Page 1

AUTOMATE

DC ARC TUBULAR MOTOR

433 MHZ

BI-DIRECTIONAL

ELECTRONIC

LIMIT

SELECTABLE

RPM

FAVORITE

POSITION

LEVEL CONTROL

AUTOMATE | DC ARC motors offer a low voltage easy to use and program solution to suit

a large range of applications, torques and speeds.

Leveling Control allows for precise positioning of multiple shades ensuring perfect

alignment.

Additionally, a favorite position can be pre-set and recalled at any time.

FEATURES:

• Electronic Limits

• 433 MHz Bi-Directional RF Communication

• Leveling Control

• 3 x Selectable Rpm

• Favorite Position

• Roller & Tilt Modes

• Narrow Shade Options

INSTR. MTDCBRF_Automate_DC V1.0 NOV 2016

Page 2

NOTES

2 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 3

CONTENTS

1 ASSEMBLY 5

2 WIRING 6

2.1 Power options 6

3 P1 BUTTON FUNCTIONS 7

4 INTIAL SETUP 8

4.1 Pair motor with controller 8

4.2 Check motor direction 8

4.3 Set limits 9

5 ADJUSTING LIMITS 10

5.1 Adjust upper limit 10

5.2 Adjust lower limit 10

6 ADDING OR REMOVING CONTROLLERS AND CHANNELS 11

6.1 Using motor P1 button 11

6.2 Using a pre-existing controller 11

7 FAVORITE POSITIONING 12

7.1 Set a favorite position 12

7.2 Send shade to favorite position 12

7.3 Delete favorite position 12

8 ADJUSTING MOTOR SPEED 13

8.1 Increase or decrease motor speed 13

9 TILT & ROLLER MODE 14

9.1 Enter tilt mode 14

9.2 Enter roller mode (Default) 14

10 SLEEP MODE 14

11 TROUBLESHOOTING 15

3 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 4

SAFTEY INSTRUCTIONS

5005833

WARNING: Important safety instructions to be read before installation.

Incorrect installation can lead to serious injury and will void manufacturer’s liability and warranty.

CAUTION

• Do not expose to moisture or extreme temperatures.

• Do not allow children to play with this device.

• Use or modification outside the scope of this instruction manual will void warranty.

• Installation and programming to be performed by a suitably qualified installer.

• For use within tubular blinds.

• Ensure correct crown and drive adaptors are used for the intended system.

• Keep antenna straight and clear from metal objects

• Do not cut the antenna.

• Use only Rollease Acmeda hardware.

• Before installation, remove any unnecessary cords and disable any equipment not needed for powered operation.

• Ensure torque and operating time is compatible with end application.

• Do not expose the motor to water or install in humid or damp environments.

• Motor is to be installed in horizontal application only.

• Do not drill into motor body.

• The routing of cable through walls shall be protected by isolating bushes or grommets.

• Ensure power cable and aerial is clear and protected from moving parts.

• If cable or power connector is damaged do not use.

Important safety instructions to be read prior to operation.

• It is important for the safety of persons to follow the enclosed instructions. Save these instructions for future reference.

• Persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge

should not be allowed to use this product.

• Keep remote controls away from children.

• Frequently inspect for improper operation. Do not use if repair or adjustment is necessary.

• Keep motor away from acid and alkali.

• Do not force the motor drive.

• Keep clear when in operation.

4 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 5

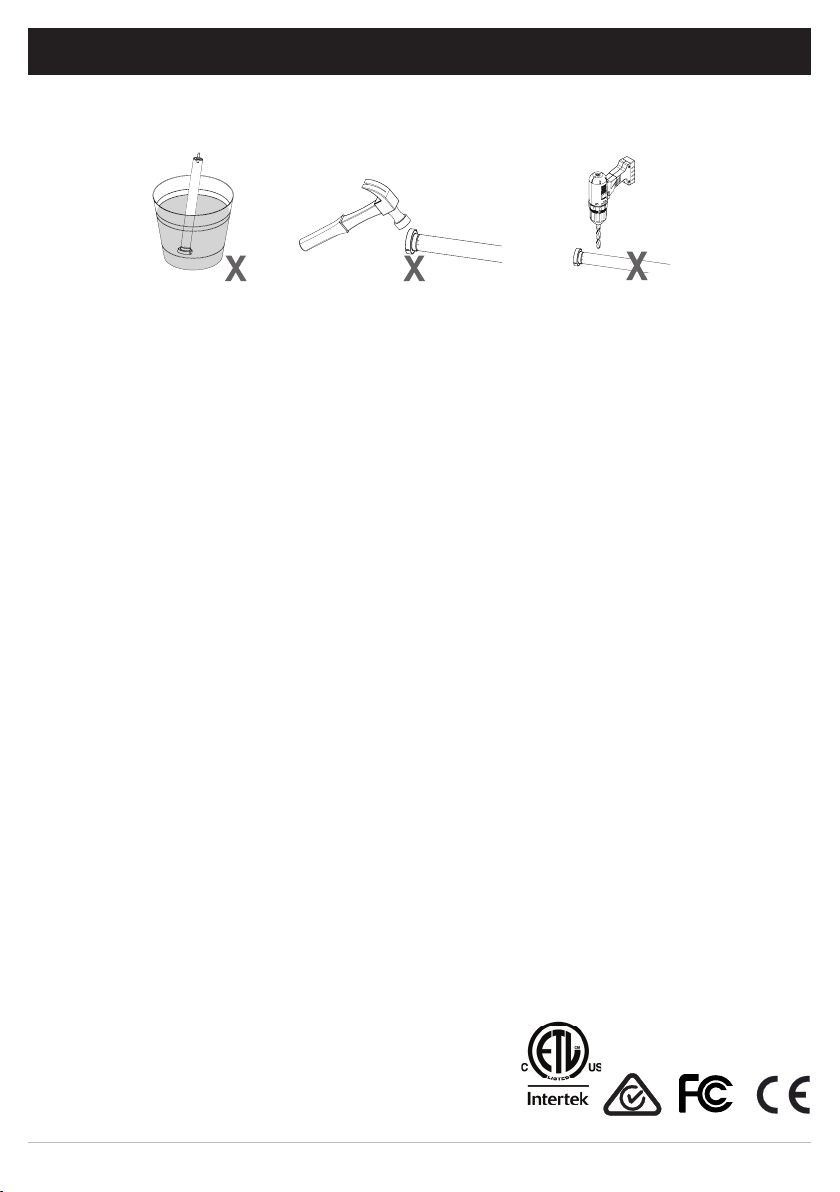

1 ASSEMBLY

Please refer to Rollease Acmeda System Assembly Manual for full assembly instructions relevant to the hardware system being used.

Step 1. Cut roller tube to required length.

Step 2. Ensure roller tube is clean and free from burrs.

Step 3. Fit required crown, drive and bracket adapters.

Tube must be close fitting with chosen crown

and drive adapters. Refer to Rollease Acmeda

System Assembly Manual for recommended

crown, drive, and bracket adapter kits.

Step 4. Slide Motor into tube.

Insert by aligning keyway in crown and

drive wheel to the tube.

Step 5. Mount motorized tube onto brackets.

Refer to Rollease Acmeda System

Assembly Manual for recommended crown,

drive, and bracket adapter kits.

Motor Head

Bracket

Adapter

Crown

Drive

Retaining

Clip

5 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 6

2 WIRING

2.1 Power options

Automate DC motors are powered from a 12V DC power source. AA Battery wands, re-chargeable battery

packs and A/C power supplies are available, with a variety of quick connect extension cords. For centralized

installations, power supply range can be extended with 18/2 wire (not available through Acmeda Rollease).

• During operation, if voltage drops to less than 10V, the motor will beep 10 times to indicate a power

supply issue.

• Motor will stop running when the voltage is lower than 7V and it will resume again when the voltage is

greater than 7.5V.

DC Power Supply

Power Supply Motor

MTBWAND18-25 Battery Tube for 18/25mm DCRF (no Battery) Mtrs

(inc Mt clips)

MTDCPS-18-25 Power Supply for 18/25-CL/Tilt DCRF (no Bttry) Mtr

MTDCPS-28-35-45 Power Supply for 28/35/45mm DCRF (no Battery)

Mtr 28mm DC ARC

MTDCKR-28 Rechargeable Wand

MTDCRF18-0.2 - 18mm DCRF Motor, .2N/80

MTDCRF25-1.1 25mm DCRF Motor, 1.1N/40r

MTDCRF18-0.2 - 18mm DCRF Motor, .2N/80

MTDCRF25-1.1 25mm DCRF Motor, 1.1N/40r

MTDCRFQ28-2 28mm DCRF Quiet Motor, 2N/28r

MTDCRF35-3 35mm DCRF Motor, 3N/28r

MTDCRFQ45-3 45mm DCRF Quiet Motor, 3N/28r

MTDCRF45-10 45mm DCRF Motor, 10N/9r

MTDCRF18-0.2

MTDCRF25-1.1

MTDCRFQ28-2

Extension Cables Length

MTDC-CBLXT6 DC Battery Motor Cable extender 6” / 155mm 6 inch

MTDC-CBLXT48 DC Battery Motor Cable extender 48” / 1220mm 48 inches

MTDC-CBLXT96 DC Battery Motor Cable extender 96” / 2440mm 96 inches

Ensure cable is kept clear of fabric.

Ensure antenna is kept straight and away from metal objects.

6 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 7

3 P1 BUTTON FUNCTIONS

3.1 Motor state test

This table describes the function of a short P1 button press/release (<2 seconds) depending on current

motor configuration.

P1 Press Condition Function Achieved Visual

Feedback

Short Press

If limit is NOT

set

If limits are set

If motor is in

“Sleep Mode” &

limits are set

None No Action None No Action

Operational control

of motor, run to limit.

Stop if running

Wake and control

Motor runs

Motor wakes

and runs in a

direction

3.2 Motor configuartion options

The P1 Button is utilized to administer motor configuration as described below and beginning in Section

Activate Pairing

Mode

Approx.

Motor Response

Hold P1

Audible

Feedback

None

None

Function Described

Operational control

of motor after pairing

and limit setting is

completed first time

Motor is restored from

Sleep Mode and RF

control is active

P1

Sleep Mode

Approx.

Motor Response

Reverse

Direction

Approx.

Motor Response

NOTE

Reverse motor direction from P1 button only when

motor does not have any limits.

Reset To Factory

Settings

Approx.

Motor Response

7 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 8

4 INTIAL SETUP

4.1 Pair motor with controller

Select channel on

controller.

IMPORTANT Motor Response Motor Response

Consult user manual for your

controller for information on

selecting channel.

Hold P1 button on motor

head.

Motor is now in step mode and ready for setting limits

4.2 Check motor direction

To check travel direction of shade, press UP

or DOWN on controller.

To reverse shade direction, hold both UP and

Until the motor responds.

Hold STOP on controller.

DOWN.

Quick Press = Step

Long Press = Continuous Travel

IMPORTANT

Damage to shade may occur when operating motor prior to

setting limits. Attention should be given.

8 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Motor Response

IMPORTANT

Reversing motor direction using this method is only possible

during initial set-up.

Page 9

4.3 Set limits

Move shade to the desired highest or lowest

position by pressing the UP or DOWN buttons

on controller.

IMPORTANT Motor Response

Cycle shade up and down prior to setting limits to settle fabric

To save upper limit, hold UP and STOP.

To save lower limit, hold DOWN and STOP.

SECS

5

IMPORTANT

After setting limits, motor will automatically exit from initial

set-up mode.

Initial set-up is now complete

9 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 10

5 ADJUSTING LIMITS

5.1 Adjust upper limit

Hold UP and STOP on

controller.

Move shade to the desired

highest position by

To save upper limit, hold

UP and STOP.

pressing the UP button.

Motor Response Motor Response

SECS

5

SECS

5

5.2 Adjust lower limit

Hold DOWN and STOP on

controller.

Move shade to the

desired lowest position

by pressing the DOWN

button.

To save lower limit, hold

DOWN and STOP.

Motor Response Motor Response

SECS

5

10 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

SECS

5

Page 11

6 ADDING OR REMOVING CONTROLLERS AND CHANNELS

6.1 Using motor P1 button

Hold P1 button on motor head. Hold STOP on controller to add or remove.

Motor Response Motor Response

6.2 Using a pre-existing controller

Press P2 on existing

controller.

Motor Response Motor Response Motor Response

IMPORTANT

Consult user manual for your

controller or sensor.

11 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Press P2 on existing

controller.

Press P2 on new

controller.

Page 12

7 FAVORITE POSITIONING

7.1 Set a favorite position

Move shade to the desired position by pressing the UP or DOWN button on the controller.

Press P2 on controller. Press STOP on controller. Press STOP on controller.

Motor Response Motor Response Motor Response

7.2 Send shade to favorite position

Hold STOP on controller.

7.3 Delete favorite position

Press P2 on controller. Press STOP on controller. Press STOP on controller.

Motor Response Motor Response Motor Response

12 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 13

8 ADJUSTING MOTOR SPEED

8.1 Increase or decrease motor speed

Press UP. Press UP.

Press P2 on controller.

Press DOWN. Press DOWN.

Motor Response Motor Response Motor Response

IMPORTANT

If motor does not react to speed

adjustment, the maximum or

minimum speed has already been

reached.

13 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 14

9 TILT & ROLLER MODE

9.1 Enter tilt mode

For slat adjustment on venetians.

Hold UP and DOWN on controller. Press STOP.

Motor Response Motor Response

SECS

5

9.2 Enter roller mode (Default)

Hold UP and DOWN on controller. Press STOP.

Motor Response Motor Response

SECS

5

10 SLEEP MODE

Enter Sleep Mode Exit Sleep Mode

Sleep mode is utilized to prevent a motor from

moving during shipping of a fabricated shade

Hold P1 button on the motor head Hold P1 button on the motor head

Motor Response Motor Response

14 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Exit sleep mode once the shade is installed

Page 15

11 TROUBLESHOOTING

Problem Cause Remedy

Batteries in wand are depleted Replace 8 x AA alkaline batteries.

A/C power supply not plugged in.

Transmitter battery is discharged Replace battery

Battery is inserted incorrectly

into transmitter

Motor is not responding

Motor beeps 10 times when in use Battery voltage is low.

Cannot program a single Motor

(multiple motors respond)

Radio interference/shielding

Receiver distance is too far from

transmitter

Power failure

Incorrect wiring

Multiple motors are paired to the

same channel.

Check motor to power cable

connection and AC plug.

Check battery polarity

Ensure transmitter is positioned

away from metal objects and the

aerial on motor or receiver is kept

straight and away from metal

Move transmitter to a closer

position

Check power supply to motor is

connected and active

Check that wiring is connected

correctly (refer to motor

installation instructions)

Replace batteries in battery wand

-OR-

Recharge rechargable battery

pack.

Always reserve an individual

channel for programming

functions

SYSTEM BEST PRACTICE - Provide

an extra 15 channel controller in

your multi motor projects, that

provides individual control for each

motor for programming purposes

Place all other motoprs into sleep

mode (ref to P1 button function

overview - Section 3)

15 | Automate Programming Instructions | DC Tubular Motors ROLLEASE ACMEDA

Page 16

This device complies with Part 15 of the FCC Rules / Industry Canada licence-exempt

RSS standard(s). Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

This equipment has been tested and found to comply with the limits for

a Class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates

uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following

measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

ROLLEASE ACMEDA

AUSTRALIA

110 Northcorp Boulevard,

Broadmeadows VIC 3047

T +61 3 9355 0100 | F +61 3 9355 0110

Western Australia Branch

Unit 1, 41 Mulgul Road,

Malaga WA 6090

T +61 8 9248 5571 | F +61 8 9248 5572

Queensland Branch

Unit 2/62 Borthwick Avenue,

Murarrie QLD 4172

ROLLEASE ACMEDA

USA

200 Harvard Avenue

Stamford, CT 06902 6320

T +1 203 964 1573 | F +1 203 964 0513

ROLLEASE ACMEDA

EUROPE

Via Conca Del Naviglio 18, Milan

(Lombardia) Italy

T +39 02 8982 7317 | F +39 02 8982 7317

info@rolleaseacmeda.com

rolleaseacmeda.com

16 | Automate Programming Instructions | DC Tubular Motors

Loading...

Loading...