Romac Industries EC501 Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

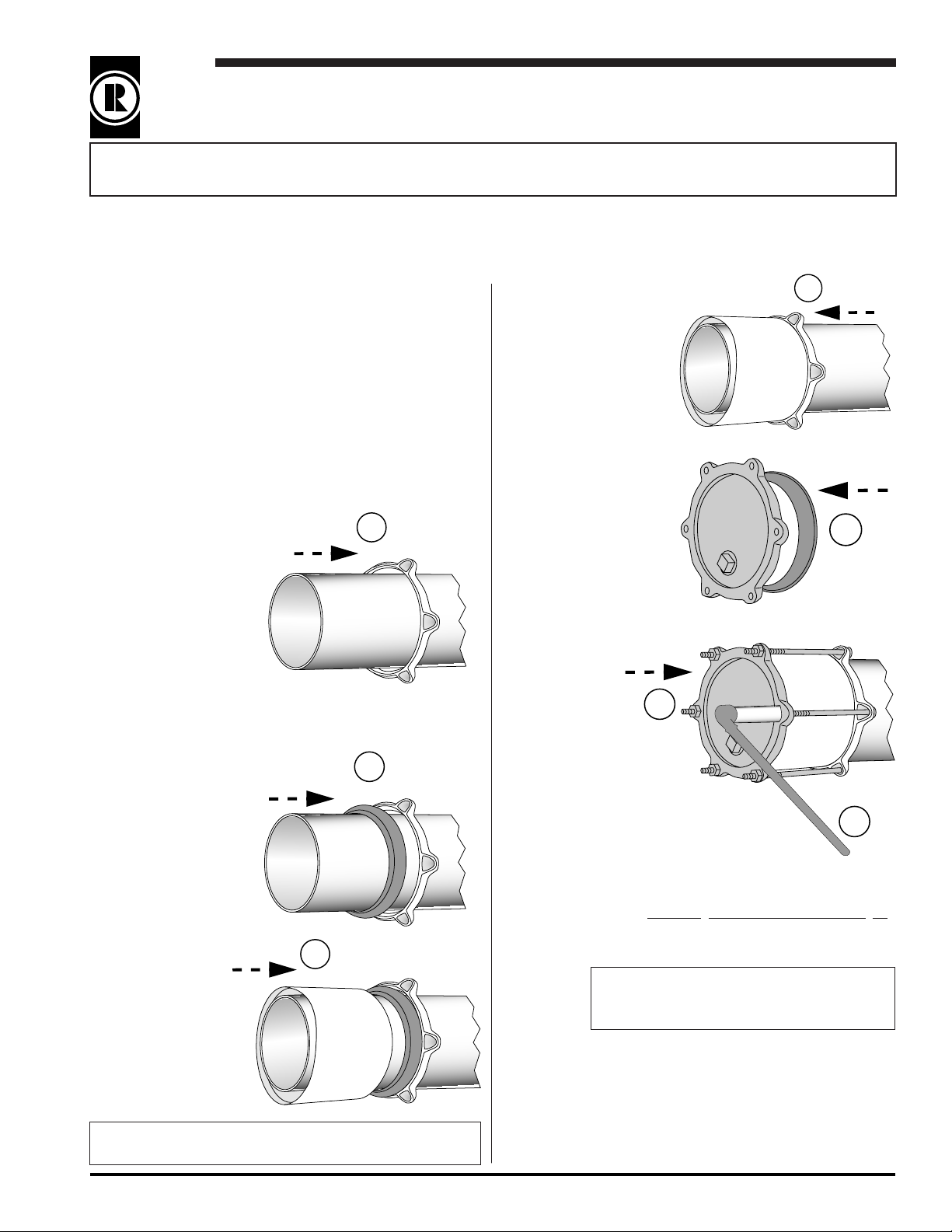

8

7

5

9

10

11

12

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the coupling to ensure you have the proper size.

Style EC501 Coupling

Step 1 • Check the coupling parts to insure that no damage

has occurred during transit and that no parts are missing.

Step 2 • Clean pipe end for a distance of 2" greater than

length of the coupling.

Step 3 • Check area where gasket will seat on the pipe

to make sure there are no dents, projections, gouges, etc.,

that will interfere with the gasket seal. Welds must be ground

ush.

Step 4 • Place reference mark on the pipe, use the refer-

ence mark to insure a minimum of 3" inches of pipe insertion

into the center ring.

Step 5 • Place an end

ring on pipe end.

Step 6 • Lubricate the gaskets and pipe surface with a

suitable gasket lubricant.

Step 7 • Place a gasket

next to end ring, with beveled edge toward the pipe

end.

Step 8 • Slide center ring

on pipe end. The

center ring should be

centered such that the

space between the OD

of the pipe and the ID of

Document #20-9-EC501-0007 11/09/2016

the center ring is even

all around the pipe.

Step 9 • Slide gasket

into position with the beveled edge engaging the

ared end of the center

ring. Slide the end ring

into position against the

gasket.

Step 10 • Install the

end ring/end cap assembly.

4" through 8" sizes have

two separate pieces, the

end ring and the end cap.

10" and 12" sizes are one

piece. Place gasket in the

end cap.

Step 11 • Slide end cap

assembly into

center ring, with

beveled edge

of gasket facing toward center

ring. Check coupling

for proper positioning over

pipe ends using reference

marks. (See Step 4)

Step 12 • Insert bolts into end rings and

tighten. Bolt tightening should be done evenly,

alternating to diametrically opposite positions at approxi-

mately 20

ft-lbs. increments to

bring bolts

to recommended

tightness.

Note:

50 ft-lbs. torque = 12" wrench w/50 lbs. force

70 ft-lbs. torque = 12" wrench w/70 lbs. force

Nom. Pipe Diameter Torque

4" - 12" 40-50 ft-lbs.

16" 60-70 ft-lbs.

Step 13 • After pipe is pressurized, check for leakage

and tighten as necessary.

Note: Flexible Couplings do not provide protection against

possible pullout of pipe ends in unrestrained conditions.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

Style EC501 Coupling

PRECAUTIONS

1. Check diameter of pipe to make sure you are using the correct size coupling; also check gasket

to make sure it is the size you think it is.

2. Clean pipe to remove dirt and corrosion from pipe surface. Lubrication and additional cleaning

should be provided by brushing both the gasket and plain pipe end with soapy water or approved

pipe lubricant per ANSI/AWWA C111/A21.11.

3. Make sure no foreign materials lodge between gasket and pipe.

4. Avoid loose tting wrenches, or wrenches too short to achieve proper torque.

5. Keep threads free of foreign material to allow proper tightening.

6. Take extra care to follow proper bolt tightening procedures and torque recommendations. Bolts

are often not tightened enough when a torque wrench is not used.

7. Pressure test for leaks before backlling.

8. Backll and compact carefully around pipe and ttings.

9. When reinstalling parts with stainless steel hardare there may be a loss in pressure holding ability

due to worn or damaged threads during the original installation.

COMMON INSTALLATION PROBLEMS

1. Bolts are not tightened to the proper torque.

2. Rocks or debris between pipe and gasket.

3. Dirt on threads of bolts or nuts.

4. Pipe not inserted into the coupling far enough.

5. Center ring not centered evenly around pipe.

6. Too much pipe deection.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...