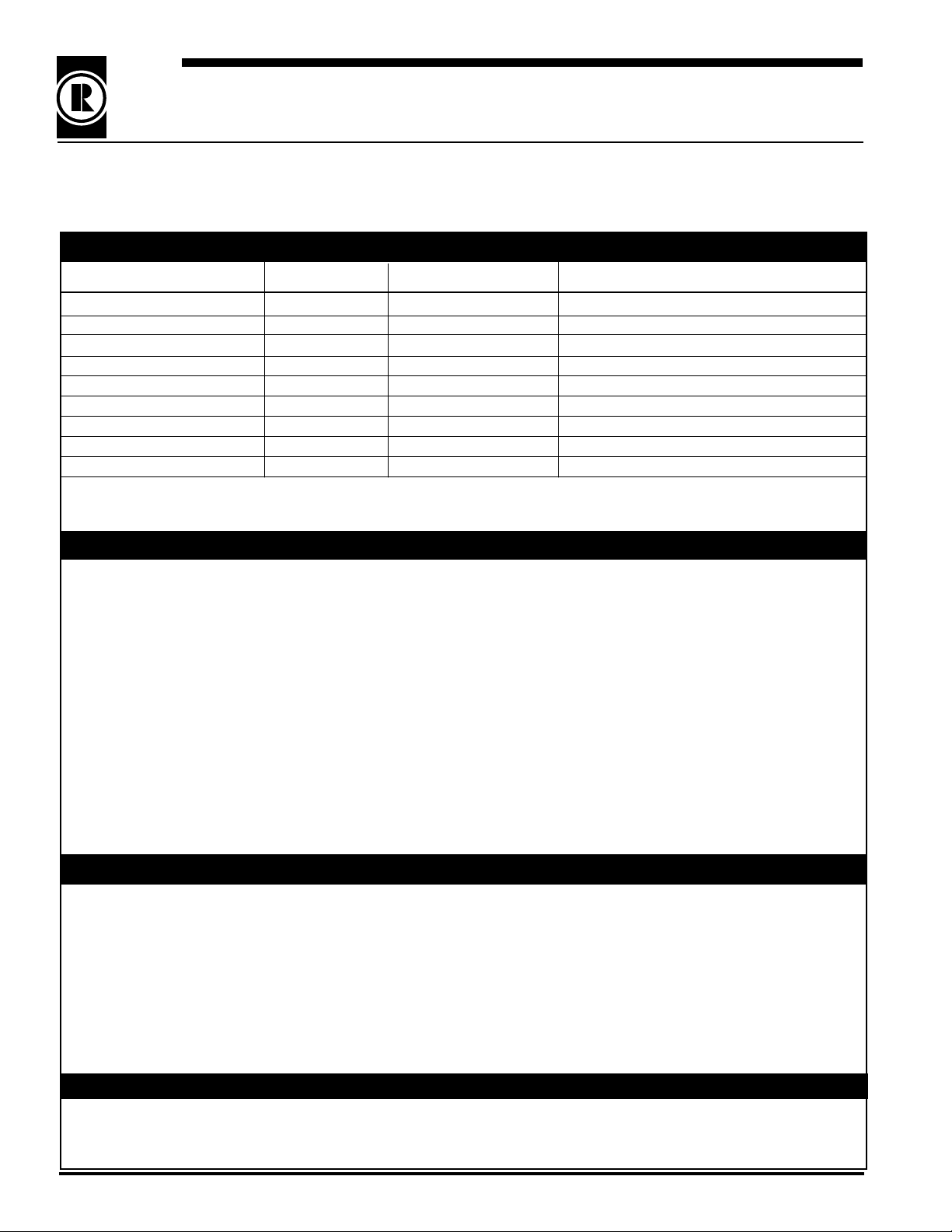

Step 6 • Tighten T-bolts

to the torque recommended

in AWWA C111. Maintain the

same overall gap between the

RG-PVC and the MJ bell face

by tightening the T-bolts in a

uniform criss-cross pattern (12

o’clock, 6 o’clock, 3 o’clock,

9 o’clock) until proper torque

is achieved. Using a torque

wrench is highly recommended. For best results, wait 10

minutes and retighten bolts to proper torque.

RECOMMENDED TORQUE FOR T-BOLTS

3" RG-PVC 45 - 65 ft-lbs.

4 - 12" RG-PVC 75 - 90 ft-lbs.

Thin Wall PVC 40 - 50 ft-lbs.

Note:

90 ft-lbs. torque = 12" wrench w/90 lbs. force

Step 7 • Tighten the restraining bolts until all the lugs just

touch the pipe. Then, tighten each bolt, alternating between

bolts in a uniform criss-cross

pattern until the heads break

off.

Note: On thin wall D.I. size

PVC pipe such as C909,

Class 100 C900 and IPS

PVC less than Class 160,

torque the restraining bolts

to 30-40 ft-lbs. (In this case,

the torque off bolts may not

break off.)

Step 8 • Pressure test for leaks before backlling.

Note: In the event you need to remove the RG-PVC

restrainer, be sure the pipe is not pressurized. To loosen

the restraining bolts, use a 5/8” hex wrench or socket.

To reassemble, follow the above procedure and tighten the

restraining bolts using a 5/8" wrench to 30 - 40 ft-lbs.

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

Style RG-PVC Mechanical Joint Retainer

FOR PVC PIPE 3" - 12" DO NOT USE ON HDPE, DUCTILE IRON OR STEEL PIPE.

RG for PVC PIPE MATERIAL COMPATIBILITY CHART

Pipe Material Pipe Size Working Pressure Comments

PVC - D.I. Size (C900) 4" - 12" Rating of pipe All Classes

PVC - “Class Pipe” (IPS Size) 3" - 12" Rating of pipe ASTM D 2241. Class 160 & 200

PVC - Sched. 40 & 80 3" - 12" Rating of pipe ASTM D 1785

PVC - D.I. Size (C909) 4" - 12" Rating of pipe AWWA C909 DI size

Ductile Iron - - RG-PVC not for use on ductile iron

Steel - - RG-PVC not for use on steel

Asbestos Cement - - RG-PVC

Fiberglass - - RG-PVC not for use on berglass

HDPE - - RG-PVC not for use on HDPE

May be used on thin wall DI size PVC such as C909, Class 100 C900 and IPS PVC less than Class 160 with special torque requirements, see Steps 6 & 7.

NOTE: Angular deection of up to 5º is allowable between the pipe and tting for RG-PVC sizes 3"-12".

PRECAUTIONS

1. Make sure the correct gasket is being used. The Romac DI/IPS combination gasket can be used on both C-900 and IPS pipe.

A standard MJ gasket can be used on C-900 pipe and an MJ x IPS transition gasket on IPS pipe.

2. Check diameter of pipe to make sure you are using the correct size RomaGrip; also check gasket to make sure it is the size you think it is.

3. Be sure to clean pipe of as much dirt and corrosion as possible in the area that the gasket will seal.

4. Lubrication both the gasket and the pipe end with soapy water or approved pipe lubricant per ANSI/AWWA C111/A21.11.

5. Make sure no foreign materials lodge between gasket and pipe.

6. Avoid loose tting wrenches, or wrenches too short to achieve proper torque.

7. Keep threads free of foreign material to allow proper tightening.

8. Take extra care to follow proper bolt tightening procedures and torque recommendations. Bolts are often not tightened enough when a

torque wrench is not used.

9. Be sure that the RG-PVC is centered around the pipe.

10. Pressure test for leaks before backlling.

11. Backll and compact carefully around pipe and ttings.

not for use on asbestos cement

COMMON INSTALLATION PROBLEMS

1. T-Bolts are not tightened to the proper torque.

2. Rocks or debris between pipe and gasket.

3. Dirt or debris between pipe and restraining pad.

4. Dirt on threads of bolts or nuts.

5. Not enough pipe inserted into bell.

6. Not using a Romac DI/IPS combination gasket or MJ x IPS transition gasket when using the RG-PVC on IPS size PVC pipe.

7. Using the RG-PVC on IPS PVC pipe with wall thickness thinner than Schedule 40 PVC pipe.

8. Using the RG-PVC on the wrong pipe.

IF RESTRAINER MUST BE REMOVED Rocks or debris between pipe and gasket.

1. Make sure pipe is not pressurized. Removing the restrainer could cause the pipe joint to separate.

2. To remove the RG-PVC use a 5/8" hex wrench or socket.

3. To reassemble, follow installation procedures and tighten the restraining bolts using a 5/8" hex wrench to 30-40 ft-lbs.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...