Page 1

BATTERY USER

MANUAL

Recommended installation, charging and maintenance

procedures for Rolls deep cycle Flooded, VRLA AGM

& OPzV GEL batteries.

Page 2

FLOODED

AGM

GEL

RENEWABLE

ENERGY

MARINE

MOTIVE

POWER

Page 3

TABLE OF CONTENTS

02 Equipment & Safe Handling Procedure

02 Inspection

03 Quick Ch

03 Disposal Procedure

04 Installation

04 Battery Orientation

04 Cable Sizing

05 Warning

05 Terminals

06 Parallel & Series Connections

09 Inspection & Initial Charge of Flooded Lead-Acid Batteries

10 Rolls Flooded Lead-Acid Battery Charging

10 Bulk Charge, Absorption Charge

11 Absorption Charge Time - Flooded

11 Float Charge, End Amp or Return Amps

12 Low Voltage Disconnect

13 Rolls Flooded Battery Charge Voltage Parameters

14 Temperature Compensation & Sensor Installation

15 Specific Gravity

16 Battery Maintenance & Storage

16 Electrolyte - Adding Distilled Water

18 Cleaning Vent Caps

19 Equalization, Corrective Equalization

21 Preventative Equalization & Frequency

23 Rolls VRLA AGM Battery Charging Instructions

24 VRLA AGM Absorption Charge Time

24 Rolls VRLA AGM Battery Charge Voltage Parameters

27 Rolls OPzV GEL Battery Installation & Charging

27 Rolls OPzV GEL Battery Charge Voltage Parameters

29 OPzV GEL Absorption Charge Time

31 Renewable Energy Applications - Off-grid & Grid-tied

37 Warranty

39 Lead-Acid Battery Glossary

41 Troubleshooting & Frequently Asked Questions

46 Contacts

eck List

1

Page 4

Rolls Battery has been manufacturing deep cycle lead-acid batteries since 1935.

Experience and commitment to quality has helped us achieve an unmatched

reputation in the industry. Our goal is to provide our customers with a premium

product providing dependable performance and long-lasting cycle life. This manual

provides the recommended setup, charging, Equalization and preventive maintenance

procedures necessary to maximize the life of your Rolls batteries. If you have batteryrelated questions beyond the contents of this manual, we encourage you to visit our

online Technical Support Desk (support.rollsbattery.com) for additional information

or file a support ticket and our Technical Support team will be happy to assist you.

EQUIPMENT & SAFE HANDLING PROCEDURE

• Goggles, rubber gloves & rubber boots

• Distilled water

• Baking soda, soda ash

To prevent injury, always wear acid-resistant clothing, PVC gloves, goggles and

rubber boots. Flooded batteries must be maintained in an upright position at all times.

Always have plenty of water and baking soda on hand in the event of an acid spill

during transport.

• hydrometer, refractometer

• voltmeter, ammeter

• battery charger

INSPECTION

When receiving shipment of your batteries, it is important to thoroughly inspect each

pallet, battery and packaging. Before signing acceptance of the shipment, remove the

shrink-wrap from the pallet and inspect each battery for damage (i.e. cracks, dents,

punctures, deformations, acid leaks or other visible abnormalities).

Do not accept shipment if the batteries appear to have been damaged in any way.

Confirm that connection terminals are secure and clean. If the battery is dirty, or if

any minor amount of acid has spilled onto the case due to loose bayonets, refer to the

cleaning instructions in this manual to properly neutralize and clean as necessary. Wet

pallets or signs of acid leak on or around the batteries could indicate shipping damage

or improperly sealed battery casing. Perform a voltage check to confirm the battery

polarity and marking of the terminals are accurate.

In the event of a suspected leak or damage, do not accept the shipment.

Contact your battery retailer or Rolls Battery to determine whether the batter(ies)

require replacement.

Battery shipments which are known to be damaged, but accepted, will not

be replaced under the terms of Rolls Battery manufacturer warranty.

2

Page 5

QUICK CHECK LIST

SHIPPING/RECEIVING (MUST INSPECT PRIOR TO DRIVER RELEASE!)

• All parts are included

• No acid spill

• No visual damage to the batteries

• Verify electrolyte levels

INSTALLATION

• Protective equipment should be worn

• All electrical components should be turned off

• Acid spill cleanup material should be readily available

INITIAL CHARGE

• Verify electrolyte levels (add distilled water as necessary)

• Measure specific gravity

• Set up battery charge voltage/current limits

GENERAL

• Safety first!

DISPOSAL PROCEDURE

Batteries must NEVER be disposed of in household waste. To reduce environmental

impact, bring your spent lead-acid batteries to a certified recycling depot. Lead-acid

batteries are 97% recyclable and are the most recycled consumer product in the world.

Closed-loop manufacturing and recycling programs allows nearly all of the components

to be recycled or re-purposed. A credit by weight for lead may be offered by recycling

depots or facilities for spent batteries.

When processed safely, recycling batteries reduces the release of lead to the

environment and conserves natural resources. Recycled lead production takes only

35-40% of the energy necessary to produce primary lead from ore. Lead may

be recovered and re-purposed multiple times.

For more information on lead-acid battery recycling, visit https://batterycouncil.org

3

Page 6

INSTALLATION

Rolls deep cycle batteries are manufactured for use in a variety of applications. In all

cases, it is important that the battery is installed securely, free of contaminants and

that all connections are in good contact with the terminals.

For all Rolls models it is recommended that the batteries are separated 2.5cm-7.5cm

(1"-3”) inches apart to allow proper airflow, cooling and ease of maintenance. Flooded

batteries should be installed in a temperature-controlled room or enclosure with

adequate battery spacing to allow cooling and/or insulating to prevent freezing in very

cold temperatures. Excessive heat or cold temperatures will result in the reduction of the

overall cycle life. Batteries should never be installed in a completely sealed enclosure.

Enclosures for Valve Regulated batteries (VRLA such as sealed AGM & GEL models,

should, at minimum, be passively ventilated. Enclosures for Flooded models should

be actively ventilated with both positive and negative airflow installed to remove and

replace any hydrogen gas generated during charging (produced as cell voltage reaches

2.25 VPC or above. Every effort should be made to avoid hydrogen accumulation as

concentrations in excess of 2-4% may ignite with electrical spark and are explosive.

The outer container of Rolls Series 5000 models is molded with handles to safely lift

and transport the battery. This also provides structural support to maintain cell shape

and offers an added layer of protection. Rolls individual 2V industrial cells are typically

housed in steel or plastic trays. These cells must be properly supported on each side

to protect against puncture, prevent bulging and should not be lifted by the terminals

as this may damage the posts or compromise the cells internally. When moving,

support straps should be used to safety and securely lift the cell from the bottom.

Dual-container models are better-suited and strongly recommended over industrial

cells for use in Renewable Energy and Marine applications as the stand-alone case

design allows easier transport and the ability to install the batteries with adequate

spacing for airflow. Series 5000 dual-container models are backed by a 5-year

(60 month) full replacement warranty, offering an additional 2 years of coverage over

the equivalent 2V industrial cell.

BATTERY ORIENTATION

Flooded lead-acid batteries must be kept in an upright position at all times. The electrolyte

in a Flooded battery may spill if tilted more than 20 degrees. Rolls VRLA AGM & OPzV GEL

batteries may not be mounted upside down or horizontally on the end (shortest side of the

case. Rolls VRLA AGM batteries may be mounted upright or horizontally on the side (longest

of the battery case. Rolls OPzV GEL models must be installed vertically unless otherwise

specified. Special order models compatible with horizontal installation are available. Use

caution not to cover or apply pressure to valves located on the top of the batteries when

using strapping to install or secure cells as damage may occur.

Rolls OPzV GEL models compatible with horizontal installation as well as racking systems

are available upon request. Please contact your Rolls Battery distributor or dealer for

more information.

4

Page 7

CABLE SIZING

Cabling should be proportionate to the amperage of your system. The following table

notes the maximum current carrying capacity based on cable gauge. Battery cables

should be selected allowing a maximum voltage drop of 2% or less across the entire

length of the cable. Interconnection cables (battery to battery) should also be sized

at the same gauge and of equal length between connections. When choosing

interconnect cables or custom bus bars, size to allow adequate spacing between

batteries for airflow as outlined above.

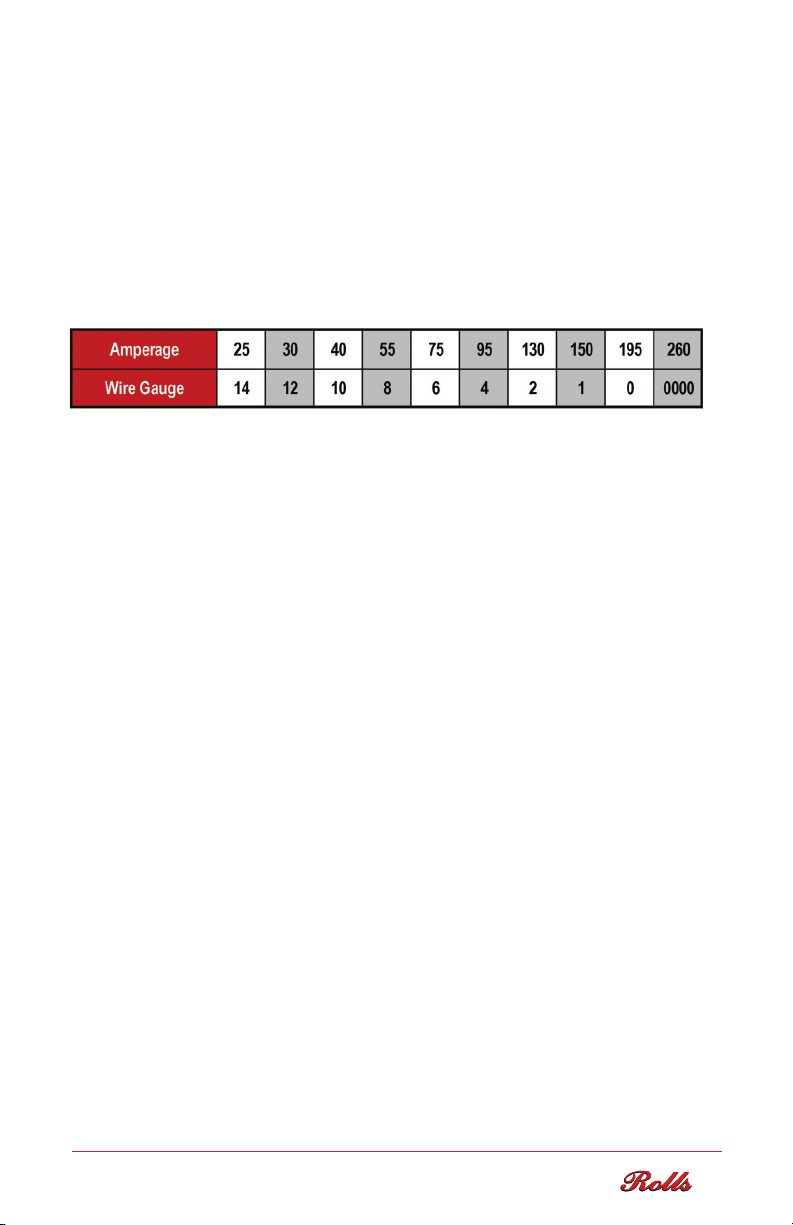

TABL E 1: Wire gauge sizing by amperage

WARNING

The charger cabling should be insulated and free of damage. The cable connectors should

b

e clean and properly mated with the battery terminals to ensure a snug connection.

Loose or overtightened connections may cause high resistance. The result is an

unwanted voltage drop as well as excessive terminal heating, causing the terminal to

melt or even catch fire. To limit the possibility of damage or fire, use a torque wrench

to properly adjust terminal connections during your regular maintenance schedule.

Undertorqued connections may become loose as the terminal warms & cools causing

possible arching and risk of spark. Over-torqued connections may indent, crack or

bend the terminal and/or washers or terminal connectors. Terminal damage from

overtorque is often irreparable. The use of an Infrared (IR temperature) sensor may

assist in identifying poor connections when testing under load or during charge.

Using an Infrared (IR) temperature sensor may assist in identifying poor connections

when testing under load or during charge.

Connections which have overheated and/or developed problems will often be welded

to the terminal. Visual inspections may not always detect poor connections. It is

recommended that terminal connections are disconnected, cleaned and re-torqued

periodically as part of the regular maintenance routine.

TERMINALS

Inspection of battery terminal connections is also important. Loose connections

may result in ignition of hydrogen gases or cause a short, melting the terminals.

It is important to inspect, disconnect, clean and properly torque these connections

on a regular basis. Use a proper torque wrench, noting the required torque setting

for the particular terminal.

5

Page 8

Flooded LEAD-ACID TERMINALS

Terminal connections should be tightened to 25 ft/lbs or 33 N.m for all Flooded

Series 4000, 4500 & 5000 models.

VRLA AGM & OPzV GEL TERMINALS

Torque settings vary by terminal type, please refer to the chart below and/or

provided specifications. Contact Rolls Battery Technical Support if your terminal

type is not listed.

AGM-S & AGM-R Terminals Torque N.m

Button Terminal (M8) 9.6-10.7

Button Terminal (M10) 12.2-14

AP 5.6-7.9

LT 9.6-10.7

DT (AP and stud terminal) 5.6-7.9

M6 (TP08) 3.9-5.4

M8 (TP08) 9.6-10.7

OPzV GEL Terminals Torque N.m

M10 Female 20-22

PARALLEL & SERIES CONNECTIONS

Applications often demand more voltage or more ampere capacity than the

capacity of one battery. By connecting multiple batteries of the same make/

model/capacity in series, parallel or series parallel configurations, output voltage

or battery bank amperage may be increased as needed.

To increase voltage, batteries are connected in series. Capacity of the battery

bank remains the same as voltage increases. To increase the available amount

of current and capacity, batteries are connected in parallel. In this situation it

is best to use lower voltage, higher capacity cells to minimize the amount of

parallel strings.

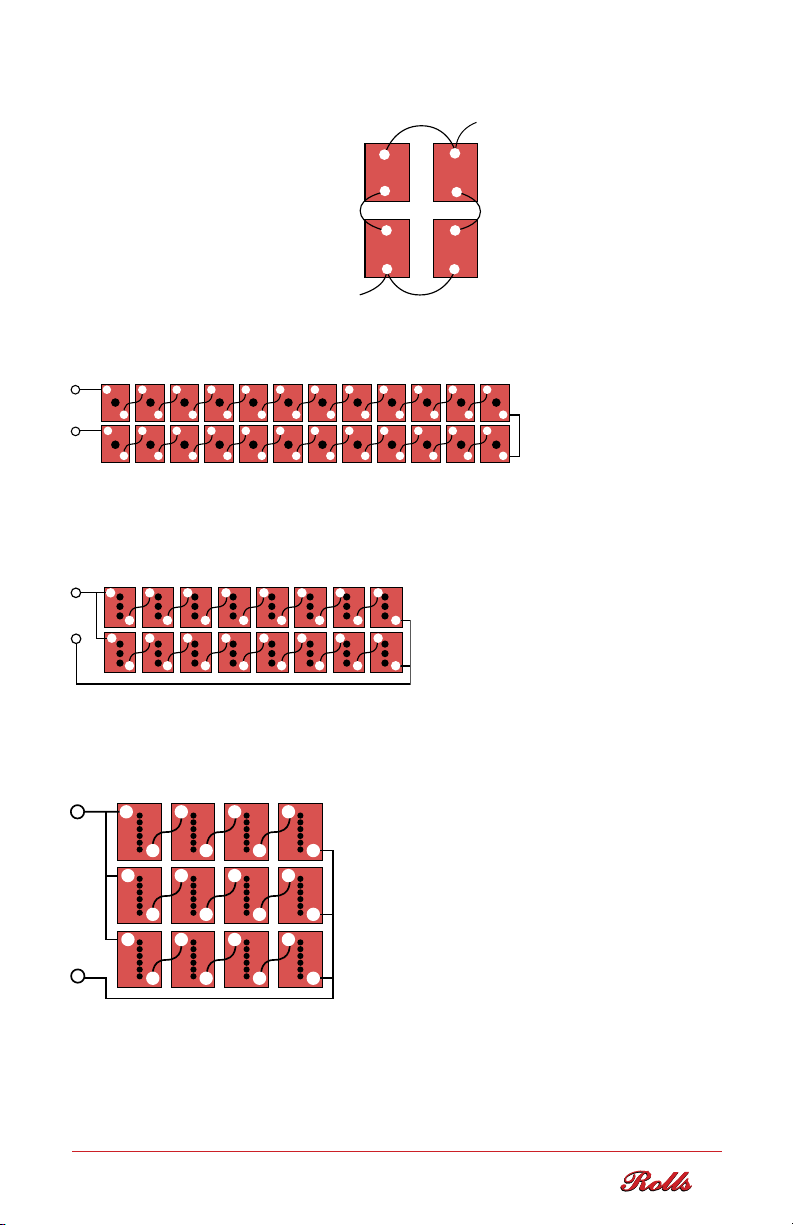

To increase voltage, connect the batteries in series as shown in Figure 1.

-

+

FIGURE 1:

Voltage Increase

+

-

6

Page 9

To increase capacity and voltage, connect the batteries in series parallel

-

++ + + + + + + + + + ++

++++++ +++++

---

+

++ + + + + + ++

++ + ++

++

++

as shown in Figure 2.

EXAMPLE:

Battery = 6-volt (S6 L16-HC)

Battery Voltage = 6V each

Battery Capacity = 445 AH each

+

-

+

-

++

FIGURE 2:

Voltage/Capacity

Increase

System Voltage = 12V System

Capacity = 890 AH total

-

-

EXAMPLE:

Twenty-four (24) 2-volt batteries at 2527 AH each = 2527 AH at 48 Volts

- - - - - - - - - - --

- +

-

- -

---- ---

FIGURE 3:

Single Series String

-

+ “Best Option”

EXAMPLE:

Two (2) strings of eight (8) 6-volt batteries at 445 AH each

= 2 x 445 AH at 48 Volts = 890 AH at 48 Volts

- - - - - --

++++++ +

-

-

+

---- ---

-

FIGURE 4:

Two Parallel Strings.

Series/Parallel

EXAMPLE:

Three (3) strings of four (4) 12-volt batteries at 371 AH each

= 3 x 371 AH at 48 Volts = 1113 AH at 48 Volts

- --

++

---

-

Three Parallel Strings.

Series/Parallel

-

++

FIGURE 5:

-

NOTE: Connecting more than three (3) series strings in parallel is not recommended. Multiple

-

--

-

parallel connections increase resistance between batteries and strings, causing an imbalance of

charge and discharge currents and may result in cell damage or premature failure which is not

covered under Rolls Battery manufacturer warranty.

7

Page 10

FLOODED

LEAD-ACID

BATTERIES

Page 11

INSPECTION & INITIAL CHARGE OF FLOODED

LEAD-ACID BATTERIES

WARNING

• ALWAYS WEAR THE PROPER PERSONAL PROTECTIVE EQUIPMENT

(GOGGLES, GLOVES, CLOTHING) WHEN HANDLING FLOODED BATTERIES

AND ELECTROLYTE.

• WET BATTERIES MUST BE FULLY CHARGED BEFORE BEING DELIVERED

TO THE END USER.

• UNLESS INSTRUCTED BY ROLLS TECHNICAL SUPPORT, NEVER ADD ACID

TO THE BATTERIES AT ANY TIME. USE DISTILLED WATER ONLY.

FAILURE TO

AND WILL VOID WARRANTY.

A battery may not be fully charged when received. An initial charge brings the battery

to an operational state. Before charging, inspect for physical damage, check polarity

and electrolyte levels in each cell. Ensure the electrolyte (liquid) covers the plates

completely. It is normal for electrolyte levels to lower as the battery case will relax

(bulge) slightly after filling. If the plates are exposed, add distilled water until all are

just submerged. It is important not to overfill each cell as the electrolyte level will

rise during the charging process. Charge voltages are indicated in Table 2 (a & 2 (b

Flooded Charging Parameters.

INITIAL INSPECTION & CHARGING

1. I nspect the batteries for damage. Important: read all warning labels on batteries

b

efore proceeding.

2. Flooded batteries are fully charged and tested before shipping. However, deep cycle

batteries will self-discharge when not in use during transportation and storage. Upon

installation, the initial charge brings the battery to an operational state. Before this

charging process, electrolyte levels should be checked, making sure the plates are

covered in each cell. If required, add distilled water until the plates are fully submerged.

It is important not to overfill as the electrolyte level will rise slightly during charge.

3. Check for correct polarity. Attaching the positive and negative voltmeter lead to the

positive and negative battery terminal should provide a positive voltage reading. If it is

negative, a reverse polarity condition exists and you should contact your dealer or

Rolls Battery Technical Support to advise.

FOLLOW THESE INSTRUCTIONS MAY RESULT IN MALFUNCTION

4. Place batteries on charge. Please see Table 2 (a & 2 (b Flooded Charging Parameters

for required charging parameters. Do not let the cell temperature exceed 52°C (125°F). If

the temperature becomes excessive or the cells begin to gas vigorously, reduce the

rate of charge. Continue charging until all cells reach the specific gravity of the filling

acid. All cell specific gravities should be even (1.260-1.280) when resting at full charge.

9

Page 12

FLOODED LEAD-ACID BATTERY CHARGING

I

NITIAL CHARGE

Although all Rolls batteries are tested and charged prior to shipping, batteries will

self-discharge when stored and not in use. Upon installation, the initial charging

may take 10+ hours or more depending on the size of the battery bank and charge

current. Once the battery is fully charged, recheck the electrolyte level in the cell.

The fluid should be 6-12mm (1/4”-1/2”) below the vent tube on each cell as shown

in Figure 7. Carefully add distilled water to adjust as needed.

MULTI-PHASE CHARGING

The most common charge method for Flooded deep cycle batteries is a three-phase

charge cycle with periodic equalizations. Always be sure to follow the recommended

charging parameters as these will vary. Often, pre-programmed default settings are

not in line with the battery manufacturer's recommended voltage settings. Using these

may result in damage or battery failure which is not covered under the manufacturer

warranty. Refer to the charger manufacturer for specific programming instructions.

BULK CHARGE

The first of the three-phase charging process is the Bulk charge. During this stage the

maximum amount of current flows into the battery bank until a desired programmed

voltage is reached. For Flooded models, the recommended Bulk charge current is 10%

of the AH capacity of the battery bank, based on the 20 Hr AH rate (C/20) (min 5%, max

20%). Higher charge current may cause the battery bank to overheat or damage the

cells. A lower charge current may be used, however, this will prolong the required charge

time and increase the potential for sulfation build-up. Bulk charge voltage set points are

outlined in Table 2 (a & 2 (b Flooded Charging Parameters.

ABSORPTION CHARGE

The second and most important phase of the charge cycle is the Absorption charge.

Bulk charge typically charges the battery bank to approx. 80% SOC. Once reached, the

charger will then switch to the programmed Absorption voltage to complete the charging

cycle. Most three-phase chargers include an Absorption charge time setting allowing

the user to program the duration of time needed to reach a full state of charge (100%

SOC). To set the Absorption charge time, a calculation is done using the 20 Hr AH

rating of the battery bank (C/20) and the available charge current and/or max charger

output. As the battery bank nears 100% SOC, internal resistance in the battery

increases and charge current begins to decrease. It is assumed that over the time of the

Absorption charge that 50% of your maximum charge current will be available (factored

into the equation) 0.42 = (20%/50%) + 5%. 5% is added due to losses.

10

Page 13

ABSORPTION CHARGE TIME - FLOODED

Where : T = 0.42 x C /I

T = ABSORPTION CHARGE TIME

C = 20 hr RATED CAPACITY (total battery bank)

I = Charging Current (Amps)

(recommended 10-20% of C/20 discharge rate for Flooded models)

0.42 = ( 20%/50%) + 5% (5% is added due to losses)

EXAMPLE:

2 strings of 6 Volt 6 CS 25P models

20 hr AH rate = 853 AH x (2 strings) = 1706 AH

I = 10% of 1706 AH = 170 Amps (10-20%, 170-340 Amps)

T = 0.42 x 1706/170 = 4.2 hrs

However, if maximum charger output is 120 Amps, 120 is used.

T = 0.42 x 1706/120 = 5.97 hrs

NOTE: Actual Amp output from the charge source(s) should be used. Maximum

charger output applies when the generated output meets or exceeds this threshold.

FLOAT CHARGE

When the Absorption charge phase has completed and the batteries have reached

100% SOC, the charger will continue to output at a lower voltage setting known as

Float. Float voltage maintains the battery bank at a constant 100% SOC until the

charge output diminishes (ex: solar) and/or a load is applied which begins to discharge

the battery bank. To prolong battery life, the Float settings on the power supply

should be adjusted to the voltage indicated in Table 2 (a & 2 (b Flooded Charging

Parameters. Higher or lower voltage settings may result in unnecessary overcharge

or sulfation buildup.

END AMPS OR RETURN AMPS

As batteries near full capacity, charge current decreases. End Amps or Return

Amps refers to the lowest output of current (Amps) running to the batteries once

they have reached full capacity. Some charges will measure the actual current

output. If the charge current drops to the End Amps or Return Amps set point before

the programmed Absorption time has completed this will trigger the charger to shut

off or switch to the Float voltage phase, maintaining the bank at 100% SOC.

End Amps or Return Amps for new Series 4000 Flooded models should be set at

2-3% of the 20 Hr AH rating (C/20) of the battery bank.

NOTE: Rolls 4500 & 5000 Series models with Advanced NAM carbon additive may

see higher End Amps or Return Amps values as the cells are less resistant to charge

and current output will remain slightly higher at 100% SOC. A set point of 2-5% may

be used with these models. Adjustments may be required when these are used to

replace other Flooded models.

11

Page 14

WARNING: The End Amps or Return Amps setting combined with a sulfated battery

may confuse the charger, cause a state of charge reset prior to actually reaching 100%

SOC. Check specific gravity regularly to confirm the battery bank reaches 100% SOC

as this set point may require adjustment.

LOW VOLTAGE DISCONNECT (LVD OR LVCO)

Many charging systems offer the ability to program a Low Voltage Disconnect (LVD)

or Cut Off (LVCO) which triggers an alternate power source (often a generator) to turn

on and begin charging the battery bank. When the programmed low voltage setting

is reached, the system initiates the charge source which then safeguards from

overdischarge. By default, this may be set by the charger manufacturer at 1.75 volts

per cell (VPC). Always verify the default settings and adjust as required.

LVD/LVCO setting is often a personal preference. Deep cycle batteries are intended

to be discharged no more than 50%. Allowing the battery bank to discharge to a lower

voltage will reduce over all cycle life. Alternatively, a higher set point may result in more

frequent use of the alternate charging source (ex: generator) when discharge reaches the

low voltage cut-off. To maintain cycle life and prevent heavy discharge, Rolls recommends

setting LVD/LVCO between 1.85-1.95 volts per cell (VPC). This may be adjusted up or

down, depending how often you wish to run the alternate charging source (generator or

alternative power) when the voltage of the battery bank reaches the programmed set point.

WARNING: LVD/LVCO only cuts off the draw from the inverter/ charger. It does not

disconnect all loads from the battery bank. A prolonged draw will eventually lead

to overdischarge and possible battery failure or damage.

OTHER CHARGER MODES

Inverter and charge controller manufacturers may include additional settings. Rolls

recommends contacting the manufacturer for guidance and to better understand how

these settings function. Default settings are typically not in line with the required

charge voltages and time. Charge & Float voltages and Absorption time calculations

are provided by the battery manufacturer and are specific to the make & model.

See Table 2 (a & 2 (b Flooded Charging Parameters.

FLOODED LEAD-ACID BATTERY - CHARGE EFFICIENCY / CHARGE FACTOR

Charge efficiency is a measure of the energy you may take out of a charged battery

divided by the energy required to charge it. Charge efficiency will depend on a number

of factors including the rate of charging or discharging. Charge efficiency for Flooded

deep cycle models is typically 80-85%. This should be reduced 1% per year after the

third (3) year of operation.

12

Page 15

ROLLS FLOODED BATTERY CHARGE

VOLTAGE PARAMETERS

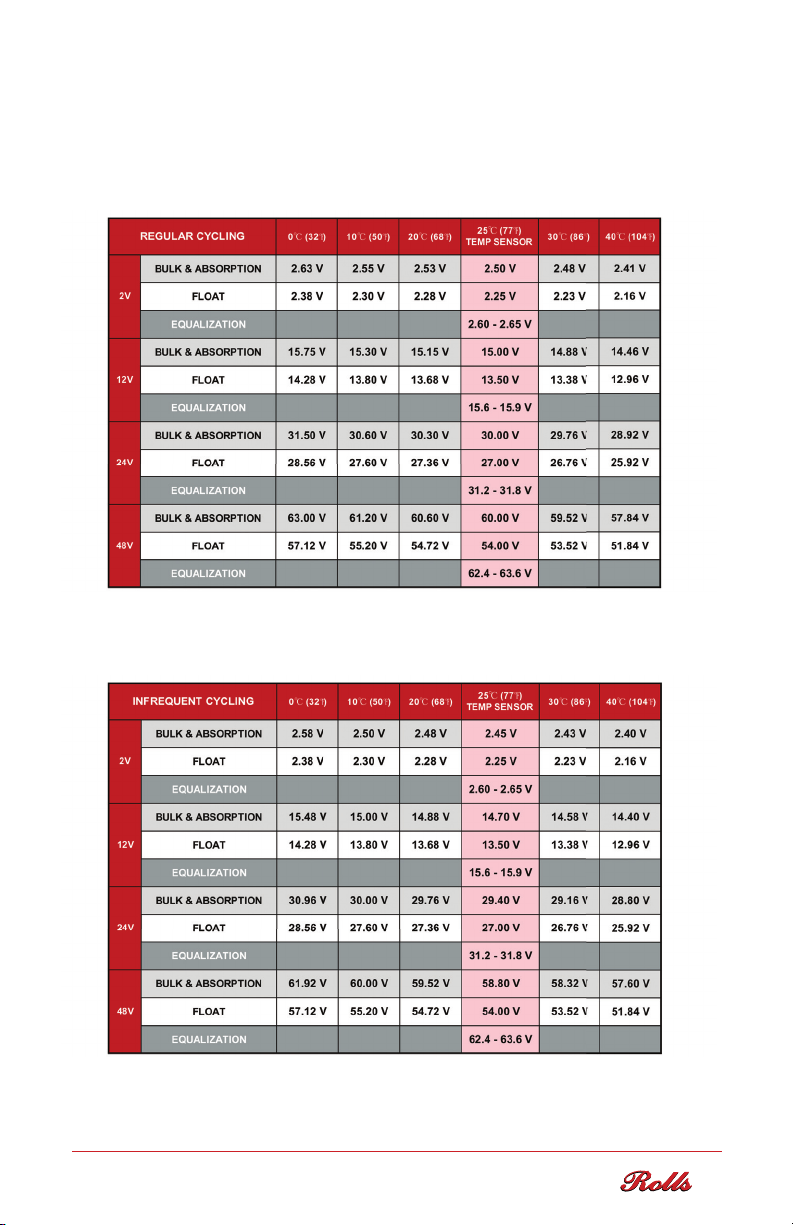

NOTE: Use the highlighted voltage set points when charge equipment is supplied

with a temperature sensor. Set at 5mV/ºC/Cell...(+/- 120mV per ºC from a 25ºC

Delta - 48V System)

TABLE 2 (a): Flooded Charging Parameters: Regular Cycling - daily to 48-hour

cycling (max 50% DOD) with limited charge time (solar). Example: full-time off-grid

applications and Partial State of Charge (PSOC) recovery.

TABLE 2 (b): Flooded Charging Parameters: Infrequent Cycling - infrequent cycling

with grid-connected charging (Marine/RV/Industrial), off-season/part-time off-grid

solar applications or grid-tied battery-backup systems.

13

Page 16

TEMPERATURE COMPENSATION

& SENSOR INSTALLATION

For charge accuracy and safety, many systems use a sensor mounted to the battery to

measure cell temperature and adjust charge voltage accordingly. Temperature sensors

should be installed directly on the side of a cell or battery in the center of the bank

and must be securely mounted below the electrolyte level to determine accurate cell

temperature. See Figure 6 Temperature Sensor below. When using chargers that do not

feature temperature compensation, voltage settings should be monitored and adjusted

based on actual cell temperature. Failure to use or properly install the provided sensor

may cause damage due to over/undercharge which is not covered under Rolls Battery

manufacturer warranty. As a precaution, this sensor may also trigger a programmed

safety charge cut-off as the battery bank should not exceed an operating temperature

of 52ºC (125ºF).

NOTE: FOR ACCURACY, THE TEMPERATURE SENSOR SHOULD NOT BE MOUNTED

TO THE BATTERY TERMINAL OR TOP OF THE BATTERY CASE.

Series 4000, 4500, VRLA AGM & OPzV GEL models – the temperature sensor should

be mounted on a battery in the middle of the string or battery bank. To ensure an accurate

reading of cell temperature, the sensor must be mounted below the liquid level on Flooded

models and not attached to a terminal or top of the battery case as these areas are

generally cooler than the internal cell. For traditional Flooded, VRLA AGM & OPzV GEL

models, Rolls recommends attaching the sensor half way down the side of the battery and/

or 10-12cm (4-5”) from the top of the case for the most accurate temperature reading.

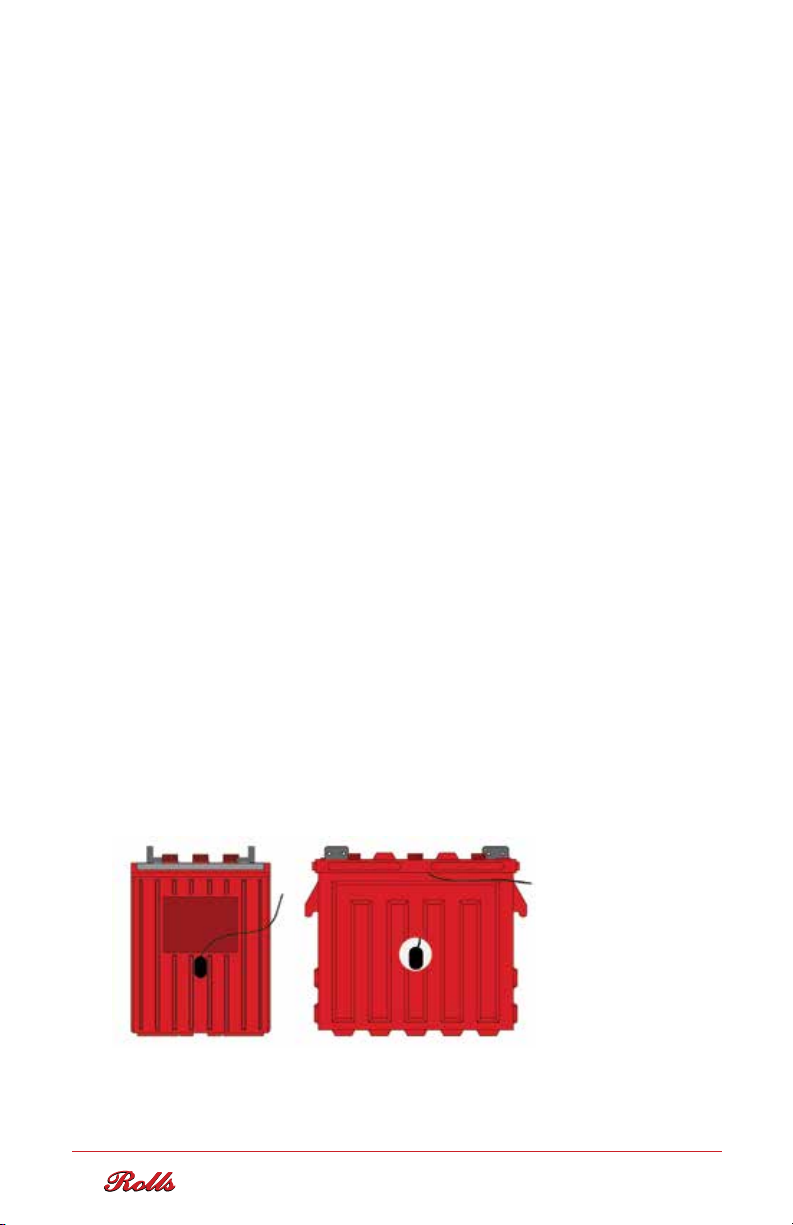

Dual-Container Models – If the battery has a modular, dual-container construction, the

temperature sensor must be mounted directly to the side of an internal cell. To access the

cell, disconnect the terminal connections and remove the outer cover which snaps on

to the case or may use small removable plastic pins. Mount the sensor to the internal

cell and run the connecting cable between the case, being careful not to pinch or damage

the wire when placing the cover back on. Automotive silicone is used to seal around each

terminal to protect against spills, dust & debris. This may be reapplied when the case has

been reassembled.

FIGURE 6:

Temperat ure

Sensor

Dual-Container Models - Remove case cover. Mount sensor to the side of internal

cell below liquid level. Replace the cover and re-seal around terminals with silicone.

14

Page 17

SPECIFIC GRAVITY

The specific gravity of electrolyte in a battery is the most accurate measurement of actual

state of charge. To determine if the batteries have reached full SOC, testing should be done

when the charge cycle has been completed and the battery bank is resting a Float voltage.

The specific gravity (SG) reading should remain constant for 3+ hours for an accurate 100%

SOC reading.

*Test and record specific gravity readings regularly to confirm charging parameters are

properly programmed and to avoid possible over/undercharge, cell damage and/or battery

failure. Rolls Battery provides a Flooded Deep Cycle Battery Maintenance log book

to track these readings and includes reminders to perform regular system inspections.

Request a copy from your Rolls Battery Distributor or Dealer.

Recommended testing: every 45-60 days

Minimum: every 90 days

Routine testing of specific gravity in Flooded models provides an opportunity to quickly

identify any notable changes in battery performance caused by charge-related issues

such as over/undercharging, sulfation buildup, capacity loss or cell/battery performance

or failures. Regular testing and tracking offers peace of mind and is expected as part of

the normal maintenance procedures. When monitored, necessary system adjustments

may be made to quickly correct & prevent any further issue or damage.

NOTE: Failure to adhere to ongoing maintenance requirements, including routine testing

and logging of specific gravity and voltage readings, may result in denial of a filed warranty

claim where the performance history and cause of cell/battery failure cannot be determined.

% Charge Specic Gravity* (SG)

100 1.255 - 1.275

75 1.215 - 1.235

50 1.180 - 1.200

25 1.155 - 1.165

0 1.110 - 1.130

TABLE 3: Specific Gravity vs State of Charge @ 25°C (77°F)

NOTE: Specific Gravity is dependent on the electrolyte temperature. These values are

for a temperature of 25°C (77°F). To adjust, add/subtract 0.003 for every 5°C (10°F)

increase/decrease.

15

Page 18

Electrolyte should be kept

at 1/2” below vent tube.

Electrolyte

level

Open cell

1/4” - 1/2”

Maximum electrolyte level specified

by the battery manufacturer

BATTERY MAINTENANCE & STORAGE

Batteries should be kept clean at all times. If installed or stored in a dirty location, regular

cleaning should be performed. Before doing so, assure that all the vent caps are tightly

fastened. Using a solution of water and baking soda (100g per litre), gently wipe the battery

and terminals with a damp sponge, then rinse with water and wipe dry.

A common cause of failure with Flooded battery banks is poor maintenance. Systems are

often professionally installed and maintenance left to homeowners who are unaware of

the requirements or simply choose not to complete the proper maintenance procedures. To

maintain cycle life and protect your investment, Flooded batteries should be checked regularly

and topped up with distilled water as needed. Customers will often neglect this for extended

periods of time, and when doing so, over-water the cells resulting in loss of electrolyte,

overflow during charging and/or corrosion issues. Failing to top up cells may result in plate

exposure, overheating and possible explosion.

ELECTROLYTE - ADDING DISTILLED WATER

Only distilled (preferred), deionized or reverse osmosis water should be used in Flooded

battery cells. Improper watering may cause internal cell damage. Test water to confirm

a PH reading of 7 or less and no Total Dissolved Solids (TDS < 5 PPM).

NOTE: Do not add sulfuric acid to Flooded battery cells during normal top up. In the case

of accidental spill, premixed electrolyte (1.265 S.G.) may be used to refill cells.

FIGURE 7:

Electrolyte level

6mm - 13mm

1/4" - 1/2"

Electrolyte level should

be kept below vent

tube to prevent overflow

during charge.

CAUTION: Do not add water or electrolyte to cells before initial charging unless plates are

e

xposed. If so, add distilled water until plates are submerged. Please contact Rolls Technical

Support if you have any questions or concerns.

NOTE: If the battery cells require watering more than once every two (2) months the

programmed charging voltages may be too high. Adjust and monitor accordingly. If a particular

cell requires significantly more water than others this may be a sign of charge imbalance in the

battery bank caused by resistance and/or cell failure. Typically, Series 4000 & 4500 models will

require watering every 30-60 days. Series 5000 batteries generally require watering every

60-90 days as these models are designed with a higher electrolyte reserve allowing longer

watering intervals. Frequency may vary considerably due to operating temperature, depth of

discharge, cycle frequency and humidity.

16

Page 19

MAINTENANCE SCHEDULE

For the first 12 months of usage, the following tests should be completed:

MONTHLY

• Measure and record resting/loaded voltage

• Check electrolyte levels and top up with distilled water as necessary

• Test and record specific gravity measurements in Float charge

• Record ambient temperature where the batteries are installed

• Inspect to ensure temperature sensor is securely attached

• Inspect cell integrity for corrosion at terminal, connection, racks or cabinets

• Check battery monitoring equipment to verify operation

QUARTER LY

• Test Ventilation

• Check terminals/connections, remove corrosion and properly re-torque

• Check for high resistive connections

• Check cabling for broken or frayed cables

• Verify Charge Output, Bulk/Absorption voltage of Inverter/Charge Controller

• Check cells for cracks or indication of a possible leak

• Check Ground connections

Deep cycle batteries will increase in capacity during the initial break-in period

of 60-90 cycles. Adjustments to charging parameters may be necessary during

this time. Battery performance, charging and maintenance requirements will

depend on usage. Following the break-in period, a regular maintenance routine

will be established after 9-12 months of service.

Following these recommendations will ensure the batteries reach their rated

capacity and operate in good working order.

STORAGE

NOTE: When not in use, it is normal to expect 10-12% self-discharge per month

at 25ºC (77ºF) for Flooded models. This rate slows as ambient temperatures

decrease and increases at higher temperatures. Stored Series 4000 Flooded

batteries should be recharged every 3 months until the battery is put in service

to avoid sulfation buildup and possible freezing in cold temperatures.

Rolls Series 4500 & 5000 models with Advanced NAM carbon additive may see

an increased self-discharge rate of 20-25% per month at 25ºC (77ºF) when not

in use. A refresher charge may be necessary every 2-3 months.

17

Page 20

WINTER STORAGE

Prior to placing Flooded batteries into winter storage, charge to 100% SOC and

make certain the liquid level is approximately 13 mm (1/2”) above the top of the

separators. Electrolyte in a very cold battery will be lower than normal. Allow

the battery to warm to a normal ambient temperature before judging electrolyte

levels. Self-discharge rate will vary by ambient temperature. Apply a refresher

charge as necessary when stored for extended periods.

Example: Electrolyte may freeze if the batteries become discharged

to approximately 50% SOC at -20ºC (-4ºF).

Specic Gravity Freezing Temperature

1.280 -69ºC (-92ºF)

1.265 -57.4ºC (-72.3ºF)

1.250 -52.2ºC (-62ºF)

1.200 -26.7ºC (-16ºF)

1.150 -15ºC (5ºF)

1.100 -7ºC (19ºF)

TABLE 4:

Specific Gravity

vs Freezing

CLEANING VENT CAPS:

You might notice a sticky dark gray residue on the inside of the standard 1/4-turn

bayonet, R-Caps or Watermiser vent caps on Flooded battery cells. This buildup

of dirt and dried electrolyte is fairly common and may clog the vent holes, preventing

the release of hydrogen off-gas during charge. Inspect the caps and clean using

a neutralizing baking soda and water solution as necessary.

CLEANING STEPS:

1. Clean the caps by soaking in a solution of water and baking soda (100g per litre) in

a bucket or small bowl. Let the vents sit overnight to neutralize and break down any

electrolyte in the caps.

2. Flush the caps clean by forcing water through the vent holes. Water should drip

freely. A trickle of water should flow from all vent holes, indicating the cap is clear

of debris.

3. Allow the vents to dry completely. Once dried, shake recombination caps to make

sure the condensing beads on the inside of the cap rattle slightly. If you do not hear

the beads, let the cap dry for an additional 12 hours or repeat the process above.

18

Page 21

EQUALIZA

Individual cell readings will vary slightly in specific gravity after a charging cycle.

Equalization, or a “controlled overcharge", is required to bring each battery plate to

a fully charged condition. This reduces stratification and build-up of sulfation on

the plates; two circumstances that shorten battery life.

One of the most commonly asked questions is “When is it time to equalize my battery

bank?“ As usage is unique for each system, this will depend on several factors

including depth of discharge, cycle frequency, operating temperature, charging

voltage and current. Monitor specific gravity and voltage regularly as these readings

will indicate when an Equalization may be necessary.

An Equalization should be completed when the specific gravity of individual cells

within the battery bank are varied by more than .025 -.030.(Ex. 1.265, 1.235,

1.260, 1.210...) Do not attempt to equalize a battery bank with failed cells or missing

batteries as this will force an overcharge on the remaining cells which may cause

permanent damage.

When resting in Float charge, if specific gravity readings are consistently lower than

recommended it may be necessary to adjust Bulk/Absorption voltages slightly and/or

Absorption time to increase charge time.

To properly equalize the battery bank, follow the Correction Equalization procedure

using the recommended Equalization set point in Table 2 (a & 2 (b Flooded Charging

Parameters starting at the lower end of the provided voltage range.

TION

CORRECTIVE EQUALIZATION

Corrective Equalizations should be performed when the battery bank is at 100% SOC.

Review and complete the provided preparations before initiating the Equalization charge.

Equalization time will vary depending on the level of sulfation, balance of charge, size

of the battery bank and available charging source. Typically, a corrective Equalization

is necessary every 60 to 180 days to desulfate and balance a battery bank in systems

which are deficit cycled and/or charged at lower charge currents. If multiple parallel

strings show charge imbalance it may be necessary to equalize each string individually.

It is important to monitor specific gravity and voltage throughout the Equalization

process. When specific gravity readings remain constant for 45-60 minutes this

generally indicates completion.

19

Page 22

PREPARATION:

- Required Equipment: protective

or refractometer, voltmeter, distilled water, baking soda or soda ash for possible

overflow or spills

- Standard 1/4-turn bayonet caps and Rolls R-Cap flip-top recombination caps may

be left on during this procedure. Dirty or clogged caps may prevent the release of

hydrogen gas. Inspect and clean caps as necessary. Hydrocaps must be removed.

- Check each cell for low electrolyte levels and/or exposed plates and top up with

distilled water as necessary. If the cells require watering, do so before starting

the Equalization process to allow sufficient mixing with the existing electrolyte.

Be careful not to overfill as the electrolyte will bubble and may overflow during

the process.

- Program the Equalization voltage as recommended in Table 2 (a & 2 (b Flooded

Charging Parameters starting at the lower end of the voltage range for newer

models.

PROCEDURE:

1. Complete a Bulk & Absorption charge to bring the battery bank to 100% SOC

before starting a corrective Equalization.

2. Measure the temperature of a test cell and record the specific gravity of each

cell in the battery bank. Identify cells with high/low readings.

NOTE: Do not attempt to equalize a battery bank with known failed batteries

or cells as this may force a severe overcharge, damaging the remaining cells.

goggles, rubber gloves & rubber boots, hydrometer

3. Initiate the Equalization charge mode at a steady low DC current (5-10% of C/20

battery capacity). If grid power is not available, use a DC power source (generator)

or PV array with sufficient current when possible.

4. Specific gravity will rise across the battery bank, ideally reaching 1.265-1.270

in each cell upon completion. Readings in some cells may be slightly elevated

due to electrolyte temperature (Ex. 1.280) and will return to normal when cooled

but should not exceed 1.30. If the cell temperature rises above 46ºC (115ºF)

and approaches 52ºC (125ºF), terminate the Equalization process and allow the

batteries to cool. If available, check individual cell temperatures using an IR temp

sensor to isolate any possible damaged cells.

5. If cells are severely sulfated it may take several hours for the specific gravity to

rise and/or balance. If the readings plateau for 45-60 minutes, but do not reach

1.265-1.270, stop the process to prevent cell damage and allow the batteries to

cycle normally for 2-4 weeks before repeating. The cells will continue to desulfate

following an Equalization as sulfate dissolves during normal charging.

20

Page 23

Allow the battery bank to cool for 1-2 hours. Check and record the specific gravity

of each cell. The gravities should be 1.265 ± 0.005 or lower. Check electrolyte levels

and add distilled water as necessary.

It is recommended that a specific gravity reading of one pilot cell is measured and

recorded on a regular basis when it is thought that the bank is fully charged. The

measurement should be compared to previous readings. If the measurement is lower

than the previous reading, a longer absorption time and/or higher voltage setting

should be used. The longer the Absorption time and the higher the Bulk voltage,

the more water will be consumed but less Equalization will be required.

NOTE: The specific gravity should rise as the cells use water. Look for trends in the

specific gravity over a period of time and make small adjustments as necessary.

PREVENTATIVE EQUALIZATION & FREQUENCY

Most multi-phase charge controllers offer pre-programmed Equalization schedules

commonly referred to as preventative equalizations. These are typically set to run for

a shorter 1-2 hour period every 30, 60 or 90 days and may be beneficial in balancing

and removing small amounts of accumulated sulfation on an ongoing basis.

It should be noted that running frequent equalizations on batteries which do not

require balancing or desulfation will overcharge and deteriorate the cells prematurely,

shortening the life of the battery. For this reason, Rolls recommends monitoring

specific gravity and voltage on a regular basis to ensure scheduled Equalization times

are appropriately set. Alternatively, a corrective Equalization may be necessary if

symptoms arise such as running a backup generator more frequently (low capacity) or

the battery bank will “no longer hold a charge”. These symptoms are typical of heavy,

accumulated sulfation. If a battery is not being fully charged on a regular basis or

limited or inadequate Equalization is performed using a generator, sulfating will occur

from “deficit” cycling‘. This undercharge and buildup will gradually lower available

capacity. It is best to monitor the condition of the bank regularly as accumulation of

sulfation may take months to reach a point where the loss is noticeable.

NOTE: Properly charging a battery bank with sufficient voltage and current on each

cycle is essential to long cycle life. Equalizations may be required periodically to

balance and desulfate but should not be relied on to compensate for insufficient

charging sources. This procedure may not fully recover a loss of capacity from a

buildup of sulfation over time. Repeated Equalizations may be required in situations

where the battery bank has been consistently undercharged. Recovered capacity,

generally partial, may take 1-3 months with monitoring and repeated procedures

in battery banks with consistently low specific gravity measurements.

21

Page 24

VRLA AGM

BATTERIES

Page 25

ROLLS VRLA AGM BATTERY

CHARGING INSTRUCTIONS

To maximize the life of your Rolls VRLA AGM battery, it is important that it is properly

charged. Over or undercharging a VRLA AGM battery will result in shortened cycle life.

The best protection from improper charging is to use a quality charger and routinely

checking that the charge current and manufacturer-recommended voltage settings

are properly maintained.

VRLA AGM CHARGING GUIDELINES

To maintain good health, VRLA AGM batteries should be brought to a full charge

on each cycle or, at minimum, once every 6-7 days. Charge should be completed

in a ventilated area as hydrogen gas may still be released through the pressure

relief valve if the batteries are excessively overcharged. Never charge a frozen

battery. Ideal charging temperatures: 0°C-40°C (32°F-104°F).

VRLA AGM CHARGING CHARACTERISTICS

To maximize your battery life, a voltage regulated charger with temperature

compensation is strongly recommended. Refer to Table 5 VRLA AGM Charge Voltage

for the recommended charging parameters. Charge voltage should be set to 2.45vpc

@ 25°C (77°F) to allow the charger to properly adjust voltage with temperature

compensation. Temperature compensation should be programmed as specified in

Table 5 with adjustment in increments of 4mv/ºC/Cell. Without temperature compensation,

voltage settings should be manually adjusted for temperatures varying from 25°C (77°F).

As temperature decreases, the voltage should increase and vice versa. If the charger

has a preset charge profile for VRLA AGM type batteries, verify that these voltage

settings follow the battery manufacturer's specific charging parameters.

VRLA AGM BULK & ABSORPTION CHARGE

VRLA AGM batteries have a lower internal resistance than Flooded models, allowing

them to accept current more efficiently. It is recommended that the initial charge current

is set at 20% of C/20 of the battery bank (min 10% / max 30% of C/20) in order to fully

charge the batteries within a reasonable amount of time. It may be set lower, however,

this will increase the required charge time. It is very important that VRLA AGM batteries

are brought to a full charge frequently to prevent capacity loss. It should also be noted

that, unlike Flooded models, these batteries should NOT be equalized to recover capacity

loss. This program setting should be disabled in the charge controller to prevent

accidental overcharge.

The charger should deliver the initial max current at the programmed Bulk voltage

until the voltage limit is reached, then switching to the Absorption charge phase.

The charger should maintain the Absorption voltage until current tapers to the

programmed End Amps value (3-4% for VRLA AGM models).

23

Page 26

VRLA AGM ABSORPTION CHARGE TIME

Where : T = 0.38 x C /I

T = ABSORPTION CHARGE TIME

C = 20 hr RATED CAPACITY (total battery bank)

I = Charging Current (Amps) (recommended 20% of C/20 discharge rate)

0.38 = ( 20%/50%) + 5% (5% is added due to losses)

EXAMPLE:

2 strings of 6 Volt S6-460AGM models

20 hr AH rate = 415 AH x (2 strings) = 830 AH

I = 20% of 830 AH = 166 Amps

T = 0.38 x 830/166 = 1.9 hrs

VRLA AGM FLOAT STAGE AND TERMINATION

To maintain 100% SOC, the charger continues output to the battery bank at the

programmed Float voltage and End Amps current indefinitely or until the charger

is shut off or unplugged. The profile in Table 5: VRLA AGM Charge Voltage may

be used with or without the Float stage. Without the Float stage, recharge may be

terminated based on time. This will vary by depth of discharge and charge current,

or percentage recharge (105-110%).

NOTE:

If charger output is 120

Amps max, 120 is used.

T = 0.38 x 830/120 = 2.9 hrs

ROLLS VRLA AGM BATTERY CHARGE

VOLTAGE PARAMETERS

TABLE 5: VRLA AGM Charge Voltage

NOTE: Use the highlighted voltage set points when charge equipment is supplied

with a temperature sensor. Set at 4mV/ºC/Cell...(+/- 96mV per ºC from a 25ºC

Delta - 48V System) Higher or lower settings may cause incorrect adjustments

in charge voltage. Without a temperature sensor, charge settings must be

adjusted manually based on the battery temperature when in use, not just

ambient temperatures.

24

Page 27

VRLA AGM CHARGE EFFICIENCY/CHARGE FACTOR

Charge efficiency is a measure of the energy you may take out of a charged battery

divided by the energy required to charge it. Charge efficiency will depend on a

number of factors including the rate of charging or discharging. VRLA AGM batteries

have an average charge efficiency of ~85%. This should be reduced 1% per year

after the third (3) year of operation.

VRLA AGM REFRESH CHARGE

If Rolls VRLA AGM batteries are properly charged they should not experience varied

capacity loss or require balancing. If they were not properly charged and there is

a decrease in capacity, fully recharge the batteries at the recommended voltage. It

is important to prevent heavy discharge. If the batteries will be stored for extended

periods of time, apply a periodic refresh charge. Frequency will depend on storage

temperature as noted below.

STORAGE

NOTE: When not in use, it is normal to expect 2% self-discharge per month (at 25ºC

(77ºF) for sealed VRLA AGM models. This rate slows as ambient temperatures

decrease and increases at higher temperatures. Stored batteries should be recharged

every 3-4 months until the battery is put in service to avoid sulfation buildup and

possible freezing in cold temperatures.

Storage Temperature Refresh Charge Interval

Below 20ºC (68ºF) 9 Months

20ºC (68ºF) - 30ºC (86ºF) 6 Months

Higher than 30ºC (86ºF) 3 Months

TABLE 6: VRLA AGM Storage Temperature & Refresh Charge

DISPOSAL PROCEDURE

Batteries must NEVER be disposed of in household waste. To reduce

environmental impact, bring your spent VRLA AGM batteries to a certified

recycling depot to be recycled.

25

Page 28

OPzV GEL

BATTERIES

Page 29

ROLLS OPzV GEL BATTERY INSTALLATION

& CHARGING

Designed and well-suited for regular cycling as well as float and backup applications,

Rolls sealed OPzV GEL batteries have a low internal resistance than Flooded deep

cycle models allowing quick recharge and a low self-discharge rate (2% per month).

Rolls OPzV GEL batteries perform well in installations requiring frequent cycling even

under extreme operating conditions and offer more than 20 year cycle life in float

applications at 25ºC (77ºF).

INSTALLATION

Rolls OPzV GEL batteries should be installed upright unless otherwise specified and

should not be mounted upside down or horizontally on the end (shortest side) of the

case. Models compatible with horizontal installation (longest side) as well as custom

racking systems are available upon request. Contact your Rolls Battery Distributor

or Dealer for more information.

Use caution not to cover or apply pressure to valves located on the top of the batteries

when using strapping to move or secure the batteries as damage may occur.

OPzV GEL BATTERY CHARGING

Rolls OPzV GEL batteries have similar installation and charging requirements as VRLA

AGM models with the exception of unique Bulk, Absorption and Float voltage set points.

ROLLS OPzV GEL BATTERY CHARGE

VOLTAGE PARAMETERS

TABLE 7: OPzV GEL Charge Voltage

NOTE: Use the highlighted voltage set points when charge equipment is supplied with

a temperature sensor. Set at 3mV/ºC/Cell...(+/- 72mV per ºC from a 25ºC Delta

- 48V System) Higher or lower settings may cause incorrect adjustments in charge

voltage. Without a temperature sensor, charge settings must be adjusted manually

based on the battery temperature when in use, not just ambient temperatures.

27

Page 30

OPzV GEL CHARGER INSPECTION

The charger cabling should be insulated and free of breaks or cuts. The cable

connectors should be clean and properly mated with the battery terminals to ensure

a snug connection. The charger’s AC cord should be free of breaks or cuts and the

wall plug should be clean.

OPzV GEL CHARGING GUIDELINES

To maintain good health, VRLA AGM batteries should be brought to a full charge

on each cycle or, at minimum, once every 6-7 days. Charge should be completed

in a ventilated area as gasses may still be released through the pressure relief

valve if the batteries are excessively overcharged. Never charge a frozen battery.

Ideal charging temperatures: 0°C-40°C (32°F-104°F).

OPzV GEL CHARGING CHARACTERISTICS

To maximize your battery life, a voltage regulated charger with temperature

compensation is strongly recommended. Refer to Table 7 OPzV GEL Charge

Voltage for the recommended voltage regulated charge profile. If using battery

temperature compensation, charger voltage should be set to 2.38vpc - 25°C

(77°F) to allow the proper voltage adjustment by the charger (3mv/ºC/Cell). If the

charger has a preset charge profile for OPzV GEL type batteries, verify that these

voltage settings follow the battery manufacturer's specific recommendations.

OPzV GEL BULK & ABSORPTION CHARGE

OPzV GEL batteries have a lower internal resistance than Flooded models, allowing

them to accept current more efficiently. It is recommended that the initial charge

current is set at 20% of C/20 of the battery bank (min 10% / max 30% of C/20) in

order to fully charge the batteries within a reasonable amount of time. It may be set

lower, however, this will increase the required charge time. It is very important that

OPzV GEL batteries are brought to a full charge frequently to prevent capacity loss.

It should also be noted that, unlike Flooded models, these batteries should NOT be

equalized to recover capacity loss. This program setting should be disabled in the

charge controller to prevent accidental overcharge.

The charger should deliver the initial max current at the programmed Bulk voltage

until the voltage limit is reached, then switching to the Absorption charge phase.

The charger should maintain the Absorption voltage until current tapers to the

programmed End Amps value (3-4% for OPzV GEL models).

28

Page 31

OPzV GEL ABSORPTION CHARGE TIME

Where : T = 0.38 x C /I

T = ABSORPTION CHARGE TIME

C = 20 hr RATED CAPACITY (total battery bank)

I = Charging Current (Amps) (recommended 20% of C/20 discharge

rate) 0.38 = ( 20%/50%) + 5% (5% is added due to losses)

EXAMPLE:

1 string of 2-Volt S2-1380GEL models

20 hr AH rate = 1571 AH

I = 20% of 1571 AH = 314 Amps

T = 0.38 x 1571/314 = 1.9 hrs

OPzV GEL FLOAT STAGE AND TERMINATION

To maintain the battery bank at 100% SOC, the charger continues to apply a Float

charge to the battery bank at the End Amps output current indefinitely or until the

charger is shut off or unplugged.

OPzV GEL REFRESH CHARGE

If Rolls OPzV GEL batteries are properly charged they should not experience

varied capacity loss or require balancing. If they were not properly charged and

there is a decrease in capacity, fully recharge the batteries at the recommended

voltage. It is important to prevent heavy discharge. If the batteries will be stored for

extended periods of time, apply a periodic refresh charge. Frequency will depend

on storage temperature as noted:

Storage Temperature Refresh Charge Interval

Below 20ºC (68ºF) 9 Months

20ºC (68ºF) - 30ºC (86ºF) 6 Months

Higher than 30ºC (86ºF) 3 Months

NOTE:

If charger output is 288 Amps max

(ex 3 x 96 Amp controllers), 288 is used.

T = 0.38 x 1571/288 = 2.1 hrs

TABLE 8: OPzV GEL Storage Temperature & Refresh Charge

DISPOSAL PROCEDURE

Batteries must NEVER be disposed of in household waste. To reduce

environmental impact, bring your spent OPzV GEL batteries to a certified

recycling depot to be recycled.

29

Page 32

RENEWABLE

ENERGY

APPLICATIONS

Page 33

RENEWABLE ENERGY APPLICATIONS

Most deep cycle batteries used in the Renewable Energy Industry were originally

designed and manufactured for use in commercial and industrial applications

where consistent charge cycles are carried out from six to twelve hours until the

batteries reach a full state of charge. In Renewable Energy (RE) applications,

a lengthy charge time is not typical and in most instances a maximum of 4-6

hours of peak charge is achieved each day due to limited daylight and varying

weather conditions. To ensure the batteries received sufficient charge, charging

systems must be adequately sized or additional charge sources added to prevent

undercharge, deficit cycling and premature battery failure.

There are two definitive types of battery-based systems used in Renewable

Energy applications; off-grid and grid-connected. Off-grid systems are often used

where a customer does not have access or chooses not to connect to a public

utility. This customer may live remotely and have chosen to install a renewable

energy system from a single or combination of renewable sources to generate and

store adequate power to run all electrical requirements within the home.

With grid-connected systems, a customer typically lives in an area where they

may experience frequent or extended service interruptions from their public

utility. This may be a result of poor weather conditions, an unreliable power grid

or natural disasters. The renewable energy system is used as a backup power

supply, meant to supplement power to support critical loads (e.g. lighting and

refrigeration) during brief outages and/or to reduce energy costs by selling excess

power generated from the system back to the utility.

DEPTH OF DISCHARGE

Depth of Discharge (DOD), is used to describe how deeply the battery has been

discharged. A battery which is 100% fully charged would have a DOD of 0%. A

battery which has been discharged by 20% of its capacity, maintaining 80% of its

capacity, would have a DOD of 20%. If a battery has been completely discharged

with no remaining capacity, the DOD is 100%.

CYCLE LIFE

Battery manufacturers rate the cycle life of their batteries by comparing the level

of discharge on the battery and the frequency of cycling. Higher battery discharge

will result in shorter cycle life. In reverse, a smaller discharge percentage will

extend the expected cycle life of the battery as the battery will provide more

charge/discharges. To provide an example of cycle life, a 48V string of 8 x 6-volt

S6 L16-HC models in series (445 AH capacity @ C/20 ) which are consistently

discharged to 50% state of charge (222 AH of capacity drawn) and consistently

recharged to a full state of charge should provide approximately 1400 cycles

before end of life.

31

Page 34

CYCLE LIFE VS. DEPTH OF DISCHARGE – ROLLS BATTERY ENGINEERING

SERIES 5000 WITH ADVANCED NAM

Off-grid Renewable Energy systems are typically sized to operate between 20%

and 50% DOD. Deep cycle batteries should be used to a maximum 50% DOD as

this offers a balance between capacity vs. cycle life, also taking into consideration

the cost of replacement.

For grid-connected backup systems, Installers will typically size battery banks to

operate to a greater depth of discharge to lower initial installation costs. Cycling of

grid-connected systems is significantly less frequent than off-grid applications

where this typically occurs on a daily basis. With infrequent cycling, a maximum

80% DOD is acceptable as long as the customer understands that the overall

cycle life is affected when the battery bank is discharged beyond 50% SOC.

These systems should not be designed to fully discharge the battery bank.

32

Page 35

BATTERY SELECTION FOR OFF-GRID SYSTEMS

Choosing the appropriate battery for the application is key to long battery life and

performance. Once the load is calculated, a battery bank should be selected to

meet the system design as well as installation requirements. Flooded lead-acid

models using lead-antimony plates require frequent cycling to maintain capacity

and prevent sulfation buildup.

Lead-Calcium plates used in VRLA AGM and GEL models are more tolerant and

better suited to float applications where the battery may not be cycled as often.

If a battery bank of a specific capacity is needed, it is important to select a battery

model which offers sufficient capacity, without oversizing, and also minimizes the

number of parallel strings required to accomplish the desired voltage and capacity.

Systems with multiple parallel strings will often experience an imbalance of

charge. These banks will also require additional maintenance as this increases

the number of terminal connections requiring cleaning as well as the number

of Flooded cells to inspect, test and water. When a charge imbalance is not

addressed through adjustments in charge time and corrective Equalizations this

will lead to capacity loss and premature battery failure.

Determining the capacity requirement for off-grid systems is done by completing

an audit of energy consumption based on actual load requirements. The load is

calculated by the total amount of power necessary to support the load for a 1 day

period and then factors in how many days it may be required before recharging. In

a Renewable Energy system the 20 hr AH rate (C/20) is used when sizing systems

to cover three days of autonomy or less. The 100 hr AH rate (C100) is used when

designing systems to cover more than 3 days of autonomy.

Most systems are designed for 1-2 days of autonomy due to the cost of batteries

verses the cost of adding a generator and/or additional renewable energy sources.

This is also most typical for solar applications as these systems allow the battery

bank to be charged each day.

Deep cycle batteries will perform best when maintained at a full charge.

By holding at a 100% SOC this will extend the overall life of the battery bank.

For float applications such as backup systems, it is important to discharge and

charge the battery bank periodically to exercise the battery bank as this will

prevent stratification and sulfation buildup.

Backup systems are often sized to meet the load requirement at the time of

install. It is important to note that as load profiles change this will also affect

how quickly battery capacity will be reduced.

33

Page 36

DISCHARGE RATES

Discharge and recharge rates should be considered when selecting and sizing

a battery bank. Battery manufacturers publish multiple discharge rates for each

battery model, which range from 100 hrs to 1 hr. These are often referenced for

various type of applications. The most common in Renewable Energy applications

is the 20 hr rate as this closely matches a 1 day period. The rating, (ex C/20)

refers to a controlled load (Amps) which can be placed on the battery for a period

of time before the battery voltage reaches 1.75 VPC (volts per cell). A high amp

draw may be run for a shorter period of time and vice versa.

As an example, a 400 AH battery can support a controlled 20 Amp draw for 20

hours (C/20). Alternatively, the same battery can support a controlled 34 Amp

draw over a 10-hour period (C/10), meaning it supplies 340 AH capacity for that

period of time. Batteries which are discharged should be recharged as promptly

as possible.

An off-grid PV system should be designed to provide a charge current that is

capable of recharging the batteries quickly, efficiently and within the window of

time when the system is generating peak power (peak sun). The charge current

should be within 10-20% of the 20 Hr AH rate (C/20) rate of the battery bank,

or the C/4, C/5, or C/6 rate of the battery. Using the Absorption charge time

calculation (charge current of 10% of the C/20 rate of the battery bank will take

approximately 4.2 hours, plus the Bulk phase (usually 1-2 hours) to bring the bank

from 50% to 100% SOC. This is an ideal scenario as a lower charge current will

often increase the required charge time beyond the available sun hours

causing deficit cyling and/or the use of supplemental charging such as a

generator. Often customers who need to supplement charge with a generator

do not run it long enough to allow the batteries to reach 100% SOC on a regular

basis, causing sulfation problems and capacity loss which then needs to be

addressed through corrective equalizations.

In some situations, after and energy audit has been completed and the system

is sized and installed, the customers will inadvertently add additional and/or

unexpected loads. As system size is calculated with a desired depth of discharge

and charge requirement based on expected usage, this increases both the storage

needs and subsequent charge source to bring the battery bank to a full charge.

It will often cause problems as a result of deficit cycling and over-discharge which

will shorten cycle life.

To avoid this, the customer should be made aware of the importance of properly

sizing the system to meet their specific needs. Discuss any expected short/longterm changes in usage and set the expectation that storage and charging needs

may increase to meet their changing requirements.

34

Page 37

GRID-CONNECTED BACKUP

There are two distinct uses for a grid-connected battery bank. The first, and the

most common is a power backup system. The purpose is to provide temporary

power in the instance of grid loss. This is simular to a UPS system, but is typically

on a much larger scale with higher storage capacity.

The second is a grid-tied system with battery backup. This system setup is used

to generate and sell excess power produced by a renewable source to your utility

provider when you are connected to the grid. In the event of a grid failure, the

battery bank then provides storage power for the critical loads during the outage.

Systems are configured according to how much power is to be sold to the utility

vs. how much will be stored. If a higher percentage of the power generated is

pushed to the utility, this will decrease the remaining amount available for backup

and vice versa. This may be determined by personal preference or may be limited

or regulated by the utility.

For grid-tied battery backup systems, the battery bank should only be sized to

handle the loads supported for the duration of a temporary outage. These systems

are commonly used to run household necessities such as limited lighting and

refrigeration, etc. It is ideal to limit the size of the supported load to essential

services only as higher capacity battery banks require more maintenance as well

as power usage to hold at full charge, reducing the amount of generated power

which can be sold to the utility.

Typically, because outages are infrequent and occur only a few times per year

in most regions, these systems are designed for greater depth of discharge than

off-grid applications. In some cases they may be designed to discharge as far

as 80% DOD over a relatively short period of time.

In regions where the grid may not be reliable and extended or intermittent outages

occur frequently, it is necessary to size the battery bank and charging source(s)

to support a larger load over a longer period of time. This prevents the battery

bank from overdischarging and/or deficit cycling.

35

Page 38

WARRANTY

GLOSSARY

& FAQ'S

Page 39

WARRANTY

We build one mean battery and we back them with comprehensive warranties

that lead the industry in length of coverage. We’re confident that our batteries

will perform time after time, year after year. However, should a problem arise,

you may be assured that you're covered better than any other battery warranty

in the business.

Surrette Battery Company warrants that Rolls-branded batteries sold by it are

quality tested, merchantable and free of defects in workmanship and material

at the time they are shipped from the Company’s factory.

In the event that the Company makes a drop shipment to a distributor’s customer,

that customer must be instructed to perform an inspection of the goods BEFORE

signing the delivery slip. The Company is not responsible for damaged product

reported after shipment has been signed “Received in Good Condition”.

NOTE: ALL SHIPMENTS SHOULD BE THOROUGHLY INSPECTED FOR DAMAGE

BEFORE SIGNING THE DELIVERY SLIP.

The Company will replace or, at its option, repair any Rolls Battery sold by it that

fails to conform to the warranty stated above on a NO CHARGE BASIS as follows:

For warranty terms, conditions and model-specific details, please refer to the

warranty document found on the Rolls Battery website.

www.rollsbattery.com/technical-resources

A copy of the Rolls Battery Warranty Claim Form & Battery Test Sheet

is also available for download in PDF format.

To claim a manufacturing warranty, proof of purchase must be presented,

showing the date of purchase and the battery’s model & date of manufacture

(date code). A completed Rolls Battery Warranty Claim Form & Battery Test Sheet

must also be provided. Upon review, it may be necessary to have the battery

returned to the manufacturer or inspected and tested by an authorized battery

outlet for actual defect. All valid claims must be approved by Rolls Battery

Technical Support before replacement product may be issued.

The warranty does not cover shipping damage, cracked covers, cracked cases,

bulged cases from heat, freezing or explosion, discharged batteries or the use

of undersized batteries damaged from electrical equipment.

This warranty covers only manufacturing defects.

The Company makes no warranty with respect to its batteries other than the

warranty stated above. All implied warranties of merchantability and all expressed

and implied warranties of any other kind are hereby excluded.

37

Page 40

ROLLS BATTERY WARRANTY PROCEDURE

Please refer to product warranty for the specific model as terms and conditions

may vary.

For warranty requests and inquiries, please submit your request via support ticket

(www.rollsbattery.com/support) or by email to support@rollsbattery.com.

DAMAGED BATTERY

NO

Check individual

cell voltages

> 2.1 VPC

Check

specic

gravities

All cells > 1.250

and even

Submit support ticket or

call Rolls Battery Technical

Support at 1-800-681-9914.

Holds 1.75VCP

for C/10 or

C/20 rate

< 2.1 VPC

Cells

< 1.250

All cells

> 1.250

and uneven

YES

Damaged batteries DO NOT qualify

for Rolls Battery product warranty

Charge battery at

0.1/C/20 for 10 hours

Charge battery at

0.1/C/20 for 10 hours

Equalize

@ 2.58 VPC

for 2 hours*

NO

YES

First time

through cycle

NO

One cell is

0.040 points lower

than others

YES

Battery does NOT meet

warranty criteria. Battery is

charging and discharging

properly. Product warranty

does not apply. Please refer

to dealer for assistance.

38

Complete and submit Rolls

Battery warranty claim form

via support ticket (www.

rollsbattery.com/support) or

by fax (1-800-681-9915) for

further instruction.

Page 41

LEAD-ACID BATTERY GLOSSARY

ABSORBED (OR ABSORPTIVE) GLASS MAT

A type of sealed lead-acid batteries. The electrolyte is absorbed in

a matrix of glass fibers which holds the electrolyte next to the plate and

immobilizes it, preventing spills. AGM batteries tend to offer good power

characteristics, low internal resistance and high charge efficiency.

AMP, AMPERE

Unit of electrical current. Abbreviated “A”.

AMP-HOUR, AMPERE-HOUR

Unit of electrical energy, one Amp of current flowing for one hour.

Abbreviated AH.

CELL

A single battery canister usually grouped together with other cells to form

batteries of various voltage configurations. Open circuit voltage (OCV) of a

charged and rested lead-acid battery is 2.1V/cell.

CYCLE

A “cycle” is a somewhat arbitrary term used to describe the process of

discharging a fully charged battery down to a particular state of discharge.

The term “deep cycle” refers to batteries in which the cycle is from full charge

to 80% discharge. A cycle for an automotive battery is about 5%, and for

telephone batteries is usually 10%.

ELECTROLYTE

An electrically conductive medium in which current flow is due to the

movement of ions. In a Flooded lead-acid battery the electrolyte is a solution

of sulfuric acid and water.

FLOODED CELL

A traditional lead-acid battery. The electrolyte is an ordinary liquid solution of

acid and water. Flooded cells are prone to off-gassing hydrogen during charge.

They must be periodically checked for fluid level and distilled water added as

necessary. Flooded cells are also typically less expensive than AGM or GEL-type

lead-acid batteries.

GEL

A sealed VRLA lead-acid battery. The gelified electrolyte used in these models

is a mixture of sulfuric acid and fumed silica. GEL batteries typically offer

extended cycle life over sealed VRLA AGM batteries when operating in higher

temperatures and are better-suited to slower, deep discharge applications.

3939

Page 42

HYDROMETER

A tool for testing the specific gravity of a fluid such as the electrolyte in a

Flooded battery. Hydrometers use a squeeze-bulb to suck up a sample of the

fluid and a float indicates the specific gravity of the electrolyte.

REFRACTOMETER

A tool for testing the specific gravity of a fluid such as the electrolyte in