Original instruction : French NT0002 V –h –

03/2012

1

Dear Customer,

You have just purchased a ROLLAND Spreader.

We appreciate the trust you place in us.

The Spreaders by ROLLAND were designed to make the most of

spreading techniques. They result from our technology and our

experience in this field.

This manual should be considered as part of your Rolltwin or

Rollmax Spreader.

For proper use, and to exploit all the capabilities of your Spreader,

we recommend that you carefully read and follow all instructions in

this manual.

The proper function and longevity of your spreader depends on

it as well as your safety and that of others.

Keep this instruction manual so that you can consult it in due

course. It must always accompany the spreader, even in case of

resale.

Non-compliance with the said instructions indemnifies the

manufacturer and the dealer of all liability.

We reserve the right to make any changes to our products at

any time we deem useful without obligation to modify products

previously delivered or on order. We also reserve the right to change

without notice models that are defined in our catalogues, brochures

or on our website.

Yours faithfully.

Z.A des Landes

29800 TREFLEVENEZ - FRANCE

Tél. : 00 33 (0)2 98 85 13 40

Fax : 00 33 (0)2 98 21 38 15

www.remorquerolland.com

Original instruction : French NT0002 V –h –

03/2012

2

Summary

1-Safety instructions 3

2-Conditions of warranty 4

3-Presentation of the vehicle 5

-Areas of use

-Vehicle identification

-Technology and options

4-Commissioning (PDI) 16

5-Normal use and instructions 25

-parking

-loading

-transport

-spreading

6-Settings 28

-Drawbar

7-Care and maintenance 29

-Braking systems

-undercarriage

-Cleaning/lubrication

-Adjusting the bed tension

-Adjusting the steering axle

-Maintenance of controller and hydraulic unit

- Wearing parts

-Maintenance of the beater frames

-Wheels and tyres

-Lighting

8-Assembly 42

-Revolving light flashing beacons

-Equipment

9-Annexes 48

-Hydraulic drawbar

-Passive suspension

-Hydropneumatic suspension (active suspension)

10-Maintenance logbook 58

11-Declaration of Conformity 60

12-Certificate of warranty –Declaration of commissioning 61

Original instruction : French NT0002 V –h –

03/2012

3

1-Safety instructions

Before commissioning, study the instructions and follow the safety guidelines!

In this user guide we have marked with this symbol all hazards or

risks that operators are subject or exposed to.

Signs and security stickers attached to the spreader show you that it is

safe to use the machine: Respecting the instructions = safety

A. Normal use

The spreader is designed and manufactured for normal use as described in this

manual.

Four situations are thereby defined as: parking, loading, transporting and spreading

(Chapter 5).

All uses other than specified are considered non-compliant. However, a number of

predictable non-conform situations are discussed and specifically prohibited. The

manufacturer is not liable for resulting damages.

We must respect the rules of accident prevention and other legal safety

regulations, occupational medicine and the Highway Code.

The manufacturer accepts no liability for damage resulting from an unauthorised

modification of the machine.

B. General safety regulations and accident prevention.

a. Vehicle shutdown: Before

working on the machine, stop the

engine, release the hydraulic

pressure engage the brakes

(tractor and trailer) and remove the

ignition key.

b. Before starting the tractor

engine, ensure that the PTO is not

engaged, that all safety devices

are fitted and in good condition.

c. Never deregulate or

override safety devices. For

settings, care and maintenance,

follow the procedures described in

the manual (especially chapter 6/7)

d. It is strictly forbidden to go

under the vehicle when in

operation.

e. The use of the machine

remains the sole responsibility of

the driver. He must ensure the

absence of third parties in the

proximity during any manoeuvre.

f. Given the residual risk of

shock or damage to the spreading

device (AND its projection area)

and that it is technically impossible

to protect (at least in the work

phase), it is the responsibility of

the driver of the machine to ensure

the absence of a third party in this

area when the machine is in

motion.

g. The driver must be in

possession of all necessary means

to use the machine under optimum

conditions.

Original instruction : French NT0002 V –h –

03/2012

4

h.

2- Conditions of warranty

To take full advantage of the manufacturer's warranty, ensure compliance with

maintenance and usage advice given in this manual. In case of problems users

should contact their dealer.

Conditions of warranty :

Spreaders lifts are covered against defects in parts and workmanship for one

year from the date of commissioning.

In no event can ROLLAND SA be held responsible for an incident due to a

failure to comply with instructions for use, safety or maintenance.

The warranty covers only the provision of defective parts.

The guarantee is withdrawn and we disclaim any liability :

- When the machine has been transformed by elements built outside of our

workshops or those of our distributors without our permission.

- When the serial number of origin has been falsified

- If the ROLLAND factory fitted parts have been replaced by parts of another

origin.

- If the damage is due to any negligence, improper use, overloading, even

temporarily, to the inexperience of the user, to the penetration of a foreign

body in an element of the machine during operation or from non-lubrication.

Repair, modification or replacement of parts during the warranty period cannot

have the effect of extending the warranty period of equipment.

Upon receipt of your trailer, make sure it is fully compliant with the technical

specifications and that it has suffered no damage.

To actuate the warranty process

"CERTIFICATE OF WARRANTY - DECLARATION OF COMMISSIONING"

accompanying this data sheet must be completed and returned within one month of

delivery.

Original instruction : French NT0002 V –h – 03/2012

5

3 – Presentation of the vehicle

This manual is common to all spreaders in the ROLLAND range. It was designed to

give you all necessary information about the vehicle you have just purchased and to

allow you to get the get the most out of it.

DESCRIPTION :

The spreaders are equipped with either a single axle, rocker, tandem or tri axle.

They can also be equipped with the "ROLLFAST" hydraulic suspension.

They are mounted on a chassis with a drawbar, sprung or hydraulically adjustable.

Identification :

For full features of your trailer, refer to the conformity plate attached to the front right

of your vehicle. In addition, a tare plate sticker specifies the permissible gross

weight (GVWR) and unladen weight (UW). A stamped (serial number) is carried on

the vehicle chassis

This serial number is required for any exchange warranty with your dealership or the

factory

Tare sticker

Conformity plate

PTAC _ _ _ _ kg

PV _ _ _ _ kg

Original instruction : French NT0002 V –h – 03/2012

6

Drawn agricultural vehicles fall under two distinct regulations :

The highway code

The labour code

Rolland vehicles come with a sheet crossed out with a red bar and a notice

containing a statement of compliance. These two documents show that the two

regulations have been met.

In addition to these instructions, depending on options chosen, additional

instructions (DASP, hydraulic weighing or on gauges 1.2 or 3 axles, Rollcontrol ...),

will be given to you at the start by your dealer.

Original instruction : French NT0002 V –h – 03/2012

7

Side view

ROLLTWIN ROLLMAX

ROLLMAX

Front and rear view

1

Body

7

Running gear

2

Front panel

8

Beaters

3

Protection cover

9

Slurry door

4

Hose arrier

10

Spreader frame (2100Kg maxi)

5

Drawbar

11

Spreader table

6

Drawbar adjustment

ROLLTWIN

ROLLMAX

Original instruction : French NT0002 V –h – 03/2012

8

Technology and options available :

Rings :

Welded flat ring

Removable ring

Drawbars with 8 holes interface allowing several types of ring to be fitted (flat,

rotating, spoon, DIN)

Hydraulic drawbar only on "ROLLMAX"

Welded rotating ring

Original instruction : French NT0002 V –h – 03/2012

9

Running gear :

Single axle

Bogey

Rocker with

offset shaft

Tandem with

tie rods

Tridem

Rollfast

Driving direction

Original instruction : French NT0002 V –h – 03/2012

10

Bed control: There are several types of floor controls, in each, several functions can be

managed from the electrical control box in the cabin in addition to the tractor control valve that is

always available. Here in this table are the various available combinations: Wiring diagram for

tractor troubleshooting (independent hydraulics).

Procedure for carrying out a tractor repair: 1Disconnect push-pull 1 + 2 and push-pull 3 + 4

1- Connect push-pull 2 + 4 together with connection kit K1

2- Connect push-pull 1 pressure side of tractor distributor

3- Connecte push-pull 3 to reflux side of tractor distributor

Floor control

Function

Command

n° feed

1) Directly from the tractor:

operates through

hoses connected to the

tractor

1) Basic:

Bed only

manual control

110

no display

111

with display

112

with display + DPA

113

2) 2 functions :

Bed + slurry door

no display

121

with display

122

with display + DPA

123

3) 3 functions :

Bed + slurry door +

hood

no display

131

with display

132

with display + DPA

133

2) Pump:

The pump is operated

mechanically from the PTO and

the gearbox located upstream

(during maintenance or repair,

the hoses can be connected to

the tractor as in the diagram

here below)

1) Basic:

Bed only

no display

211

with display

212

with display + DPA

213

2) 2 functions :

Bed + slurry door

no display

221

with display

222

with display + DPA

223

3) 3 functions :

Bed + slurry door + hood

no display

231

with display

232

with display + DPA

233

to tractor

Do not forget to

plug in this

connector set K1

N.B : To reverse the direction, P and T1 must be inverted, i.e. the push-pull 1 and 3 on the tractor.

Original instruction : French NT0002 V –h – 03/2012

11

This table explains the function of the components that make up the 18 existing

types of feeds. In the column "relevant system" there are numbers that use the line

advances (for example a two section distributor is used in the feeds 121, 122, 123,

221, 222, 223).

Element

Function

Relevant system

Reservoir

Contains about 80litres of oil

to power the pump (1 oil

change / year or every 200

hours)

Viscosity index: 46

211, 212, 213, 221,

222, 223, 231, 232, 233

Gear box

Allows the PTO running

at 1000 rpm to drive the

pump at 3000 rpm (1 oil

change / year or every

200 hours)

Qty: 0.3 litres max

Viscosity index: 400

211, 212, 213, 221,

222, 223, 231, 232, 233

Pump

Pumps the oil from the

reservoir for distribution

at a rate of 50 l / min at

1000 rpm (PTO)

211, 212, 213, 221,

222, 223, 231, 232, 233

Connector set K1

This set allows

connection and

disconnection of the

pump controller. It is

imperative for its

protection

211, 212, 213, 221,

222,

223, 231, 232, 233

Terminal

Connects all the various

sensors wires into one

harness

112, 113, 122, 123,

132, 133, 212, 213,

222, 223, 232, 233

Réducteur 1/40

Reduces the motor

speed so that the belt

runs at feed rate.

All models

Original instruction : French NT0002 V –h – 03/2012

12

Element

Function

Relevant system

Hydraulic motor

Supplied with oil, it

drives the gear which

drives the bed. One

motor 160 cm ³ for the

single drives and two

motors 130 cm³

connected in parallel for

the double drives.

All models

Proportional controller

Ensures the distribution

of oil in the circuit in

proportion to a given

electrical transfer.

Pressure filter to be

changed yearly. This

block is equipped with

two pressure relief

valves for secure

drainage and cleansing.

All electrically controlled

models

Distributor dual function

Allows the oil supply for

the belt and for the hatch

functions

121, 122, 123, 221, 222,

223

Distributor tri-function

Allows the oil supply for

the belt, hatch and hood

functions

131, 132, 133, 231, 232,

233

Wheel inductive sensor

Gives the distance

travelled by the spreader

112, 113, 122, 123, 132,

133, 212, 213, 222, 223,

232, 233

Gearbox inductive

sensor

Indicates the distance

traveled by the bed and

the speed of the bed

112, 113, 122, 123, 132,

133, 212, 213, 222, 223,

232, 233

Pressure sensor

Informs the user of the

oil pressure in the circuit.

112, 113, 122, 123, 132,

133, 212, 213, 222, 223,

232, 233

Manual control

Ensures the distribution

of oil in the circuit. The

adjustment is made with

the rotary selector.

110

Original instruction : French NT0002 V –h – 03/2012

13

The various control boxes

Element

Function

Relevant feed

Controls the bed and regulates

its speed, two setting ranges

(hare / tortoise) for optimum

accuracy. The driving is done

via the tractor control valve

111, 211

Controls the bed and regulates

its speed, two setting ranges

(hare / turtle) for optimum

accuracy. The screen displays

bed speed, hydraulic pressure,

and the distance traveled by

the bed. The clearing is done

via the tractor control valve

112, 212

In addition to basic functions, it

can reverse the direction of the

bed, control the opening of the

hatch (2 functions) and the

operation of the TCE hood (3

functions).

121, 131, 221, 231

In addition to basic functions, it

can reverse the direction of the

bed, control the opening of the

hatch (2 functions) and the

operation of the TCE hood (3

functions). The screen displays

belt speed, hydraulic pressure,

and the distance traveled by

the bed.

122, 132, 222, 232

3 function control unit and DPA

(Output proportional to the

progress). The screen displays

bed speed, hydraulic pressure,

the distance travelled by the

bed.

113, 123, 133,

213, 223, 233

Original instruction : French NT0002 V –h – 03/2012

14

Steering axle :

The steering axle follows the vehicle and works from the movement caused by

the curves, it must be locked on the highway (at medium or high speed) and in

reverse.

The self-steering axle is a follower controlled by a cylinder located on the

drawbar of the vehicle, it is a closed hydraulic circuit with accumulators to

maintain pressure. It requires the installation of a clevis on the tractor. Note that

the self-steering Rolland axle can become a follower axle when a tractor is

without a clevis because locking cylinders of the follower axle have been

retained. The advantage of this system is that the driver does not need to

intervene when driving, neither forward nor in reverse.

The running gear with 1 self-steering axle are composed mainly of the following

element :

Component

Quantity

Illustration

Hydraulic block 1 axle

1

The running gear with 2 self-steering axles are composed mainly of the following

element :

Component

Quantity

Illustration

Hydraulic block 1

2

Do not connect the follower axle's locking hose during a self-steering

operation.

Original instruction : French NT0002 V –h – 03/2012

15

Hydraulic headland kits:

Hydraulic headland kits are available as options on the frames C8, C11, C12, C22,

C13, C23 for the ROLLTWIN spreaders and C10 for the ROLLMAX spreaders.

These headland kits allow spreading at the edge of the plot. It is possible to have

headland kits on the left or on the right or one on each side.

Weighing :

It is possible to equip the ROLLTWIN and ROLLMAX spreaders with a weighing

system. Weight information is detected by sensors on the drawbar and the axle. The

data is then memorised in the weight conrol box per client or plot. In addition to the

weighing system the user can have a data processing software for managing

customers or plots (storage up to 65,000 weighings). Also optionally available is a

compact printer equipped with a battery rechargeable at the mains that can publish

tickets with weight totals, per customer or plot.

Weight control box

Weight sensor

Data processing software

Compact printer

Original instruction : French NT0002 V –h – 03/2012

16

4 – Commissioning (PDI)

Vehicle coupling system :

The coupling may not exceed the speed of 32 km/h or 20 mph road speed. The

connection is provided by a standard ring (all types of couplings can be used with

hook, ring bolt or spoon coupling).

PROCEDURE

. Make sure that the tractor used can carry the nominal load of

the trailer.

. After coupling the trailer to the tractor, make sure the skid is

raised properly and in the resting position, securely locked.

. Check all lubrication points before the first use (see chapter

Maintenance)

Adjustable tractor coupling(automatic hook or pick-up coupling):

• Approach slowly in reverse, lower hitch to coincide with the ring.

• Once in place, raise the hitch (the ring will position itself).

• Lock the device.

• Raise the hydraulic or mechanical skid.

Fixed tractor coupling (ring bolt, autohitch, drawbar) :

Place the prop in position (ring above the ring bolt coupling or drawbar).

Approach to adjust coupling devices (tractor and machine): :

the ring bolt and lower the ring (it will position itself).

Pick up hitch

The drawbar

Manoeuver the tractor if necessary

Lock and raise the skid.

Connect all hydraulic hoses (pneumatic optional).

Connect the lights.

Tyres :

On commissioning the vehicle, it is imperative that the tyre pressures be

determined and adjusted according to the load on the tyres and the actual

conditions of use.

OR

OR

Original instruction : French NT0002 V –h – 03/2012

17

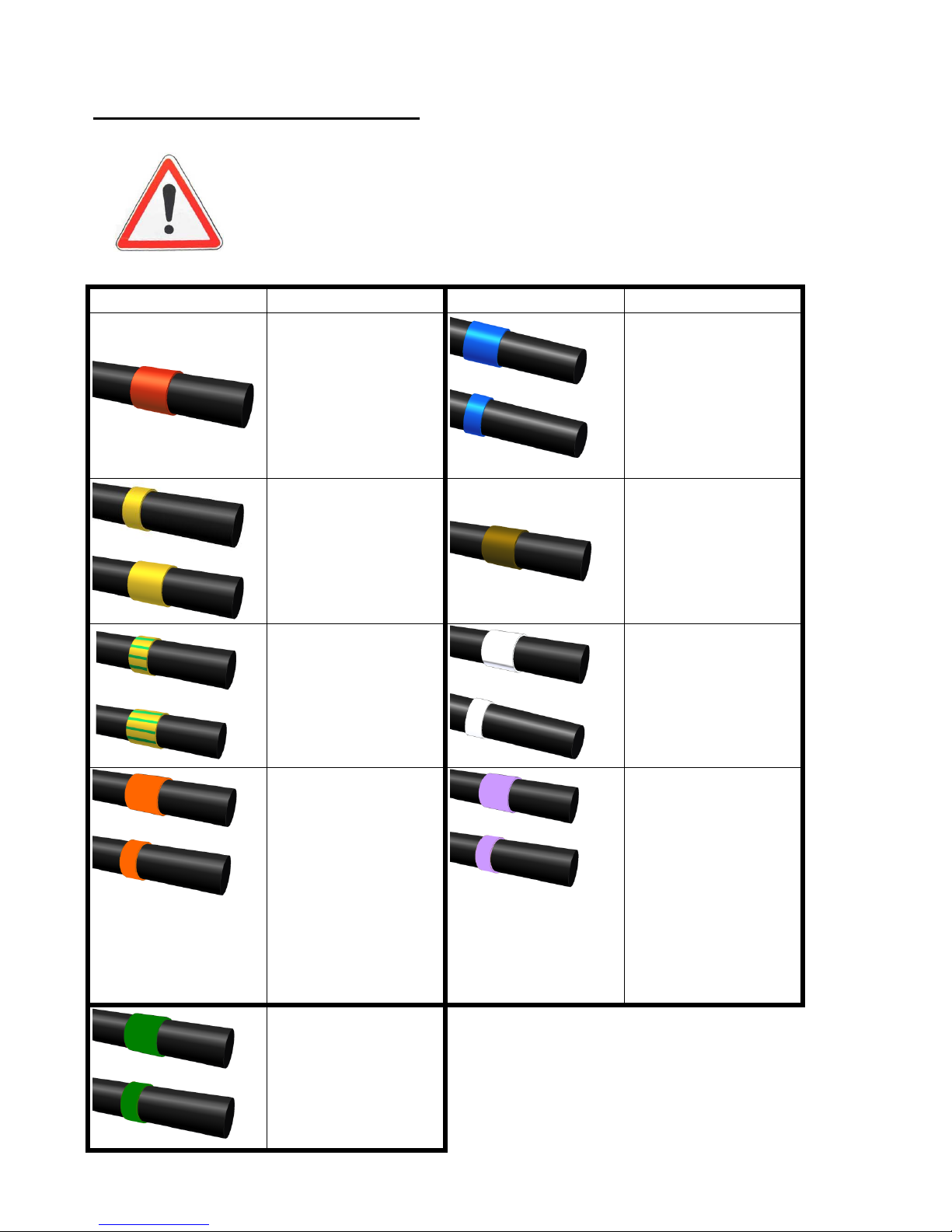

Connecting the pressure outlets :

. The connections must be made with the engine shutdown,

hydraulic pressure released and ignition key removed

Hose marking

Function

Hose marking

Function

Brakes

Bed pressure

(DE)

Bed reverse

(DE)

Close hood

(DE)

Open hood

(DE)

Load transfer

(SE)

Lock steering

(SE)

Lock steering

(DE)

Slurry door open

(DE)

Close slurry door

(DE)

Extend hydraulic

drawbar cylinder

(DE)

Retract hydraulic

drawbar cylinder

(DE)

Pressure

hydropneumatic

suspension

(DE or SE)

Return

hydropneumatic

suspension

(DE or reflux)

Pressure passive

suspension (SE)

Passive

suspension drain

(Reflux)

*SE : single acting valve (pressure /

float)

*DE : dual acting valve

Original instruction : French NT0002 V –h – 03/2012

18

Brake system :

The spreaders are equipped with three brake systems, each one assuring a specific

function.

When parking, use the mechanical hand brake. During the transport it is the

hydraulic brake that is used. The third system is a safety device for in case the

coupling breaks (a cord between the hand brake and a fixed point on the tractor).

Connect the safety cord in case of breakage of the coupling that operates the

parking brake. Check at the start of every season, the tension of the cable

connecting to the brake rods.

PROCEDURE

. Any trailer with a GVWR more than 1.5 tons is obligatorily

equipped with the braking device. It must be coupled to the

tractor braking system.

Hydraulic braking system :

Install the red hose (4) on the pressure outlet "BRAKES" on the tractor.

Ensure the proper functioning of control and check connections for leaks. Brake

pressure: 100 to 130 bar.

Reference

Element

Function

1

Brake drum

Ensures braking

2

Brake cylinders

Actuates the brake rods during transport

3

Brake cables

Is the link between the hand brake and

the brake rods

4

Hose (connected to the tractor)

Supplies the brake cylinders with oil

5

Parking brake

Hand brake

6

Coupling failure cord (attached to a

fixed point on the tractor)

Engages the handbrake should the

coupling break

Original instruction : French NT0002 V –h – 03/2012

19

Pneumatic braking system

Element

Function

Illustration

Emergency relay valve

(VRU)

Ensuring the service brake and

the automatic braking of the

trailer in case of coupling

breakage or pressure drop in the

supply line

Static corrector

(optional)

Adjusts the brake pressure, that

is the brake force, depending on

the load condition of the vehicle.

Relay valve (optional)

Allows the control circuit to

control the permanent circuit.

Shunt valve

Allows the release of the service

brake of the trailer after initiation

of automatic brake caused by the

disconnection of the hoses.

Reservoir + purge

Compressed air tank. The purge

allows the moisture in the circuit

to be evacuated.

Coupling control

controler

(yellow)

Permits the braking between

tractor and trailer

Coupling Feed

(red)

Ensuring the continuous supply

between the tractor and trailer.

Brake chamber

Ensuring the service brake

system with its front part and the

parking brake with its rear part for

the dual spring cylinder.

Pressure outlet

Used to control the pressure in

the system

N.B : The brake can also be mixed (hybrid pneumatic/ hydraulic fitting)

(mounting for 40 kmh prohibited)

Or

Or

Original instruction : French NT0002 V –h – 03/2012

20

Example of air braking system on 2 axles (40 kmh)

Installation of the drive shaft :

PROCEDURE

. All drive shafts must be equipped with safety guards in good

condition.

. Deteriorated guards must be replaced immediately

. Do not forget to install guards and to restrain them with

chains.

. Never operate a PTO without the foreseen guards.

. Wearing loose clothing may be the cause of accidents.

. During the first use, it may be necessary to adjust the length of the drive

shaft. To do this :

Ensure the correct length of the drive shaft tubes.

Tube can be damaged if the turning circle is too severe

Interlock the tubes a minimum of 4500 mm.

On transmissions there are several types of security, safety shear bolt or torque

clutches cams. In case of a shear bolt, it should be replaced by a bolt of the same

type and same quality as the original. Replacement by a stronger bolt will damage

the vehicle.

N.B : for commissioning, operation and maintenance of the transmission

(primary and secondary), refer to the manufacturer's specific instruction

manuals provided with the machine.

T

R

A

C

T

O

R

Or

Or

1 Emergency relay

2 Fixed correcteur

3 Relay valve

4 Brake valve

5 Reservoir

6 Feed

7 Control

8 Pressure

9 Brake cylinders

Original instruction : French NT0002 V –h – 03/2012

21

Electrical connections :

1- LIGHTING

The machines are equipped with standard lighting which follow the legal

requirement for road use.

Spreaders are fitted with regulation lighting, for that reason, it is necessary to

connect them to the tractor electrically.

PROCEDURE

. Never leave without checking the operation of the vehicle

lighting: your safety and that of others depend on it.

. Do not leave the wires hanging near the transmission

Connect the multipin (A) without forcing it and in the right direction, the tongue

must be in the slot.

Careful: our wiring is designed to cope with the flow of current independently to the

left and right hand lights. Depending on your tractor a bridge on your tractor socket

may be necessary. If this is the case: Rolland cannot take any responsibilty for an

overheated circuit. This modification is done by the client and is his responsibilty.

2- OPTIONAL EQUIPMENT

Connect the 3-pin plug (B) without force, the direction is indicated by the flat

section.

This socket is present on all machines equipped with electronic boxes or those

equipped with weighing or centralised lubrication.

A

Polari

B

Flat

Polarising slot

tongue

Left indicator

Not Used

Brake

Right indicator

Right light

Left light

Earth

Original instruction : French NT0002 V –h – 03/2012

22

Installing the self-drive system :

The option of self-steering axle requires the installation of a steering actuator.

Depending on your trailer, one or two clevis forks must be mounted on your tractor.

These are provided but the adaptation and installation are not covered by

ROLLAND. In fact, depending on the make and model of tractor, the forks' position

may vary slightly.

For 1 self-steering axle

For 2 self-steering axles

While the tractor is completely turned (wheel in contact with the

drawbar), verify that approximately 20mm margin at extremeties

of the undercarriage piston rods remains, i.e. that they are not

fully retracted or extended.

Installation of the clevis forks:

The axes of the cylinder swivel and the ring of the drawbar must be at a distance of :

180 mm for mounting in a single cylinder link

120 mm / 160 mm for mounting in a double cylinder link

The axis of the cylinder swivel must be decreased by :

18 mm with respect to the axis of the ring.

18

180

Axe anneau de flèche

Clevis fixed to

the tractor

Original instruction : French NT0002 V –h – 03/2012

23

120

Actuator of the rear

axle

Actuator of the front

axle

120

Axis of the

drawbar ring

160

18

Installing the cylinder :

For this operation, no pressure may be present in the circuit. If your installation has

only one cylinder, the automatic latching system allows its installation easily. Simply

attach the cylinder to the tractor and slowly steer it round to lock it. However if your

vehicle has two cylinders on its drawbar, install the cylinders manually.

The adjustment should be made with tractor and trailer coupled

and properly aligned, wheels straight, cylinder(s) attached. It is

advisable to advance in a straight line for about 10 meters.

Make sure the tractor handbrake is engaged.

.

PROCEDURE

Close the circuit selector valve(s)

Open the isolating valves of the different circuits.

Using a hand pump, raise the pressure in the different circuits

Between 20 and 35 bar for mounting a single cylinder with a diameter 40/80 (the

valve on the hand pump must be closed)

Between 20 and 35 bar for mounting two cylinders

Once the pressures are stable (a difference of 5 bar can be tolerated), close the

valves of the different circuits.

To reuse the hydraulic support, simply reopen the valve(s) selector. (make sure

the valves of the self-drive circuit are closed)

To release the pressure from the circuit, the valves on the circuit selector must be

closed, open the valves for the various circuits and open the tap of the hand

pump. The oil then returns to the pump.

Original instruction : French NT0002 V –h – 03/2012

24

Concerning follower and self-steering axles

Any self-controlled running gear can be used in steering mode. To do this, simply

place the cylinder(s) to the side(s) of the drawbar in the space provided for this

purpose. The axis ball cylinder - tractor clevis then serves to block the cylinders.

The pressure in the circuit must always be released (monitor through the

pressure gauges). For locking the follower axle, a hose, labeled yellow-green, is

located on the hose holder.

Fixation axis

cylinder ball

coupling - tractor

In the self-steering (or forced) mode, it is forbidden to use the

steering axle locking hose, as this may cause great damage to

the hydraulic system. Thus, to avoid any risk of error, it is highly

recommended not to connect this hose (marked by striped

yellow and green markings) to the tractor in self-steering mode.

. Before steering, ensure that nothing is blocking the rotation of the wheels.

It is imperative that the hydraulic system of the axles is purged of all air.

Do not exceed recommended pressures in the process of pressurizing the circuit

because the membranes of the accumulators may be damaged and no longer

fulfill their role.

Concerning the follower axles

For locking the steering axle, a hose labeled yellow-green is located on the hose

holder.

. On the highway in steering mode, it is advisable to lock the

axle(s) to avoid any risk of an accident involving an unplanned

movement of the trailer, especially when your vehicle is laden.

Original instruction : French NT0002 V –h – 03/2012

25

5 – Normal use and instructions

Above, the explicit representation of icons shown on the vehicles

representing the various risks (risk of crash, fall risk, etc. ...).

Parking:

During storage of the vehicle the observance of certain rules is mandatory for your

safety but also in order to have a vehicle ready for use when needed.

.

It is recommended to store the vehicle in a covered location.

The vehicle must be unladen on its stand.

The brakes on.

The storage area must be flat (slope of 10° maximum) and stable.

The hydraulic hoses re-connected on the hose holder.

Lubrication has been carried out (see maintenance chapter)

Lubricate extended cylinder rods (rams).

Original instruction : French NT0002 V –h – 03/2012

26

Loading :

Any damage due to overloading is in no case covered by manufacturer's

warranty.

.Never exceed the vehicle payload

.Check the good load distribution on the vehicle

.Check the balance of the load, good stability and

manoeuverability of the vehicle.

. Ensure during loading that no hard substance (stone, pieces of

wood, iron, etc.) is loaded into the spreader, it could cause

damage.

. When used in freezing weather check the mobility of the slats of the bed

before loading.

Transport

The spreaders are designed to travel at 32 km / h or 20 mph (see table) according to

the model. They are approved for the highway.

. Respect the highway code.

. Never leave without first checking the correct function of the

vehicle’s lighting: your safety and that of others depends on it.

. Check the inflation pressure of the tyres (see chapter

Maintenance).

. Moving across a hillside with a loaded hook lift can be

dangerous. To the extent possible, move with the axis of the slope. If not

possible, avoid driving with a load greater than 50% of the nominal load.

. For maximum safety, it is imperative not to exceed a gradient of 15%

(obstacles, ruts, ditches).

Bed shaft counter (hubodometer) optional..

This meter is configured for a wheel type 305 70 R 19.5. If your vehicle is

equipped with different wheels, a correction of the display of the hubodometer is

necessary to obtain an exact distance.

.Examples of correction values :

Real value = value read x correction value

For all other dimensions, please go to page 40.

Description of the

wheel

Circumference

Diameter

Correction value

18/22.5 (445 65 R

22.5)

3505

1130

1.26

500 60 R 22.5

3705

1180

1.33

550 60 R 22.5

3862

1230

1.38

600 55 R 26.5

4176

1330

1.5

Original instruction : French NT0002 V –h – 03/2012

27

Spreading

Set the PTO in motion without accelerating and bring it to normal speed of 1000

rpm. All ROLLAND spreaders are designed to operate in this regime except in

exceptional cases (540 rpm). In all cases, the plan to use is specified by a sticker on

the hose carrier at the front of the vehicle.

If the quality of the spreading is not satisfactory, several factors may be the cause,

seek the reason among the following points:

Adjust the settings relative to the dung.

The load (irregular, non-homogeneous).

The power of your tractor (too weak).

The speed of the PTO (too slow - monitor the plan). Check the flow.

If a beater jams on the deck, reverse or advance the bed to clear the beaters, stop

the machine (see § 1-1 on page 3) and manually remove the material blocking the

machine from the rear (see page 32). To perform this operation, it is advisable to

wear personal protective equipment (gloves, goggles, helmet, ...)

The controller can also be operated manually in case of failure. To switch to manual

mode you must turn the screw 1 clockwise. From the tightening of the screw the

controller switches to manual mode, then just fine tune as needed. To return to the

electrical control, simply wind out the screw entirely. In case of failure of the

distributor or control box, it is possible to connect the hoses directly to the tractor.

1

ALL WORK AT THE REGULATOR (MANUAL

ADJUSTMENT AFTER A REPAIR FOR EXAMPLE)

MACHINE MUST BE SHUTDOWN COMPLETELY

(TRACTOR ENGINE OFF, IGNITION KEY REMOVED).

TO RESTART, SEE § 1-2 on page 3).

THE SAME INSTRUCTIONS MUST BE RESPECTED IN

THE CASE OF THE MANUAL REGULATOR (SEE

PAGE 12). IN ADDITION, THE REAR WINDOW OF

THE TRACTOR CAB MUST BE CLOSED WHEN

OPERATING THE MACHINE.

(SEE, GENERAL SAFETY REGULATIONS PAGE 3)

Original instruction : French NT0002 V –h – 03/2012

28

6 – Settings

Preamble: Unplug the power supply before carrying out any adjustments (see

§ 1-1 on page 3)

Adjustments to the mechanical drawbar :

Adjustments to the mechanical drawbar :

The setting of the drawbar enables a level body according to the coupling height,

giving a greater flexibility and a maximum weight transfer to the rear axle of the

tractor.

N.B : For the first commissioning, the dealer will take care of adjusting the drawbar.

PROCEDURE

. Carry out the adjustments on an empty vehicle.

. Operate on a firm, level ground.

. Make sure the parking brake (tractor and trailer) is engaged..

. Install the safety peg above the ring bolt of the tractor..

Put the machine on chocks with the help of a jack (lifting capacity: 5T) placed at

the front of the chassis.

Remove the setting pin of the drawbar (item B).

Position the drawbar so that the spreader is level when coupled to the tractor.

The position of the drawbar will be adjusted to the next higher hole. Thus the

spreader will be slightly nose up.

Replace the setting pin.

Remove the jack.

The top hole is used for large diameter wheels, the distance between each hole

being 7cm.

Jack 5T

Original instruction : French NT0002 V –h – 03/2012

29

7 – Care and maintenance

To carry out the maintenance under good conditions, the following safety

rules must be met :

Block the wheels.

Engage the mechanical brake. (hand brake)

Unload the vehicle.

1- Check the brake system (every 6 months)

a- Parking and emergency brake

Verify the correct tension of the parking / emergency brake. The parking brake

lever should not be able to reach the last ¼ of the ratchet. If this is not the case,

tighten the cable.

Procedure for tensioning the cable :

Set the parking brake lever in the off position and ensure the

immobilisation of the vehicle by placing chocks in front and behind the wheels.

Loosen the cable clamps on one side,

Re-tension the cable

Re-tighten the cable clamps

Perform a test

If it appears that the brake rods (see fig.1 below) require too much

angle to allow for efficient braking, take up the play at the pads (see

the following: b)

b- Service brake

Check operation of the brake cylinders, make sure they are not at full-stroke and

control their mounts and the return springs (cylinders should not extend more

than two thirds of their maximum stroke or 100mm).

If this is not the case, proceed to remedy the brake linings.

To do this :

Set the parking brake lever in the off position and ensure the

immobilisation of the vehicle by placing chocks in front and behind the

wheels.

Remove the circlip at the end of the brake cam (see fig1 next page)

Disconnect the link rod of the cam.

Using a pipe wrench for example, exert a torque on the brake cam

simulating the braking.

Replace the link rod on the cam in this position.

Replace the circlip.

N.B :

Original instruction : French NT0002 V –h – 03/2012

30

If your vehicle is equipped with brake slack adjusters, bring the pads

closer by turning the bolt provided for this purpose with a 19 spanner (see

Fig. 2).In a clockwise direction close the bolt until you feel resistance and

then back off a ¾ turn (see Fig. 2).

If your vehicle is equipped with self-adjusting rods, the operation of

lining play compensation manages itself.

Check lining wear through the hole provided for this purpose.

If the pads are unusable or questionable, contact your local ROLLAND

dealer.

Fig. 2

Fig. 1

c- Check wheel hub bearings :

The bearings are wearing parts; their lifespan depends on working conditions, load,

speed and especially their adjustment and lubrication.

To check the play of hub bearings, lift the axle (vehicle shut down (see § 1-1 on

page 3) and empty) so that the wheel does not touch the ground (need for a jack

5T capacity in line under the axle) and grasp the wheel right and left trying to

move it.

Monitor after the first commissioning.

Every 2 years, verify the adjustment of tapered bearings. Excessive play may

damage the bearing seats and braking devices.

d- Checking the hub caps :

For push on caps, visually check that they are fully fitted into the hubs.

For screw caps, make sure they are properly seated at the front of the

hub.

View port - linings

Brake rod

Brake cam

Circlip

Original instruction : French NT0002 V –h – 03/2012

31

2- Maintenance of the running gear :

Maintenance work on the running gear must be performed by qualified and

competent staff with the appropriate tools and a specialised workshop

approved by the vehicle manufacturer.

General inspection

For : ½ tandem, tandem rods

Check and tighten all the nuts on the axle fixation flanges and the draw rods if

present. (follow the order of Diagram 2)

Grease the various pivot pins and the end of the springs in their slide (Figure 1).

Lubrication

Lubrication

Tightening

1

2

3

4

Plan 1 Plan 2

Case of the rocker axle or Rollfast

Check the absence of play in the axis of the rocker bar.

Lubricate the various points (14 per axis of the rocker bar or Rollfast)

14 grease nipples along this axis

Original instruction : French NT0002 V –h – 03/2012

32

3- Cleaning and lubricating :

Clean the body with copious amounts of water after each transport of corrosive or

soiled goods. After washing, follow up with a general lubrication (oil spray) and verify

the brake functions. For all cleaning and lubrication operations, the machine should

be shut down (see §1-1 of page 3)

Every 10 hours:

-Grease the bed chain drive front and rear

- Greasing of the PTO drive shaft

Every 50 hours:

-Grease the axle, the drawbar and the drive shaft bearings

1 to 3 times/year (depending on use intensity) :

- Grease the beater bearings (to the right of the TCE, at the top of the verticals

(in the upper casing)) Provide adequate means of access (see page 32)

-Grease the drive shaft bearings

The grease points are represented by red dots on the diagram below. The oil of the

various mechanical boxes (gearboxes, gearbox and bevel) should be replaced every

year or every 200 hours in accordance with the amounts shown in the "maintenance

of mechanical boxes." The recommended oil is SAE 140.

Original instruction : French NT0002 V –h – 03/2012

33

Instructions for cleaning

Caution: this operation requires special precautions in addition to those cited

throughout this document (pages 3, 17, 20 and 26 in particular) and in this chapter.

Mandatory:

Ensure the machine is stopped and the discharge of the device is

complete.

Use the side ladder for this purpose

Warning, there is no means of access to the interior of the vehicle.

If, however, an intervention inside the body is required, equipment (not

supplied) type scaffolding must be used to enter, with railings and other safety

precautions. In general, all interventions higher than the floor must be done with

adequate means of access.

All interventions, which are more toward the back of the machine, must

be done with the machine off, PTO disconnected and using personal protective

equipment (goggles, gloves etc..) recommended for the use of specific tools by

their manufacturer for example :

High pressure cleaner for washing the screws and beaters

A cutting tool to cut the strings

Etc

The rotation of the bed and all other functions (slurry door, hood) are

sometimes necessary. All our machines permit these functions independently of

the rotation of the PTO. This ensures the non-rotation of moving parts particularly

with the " autonomous control". In fact in the latter case, a connection kit comes

with the machine (see pages 10 to 13) to allow the bed to be supplied directly

with oil from the tractor.

Original instruction : French NT0002 V –h – 03/2012

34

A

B

A

B

A

B

4- Adjustment of the bed tension :

This adjustment must be performed every 50 hours of use. It prevents premature

wear of components and keeps the chains in position. To carry out the tension

adjustment of the 2-chain there are 2 stretchers (A) outside the skip, for the 4-chain,

there are the two tensioners (A) and 2 more (B) in the middle.

Loosen the counter-nuts A

The tensioning of the bed is done by compressing the spring by tightening the

nuts B

Proper tension translates into a lift-off between 5 and 10 millimeters of the first

bar of the bed in relation to the guide plates under the spreader.

Tension control to be performed every 10 hours (adjust tension if

necessary)

Original instruction : French NT0002 V –h – 03/2012

35

5- Steering axle :

Checking and adjusting the alignment

Immobilise the vehicle, the steering axle well inline, lock cylinders retracted, on a

level surface.

Measure the distance between the front wheels and the rear follower axle. The

same value should be found.

If this is not the case, unblock the 2 lock nuts of the coupling rod, and rotate it in

order to get the distance at the front to be identical to that at the back.

Tighten the lock nuts firmly.

The coupling rod

Lock nuts

Adjusting the locking cylinders

Periodically check the cap-nut and its lock-nut. After the alignment, proceed to

adjust the locking cylinders as follows

Unscrew the lock-nuts

Screw on the cap nuts.

Develop and maintain pressure in the cylinders.

Unscrew the cap nuts to have them pressing against the stops

Screw down the lock-nuts firmly in order to lock the setting.

Cap-nuts

Lock-nuts

Original instruction : French NT0002 V –h – 03/2012

36

6- Maintaining the regulator and hydraulic unit :

Shutdown the vehicle (see §1-1 of page 3)

Check the oil level and tightness of the tank. Remember to change the oil and

regulator filter every year. To change the filter, unscrew the protection bowl (red).

Clean the inside of the bowl with a cleaning agent (do not use cloth or paper

towels), change the filter and then replace the bowl.

Check the oil level of the gear-box. Make a first oil-change after 50 hours of use

and thereafter annually at least.

Check the condition of the hose.

7- Bed control :

Shutdown the vehicle (see §1-1 of page 3)

Check the wear of chain drives and bearings, lubrication is mandatory

(centralised lubrication).

Check the condition and fastening of the bed slats.

8- Transmission maintenance :

The maintenance of this element is primordial for your safety.

Shutdown the vehicle (see §1-1 of page 3)

Check as often as possible the protection cover of the universal joints

Lubricate the various elements of the PTO and the bearings of the shaft

(periodicity page 31).

Check the wear of shims on the drive shaft and the lubrication.

Lubricate also the universal joints at the ends of the angle transmissions.

To optimise the function directly from the tractor a reflux without brake (push-pull

type) is recommended.

- Output tractor direct about 60L/min for a manual control type MTKA,

otherwise risk of overheating and possible engine failure.

- Output tractor 80L/min for a proportional type regulation with an

electrical control in the cab

- Every year, change the oil in the reservoir, change the regulator filter

and change the unit mesh filter.

WORK ON ANY ELEMENT OF

TRANSMISSION (SHAFTS, CARDANS,

BEARINGS, ...) MUST BE DONE ONLY ON A

FULLY SHUTDOWN MACHINE (STOP THE

TRANSMISSION AND TRACTOR ENGINE).

REMOVE THE KEYS

Original instruction : French NT0002 V –h – 03/2012

37

9- Replacing the wearing parts:

The spreader assembly contains parts that wear and must be replaced regularly,

there is no advised service life for these parts as they wear out faster or slower

depending on the type of manure or according to settings made by the operator.

Element

Quantity (per beater or per disc)

Wear arm - disc

3

Beater point

C8

15

C10

19

C11

20

C12

20

C13

22

C22

21

C23

19

TCE

15

2

2 types of blade: left and right

Deck wear strips

Original instruction : French NT0002 V –h – 03/2012

38

10- Maintenance of mechanical housings:

Shutdown the machine completely (see § 1-1 on page 3)

Change the oil in the various mechanical boxes every year or after 200 hours using

the SAE 140 respecting the following quantities:

Assembly

Housing

(In the direction of travel)

Oil quantity (in litres)

C8

Middle

1.2

Left

2.2

Right

2.2

C10

Middle

1

Left

1.8

Right

1.8

C11

Middle

1.2

Left

2.2

Right

2.2

C12

Middle

1.2

Left

2.2

Right

2.2

C13

Middle

1.2

Left

2.2

Right

2.2

C22

Middle

1.2

Left

2.2

Right

2.2

C23

Middle

1.2

Left

2.2

Right

2.2

TCE

Middle

1.2

Left

2.5

Right

2.2

Exterior transmission

angle

1.2

Beater (x2)

0.8

TCEI

Middle

1.8

Left

1.5

Right

1.8

Exterior transmission

angle

1

Beater (x2)

0.7

Bed

Bed drive casing (right or left

and right)

2.8

Hydraulic unit

Gear pump casing

0.3

Visco 400

Original instruction : French NT0002 V –h – 03/2012

39

11- Wheels and tyres:

Check the wheel nuts and tyre pressures regularly

Inflation

Proper inflation of tyres allows optimum grip, comfort and performance. Also the

tyres will last longer and the surfaces will be preserved.

We strongly discourage:

- An under-inflation, which distorts the carcass and may cause a tyre failure.

- The over-inflation which reduces the area of contact with the ground

resulting in a loss of adhesion. In addition the casing is more sensitive to

shocks.

Assembly

Mount the tyres only on the rims they are designed for.

Use rims clean and in good condition, working with clean surfaces.

Use the appropriate tools for the tyres and rims.

To facilitate assembly and disassembly, lubricate the seating (green) and the

beads of the casing (black) with a suitable product as shown in the sketch below.

With a new tyre, use a new inner tube. Use an inner tube corresponding to the

size of the tyre.

After mounting a tyre, ensure the correct centering of the tyre on the rim: if this is

not the case, inflate, deflate and inflate again until the centering is good. Always

use the maximum pressure for positioning the beads on the rim seat 2.5bars (35

psi). Then adjust the pressure to use or to store.

When transporting the equipment by road, rail or boat, you must inflate the tyres

to 2.5 bar (35 psi) to avoid damage from the mooring systems.

Original instruction : French NT0002 V –h – 03/2012

40

Features of tyres available for the Rolltwin :

Type

Service

pressure

Max. load at

40km/h*

Dimension

s

Correction

value

hubodometer

18 4/30 A324 Alliance

3.2

4080

1550x467

1.68

18 4/34 A324 Alliance

4.2

4200

1632x467

1.77

18 4/38 A356 Alliance

4.8

6270

1733x516

1.88

23 1 R26 Prostor

2.8

5000

1605x587

1.74

23 1/26 A347 Alliance

2.8

5030

1605x587

1.74

620/75 R26 A375 Alliance

3.8

6325

1595x625

1.73

650/60 R 34 Els Nokian

4

9400

1644x650

1.78

650/65 R 30.5 A380 Alliance

4

9660

1623x650

1.76

620/75 R 30 Michelin

4

5600

1710x604

1.85

650/75 R 32 A360 Alliance

3.9

7245

1793x645

1.94

650/65 R 26.5 A360 Alliance

4

9110

1520x650

1.65

580/70 R 38 A370 Alliance

3.3

5950

1817x577

1.97

650/65 R 30.5 Michelin

Cargo

4

9660

1623x662

1.76

650/65 R 34 Els Nokian

4

9400

1645x650

1.78

650/65 R 26.5 A380 Alliance

4

9110

1520x650

1.65

710/50 R 30.5 Michelin

Cargo

4

8840

1495x728

1.62

Characteristics of tyres available for the Rollmax

Type

Service

pressure

Max. load at

40km/h*

Dimension

s

Correction

value

hubodometer

550/60 22.5 Diagonal/Divers

3

5300

1360x645

1.48

560/60 22.5 A380 Alliance

4

6710

1245x554

1.35

560/60 R 22.5 Nokian

country

4

6300

1244x560

1.35

560/60 R 22.5 Michelin

cargo

4

6290

1250x560

1.36

580/65 R 22.5 Nokian

Country

4

7250

1300x580

1.41

600/55 26.5 16PL

4

6390

1348x626

1.46

600/55 R26.5 Michelin

Cargo

4

6390

1348x626

1.46

620/60 R26.5 Nokian

Country

4

7900

1400x620

1.52

600/55 R26.5 A380 Alliance

4

7450

1350x620

1.46

650/55 R26.5 A380 Alliance

4

7900

1360x645

1.48

* not all vehicles are approved to 40 km / h, there are versions 40km / h or 32 km / h.

For the type of vehicle, check the sticker on the left rear of the vehicle or the

certificate of conformity.

Original instruction : French NT0002 V –h – 03/2012

41

1

4

2

2

3

12- Lighting:

When replacing a bulb, be sure to respect the indicated power and the connection of

the wire.

reference

function

colours

1

Number-plate lighting

white

2

Brake lights + stop

red

3

Indicators

orange

4

Reflector

red

Note: There is an option to automatically protect the lighting against dung

spray. The lights remain in good condition and well visible to people behind

the vehicle on public roads. The principle is: the protection is activated

whenever the moving floor is engaged.

ENSURE THE ABSENCE OF THIRD PARTIES IN THE AREA OF

PROTECTION ACTION.

Original instruction : French NT0002 V –h – 03/2012

42

8 – Assembly

Installation of a Beacon :

The beacon can be powered via the sidelights, in some cases it can be powered via

a 3-pin plug.

If the power is supplied via the side lights, the maximum power of the beacon is

21 watts

(text in triangle: Caution! Revolving light 21 watts only)

C

C

C

A

A

A

U

U

U

T

T

T

I

I

I

O

O

O

N

N

N

!

!

!

R

R

R

E

E

E

V

V

V

O

O

O

L

L

L

V

V

V

I

I

I

N

N

N

G

G

G

L

L

L

I

I

I

G

G

G

H

H

H

T

T

T

2

2

2

1

1

1

W

W

W

A

A

A

T

T

T

T

T

T

S

S

S

O

O

O

N

N

N

L

L

L

Y

Y

Y

Original instruction : French NT0002 V –h – 03/2012

43

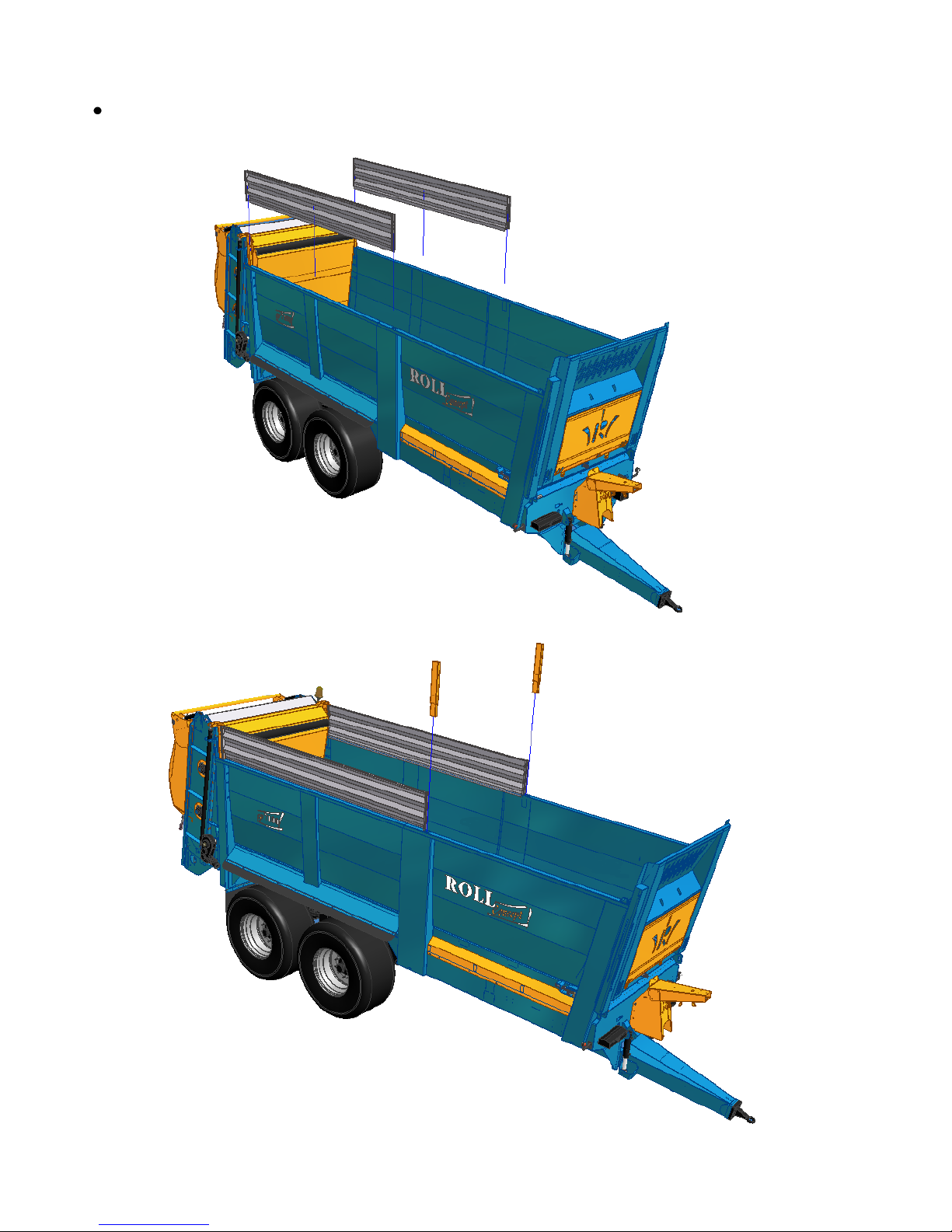

Equipment assembly :

These operations are the responsibility of the dealer, as he alone is

trained and approved. Means of access to the machine must be in

place to ensure there are no risks of falling, among others.

PROCEDURE

After having smeared with grease, install the rear posts. The grease facilitates

their mounting and demounting because adjustments are optimized to ensure the

tightness of the assembly. Fix the sheet metal cladding to the posts mounted at

the rear (side inner body).

Example of means of access for the

installation of silage equipment

Original instruction : French NT0002 V –h – 03/2012

44

Install the rear panels, the middle pillars then fix them with the bolts provided for

this purpose.

Original instruction : French NT0002 V –h – 03/2012

45

Install the front risers followed by the front pillars and then fix them with the bolts

provided for this purpose.

Original instruction : French NT0002 V –h – 03/2012

46

Procedure for mounting the silage doors (option Rollmax)

Before installing your silage door, you must remove the beater frame of your

spreader. The operation must be performed by your ROLLAND dealer, the only

ones authorised, trained and to have the tools.

Procedure for removal of the tool frame

Disconnect the secondary drive shaft

Using slings, hook the framework to an overhead crane (minimum

capacity 2.5 tons for the slings and the crane). The attachment points are

specified in the following diagram. The weight of each subassembly is

specified by stickers.

Loosen and remove the fixing bolts of the body.

Remove the frame using the crane and place it on its support. Fix it to

the support, using the nuts and strap(s) provided. After checking the tightness

and stability, the slings can be removed.

In the absence of a frame support, place the frame flat on the floor on

the hatch side.

Silage panels :

After having smeared with grease, install the rear posts. The grease

facilitates their mounting and demounting because adjustments are optimized

to ensure the tightness of the assembly. Fix to the body of the spreader using

the bolts provided.

Then install the panel (weight approximately 80 kg) using a hoist or a

loader. Lock in place with the pins provided.

Attachment points for handling

the spreading assembly

Optional assembly support

Original instruction : French NT0002 V –h – 03/2012

47

Silage Door « LOULOU »

After having smeared with grease, install the side panels. The grease

facilitates their mounting and demounting because adjustments are optimized

to ensure the tightness of the assembly. Fix to the body of the spreader using

the bolts provided.

On the ground assemble the panel with the top rail by means of the

axes provided. Be careful to put in place the pins to lock the assembly.

By means of a crane, a hoist or a loader put the assembly in place,

panel + traverses. Then fasten the side panels using the bolts provided.

Complete by installing the cylinders with the drum on the body side.

For all operations carried out at heights, a means of access, type scaffolding,

must be available, respecting the standards for this type of equipment and

respecting the standards for this type of product (railings, etc ...).

The cylinders for opening the silage door "LOULOU" are fitted with

dual control valves. Beware of any residual pressure present

between the valve and cylinder.

Left side

panel

Right side

panel

Lubrification

Lubrification

Panel

Attachment

points for

handling

Top rail

Original instruction : French NT0002 V –h – 03/2012

48

9 – Annexes

ANNEX 1

INSTRUCTION FOR USE OF THE HYDRAULIC DRAWBAR

SUSPENSION

1- PRESENTATION OF THE SYSTEM

All drawbars with a damping system rather than a mechanical leaf

spring but consisting of elements using hydraulic technology are called drawbar with

hydraulic suspension.

The system is governed by the tractor. The operator can correct at any

time the height of the drawbar.

2- OPERATING PRINCIPLE

The system is mainly composed of the following elements :

Component

Quantity

Illustration

Suspension cylinder

2

A drawbar suspension

unit equipped with 2

diaphragm

accumulators

1

Drawbar

1

Original instruction : French NT0002 V –h – 03/2012

49

The various elements are assembled according to the following plan :

3- RECOMMENDATIONS FOR SETTINGS AND USE

The drawbar should be adjusted so that the chassis of the trailer is

horizontal.

However, some cylinder movement must be possible to absorb dynamic

impacts ( 3cm)

2 modes of operation are possible :

The operator predefines once and for all its coupling height. In this case he

may leave the supply hoses unconnected on the tractor. It should be noted

that the drawbar works in closed circuit; that is to say that when loading the

spreader, the spreader will sink down, when you start tipping, the cylinders will

again be deployed and no correction will be possible.

This method is strongly discouraged despite a possible saving of a

distributor on the tractor.

Or the user leaves the hoses permanently connected to the tractor. This will

allow an instant correction of the height of the drawbar to compensate for the

movement of the cylinders due to the load variation in the vehicle.

Such use is the "normal" use of the system.

By working this way we obtain the maximum suspension flexibility.

N.B : 2 adjustments are possible at the upper catch of the cylinder. The

method for changing the catch is identical to that of the sprung drawbar (see

page 28)

Original instruction : French NT0002 V –h – 03/2012

50

ANNEX 2

INSTRUCTIONS FOR THE PASSIVE SUSPENSION OF AN

Axle (closed circuit)

1- PRESENTATION OF THE SYSTEM

All axles are equipped with an independent damping system that are

said to be with passive or closed circuit suspension.

.

The circuit is completely independent of the tractor. The suspension is

set once and for all (even though it is changed occasionally). The adjustment is

made so that an optimal displacement is supported. The cylinder movement being

200 mm, the optimal displacement is ± 100 mm.

The user cannot correct the height of his vehicle on the move.

2- OPERATING PRINCIPLE

The system is composed mainly of the following components:

4 suspension cylinders for a vehicle with 2 axles (6 for a 3-axled

vehicle)

1 hydraulic suspension control block

2 piston accumulators

The system is composed mainly of the following components:

Component

Quantity

Illustration

Suspension cylinder

4 cylinders for a vehicle

with 2 axles (6 for a 3-

axled vehicle)

Passive suspension

block

1

Accumulators

2

Original instruction : French NT0002 V –h – 03/2012

51

2 comments :

A system for counter roll of the vehicle is provided in the assembly. Oil will never

"take the easy route". The load will constantly be equal over the four wheels, which

allows us also to "dispense" with tipping stabiliser.

The pressure relief valve is intended for smoothing out any abnormal pressure

peaks (violent dynamic shocks).

3- RECOMMENDATIONS FOR SETUP AND USE

a. To increase the height of the suspension (raising the body) :

To add oil to the suspension system (if, for example, the height is

considered insufficient), proceed as follows:

Connect the hose identified by a marking (long green) to the tractor.

Open the two outer taps of the block (see photo). The middle tap must be

closed.

Supply the oil circuit via the hose connected to the tractor until the required

height is achieved.

Close the two outer taps again and open the middle tap.

Release the residual pressure present in the hose by positioning the tractor

distributor on "float"

Disconnect the hose (long green) from the tractor.

Only the return drain hose (short green) remains connected.

WARNING Note that the height of the skip will vary depending on

the load present inside.

Original instruction : French NT0002 V –h – 03/2012

52

b.To decrease the height of the suspension (lower the body) :

To remove the oil from the suspension system (for example, if the

height is considered too high), proceed as follows:

Connect the hose identified by a marking (long green) to the tractor.

Open the two outer taps of the block (see photo). The middle tap must be closed

Set the relevant distributor of the tractor on position "float" until the required

height is achieved.

Close the two outer taps again and open the middle tap.

Release the residual pressure present in the hose by positioning the tractor

distributor on "float".

Disconnect the hose (long green) from the tractor.

Only the return drain hose (green short) remains connected.

RECOMMENDATIONS FOR USE :

The hose used to adjust the height of the skip should be connected only in case of

need to work on the suspension. In normal operation, this hose should be stored on

the hose holder.

In contrast, the hose "drain" (oil reflux by high over pressures) must be permanently

connected to the tractor.

Original instruction : French NT0002 V –h – 03/2012

53

ANNEX 3

INSTRUCTIONS FOR THE HYDROPNEUMATIC SUSPENSION

OF AN AXLE (open circuit)

PRESENTATION OF THE SYSTEM :

All undercarriages equipped with a damping system with instant

automatic level correction are said to have hydropneumatic suspension.

The system is permanently coupled to the tractor. The ideal is to

provide a single acting valve (LS if possible) and a free return to the source.

Pressure can also be taken at the pump outlet without using a distributor since a

continuous pumping is required.

The vehicle corrects its height instantly, which is to say that when

loading the vehicle, the hydraulic system will demand the tractor to re-adjust the

height of the skip and vice versa, during unloading, the system will return oil to the

tractor..

PRESENTATION OF THE SYSTEM :

2-1 : The system is composed mainly of the following components :

Component

Quantity

Illustration

Suspension cylinders

4 cylinders for a

vehicle with 2 axles (6

for a 3-axled vehicle)

Diaphragm accumulators

4 cylinders for a

vehicle with 2 axles (6

for a 3-axled vehicle)

Hydraulic suspension

control block

1

Pressure compensator

1

Vehicle level detectors

2

Cab-located control box

1

Original instruction : French NT0002 V –h – 03/2012

54

2-2 Functions of the buttons on the control box :

Red button:

Up manual raising of the vehicle

Down manual lowering of the vehicle

Green button :

set to automatic mode or system initialisation (chapter 3-1)

2-3 Hydraulic connection diagram :

For confidentiality reasons, we will not disclose our hydraulic circuit

diagram. In case of hydraulic concerns, please contact us..

Comment :

- A system for counter roll of the vehicle is provided in the assembly. Oil

will never "take the easy route". The load will constantly be equal over the four

wheels, which allows us also to "dispense" with a tipping stabiliser.

-The pressure relief valve is intended for smoothing out any abnormal pressure

peaks (violent dynamic shocks).

Original instruction : French NT0002 V –h – 03/2012

55

3. RECOMMENDATIONS FOR SETUP AND USE

3-1 Initialisation of the system :

Like with any electronic control system, an initialisation is required so

that the system is able to instantly know its position relative to its upper and lower

limits.

The initialisation consists of the detection, validation and memorisation

of the upper and lower limits.

- Initialisation procedure :

A blinking 1-1 appears on the box (see decoding blinks p8-9)

Using the red button, fully raise the suspension manually. Do not release the button

until the cylinders are completely deployed (200 mm travel)

Wait 2 seconds in the upper position.

Using the red button, fully lower the suspension manually. Do not release the

button until the cylinders are completely retracted (the vehicle must be

horizontal)

Wait 2 seconds in the lower position.

Return to the "auto" mode by tilting the green button.

The vehicle will automatically find its position and the LED lights permanently on

the box

Remarks :

The initialisation parameters are stored in the box. It is not necessary to restart the

process at every power up of the system. Initialisation has already been done in the

factory. An initialisation on-site may be required only in case of an intervention on

any of the system components.

If the vehicle does not automatically find its position and blinking 1-1 on the box

indicator continues, it means there is a problem at one of two sensors at the rear

(bad adjustment range) contact us.

3-2 : Decoding the blinking of the box indicator :

When the control box light flashes, the operation is not in a "normal" state.

Either the system is in its initialisation phase (blinking 1-1)

Or the system has detected an anomaly. The system therefore closes down.

No action is possible (automatic or manual mode).

The system is able to detect the following defects :

Failure or breakage of the wire link of the position sensors (electrical

connection)

Original instruction : French NT0002 V –h – 03/2012

56

Overload or breakage of the wire connection of the solenoids (electrical

connection)

If one of these fault situations occurs, the lamp flashes and the solenoid control

switches off for safety reasons. Similarly, in manual mode, no function can be

executed.

The user must validate the fault by switching off the power to the electronics module

for 3 seconds and then putting it back on.

Flashing signals & fault codes provided by the box indicator :

Example for fault code "2-1"

:

Defect left sensor

Decoding table of the signals emitted by the box indicator:

Indicator signal

Components to be

checked

Possible cause of the defect

Permanent signal

Automatic mode, no defects

‘’1-1’’

Initialisation mode, no defects

‘’2-1’’

Left position sensor

Wire link broken or not connected.

Output signal of the position

sensor out of range, check the

mechanical adjustment

‘’2-2’’

Right position sensor

Wire link broken or not connected.

Output signal of the position

sensor out of range, check the

mechanical adjustment

‘’3-1’’

Solenoids

- WSL (WS1)

- WSR (WS2)

Wire link broken or not connected.

Possible overload

Check the connection LGND

‘’3-2’’

Solenoid WK

Wire link broken or not connected.

Possible overload

Check the connection LGND

Original instruction : French NT0002 V –h – 03/2012

57

REMARKS :

Several options can be grafted onto this system.

4-1 : Option lift axle :

An option "lift axle" is available on this type of suspension. This option

relieves the front axle or lifts the front wheels completely.

This function replaces fully the weight transfer (or tipping stabiliser)

.

: If vehicle is equipped with a steering axle (or forced follower), it is

strictly forbidden to raise the front axle at a medium or high forward

speed (on the highway). The function should be used only when tipping

or by lack of grip traction on the ground, for example, as in the case of

the spreader.

4-2 : Load weight option :

A load weight option is available for this type of suspension.

A battery of three pressure sensors measures the hydraulic pressure at

different locations within the system. This pressure information is transcribed to a

box in the cabin which gives us information on the load in the vehicle.

A patent for this system has been applied for by Ets Remorques ROLLAND

Original instruction : French NT0002 V –h – 03/2012

58

Date

Operation

Remark

Initial

-Check the wheel nuts

After 50 km, then 2 times per year or at

the beginning of each campaign.

- Check inflation pressures

2 times per year or at the beginning of

each campaign.

- Check tightness of the axles

or the rocker pin

2 times per year or at the beginning of

each campaign.

- Lubrication of the points

indicated in the instructions

Verify before each use

- Check the correct tension of

the service brakes, the

emergency and parking

brakes.

Adjust the play as necessary

Operations to be performed at the start

(the DEALER)

Original instruction : French NT0002 V –h – 03/2012

59

Maintenance log

Date

Operation

Remark

Original instruction : French NT0002 V –h – 03/2012

60

11- EC declaration of conformity for machinery

(According to Annex IIA of the Machinery Directive 2006/42/EC)

Manufacturer : Ets ROLLAND

Address : Z.A des Landes 29800 TREFLEVENEZ

Name and address of the person authorised to compile the technical file:

Name : Béatrice LE GALL

Address : Z.A des Landes 29800 TREFLEVENEZ

Hereby, we declare that

The machine :

- Make : ROLLAND

- Commercial designation:

- Type :

- Serial no. :

complies with the relevant provisions of the Machinery Directive (2006/42/EC).

Furthermore, we declare that

the following (parts / sections of) harmonised European standards were used..

-EN ISO 12100-1 & 12100-2

TREFLEVENEZ,

Name and position of the signee

Béatrice LE GALL

CEO

Original instruction : French NT0002 V –h – 03/2012

61

A copy to be stored in this manual

OPERATOR

Name : ……………………………………………………………………………………………….

Address : ………………………………………………………………………………………………

Postcode : …………………City: …………………………..Country………………………………..

Telephone : ……………………………… Mobile tel. …………………………………

Fax : ………………………… Email : ……………………………………………………………….

VEHICLE

Vehicle type : …………………………………………………………………….………………

Serial N° (on the invoice or the conformity plate) : ………………………………………………….

Date of purchase : …………………………………………………………………………………….

Date of delivery : …………………………………………………………………….……………….

WARRANTY CONDITIONS

Our vehicles are guaranteed for 1 year from the date of delivery. Conditions of use are specified in

the booklet of commissioning supplied with the vehicle. In all cases the user must observe the

rules of use prescribed, otherwise the warranty will not be accepted. Travel and transport are not

covered by the warranty. Only fully paid vehicles will benefit from the warranty. In case of

problems the user must first contact the dealership.

I certify having read the commissioning and maintenance manual and undertake to