Romac Industries 611 Installation Manual

INSTALLATION INSTRUCTIONS

ROMAC

INDUSTRIES,

INC.

4

5

6

3

Read installation instructions rst before installing. Check parts to ensure that no damage has occurred during transit and that no parts

are missing. Also check the diameter of the pipe and the range marked on the restrainer to ensure you have the proper size.

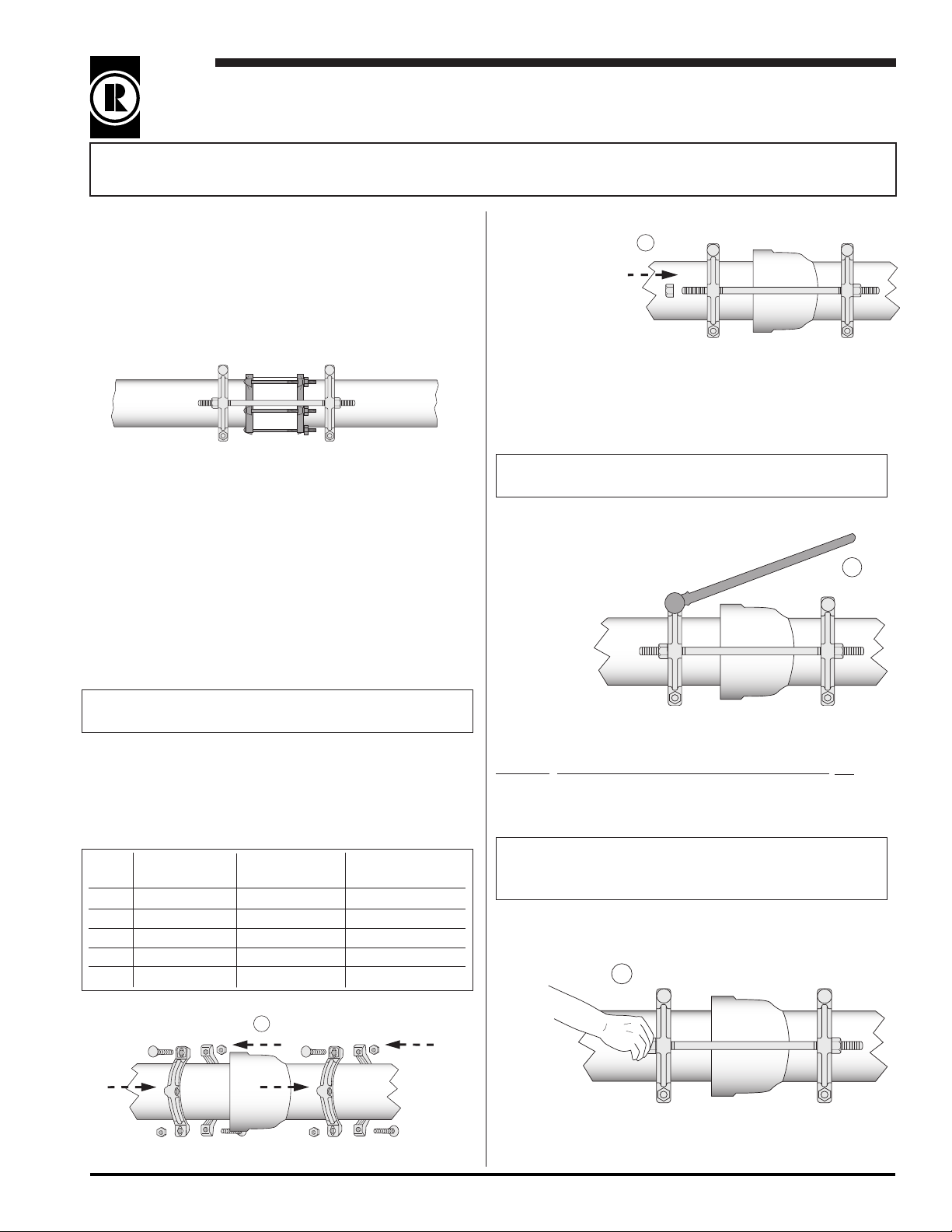

Step 4 • Rotate

4" - 12" 611 Restrainer

for Bell Joints and Romac

501 & 511 Couplings

NOTE: Not for use on polyethylene pipe, plain

end mechanical joint ttings, steel pipe or C909.

Step 1 • Assemble the bell joint or coupling per manufac-

turer’s installation instructions.

Step 2 • Clean pipe surface on both sides of the bell joint/

coupling to remove as much dirt, coating, and corrosion as

possible. Check pipe diameter and conrm that you have the

proper size restrainer.

Note: Use BLACK restrainer on ductile iron and C900 pipe.

Use RED restrainer on IPS size PVC pipe.

one of the restrainer

assemblies so

that the loops are

aligned with the

loops in the

opposing restrainer.

Slide the restraining

rods through the loops and install a nut on each rod end.

Make sure the nut is fully engaged on the rod.

Note: When used with couplings the restrainers may need

to be rotated so the rods clear the coupling bolts.

Step 5 • Make sure both restrainer as-

semblies are perpendicular to the

pipe and the restraining rods

are parallel to the pipe.

Tighten the

clamping

bolts to the

proper torque

per the chart

below.

Document #20-9-0028 11/22/2016

Step 3 • Place one set of restrainer castings on each

side of the bell joint/coupling. Loosely install clamping bolts.

Restrainers should be equally spaced on each side of the joint.

Use the following chart to determine spacing:

Nom.

Size

4" 2 18" 12"

6" 2 20" 12"

8" 2 20" 12"

10" 4 22" 14"

12" 4 22" 14"

Number of

Restraining Rods

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Restraining Rod

Length

Suggested Distance

between Restrainers

Nom. Pipe Diameter Bolt Size Torque

4" & 6" 5/8" 90 ft-lbs

8" 3/4" 150 ft-lbs.

10" & 12" 7/8" 190 ft-lbs.

Note: The clamping bolts should be tightened in a manner

that keeps the gaps between the castings equal on both

sides.

Step 6 • Tighten all nuts on the restraining rods hand

tight.

ROMAC

INDUSTRIES,

INC.

INSTALLATION INSTRUCTIONS

4" - 12" 611 Restrainer

for Bell Joints and Romac 501 & 511 Couplings

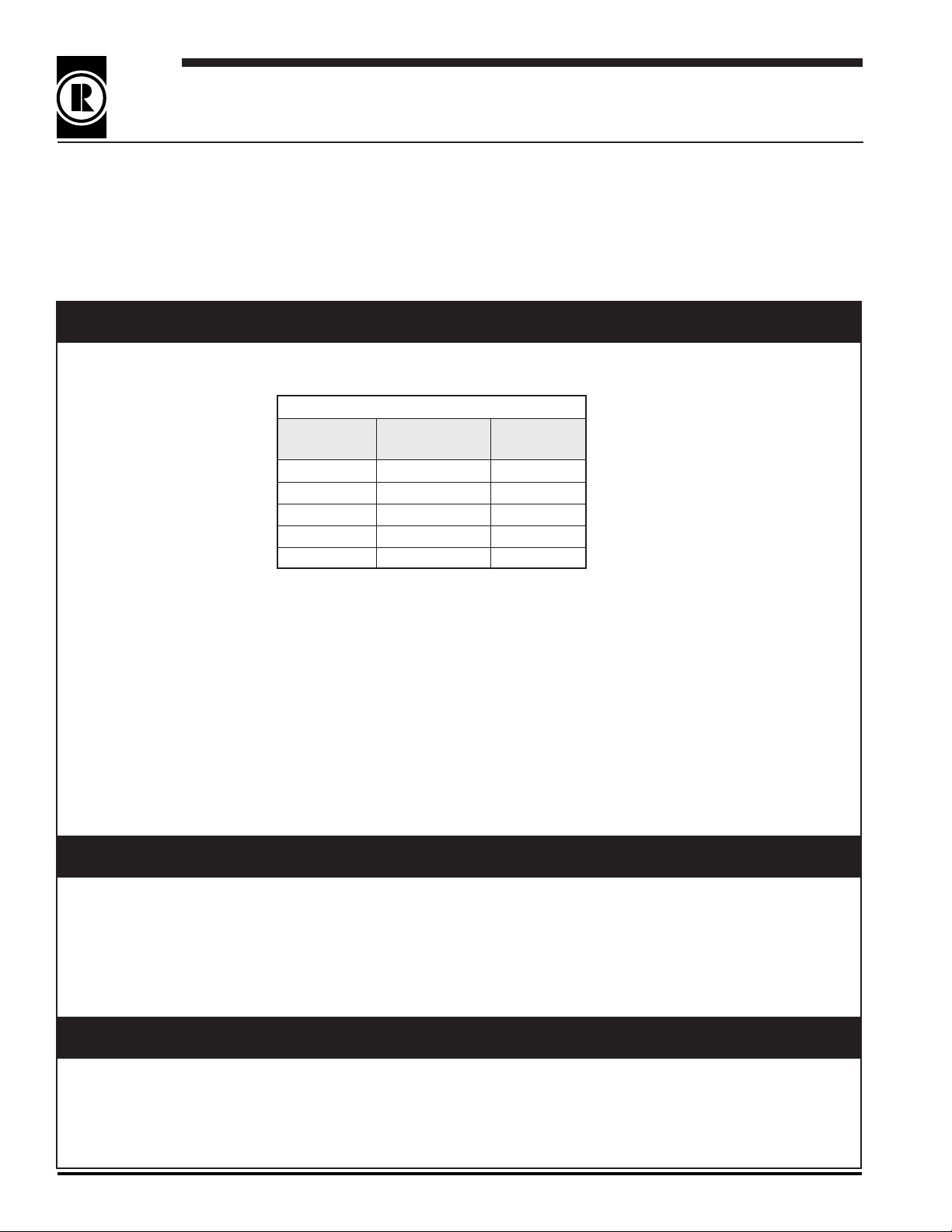

PRECAUTIONS

1. Check diameter of pipe to make sure you are using the correctly sized restrainer. Black is for ductile iron

and C900 pipe, Red is for IPS PVC.

PIPE SIZES

Nominal D.I. / C-900 IPS

Pipe O.D. Pipe O.D. Pipe O.D.

4" 4.80 4.50

6" 6.90 6.63

8" 9.05 8.63

10" 11.10 10.75

12" 13.20 12.75

2. Clean pipe to remove as much dirt, coatings, and corrosion as possible from the surface.

3. Make sure no foreign materials become lodged between the restrainer halves or between the restrainer

and pipe.

4. Avoid loose tting wrenches, or wrenches so short that achieving proper torque is difcult.

5. Keep threads free of foreign material to allow proper tightening.

6. Bolts are often not tightened enough when a torque wrench is not used. Take extra care in this situation to

make sure bolts are properly tightened.

7. Over-tightening the restraining rod nuts can dislodge the bell joint (coupling) and draw the pipe ends together.

This can put excessive stress on the pipe.

8. Pressure test for leaks before backlling.

9. Backll and compact carefully around pipe and ttings.

COMMON INSTALLATION PROBLEMS

1. Not enough torque on clamping bolts.

2. Debris lodged between restrainer halves or between restrainer and pipe.

3. Dirty threads on bolts or nuts.

4. Not using the proper size restrainer for the pipe.

5. Forgetting to tighten clamping bolts and/or coupling bolts.

IF RESTRAINER MUST BE REMOVED

1. Make sure pipe is not pressurized. Removing the restrainer could cause the pipe joint to separate.

2. Make sure a restraining system is in place before re-pressurizing pipe.

21919 20th Avenue SE • Suite 100 • Bothell, WA 98021 • Phone (425) 951-6200 • 1-800-426-9341 • Fax (425) 951-6201

Loading...

Loading...