Page 1

1 Introduction

2Safety

User Manual

Rolls-Royce Helicon X3

P&T Control System

PRODUCT INFORMATION

Yard:

Alianca

NB/Hull No.:

AL 021

3 System Description

4 Delivery Specification

5 Technical Data

6 Operating Instructions

7 Maintenance Instructions

8 Trouble Shooting

Project No.:

13S000411

Installation Id.:

BOW1 / BOW2

PORT_MP / STBD_MP

Vessel type:

Offshore

Owner:

Asgaard Navegac„o

Date:

03/07/2014

Revision:

A

9 Contact List

10 Spare Parts

11 Tools

12 Design Drawings

13 Revision

Copyright © 2010 Rolls-Royce plc

The information in this document is the property of Rolls-Royc e plc and may not be copied or communicated to a third party, or used for any purpose other than that for which it

is supplied without the express written consen t of Rolls-Royce Marine plc.

This information is given in good faith based u pon the latest information available to

Rolls-Royce plc, no warranty or representation is gi ven concerning such information,

which must not be taken as establishing any contractual or other commitment binding

upon Rolls-Royce plc or any of its subsidiary or associated companies.

14 Subsuppliers Manuals

Page 2

Page 3

1

Introduction

1 Purpose ........................................................................................................3

2 Warranty .......................................................................................................3

3 Contents .......................................................................................................3

4 Target Groups .............................................................................................. 4

5 Terms and Abbreviations ...........................................................................4

Copyright © 2010 Rolls-Royce plc

The content of this document is the property of Ro lls-Royce plc and may not be redistributed in whole or in part thereof without

express written consent of Rolls-Royce plc.

Doc. No.: 13S000411

Revision: A

Page 4

Doc. No.: 13S000411

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 5

Introduction

1

1Purpose

The purpose of the Helicon X3 User Manual is to provide the necessary information to

plan and perform a safe and correct operation of the installed delivered system, as well

as under-standing the basic functionality of the equipment. The User Manual covers

both operational and technical aspects of the system.

The personnel involved in using the system must have relevant experience and training

with regards to the use of such systems.

2 Warranty

The product has a limited warranty. Please note that the warranty will be void if the

equipment is misused or not handled in accordance to prescribed standards, for example

dismantling the equipment to a level greater than described.

3 Contents

This manual contains the following chapters:

Chapter Contents

1. Introduction This chapter specifies the purpose and target groups for the

manual. It also contains list of used abbreviations and a

specification of the document conventions.

2. Safety This chapter specifies safety instructions to follow when

operating and maintaining system.

3. System Description This chapter briefly describes the system components, the

system design and the functionality.

4. Delivery Specification This chapter specifies the delivered equipment.

5. Technical Data This chapter contains technical specifications and

performance data.

6. Operating Instructions This chapter describes how to use the Helicon X3 system.

7. Maintenance Instructions This chapter describes how to maintain the Helicon X3

system, including both preventive and corrective actions.

8. Trouble Shooting This chapter describes how to act when a malfunction occur

in the Helicon X3 system.

9. Contact Information This chapter contains contact information for Rolls-Royce

Marine, Dept. Propulsion Ulsteinvik and Rolls-Royce World

Wide Support Organization.

10. Spare Parts This chapter specifies recommended spare parts for the

Helicon X3 system.

11. Tools This chapter describes required and recommended tools for

the maintenance of the system to use during the installation.

12. Design Drawings This chapter consists of design drawings that serve as an

information source about the installed system for the

installation.

13. Revision This chapter contains the revision history for the total binder.

14. Subsuppliers Manuals This chapter contains documentation from other suppliers

than Rolls-Royce, if such has been delivered by RRM.

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 3 of 6Doc. No.: 13S000411

Page 6

4 Target Groups

The User Manual is primarily intended for the user of the system. The user must be

properly trained in using and maintaining the system.

The installation of the system components must be made by yard mechanics with

experience in fitting marine electronic equipment. Cabling into the units, wire

termination and screen/shield termination should be made by yard electricians that have

a certificate of apprenticeship or equal qualification on ship electrical installation.

Commissioning and testing must be carried out by field service personnel from RollsRoyce Marine, Dept. Propulsion Ulsteinvik or qualified service engineers from RollsRoyce Marine Global Support Network (GSN).

5 Terms and Abbreviations

Abbreviation or term Description

AC/DC Alternating Current/ Direct Current

AQM Aquamaster

AZP Azipull Thruster

BC Backup Control

CAN Controller Area Network

CCW Counter Clock Wise

CW Clock Wise

DC/DC Direct Current/ Direct Current

ESD Electrostatic Discharge

EU European Union

GSN Global Support Network

GUI Graphical User Interface

I/O Input/Output

LCD Liquid Crystal Display

LED Light Emitting Diode

MP Main Propulsion

NC Normally Closed

PMS Power Management System

PTI Power Take In

PTO Power Take Out

RC Remote Control

RPM Revolutions Per Minute

RR Rolls-Royce

RRM Rolls-Royce Marine

RUP Running Up/Down Program

SAT Sea Trial Acceptance Test

STBD Starboard

TCNS Thruster Compass Nozzle Swing-Up

TT Tunnel Thruster

VVolt

Introduction

Page 4 of 6 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 7

Introduction

1

Abbreviation or term Description

VAC Volts Alternating Current

VDC Volts Direct Current

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 5 of 6Doc. No.: 13S000411

Page 8

Introduction

Page 6 of 6 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 9

2

Safety

1 Introduction ..................................................................................................3

2 Disclaimer ....................................................................................................3

3 Safety Instructions ......................................................................................4

3.1 Safety Functions ............................................................................................4

3.1.1 Pitch Control .......................................................................................4

3.1.2 RPM Control Electric Engine ..............................................................4

3.1.3 Azimuth Control ..................................................................................5

3.1.4 Dynpos and Joystick ..........................................................................5

3.1.5 Autopilot .............................................................................................5

4 Safety Messages ..........................................................................................6

Copyright © 2010 Rolls-Royce plc

The content of this document is the property of Ro lls-Royce plc and may not be redistributed in whole or in part thereof without

express written consent of Rolls-Royce plc.

Doc. No.: 13S000411

Revision: A

Page 10

Doc. No.: 13S000411

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 11

Safety

2

1Introduction

This chapter provides information regarding safety precautions that must be taken to

prevent injury to people and damage to equipment.

Whoever is responsible for the installation, operation or maintenance of this RollsRoyce system, is obliged to read this chapter and fully understand its content before any

installation, operation or maintenance of the system may take place.

2 Disclaimer

Undertaking any work envisaged by this document may either directly or indirectly

create risks to the safety and health of the person undertaking the work or the product

and/or its components while the work is being performed.

It is the responsibility of the user to protect the health and safety of the persons

undertaking the work as well as risk to the product and/or its components. Therefore the

user must ensure that appropriate controls and precautions are identified and taken in

relation to the work envisaged by this document in accordance with the relevant

statutory and legal and industrial requirements.

Neither this document, nor its use, in any way absolves the user from the responsibility

to ensure that the controls and precautions referred to above are implemented.

If any Rolls-Royce product design related features which could create risks to persons,

the product and/or its components are identified, Rolls-Royce should be contacted

immediately.

It is the user's responsibility to make all relevant hazard identifications and risk

assessments of all the activities associated with the use of this document.

It is the user's responsibility to design and implement safe systems of work and to supply

safe equipment (including, without limitation, safety equipment) and training

(including, without limitation, health and safety training) to anyone using this document

to work on products to which it relates.

A user without relevant experience of working in accordance with this document, or

with products to which it relates, should seek appropriate advice to identify the health

and safety controls and precautions that need to be taken while working.

Technical assistance can be sought from Rolls-Royce and will be subject to RollsRoyce's terms and conditions.

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 3 of 6Doc. No.: 13S000411

Page 12

Safety

3 Safety Instructions

This Rolls-Royce system is a remote control system that is controlling propulsion units

on the vessel. By operating the system, the thrusts direction and pitch/speed

performance can be controlled.

The operator must at all times be aware of:

• Consequences of operating the system to prevent injury to people, damage of

equipment, damage to the vessel operated and damage to the surroundings.

3.1 Safety Functions

A number of safety functions are included in the system. These functions will become

operative if a failure should occur in the propeller control system itself, or in external

systems connected to the propeller control system.

Note: The backup control system has only interface to the control levers. The

backup control system does not have interface to external control

systems like Dynpos, Joystick or Autopilot

Note: No azimuth restrictions or load control functions are included in the

backup system. When operating using the backup system, the operator

must be careful not to overload the engine or the propeller system. If a

load control system is included in the Rpm Drive, this will still be in

operation.

Note: The safety functions described underneath will only be available if the

thruster(s)/gear(s) have got the described function in the first place.

3.1.1 Pitch Control

The pitch control is one of the redundant functions in the control system. The backup

control system will automatically be engaged if a serious failure occurs in the normal

control system. This includes loss of power supply to the normal control system, halt in

the normal control cpu, failure on the normal control order potentiometer in the lever on

the manoeuvre station currently in command, failure on the normal control field bus and

failure on the normal control feedback potentiometer. Alarm will be given in the control

system and in the ship's alarm system.

3.1.2 RPM Control Electric Engine

The RPM control is a redundant function in the control system. The backup control

system will automatically be engaged if a serious failure occurs in the normal control

system. This includes loss of power supply to the normal control system, halt in the

Page 4 of 6 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 13

Safety

2

normal control cpu, failure on the normal control order potentiometer in the lever on the

manoeuvre station currently in command and failure on the normal control field bus.

Alarm will be given in the control system and in the ship's alarm system.

3.1.3 Azimuth Control

The azimuth control is a redundant function in the control system. The backup control

system will automatically be engaged if a serious failure occurs in the normal control

system. This includes loss of power supply to the normal control system, halt in the

normal control cpu, failure on the normal control order potentiometer in the lever on the

manoeuvre station currently in command, failure on the normal control field bus and

failure on the normal control feedback potentiometer. Alarm will be given in the control

system and in the ship's alarm system.

3.1.4 Dynpos and Joystick

If operating using an external Dynpos or Joystick system and a failure occurs either on

the pitch order, the rpm order or the azimuth order signal from the external system, the

external system is disengaged and the propeller responds to the control lever order on

the manoeuvre station in command. Alarm will be given in the control system and in the

ship's alarm system.

3.1.5 Autopilot

If operating using an external autopilot system and the azimuth lever order on the

manoeuvre station in command is changed more than the adjustable limit, normally 20

degrees, the autopilot is disengaged and the thruster will respond to the control lever.

This is indicated by blinking the Autopilot button, and the buzzer will sound until the

Autopilot button is pressed to acknowledge the mode change back to lever control.

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 5 of 6Doc. No.: 13S000411

Page 14

Safety

4 Safety Messages

Safety messages in this manual are always accompanied by a safety alert symbol and a

signal word. The safety alert symbol is used to alert the reader about a potential risk of

personal injury or damage to the equipment.

The following types of safety messages are used within this manual:

Warning: Risk of... Indicates the presence of a hazard which could result in death or

personal injury.

Caution: Indicates the presence of a hazard which could result in damage to

equipment or property and seriously impact the function of the equipment.

Note: Alerts the reader to relevant factors and conditions which may impact the

function of the equipment.

Page 6 of 6 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 15

3

System Description

1 General .........................................................................................................3

2 System Overview ......................................................................................... 3

3 Design ..........................................................................................................4

3.1 Lever .............................................................................................................4

3.2 Control Panel .................................................................................................5

3.3 Emergency stop and dimmer panel (optional) ...............................................7

3.4 Indicators .......................................................................................................8

3.5 Viewcon .........................................................................................................8

3.6 Controller cabinet ..........................................................................................9

3.7 I/O Cabinet ....................................................................................................9

4 Functions ...................................................................................................10

4.1 Pitch Control ................................................................................................10

4.1.1 Normal Control .................................................................................11

4.1.2 Backup Control .................................................................................11

4.1.3 Backup Control Operation ................................................................11

4.1.4 Backup Control Limitations ...............................................................11

4.1.5 Local Control ....................................................................................11

4.1.6 Pitch Indication .................................................................................12

4.1.7 Pitch Order Scaling ..........................................................................12

4.2 Thruster Azimuth Control .............................................................................12

4.2.1 Normal Control .................................................................................12

4.2.2 Backup Control .................................................................................12

4.2.3 Backup Control Operation ................................................................13

4.2.4 Backup Control Limitations ...............................................................13

4.2.5 Local Control ....................................................................................13

4.2.6 Azimuth Indication ............................................................................13

4.3 RPM Control ................................................................................................14

4.3.1 RPM Control Electric Drive Motor ....................................................14

4.3.2 External RPM Control .......................................................................14

4.3.3 RPM Order Output ........................................................................... 14

4.3.4 Propeller/Shaft RPM Indication ........................................................14

4.4 Command Transfer ......................................................................................14

5 Location of Manufacturing Number ......................................................... 14

5.1 Marking Locations .......................................................................................14

5.1.1 Company Identification .....................................................................15

Copyright © 2010 Rolls-Royce plc

The content of this document is the property of Ro lls-Royce plc and may not be redistributed in whole or in part thereof without

express written consent of Rolls-Royce plc.

Doc. No.: 13S000411

Revision: A

Page 16

Doc. No.: 13S000411

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 17

System Description

3

1 General

This chapter provides an overview of the Helicon X3 system and a technical description

of the main components that give the required knowledge about the system.The figures,

drawings and text in this chapter are general and may not comply to the actual

installation on the vessel. For details on the delivered equipment, see chapter 4 Delivery

Specification.

2 System Overview

The Helicon X3 remote control system is a micro-processor-based system, controlling

the propulsion units on the vessel. The following main functions are included:

• Combinator control, allowing accurate and reliable control of the propeller pitch and

motor speed (RPM). The combinator curve optimises the pitch/speed performance to

give the best operational conditions and fuel economy.

• Pitch control, allowing accurate and reliable control of the thruster pitch.

• Speed control, allowing accurate and reliable control of the motor speed (RPM).

• Direction control, allowing accurate and reliable control of the thrust direction.

• Follow-up backup control from control levers.

Helicon X3 consists of the following main components:

• Instruments, screens, levers and Viewcon on the bridge (1).

• Electrical cabinets in the instrument room (2) and thruster room (4).

• Instruments, screens and levers in the engine control room (3).

Helicon X3 may interface several external systems (5), like Dynamic positioning

systems and Autopilots.

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 3 of 16Doc. No.: 13S000411

Page 18

System Description

Bridge

Instrument room ECR

Fore bridge

Dynpos

Joystick

Autopilot

GPS

Automation

LOG

VDR

El.unit

El.unit El.unit

I/0 I/0 I/0I/0I/0

El.unit El.unit

Aft bridge

Slave Chair

Viewcon

Main Chair

Port Wing

Stbd Wing

1

2

3

4

5

3 Design

3.1 Lever

Each thruster has its own lever. Their main functions are:

• Control of pitch, RPM and azimuth direction (dependant of application)

• In operation

• Command transfer

• Lever in command

• Back-up control

• Alarm

The control lever has integrated buttons and indication lamps for command transfer,

backup system on/off, alarm indication/buzzer and push button for reset of buzzer. The

display in the base shows set command (pitch and direction) from the lever.

The lever contains two redundant electronic circuits, one for the normal control system

and one for the backup system.

Page 4 of 16 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 19

System Description

3

Figure 1 Lever

Symbol Command Description

In operation/running Thruster is started and ready to use.

Control transfer Transfer command between bridge and ECR.

Command transfer Take command. If light is lit, the lever is in command.

Backup control Independent controller that takes over if the main

controller stops. Redundant system.

Alarm Alarm indicator, see alarm screen for details.

3.2 Control Panel

The control panel (touch screen) is the main user interface for the operator and gives an

overview of all the thrusters on the vessel. It shows the status of the system, indicates

thruster forces, displays alarms, and shows selected modes. The flat button on the top of

the screen is for dimming the illumination of the LCD display.

The screen is divided in two areas: a menu area in the left part of the screen, and a bigger

command area to the right. The menu buttons to the left selects the content of the

command area.

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 5 of 16Doc. No.: 13S000411

Page 20

System Description

There is one command page for each thruster, in addition to one system overview page

and one alarm page. The overview page shows the most essential information for all

thrusters, but to activate functions or to view all available information for a thruster, the

particular thrusters' page must be selected.

The graphical design is based on the following principles:

• All functions pages are only one click away

• Large and simple buttons which are easy to read.

• Same design theme for all clickable objects.

• To avoid unintentional activation of functions, all function activation buttons require

press on the accept button to proceed.

Figure 2 Menu area

Page 6 of 16 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 21

System Description

3

Figure 3 Command area

Colour on button Function

A ring around the button The button is push able

Blue Indicates current status

Green Start

Red Stop

2 buttons flashing Select function

1 button flashing The button has been activated and will flash until the function

has started/stopped

3.3 Emergency stop and dimmer panel (optional)

The emergency stop is used to shut down the thrusters immediately.

There is one button per thruster unit.

The wheel (1) is used for dimming the background light on the indicators situated on the

same control station.

The dimmer may be delivered in a separate panel, if the emergency stop buttons are not

part of the delivery scope.

1 2

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 7 of 16Doc. No.: 13S000411

Page 22

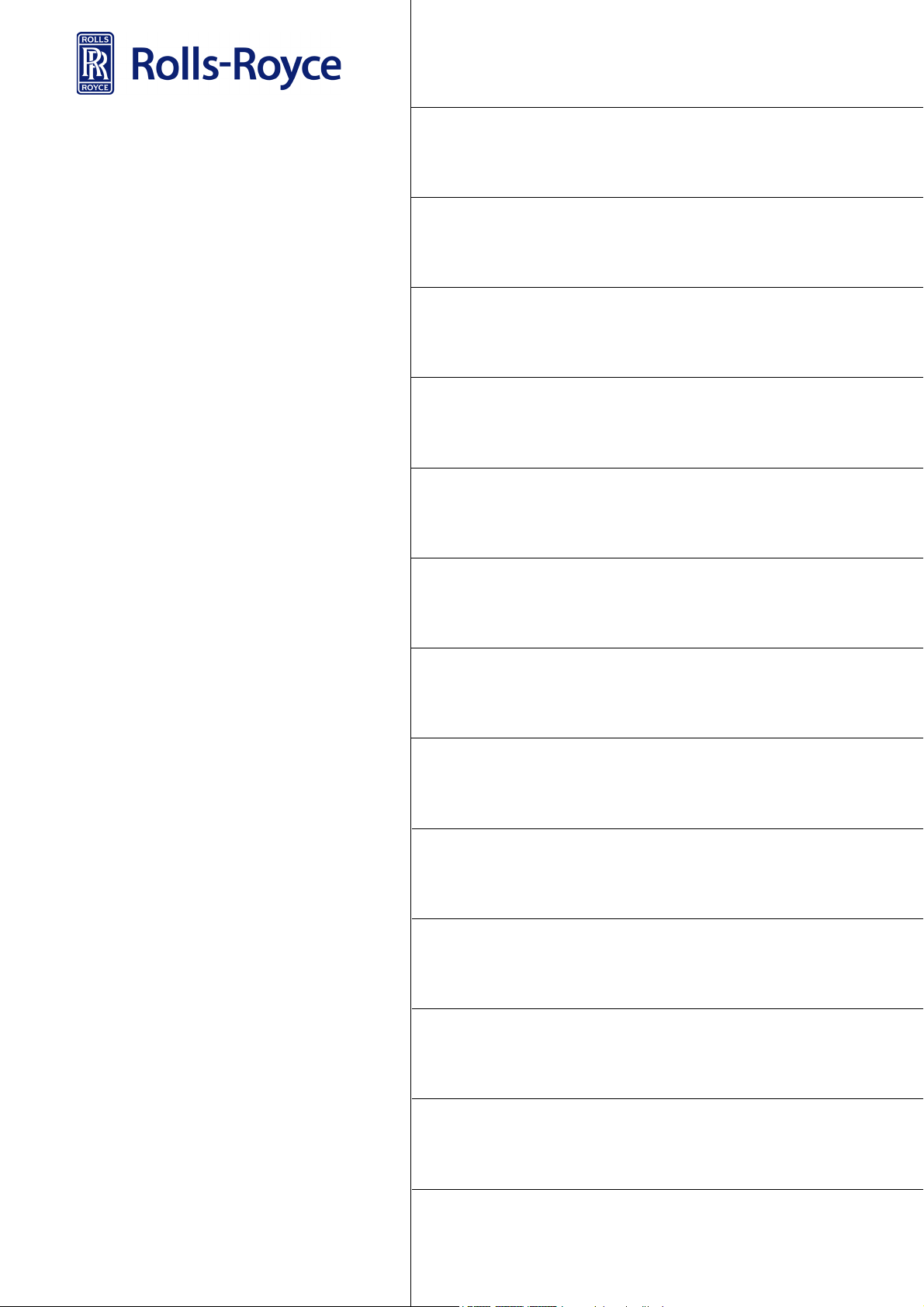

3.4 Indicators

BOW AZIMUTH THRUSTER 1BOW THRUSTER 2

STBD MAIN PROPULSIONPORT MAIN PROPULSION

MIN MAX

RPM

MIN MAX

RPM

ASTERN AHEAD

PITCH

ASTERN AHEAD

PITCH

PORT STBD

PITCH

MIN MAX

RPM

BOW THRUSTER 1

PORT STBD

PITCH

MIN MAX

RPM

MIN MAX

RPM

DC 1

DC 2

FRNT

ST 1

ST 2

1

2

3

4

5

6

7

8

ON

The indicators give feedback on various data and can be found on the bridge and in the

engine control room.

There are three main types of indicators:

• Azimuth indicator

• RPM indicator

• Pitch indicator

In addition a bridge order indicator may be delivered on some vessels.

System Description

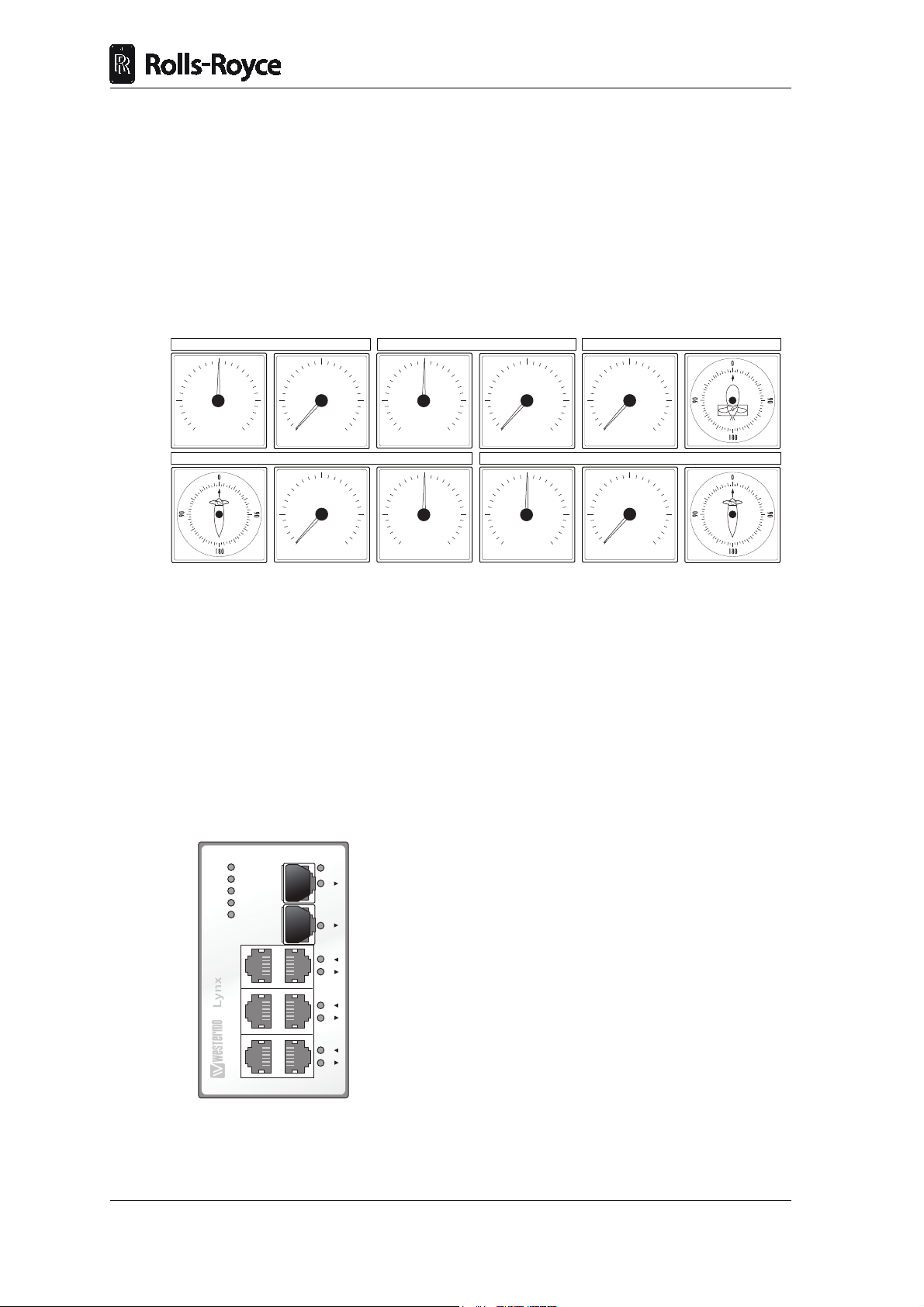

3.5 Viewcon

Network cabinet

The network cabinet(s) contains several switches. The network cabinet(s) connects the

panel PCs and the controller cabinets.

Network

Operator stations and electronic units are linked together in an Ethernet network. The

network is single and may contain several separate switches.

(CAN bus is the internal communication between levers, I/O modules and Marine

Controller.)

Page 8 of 16 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 23

System Description

3

3.6 Controller cabinet

Usually located on bridge or in instrument room. This cabinet distributes signals to and

from the bridge and ECR. It controls all the signals from the Helicon X3 and send them

to the I/O cabinet. There is one controller cabinet per propeller/thruster.

Communicates with the I/O cabinet located in the thruster room.

1 2

Marine Controller Marine Controller

3

7

8

1. Rolls-Royce Marine Controller (Normal)

2. Rolls-Royce Marine Controller (Backup)

3. I/O modules

4. Power distribution

5. Network switches and terminals

6. Signal isolation amplifiers (optional)

7. Power Distribution

8. Main power supply (AC) / fuses

9. Backup power supply (DC) / fuses

4

5

6

9

3.7 I/O Cabinet

The I/O cabinet is often located in the thruster room near sensors and actuators. This

cabinet distributes signals to the different propulsion/thruster units. There is one I/O unit

per propeller/thruster.

The I/O cabinet sends signals to the actuators on the propellers/thrusters and receives

signals from the sensors. There is CAN bus communication between each I/O and

controller cabinet.

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 9 of 16Doc. No.: 13S000411

Page 24

System Description

6

1

7

2

3

4

5

1. I/O modules

2. Capacitors (optional)

3. Power distribution

4. Power distribution

5. Power / network / CANBus terminals

6. Local panel connection

7. Actuator interface card(s) (optional)

8. Relays (optional)

9. Signal isolation amplifiers (optional)

10. I/O terminals

8

9

10

4Functions

Tunnel Thruster Control Functions

The control functions included in the Tunnel Thruster Control system:

• Pitch control

• Command transfer

Main Propulsion Azimuth Control Functions

The control functions included in the Main Propulsion Azimuth Control system:

• RPM control

• Azimuth control

• Command transfer

4.1 Pitch Control

The function of the pitch controller is to move the propeller blades in accordance to the

control lever order. The actuator unit represents the interface between the remote control

and the main servo system, which performs the actual positioning of the blades.

Page 10 of 16 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 25

System Description

3

4.1.1 Normal Control

The output from the pitch controller is computed on the basis of the input signals from

pitch lever and the actuator position feedback.

Lever and feedback signals are scaled and checked against adjustable limits, with

corresponding alarm for exceeding the normal range. The levers have one set of

adjustments (minimum, zero and maximum) for each manoeuvre station. Multiple sets

of feedback adjustments (minimum, zero and maximum) are available for various

engine power take-outs.

In combined mode the lever signal is modified in a Combinator program, see chapter

Pitch and RPM Combinatory (combined Control).

4.1.2 Backup Control

The Backup Control system consists of closed loop control identical to the Normal

Control system. The Backup Control is a separate system, and is independent of the

Normal Control system. A system failure in the Normal Control system will

automatically switch to and engage the Backup Control.

Lever order signals and feedback are monitored and verified against adjustable alarm

limits. If the signals exceed the limits this will release an alarm to the alarm plant and

both visual and audible system failure alarm will be actuated at the manoeuvre stations.

4.1.3 Backup Control Operation

If a failure occurs on important parts of the Normal Control for the Pitch, Azimuth or

RPM Control function, the control will automatically be switched over to the Backup

Control system. A system failure audible and visible alarm will be activated on each of

the control panels.

The thruster control will continue to follow the lever in command and transfer is done

by using the common in command buttons. The command can be transferred between

all bridge position and the bridge control levers will continue to work as in normal

control.

A failure that occurs on important parts of the Backup Control for the Pitch, Azimuth or

RPM Control function will not affect the Normal Control system. If a system failure

occurs on the Backup Control an audible and visible alarm will be activated on each of

the control panels.

4.1.4 Backup Control Limitations

The Backup Control system has only interface to the control levers. The Backup Control

system does not have interface to External Control systems like Dynamic positioning

systems, Joysticks or Autopilots.

Note: No pitch reduction or load function are included in the Backup system.

When operating using the backup system, the operator must be careful not to overload

the engine or the propeller system.

4.1.5 Local Control

If both the Remote Control system and the Backup Control should fail it is possible to

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 11 of 16Doc. No.: 13S000411

Page 26

operate the propeller pitch locally from the pitch control valve.

4.1.6 Pitch Indication

The Pitch Indication system is independent of the Normal Pitch Control system by

means of separate transmitters and electronic circuits. The pitch indicators are connected

in series and are driven from the Backup Control system.

4.1.7 Pitch Order Scaling

The system may need to reduce the pitch order for different reasons. The pitch reduction

can either be activated from a digital or anlogue input signal.

To reserve engine power to heavy consumers as alternators, fire pumps, etc., it may be

necessary to reduce the available propeller output power. This is normally done by

means of a fixed propeller pitch reduction.

If the drive motor is a diesel engine the system is prepared to handle a fuel limiter

contact, from the RPM governor (i.e. high scavange air pressure). If the contact is closed

the pitch order will stop increasing to a higher value, only decrease of pitch order against

zero is possible.

For azimuth thrusters, a pitch reduction will be activated if the azimuth order is changed

faster then the thruster azimuth servo can follow.

System Description

4.2 Thruster Azimuth Control

The azimuth control function is to obtain the correct thruster azimuth position in

accordance to the control lever order. Valve controlled hydraulic motors or frequency

controlled electro motors perform the positioning of the thruster azimuth.

Detailed information regarding the hydraulic system or motor data is available in the

Thruster Instruction manual.

Note: Test point angle signals are ranged +/- 100%, representing +/- 180 degrees.

Some test points are named with degrees, displaying the angle in degrees

(+/- 180 degrees).

4.2.1 Normal Control

The azimuth controller computes the thruster position and order on the basis of signals

from the thruster feedback and control levers. A two-wiper linear potentiometer

provides two outputs with 90 degrees of phase shift named cosine and sine phase

respectively.

The lever order signals and feedback signals are monitored and verified against alarm

limits. If the signals exceed the limits this will release an alarm to the alarm plant with

a visual and audible system failure alarm on the manoeuvre stations.

4.2.2 Backup Control

The Backup Control system consists of closed loop control identical to the normal

control system. The Backup Control is a separate system, and is independent of the

Normal Control system. A system failure in the Normal Control system will

Page 12 of 16 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 27

System Description

3

automatically switch to and engage the Backup Control.

Lever order signals and feedback are monitored and verified against adjustable alarm

limits. If the signals exceed the limits this will release an alarm to the alarm plant with

a visual and audible system failure alarm on the manoeuvre stations.

4.2.3 Backup Control Operation

If a failure occurs on important parts of the Normal control for the Pitch/Azimuth/RPM

control function, the control will automatically be switched over to the backup control

system. A system failure audible and visible alarm will be activated on each of the

control panels.

The thruster control will continue to follow the lever in command, and command

transfer is done by using the common in command buttons. The command can be

transferred between all bridge position and the bridge control levers will continue to

work as in Normal Control.

A failure that occurs on important parts of the Backup control for the Pitch/Azimuth/

RPM control function, will not affect the Normal control system. If a system failure

occurs on the Backup Control an audible and visible alarm will be activated on each of

the control panels.

4.2.4 Backup Control Limitations

The backup control system has only interface to the control levers. The backup control

system does not have interface to external control systems like Dynpos, Joystick or

Autopilot.

Note: No azimuth restrictions or load control functions are included in the

backup system.

When operating using the backup system, the operator must be careful not to overload

the engine or the propeller system.

4.2.5 Local Control

Local control is used if both the normal control and the backup control fail to operate the

thruster azimuth. The thruster azimuth can be operated locally on the actuator unit. The

Control System must first be disconnected from the actuator unit. This can be done by

means of the Local Control switch mounted in front of the Actuator Interface Unit, or

by disconnecting the plug from the actuator unit. If frequency converter used, operate

service switch inside converter cabinet.

The Thruster Instruction Manual will give more details for Local Control operation.

4.2.6 Azimuth Indication

The azimuth indication system independent of the normal control system by means of

separate transmitters and electronic circuits. The Azimuth indicators are connected in

series, and are driven from the Backup Control system.

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 13 of 16Doc. No.: 13S000411

Page 28

4.3 RPM Control

The RPM Control function system controls the speed signal to the frequency converter

for electrical drives or the engine governor for diesel or gas engines.

4.3.1 RPM Control Electric Drive Motor

The RPM Control system includes selection of different operational modes:

• Separate Mode

• Combined Mode

Selection between modes is possible by means of push buttons. RPM Control can be

managed from engine control room only or from additional control panels.

4.3.2 External RPM Control

External RPM order signals from system as DP/Joystick/Auxiliary systems can be

connected to the rpm controller.

The external rpm signal are checked against adjustable preset limits. Any error

conditions on the rpm input signal will initiate a warning to the alarm plant and an error

message will be displayed on the control panel.

System Description

4.3.3 RPM Order Output

The output signal from the controller is scaled to meet the actuator signal range from idle

to full rpm, and then fed to external governor, IP converter or frequency converter. The

output will follow a linear curve between idle and full rpm order.

The RPM output rate of change is adjustable and can be adapted to the engine/frequency

converter reversing speed from idle to full rpm (increasing order) and vice versa

(decreasing order).

4.3.4 Propeller/Shaft RPM Indication

The propeller/shaft RPM indicators are connected in series and are driven from the

Backup Control system.

4.4 Command Transfer

The term Command transfer is used to describe the procedure performed when the

control is transferred between manoeuvre stations without acceptance on either of the

stations. This is normally the procedure between wheelhouse (bridge) stations.

5 Location of Manufacturing Number

5.1 Marking Locations

Electrical cabinets and junction boxes are physically marked with a unique tag, and also

on all applicable drawings. The I/O cabinets are marked with the Rolls-Royce logotype

in the upper left corner.

Page 14 of 16 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 29

System Description

3

The Rolls-Royce logotype is imprinted in remote control panels, alarm panels and cabin

panels.

Cables are marked with a cable tag at both ends.

5.1.1 Company Identification

The Rolls-Royce Company Identification sticker shows where the product has been

produced and is found on discrete places on all delivered items, e.g. on the inside of the

cabinet doors.

1

2

Figure 4 Company Identification Sticker

Pos Denomination Meaning

1 TYPE NO Corresponding drawing number with the revision letter in

closed brackets

2 SERIAL NO Production order number

3 INST. NO Installation number

4 Q.A. DATE Date and signature by test responsible

3

4

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 15 of 16Doc. No.: 13S000411

Page 30

System Description

Page 16 of 16 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 31

4

Delivery Specification

1 General .........................................................................................................3

Copyright © 2010 Rolls-Royce plc

The content of this document is the property of Ro lls-Royce plc and may not be redistributed in whole or in part thereof without

express written consent of Rolls-Royce plc.

Doc. No.: 13S000411

Revision: A

Page 32

Doc. No.: 13S000411

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 33

Delivery Specification

4

1 General

For Delivery specification see the Technical specification.

Note: Upon reception of the Rolls-Royce equipment, the receiver must compare

the shipping documents with the physical items received. If any

discrepancy is found, Rolls-Royce must be informed immediately.

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 3 of 4Doc. No.: 13S000411

Page 34

Delivery Specification

Page 4 of 4 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 35

Rev.

Date:

Sign.

Changed

pages:

Description:

-

17.01.2012

TR

-

New specification

15.01.2013

OHV

New project number

Technical Specification

Propulsion & Thruster Control System

Project no. : 20-12-00136

Version : Vessel type (design) : UT535E

Customer Project no. : RRM STO – P12/7210

Shipowner :

Shipyard :

Yard no. :

Rolls-Royce Marine

Propulsion Ulstein Unit nos : 2xTT CP (bow), 2xUS FP (main)

Author(s): Trude Rånes

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 1 of 14

Page 36

Table of contents

00.01 GENERAL .................................................................................................................... 3

01.00 SCOPE OF SUPPLY/ TECHNICAL DESC RIP TI ON .................................................... 5

01.01 System Ove r vie w ......................................................................................................... 5

01.02 Description of equipment common for all propulsion units ........................................... 6

Control Stations .......................................................................................................................... 6

Control panel functions ............................................................................................................... 7

Control lever functions ................................................................................................................ 8

01.03 Description of equipment for main thruster units (diesel-electric systems). ................. 9

Cabinets ..................................................................................................................................... 9

Interface to external systems ..................................................................................................... 10

01.04 Description of equipment for bow tunnel thrusters ....................................................... 12

Cabinets ..................................................................................................................................... 12

Interface to external systems ..................................................................................................... 13

01.05 Spare Parts and Tools .................................................................................................. 14

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 2 of 14

Page 37

00.01 General

Remote control

Type of remote control : Propulsion and Thruster

Power supply to remote control (main supply) : 230V AC 50/60 Hz

Power supply to remote control (backup supply) : 24V DC from ships battery

Classification requirements

Survey : DNV +1A1, SF, E0, OILREC, Fire

Fighter 1, DYNPOS AUT (DP1),

CLEAN

The equipment is dimensioned in accordance with the above classification society rules valid on

the date of this specification.

Equipment not supplied

Scope of supply is defined in the technical specification.

Not included in scope of supply are:

- External cabling

- Cable glands.

- 24 V DC power supply

Technical information - Drawings

Dimension drawings, wiring diagrams, technical data and installation instruction for the propulsion

remote control system will be delivered. All accordi ng to documentation list issued for each order.

Workshop testing

The propulsion remote control system is workshop tested according to the class requirement and

RRM standard.

Shipment

Depending on transport methods and delivery time’s components may be shipped separately.

Installation into the ship and mounting of components are client's responsibility if not otherwise is

stated.

Safe storage

All equipment is prepared for storage in dry and dust free environments up to 6 months from

delivery.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 3 of 14

Page 38

Cabling

Connections between components supplied by RRM are the client's responsibility. However, cable

type recommendations are given in the diagrams and mounting instructions.

Installation, inspection, starting up and seatrial

Installation of the propulsion remote control system in the ship and mounting of components are

the client's responsibility if not otherwise stated.

Instruction manuals - Language

Users Manuals and Installation Manuals in English language containing all technical data, are

included.

All drawings, documents and sign plates on the equipment will also be delivered in English

language.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 4 of 14

Page 39

Example only, project dependent

01.00 Scope of supply/ technical description

01.01 System Overview

The Propulsion & Thruster control system is a mic roprocessor based system. Following main functions

are included:

- Speed control, allowing accurate and reliable cont rol of the motor speed (RPM).

- Pitch control, allowing accurate and reliable control of the t hruster pitch.

- Direction control, allowing accurate and reliable contr ol of the thrust direction.

- Follow-up backup control from control lever.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 5 of 14

Page 40

01.02 Description of equipment common for all propulsion units

Control Stations

The purpose of the control stations is:

- Selection and indication of panel In Command

- Selection and indication of operational modes, settings and functions

- Selection and indication of thruster status and thruster settings.

- System and operational alarm indication

- Monitoring of signals

Main Bridge control station (Aft)

2 pc. Main propulsion (azimuth ) - Combined Speed and Steering control lever

1 pc. Bow 1/ 2 Tunnel thrusters - Pitch control lever (double)

1 pc. 10.4” LCD - high-resolution colour dis pl ay with touch-screen interface and built-in display

computer.

Indicator panel in overhead console:

2 pcs. Pitch indicator.

2 pcs. Propeller RP M i ndi cat or.

2 pcs. Steering indicator.

Emergency stop panel for thrusters:

4 pcs. Emergency Stop push buttons, hardwired to the variable speed drive (alternati vely to the main

switchboard).

Slave Bridge control station (Fore)

2 pc. Main propulsion (azimuth ) - Combined Speed and Steering control lever

1 pc. Bow 1/ 2 Tunnel thrusters - Pitch contr ol l ever (double)

1 pc. 10.4” LCD - high-resolution colour displa y with touch-screen interface and built-in display

computer.

Indicator panel in overhead console:

2 pcs. Pitch indicator.

2 pcs. Propeller RP M i ndi cat or.

2 pcs. Steering indicator.

Emergency stop panel for thrusters:

4 pcs. Emergency Stop push buttons, hardwired to the variable speed drive (alternatively to the main

switchboard).

ECR station

1 pc. 10.4” LCD - high-resolution colour displa y with touch-screen interface and built-in display

computer.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 6 of 14

Page 41

Control panel functions

Any operation of the system can be performed through the graphical interface. The most vital operations

can in addition be performed by using dedicat ed pushbuttons in the control lever base (see next section).

Summary of features on the screen:

- LAN contact

- Dimmer

- Speaker (not used)

- 24V power input

Display pages

The Main View Page includes the following:

- A shortcut area where the detail-level pages can be r eached.

- An area for COMMON IN COMMAND for all the thrusters.

- A vessel overview area with graphical and numeric information of all thrusters:

- Indication thruster pitch command and actual pitc h feedback

- Indication thruster steering command and actual steering feedback.

- Indication thruster speed command and actual propeller speed.

When selecting one of the detail pages these will replace the overview area. The short-cut area will

remain available from all pages.

Thruster page information is project depende nt. Below are typical examples of each propeller/ thruster

type:

Main Thruster (diesel-electric system) p ages includes the following functions:

- Indication thruster steering command and act ual steering feedback.

- Indication thruster speed command and actual propeller speed.

- Selection and indication of IN COMMAND.

- Indication of STEERING LOCAL CONTROL.

- Indication of SPEED LOCAL CONTROL.

- Indication of ZERO LEVER.

- Selection and indication of START/ STOP OF SYSTEM.

- Selection and indication of START/ STOP O F THRUSTER.

- Selection and indication of COMMON PORT CO NTRO L.

(Common control of both thrusters from port lever).

- Selection and indication of AUTOPILOT ON/OFF .

- Indication of DP/JOYSTICK CONTROL.

- Indication of POWER REDUCED.

- Dimming of lever.

Tunnel Thruster page includes the following funct i ons:

- Indication thruster pitch command and actual pi tch feedback.

- Selection and indication of IN COMMAND.

- Indication of SPEED LOCAL CONTROL.

- Selection and indication of START/ STOP OF SYSTEM.

- Selection and indication of START/ STOP O F THRUSTER.

- Indication of DP/JOYSTICK CONTROL.

- Indication of POWER REDUCED.

- Dimming of lever.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 7 of 14

Page 42

The Alarm Page is common for all thrusters and includes the following:

- Listing of all alarms relevant for the contr ol sy st em (alarm buzzer in control lever base)

- Acknowledge of all alarms (alarm buzzer may also be silenced from button in control lever base)

- Acknowledged alarms remains until error condition disappears.

Viewcon (1 pc.)

The unit is designed for bulkhead mounting and should be located on the bridge. Cable access is through

a cover plate that can be removed for fitting of cable glands. Location of the unit should be selected with

due to emphasis on service access.

The Viewcon cabinet includes a switch for routin g of Ethernet signals to the bridge control panels.

Control lever functions

Potentiometers and electronics for I/Os and control, both for normal and backup system, are included

inside the lever. The display in the base shows set c ommand (pitch and direction) from the lever.

Symbol Command Description

In operation/running Thruster is started and rea dy to use.

Control transfer

Command transfer

Backup control

Alarm

Transfer command between bridge and

ECR

Take command. If light is lit, the lever is

in command

Independent controller that takes over if

the main controller stops. Redundant

system.

Alarm indicator, see alarm screen for

details.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 8 of 14

Page 43

01.03 Description of equipment for main thruster units (diesel-electric

systems).

Cabinets

Electronic unit (one per unit)

The electronic unit is designed for bulkhead mou nting and should be mounted in the instrument room or

nearby the bridge. (Note! Electronic unit must not under any ci rcumstance s be rem oved from the

electronic cabinet and mounted into any console separately). Cable access i s t hrough a coverplate

that can be removed for fitting of cable gl ands. Location of the unit should be selected due emphasis on

service access.

The electronic unit contains the following:

- Power supply

- Application CPUs (Main and backup) including flash memory

- CAN fieldbus

- Ethernet communication with control panels

- I/O cards (DI, DO, AI, AO, serial line interfaces)

- Circuitry monitoring w/alarm output

- Indication circuitry

- Cable termination

Power Supply requirement:

Main supply : 230 VAC (+/- 15%) 50/60 Hz

Back-up supply : 24 VDC (+20% - 17%) (Battery back-up)

Power consumption: : Typical 100 - 200 watt

The Remote Control System is designed to acc om plish prevailing rules of DNV, ABS, LRS, BV, GL and

RINA.

Distributed IO cabinet (one per unit)

The unit is designed for bulkhead mounting and should be located in the thruster room. Cable access is

through a cover plate that can be removed for f itting of cable glands. Location of the unit should be

selected with due to emphasis on service access.

The IO cabinet contains the following:

- I/O to/from external connections.

- Power supply

- CAN field bus

- Cable termination

- Local indicator/Control panel

Lub pump control unit (one per main thruster)

The unit selects duty and stand-by pump and is desi gned for bulkhead mounting and should be located

close to the lub. pumps. Cable access is through cable glands. Location of the unit should be selected

with due to emphasis on service access.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 9 of 14

Page 44

Interface to external systems

Interface to drive motor starter. (Project dependent. To be settled at interface meeting)

- Drive motor RPM order signal, 4 - 20 mA.

The signal has to be galvanic isolated at the governor side.

- RPM feedback signal

4-20mA signal from the frequency converter. Closed when frequency converter fault.

- Common Alarm Drive RPM (Reduce load)

Potential free contact from the frequency converter. Closed = frequency converter alarm

- Frequency Converter fault/ trip (autostop).

Potential free contact from the frequency conv ert er. Closed = frequency converter fault.

- Frequency Converter reset.

Potential free contact to the frequency conv ert er. Closed = reset (pulse)

- Start Frequency Converter

Potential free contact to the frequency converter. Closed = start (pulse)

- Stop/ Autostop Frequency Converter

Potential free contact to the frequency converter. Closed = stop (pulse)

- Emergency Stop Frequency Converter

Potential free contact to the frequency converter. Closed = stop (pulse)

Loop monitored in Frequency Converter (resist ors in each control panel)

- Interlock start/Auto stop Motor

In case of too low gear lub. oil pressure, a potent i al free relay contact is given to the engine control

system for immediately stop of the engine.

Open = stop.

- Frequency Converter ready to run if handle out of zero.

Potential free contact from the frequency conv ert er.

Closed = frequency converter started.

- Power limitation.

Potential free contact from the frequency conv ert er. Closed = power limited in drive.

- Local/ emerg. control

Potential free contact from the frequency conv ert er. Closed = local

DP Interface

The remote control is provided with interface for an ICON DP system.

Communication is via Ethernet.

(Other DP system will be interfaced through hardwired signals)

Signals required from the DP system:

- Closing contact (potential free) to engage the DP m ode. (From selector switch).

- Request for control.

- Speed control signal

- Steering control signal

Signals available to the DP system:

- Remote control is ready for DP

- Remote control acknowledge of DP mode.

- Propeller RPM feedback signal

- Steering feedback signal

- Power reduced signal

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 10 of 14

Page 45

Joystick Interface

The remote control is provided with interf ace f or a P OSCON Joystick system.

Communication is via Ethernet.

(Other joystick system will be interfaced through hardwired signals)

Signals required from the JOYSTICK system:

- Closing contact (potential free) to engage the JOYSTICK mode. (From selector switch).

- Request for control.

- Speed control signal

- Steering control signal

Signals available to the JOYSTICK system:

- Remote control is ready for JOYSTICK

- Remote control acknowledge of JOYSTICK mode.

- Propeller RPM feedback signal

- Steering feedback signal

- Power reduced signal

Autopilot interface

The remote control is provided with interface for an Autopilot system.

Signal required from the Autopilot:

- Steering control signal

-10VDC for 30 degrees, turning clock wi se

0VDC for straight ahead 0 degrees.

+10VDC for 30 degrees, turning counter clo ck wise

The signal to be galvanic isolated at the AP system

Signal available to the AP system:

- Closing contact (potential free) when the remote control is ready for AP.

ACON Interface

The remote control is provided with interf ace f or an ACON Automation system.

Communication is via Ethernet.

(Other automation system will be interfaced through serial line or hardwired signals)

Signal available to the ACON system:

- Thruster alarms.

- Thruster running.

- Steering feedback signal

- Propeller RPM feedback signal

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 11 of 14

Page 46

01.04 Description of equipment for bow tunnel thrusters

Cabinets

Electronic unit (one per unit)

The electronic unit is designed for bulkhead mount i ng and should be mounted in the instrument room or

nearby the bridge. (Note! Electronic unit must not under any ci rcumstance s be rem oved from the

electronic cabinet and mounted into any console separately). Cable access i s t hrough a coverplate

that can be removed for fitting of cable glands. Location of the unit should be selected due emphasis on

service access.

The electronic unit contains the following:

- Power supply

- Application CPUs (Main and backup) including flash memory

- CAN fieldbus

- Ethernet communication with control panels

- I/O cards (DI, DO, AI, AO, serial line interfaces)

- Circuitry monitoring w/alarm output

- Indication circuitry

- Cable termination

Power Supply requirement:

Main supply : 230 VAC (+/- 15%) 50/60 Hz

Back-up supply : 24 VDC (+20% - 17% ) (Battery back-up)

Power consumption: : Typical 100 - 200 watt

The Remote Control System is designed to acc om plish prevailing rules of DNV, ABS, LRS, BV, GL and

RINA.

Distributed IO cabinet (one per unit)

The unit is designed for bulkhead mounting and should be located in the thruster room. Cable access is

through a cover plate that can be removed for f itting of cable glands. Location of the unit should be

selected with due to emphasis on service access.

The IO cabinet contains the following:

- I/O to/from external connections.

- Power supply

- CAN field bus

- Cable termination

- Actuator interface Pitch

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 12 of 14

Page 47

Interface to external systems

Interface to drive motor starter

The following signals are given to the drive motor starter:

- Zero Pitch Signal.

A potential free relay contact for interlock st art of thruster motor.

The contact is closed at zero pitch position.

- Start motor.

Impulse push button for start of motor (normal ly open - closes for start)

- Stop motor.

Impulse push button for stop of motor (normally closed - opens for stop)

- Emergency stop motor.

Impulse push button for emergency stop of motor.( normally closed – opens for stop)

- Servo pump running.

Potential free relay contact from servo p um p st arter, opens when servo pump stops.

The following signals are required from the driv e m otor starter to the control system:

- Running signal

A potential free relay closing contact when the motor is running and ready for thruster operation.

Indication light on the START push button on Mai n Bridge Panel.

- Overload signal (high temp. in windings). A potential free relay contact from the thermal relay for

overload indication in control panels.

- Drive motor current signal.

4-20mA signal from the drive motor starter.

The load control continuously monitors the power output from the drive motor and the propeller pitch

is automatically adjusted in response to the load changes detected.

DP Interface

The remote control is provided with interf ace f or an ICON DP system.

Communication is via Ethernet.

(Other DP system will be interfaced through hardwired signals)

Signals required from the DP system:

- Closing contact (potential free) to engage the DP m ode. (From selector switch).

- Request for control.

- Pitch control signal

Signals available to the DP system:

- Remote control is ready for DP

- Remote control acknowledge of DP mode.

- Pitch feedback signal

- Power reduced signal

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 13 of 14

Page 48

Joystick Interface

The remote control is provided with interf ace f or a P OSCON Joystick system.

Communication is via Ethernet.

(Other joystick system will be interfaced through hardwired signals)

Signals required from the JOYSTICK system:

- Closing contact (potential free) to engage the JOY S T ICK mode. (From selector switch).

- Request for control.

- Pitch control signal

-

Signals available to the JOYSTICK system:

- Remote control is ready for JOYSTICK

- Remote control acknowledge of JOYSTICK mode.

- Pitch feedback signal

- Power reduced signal

ACON Interface

The remote control is provided with interf ace for an ACON Automation system.

Communication is via Ethernet.

(Other automation system will be interfaced thr ough serial line or hardwired signals)

Signal available to the ACON system:

- Thruster alarms

- Pitch feedback signal

01.05 Spare Parts and Tools

One set RRM standard spare parts for two years operation, consisting of:

- Fuses for remote control.

- Bulbs for remote control.

This document is the property of Rolls-Royce and may not be redistributed or reproduced in any way, without the written permission of Rolls-Royce.

Failure to do so is a violation of copyright laws.

P&T Control_20-12-00136_UT535E_Brasil _V2

Page 14 of 14

Page 49

5

Technical Data

1 General .........................................................................................................3

2 Environmental Data ..................................................................................... 4

3 Electrical Data .............................................................................................. 4

3.1 Power Supply ................................................................................................4

3.2 I/O Modules ...................................................................................................4

3.3 Levers ............................................................................................................ 4

3.4 10.4 inches LCD ............................................................................................4

Copyright © 2010 Rolls-Royce plc

The content of this document is the property of Ro lls-Royce plc and may not be redistributed in whole or in part thereof without

express written consent of Rolls-Royce plc.

Doc. No.: 13S000411

Revision: A

Page 50

Doc. No.: 13S000411

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 51

Technical Data

5

1 General

This section provides the technical data of the Helicon X3 system, with focus on the

main hardware components. Detailed drawings and interface descriptions are found in

the delivery specific drawings, see chapter 12 Design Drawings.

The Helicon X3 system is designed to meet the type approval requirements stated by EU

standards and the following classification societies:

• American Bureau of Shipping (ABS)

• Bureau Veritas (BV)

• China Classification Society (CCS)

• Det Norske Veritas (DNV)

• Germanischer Lloyds (GL)

• Korean Register of Shipping (KR)

• Lloyd’s Register (LR)

• Nippon Kaiji Kyokai (NK)

• Registro Italiano Navale (RINA)

• Russian Maritime Register of Shipping (RS)

• Croatian Register of Shipping (Hrvatski Register Brodova) (CRS)

• Indian Register of Shipping (IRS).

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 3 of 4Doc. No.: 13S000411

Page 52

2 Environmental Data

Temperature: 0–70 °C ambient

Humidity: 97 %

Vibration: 3–100 Hz, frequency ranges

3-13.2 Hz, displacement limited to 1 +/- 1.0 mm

13.2-100 Hz, acceleration limited to 0.7G

EMC: According to the rules of the Classification Societies, and the

IEC945 standard for Electromagnetic Compatibility

Enclosure: IP22 (Control room, Accommodation and Bridge)

IP44 (Engine room)

3 Electrical Data

3.1 Power Supply

Technical Data

Main supply 230 VAC (85-264VAC) 50/60 Hz

Backup supply 24 VDC (18-32 VDC) (Battery backup)

Power consumption Typical 100-200 Watt

3.2 I/O Modules

Analogue inputs 12 bit +/-0.5% absolute accuracy

Analogue outputs 12 bit +/-0.5% absolute accuracy

3.3 Levers

Analogue inputs 10 bit +/- 0.4% linear error, and +/- 1% absolute accuracy

3.4 10.4 inches LCD

Power supply 24VDC +20%, -17%

Power consumption 50 Watt max

Page 4 of 4 Doc. No.: 13S000411

Copyright © 2010 Rolls-Royce plc

Revision: A

Page 53

6

Operating Instructions

1 General .........................................................................................................3

2 Controlling the thrusters ............................................................................3

2.1 System Overview ...........................................................................................3

3 Standard Operations ...................................................................................8

3.1 Port/Stbd Main Propulsion .............................................................................8

3.2 Bow/Stern Tunnel Thruster ............................................................................8

3.3 In Command ..................................................................................................8

3.4 RPM / Power Mode .......................................................................................9

3.5 Start/Stop pump ............................................................................................9

3.6 Start/Stop thruster .......................................................................................10

3.6.1 Start Thruster ...................................................................................10

3.6.2 Stop Thruster ....................................................................................11

3.7 Reset Drive ..................................................................................................11

3.8 Separate/Common Lever ............................................................................12

3.9 Autopilot ......................................................................................................12

3.9.1 Enabling / Disabling Autopilot ...........................................................12

3.9.2 Automatic Autopilot Disengage ........................................................13

4 Alarm ..........................................................................................................13

4.1 Silence .........................................................................................................14

4.1.1 Alternative 1 .....................................................................................14

4.1.2 Alternative 2 .....................................................................................14

4.2 Acknowledge All ..........................................................................................15

4.2.1 Alternative 1 .....................................................................................15

4.2.2 Alternative 2 .....................................................................................15

4.3 Wash screen ................................................................................................15

4.4 Lever Light ...................................................................................................15

4.5 Day/Night .....................................................................................................16

5 Steering the Ship with Azimuth Thrusters ..............................................16

5.1 Position Keeping .........................................................................................16

5.2 Ahead ..........................................................................................................17

5.3 Astern ..........................................................................................................18

6 Crash Stop .................................................................................................18

6.1 Crash Stop Procedure .................................................................................18

7 Backup Operation ......................................................................................19

7.1 Steering Backup Control at Bridge or Engine Control Room .......................19

7.2 Steering (direction) Local Control ................................................................20

7.3 Steering (direction) Emergency Operation, Local ........................................20

8 Emergency Operation ...............................................................................20

8.1 Emergency Control/Local Control ................................................................20

8.1.1 From Bridge ......................................................................................21

8.1.2 From Thruster Room ........................................................................21

Copyright © 2010 Rolls-Royce plc

The content of this document is the property of Ro lls-Royce plc and may not be redistributed in whole or in part thereof without

express written consent of Rolls-Royce plc.

Doc. No.: 13S000411

Revision: A

Page 54

Doc. No.: 13S000411

Revision: A

Copyright © 2010 Rolls-Royce plc

Page 55

Operating Instructions

6

1 General

This chapter gives a brief overview on how to operate the Helicon X3 system. For

practical reasons, it is not possible to go into particulars about all available functions.

Instead, the graphical user interface (GUI) is designed to be as self-explanatory as

possible. In the following sections, the most common functions are described in detail.

Caution: Before operating the equipment, please refer to chapter 2, Safety for the

general statement, safety and warnings instructions.

2 Controlling the thrusters

There are three ways of controlling the thrusters with Helicon X3:

• Control lever

• Control panel

• Emergency operation

2.1 System Overview

The system overview page on the control panel gives an overview of the most essential

information for all propulsion units. The system overview page is the normal view if not