Romac Industries Armor Lock Installation Manual

ROMAC

INDUSTRIES,

3

INC.

Armor Lock

INSTALLATION INSTRUCTIONS

ations (on label) to ensure that you have the proper product for your application.

™

Stainless Steel Restraint Coupling

Armor Lock™ is compatible with steel, CI, DI,

PVC and HDPE pipe.

Pipe stiffeners are required on HDPE pipe.

For applications on thin wall PVC and pipelines subject

to vacuum conditions, contact Romac Engineering.

TEMPERATURE

WORKING

SIZE

PRESSURE

(inches)

4.50 230 86º 12 4º 6

4.80 230 86º 12 4º 8

6.63 230 86º 12 2º 8

6.90 230 59º 25 2º 10

8.63 230 59º 25 2º 10

9.05 230 59º 25 2º 10

10.75 230 59º 30 2º 10

11.10 230 59º 30 2º 10

12.75 145 68º 30 2º 10

13.20 145 68º 30 2º 14

(PSI)

LIMITATIONS

FOR

APPLICATIONS

ON HDPE PIPE

(∆T) ºF

BOLT

TORQUE

(ft-lbs)

ALLOWABLE

DEFLECTION

WRENCH

SIZE

(MM hex key)

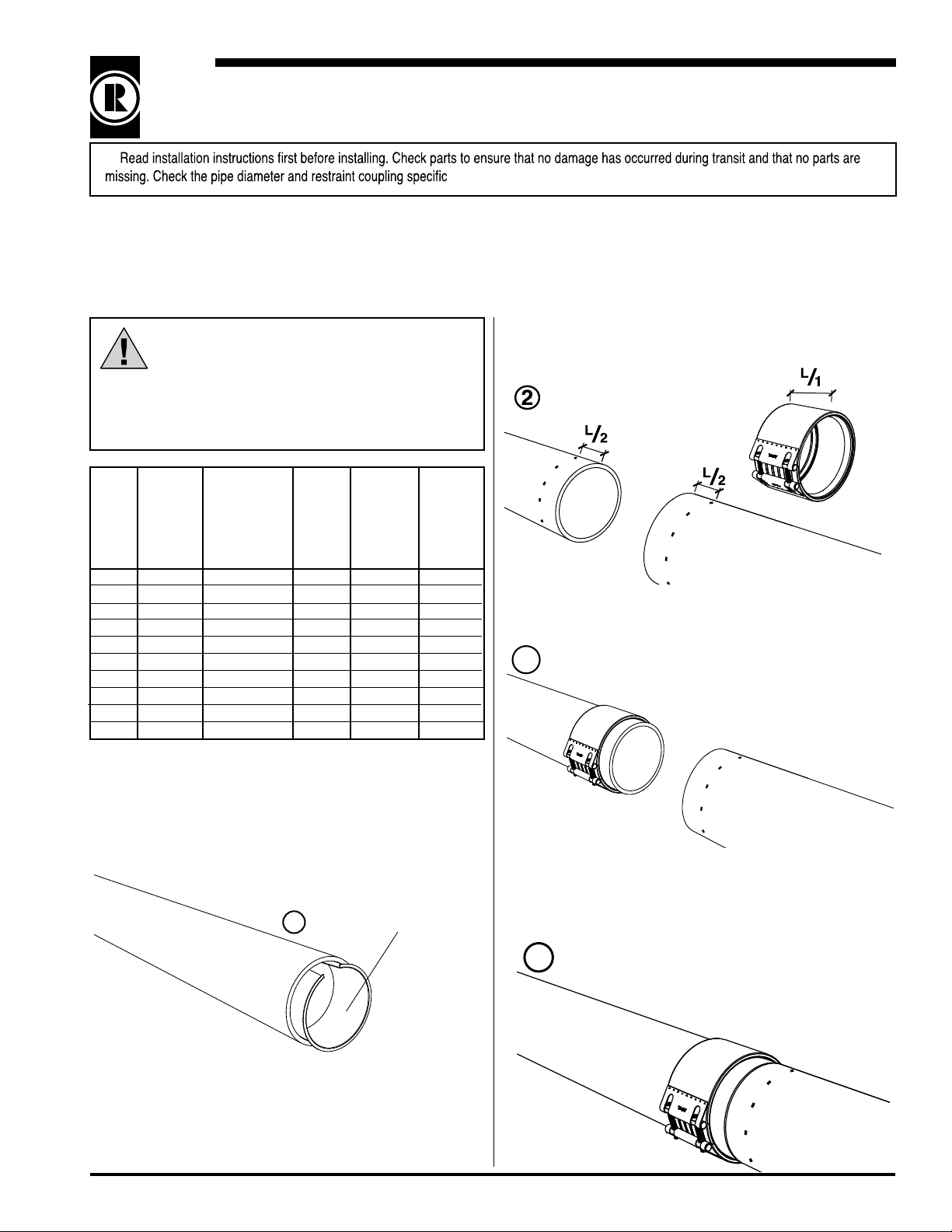

Step 2 • On each pipe end, make a mark at a dis-

tance equal to half the width of the coupling.

Step 3 • Without opening the coupling, slide the

coupling over one pipe end.

Step 1 • Clean and eliminate any irregularities on

the pipe ends. For applications on HDPE, install a pipe

stiffener in each pipe end.

1

Document # 10-9-0040 02/23/2015

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

STIFFENER

Step 4 • Bring the other pipe end to a facing

position. Make sure the pipes are aligned concentrically and that both pipe ends are correctly supported.

See tolerances indicated on the label.

4

ROMAC

INDUSTRIES,

INC.

™

Armor Lock

INSTALLATION INSTRUCTIONS

Stainless Steel Restraint Coupling

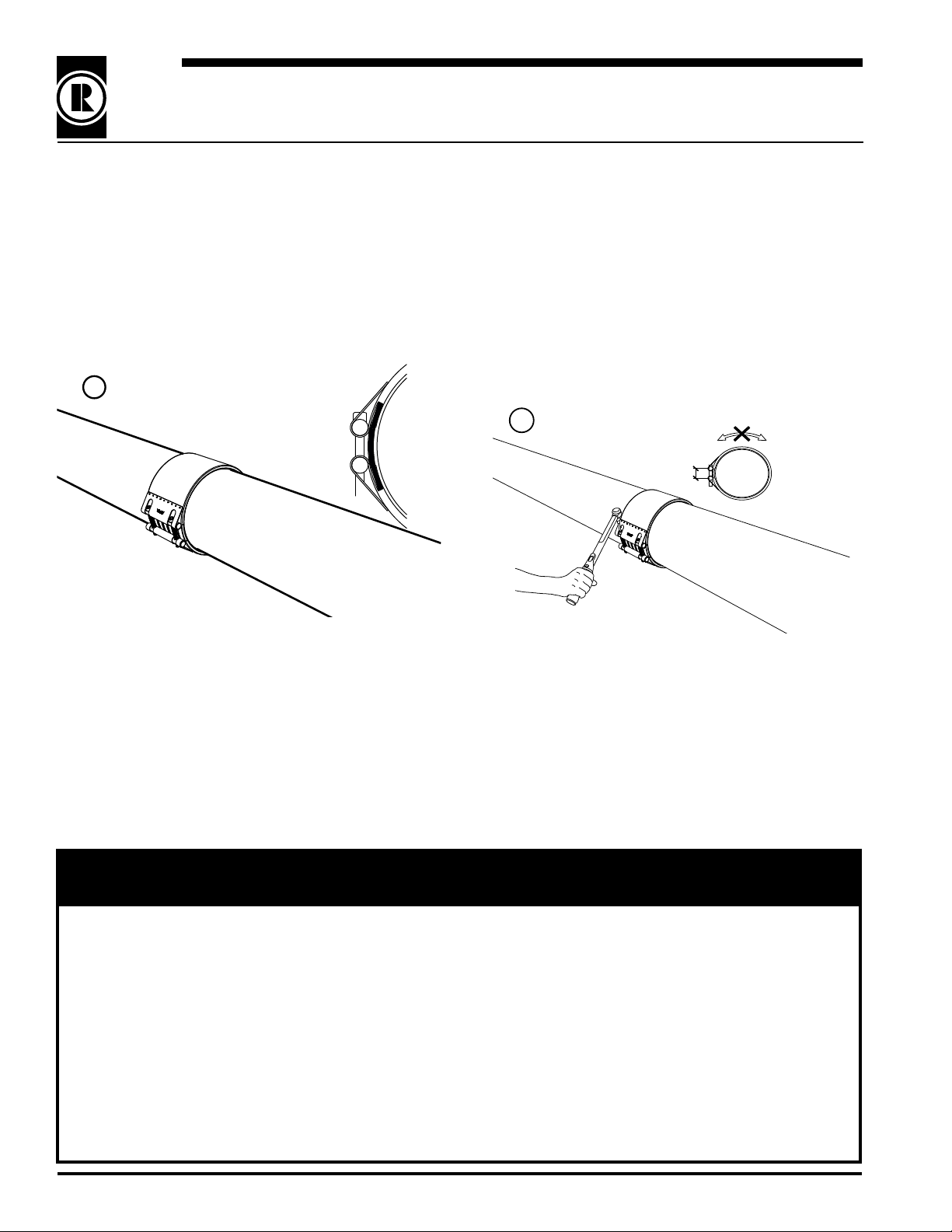

Step 5 • Place the coupling between the marks and

make sure that the armor is under the bolts.

5

Step 6 • Do not rotate the coupling or the pipe dur-

ing tightening. Tighten the bolts alternately and evenly to

the required torque. If there are three bolts, start with the

center bolt, and begin tightening.

6

NOTE: Do not exceed the torque requirements

indicated on the product label.

Step 7 • If necessary, you may hydraulically test

the coupling up to 1.25 times the working pressure shown

on the product label.

HELPFUL HINTS

1. Be sure that the bolts are tightened to the proper torque shown on the label.

2. Eliminate any rocks or debris between pipe and gasket.

3. Eliminate any dirt on threads of bolts or nuts.

4. Pressure test for leaks before backlling.

5. Backll and compact carefully around restraint.

6. Reusing parts with stainless steel hardware may lead to a loss in pressure holding ability due to wear.

7. Make sure you have the proper size restraint coupling.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...