Romac Industries Armor Seal Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no parts are

missing. Check the diameter of the pipe and clamp specications (on label) to ensure you have the proper clamp for your application.

™

Armor Seal

Stainless Steel Repair Clamp

The Armor Seal™ is not designed to withstand

the weight or the axial forces of the pipe. Conrm

that the product label matches your application.

Armor Seal™ is compatible with steel, CI, DI, A/C, Concrete,

PVC and HDPE pipe.

Pipe stiffeners are required when coupling HDPE pipe.

SIZE

(inches)

4.50 4.33 - 4.57 440 1.38" 4º 8 6

4.80 4.65 - 4.92 440 1.38" 4º 8 6

6.63 6.54 - 7.01 340 3.94" 2º 15 10

6.90 6.54 - 7.01 340 3.94" 2º 15 10

8.63 8.27 - 8.74 260 3.94" 2º 20 10

9.05 8.82 - 9.29 260 3.94" 2º 20 10

10.75 10.43 - 10.91 220 3.94" 2º 20 10

11.10 10.67 - 11.14 220 3.94" 2º 20 10

12.75 12.60 - 13.07 230 3.94" 2º 25 10

13.20 12.95 - 13.43 230 3.94" 2º 25 10

17.40 17.05 - 17.52 230 3.94" 2º 25 10

25.80 25.35 - 25.98 250 3.94" 2º 40 14

RANGE

(inches)

MAX.

WP

(PSI)

MAX.

CRACK

WIDTH

MAX.

DEF.

BOLT

TORQUE

(ft-lb)

WRENCH

SIZE

(MM

hex key)

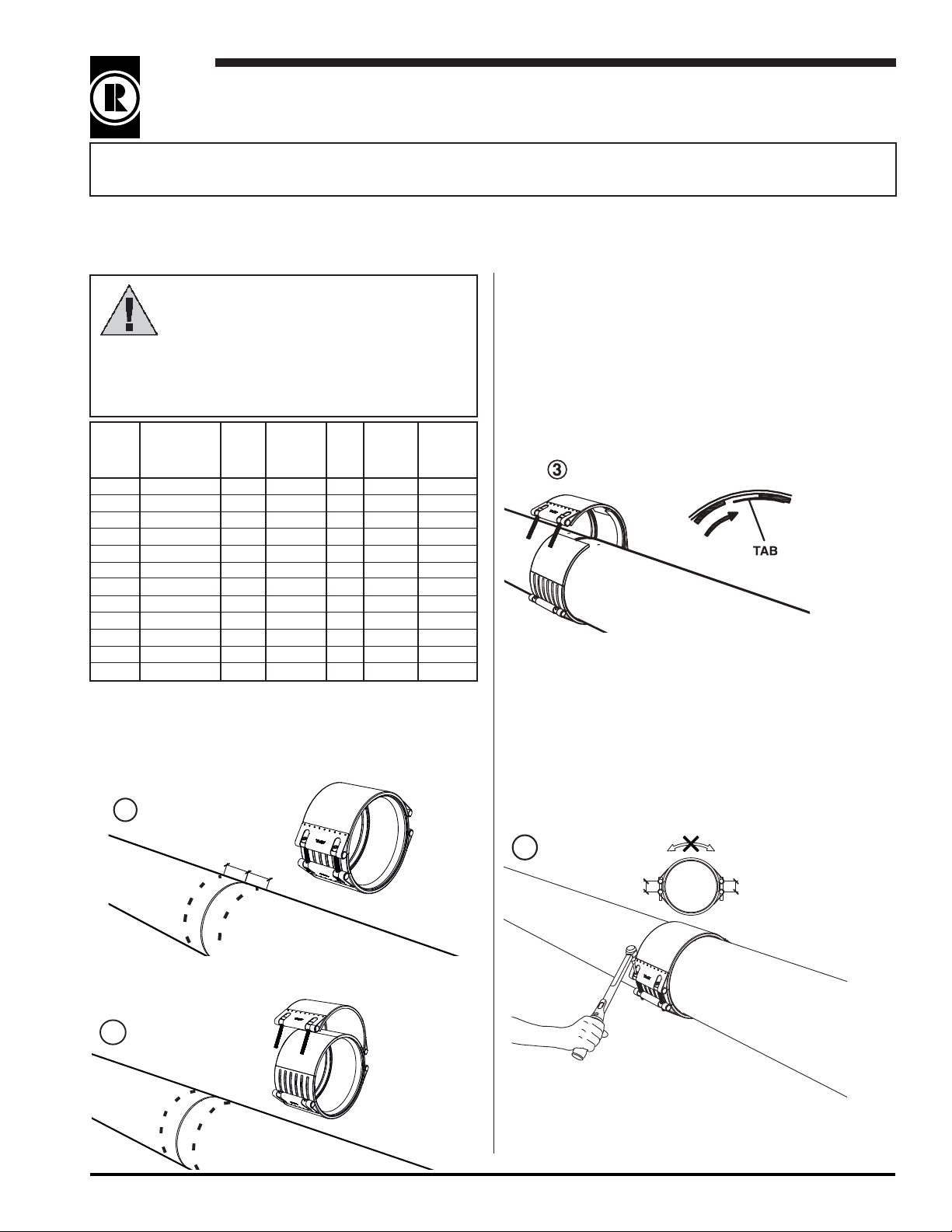

Step 1 • Thoroughly clean pipe surface that will be

covered by the clamp. Remove any irregularities on the damaged area or the pipe ends. To help position the clamp, place

reference marks on the pipe slightly wider than the clamp.

1

Step 3 • Place the gasket around the pipe using the

reference marks made in Step 1. Make sure the gasket slides

between the tab and the shell.

NOTE: Do not cut the gasket.

Close the clamp and start the bolts.

If necessary, because of owing water, Step 3 can be performed beside the crack or hole. Slide the clamp over the damage and begin the bolt tightening.

Step 4 • Do not rotate the coupling or the pipe

during tightening.

NOTE: Do not exceed the torque requirements

indicated on the product label.

On clamps with three bolts, start at the center bolt, and begin

tightening all bolts evenly. Keeping the torque as even as possible between bolts, apply the required torque.

½

½

Step 2 • Loosen the bolts with the o-rings until the

clamp can be opened.

2

Document # 10-9-0038 06/06/2019

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

4

Step 5 • If necessary, you may hydraulically test the

clamp up to 1.5 times the working pressure shown on label.

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

™

Armor Seal

HELPFUL HINTS

1. Be sure that the bolts are tightened to the proper torque shown on the label.

2. Eliminate any rocks or debris between pipe and gasket.

3. Eliminate any dirt on threads of bolts or nuts.

4. Pressure test for leaks before backlling.

5. Backll and compact carefully around clamp.

6. Reusing parts with stainless steel hardware may lead to a loss in pressure holding ability due to wear.

7. Make sure you have the right size clamp for the pipe being repaired.

Stainless Steel Repair Clamp

8. Make sure the pipe damage is between the gasket ribs.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...