SERVICE

DVD PLAYER

DVD PLAYER CONTENTS

Manual

STANDBY/ON

STANDBY / ON

OPEN /CLOSE

STOP SKIP SKIP

PLAY / PAUSE

OPEN/CLOSE

STOP

1. Precautions

2. Disassembly

3. Exploded Views

4. Deck

5. Block Diagrams

6. PCB Diagrams

7. Schematic Diagrams

8. Electrical Part List

1. Precautions

Prior to shipment from the factory, the products are strictly inspected to conform with the recognized product safety

and electrical codes of the countries in which they are to be sold. However, in order to maintain such compliance, it

is equally important to implement the following precautions when a set is being serviced.

1-1 Safety Precautions

(1) Locations requiring special caution are denoted

by labels and inscriptions on the cabinet, chassis

andcertain parts of the product. When performing

service, be sure to read and comply with these and

other cautionary notices appearing in the

operation and service manuals.

(2) Some parts are critical for safety. Replace only

with specified part numbers.

Note: Parts in this category also include those

specified to comply with X-ray emission standards for products using cathode ray tubes and

those specified for compliance with various

regulations regarding spurious radiation emission.

(3) Use specified internal wiring. Note especially:

1) Double insulated wires

2) High voltage leads

(4) Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulation sheets for transistor

(5) Observe that wires do not contact heat producing

parts (heatsinks, oxide metal film resistors, fusible

resistors, ets.)

(6) Check that replaced wires do not contact sharp

edged or pointed parts.

(7) 1) When a power cord has been replaced, check

that A mark is made on the cord, under strain, near

the aperture, and the flexible cord is subjected 100

times to a pull of 40N for a duration of 1 second

each.

2) During the test, the cord shall not be displaced

by more than 2mm.

(8) Also check areas surrounding repaired locations.

1-1

1-2 ESD Precautions

Electrostatically Sensitive Devices(ESD)

Some semiconductor (solid state) devices can be

damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices (ESD). Examples of

typical ESD devices are integrated circuits and some

field-effect transistors and semiconductor chip

components. The following techniques should be used

to help reduce the incidence of component damage

caused by static electricity.

(1)

Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively, obtain

and wear a commercially available discharging wrist

strap device, which should be removed for potential

shock reasons prior to applying power to the unit

under test.

(2) After removing an electrical assembly equipped with

ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Some solder removal devices not classified as "anti-

static" can generate electrical charges sufficient to

damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ESD

devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before you are

ready to install it. (Most replacement ESD devices

are packaged with leads electrically shorted together

by conductive foam, aluminum foil or comparable

conductive materials).

(7)

Immediately before removing the protective

materials from the leads of a replacement ESD

device, touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the

chassis or circuit, and observe all other safety

precautions.

(8)

Minimize bodily motions when handling

unpackaged replacement ESD devices.

(Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static

electricity sufficient to damage an ESD device).

1-2

2. Disassembly

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to

secure metal parts. If they are used improperly, the screw holes will be easily damaged and the parts

can not be fixed.

2-1 Cabinet Disassembly

(1) Top Cabinet Removal

1) Release 5 screws. (See Fig.2-1)

2) Lift up the Top Cabinet in the direction of the arrow.

1

2

1 SCREW

3 SCREW

CABINET-TOP

2

1 SCREW

Fig. 2-1 Top Cabinet Removal

2-1

2. Disassembly

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to

secure metal parts. If they are used improperly, the screw holes will be easily damaged and the parts

can not be fixed.

2-1 Cabinet Disassembly

(1) Top Cabinet Removal

1) Release 5 screws. (See Fig.2-1)

2) Lift up the Top Cabinet in the direction of the arrow.

1

2

1 SCREW

3 SCREW

CABINET-TOP

2

1 SCREW

Fig. 2-1 Top Cabinet Removal

2-1

2

1 SCREW

CABINET-TOP

1

3 SCREW

2

1 SCREW

Fig. 2-1 Top Cabinet Removal

2-1

2. Disassembly

CAUTION BEFORE STARTING SERVICING

Electronic parts are susceptible to static electricity and may easily damaged, so do not forget to take a

proper grounding treatment as required.

Many screws are used inside the unit. To prevent missing, dropping, etc. of the screws, always use a

magnetized screw driver in servicing. Several kinds of screws are used and some of them need special

cautions. That is, take care of the tapping screws securing molded parts and fine pitch screws used to

secure metal parts. If they are used improperly, the screw holes will be easily damaged and the parts

can not be fixed.

2-1 Cabinet Disassembly

(1) Top Cabinet Removal

1) Release 5 screws. (See Fig.2-1)

2) Lift up the Top Cabinet in the direction of the arrow.

1

3 SCREW

2

1 SCREW

CABINET-TOP

2

1 SCREW

Fig. 2-1 Top Cabinet Removal

2-1

2-2 Door-Tray Removal

1) Open the Tray

2) Disassemble the Door-Tray in direction of arrow "A"

3) Close Tray and power off.

Note : If Tray doesn't open, insert a screw driver into the Emergency hole

1

TRAY

1

2

1

1 3

2-2

2

DOOR-TRAY

Fig. 2-2 Door-Tray Removal

3

EMERGENCY HOLE

2-2 Door-Tray Removal

1) Open the Tray

2) Disassemble the Door-Tray in direction of arrow "A"

3) Close Tray and power off.

Note : If Tray doesn't open, insert a screw driver into the Emergency hole

1

TRAY

1

2

1

1 3

2-2

2

DOOR-TRAY

Fig. 2-2 Door-Tray Removal

3

EMERGENCY HOLE

2-2 Door-Tray Removal

1) Open the Tray

2) Disassemble the Door-Tray in direction of arrow "A"

3) Close Tray and power off.

Note : If Tray doesn't open, insert a screw driver into the Emergency hole

1

TRAY

1

2

1

1 3

2-2

2

DOOR-TRAY

Fig. 2-2 Door-Tray Removal

3

EMERGENCY HOLE

2-2 Door-Tray Removal

1) Open the Tray

2) Disassemble the Door-Tray in direction of arrow "A"

3) Close Tray and power off.

Note : If Tray doesn't open, insert a screw driver into the Emergency hole

1

TRAY

1

2

1

1 3

2-2

2

DOOR-TRAY

Fig. 2-2 Door-Tray Removal

3

EMERGENCY HOLE

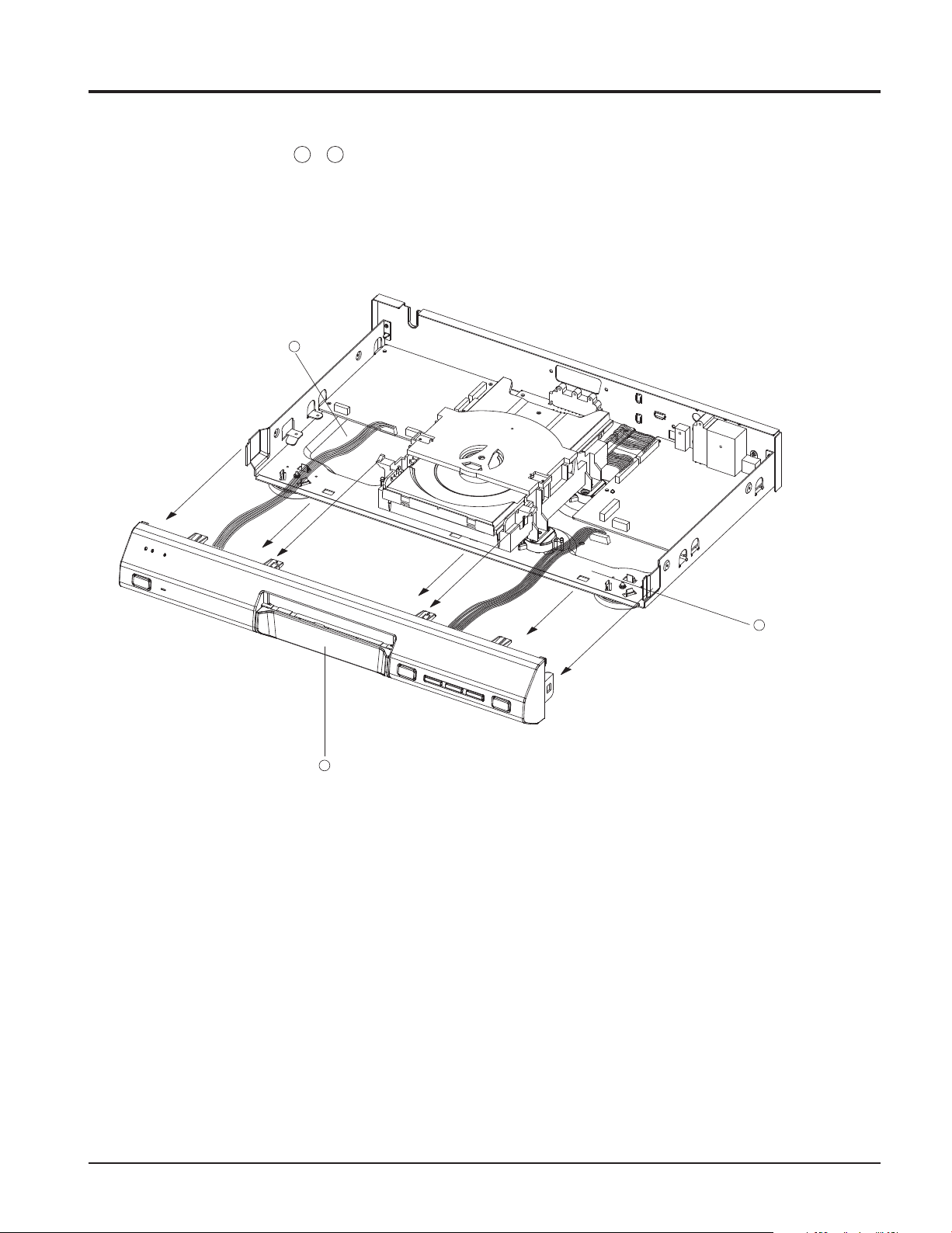

2-3 Ass'y Front-Cabinet Removal

1

1) Disconnect wire , (See Fig. 2-3)

2

1

3

FRONT-ASS'Y

2

Fig. 2-3 Ass'y Front-Cabinet Removal

2-3

2-3 Ass'y Front-Cabinet Removal

1

1) Disconnect wire , (See Fig. 2-3)

2

1

3

FRONT-ASS'Y

2

Fig. 2-3 Ass'y Front-Cabinet Removal

2-3

2-3 Ass'y Front-Cabinet Removal

1

1) Disconnect wire , (See Fig. 2-3)

2

1

3

3 FRONT-ASS'Y

Fig. 2-3 Ass'y Front-Cabinet Removal

2

2-3

2-3 Ass'y Front-Cabinet Removal

1

1) Disconnect wire , (See Fig. 2-3)

2

1

3

FRONT-ASS'Y

2

Fig. 2-3 Ass'y Front-Cabinet Removal

2-3

2-4 Ass'y Deck Removal

1) Disconnect wire housing and flat-cable .

2) Remove 4 screws and lift the deck Ass'y up.

3

1 2

3

SCREWS(4EA)

2

1

1

2-4

Fig. 2-4 Ass'y Deck Removal

2-4 Ass'y Deck Removal

1) Disconnect wire housing and flat-cable .

2) Remove 4 screws and lift the deck Ass'y up.

3

1 2

3

4 SCREWS

2

1

2-4

Fig. 2-4 Ass'y Deck Removal

2-5 PCB Removal (2CH, 1SCART)

1) Disconnect wire ,

2) Remove Screws , , , (See Fig. 2-5)

4

4 SCREWS

1

2

3 4 5 6

SMPS PCB

5

1

2 SCREWS

SCART PCB

2

MPEG-PCB

6

4 SCREWS

Fig. 2-5 PCB Removal

3

4 SCREWS

2-5

2-6 PCB Removal (2CH)

1) Disconnect wire

2) Remove Screws , , (See Fig. 2-6)

4

4 SCREWS

1

3 4 5

SMPS PCB

5

4 SCREWS

1

MPEG-PCB

Fig. 2-6 PCB Removal

3

3 SCREWS

2-6

2-7 PCB Removal (5.1CH, 1SCART)

1) Disconnect wire ,

2) Remove Screws , , , (See Fig. 2-5)

4 4 SCREWS

1

2

3 4 5 6

SMPS PCB

5 2 SCREWS

1

SCART PCB

2

6 4 SCREWS

MPEG-PCB

Fig. 2-7 PCB Removal

3 6 SCREWS

2-7

2-8 PCB Removal (5.1CH)

1) Disconnect wire

2) Remove Screws , , (See Fig. 2-8)

4 4 SCREWS

1

3 4 5

SMPS PCB

1

5 4 SCREWS

MPEG-PCB

Fig. 2-8 PCB Removal

3 5 SCREWS

2-8

3. Exploded Views

3-1 Cabinet and Main Frame Section

15

15

13

15

14

14

8

16

16

9

14

6

4

5

3

7

4

6

5

3-1

14

16

10

11

12

1

2

3. Exploded Views

3-1 Cabinet and Main Frame Section

15

15

13

15

14

14

8

16

16

14

7

9

6

5

4

3

6

4

3-1

12

14

11

16

10

1

2

3. Exploded Views

3-1 Cabinet and Main Frame Section

15

15

13

15

14

14

8

16

14

9

16

6

4

5

3

7

4

6

5

14

16

10

11

12

1

2

3-1

3. Exploded Views

3-1 Cabinet and Main Frame Section

15

13

16

14

15

9

6

15

14

3

14

8

16

14

16

10

7

6

12

11

4

1

5

4

2

3-1

SET EXPLODED - VIEW LIST

NO.

1

2

3

4

5

6

7

8

9

10

11

12

CODE NO. PART NAME DESCRIPTION Q'TY REMARK

DP00-A0001

DP00-A0002

DP00-M0019

DP00-M0023

DP00-L0003

DP00-L0004

DP00-M0022

DP02-A0011A

APSM-00002A

APSC-00001A

APMP-00002A

DPEX-10002

FRONT-ASS'Y

DOOR-ASS'Y

CHASSIS-BOTTOM

FOOT-FRONT

CUSHION-FRONT

CUSHION-BOTTOM

HOLDER-CHASSIS

LOADER-ASS'Y

CHASSIS-REAR

ASS'Y-PCB SMPS

ASS'Y-PCB SCART

ASS'Y-PCB MPEG

MOLD + PCB ASS'Y

ASS'Y, SILVER

SECC T1.0

ABS 94HB GRY

EVA 60 T3.0

EVA 60 T2.0

HIPS GRY

DM-L1

SECC TO.8

ASS'Y

ASS'Y

ASS'Y

1

1

1

2

2

2

4

1

1

1

1

1

13

14

15

16

DP00-M0021

DP00-P0001A

DP00-P0003

DP00-P0011A

CABINET-TOP

SCREW 3 * 10 YEL

SCREW 3 * 8

SCREW 3 * 8 YEL

SECC TO.6

TAP TITLE 3 * 10 YEL

TAP TITLE 3 * 8

TAP TITLE

3 * 8 YEL

1

17

5

14

COLOR

3-2

SET EXPLODED - VIEW LIST

NO.

1

2

3

4

5

6

7

8

9

10

11

12

CODE NO. PART NAME DESCRIPTION Q'TY REMARK

DP01-A0003

DP01-A0004

DP00-M0019

DP00-M0023

DP00-L0003

DP00-L0004

DP00-M0022

DP00-A0007

DP00-M0020

APSM-00002A

APSC-00001A

APMP-00002A

FRONT-ASS'Y

DOOR-ASS'Y

CHASSIS-BOTTOM

FOOT-FRONT

CUSHION-FRONT

CUSHION-BOTTOM

HOLDER-CHASSIS

LOADER-ASS'Y

CHASSIS-REAR

ASS'Y-PCB SMPS

ASS'Y-PCB SCART

ASS'Y-PCB MPEG

MOLD + PCB ASS'Y

ASS'Y, SILVER

SECC T1.0

ABS 94HB GRY

EVA 60 T3.0

EVA 60 T2.0

HIPS GRY

DM-L1

SECC TO.8

ASS'Y

ASS'Y

ASS'Y

1

1

1

2

2

2

4

1

1

1

1

1

13

14

15

16

DP00-M0021

DP00-P0001A

DP00-P0003

DP00-P0011

CABINET-TOP

SCREW 3 * 10 YEL

SCREW 3 * 8

SCREW 3 * 8 YEL

SECC TO.6

TAP TITLE 3 * 10 YEL

TAP TITLE 3 * 8

TAP TITLE

3 * 8 YEL

1

7

5

14

COLOR

3-2

SET EXPLODED - VIEW LIST

NO.

1

2

3

4

5

6

7

8

9

10

11

12

CODE NO. PART NAME DESCRIPTION Q'TY REMARK

DP01-A0010

DP01-M0027

DP00-M0019

DP00-M0039

DP00-L0003

DP00-L0004

DP01-M0038

DP02-A0012

DP01-M0025

APSM-00002A

APSC-00001A

APMP-00002A

FRONT-ASS'Y

DOOR-TRAY

CHASSIS-BOTTOM

FOOT-FRONT

CUSHION-FRONT

CUSHION-BOTTOM

HOLDER-CHASSIS

LOADER-ASS'Y

CHASSIS-REAR

ASS'Y-PCB SMPS

ASS'Y-PCB SCART

ASS'Y-PCB MPEG

MOLD+PCB ASS'Y

SILVER

SECC T1.0

ABS 94HB GRY

EVA60 T3.0

EVA60 T2.0

HIPS GRY

DM-L2

SECC T0.8

ASS'Y

ASS'Y

ASS'Y

1

1

1

2

2

2

4

1

1

1

1

1

13

14

15

16

DP00-M0021

DP00-P0001A

DP00-P0003

DP00-P0011

CABINET-TOP

SCREW 3 * 10 YEL

SCREW 3 * 8

SCREW 3 * 8 YEL

SECC T0.6

TAP TITLE 3 * 10 YEL

TAP TITLE 3 * 8

TAP TITLE 3 * 8 YEL

1

7

5

14

COLOR

3-2

SET EXPLODED - VIEW LIST

NO.

1

2

3

4

5

6

7

8

9

10

11

12

CODE NO. PART NAME DESCRIPTION Q'TY REMARK

DP01-A0001

DP01-A0002

DP00-M0019

DP00-M0023

DP00-L0003

DP00-L0004

DP00-M0022

DP00-A0007

DP00-M0020

APSM-00002A

APSC-00001A

APMP-00002A

FRONT-ASS'Y

DOOR-ASS'Y

CHASSIS-BOTTOM

FOOT-FRONT

CUSHION-FRONT

CUSHION-BOTTOM

HOLDER-CHASSIS

LOADER-ASS'Y

CHASSIS-REAR

ASS'Y-PCB SMPS

ASS'Y-PCB SCART

ASS'Y-PCB MPEG

MOLD + PCB ASS'Y

ASS'Y, SILVER

SECC T1.0

ABS 94HB GRY

EVA 60 T3.0

EVA 60 T2.0

HIPS GRY

DM-L1

SECC TO.8

ASS'Y

ASS'Y

ASS'Y

1

1

1

2

2

2

4

1

1

1

1

1

13

14

15

16

DP00-M0021

DP00-P0001A

DP00-P0003

DP00-P0011

CABINET-TOP

SCREW 3 * 10 YEL

SCREW 3 * 8

SCREW 3 * 8 YEL

SECC TO.6

TAP TITLE 3 * 10 YEL

TAP TITLE 3 * 8

TAP TITLE 3 * 8 YEL

1

7

5

14

COLOR

3-2

3-3 Front Exploded views (push - s/w)

14

14

17

7

6

13

17

16

4

9

12

14

8

1

15

5

10

11

11

3-3

3

2

Loading...

Loading...