Romac Industries CB Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

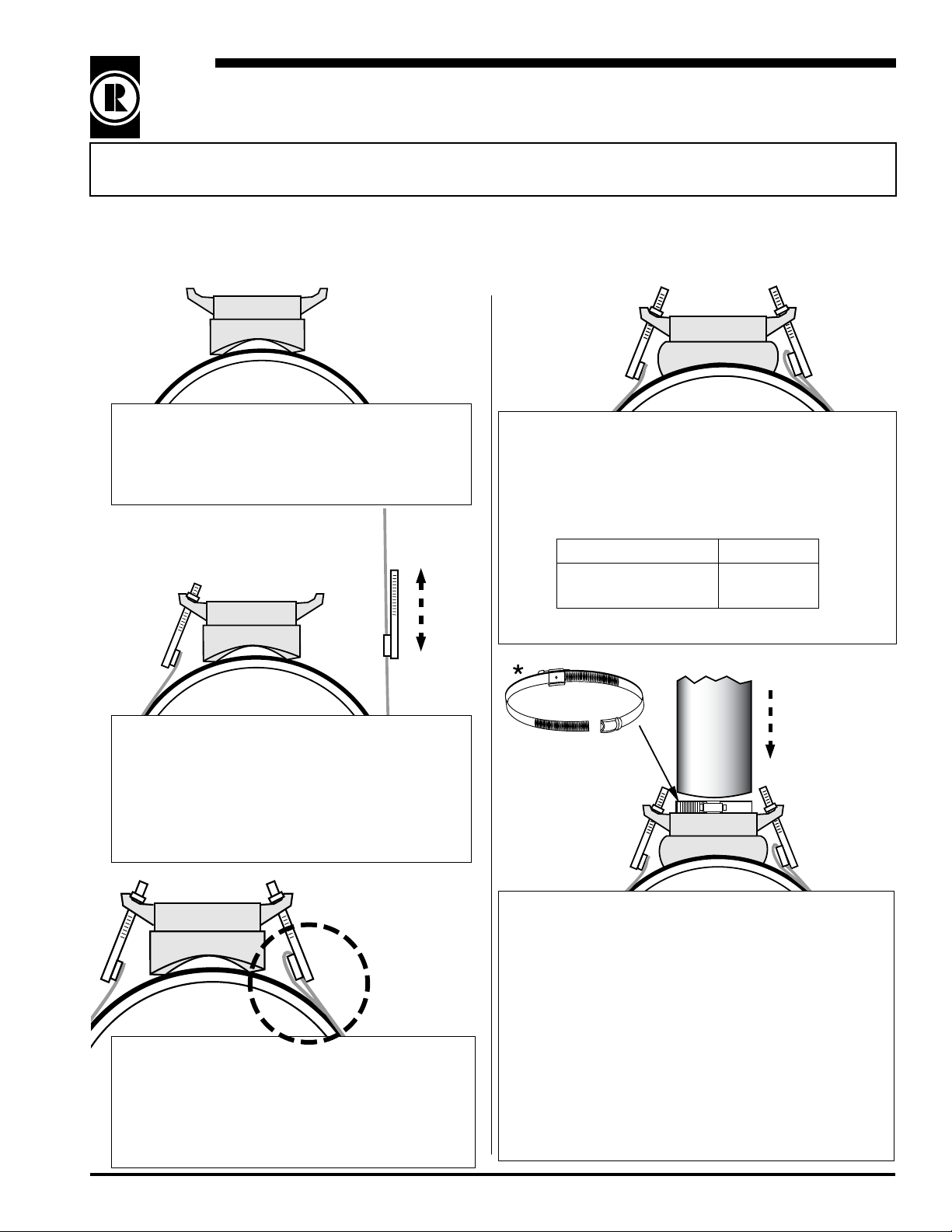

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no

parts are missing. Also check the diameter of the pipe and the range marked on the saddle to ensure you have the proper size.

Style “CB” Sewer Saddle

Step 1

Place saddle on pipe.

4" Gasket ID: 5.20"

6" Gasket ID: 6.40"

Step 2

Wrap strap around pipe, with “This Side Out” as printed

on strap. Slide the adjustable bolt assembly to a point

which leaves most of the thread for tightening.

Step 4

Tighten nuts evenly, alternating between them until appropriate

torque is reached (see below).

Signicant attening of PVC pipe indicates overtightening.

In all cases wait 10 minutes and retorque.

Nom. Pipe Diameter Torque

6" - 12" 15-20 ft-lbs.

14" - 48" 20-30 ft-lbs.

Note: 25 ft-lbs. = 12" wrench w/25 lbs. force

Document #10-9-CB-0018 10/21/2012

Step 3

Fold strap back against itself, placing free end

between strap and pipe. (On small pipe, it may

be necessary to fold loose end twice).

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Step 5

Lubricate and insert branch end.

*The CB UN saddles are provided with a band clamp (hose

clamp) which allows it to have a range. The band clamp

comes with two adjusting screws which provide much greater clamping force than band clamps with only one adjusting

screw. The band clamp needs to be assembled around the

outlet and both adjusting screws tightened evenly.

Note: A pipe stop capable of withstanding 1,000 pounds of

thrust is molded into the CB saddle gasket. Care must be

taken during system design and installation to assure that

this thrust limit is not exceeded.

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

Style “CB” Sewer Saddle

PRECAUTIONS

1. Check diameter of main and branch pipe to make sure you are using the correct size saddle gasket; also

check gasket to make sure it is the size you think it is.

2. Remove as much dirt and corrosion from pipe surfaces as possible.

3. Make sure no foreign materials lodge between saddle gasket and pipe as nuts are tightened.

4. Avoid loose tting wrenches or wrenches too short to achieve proper torque.

5. Take extra care to follow proper bolt tightening procedures and torque recommendations:

15-20 ft-lbs. for 6" - 12" mains and 20-30 ft-lbs. for 14" - 48" mains (wait 10 minutes and retorque).

6. Backll and compact carefully around branch.

7. The hole cut in the main should be no larger than the inside diameter of the saddle gasket. The 4" gasket

has an I.D. of 5.20, the six inch gasket has an I.D. of 6.40.

8. Lubricating between the saddle gasket and the main on rough or large O.D. pipe can improve the sealing

capacity of the saddle.

10. During installation the temperature of the saddle gasket itself can be important. The temperature of the

saddle gasket should not fall below ~ 45° F.

11. It is necessary to bevel the branch pipe end and lubricate pipe end and saddle gasket hub.

12. When reinstalling parts with stainless steel hardware there may be a loss in pressure holding ability due

to worn or damaged threads during the orignal installation

COMMON INSTALLATION PROBLEMS

1. Bolts are not tightened to the proper torque.

2. Rocks or debris cutting gasket.

3. Dirt on threads of bolts or nuts.

4. Strap is installed improperly.

5. Using excessive force to insert branch pipe (do not use a backhoe, hydraulic jack or similar mechanical devices

to insert branch pipe).

6. Inserting pipe with jagged ends or pipe with uneven cut ends into saddle gasket

7. Not using band clamp on CB UN saddles.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...