Romac Industries FTS 419 Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

5

7

7

8

6

4

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no parts

are missing. Also check the diameter of the pipe and the range marked on the tapping sleeve to ensure you have the proper size.

Style FTS 419 Fabricated Steel Tapping Sleeve

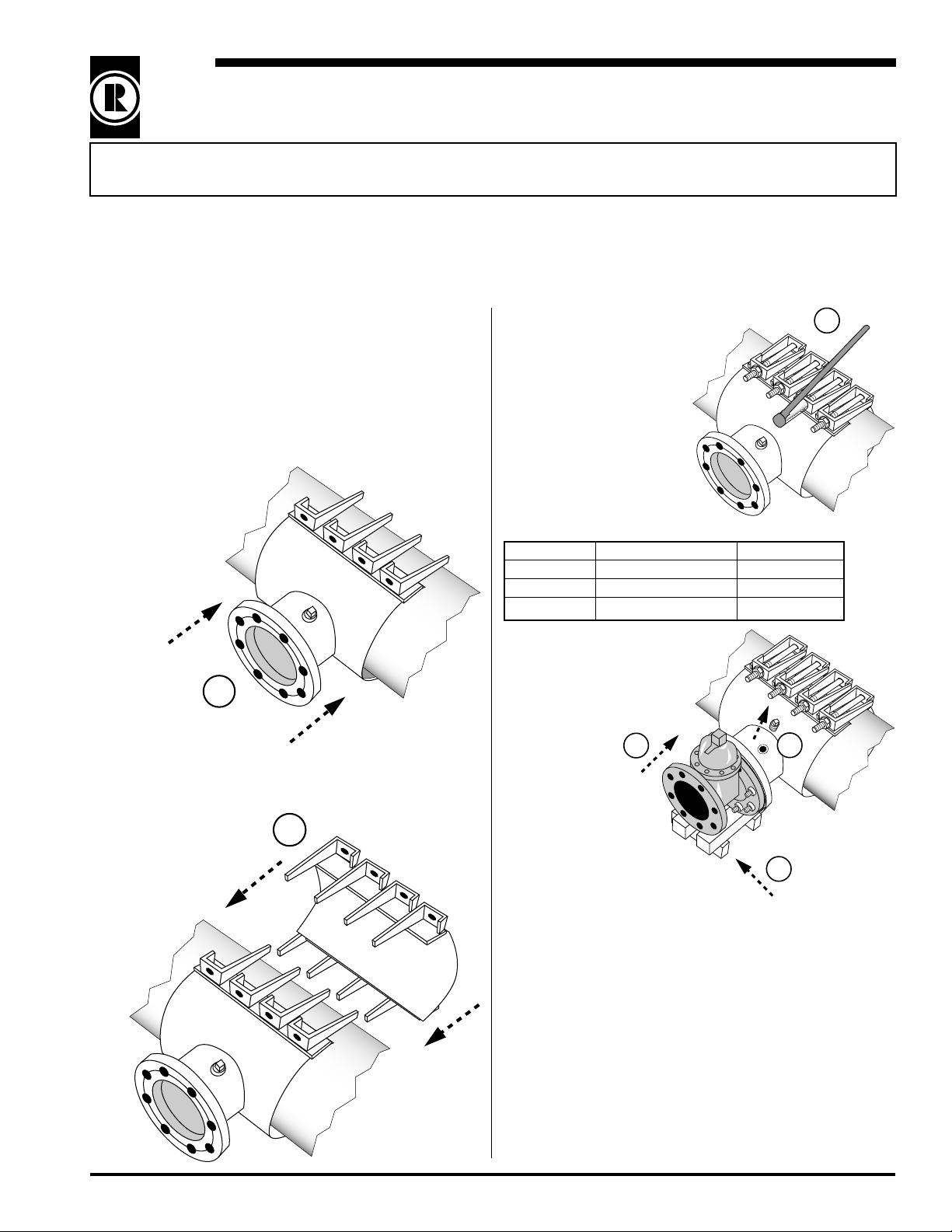

Step 1 • Clean pipe surface, particularly in the gasket

sealing area.

Step 2 • Remove bolts and separate sleeve halves.

Step 3 • Lubricate gasket and pipe surface with a suitable

gasket lubricant.

Step 4 • Place the

outlet half of sleeve onto

the pipe and move

into position. Do not

slide outlet half of

sleeve around pipe.

Step 6 • Well tightened nuts

are important to ensure a proper

seal. Tighten nuts, starting

with the center bolts, alternating on either side of the

sleeve. The gaps between

sleeve halves should be

the same when the nuts

are fully torqued. Tighten

nuts evenly in 25 ft-lb

increments.

Pipe Size Pipe Material Torque

4" PVC 25 - 30 ft-lbs.

6" - 24" PVC 45 - 50 ft-lbs.

4" - 24" Steel / DI 45 - 50 ft-lbs.

Step 7 • Install tapping

valve. Tapping valve must

be supported.

Step 5 • Bring the

back half of sleeve into

position and insert the

bolts.

Document #30-9-419-0004 02/10/2017

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Step 8 • Remove test plug and pressure test

assembly to determine a tight joint. Test at pressure up to

1.25 times ange rating. For AWWA Class D anges, sizes

4-12 inch, maximum working pressure of 175 psi, and up to

220 psi for test.

Step 9 • When it is ascertained that sleeve is leak-tight,

proceed with the tapping operation.

Step 10 • Tapping equipment must be supported so that

its weight is not supported by the sleeve.

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

Style FTS 419

Fabricated Steel Tapping Sleeve

PRECAUTIONS

1. Check diameter of pipe to make sure you are using the correctly sized sleeve.

2. Clean pipe to remove as much dirt and corrosion as possible from the surface.

3. Make sure no foreign materials stick to the gasket as it is brought around the pipe, nor become lodged

between gasket and pipe as nuts are tightened.

4. Avoid loose tting wrenches, or wrenches too short to achieve proper torque.

5. Keep threads free of foreign material to allow proper tightening.

6. Bolts are often not tightened enough when a torque wrench is not used. Take extra care in this situation to

make sure proper tightening occurs.

7. Install tapping sleeve with outlet in the direction of the branch pipe. Do not spin or rotate tapping sleeve

on pipe.

8. Pressure test for leaks before tapping pipe.

9. Backll and compact carefully around sleeve.

10. Caution, when reinstalling parts with stainless steel hardware there may be a loss in pressure holding ability

due to worn or damaged threads during the original installation.

11. For personal safety reasons, do not use a compressible uid (such as air) to check for water tightness.

COMMON INSTALLATION PROBLEMS

1. Not enough torque on bolts.

2. Rocks or debris cutting gasket.

3. Dirty threads on bolts or nuts.

4. Allowing tapping sleeve to support the

cantilever load of the valve, tapping

machine or pipe.

5. When insufciently restrained and sup-

ported, pipe pullout or movement may

occur. To prevent movement, sufcient

support must be provided using: thrust

blocks, anchors, soil friction, or other

restraint devices.

6. Not using thrust block or other form of restraint.

7. Spinning or rotating tapping sleeve on the

pipe.

NOTE: Tapping

sleeves are designed for sealing

purposes only, not

structural support

or restraint.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...