Rollseal RS500 WIC User Manual

RollSeal RS500 WIC

Door User Manual

Manual No. 4801-5164 REV 3/19 Users Manual RollSeal RS500 WIC Door

Table of Contents:

1. Limited Warranty .................................................................................................................................. 4

2. RollSeal RS500 WIC Door Overview .................................................................................................. 5

3. Ratings, Specifications, and Certifications ........................................................................................... 5

4. RS500 WIC Door Components ............................................................................................................. 6

5. RS500 WIC Door Dimensions .............................................................................................................. 7

6. Installation of RS500 WIC Doors ......................................................................................................... 8

6.1. Adjusting the Door Framing or Clear Opening ............................................................................. 8

6.2. Attachment Points of the Door ...................................................................................................... 8

6.3. Assembly of Tracks to the Head Unit ........................................................................................... 8

6.4. Fastening Door Assembly to Clear Opening .............................................................................. 10

6.5. Infrared Safety Sensor Connection ............................................................................................. 12

6.6. Egress Track System (ETS) ........................................................................................................ 14

7. Connecting Electrical Power to RS500 WIC Door ............................................................................. 15

8. Installation and Connection of Prewired Switch ................................................................................. 17

8.1. Connection of the Front Prewired Switch ................................................................................... 17

8.2. Installation and Connection of the Interior Prewired Switch ...................................................... 17

9. Field Installed Labels .......................................................................................................................... 18

10. RollSeal Smart Switch Indicator LEDs .......................................................................................... 19

10.1. Indicator LEDs ........................................................................................................................ 19

10.2. Open and Close Switches/LEDs ............................................................................................. 19

10.3. Smart Power Functions: (Future Functions) ........................................................................... 19

11. Optional Power Connection with Disconnect ................................................................................. 21

12. Preparation for Operation................................................................................................................ 22

13. Operation of RS500 WIC Door ...................................................................................................... 22

14. Smart Controller User Interface ...................................................................................................... 23

14.1. Overview ................................................................................................................................. 23

14.2. Interpreting the Display Indicator ........................................................................................... 24

14.2.1. Software Version and Model Number .................................................................................... 24

14.2.2. Actual Position Reading ......................................................................................................... 24

14.2.3. Unknown Position Indication ................................................................................................. 24

14.2.4. Assumed Position Indication .................................................................................................. 24

14.2.5. Jog Mode Indication .............................................................................................................. 25

14.2.6. Service Reminder Indication .................................................................................................. 25

14.2.7. Infrared Safety Sensors ........................................................................................................... 25

RollSeal RS500 WIC User Manual Page 2

14.2.8. Leading Edge Switches ........................................................................................................... 25

14.2.9. Home Switch ........................................................................................................................... 25

14.2.10. Secondary Safety (Fly Sensor) ............................................................................................ 25

14.3. Program Mode ........................................................................................................................ 26

14.4. Deceleration Range ................................................................................................................. 30

14.5. Jog Mode ................................................................................................................................. 30

15. Troubleshooting Controller and/or Door ........................................................................................ 31

15.1. P12 – Input Status Indicators .................................................................................................. 31

15.2. Error Codes and Recommended Action .................................................................................. 32

16. Manual Operation of RS500 WIC Door ......................................................................................... 32

17. Replacement of an Existing Panel .................................................................................................. 33

17.1. Removal of Existing Panel ...................................................................................................... 33

17.2. Replacement Panel Installation ............................................................................................... 35

16. Cleaning Panels ............................................................................................................................... 38

17. Emergency Egress ........................................................................................................................... 38

17.1. Exiting (Opening) the Door .................................................................................................... 38

17.2. Resetting (Closing) the Door .................................................................................................. 39

18. Removing and Replacing Front Egress Tracks (Floating) .............................................................. 40

19. RS500 WIC Series Door Wiring Diagram ...................................................................................... 42

20. Wiring Optional Accessories .......................................................................................................... 44

20.1. Wiring Falcon Motion Detectors ............................................................................................ 44

20.2. Wiring Wave Switch ............................................................................................................... 45

20.3. Wiring BEA Receiver ............................................................................................................. 46

21. Replacement Parts ........................................................................................................................... 47

22. Warnings (Avertissements) ............................................................................................................. 49

RollSeal RS500 WIC User Manual Page 3

Warrantor:

RollSeal

1733 County Road 68

Bremen, Al 35033

256-287-7000

1. Limited Warranty

All products are warranted to be free from defects in material and workmanship for a period of one

(1) year or 100,000 cycles, whichever occurs first, from the date of purchase if installed and used

in strict accordance with the installation instructions. Liability is limited to the sale price of any

products proved to be defective or, at manufacturers’ option, to the replacement of such products

upon their return. No products are to be returned to the manufacturer, until there is an inspection

and/or a return-goods authorization (RGA) number is issued.

All complaints should be directed first to the authorized distributor who sold the product. If

satisfaction is not obtained or the name of the distributor is not known, write the manufacturer that

appears below, directed to the attention of Customer Service Manager.

This limited warranty is expressly in lieu of any and all representations and warranties expressed

or implied, including any implied warranty of merchantability or fitness for a particular purpose.

The remedy set forth in this limited warranty shall be the exclusive remedy available to any person.

No person has authority to bind the manufacturer to any representation or warranty other than this

limited warranty. The manufacturer shall not be liable for any consequential damages resulting

from the use of our products or caused by any defect, failure or malfunction of our products. (Some

areas do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.)

This warranty gives you specific legal rights and you may also have other rights that vary from area

to area.

RollSeal RS500 WIC User Manual Page 4

2. RollSeal RS500 WIC Door Overview

RS-500 WIC Door Specifications

Technical Specifications

Power Supply

115 VAC 50/60 Hz Single Phase or

230 VAC 50/60 Hz Single Phase

Temperature Range

32°F - 115°F (0°C - 46°C)

Input Power

10 Amps @ 115 VAC Single Phase

or 6 Amps @ 230 VAC Single Phase

Operational Power

3 Amps @ 115 VAC Single Phase or

1.5 Amps @ 230 VAC Single Phase

Standby Power

0.2 Amps @ 115 VAC Single Phase

or 0.1 Amps @ 230 VAC Single

Phase

Outputs

230 VAC Three Phase 1/6 HP

Speed

Up To 18"/Sec.

Horsepower

1/6 hp

Features

Soft Start / Soft Stop

Yes

Programmable Control

Yes

Auto Closure Feature

Yes

Manual Override

Yes (3/4" Socket)

Safety Beams

Monitored (Per UL 325)

Tension Pipes

Foam Covers Fiberglass

Emergency Egress

Egress Track System (ETS)

Certifications

EISA Exempt

Yes

NSF (National

Sanitation

Foundation)

Yes

UL

UL325

The RollSeal RS500 WIC Door is specifically designed for walk in cooler applications. This RollSeal Door

has an integrated controller, motor, and switch that reduces the footprint and gives the door a clean and

sleek appearance. This door features a patented egress track system that is effortless for the user to exit the

cooler in case of an emergency.

3. Ratings, Specifications, and Certifications

RollSeal RS500 WIC User Manual Page 5

Table 1: Technical Specifications

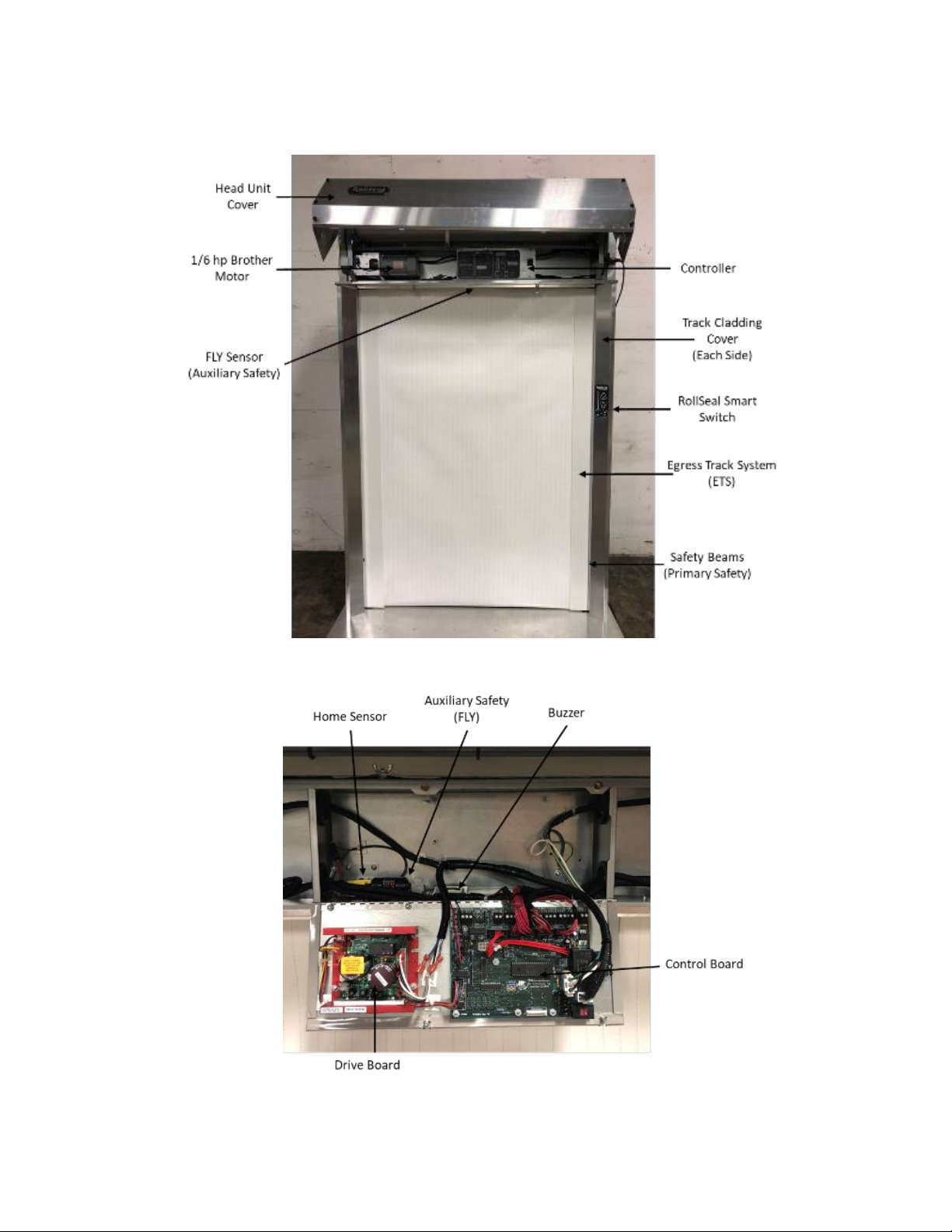

4. RS500 WIC Door Components

Figure 1: Door Components

Figure 2: Controller Components

RollSeal RS500 WIC User Manual Page 6

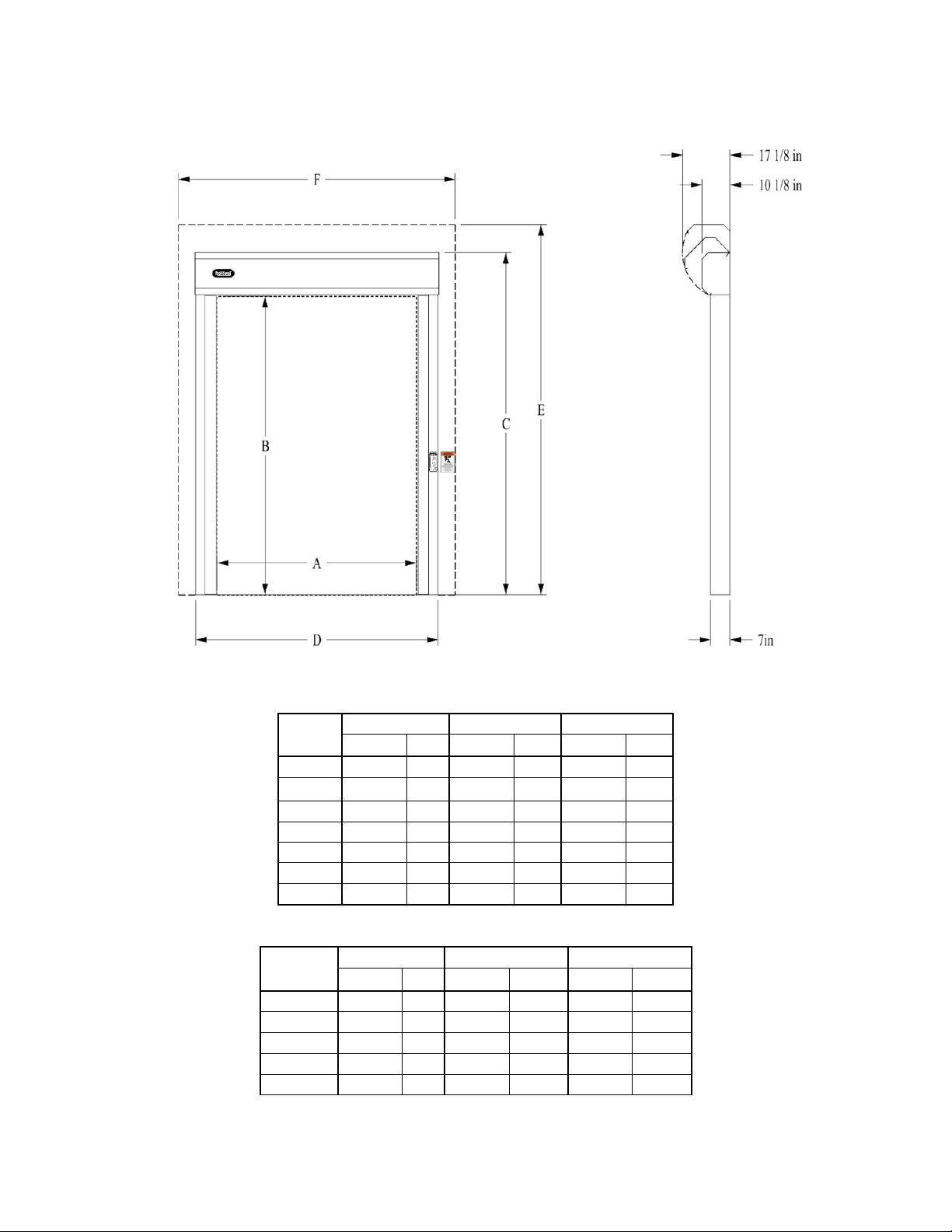

5. RS500 WIC Door Dimensions

WIDTH Related Dimensions

Door

Width A D

F

Inches

cm

Inches

cm

Inches

cm

3'-0"

36

91

52.25

133

64

163

3'-6"

42

107

58.25

148

70

178

4'-0"

48

122

64.25

163

76

193

4'-6"

54

137

70.25

178

82

208

5'-0"

60

152

76.25

194

88

224

5'-6"

66

168

82.25

209

94

239

6'-0"

72

183

88.25

224

100

254

HEIGHT Related Dimensions

Door

Height

B C E

Inches

cm

Inches

cm

Inches

cm

7'-0"

84

213

100

254

110

279

7'-6"

90

229

106

269

116

295

8'-0"

96

244

112

284

122

310

8'-6"

102

259

118

300

128

325

9'-0"

108

274

124

315

134

340

Figure 3: RS500 WIC Dimensions

Table 2: Door Width Dimensions

RollSeal RS500 WIC User Manual Page 7

Table 3: Door Height Dimensions

6. Installation of RS500 WIC Doors

This door was designed and manufactured for easy assembly and installation. Follow the below

instructions to install and set up your RollSeal RS500 WIC Door.

6.1. Adjusting the Door Framing or Clear Opening

Referring to Table 2 and Table 3, determine the particular system that you are installing. Read the values

of the height and width of the clear opening for the door size you are installing. This gives the required

dimensions of the clear opening. If necessary, adjust the dimensions of the mounting posts or framing

members to the height and width of your RS500 WIC series door system as shown. Refer to Section 6.4

for details of attaching door to framing members. Framing material must provide suitable support for

attachment of screws. Make sure that mounting posts or framing members are positioned so that the screw

holes will align with the mounting posts or framing members.

NOTE: It is optimal that there be 1' (30.4 cm) clearance above the Head Unit for future panel

maintenance or replacement. Allow 6” (15.2 cm) clearance on the sides to allow for track cladding access.

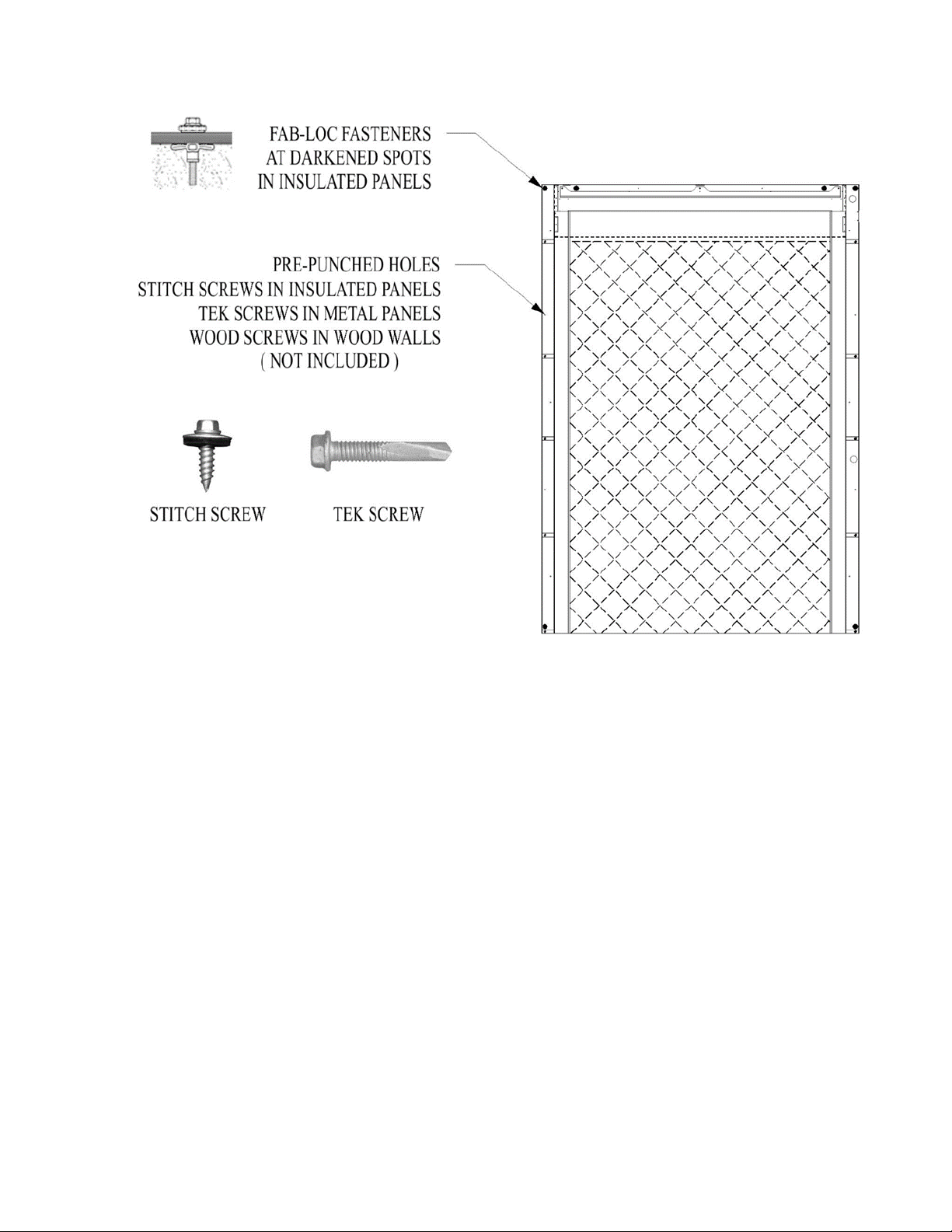

6.2. Attachment Points of the Door

When sizing the clear opening for attachment of the door, pay close attention to the following guidelines.

Door tracks and back plate have pre-drilled holes that serve as mounting points of door.

1. Make sure the door assembly is plumb & square.

2. The back plate has mounting holes in it for ease of installation. Make sure these fasteners are

secured into structural members if possible.

3. The vertical track members have pre-drilled holes for installation. With the track cladding cover

removed, the mounting holes should be aligned with the structural members if possible.

4. When the door is raised in front of clear opening as shown in Figure 9, ensure that all mounting

holes are aligned and flush with the attachment surface.

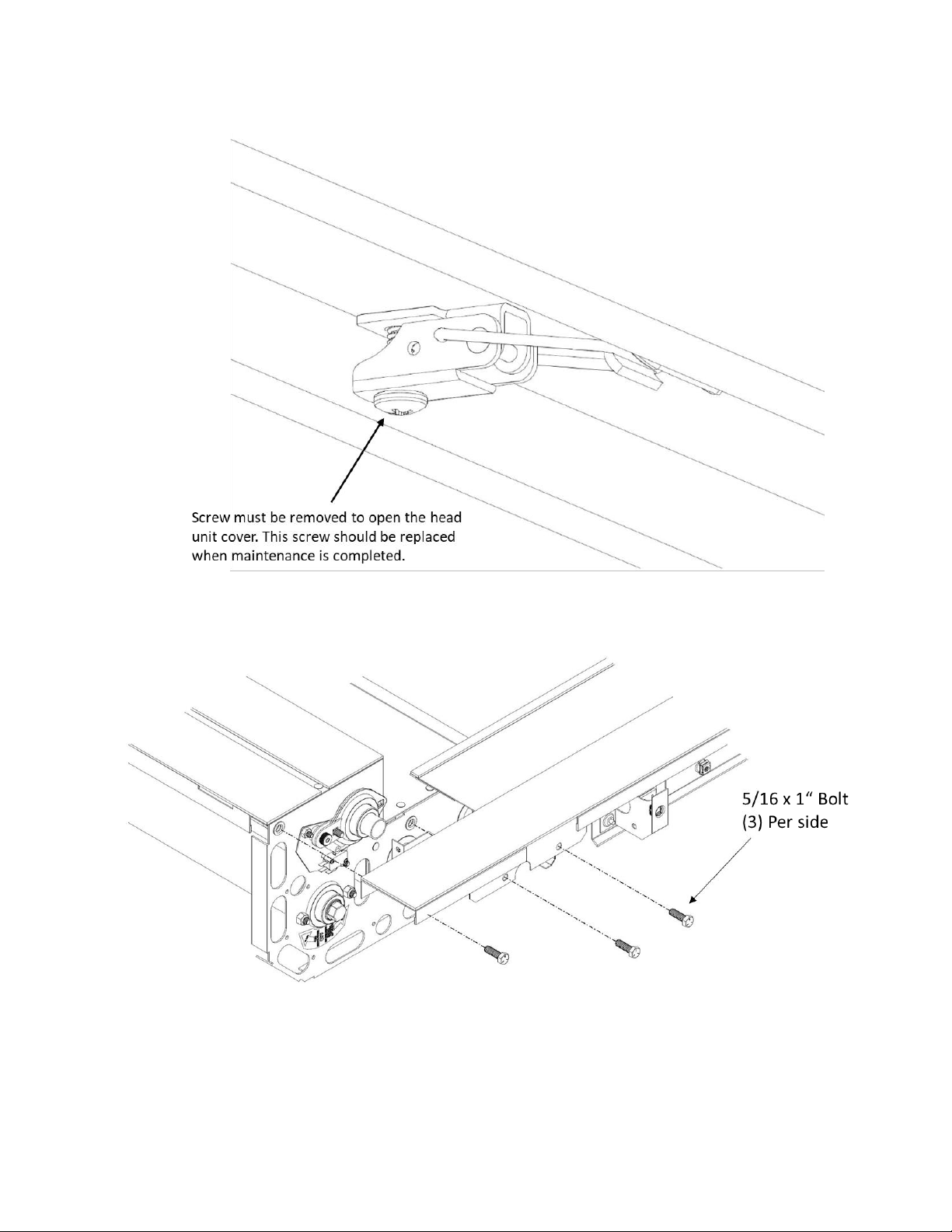

6.3. Assembly of Tracks to the Head Unit

It is recommended that the tracks be assembled to the head unit in close proximity to the clear opening

that the door is being installed on. Install the tracks to the head as follows:

1. Remove the cover from the head unit by unlatching the two latches at the bottom of the cover and

rotating the cover upward. One of the latches will have a phillips head screw in the bottom of the

latch. This screw will be required to be replaced when the door is fully installed and the cover is

closed. Refer to Figure 4 for screw placement in the latch. With the cover rotated slightly, push

up and the two hinge plates will be lifted out of the alignment slots at the top of the head unit.

Once the cover is removed, place it to the side until the door is installed.

2. Turn the head unit over and lay it front down on a piece of cardboard to prevent damage to the

head unit. This will make it easier to stand the door up against the wall after track installation.

3. Remove the track cladding covers by removing three screws on the left and right side of each

cover. With the six screws removed, pull the cladding cover upward away from the track frame to

allow the tracks to be mounted to the head unit.

4. With the cladding removed and the tracks facing downward, align the upper track holes with the

threaded holes on either end of the head unit as shown in Figure 5.

5. Using the supplied hardware that has been hand tightened in the fastener holes on the head unit,

fasten the tracks to the head unit be removing the three 5/16 x 1” bolts and aligning the tracks

with these holes. Once the tracks are aligned, replace the bolts and tighten.

RollSeal RS500 WIC User Manual Page 8

Figure 4: Latch Securing Screw

Figure 5: Assembly Tracks to Head

RollSeal RS500 WIC User Manual Page 9

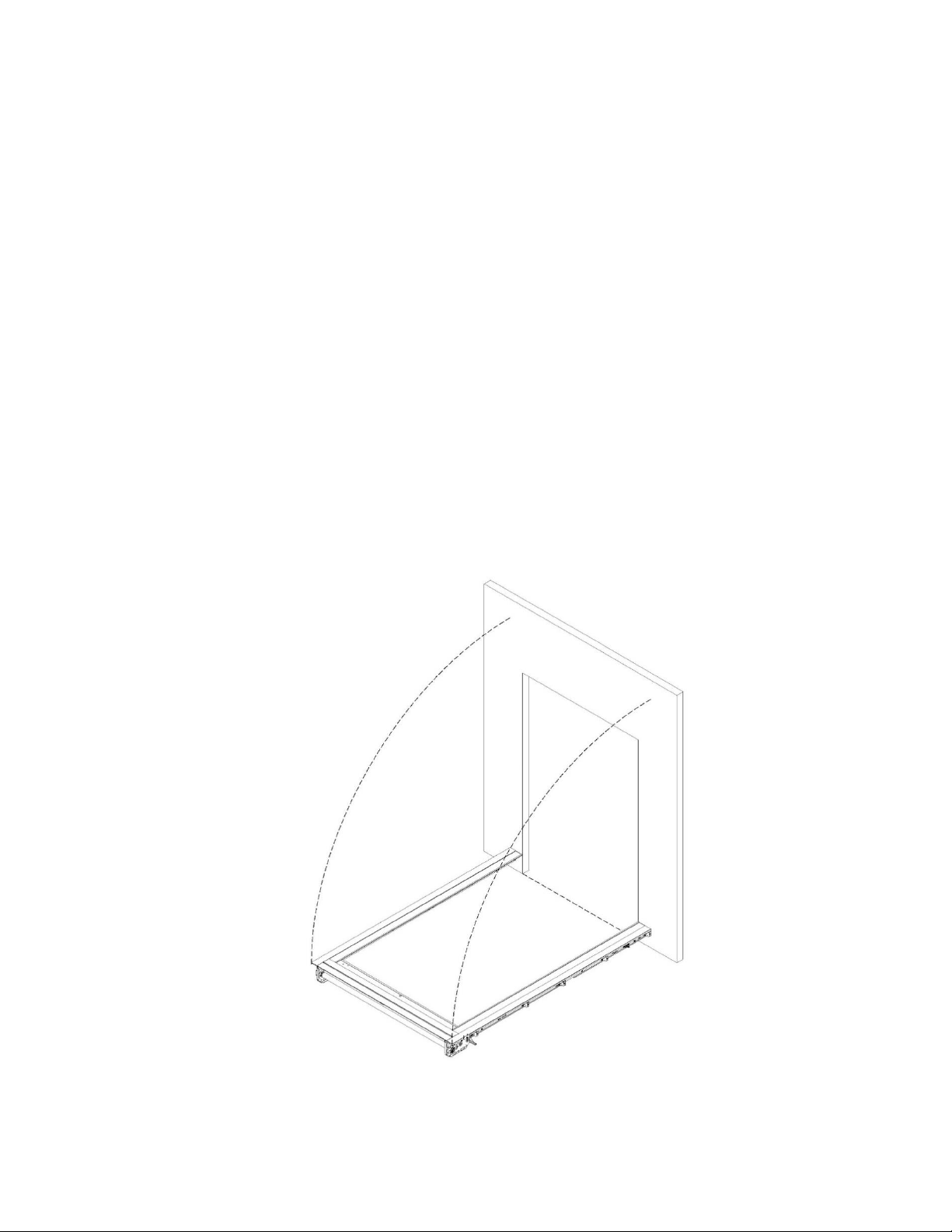

6.4. Fastening Door Assembly to Clear Opening

Now that the tracks have been secured to the head unit, the door is ready to be installed to the clear

opening. In order to do this, follow the below steps:

1. To begin this installation process, the door should be lying on the ground facing downward with

the bottom of the tracks near the bottom of the clear opening.

2. Slowly lift the head unit and walk the door up to the upright position as shown in Figure 6.

3. Slide the bottom of the tracks backwards to the point that the back of the tracks make contact with

the clear opening mounting structure.

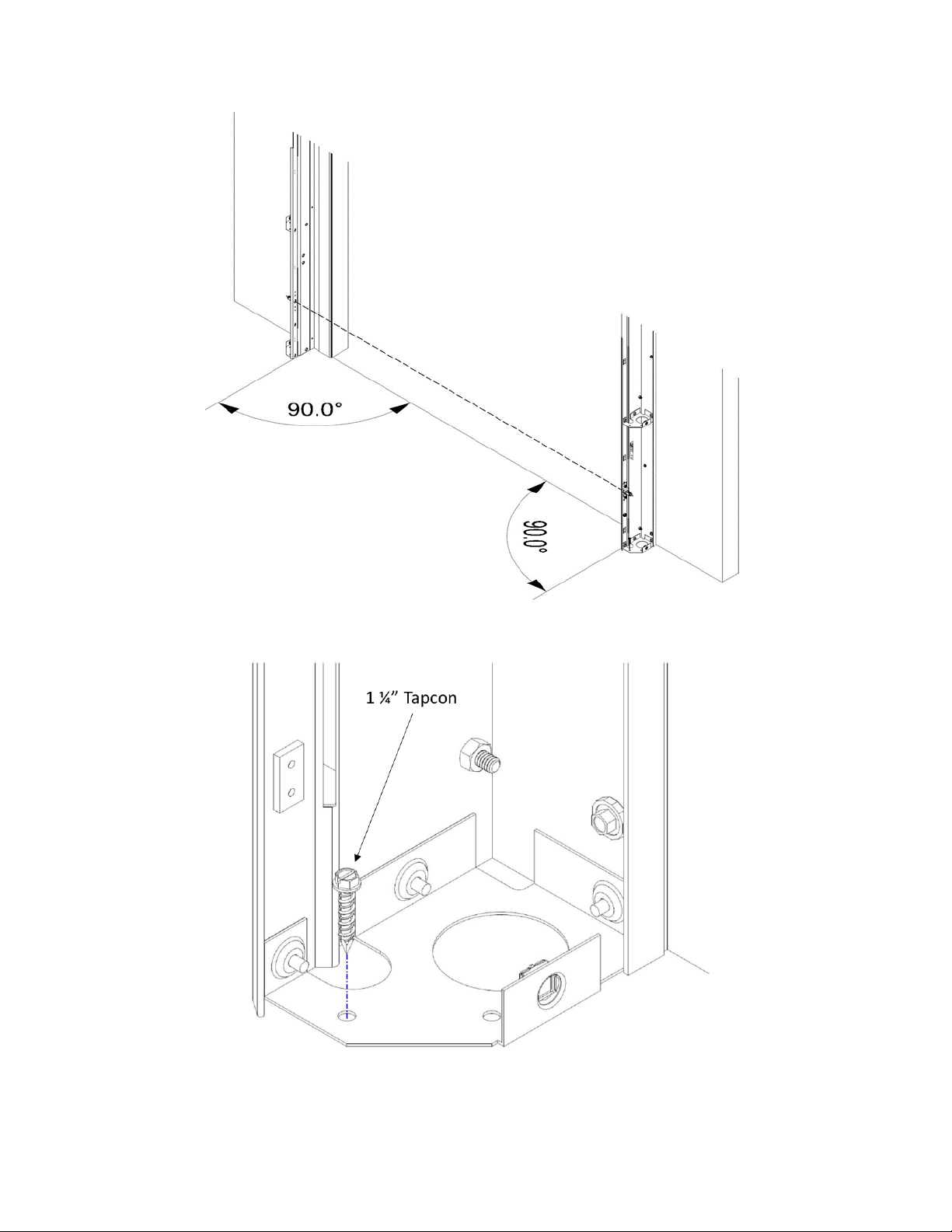

4. Before securing the door in position, ensure that the door assembly is plumb and square.

5. Ensure that all the track and back plate mounting holes are aligned with the structural support

members if possible.

6. Once step 4 and step 5 have been performed, the door can be secured in position with the use of

the provided hardware as shown in Figure 9.

7. It is imperative that the tracks be secured to the floor properly so that the Infrared Safety Beams

are aligned with each other as shown in Figure 7. Once the tracks are square, at least one tapcon

should be used to secure the bottom of the tracks to the floor as shown in Figure 8. If the Safety

Beams are not aligned, the “PS” LED will be on when looking at the smart switch.

8. The head unit cover can be installed by inserting the two downward facing tabs on the back of the

cover in the two slots located at the top of the frame of the door. Leave the cover open and

propped on the stand while proceeding to Section 6.5.

Figure 6: Standing RS500 WIC Door

RollSeal RS500 WIC User Manual Page 10

Figure 7: Infrared Safety Sensor Alignment

Figure 8: Tapcon Installation

RollSeal RS500 WIC User Manual Page 11

Figure 9: RS500 WIC Fastener Locations

6.5. Infrared Safety Sensor Connection

With the door installed and the cover open, the Infrared Sensors and Integrated Switch can be connected

and the Track Cladding Covers can be installed. Refer to the below steps to install the track covers.

1. Beginning with the left track section, there will be a three wire harness gathered in the head unit

between the motor and the controller enclosure.

2. Navigate this harness under the motor and through the rubber grommet on the left end plate.

3. Proceed to run the harness down the left track through the large holes in the track braces and plug

the connector at the end of the harness into the infrared safety sensor connector. If there is any

excess wire length, neatly bundle it and secure it to the inside track frame.

4. At this time, the left track cladding cover can be installed with the hardware removed in Section

6.3. To install the track cladding cover, feed the cladding cover up at an angle from the face of the

door pushing it up against the rubber seal at the head unit, in toward the track frame and then

sliding it toward the track frame at the floor.

5. There will be a harness gathered to the right side of the controller enclosure in the head unit.

Navigate this harness with the 20 pin connector on the end through the rubber grommet at the

bottom of the right endplate.

6. Bring the harness down the right track through the large holes in the track braces.

7. Position the right track cladding cover next to the track frame.

RollSeal RS500 WIC User Manual Page 12

8. As explained in Section 8.1, plug the 20 pin connector into the back of the switch card to power

the smart switch.

9. There will be a harness bound together next to the Infrared Safety Sensor in the right track. Unroll

this harness and run it up the right track through the large holes in the track braces to the smart

switch.

10. Plug the harness into the 4 pin connection on back of the smart switch. At this point, the Infrared

Safety Beams will be connected. Refer to Figure 10 for more details as to the location of these

connectors.

11. Once the infrared safety beams and integrated switch are connected, neatly bundle any excess

wire and secure it to the inside track frame with a drip loop.

12. Before installing the right track cladding cover, the interior switch needs to be mounted and

connected. Refer to Section 8.2 for installation instructions on installing the interior switch.

13. At this time the right track cladding cover can be installed in the same manner as the left side was

installed.

Figure 10: Front Switch & Infrared Safety Sensor Connection

RollSeal RS500 WIC User Manual Page 13

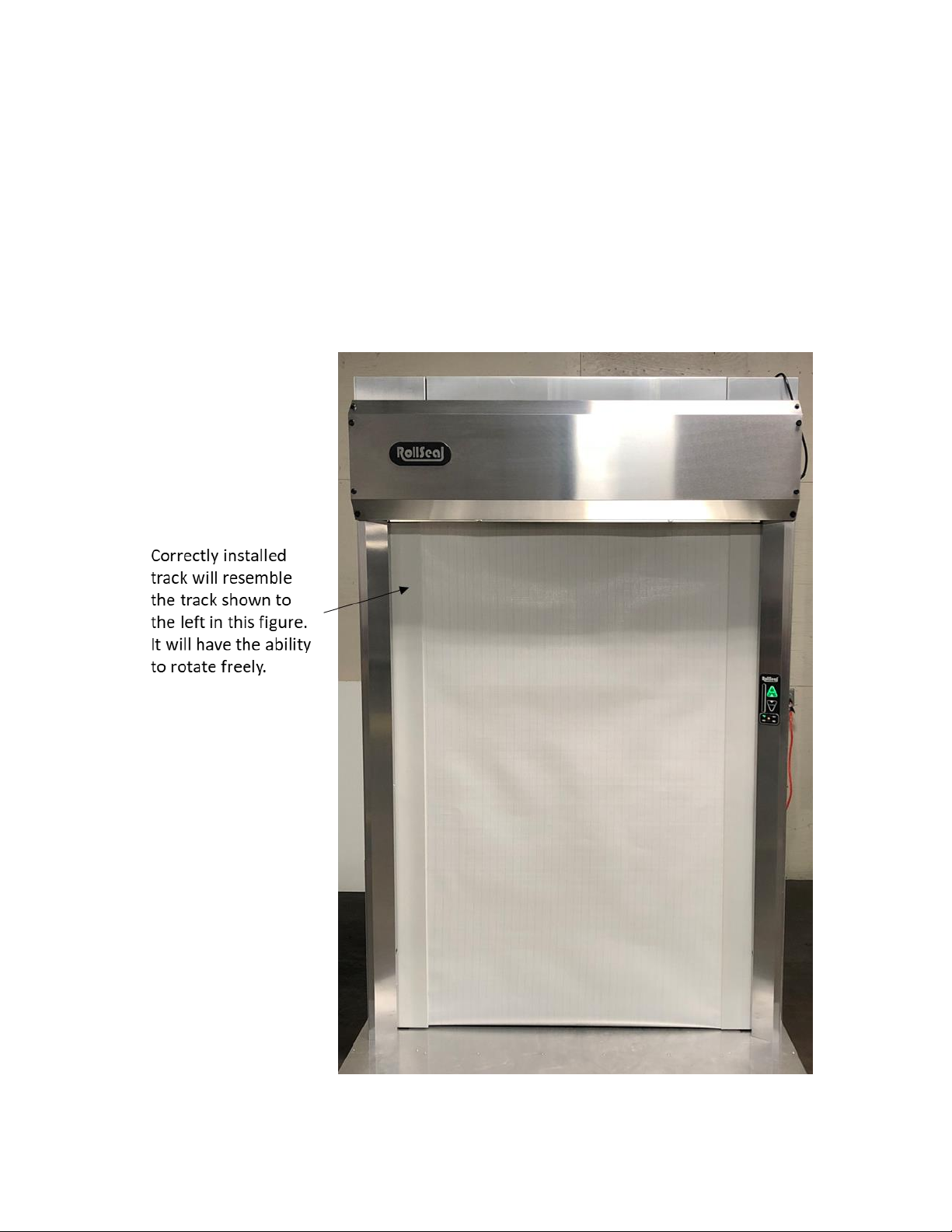

6.6. Egress Track System (ETS)

After the completion of Section 6.5, the egress tracks can be installed.

1. With the head unit cover open, take one egress track at a time and position it with the tab facing

toward the ground. The Egress Tracks are not interchangeable for the left and the right. In order

to determine which side they should be installed, the magnets should be facing the rear of the

door and the mounting tabs should be facing the ground. Refer to Figure 29

2. Position the tabs horizontally in the slots.

3. Pull the egress track down so that the tabs are engaged in the slots.

4. Refer to Figure 11 and Section 18 for more details as to how to install these egress tracks.

5. Once the folding egress tracks are installed, you may proceed to Section 7.

Figure 11: Install of Egress Tracks (ETS)

RollSeal RS500 WIC User Manual Page 14

7. Connecting Electrical Power to RS500 WIC Door

The RS500 WIC Door is designed to accept either 115v or 230v power supply.

The electrical wire should be a minimum 3 wire, 16AWG or larger. There is a pre-determined location for

line power wire to be brought into the unit by an electrician. There is a CPC connector on the right track

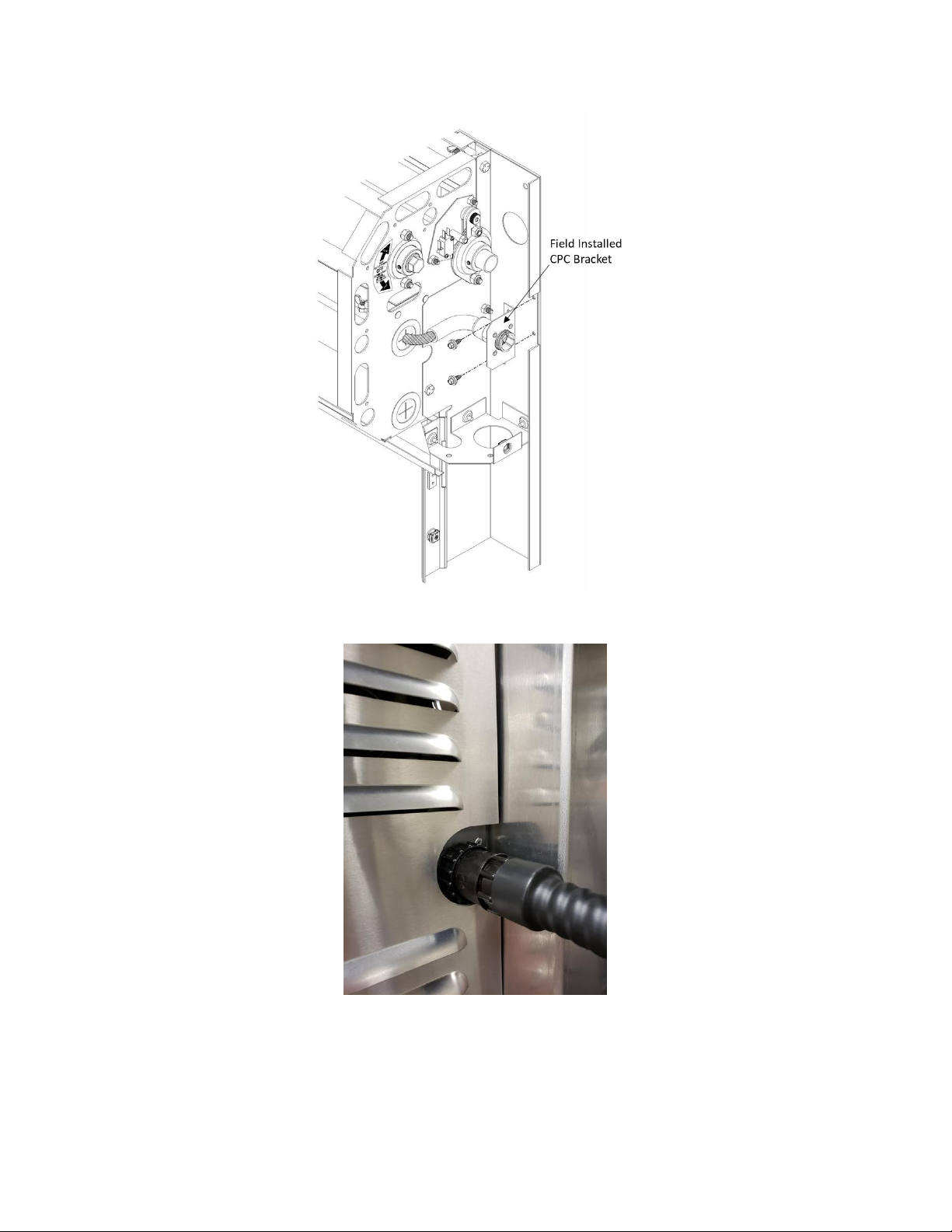

midway of the head unit. There will be a bracket attached to the CPC connector that will be secured to the

right track after the door is secured to the wall as shown in Figure 13. The standard harness that is sent

with this door is a 3-wire pigtail that has the mate to the CPC located on the right track. There is also an

optional disconnect that is shown in Section 11. This optional disconnect will hook up to the door in the

same manner as the 3-wire pigtail. This location allows the head unit cover to still move freely after line

power is hooked up. Refer to Figure 14.

Both the 3-wire pigtail harness and the optional disconnect require that the line power be connected in a

junction box (not supplied).

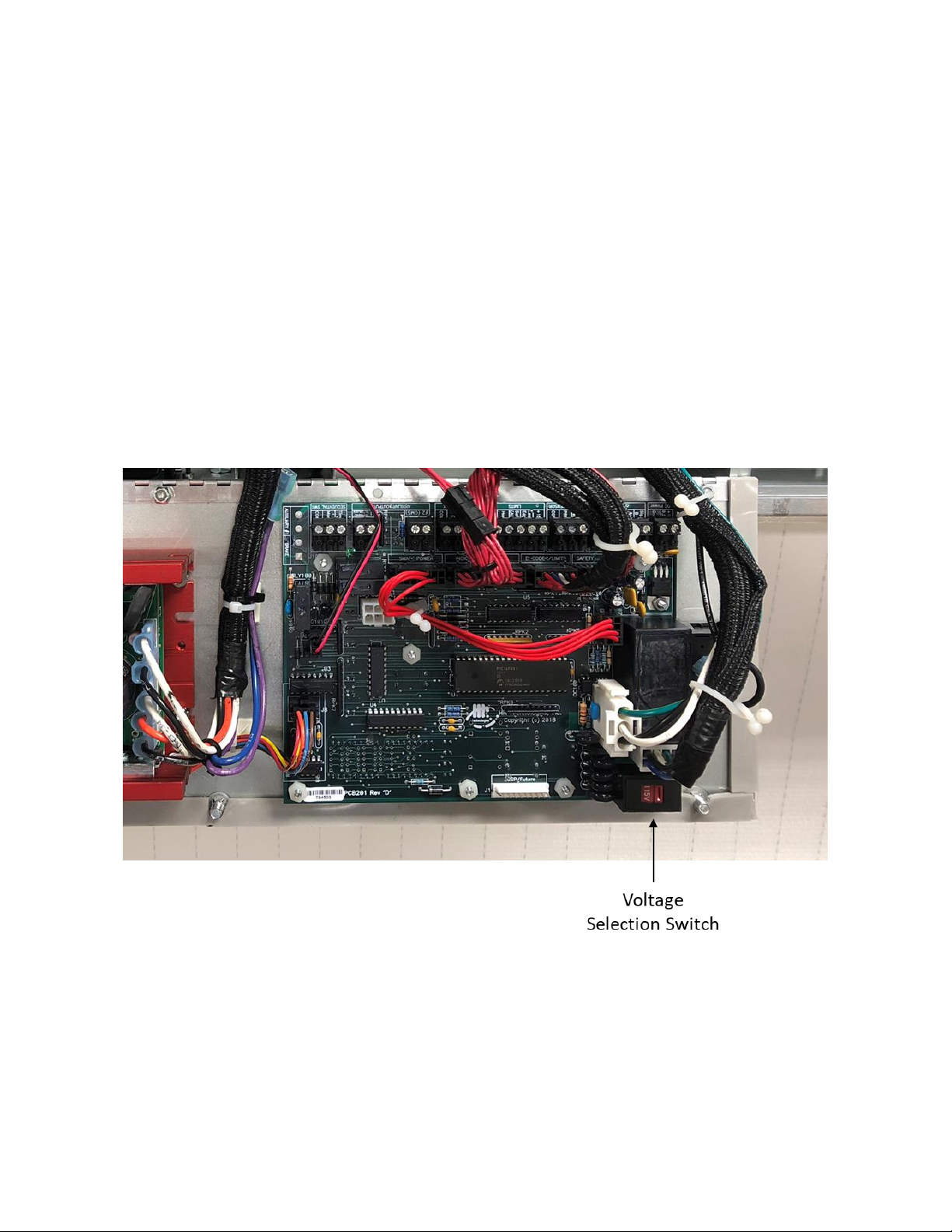

Look to the bottom right side of the open controller door and make sure that the voltage selection switch

is positioned properly for the power voltage being supplied as shown in Figure 12.

Figure 12: Voltage Selection Switch

Only activate line power if the voltage selection switch is configured to match the line power.

RollSeal RS500 WIC User Manual Page 15

Figure 13: Line Power CPC Bracket

Figure 14: Line Power CPC (Head unit cover Closed)

RollSeal RS500 WIC User Manual Page 16

8. Installation and Connection of Prewired Switch

8.1. Connection of the Front Prewired Switch

The front facing RollSeal Smart Switch is built into the front track. There is a harness with a twenty pin

connector proceeding out from the right hand side of the controller enclosure. That harness will run down

the right track and plug into the back of the switch card. This will power the switch as well as allow the

Indicator LEDs to function as designed. Refer to Figure 10 for more information.

8.2. Installation and Connection of the Interior Prewired Switch

The rear facing RollSeal Smart Switch is mounted in an enclosure due to its mounting location inside of

the conditioned space. This assembly comes wired and pre-assembled. The front and rear switches will be

in line with each other on either side of the wall.

1. Drill a 1 ¾ inch through hole using the 1 ¾ inch hole in the back of the right track four feet up

from the floor as a guide as shown in Figure 10.

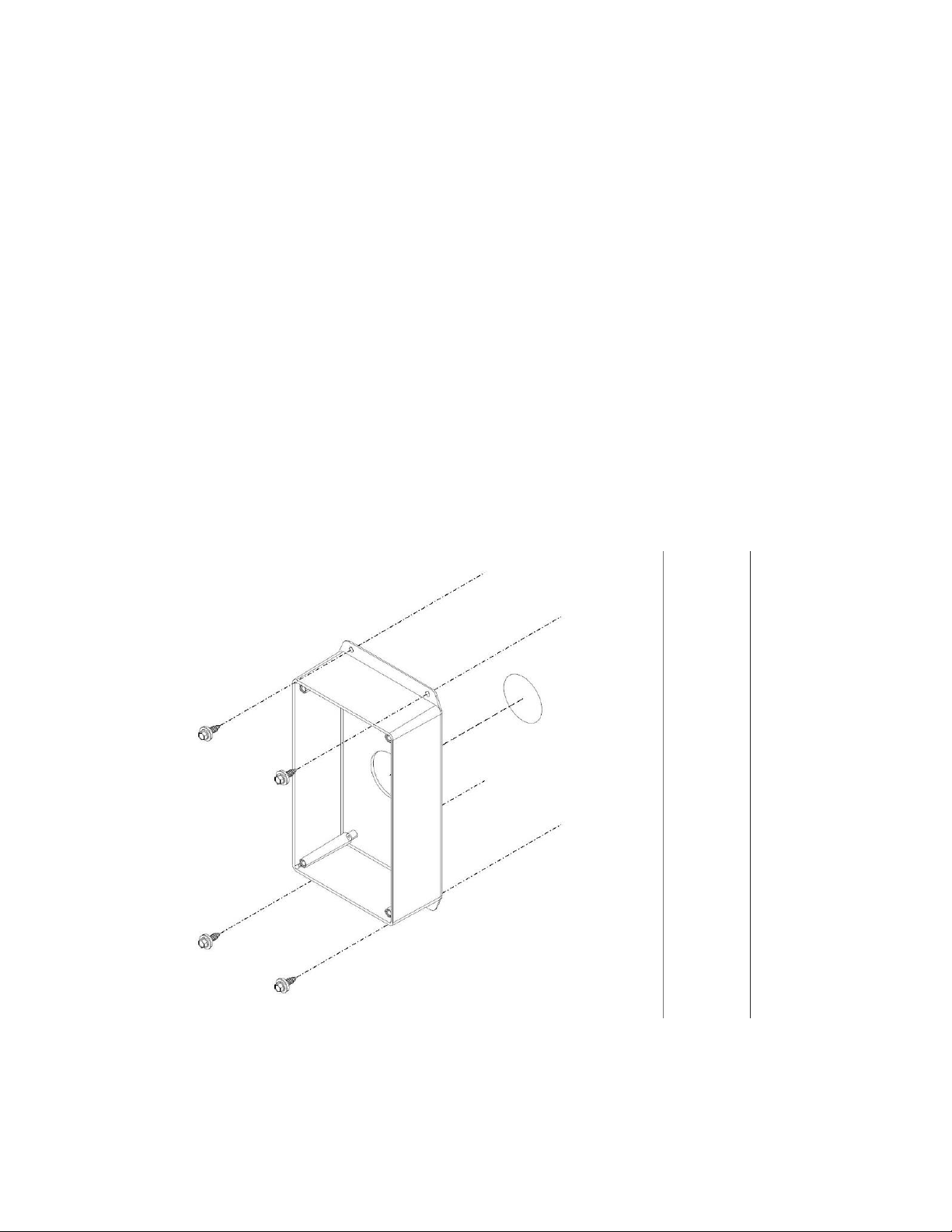

2. Remove the lid from the interior switch assembly enclosure. Be careful not to lose the four

screws.

3. The base of the box has a 1 ¾ inch hole predrilled to mount over the hole in the wall. Make sure

the box is centered over the hole and level before attaching it to the wall with 4 screws in the

predrilled holes of the top and bottom flanges of the enclosure. Refer to Figure 15 for installation

of the interior switch housing.

Figure 15: Installing the Interior Switch Housing

RollSeal RS500 WIC User Manual Page 17

Loading...

Loading...