Romac Industries Alpha FC Installation Manual

ROMAC

INDUSTRIES,

INC.

Read installation instructions rst before installing. Check parts to ensure that no damage has occured

during transit, the bolt guides are aligned with the axis of the pipe, and no parts are missing.

™

Style Alpha FC

INSTALLATION INSTRUCTIONS

Restrained Flanged Coupling for 4" & 6" Pipe Sizes

When properly installed, ALPHA can be used at working pressures

equal to the lesser of 350 psi, pipe rating, or value listed below:

PIPE

MATERIAL

Ductile Iron 4-12" 350 psi

Cast Iron 4-12" 350 psi

PVC, IPS size 4-12" 350 psi

PVC, DI size 4-12" 350 psi

C909 4-6" 235 psi

C909 8-12" 150 psi

HDPE: SDR 9, 11, 13.5 & 17* 4-12" rating of pipe

* For SDRs greater than 17, pipe stiffeners are required.

For other SDR's and pipe materials, contact Romac.

SIZE

WORKING

PRESSURE

ALPHA RANGES

STANDARD ALPHA:

ALPHA XL:

SIZE

4” 4.50 - 4.90 4.80 - 5.10

6” 6.60 - 7.00 6.90 - 7.10

For DI sized through Oversize Cast pipe diameters.

STANDARD ALPHA ALPHA XL

For IPS through DI sized pipe diameters.

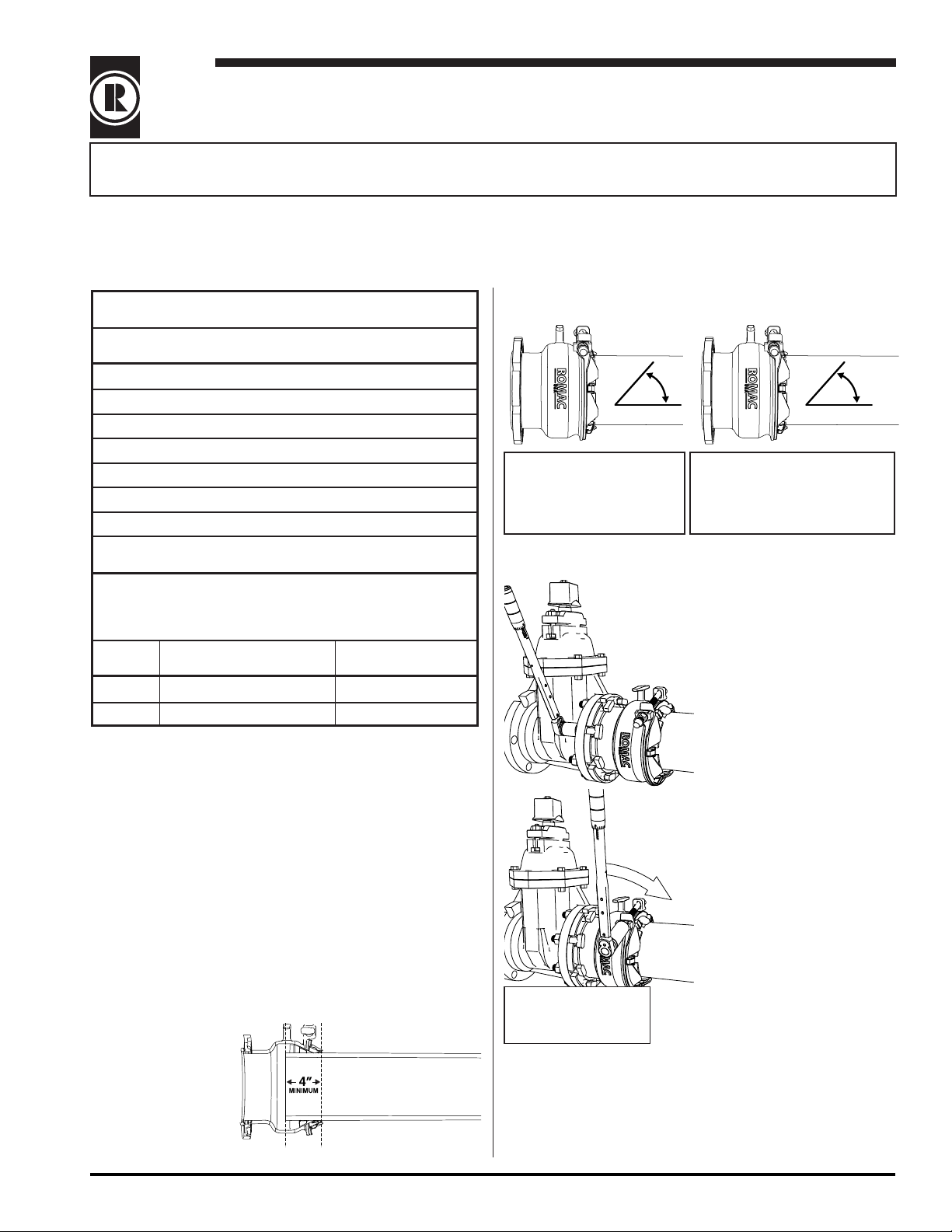

Step 1 • Measure pipe diameter and verify with the ranges

listed above to ensure the correct size ange coupling has

been selected.

Step 2 • Remove any scale or debris that could interfere

with gripper engagement of the pipe. Clean the pipe surface

wherever the gasket will come in contact with the pipe, and

check to see that the pipe surface is smooth (no dents, projections, gouges, etc.) where the gasket seals against the pipe.

Step 3 • Lubricate the gasket and pipe surface with a

suitable gasket lubricant.

Step 4 • With the bolt in the extended position, place the

ange coupling onto the plain pipe end.

Step 5 • Set the desired pipe deection.

4º MAX

Std. Alpha & Alpha XL

Maximum deection:

4 degrees

Note: Do not deect pipe joint after installation.

Alpha XL installations at the

top of the range

Maximum deection:

2 degrees

2º MAX

Step 6 • Bring the

mating ange into position

and assemble the ange

joint using the ange bolts.

Be sure to maintain proper

pipe insertion described in

Step 4.

Step 7 • With the ange

coupling properly located,

tighten the nut to 30 ft-lbs

using a torque wrench.

NOTE: Do not use an

impact wrench. Do not

overtorque, or retighten. If

a good seal is not achieved

at 30 ft-lbs of torque, refer

to the Common Installation

30 ft-lbs.

DO NOT OVERTORQUE

Problem listed on side two.

Document #02-9-0023 03/25/2019

There should be

a minimum of 4"

of pipe insertion.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Step 8 • Conrm proper installation by pressurizing

the line and checking for leaks.

Step 9 • Backll and compact carefully around pipe

and ange coupling.

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

™

Style Alpha FC

PRECAUTIONS

1. Check diameter of pipe to make sure the correct sized ange coupling has been selected.

2. Conrm the pipe is round. The ange coupling may not t or function on pipe that is too far out of round.

3. Clean pipe to remove dirt and corrosion from pipe surface. Use appropriate scale removal tools where appropriate

to assure all scale and debris is properly removed.

4. Lubrication and additional cleaning should be provided by brushing both the gasket and plain pipe end with

soapy water or approved pipe lubricant per ANSI/AWWA C111/A21.11.

5. Make sure no foreign materials lodge between gasket and pipe, between the grippers or in the end ring mechanism.

6. Avoid loose tting wrenches, or wrenches too short to achieve proper torque.

7. Keep threads free of foreign material to allow proper tightening.

8.

For cold weather conditions (below 40º F), performance can be improved by warming up the ange coupling and gasket.

9. Verify that the grippers are in contact with the pipe surface.

10. Do not strike or pry on the ange coupling with hammers, shovels or other equipment.

Restrained Flanged Coupling for 4" & 6" Pipe Sizes

11. When reinstalling, prior to pressure applications, be sure to inspect all parts for damage and apply additional

lubricant to the fasteners.

12. If it's necessary to remove Alpha, loosen the bolt and tap the end ring bolt receiver open. Tapping the hooks into their

notches may also be required

13. Do not reuse ange coupling after pressure application.

14. It is common for the bolt receivers to meet on installations at the bottom of the range.

15. Directional drilling requires special consideration prior to installation. Contact Romac Engineering

for any directional drilling applications.

16. Romac mechanical restraint products are designed and tested to provide axial load restraint as specied.

System design must be such that the restraint is only exposed to this type of loading. Special consideration may be

required for above ground installations where the alignment and support benets of earth are not present.

PRECAUTIONS FOR HDPE PIPE

1. Alpha working pressure not to exceed pressure rating of pipe.

2. For SDR's greater than 17, pipe stiffeners are required.

3. Operating temperatures are limited to 85º F maximum and 32º F minimum.

4. Recommended for buried applications only. For above ground use, contact Romac Engineering.

COMMON INSTALLATION PROBLEMS

1. Flange gasket installed over existing o-ring gasket.

2. Pipe not inserted into the ange coupling far enough.

3. Too much pipe deection.

4. Damage to the outer pipe surface (dents, projections, gouges, etc.)

5. Bolts not tightened to proper torque.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...