Romac Industries GripRing Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

R

R

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the restrainer to ensure you have the proper size.

™

4"-12" GripRing

Pipe Restrainer

Patent #5335946

Not for use on polyethylene pipe, steel pipe, plain end

mechanical joint ttings, Molecularly Oriented Polyvinylchloride (PVCO) AWWA C909-02. See pipe material

compatibility chart for details.

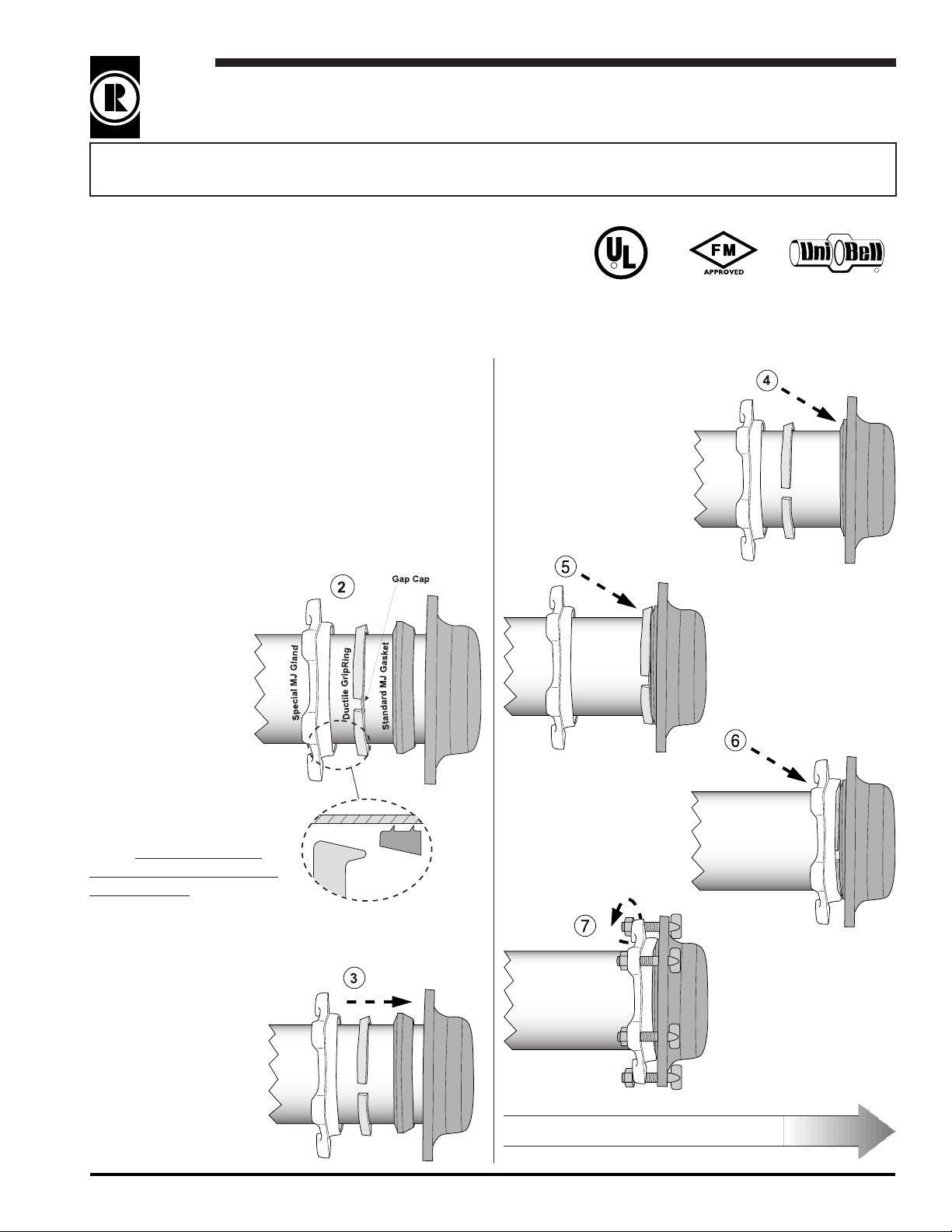

Step 1 • Clean pipe to remove as much dirt, coating,

and corrosion as possible from the surface. (Asphaltic

coating common to DI pipe does not have to be removed).

Check diameter of pipe to make sure you are using the correctly sized GripRing. Coat both the gasket and plain pipe

end with approved lubricant.

Step 2 • Slide the

gland, GripRing, and MJ

gasket onto pipe end.

The GripRing should

slide easily along

the pipe. It can be

sprung open slightly

if needed, to facilitate

moving it into position.

UNI-B-13-92

Step 4 • Slide the gasket into

the MJ bell pocket as far as

possible. The gland (and

GripRing) may be used to

tap the gasket into place if

required. In rare circumstances a hammer may

be required to seat the

gasket properly.

Step 5 • Slide the

GripRing up the pipe until

its face is against the MJ

gasket.

Document #05-9-0010 01/19/2010

Step 6 • Slide the gland

up the pipe until it engages

the GripRing.

Note: Make sure that the

tapered side of the GripRing

faces the gland. This is very

important, since the GripRing taper

engages the taper in the gland. 10 & 12" GripRings have a

Gap Cap.

Step 7 • Install T-bolts

in the MJ tting and gland.

Tighten hand tight.

Step 3 • Insert the

pipe end into the MJ

tting.

Installation Instructions continued on back

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

™

4" - 12" GripRing

(continued from front)

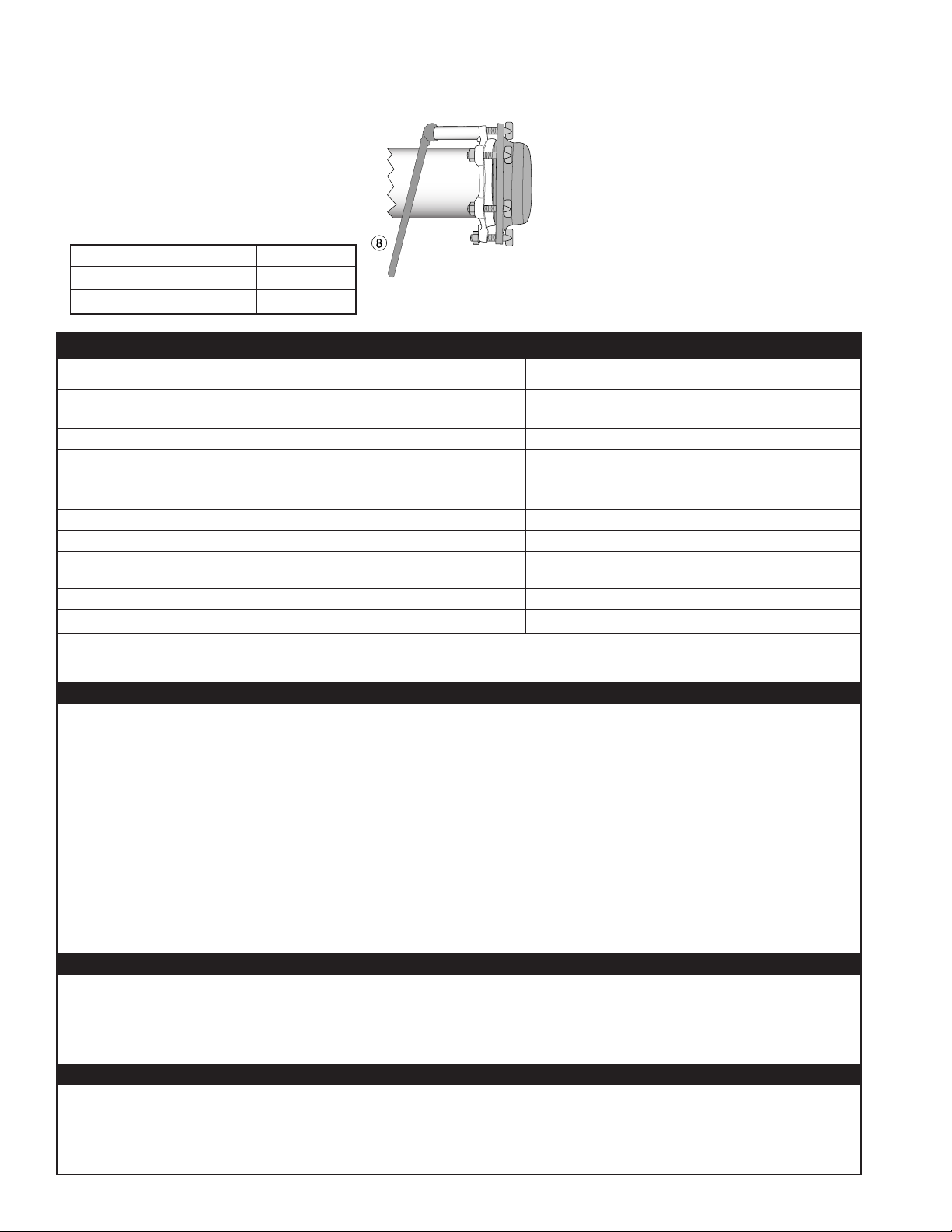

Step 8 • Using a torque wrench, tighten the

nuts to the proper torque shown on torque chart

(below). Care must be taken to assure that the

anges of the gland and MJ tting remain parallel. This can be done by alternating side-toside while tightening.

Nom. Size Bolt Size Torque

4", 6" & 8"

10" & 12"

3

/4" 75-90 ft-lbs

3

/4" 90-110 ft-lbs

For best results, wait 10 minutes and re-torque.

Proper torque is necessary to get a proper gasket seal and assure that the GripRing engages

the pipe to provide restraint.

Pressure test for leaks before backlling.

GRIPRING™ PIPE MATERIAL COMPATIBILITY CHART

Pipe Material Ring Color Working Pressure Comments

* Ductile Iron - AWWA C151 Black 350

Cast Iron - Obsolete Std. Black 350 OD is same as DI, C151

* PVC - D.I. Size AWWA C900 Black Rating of pipe Class 235 (SDR18) & 305 (SDR14) only.

PVC - “Class Pipe” ASTM D2241 Red Rating of pipe

PVC - Sched. 80, ASTM D1785 Red Rating of pipe 4"-8" Class Sched 40-80. 10" & 12" Sched. 80 only.

PVC C900 DR Class 100/165 (DR25)

PVC Molecularly Oriented (C909) – – GripRing is not for use on C909 pipe

Steel – – GripRing is not for use on steel pipe

Asbestos Cement – – GripRing not for use on asbestos cement

Fiberglass – – GripRing not for use on berglass pipe

HDPE – – GripRing not for use on HDPE pipe

Plain end mechanical joint ttings – – GripRing not for use on plain end MJ ttings

– –

4"-8" Class 160 (SDR26) - 200 (SDR21). 10" & 12" Class 200 only.

GripRing is not for use on C900 DR Class 100/165 (DR25) pipe.

NOTE: Angular deection of up to 5° is allowable

between the pipe and tting for all GripRing sizes.

PRECAUTIONS

1. MJ gasket must comply with ANSI/AWWA C111/A21.11.

2. Check diameter of pipe to make sure you are using the cor-

rectly sized GripRing. Red rings are for IPS sized pipe, Black

rings for Cast Iron size (C900).

3. Clean pipe to remove as much dirt, coatings, and corrosion as

possible from the surface. Lubrication and additional cleaning should be provided by brushing both the gasket and plain

pipe end with soapy water or approved pipe lubricant per

ANSI/AWWA C111/A21.11.

4. Make sure no foreign materials become lodged between the

GripRing and pipe, gasket and GripRing, or between the

GripRing and gland.

5. Avoid loose tting wrenches, or wrenches so short that achiev-

ing proper torque is difcult.

COMMON INSTALLATION ERRORS

1. Not enough torque on bolts.

2. Debris lodged between GripRing and pipe/gasket/gland.

3. Dirty threads on bolts or nuts.

4. Not using the proper size GripRing for the pipe.

IF GRIPRING MUST BE REMOVED

1. Make sure pipe is not pressurized. Disassembling the joint

compromises gasket seal and restraint.

2. Remove all bolts and nuts from gland. Slide gland away from

MJ bell, disengaging it from the GripRing.

* UL Listed & FM Approved

6. Keep threads free of foreign material to allow proper tight-

ening.

7. Bolts are often not tightened enough when a torque wrench

is not used. Take extra care in this situation to make sure

bolts are properly tightened.

8. Pressure test for leaks before backlling.

9. If a good seal is not attained at 90 ft-lbs torque, the joint

should be disassembled, thoroughly cleaned, and carefully

reassembled.

10. Backll and compact carefully around pipe and ttings.

11. When reinstalling parts with stainless steel hardware there

may be a loss in pressure holding ability due to worn or damaged threads during the original installation.

5. Allowing the gland to get cocked at an angle to the bell

ange.

6. Forgetting to install the GripRing (provides gasket seal, but

no restraint).

3. Pry open the GripRing gap to approximately 3/4" using a

screw driver, snap ring pliers, or other available tool. This

will disengage the GripRing from the pipe.

Loading...

Loading...