Page 1

Page 2

Page 3

Page 4

Manual 605

Rolls Battery has been manufacturing deep cycle lead-acid batteries since 1935. Experience gained has helped us achieve an

unmatched reputation along with specifi c measures to obtain the maximum performance and life from our product. This manual

describes the recommended charging, equalization and preventive maintenance procedures for Rolls Solar Batteries in order

to maximize battery life.

Equipment Needed

• Goggles, rubber gloves and rubber boots • Distilled water

• Baking soda • Voltmeter

• Hydrometer • Battery charger

Safe Handling Procedure

Always wear acid-resistant clothing, PVC gloves, goggles and rubber boots – especially where there is risk of splashing. Always keep

the batteries in an upright position. Always have plenty of water available in case of acid spillage.

Inspection

Upon arrival, check the battery for visible damage (i.e. cracks, dents, deformation and other visible abnormalities). Verify connections,

assure that they are clean. If the battery is dirty, or if any minor amount of acid has spilled onto the case, check cleaning section. Any fl uid

on or around the battery could indicate that the case is not properly sealed. Please verify the polarity of the terminals. Please contact your

retailer or Rolls Battery Company Limited to determine if the battery needs replacement.

Installation

Rolls offers batteries for a wide variety of applications. No matter the application, always be certain that the battery is properly

secured, free of contaminants and that all connections are in good contact with the terminals. Contact your retailer or Rolls Battery

Company Limited for additional information.

Battery Orientation:

Flooded lead acid batteries must be kept in an upright position at all times. Electrolyte in the battery will spill if tilted.

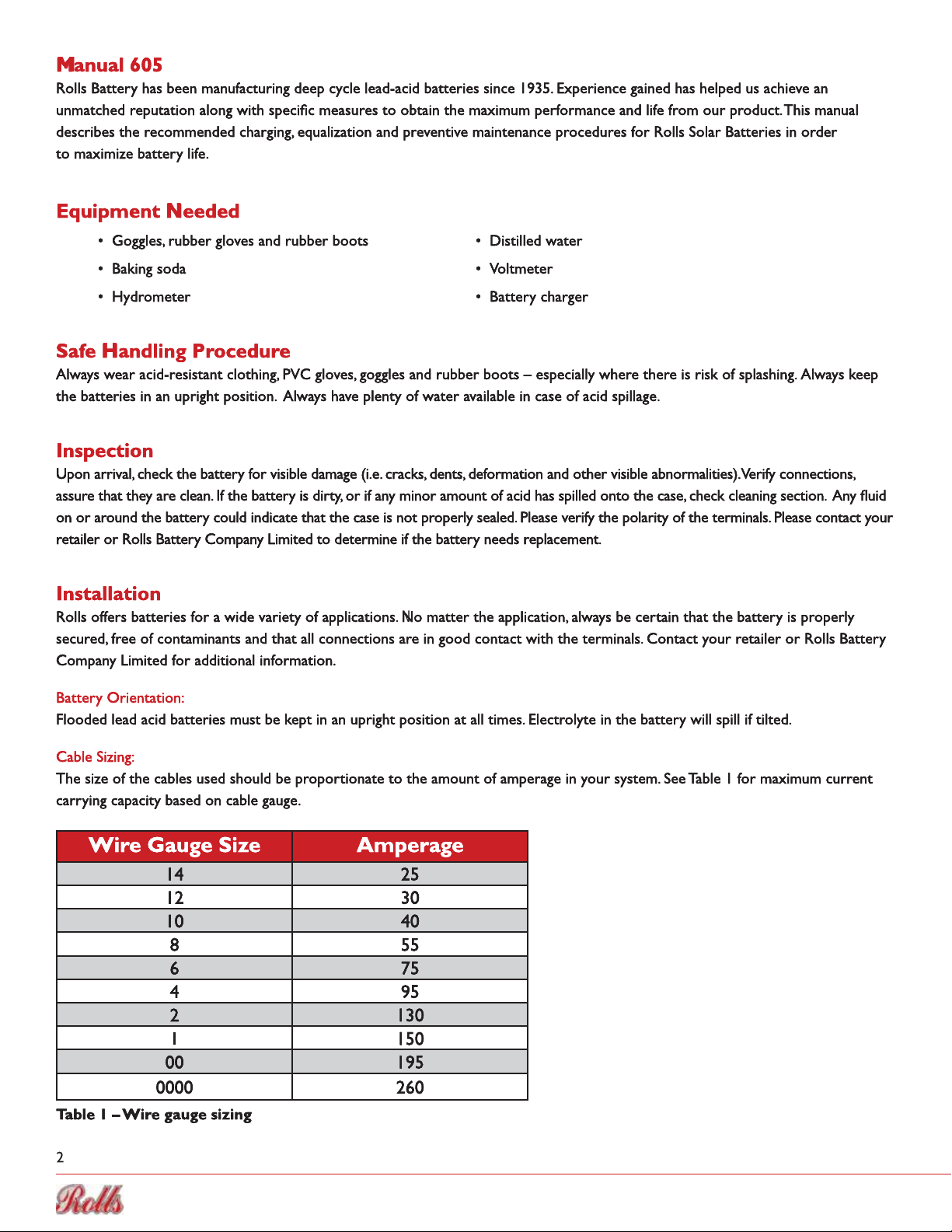

Cable Sizing:

The size of the cables used should be proportionate to the amount of amperage in your system. See Table 1 for maximum current

carrying capacity based on cable gauge.

Wire Gauge Size Amperage

14 25

12 30

10 40

855

675

495

2 130

1 150

00 195

0000 260

Table 1 – Wire gauge sizing

Page 5

Page 6

Top up or remove electrolyte as necessary for proper level. Never add electrolyte (only approved water) after activation. Replace

vent caps and remove any spillage of electrolyte. If necessary, clean with bicarbonate of soda and water (100 grams of soda to one

liter of water). Rinse with water and wipe dry. Ensure that soda solution does not get into cells.

*Do not place on charge until electrolyte temperature is below 35°C.

Battery Charging

Table 2 – Charge parameters

Initial Charge

A battery may not be fully charged when received. The fi rst charge brings the battery to an operational state. Before this charging

process, the cell electrolyte level should be checked. Please ensure the electrolyte (liquid) covers the plates. If this isn’t the case, add

distilled water until all the plates are just submerged. It is important not to over fi ll because the level will rise during the charging

process. Charge voltages are indicated in Table 2.

The electrolyte’s specifi c gravity is the most accurate measurement and it is recommended to verify its value to determine if the

cells are in fact fully charged. The specifi c gravity should be constant for 3 hours for an accurate full charge reading. Check the state

of charge as related to specifi c gravity. Initial charging may take 10 hours. Once the battery is fully charged, verify the electrolyte level

in the cell once more. The fl uid should be 1/4 - 1/2 inch below the vent tube on each cell as shown in Figure 1. Carefully add distilled

water to adjust the level if needed.

% Charge

100 1.255 – 1.275

75 1.215 – 1.235

50 1.200 – 1.180

25 1.165 – 1.155

0 1.130 – 1.110

Table 3 - Specifi c Gravity vs State of Charge

Specifi c Gravity* (SG)

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

BATTERY ENGINEERING

www . rollsbattery .com

Loading...

Loading...