Page 1

OPERATION and MAINTENANCE

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

Initial issue 20 January 2008

Revision 6 Aug.15/2012

Publication ref. CSP21009

Export controlled

This document may contain information whose

export is restricted by the Arms Export Control

Act (Title 22, U.S.C., Sec 2751, Et Seq.) or the

Export Administration Act of 1979, as ammended,

(Title 50, U.S.C., App. 2401, Et Seq.). Violations

to these export laws are subject to severe criminal

penalties. This technical data is exported from the

United States in accordance with the Export

Administration regulations. Diversion contrary to U.S.

law is prohibited. This technical data has been identified

as 9E991, No License Required, by the Global

Trade Compliance Office, Rolls-Royce Corp.

Liability disclaimer

This information is given in good faith, based on

the latest information available. No warranty or

other representation is given concerning such

information, which must not be taken as

establishing any contractual or other commitment

by the company or any of its subsidiaries or

associated companies

RR300 Series

Notice

The procedures, guidelines, and information set

forth in this publication are based solely upon the

Rolls-Royce FAA approved type design and are intended

only for the operation, maintenance, repair and overhaul

of Rolls-Royce type design parts. Rolls-Royce has no

knowledge regarding the applicability of these

procedures and guidelines or subsequent revisions

thereof to parts designed and/or manufactured by

entities other than Rolls-Royce or Rolls-Royce

approved vendors and suppliers.

Proprietary rights legend

Rolls-Royce Corporation

These technical data and the information

embodied herein are the property of and

proprietary to Rolls-Royce Corporation, and

shall not, without prior written permission of

Rolls-Royce Corporation be disclosed or

duplicated in whole or in part. This legend shall

be included on any reproduction of this data in

whole or in part.

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Printed in USA

Federal Aviation Administration Approved

Page 2

Aug.15/2012

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

Date

OPERATION and MAINTENANCE

Publication Ref: CSP21009

TRANSMITTAL LETTER No.6

Remove: Incorporate: Reason For Change:

CHAPTER 05

List of Effective Pages Page 1/2 Page 1/2

05-50-00-100-801 All Pages Pages 701 and 702 Revised - Changed

internal and external flush

task sequence numbers WP191890

CHAPTER 72

List of Effective Pages Pages 1 to 3/4 Pages 1 to 3/4

72-00-00-100-803 All Pages Pages 701 to 703/704 Deleted tasks for external

rinse - WP191891

72-30-00-200-801 All Pages Pages 601 to 605/606 Revised - Revised

illsutration, FIG. 602 to

match RR300 part WP195413

72-30-00-300-801 All Pages Pages 801 to 803/804 Revised - Revised

illustration, FIG. 801 to

match RR300 part WP209753

72-30-05-200-801 All Pages Pages 601 to 603/604 Note added & illustration

modified - WP207805

72-40-50-300-801 All Pages Page 801/802 Revised - Task Deleted,

cannot repair dents in

combustion liner assembly

at OMM level - WP

217855.

72-60-10-000-805 All Pages Pages 401 to 404 Revision - Change to add

new removal tool

23083912 - WP215606

Page 3

Remove: Incorporate: Reason For Change:

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

72-60-10-400-805 All Pages Pages 401 to 406 Revision - Change to add

new installation tool

23083918 - WP215607

CHAPTER 73

List of Effective Pages Pages 1 and 2 Pages 1 and 2

CONTENTS Pages 1 and 2 Pages 1 to 3/4

73-11-10-700-801 Pages 501 to 503/504 First Issue - Test the fuel

nozzle - WP 209769

73-11-10-200-801 All Pages Pages 601 to 603/604 Revised - Added

instructions to inspection

table to clean the fuel

nozzle - WP 209768

73-11-10-100-801 Pages 701 to 705/706 First Issue - Clean the fuel

nozzle without

disassembly - WP 209767

CHAPTER 79

List of Effective Pages Page 1/2 Page 1/2

79-23-10-400-801 All Pages Pages 401 to 404 Revised - Oil change

process to add bleeding of

the #1 and 8 scavenge

lines along with bleeding

of the filter bowl WP191608

79-33-10-700-801 All Pages Pages 501 to 503/504 Revised - WP120364 :

Added tooling and

changed nomenclature of

part - WP120364

79-33-15-700-801 All Pages Pages 501 to 503/504 Revised - WP120366 :

Changed part

nomenclature - WP120366

Record of Revisions Sheet Record incorporation

of TL 6 and date of

incorporation on

RECORD OF

CERTIFIED

REVISIONS

2

Page 4

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

EFFECTIVITY: ALL

SERVICE BULLETIN LIST

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 1/2

Jan 20/08

Page 5

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

INTRODUCTION

A. General

(1) Operation and Maintenance Manual

(a) The engine model designation used throughout this manual (RR300 Series) refers to the same

engine model (250-C300/A1) that is both stamped on the engine data plate and listed on the

official Engine Type Certificate, Number E4CE, issued by the FAA. The RR300 Series

Operation and Maintenance Manual (OMM) is part of a set of manuals that helps the operator

do the necessary maintenance to the engine. It is written so a technician who does not know

the engine can:

- Do the maintenance and the servicing of the engine systems and components

- Isolate failures of the engine systems and components.

- Use the OMM when the engine is installed on the aircraft.

(b) Rolls-Royce technical publications, in whole or in part, cannot be utilized as a means to

establish serviceability of material not manufactured or approved by Rolls-Royce. Rolls-Royce

technical publications and documents are developed solely for use in support of applicable

Rolls-Royce parts. Parts, materials, or processes not approved by Rolls-Royce were not

considered in the development of Rolls-Royce technical publications due to Rolls-Royce not

having knowledge of any specifications or design criteria for parts, overhaul or repair processes

of parts or material not authorized by Rolls-Royce. Therefore, Rolls-Royce technical

publications must not be used to support or maintain engines, modules, or parts using details,

parts, materials, or processes that are not Rolls-Royce approved. Rolls-Royce disclaims any

liability for the performance or the failure to perform of engines, modules or parts that have

been maintained or supported using parts, materials, or processes not authorized by

Rolls-Royce.

(2) Related Manuals

(a) The manuals included in the set are the:

- Operation and Maintenance Manual (OMM)

- Line Level Illustrated Parts Catalog (LLIPC).

B. Potential Safety Issues

(1) When performing maintenance on RR300 Series engines, the approved maintenance facilities are

responsible for reporting safety related items. Safety related items must be reported to Rolls-Royce

Customer Service (REF. Section L.) and the Federal Aviation Administration. Refer to FAR 145.221

Service Difficulty Reports.

C. The Specifications of this Manual

(1) This manual is written to the Air Transport Association of America Specification No. 100 (ATA 100),

Revision 31. The writing rules and the vocabulary are in accordance with the ASD Simplified

Technical English, Specification ASD-STE-100, Issue 3. All the spelling is in American English.

D. Manual Content

(1) Manual Frontmatter.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 1

Dec 15/11

Page 6

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

(a) The OMM contains a set of manual frontmatter and a set of chapters. The manual frontmatter

includes:

- The Title page

- The Record of Revisions

- The Frontmatter List of Effective Pages

- The Table of Contents

- The List of Service Bulletins

- The Introduction.

(2) The Chapter Number System.

(a) The OMM has these groups of chapters:

1 General

- Chapter 05 - Time Limits/Maintenance checks

- Chapter 12 - Engine Servicing

- Chapter 70 - Standard Practices - Engine

2

Power Plant

- Chapter 71 - Power Plant

- Section 1 - Engine Description

- Section 2 - Engine Performance and Operation

3 Engine

- Chapter 72 - Engine

- Chapter 73 - Engine Fuel and Control

- Chapter 74 - Ignition

- Chapter 75 - Air

- Chapter 77 - Engine Indicating

- Chapter 79 - Oil

- Chapter 80 - Starting.

(3) Tab Dividers.

(a) At the front of each chapter there is a yellow tab card. The chapter number and title are printed

on the tab. There is also a yellow tab card at the front of the Introduction.

(4) Identification Code.

(a) An identification code that has six numbers divides the chapter into its related parts. This

identification code is divided into three elements. Each element contains two numbers. The

code divides the data into:

- Chapter/System (First element)

- Section/Sub-system (Second element)

- Subject/Unit (Third element).

(5) The List of Temporary Revisions.

(a) The List of Temporary Revisions (LETR) lets the operator make a record of the Temporary

Revisions (TRs) that affect each Chapter.

(6) The Page Number System.

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 2

Dec 15/11

Page 7

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

(a) A system of page numbers divides each Chapter-Section-Subject (CH-SE-SU) into page

blocks and topics, as follows:

- Page Block 1 - Description and Operation

- Page Block 101 - Fault Isolation

- Page Block 201 - Maintenance Practices

- Page Block 301 - Servicing

- Page Block 401 - Removal/Installation

- Page Block 501 - Adjustment/Test

- Page Block 601 - Inspection/Check

- Page Block 701 - Cleaning/Painting

- Page Block 801 - Repairs.

(b) The page identification code, which includes the CH-SE-SU code, is given at the bottom right

side of each page.

(7) The Chapter List of Effective Pages (LEP).

(a) The LEP of a chapter gives a list, in page block sequence, of pages contained in the chapter.

The LEP includes a list of the Contents and the LEP pages.

(b) The data adjacent to each page number on the LEP shows the correct revision date for that

page. The number of pages contained in a chapter and the data on each page must agree with

the LEP data.

(c) Each time a chapter has a revision, a new LEP is issued to give the new revision date of the

changed pages.

(8) The Chapter Contents Pages.

(a) The chapter contents pages gives a list, in CH-SE-SU number sequence, of the subjects

included in a chapter. The topics for each subject are shown in page block sequence.

(9) The Figure Number System.

(a) The figure number system in a page block is the same as the page number system. For

example, the second figure in a Maintenance Practices page block is FIG. 202. The figures for

each task are at the end of the task.

(10) Data in this Manual.

(a) The data in this manual includes:

- The data necessary to do the scheduled maintenance tasks

- The data that describes the engine, its structure and systems, and tells how the systems

operate

- The procedures and related safety precautions for on-wing servicing and maintenance

necessary for continued airworthiness.

E. Page Block and Topic Contents

(1) Page Block 1 - Description and Operation.

(a) This topic gives sufficient data to train maintenance persons to know the function, the

configuration, the operation and the control of the system or component.

(2) Page Block 101 - Fault Isolation.

(a) This topic gives the procedures to isolate and correct faults in a system or component.

(3) Page Block 201 - Maintenance Practices.

(a) This topic includes all maintenance procedures, applicable to a CH-SE-SU, easily contained in

one page block. Page Block 201 is also for those maintenance procedures that are not related

to the topics of other page blocks.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 3

Dec 15/11

Page 8

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

(4) Page Block 301 - Servicing.

(a) This page block contains the applicable data for the scheduled and the unscheduled servicing.

(5) Page Block 401 - Removal/Installation.

(a) This topic gives the data necessary for the removal and installation of a unit/assembly.

(6) Page Block 501 - Adjustment/Test.

(a) This topic gives the data necessary to adjust and/or do a test of a system, sub-system,

assembly, or unit. There are two types of tests:

1 The Operational Test is the procedure to make sure that a system, sub-system, assembly,

or unit operates. Special equipment is not necessary for this test.

2 The Functional Test is the procedure to make sure that a system, subsystem, assembly,

or unit is correctly adjusted and operates fully to its specification. The test usually uses

special equipment to measure the performance of the system, sub-system, assembly, or

unit.

(7) Page Block 601 - Inspection/Check.

(a) This topic gives the data necessary to make sure that a system, sub-system, assembly, unit, or

part is serviceable.

1

Inspection Tables tables are divided into four categories.

a The first category is ITEM. The ITEM category contains the engine component, or

sub-assembly of that component. The type of damage or condition of the part or

sub-assembly is directly under the part nomenclature and is hyphenated.

b The second category is the SERVICEABLE LIMIT. The SERVICEABLE LIMIT is

defined as the maximum degree of a specified condition which can be accepted and

lets the part be placed back into service without repair. No other action is necessary.

c The third category is the REPAIR LIMIT. The REPAIR LIMIT is defined as the

maximum degree of a specified condition which can be repaired. Any condition

exceeding this limit cannot be corrected by the specified repair procedure; therefore,

the part must be replaced.

d The fourth category is ACTION NECESSARY. The ACTION NECESSARY is defined

as the recommended corrective action for a given condition.

(8) Page Block 701 - Cleaning/Painting.

(a) This topic gives the data necessary to clean and/or paint parts or areas of the engine.

(9) Page Block 801 - Repairs.

(a) This topic gives repair procedures that are necessary during on-wing maintenance and are not

included in another manual.

F. Effectivity

(1) The EFFECTIVITY Block.

(a) The effectivity block is located in the lower left corner of the page. The effectivity block

identifies engine model, maintenance data, or other maintenance information that applies to the

configuration of the engine. The data must be considered satisfactory for all of the engine

models when the effectivity block has been removed or is blank.

G. How to Use this Manual

(1) The Applicable Data.

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 4

Dec 15/11

Page 9

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

(a) To find the data applicable to your task:

1 Refer to the list of chapters in para D. (2)(a) of this Introduction and find the chapter

related to the necessary data.

2 Read the yellow tab cards to identify the necessary chapter.

3 Open the manual at the start of the applicable chapter and refer to the contents pages.

NOTE: The contents page of each chapter gives a list of the data/procedures in the

related chapter. The list is in CH-SE-SU sequence. The page blocks of each

CH-SE-SU are in number sequence.

4 Identify the CH-SE-SU on the contents page.

5 Identify the page block applicable to the necessary data (Refer to para D. (6) of this

Introduction for a list of the page block numbers and their titles).

6 An example of the procedure given in the above para G. (1)(a) of this Introduction is as

follows:

a

To find the data to remove and install a fuel nozzle, you must:

- Identify that the item is part of the fuel system.

- Refer to the List of Chapters in para D. (2)(a)2 Power Plant.

- Identify Chapter 73 - Engine Fuel and Control.

- Use the yellow tab cards in the manual to find Chapter 73 - Engine Fuel and

Control.

- Refer to the Contents at the start of Chapter 73 and identify the necessary data,

which is 73-11-10, Page Block 401 - Fuel Nozzle Removal/Installation.

- Open the manual at 73-11-10, Page Block 401, where you will find the necessary

procedures to remove and install the fuel nozzle.

(2) Aircraft Maintenance Task Oriented Support System (AMTOSS).

(a) AMTOSS Codes.REF. FIG. 1

1 AMTOSS codes are included in page blocks 201 thru 801. AMTOSS gives each of the

maintenance procedures (tasks) and the primary steps of the procedures (subtasks) a

different number identification code.

2 The identification code numbers have a minimum of five elements and a maximum of

seven elements. These elements are an extension of the three-element ATA 100

CH-SE-SU numbers. Refer to FIG. 1 for an example of task and subtask code.

(b) Function Codes.

1 The function codes in the AMTOSS task (T) and subtask (S) numbers show the type of

work that has to be done. The function codes used and a description of each is in the list

that follows:

2 Function code 000 - Removal.

APPL FC APPLICATION OF THE FUNCTION CODES

T 000 REMOVAL

EFFECTIVITY: ALL

The subtask content of the removal task must mirror that of its

associated installation task. In particular, the 400 function codes

used must bear a direct relation to the 000 codes. This number is

only used for a task title line, i.e., Remove the Fuel Nozzle.

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 5

Dec 15/11

Page 10

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

APPL FC APPLICATION OF THE FUNCTION CODES

T/S 010 REMOVE/OPEN FOR ACCESS

S 020 REMOVE UNIT/COMPONENT/or any part of the UNIT Removal of

T/S 040 DEACTIVATE

S 080 REMOVE TEST/SUPPORT EQUIPMENT

Remove or open a panel, door, component, etc. to gain access to

the task subject or to allow the core subtask to be done. Includes

removal/disconnection of items that impede access but are not

related to the task subject.

the Unit (the ATA breakdown subject) including all attaching and

connected parts. This can also include capping of lines, electrical

connectors, etc.

Deactivation of the system. Covers making a system component etc.

inoperable for maintenance by means other than circuit breaker,

blocking tools, etc., which are covered by specific codes.

Remove or disconnect any tool that has been defined as special or

standard and that is not covered by function codes 941/942.

3 Function code 100 - Cleaning.

APPL FC APPLICATION OF THE FUNCTION CODES

T 100 CLEANING

This is not to be used for preparation for another task. This number

is only used in a task title line.

T/S 110 CHEMICAL

Use chemical agent(s) to clean. Includes preparation of the

chemical.

T/S 120 ABRASIVE

Remove unwanted materials with WET/DRY particle impingement.

T/S 130 ULTRASONIC (SOUND WAVES)

Remove unwanted surface material and other materials caught in

the surface using high-frequency sound.

T/S 140 MECHANICAL

Remove unwanted materials with a brush, lint-free cloth or other

mechanical procedure.

T/S 150 STRIPPING

Removal of paint, etc. from metal or non-metal surfaces using

mechanical or chemical process. Also includes the removal of any

residue from the process.

T/S 160 MISCELLANEOUS CLEANING

T/S 170 FLUSHING

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Remove unwanted material with compressed air, suction, by hand,

etc.

Flush unwanted material through and out of a component or system

with fluid.

INTRODUCTION

Page 6

Dec 15/11

Page 11

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

4 Function code 200 - Inspection/Check.

APPL

T 200 INSPECTION/CHECK

T/S 210 GENERAL VISUAL

T/S 220 DETAILED DIMENSIONAL

T/S 230 PENETRANT

T/S 240 MAGNETIC

T/S 250 EDDY CURRENT

FC APPLICATION OF THE FUNCTION CODES

This number is only used in a task title line, i.e. Inspect the

Desiccator Crystals.

Full inspection of

ZONE/SYSTEM/SUBSYSTEM/COMPONENT/PART to find

structural damage, failure, and/or deterioration. Gives the proper

corrective maintenance procedure if necessary. Not to be used for

FOD checks, during job close-up, etc.

Inspect dimensions, conditions, or indications of

COMPONENTS/SUBSYSTEMS/SYSTEMS. Compare with

specifications in the original design documentation to decide

whether further maintenance is required.

Include checks of indicators and other readouts to confirm that a

value is within limits.

Find surface cracks with dye penetrant techniques.

Find surface cracks in a material by means of magnetic fields.

Use electromagnetic waves to find internal cracks, porosity, very

small openings, unwanted materials, or non-homogeneous material

structure.

T/S 260 X-RAY/HOLOGRAPHIC

To find internal cracks, porosity, very small openings, unwanted

materials, or non-homogeneous material structure.

T/S 270 ULTRASONIC

To find internal cracks, porosity, very small openings, unwanted

materials, or non-homogeneous material structure.

T/S 280 SPECIFIC/SPECIAL

For procedures NOT INCLUDED in codes 210-270 and 290.

Includes abnormal operation and continued service procedures.

T/S 281 SAMPLING

Procedures to obtain small representative quantities of materials

(gas, liquid, or solid) for the purpose of analysis.

T/S 290 BORESCOPE

To do an internal examination of a component, part and/or

assembly.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 7

Dec 15/11

Page 12

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

5 Function code 300 - Repair.

APPL

T 300 REPAIR

T/S 310 WELDING/BRAZING

T/S 320 MACHINING/RENAMING/BLENDING

T/S 330 COMPOSITE

T/S 340 FIBERGLASS/PLASTIC/HONEYCOMB/EPOXY

T/S 350 MISCELLANEOUS REPAIR

T/S 360 LEAKAGE REPAIR Repair leaks (except by application of

T/S 370 PAINTING

FC APPLICATION OF THE FUNCTION CODES

This number is only used in a task title line.

Join parts together by any welding or brazing method.

Repair metal parts or assemblies.

Repair composite materials.

Repair fiberglass, plastic, honeycomb or epoxy materials. Also

includes adhesive bonding, rubber molding, fiberglass molding,

silicone rubber bonding/molding, etc.

Repair those materials or parts not included above.

sealants/compounds -see code 390).

Application of primer and top coat to any area. Includes surface

pre-treatment and cleaning, mixing, application, and curing.

T/S 380 SPECIAL

For procedures NOT INCLUDED in codes 210-270 and 290.

Includes abnormal operation and continued service procedures.

T/S 390 SEALING

Apply fairing compounds, sealants, or other materials to control

corrosion, fill clearance, prevent leakage, provide a hold, or smooth

aerodynamically. Includes preparation of materials, cleaning of

surfaces, mixing and curing.

6 Function code 400 - Installation.

APPL FC APPLICATION OF THE FUNCTION CODES

T 400 INSTALLATION

This number is only used in a task title line, i.e. Install the Fuel

Nozzle.

T/S 410 INSTALL/CLOSE FOR ACCESS

Install or close a panel, door, component, etc. used to gain access to

the task subject or to allow the core subtask to be done. Includes

installation/re-connection of items that impeded access but are not

related to the task subject.

T/S 420 INSTALL UNIT/COMPONENT Installation of the Unit (the ATA

breakdown subject) includes all attaching and connected parts. This

is the core Subtask of an installation task for the complete ATA

subject number unit.

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 8

Dec 15/11

Page 13

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

APPL FC APPLICATION OF THE FUNCTION CODES

T/S 440 DEACTIVATE

T/S 480 INSTALL TEST/SUPPORT EQUIPMENT

7 Function code 500 - Material Handling.

APPL FC APPLICATION OF THE FUNCTION CODES

Deactivation of a system. Covers making a system component, etc.

operable after maintenance by means other than circuit breakers,

blocking tools, etc., which are covered by specific codes.

Install or connect any tool that has been defined as special or

standard, and the purpose of which is to show or simulate the

condition, position, status, etc. of a system component. Does NOT

include test equipment installed as an integral part of the core

subtask unless the installation is sufficiently complex to warrant a

separate subtask. Includes items that are not physically connected

to the aircraft, such as a radio test transmitter. Also includes rigging

pins, etc. installed for purposes other than rigging the system in

which they are fitted (see code 941).

T 500 MATERIAL HANDLING

This number is only used in a task title line.

T/S 530 PACKING

Packing consists of installation of parts, sub-assemblies, or

assemblies in shipping containers. This includes all capping of lines,

installation of plugs, etc. Applicable to prepare a component after

removal from aircraft for storage.

T/S 540 UNPACKING

Unpacking is defined as the removal of items, sub-assemblies, or

assemblies from shipping containers. This includes all removal of all

protection material. The component that is the subject of an

installation task is to be considered as unpacked, depreserved, etc.

T/S 550 STORAGE/RETURN TO SERVICE

Storage is the safekeeping of the aircraft/engine and

assemblies/sub-assemblies until required for use. Can require

specific procedures not covered by any other function codes. Return

to service is the specific procedure to prepare for operation.

S 560 MARSHALLING

Marshalling refers to the collecting of individual parts,

sub-assemblies, or assemblies prior to release for assembly. This

function code must be used for replacement component preparation

before installation. One subtask must cover the complete

preparation procedure.

T 580 AIRCRAFT HANDLING

T/S 581 LIFTING

EFFECTIVITY: ALL

See breakdown below.

ATA Chapter 7.

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 9

Dec 15/11

Page 14

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

APPL FC APPLICATION OF THE FUNCTION CODES

T/S 582 JACKING

T/S 583 SHORING

T/S 584 TOWING

T/S 585 TAXIING

T/S 586 LEVELING AND WEIGHING

8 Function code 600 - Servicing/Preserving/Lubrication.

APPL FC APPLICATION OF THE FUNCTION CODES

T 600 SERVICING/PRESERVING/LUBRICATION

ATA Chapter 7.

Includes lifting and lowering the jacks.

ATA Chapter 7.

ATA Chapter 9.

ATA Chapter 9.

ATA Chapter 8.

This number is only used in a task title line.

T/S 610 SERVICING

To keep in good operational condition, including procedures not

specified by other breakdowns in this series. Includes replenishing

(filling) of fluids (oil, hydraulic, water, etc.).

T/S 614 GAS CHARGING/DISCHARGING

Tires, accumulators, etc.

T/S 620 PRESERVING

This is the preparation of a component/part for safekeeping from

decomposition or deterioration. Includes preparation for storage by

applying a preservative layer to, and desiccants in, hardware. It also

includes the prevention of microbial growth in fuel tanks, application

of corrosion inhibitants and protection, etc. Does not include aircraft

storage, which is covered by Function Code 550.

T/S 630 DEPRESERVING

Depreserving pertains to removing the preservative layer and/or

desiccants form the component/part in preparation for installation or

operation.

T/S 640 LUBRICATING

ONLY for PURE lubrication tasks and subtasks. Lubricate moving

parts.

T/S 650 FUELING/DEFUELING

Fuel movement for all operational and maintenance purposes.

T/S 660 DEICING/ANTI-ICING

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Removal and prevention of ice and snow build-up on parked aircraft

and applications to prevent the accumulation of ice and snow.

INTRODUCTION

Page 10

Dec 15/11

Page 15

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

APPL FC APPLICATION OF THE FUNCTION CODES

T/S 670 DISINFECT/SANITIZE

T/S 680 DRAIN FLUID

9 Function code 700 - Testing.

APPL FC APPLICATION OF THE FUNCTION CODES

T 700 TESTING

T/S 710 OPERATIONAL

Core subtask for health conditions. Can include draining (where

integral to the task), cleaning and handling of lavatory components,

etc.

During servicing or other maintenance procedures, such as water,

oil, fuel, lavatories, etc. This is the other half of replenishing when

the system is to be emptied and filled.

This number is only used in a task title line.

An operational test verifies that the system or component is

operable, without taking into account specifications and tolerances

that are usually established for overhaul or major maintenance

periods. The test requires no special equipment. Can include BITE

functions.

T/S 720 FUNCTIONAL

A functional test verifies that a system or component is functioning

within the minimum design specifications. This test is more detailed

than an operational test and can require special test equipment.

Values and tolerances must be specified. Can include BITE

functions.

T/S 730 SYSTEM

Contains all specifications and tolerances necessary to make sure

the system and its components are performing at maximum design

efficiency. The test must be sufficiently thorough to detect early

signs of wear, deterioration, and calibration drift. The test can

require special test equipment. Values and tolerances must be

specified. The test is self-contained and can duplicate another test.

Can include BITE functions.

T/S 740 BITE

Used for tasks (and subtasks where the test is part of a task

procedure). Those checks conducted using Built-In Test Equipment

(BITE) and Maintenance Diagnostic System (MDS) including the

power-up test.

T/S 750 SPECIAL

Used for tasks (and subtasks where the test is part of a

taskprocedure). Special checks such as smoke check, sniff checks,

etc.

T/S 760 ELECTRICAL

EFFECTIVITY: ALL

Electrical checks to determine continuity, voltage, resistance, etc.

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 11

Dec 15/11

Page 16

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

APPL FC APPLICATION OF THE FUNCTION CODES

T/S 780 PRESSURE

T/S 790 LEAK

10 Function code 800 - Miscellaneous.

APPL FC APPLICATION OF THE FUNCTION CODES

T 800 MISCELLANEOUS

T/S 810 FAULT ISOLATION

Establishes the ability of a normally pressurized system or

component to operate properly.

Make sure a system or component does not leak or does so within

specified limits. Procedures for application of leak check solutions.

This number is only used in a task title line.

Fault isolation consists of the following procedures:

- Operating the engine to locate the prime suspect deficient system

- Operating an improperly functioning system or component in order

to locate the cause of the malfunction

- Performing a series of prescribed checks to isolate a failed part or

component.

T/S 820 ADJUSTING/ALIGNING/CALIBRATING

Make a physical correction to ensure proper placement,

operation or testing of a system or component.

T/S 830 RIGGING

Check, and, as necessary, adjust mechanically operated systems

such as flight control cables, actuator arms, push-pullrods, etc.

Includes installing and removing rigging pins, blocks, boards, etc.

where specifically used to give an indication of the state of rigging.

T/S 840 PREPARE FOR . . ., RESTORE . . ., TO NORMAL . . .

Used when separate tasks are provided for preparing for

maintenance or restoring to normal after maintenance when these

procedures are lengthy and identical for several applications.

T/S 850 OPERATOR MODIFICATION INCORPORATION

Operator use only. Complete tasks only.

T/S 860 AIRCRAFT/SYSTEM CONFIGURATION

Make sure the aircraft is in an approved condition for maintenance

or to return it to an operational configuration. This code also covers

operating any system or component in order to accomplish a task.

Also specifically covers the following operations:

- Energize electrical network

- De-energize electrical network

- Pressurize hydraulics

- De-pressurize hydraulics

- Circuit breaker opening

- Circuit breaker closing.

T/S 870 BLEEDING

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Remove air from a system or unit filled with fluid.

INTRODUCTION

Page 12

Dec 15/11

Page 17

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

APPL FC APPLICATION OF THE FUNCTION CODES

T/S 880 HEATING/COOLING

11 Function code 900 - Change = Removal + Installation.

APPL FC APPLICATION OF THE FUNCTION CODES

T 900 CHANGE = REMOVAL + INSTALLATION

T/S 910 STANDARD PRACTICES

T/S 930 PAINT MARKING

T 940 JOB SET-UP/CLOSE-UP

Application of heating or cooling required for removal, installation,

adjustment, or testing.

This code links the removal and installation procedures of a

component or item.

Refer out of normal tasks to this code. Task can only be located in

Chapter 20, 51, and 70.

To paint markings and letters.

See breakdown below.

S 941 JOB SET-UP

Covers the positioning of general support equipment NOT covered

by the codes 480/080. Specifically: access platforms, steps, warning

notices, and fire extinguishers.

S 942 JOB CLOSE-UP

Covers the removal of general support equipment NOT covered by

the codes 480/080. Specifically: access platforms, steps, warning

notices, and fire extinguishers.

S 950 MASKING

Masking or unmasking required for painting, cleaning,

surfaceprotections, etc.

T/S 960 REPLACE

The removal and installation of minor components (O-rings, etc.)

when completely covered within one subtask. Normally only for

limited use within servicing tasks.

S 965 TRANSFER PARTS

To be used for the transfer of parts from the removed component to

the installed component.

S 970 DATA RECORDING/CALCULATING

Recording of data required for monitoring, testing, adjusting,

checking, etc., and subsequent calculation.

S 980 MANUAL OPERATION OR POSITIONING

Manually positioning or operating a system component or unit that is

normally powered, such as turning engine rotor manually, translating

thrust reversers, etc.

S 990 ILLUSTRATIONS

EFFECTIVITY: ALL

To be used when creating illustration tasks only.

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 13

Dec 15/11

Page 18

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

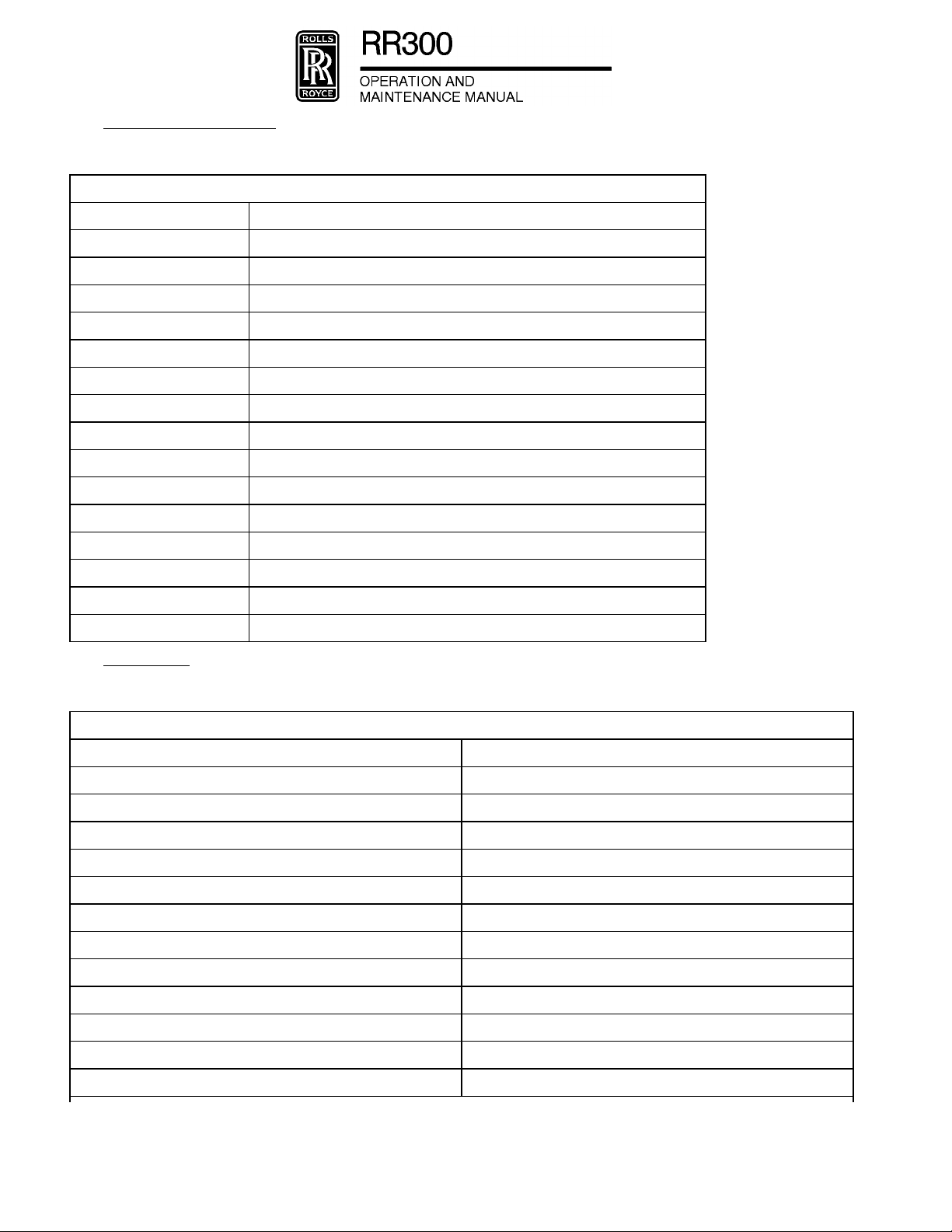

H. Abbreviations and Terms

(1) The following terms and abbreviations will be used in this manual.

ABBREVIATIONS AND TERMS

TERM DEFINITION

AGB Accessory Gearbox

GI Ground Idle

GPT Gas Producer Turbine

ID Inside Diameter

IGN Ignition

ISA International Standard Atmosphere

MGT Measured Gas Temperature

LP Low Pressure

MCT Maximum Continuous

MTO Maximum Takeoff

OD Outside Diameter

PT Power Turbine

RMS Root Mean Square

RPM Revolutions per Minute

Wf Engine Fuel Flow Rate

I. Conversions

(1) The following conversion factors will be used in this manual.

CONVERSIONS

U.S. Metric

1 in. (inch) 25.4 mm (millimeters)

1 in.² (square inch) 6.4516 cm² (square centimeters)

1 ips (inch per second) 2.54 cm/s (centimeters per second)

1 SFM (surface foot per minute) 0.3048 SMM (surface meters per minute)

°F (degrees Fahrenheit) 9/5 (°C) + 32 (°C = degrees Celsius)

1 US gal (US gallon) 3.785 liters

1 US gal (US gallon) 0.8326 Imperial gallons

1 psi (pound per square inch) 6894.757 Pa (Pascals)

1 psi (pound per square inch) 6.894757 kPa (kiloPascals)

1 psi (pound per square inch) 6894.757 N/m² (Newtons per square meter)

1 inHg (inch of mercury at 32 °F (0 °C) 0.03389 bar

1 inHg (inch of mercury at 32 °F (0 °C) 25.40 mmHg (millimeters of mercury)

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 14

Dec 15/11

Page 19

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

CONVERSIONS

U.S. Metric

1 inHg (inch of mercury at 32 °F (0 °C) 0.4912 psi (pounds per square inch)

1 inHg (inch of mercury at 32 °F (0 °C) 3.387 kPa (kiloPascals)

1 ft-lb (pound-foot) 1.35582 Nm (Newton-meters)

1 in-lb (pound-inch) 0.112985 Nm (Newton-meters)

1 lbf (pound force) 4.44822 N (Newtons)

1 tonf (ton force) 8896.44 N (Newtons)

1 lb (pound) 0.45359 kg (kilograms)

1 oz (ounce) 28.3495 g (grams)

1 SCFM (Standard Cubic Foot per Minute) 28.317 SLM (Standard Liters per Minute)

J. Revisions and Service Bulletins

(1) Issue of Revisions.

(a) The manufacturer regularly issues revisions to the maintenance manual to keep it at the correct

standard. The revisions add, remove, and/or change data as necessary. All revisions are by

replacement of pages. You must not use hand-written revisions.

(b) A letter of Transmittal is sent with each revision. The transmittal letter:

- Is the authority to put the revision into the manual

- Gives instructions on how to put the revision into the manual.

(c) You are recommended to keep the transmittal letters at the front of the manual for reference.

(d) Each revision has a specified number and date. Revisions start at No. 1 and continue in

sequence.

(e) A Record of Revisions page is located at the front of the manual. When you put a revision into

the manual, you must write the revision number and its issue date on the Record of Revisions

page.

(f) A vertical block line or an upper case "R" at the left side of a page shows that the data adjacent

to the line has changed. If a black line is aligned with the page number and date, this means

that the data has not changed, but some of the data on the page has moved to or from a

different page.

(2) Temporary Revisions.

(a) When it is necessary to include data in the manual quickly, a Temporary Revision (TR) is

issued. The first page of the TR gives the transmittal instructions. The data/instructions in a TR

replace the equivalent data/instructions in the manual. A TR can also be used to include data

before the subsequent revision.

(b) Each TR is printed on yellow paper. The TR numbers are in sequence and start at - 1 in each

chapter. The chapter number goes in front of the TR number to give each TR an identification

code. For example 72-1, 72-2, 72-3, and so on, 79-1, 79-2, 79-3, and so on.

(c) The data/instructions in a TR are included in a revision (usually, the subsequent revision to the

manual) or a subsequent TR replaces it. When a revision includes the data/instructions of a

TR, the transmittal letter includes an instruction to remove the applicable TR. When a

subsequent TR replaces a TR, the subsequent TR includes an instruction to remove the

applicable TR. You must not remove a TR from the manual unless you get an instruction to do

so in the Transmittal Letter of a revision or on the first page of a subsequent TR.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 15

Dec 15/11

Page 20

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

(d) In each chapter, immediately after the List of Effective Pages page, is a Record of Temporary

Revisions page. When you put a TR into the manual, you must write the TR number and the

date you put the TR into the manual on the Record of Temporary Revisions. When you remove

a TR from the manual, you must write the date you removed the TR from the manual on the

Record of Temporary Revisions.

(3) Service Bulletins and Service Letters

(a) At the front of this manual, immediately after the Table of Contents, is the Service Bulletin List.

The data given includes the service bulletin (SB) number, title, date, and the date of

incorporation into this manual, if applicable. When applicable, review engine records for

compliance with all mandatory service bulletins, inspections and Airworthiness Directives.

K. Consumable Materials

(1) Non-restricted Consumable Materials. You can use equivalent materials as an alternative to the

materials in these lists. You can get the materials from local suppliers and/or manufacturers.

MATERIALS

Acetone O-A-51

Acid, sulfuric

Alcohol, isobutyl MIL-E-463

Alcohol, isopropyl TT-I-735

Compound, antisieze CP-63

Compound, antisieze NSN-165

Compound, anti-sieze, Lubriplate 130A

Dessicant MIL-D-3464

Dichromate, sodium

Oil, engine AS5780 HPC

Oil, engine MIL-PRF-23699

Oil, lubricating MIL-L-7808

Oil, preservation MIL-L-6081 grade 1010 or

MIL-L-7870A

Perchloroethylene

Sodium bicarbonate O-S-576

SPECIFICATION

Solution, cleaning (Ref. Paragraph K.(2))R

Solvent, dry-cleaning P-D-680

Solvent, Pentatone ECS

Solvent, Stoddard MIL-PRF-680

Spirits, mineral, EMS-6

Trichloroethane MIL-T-81533

Water, distilled

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 16

Dec 15/11

Page 21

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

(2) The Approved Manufacturers column of the table lists a supplier for each item; equivalent products

are permitted. To find if an item is equivalent, the operator and supplier must show proof, not the

manufacture engineer. The consumable materials used to maintain the engine are in the table that

follows:

MATERIAL

Engine Oil Refer to Section

Lubricant Lubriplate 130A Fiske Brothers Refining Co.

Grease ROYCO HF-825 Royal Lubricants Co., Inc.

SPECIFICATION APPROVED MANUFACTURERS USE

12-10-79, Table 1,

Approved Oils.

129 Lockwood

Newark, New Jersey 07105

280 Complex

101 Eisenhower Parkway

Roseland, New Jersey 07068

Sundstrand P/N

718050 or 71850

(recommended)

ASTM No. 5 Oil Sun Oil Co.

Sundstrand Corp.

4751 Harrison Avenue

Rockford, Illinois 61108

1608 Walnut Street

Philadelphia, Pennsylvania 19103

Lubricate bearings, packings, fuel

pump external drive splines and

starter-generator and front spare

accessory drive splines that

require engine oil.

Lubricate accessory splines

(Starter-generator and front spare

accessory drive splines and fuel

pump external drive splines that

require engine oil are not

included).

Seal and bearing installation and

assembly aid.

Fuel pump drive shaft (internal

splines, external splines require

engine oil and are not included).

Lubricate packings in fuel control

air passages.

Alternates to ASTM

No. 5 Oil:

- 45 to 55% fuel

(MIL-C-7024B,

Type II) mixed with

45 to 55% STP oil

treatment.

- MIL-D-6081, Grade

1010 oil.

Lubriplate Aero Fiske Brothers Refining Company

Lubriplate Division

1500 Oakdale Avenue

Toledo, Ohio 43605

Petrolatum Commercial Assembly aid.

Sealer Scot Clad 776 Scotch Clad Coatings Minnesota

Mining and Mfg. Co.

3M Center

St. Paul, Minnesota 55119

Fuel pump and fuel control drive

shafts (Argo Tech/TRW pumps).

Gearbox splitline.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 17

Dec 15/11

Page 22

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

Sealer (cont) DC 994 Dow Corning Corp.

South Saginaw Road

Midland, Michigan 48641

RTV 732 or RTV 736 Dow Corning Corp.

South Saginaw Road

Midland, Michigan 48641

RTV 106 General Electric Corp.

Waterford, New York 12188

Devcon F

(aluminum)

Reisweld FE 186 H.B. Fuller Co.

Metal Set A-4 Smooth-on Inc.

Epon 934 Hysol Div. Dexter Corp.

Scotch-Weld 2214 Product of the 3M Company

Devcon Corp.

59 Endicott Street

Danvers, Massachusetts 01923

2400 Kasota Avenue

St. Paul, Minnesota 55102

1000 Valley Road

Gillette, New Jersey 07933

2850 Willow Pass Road

Pittsburgh, California 94565

Adhesives and Sealers Division

2501 Hudson Road

St. Paul, Minnesota 55119

Gearbox splitline.

Compressor case splitline.

Compressor mounting insert

installation.

Hysol EA9432NA,

EA934, EA9394

Epocast 938-A1,

938-A2

Magnobond 6398 Magnolia Plastics Inc.

Loctite 620 or 602 Loctite Corp.

Sealant No. 1372 W Permatex Co. Inc.

Silicone

resin-clear (AMS

3135)

METCOSEAL AP METCO Inc.

Locktite Corp.

705 North Mountain Road

Newington, Connecticut 06111

Huntsman Advanced Materials

10003 Woodloch Forest Drive

The Woodlands, Texas 77380

5547 Peachtree Industrial

Boulevard

Chamblee, Georgia 30341-2296

705 North Mountain Road

Newington, Connecticut 06111

Box 1350

Flagler Court Bldg.

West Palm Beach, Florida 33402

1105 Prospect Avenue

Westbury, Long Island, New York

11590

Installation of labyrinth stationary

seal bearing area.

Assembly-oil bellows seal.

Compressor mount repair.

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 18

Dec 15/11

Page 23

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

Silicone

resin-clear (AMS

3135) (cont)

Assembly fluid Ultra Chem No. 1 Ultra Chem Inc.

Antiseize

compound

Methylethyl-ketone Commercial General cleaning.

Carbon removal

compound

1-2531 Dow Corning Corp.

South Saginaw Road

Midland, Michigan 48640

1400 N. Walnut Street

Wilmington, Delaware 19899

Never-Seez Nickel

Special (NSN 165)

Bostik

DC 550 FLUID Dow Corning Corp.

CP-63

(MIL-L-25681B)

Gunk Hydroseal

Decarbonizer

(MIL-C-25107)

Emhart Chemical Group

Boston Street

Middleton, Massachusetts 01949

South Saginaw Road

Midland, Michigan 48641

E/M Lubricants Inc.

P.O. Box 2200 Highway 52

N.W. West Lafayette, Indiana

47906

Gunk Laboratories Inc.

630 North Harlem Avenue

Oak Park, Illinois 60302

Compressor mount repair.

Assembly aid.

Hot section external threads (not

used on parts that have contact

with the engine oil system) or

assembly compressor adapter

nut.

External threads protect up to

450°F (232°C).

External threads not exposed to

oil system. Protects to 1400°F

(760°C).

Clean aluminum coated steel

parts.

Cresol base

cleaning

compound

Cleaner Turbine Cleaner No.

Formula No. 3097

(MIL-C-546)

1191 (MIL-C-43616)

20-20 Plus

(MIL-C-43616)

Turbo Clean or

Turbo Clean 2

R-MC ECT, Inc.

Turco Products Inc.

Subsidiary of ELF Autochem

7320 Bolsa Avenue

Westminster, California

94684-3600

The Brulin Corp.

P.O. Box 270

2920 Dr. Andrew J. Brown Avenue

Indianapolis, Indiana 46206

B & B Chemicals Co. Inc.

P.O. Box 796

Miami, Florida 33166

Kent Chemical Co., Ltd.

George House, Bridwell Lane

Tenterton

Kent TN306HS England

771 First Avenue

King of Prussia, Pennsylvania

19422

Clean steel parts.

Clean compressor air flow path;

clean fuel nozzle tip and burner

drain valve.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 19

Dec 15/11

Page 24

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

NOTE: Rolls-Royce recommends you obey the mixture ratios identified by each aircraft skin cleaner

manufacturer. The mixture ratios change from manufacturer to manufacturer and can be found on each container

label. You must obey the application procedure described in this manual. This will prevent compressor or engine

and control system damage.

Cleaner (cont) Penair M5704 Penetone Corp.

74 Hudson Avenue

Tenafly, New Jersey 07670

B & B 3100 B & B Chemical Co. Inc.

P.O. Box 796

Miami, Florida 33166

No. 5884 Turco Products, Inc.

Subsidiary of ELF Autochem

7320 Bolsa Avenue

Westminster, California

94684-3600

Racasan 512-M Odex Racasan, Ltd.

Cromwell Road

Elesmere Port South Wirral

L654DP, England

ARDROX 624 Brent Chemicals International

Ardrox Division

Ridgeway, Iver

Buckinghamshire SLO955,

England

AERDROX 6345 Sure Chem Industries Pty., Ltd.

23 Amex Avenue

Girraween, New South Wales,

2145

Compressor wash.

EFFECTIVITY: ALL

Rochem GTE

(krankwash)

ZOK 27 Airworthy Ltd.

Turco 6783-10 and

Turco 6783-50

B & B TC-100N-1 B & B Tritech, Inc.

Ardrox 6367-Turbo

Clean 2

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Rochem, Inc.

5619 S. Wayside Drive

Houston, Texas 77087

Wedglen Industrial Estate

Midhurst Sussex G299RE,

England

Turco Products, Inc.

Subsidiary of ELF Autochem

7320 Bolsa Avenue

Westminster, California

94684-3600

Miami, Florida 33266-0766

921 Sherwood Drive

Lake Bluff, Illinois 60044-0215

INTRODUCTION

Page 20

Dec 15/11

Page 25

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

Perchlorethylene

or Methylene

chloride

Mineral spirits Commercial General cleaning.

Calibration fluid Stoddard solvent,

refine kerosene

(MIL-F-7024, type II)

300 to 400°F (148.9

to 204.4°C) boiling

range.

Carbon solvent Penmul L460 Pentetone Corp.

Brulin No. 815 QR The Brulin Corp.

Turco No. 4181 Turco Products, Inc.

Commercial Cleaning agent.

Commercial Cleaning fuel nozzle tips.

Cleaning fuel nozzle.

74 Hudson Avenue

Tenafly, New Jersey 07670

P.O. Box 270

2920 Dr. Andrew J. Brown Avenue

Indianapolis, Indiana 46206-0270

Subsidiary of ELF Autochem

7320 Bolsa Avenue

Westminster, California

94684-3600

Rust preventative

compound

Preservation oil No. 31100

Anti-corrode 204

(MIL-C-6529, type 1)

Valvoline TECTYL

890

Royco 103 Royal Lubricants Co., Inc.

(MIL-L-6081, Grade

1010)

Gulflite 6

(MIL-L-7870A)

MIL-6081, Grade

1010 or 1005 NATO

Symbol Code 0-132

and 0-133 Bray,

K-80, K-877, K-460

Cities Service Oil Co.

P.O. Box 300

Tulsa, Oklahoma 74102

Ashland Petroleum Co.

Division of Ashland Oil Inc.

P.O. Box 391

Ashland, Kentucky 41101

River Road

East Hanover, New Jersey 07936

Atlantic Richfield Co.

260 South Broad Street

Philadelphia, Pennsylvania 19101

Gulf Oil Corp.

429 7th Avenue

Pittsburgh, Pennsylvania 15230

Bray Oil Co.

1925 North Marina Avenue

Los Angeles, California 94804

Coat steel parts after cleaning.

Shipping container bolts.

Fuel system preservation.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 21

Dec 15/11

Page 26

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

Preservation oil

(cont)

Chemical film

treat

Moisture

absorbing rust

preventative

McMillan Jet Oil

1005 or 1010

Royco 460, 481 Royal Lubricants Co., Inc. East

Aeroshell Turbine Oil2Shell International Petroleum Co.,

Chem-Rite A22

(MIL-C-5541)

No. 606 Rust-Lick Inc.

Rocket WD 40

(MIL-C-23411)

WD-40 Dr. Oskar Trost Industrie and Auto

McMillan Ring Free Oil Co., Inc.

200 Petroleum Building

El Dorado, Arizona 71730

River Road

Hanover, New Jersey 07936

Ltd.

Shell Centre

London SE1 7NA, United Kingdom

M and T Chemicals Inc.

Church Street

Matawan, New Jersey 07747

755 Boylston Street

Boston, Massachusetts 02116

WD 40 Co.

San Diego, California

Chemie

2350 Numuenster

West Germany

Fuel system preservation.

Cleaned anodized aluminum alloy

parts.

External engine surfaces only.

Heat resistant

paint

Engine grey

enamel

WD-40 Betriebs and Werkstatt-Zubehoer

GmbH Riedstrasse

257302 Ostfildern 1-Ruit

West Germany

WD-40 Hawker Pacific Pty., Ltd.

4-8 Harley Crescent Condell Park

New South Wales 2200 Australia

Ardrox 3961 Ardrox Limited

Commerce Road

Brentford, Middlesex, England

Ardrox 3961 Ardrox Australia Pty. Ltd.

Birnie Avenue Lidscombe N.S.W.

2141, Australia

CRC 3-36 CRC Chemicals Division

C.J. Webb Inc.

Limekiln Pike Dresher,

Pennsylvania 19025

Actithane WC100 Saran Protective Coatings Co.

17332 Shields

Detroit, Michigan 48212

Actithane WC100

Paint and Lacquer

Reducer H251

Saran Protective Coatings Co.

17332 Shields

Detroit, Michigan 48212

Gearbox paint repair or galvanic

corrosion protection.

Gearbox touch-up.

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 22

Dec 15/11

Page 27

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

Engine grey

enamel (cont)

Corrosion

resistant

aluminum paint

Weld rod X-40 (EMS 70175) or

Weld rod AISI 349 (29-9 W

Weld rod Hastelloy W (AMS

Marking pencils See Acceptable Marking Pens and

Moisture proof

barrier material

PU Grey Paint, Code

03-GY-401 Color

#16251 Fed. Std.

595B

Sermetel 196 Teleflex Inc.

alternate Haynes 188

(AMS 5801)

Mo) (MIL-R-5031,

Class 6) (AMS 5784)

5786) (MIL-R-5031,

Class 12)

Flexkin 100P

(MIL-B-131)

DEFT Chemical

17451 Von Karmon Avenue

Irvine, California 92714-6205

P.O. Box 218

North Wales, Pennsylvania 19454

Commercial First-stage turbine nozzle.

Commercial Combustion liner and exhaust

Commercial Turbine and exhaust collector,

Pencils Table.

Acme Backing Corp.

P.O. Box 360

Stamford, Connecticut 06904

Gearbox touch-up.

Gas producer and power turbine

support.

collector support.

struts.

Marking hot section parts.

Engine packing.

Dehydrating

Agent 16-unit

bags

Pressure

sensitive masking

tape: 1- or 2- in.

(25- or 51- mm)

width.

Black stencil K-1 (TT-I-559) March Stencil Machine Co.

Methyl alcohol Fed. Spec O-M

Desiccant No. 88 Absorbent

CS-16 (MIL-D-3464) Filtrol Corp.

3250 East Washington

Los Angeles, California 90023

No. 260 Scotch

Brand

232d, Grade A;

Rolls-Royce

EMS-125. British

Standard BS 506

Amend. 1.

Protective

Dehydrating Agent

(MIL-D-3464)

Minnesota Mining and Mfg. Co.

3M Center

St. Paul, Minnesota 55101

707 East B Street

Belleville, Illinois 62222

Commercial Solvents Corp.

245 Park Avenue

New York, New York 10017

or

Union Carbide Corp. Chemicals

and Plastics

270 Park Avenue

New York, New York 10017

Delta Packing Products

4108 North Nashville Avenue

Chicago, Illinois 60634

Storage and shipment.

Storage and shipment.

Storage and shipment.

Compressor water rinse.

Shipping package humidity

control.

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 23

Dec 15/11

Page 28

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

Liquid leak

detector

Corrosion

compound

Sodium hydroxide

and phosphoric

Sealant removal Loctite “chisel”

Adhesive Loctite 290 Loctite Corp.

SNOOP (meets MIL

Spec

(MIL-L-25567C), type

I, oxygen systems)

Leak-Tec Formula

372E

Non-Rust X-210 Daubert Chemical Co., Inc.

Ardrox 3968 Chemetall Aerospace

solvent

Indiana Valve and Fitting Inc.

P.O. Box 24267

Indianapolis, Indiana 46224

American Gas and Chemical Co.

5 Tefnakil Park

Cresskil, New Jersey 07626

4700 S. Central Avenue

Chicago, Illinois 60038

Technologies

Trakehner Str. 3 D-60487

Frankfurt Main Germany

Commercial Cleaning Pc filter Bendix control

Loctite Corp.

705 North Mountain Road

Newington, Connecticut 06111

705 North Mountain Road

Newington, Connecticut 06111

Checking for pneumatic leaks.

Inhibiting fingerprint corrosion.

system.

Removal of Loctite 620 or 602.

Oil pump gearshaft retention.

Fuel additive Prist (MIL-I-27686E) PPG Industries Inc.

5629 FM 1960

West Houston, Texas 77069

Biobor JF Aviation

Fuel Additive

Torque paint Torque Seal F-900 Organic Products Co.

Torque paint

remover

High temperature

lubricant

F-100 Remover Organic Products Co.

Never-Seez Nickel

Special

Hammonds Technical Services,

Inc.

910 Franklin Road

Houston, Texas 77073

Ph: (281) 999-2900

Fax: (281) 582-4224

Email: info@hammondscos.com

Web: www.hammondscos.com

P.O. Box 428

Irving, Texas 75060-0428

P.O. Box 428

Irving, Texas 75060-0428

Never-Seez Compound Corp.

2910 South 18th Street

Broadview, Illinois 60153

Bearing Supply and Service

448-472 Notre Dame Avenue

Winnipeg 2, Canada

Fuel anti-ice.

Anti-microbial growth

MIL-S-53021A.

Application of marks to pnuematic

and lubrication system “B” nuts to

show movement.

Removal of torque paint.

Where anti-seize is specified in

this manual.

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 24

Dec 15/11

Page 29

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MATERIAL SPECIFICATION APPROVED MANUFACTURERS USE

High temperature

lubricant (cont)

R.A. Rodriguez (U.K.) Ltd.

Station House-Darkes Lane

Potters Bar

Herts, England

Consolidated Brg, Co. Pty. Ltd.

238 Victoria Road

Drummoyne, N.S.W. Australia

Kyokuto Boeki Kaisha Ltd.

7th Floor, New Otemachi Bldg. 2-1,

2-Chrome

Otemachi Chiyoda-Ku, Tokyo,

100-91 Japan

S.A. Brasileira De Rolamentos

E. Mancais BRM

Av. Senador Queiroa

605 Conj. 1609 Sao Paulo, Brazil

Tekind

Via F. Malzi D'Eril, 3

20154 Milano, Italy

DSL Super HI-Temp Davis-Howland Oil Corp.

200 Anderson Avenue

Rochester, NY. 14607

Where anti-seize is specified in

this manual.

NOTE: Even though Rolls-Royce has approved these consumables for use with Rolls-Royce engines.

Rolls-Royce assumes no liability to personnel or the environment by their use.

NOTE: The following pencils, fine tip and wide markers, ball point markers, and paint sticks are

approved for marking iron, nickel, and cobalt base alloys that get to temperatures above

800°F (427°C) by heat treatment or engine operation. Markings on these alloys do not

have to be removed from the parts before heating above 800°F (427°C).

These pencils, markers, and paint sticks are also approved for marking titanium alloys if the

markings are removed before the parts get to temperatures above 500°F (260°C) by heat

treatment or engine operation.

(3) The acceptable marking pens and pencils used to maintain the engine are in the table that follows:

MANUFACTURER TRADE NAME NUMBER COLOR

Pencils

Venus (1) Unique 1237 Carmine Red

Berol Corp. (2) Eagle Verithin 745 Carmine Red

A.W. Faber (3) The Winner 2383 Dark Green

Berol Corp. (2) Eagle Verithin 751 True Green

Venus (1) Unique 1215 White

A.W. Faber The Winner 2388 White

Berol Corp. (2) Eagle Verithin 734 White

Venus (1) Unique 1206 Blue

EFFECTIVITY: ALL

INTRODUCTION

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Page 25

Dec 15/11

Page 30

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MANUFACTURER TRADE NAME NUMBER COLOR

Koh-1-Noor (4) Flexicolor X1800X25 Blue

Berol Corp. (2) Eagle Verithin 758 True Blue

Berol Corp. (2) Eagle Verithin 737 Orange

A.W. Faber (3) The Winner 2462 Silver

Berol Corp. (2) Eagle Verithin 753 Silver

Eberhard Faber (5) Colorbrite 2101 Silver

Fine Tip Markers

Carters (6) Marks-A-Lot Yellow

Berol Corp. (2) Flash 30 Red

Lindy Green

Berol Corp. (2) Flash 30 Blue

Lindy Blue

Berol Corp. (2) Flash 30 Blue

Sanford Corp. (12) T.E.C. Marker 3201 Black

Wide Tip Markers

Berol Corp. (2) Liquid Tip 1100 Black

Berol Corp. (2) Eagle Marker 8835 Black

Berol Corp. (2) Liquid Tip 1100 Red

Berol Corp. (2) Eagle Marker 8824 Red

Berol Corp. (2) Eagle Marker 8802 Blue

Berol Corp. (2) Eagle Marker 8816 Yellow

Sanford Corp. (12) T.E.C. Marker 1501 Black

Ball Point Marker

Markall (7) Blue

Markall (7) Yellow

Paint Sticks

Markal Company (7) Paintstik Type B Yellow

Markal Company (7) Paintstik Type B White

Markal Company (7) Paintstik Type B Green

Markal Company (7) Paintstik Type B Brown

Markal Company (7) Paintstik Type B Orange

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 26

Dec 15/11

Page 31

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

MANUFACTURER TRADE NAME NUMBER COLOR

Markal Company (7) Paintstik Type B Purple

American Artclay Co. (8) Glass Cellophane 2346 Blue

NOTE: Dri-Marquette Black Ink, a product of the Irwin-Hodson Co. (9), is approved for marking on iron,

nickel, and cobalt alloy parts. The markings do not have to be removed before they get to temperature

above 800°F (427°C).

NOTE: Dri-Marquette Black Ink may be used on titanium alloys but must be removed before they get

to temperatures above 500°F (260°C).

NOTE: LNC-3 Nuclear Grade Electrolyte, a product of the Lectroetch Co. (10), is approved for

electrolytic etching on iron, nickel, cobalt, titanium, aluminum, and magnesium alloys. This process is

for permanent marking of identification on parts.

NOTE: Pyromarker, a product of Ball Point Metal Marker, Tempil Division, Big Three Industries, Inc.

(11), is approved for marking on iron, nickel, and cobalt base alloys and on titanium alloys. Markings

on these alloys do not have to be removed before they get to temperatures above 500°F (260°C).

Manufacturer Addresses

(1) Venus-Esterbrook Corp.; Lewisburg, Tennessee 37091

(2) Berol Corp.; P.O. Box 1000, Danbury, Connecticut 06810

(3) Faber-Castell Corp.; P.O. Box 1708, 41 Dickerson Street, Newark, New Jersey 07103

(4) Koh-1-Noor Rapidograph Inc.; 100 North Street, Bloomsbury, New Jersey 08804

(5) Eberhard Faber Inc.; Crestwood Industrial Park, Wilkes-Barre, Pennsylvania 18703

(6) Carters Ink Co.; 275-T Wyman Street, Waltham, Massachusetts 02154

(7) Markall Co.; 270 North Washtenaw Avenue, Chicago, Illinois 60612

(8) American Art Clay Co. Inc.; 4717 West 16th Street, Indianapolis, Indiana 46224

(9) Irwin-Hodson Co.; Ninth and S.E. Woodward, Portland, Oregon 97202

(10) The Lectroetch Co.; 14925 Elderwood Avenue, Cleveland, Ohio 44112

(11) Tempil Division Big Three Industries Inc.; 2901 Hamilton Boulevard, South Plainfield, New Jersey

07080

(12) Sanford Corp.; Bellwood, Illinois 60104

L. Customer Support Information

(1) If you find it necessary to write to Rolls-Royce about the manual, please write to:

Manager, Publication Services

Rolls-Royce Corporation

P. O. Box 420

Speed Code U-15

or contact

Rolls-Royce Corporation

PO Box 420, Speed Code P-38

Indianapolis, Indiana 46206-0420

USA

Toll Free (North America)+1-(888) 255-4766

Phone: +1 (317) 230-2720R

Fax: +1 (317) 230-3381

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

INTRODUCTION

Page 27

Dec 15/11

Page 32

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

EFFECTIVITY: ALL

© COPYRIGHT 2008, 2012 Rolls-Royce Corporation (unpublished)

Figure 1

INTRODUCTION

Page 28

Dec 15/11

Page 33

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

CHAPTER 05

LIST OF EFFECTIVE PAGES

CHAPTER

SECTION OTHER

SUBJECT PAGE IDENT DATE

05

Contents 1 Dec.15/11

Contents 2 Dec.15/11

00-00 1/ Sep.15/10

2

10-00 1/ Mar.1/10

2

11-00 1 Mar.1/10

11-00 2 Mar.1/10

12-00 1 Dec.15/11

12-00 2 Dec.15/11

13-00 801 Dec.15/11

13-00 802 Dec.15/11

20-00 1/ Sep.15/10

2

21-00 1 Dec.15/11

21-00 2 Dec.15/11

21-00 3 Dec.15/11

21-00 4 Dec.15/11

21-00 5 Dec.15/11

21-00 6 Dec.15/11

50-00 1/ Jan.20/08

2

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 603/ Mar.1/10

604

50-00 601 Jan.20/08

50-00 602 Jan.20/08

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 603/ Mar.1/10

604

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 601/ Mar.1/10

602

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 603/ Mar.1/10

604

50-00 601 Mar.1/10

50-00 602 Mar.1/10

50-00 601 Jan.20/08

50-00 602 Jan.20/08

50-00 601 Jan.20/08

50-00 602 Jan.20/08

50-00 601 Sep.15/10

50-00 602 Sep.15/10

50-00 603/ Sep.15/10

604

R 50-00 701 Aug.15/12

R 50-00 702 Aug.15/12

CHAPTER

SECTION OTHER

SUBJECT PAGE IDENT DATE

05

--------------- END ---------------

CHAPTER

SECTION OTHER

SUBJECT PAGE IDENT DATE

05

C=CONFIG B=BREAKOUT

LIST OF EFFECTIVE PAGES-05

Page 1/2

Aug 15/12

Page 34

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

CHAPTER 05

TABLE OF CONTENTS

SUBJECT

TASK TITLE CH-SE-SUB PAGE CONFIG

TIME LIMITS/MAINTENANCE CHECKS 05-00-00

Time Limits / Maintenance Checks 1

TIME LIMITS 05-10-00

RR300 SERIES TIME LIMITS 1

AIRWORTHINESS LIMITATIONS 05-11-00

Airworthiness Limitations 1

TIME LIMITS/MAINTENANCE CHECKS 05-12-00

RR300 SERIES LIFE LIMITS 1

TIME BETWEEN OVERHAULS AND ON-CONDITION

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

ACCESSORIES AND COMPONENTS 05-13-00

Time Between Overhauls 801

SCHEDULED MAINTENANCE CHECKS 05-20-00

Scheduled Maintenance Checks

SCHEDULED INSPECTIONS 05-21-00

Scheduled Inspections

UNSCHEDULED MAINTENANCE CHECKS 05-50-00

Unscheduled Maintenance Check 1

Do the Inspection for Foreign Object

Damage 601

Do the Inspection for Hard Landing Damage

Do the Inspection for Lightning Strike

Damage

Do the Inspection of theREngine After a

Sudden Stop

Do the Inspection forRthe Damage Caused by

Bird Ingestion

Do the Inspection of anREngine Involved in

an Accident

Do the Inspection after a Fire inRthe

Engine

or Incident 601

1

1

601

601

601

601

601

05−CONTENTS

Page 1

Dec 15/11R

Page 35

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

SUBJECT

TASK TITLE CH-SE-SUB PAGE CONFIG

Do the Inspection ofRthe Engine after a

R

R

R

R

R

R

R

R

R

R

R

Compressor Stall or Surge

Do theRInspection of the Engine after an

Over-torque Condition

ExamineRthe Engine Inlet for Blockage 601

Do the VibrationRInspection of the Engine 601

Do the inspection forREngine Submerged in

Water

DoRthe Inspection for Snow, Ice or Water

Ingestion 601

Do the Inspection of the Engine after

Operation in a Corrosive Environment 601

Clean the Engine after Operation in a

Corrosive Environment 701

601

601

601

05−CONTENTS

Page 2

Dec 15/11R

Page 36

EXPORT CONTROLLED

PROPRIETARY DATA - UNSECURED DATA

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY

PROPRIETARY DATA - UNSECURED COPY