Romac Industries DJ405 Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

6

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the coupling to ensure you have the proper size.

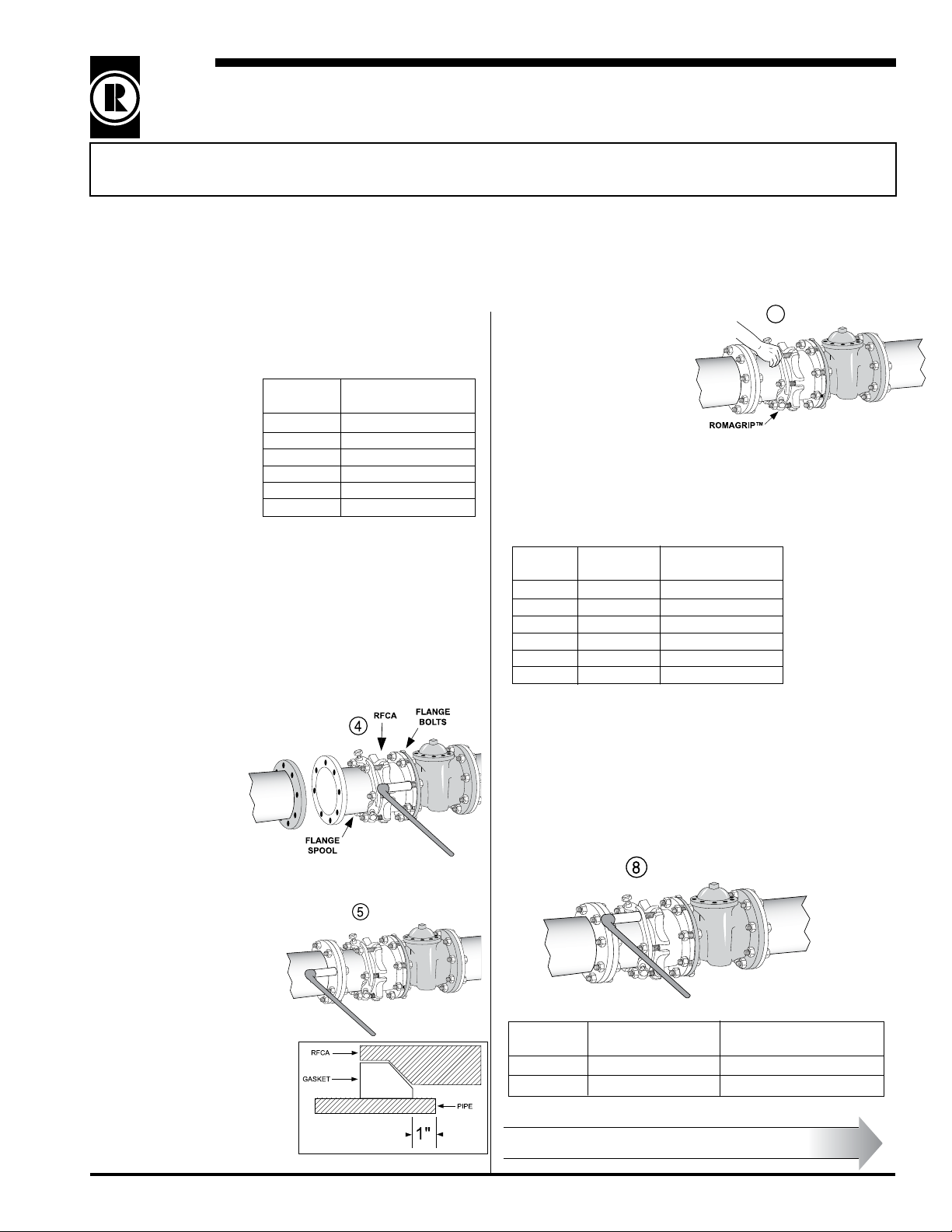

Style DJ405 Dismantling Joint

Step 1 • Check the DJ405 parts to ensure no damage oc-

curred during transit and that no parts are missing.

Step 2 • Check the

mating anges to insure

that they match the drilling

of DJ405 anges. Mating

anges must be aligned, and

angular deection must be

within the limits stated in the

chart below. Also, check the

length between the ange

faces and make sure the

DJ405 face to face length

matches.

Nom. Maximum Angular

Size Deection (degrees)

3 2.0

4 - 6 3.5

8 3.3

10 - 12 3.0

14 - 16 2.0

18 - 24 1.5

Step 3 • If needed, loosen the T-bolts to allow the spool

piece to move freely within the Restrained Flange Coupling

Adapter (RFCA) body.

When stainless steel fasteners are requested, Romac provides

all-thread-rod and two nuts. The underside of the lug on the RFCA

body is designed to capture hex nuts as well as

"T" head bolts.

Step 4 • Move

the DJ405 into position

between the mating

anges. Insert a ange

gasket between the

ange faces on ange

spool side. The RFCA

side has an o-ring ange

gasket. No additional

gasket is required.Using

ange bolts, fasten the

RFCA end of the dismantling joint

to one of the mating anges.

Step 5 • Attach the

anged spool to the opposite mating ange, and fasten together

with ange bolts. Make sure the

spool piece is inserted at least 1

inch past the gasket inside the

RFCA body. Snug up all of the

ange bolts.

Document #20-9-0033 09/18/2014

Note: The spool piece should be

within the deection tolerance of

the RFCA after bolting the anges.

If this is not the case, the mating

anges must be realigned.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Step 6 • If the RFCA

was completely disassembled,

make sure the beveled edge of

the gasket matches the gasket

pocket of the RFCA. Slide the

RomaGrip into position and

install the T-bolts, tightening

them nger tight.

Step 7 • Tighten ange

bolts evenly, alternating to diametrically opposite positions at approximately 20 ft-lb increments, to the recommended torque for

your size.

Nom. Flange Bolt Recommended

Size Size Min. Torque (ft-lbs)

3 - 4

6 -8

10 - 12

14 - 16 1 245

18 - 20 11/8 355

24 11/4 500

5

/8 60

3

/4 100

7

/8 160

Step 8 • Tighten T-bolts on RomaGrip evenly, alternating to

diametrically opposite positions at approximately 20 ft-lb increments, to the recommended torque for your size.

Note: 90 ft-lbs torque = 12 inch wrench with 90 pounds force.

For best results, wait 10 minutes and retighten all bolts to the

proper torque.

Nom. T-Bolt Recommended

Size Size Min. Torque (ft-lbs)

3 5/8 45 - 65

4 - 24 3/4 75 - 90

Installation Instructions continued on back

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

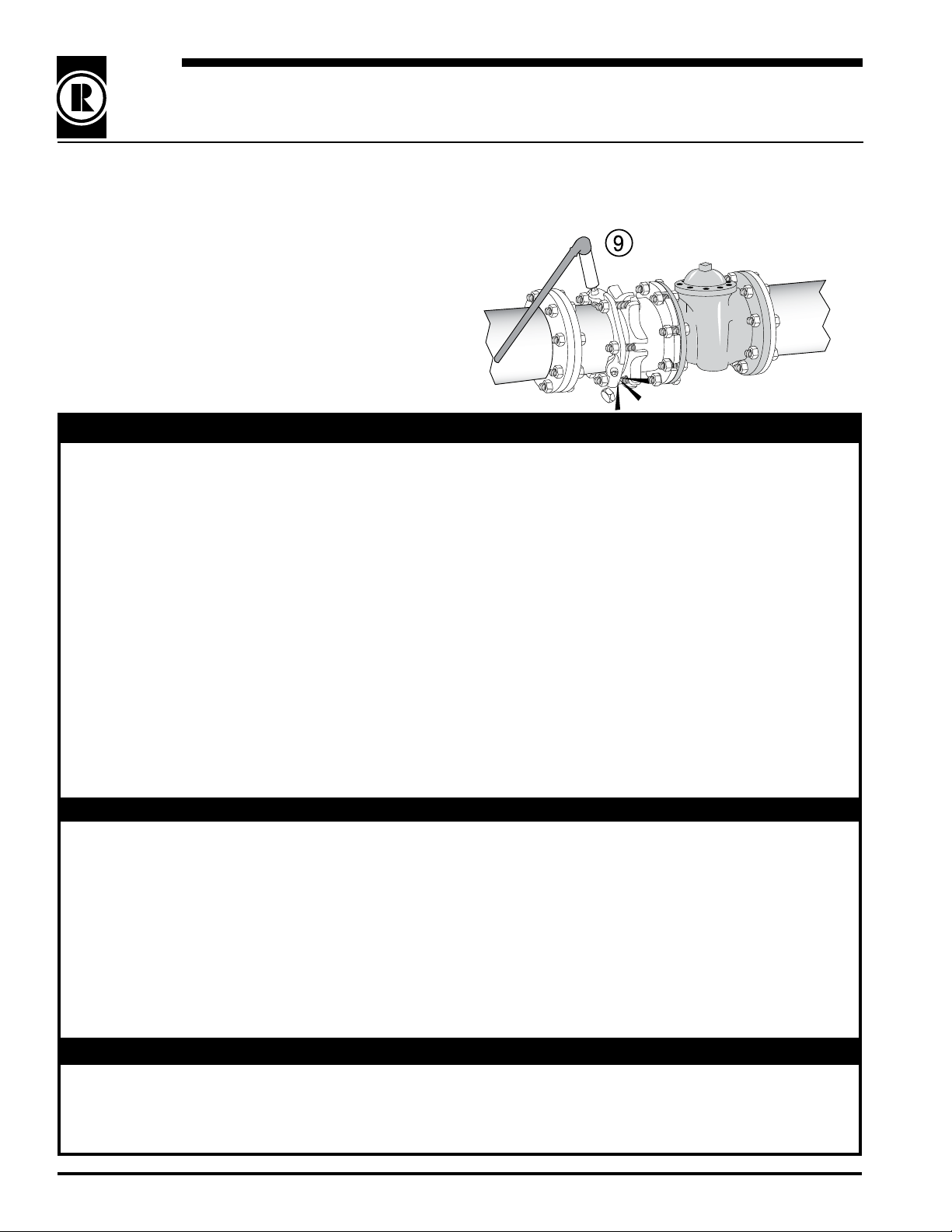

Style DJ405 Dismantling Joint

(continued from front)

Step 9 • Hand tighten the restrainer bolts until the restraining

pads touch the surface of the pipe. The bolts should then be tightened

in a uniform crisscross pattern, until the heads break off above the

notch.

Note: Do not turn a bolt more than one turn before alternating to the

next bolt.

Step 10 • Pressure test for leaks before backlling.

PRECAUTIONS

1. Check anges to make sure you are using the correct size DJ405; also check the length of DJ405 to make sure it will t in the space

allocated.

2. Make sure a ange gasket on spool side is used between mating anges.

3. Make sure no foreign materials lodge between gasket and spool.

4. Avoid loose tting wrenches, or wrenches too short to achieve proper torque.

5. Keep threads free of foreign material to allow proper tightening.

6. Make sure angular deection is within limits

7. Take extra care to follow proper bolt tightening procedures and torque recommendations. Bolts are often not tightened enough when a torque

wrench is not used.

8. Pressure test for leaks before backlling.

9. Backll and compact carefully around pipe and ttings.

10. When reinstalling parts with stainless steel hardware, there may be a loss in pressure holding ability due to worn or damaged threads during

the original installation.

11. Some initial axial movement may occur in lug style restraints as the lugs seat. Movement is directly related to the size of the piping system

and the system pressure. In general terms movement of approximately 0.25" can be expected in restraints under 16”. For larger sizes,

movement of approximately 0.4” may be seen. If this is critical to your application please contact Romac Engineering for additional

information.

COMMON INSTALLATION PROBLEMS

1. Flange gasket not installed on ange spool side.

2. Bolts are not tightened to the proper torque.

3. Rocks or debris between spool and gasket.

4. Dirt or debris between pipe and restraining pad.

5. Dirt on threads of bolts or nuts.

6. Restraining bolt heads not snapped off.

7. Not enough pipe insertion.

8. Incorrect mating ange.

IF DJ405 MUST BE REMOVED

1. Make sure pipe is not pressurized. Removing the restrainer could cause the pipe joint to separate.

2. To remove the DJ405, use a 5/8" hex wrench or socket.

3. To reassemble, follow installation procedures. Tighten the restraining bolts using a 5/8" hex wrench to 75-ft-lbs minimum.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...