1

Dear Client,

You have just purchased a ROLLAND spreader.

We would like to thank you for the trust you have placed in us.

ROLLAND spreaders have been studied so that their spreading

technique can be maximised. They are the product of our technology and

experience in this field.

This manual must be considered as forming an integral part of your

spreader.

For proper usage, and to be able to take advantage of all of your

spreader’s capability, we recommend that you read this manual carefully,

and adhere strictly to all of the instructions contained herein.

The correct functioning and durability of your spreader will depend

on this, as will your safety and that of others.

Keep this document in its entirety should you need to consult it in due

course. This must always be kept in the spreader, even in the event that it is

resold.

Failure to adhere to the instructions contained herein release both the

manufacturer and seller from all liability.

We reserve the right to add at any time those modifications that we

deem useful for our products etc, without the obligation to previously

delivered products or those under construction. We also reserve the right to

modify without forewarning the models defined in our catalogues, leaflets

or appearing on our web site.

Please accept our best wishes and most sincere thanks.

Z.A des Landes

29800 TREFLEVENEZ - FRANCE

Tél. : 00 33 (0)2 98 85 13 40

Fax : 00 33 (0)2 98 21 38 15

www.remorquerolland.com

Notice originale : Français NT0002 V –p – 03/2014

2

Contents

1-Safety Instructions……………………………….………………….3

2-Warranty Conditions…………………………………………………4

3-Vehicle Presentation……………………………………………….5

-Usage Scope

-Vehicle Identification

-Technology and Options

4-Implementation…………………………………………………...20

5-Standard Usage and Counter-Indications……………………….….29

-Parking

-Loading

-Transport

-Spreading

6-Adjustments……………………………………………………….32

-Jib

7-Servicing and Maintenance……………………………………….34

-Braking Systems

-Ro-Ro Transport

-Cleaning / Lubrication

-Regulation of Belt Tension

-Tracker Adjustments

- Maintenance Regulator and Hydraulic Power Stations

-Consumable parts

-Maintenance of Electrical Boxes

-Wheels and Tyres

-Lighting

8-Assembly………………………………………………………….48

-Rotating Warning Lights

-Equipment

9-Annexes………….………………………………………...…………..54

-Hydraulic Jib

-Passive Suspension

10-Maintenance Log……………………………………….……………59

11- Declaration of Conformity.……………………………………....... 61

12-Warranty Certificate – Service implementation declaration …….62

Notice originale : Français NT0002 V –p – 03/2014

3

1 – Safety Instructions

Before putting into service, please study the operating instructions and respect safety

guidelines!

In these user instructions all hazards and risks to which

operators or other exposed persons are subject to have been

highlighted by this symbol.

Glued onto the spreaders, safety signs indicate

how to use the machine without danger:

Respect for the notices = safety

Standard Usage

The spreader has been designed and

manufactured for the standard usages

described in this manual

Four situations are defined herein: Parking,

loading, transport and spreading (chapter 5)

Nonetheless, a certain number of foreseeable

non-conformity scenarios are questionable

and specifically forbidden. The manufacture

will not be for damages resulting from these

actions.

It is of the utmost importance to respect the

contingency regulations against accidents as

well as the other applicable legislation in

force in terms of safety, health provision in

the workplace and the Highway Code.

The manufacturer waives all liability with

respect to damages caused as a result of an

unauthorised modification of the machine.

General Safety Regulations and

Contingency Plan against Accidents.

1. Definition of the vehicle’s consignment:

before undertaking any actions on the

machine, switch off the engine, release the

hydraulic pressure, apply the parking

brakes (tractor AND trailer) and remove

the keys from the ignition.

2. Prior to starting the tractor's engine, take

care to ensure that the power take-off is

not engaged and that all safety devices

have been equipped and are in perfect

working order.

3. Never disengage or deactivate safety

device. For adjustments, servicing and

maintenance, the procedures described in

the manual must be strictly adhered to

(above all chapters 6/7.

4. It is wholly forbidden to pass under the

vehicle when operational.

5. The machine’s usage is done so entirely at

the responsibility of the driver. The

absence of third parties in the vicinity of

all manoeuvres must be guaranteed.

6. Given the residual risks from collisions or

damage at the spreader apparatus (AND in

its projection area) and that it is

technically impossible to protect it (at the

very least during the working phase=, it

falls under the responsibility of the driver

to ensure that no third parties are present

in the environs when the machine is in

movement.

7. The driver must be fully empowered to

use the machine in the most appropriate

conditions.

Notice originale : Français NT0002 V –p – 03/2014

4

2 – Warranty Conditions

In order to benefit fully from the manufacturer’s warranty, please make sure

you follow the maintenance operations and utilisation advice provided in this

manual. Should any problems arise, the user must contact the dealership.

Warranty Conditions:

Our spreaders are guaranteed for parts and labour for one year, counting

from the date the machine is into service.

Under no circumstances can ROLLAND S.A. be held responsible for an

incident arising from the failure to respect these instructions for handling,

servicing or maintenance of the machinery.

The guarantee is valid only for the supply and replacement of defective

parts.

The warranty is invalid and we waive all responsibility in the following

instances:

1°) where the machine has been modified using elements constructed outside

of our workshops or those not manufactured by our distributers without our prior

authorisation.

2°) where the original serial number has been falsified.

3°) where the factory assembled pieces produced by ROLLAND have been

disassembled and replaced by parts of a different origin.

4°) where breakdowns and malfunctions are the result of negligence, misuse,

overloading, including even passengers, the lack of operational knowledge on

the part of the user, or due to the introduction of a foreign body into the machine

during operations or failing to lubricate it properly.

Repairs, modifications or replacement of pieces during the warranty

period cannot extend the duration of the warranty for the materials.

Following the receipt of your vehicle, make sure that this is in all points,

compliant with the technical specifications and that this has not suffered any

damages.

In order to speed up the guarantee implementation process

“THE GUARANTEE IMPLEMENTATION DECLARATION” accompanying

this technical notice must be completed and returned in the month

following delivery.

Notice originale : Français NT0002 V –p – 03/2014

5

PTAC _ _ _ _ kg

PV _ _ _ _ kg

3 - Presentation of the vehicle

This manual is standard for all ROLLFORCE and ROLLMAX spreaders from the ROLLAND

range. It has been designed with the aim of giving you all the necessary information on the

vehicle that you have just purchased and to get the best from it.

DESCRIPTION :

The spreaders are all fitted with either a “ROLLAND” sturdy suspension beam , or they may

also be fitted with a "ROLLFAST” hydraulic suspension rod.

These are mounted onto a chassis fitted with an adjustable, spring, or hydraulic jib.

Identification :

To know the features of your trailer, please refer to the sticker board attached below the right

front side of your vehicle. A plate with a self-adhesive sticker will also state the total

authorised load weight (TALW) and the empty weight (EW).

A cold stamping (serial number) is fitted under the vehicle's chassis.

This serial number is necessary all warranty exchanges with your dealership or the factory

MAX WEIGHT STICKER

DISCPLATE

Notice originale : Français NT0002 V –p – 03/2014

6

Towed agricultural vehicles are governed by two different regulations:

The Labour Code

The Highway Code

Rolland’s vehicles come supplied with their official documentation and a label containing the

EC conformity stamp. These two documents verify that the two sets of regulations have been

adhered to.

In addition to this label and depending on the options selected, complementary markings

(TALW, hydraulic weighing or on rod gauges, 1,2 or 3 axles, roll-control…).

Notice originale : Français NT0002 V –p – 03/2014

7

1

Chassis

7

Ro-Ro Transport

2

Front Deck

8

Spiked roller

3

Protective Hood

9

Hatch

4

Front Nose

10

Spreader Frame (2100Kg maxi)

5

Jib

11

Spreader Deck

6

Jib regulator

ROLLFORCE

ROLLMAX

Sideways View

ROLLFORCE ROLLMAX

Front and rear view

Notice originale : Français NT0002 V –p – 03/2014

8

Rollforce

Jib

Rollmax

Jibs

Swivel ring

(std)

Flat ring

DIN Ring

K80 Spoon Ring

Technology and options available:

Demount Ring

Jibs with 8 hole interfaces allowing for the mounting of several types of rings: flat, swivel,

spoon, DIN).

Notice originale : Français NT0002 V –p – 03/2014

9

Simple axle

(ROLLFORCE)

Undercarriage

(option on

ROLLMAX

5420, 6325

and7130)

Offset pin bogie

beam (standard

on ROLLMAX

5420, 6325

and7130)

Semi - Tandem

(option on

ROLLFORCE)

Rod Tandem

(option sur

ROLLMAX)

Triple Axle

(standard on

ROLLMAX

8735)

Rollfast

(option on

ROLLMAX)

Direction of Travel

Haulage :

Notice originale : Français NT0002 V –p – 03/2014

10

Power Source

Function

Command

n° d'avance

1) Open tractor :

operates due to the tractor’s

coupling connectors

1) Base:

Forward drive belt solely

Manual adjustment

110

Without display

111

With display

112

With display+DPA

113

2) 2 functions :

With display

Without display

121

With display

122

With display+DPA

123

3) 3 functions :

forward drive belt + hatch

+fume hood

Without display

131

With display

132

With display+DPA

133

2) Pump:

The pump is mechanically

activated using the power take-off

and multiplier located upwind

(during repairs, troubleshooting or

servicing, the coupling elements

may be connected to the traction,

as per the basic diagramme below).

1) Base:

solely with forward drive

belt

Without display

211

With display

212

With display+DPA

213

2) 2 functions :

forward drive belt + hatch

Without display

221

With display

222

With display+DPA

223

3) 3 functions :

forward drive belt + hatch

+fume hood

Without display

231

With display

232

With display+DPA

233

N.B : To carry out this operation in reverse it is necessary to invert P and T1 either push-pulls 1 and 3 on

the tractor.

Flexible repair

kit

Towards tractor

Do not forget to

Advancing : There are several types of forward movement, and in each case several of these can be

managed from the junction box in the cabin as well as from the tractor control unit which is always on

standby. See the table below for the current existing combinations : Troubleshooting tractor repairs

(Insulation pump ).

connect the coupling

Procedure for carrying out traction repair: 1- Disconnect the push-pull 1 and 2 and push-pull 3 and 4.

2- Connect push-pull 2 and 4 between them with the help

of connector kit K1.

3- Connect push-pull 1 with one with one of the two

troubleshooting connectors on the pressure side of the

tractor distributor.

.

Notice originale : Français NT0002 V –p – 03/2014

4- Connect the push-pull 3 with one of the two

troubleshooting connectors on the return side of the

tractor distributor.

11

Rest on the knurled nut to

perform AR manual

operation

Use an allen key and tighten

the hc screw to empty the

machine manually (manual

repair).

For utilisation in LS mode, connect

the flexible to the opening with the

LS markings, then support and screw

the left knurled nut

Procedure for carrying out traction repair (please refer to traction repair on page 10)

Repair of the distributor in forced mode

Use a screwdriver to force open manually a section of the distributor

(Opening or closing the hood trap, as in the photo)

N.B : A collar is fitted as standard to prevent shifting to LS involuntarily (causing risk

Notice originale : Français NT0002 V –p – 03/2014

of pump deterioration !!)

12

Element

Function

Forward motion in

question

Fuel tank

Contains around 80 litres

of oil to power the pump

(1 emptying per year or

every 200 hours’ usage)

Viscosity Index: 46

211, 212, 213, 221, 222,

223, 231, 232, 233

Multiplicator

Provides the impetus to

turn at1000r/min to spin

the pump 3000 tr/min (1

emptying per year or after

every 200 hours’ usage)

Amount : 0.32 litres max

Viscosity Index : 400

211, 212, 213, 221, 222,

223, 231, 232, 233

Pump

Oil fuel pump from the

tank to the distributor with

output rate of 50 l/min to

1000 tr/min (power takeoff)

211, 212, 213, 221, 222,

223, 231, 232, 233

Connector kit K1

This coupling kit allows

for the disconnection from

the regulator and the

pump. This is essential for

its protection.

211, 212, 213, 221, 222,

223, 231, 232, 233

Terminal block

Attaches all the different

sensor threads to a harness

112, 113, 122, 123, 132,

133, 212, 213, 222, 223,

232, 233

Reductor 1/40

Reduces engine speed so

that the belt operates at

working speed.

All models

This table explains the functions of the elements that comprise the 18 types of forward

motions in use. In the column « forward motions in question>> we have the numbers of the

forward advances used by the item in that line (for example in 122, two forward motions are

used in 121, 122, 123, 221, 222, 223).

Notice originale : Français NT0002 V –p – 03/2014

13

Element

Function

Stage in question

Hydraulic Engine

Powered by oil, this

maintains the reductor that

supplies the belt. A 160

cm³ engine for simple

drills and two motors of

130 cm³ mounted side by

side for double drills.

All models

Proportional Regulator

Ensures even oil

distribution throughout the

circuit, in proportion to any

given electrical data.

Pressure filter to be

changed annually. This unit

is fitted with two pressure

caps to safeguard emptying

and clearance operations.

111, 112, 113, 211, 212,

213

2 –way distributor

Allows for oil feed for

shock absorbers and hatch

functions.

121, 122, 123, 221, 222,

223

3-way distributor

Allows for oil feed for

tappet and hatch and

tractor funnel functions.

131, 132, 133, 231, 232,

233

Inductive wheel sensor

Gives the distance run with

the spreader in tow.

112, 113, 122, 123, 132,

133, 212, 213, 222, 223,

232, 233

Inductive sensor on the

reductor

Indicate the distance

covered by the shock

absorber and their

condition.

112, 113, 122, 123, 132,

133, 212, 213, 222, 223,

232, 233

Pressure gauge

Inform the user of the oil

pressure within the circuit.

112, 113, 122, 123, 132,

133, 212, 213, 222, 223,

232, 233

Manual regulator

Ensure even distribution

of oil throughout the

circuit. This is adjusted by

a rotary selector.

110

Notice originale : Français NT0002 V –p – 03/2014

14

Element

Function

Forward

movement

Controls the fanbelt and regulates

its speed, 2 setting ranges (hare /

tortoise) for optimal operational

capacity.

Clearance is achieved through the

tractor’s distributor command

box.

111, 211

Controls the fanbelt and regulates

its speed, 2 setting ranges (hare /

tortoise) for optimal operational

capacity. The screen displays the

belt speed, the hydraulic pressure,

and the distance travelled by the

belt.Clearance is achieved through

the tractor’s distributor command

box.

112, 212

On top of the basic functions, it

can invert the belt’s direction,

give the order for the hatch (2

functions) to be opened and also

the escape funnel TCE (3

functions).

121, 131, 221, 231

On top of the basic functions, it

can invert the belt’s direction,

give the order for the hatch (2

functions) to be opened and also

the escape funnel TCE (3

functions).The screen postss the

speeds, hydraulic pressure and the

distance covered by the belt.

122, 132, 222, 232

3-Way command box with FP

(Forward Proportional Debit).

The screen posts the speeds,

hydraulic pressure and the

distance covered by the belt.

113, 123, 133, 213,

223, 233

The different control units

Notice originale : Français NT0002 V –p – 03/2014

Axle lock:

15

Component

Quantity

Illustration

Hydraulic block 1 axle

1

Component

Quantity

Illustration

Hydraulic block 1

2

The axle follows the vehicle and operates by displacement caused by turns, and should be

blocked whilst travelling (at average or high speeds) and in reverse.

The auto-pilot axle is an axle controll cylinder located on the vehicle’s jib, a closed

hydraulic circuit with nitrogen-filled spheres to keep up the pressure. A tread needs to be

placed on the tractor. It is to be noted that Rolland auto-pilots can be turned into axles

when attached to a treadless tractor since the blocking cylinders of the axle lock have been

preserved. The advantage of this system is that heat doesn’t need to enter at the point of

driving motion, whether forwards or in reverse.

Rolling mechanisms with 1 auto-piloted axle mainly comprise of the following element:

Rolling mechanisms with 2 auto-piloted axles are mainly composed of the following

elements :

Do not connect the shut-off tube on the axle lock when pipe is in auto-pilot

mode.

Notice originale : Français NT0002 V –p – 03/2014

16

Weighing box

Weighing sensor

Data analysis software

Compact printer

Hydraulic flaps:

Hydraulic flaps are available as an option with models V17, V21 and V25 for C10 and

ROLLFORCE spreaders. Thjese flaps facilitate spreading operations on the borders of land

plots. It is possible to have a left or right-sided flap, or even one on both sides.

Weighing:

ROLLFORCE and ROLLMAX spreaders are able to be fitted with weighing

systems.Weighing information is shown on the jib or axle mounted sensors.Weighing

information is then caught on the weighing control box. The data is then recorded in the box

by client or plot of land worked. Over and above the weighing system, the user may instal

data evaluation software which enables client or plot management (data memory up to 65

000 weighings).A compact, on-board battery operated printer which issues a ticket giving

information on load weight, cumulative totals, by client or land plot is also available as an

option.

Notice originale : Français NT0002 V –p – 03/2014

17

Characteristics :

- Aluminium box

(Dimensions : l = 160mm, L= 110mm, P= 40mm)

- IP 67.

- Protected against reverse polarity. -

Beam base IP68.

- Screen 2*12 characters with blue backlight.

- Printing option.

- Command 6 solenoid valves (3A max)

Printer

(Optional)

Prininting plate

(Optional)

FPD (Foward Proportional Decrease) :

Please note :

As soon as the box is correctly wired, you may go ahead and use the product as

follows :

-Press the ON/OFF switch (1) to the ON position.

Notice originale : Français NT0002 V –p – 03/2014

18

Normal Menu

Operation

A page which permits spreader speed

reference configurations in FPD mode.

A page which permits previously returned belt

speed configurations.

A page which indicates the number of

hectares worked since the spreader set off ;

this counter can be reset to zero by pressing

Page signalling the distance travelled by the

bbelt in metres since the spreader was

brought into service.

A page which indicates the number of hectares

worked since the spreader set off; this counter cannot

be reset to zero.

A page which allows the length of the

spread to ber configured, this set-up is

important in calculating surface areas

worked.

Normal display :

The machine’s speed of travel is given in kilometres per hour and emanates from the sensor attached to

the machine’s wheel.

Fan belt speed is given in metres per hour and originates from the sensor mounted on the belt (on the

reducer).

FPD mode : allows for the setting up of machine tuning guides

This function is activated by pressing on button « » (5).The setting up of parameters is carried out

by touch « » (4) which in turn causes the cursor to move. Cursor position signals the number which will be

modified on touching « + » (3) et « - » (2).

After set-up of first adjustment, press on 1

set-up .

The adjustable set ups are :

st,

press by touch « » (5) to change menu and save the

Notice originale : Français NT0002 V –p – 03/2014

19

A page which allows the configuration of

the system reactivity index, this setting is to

be adjusted in order to avoid belt pumping.

A page indicating work time (belt

deployment time) since it was last reset to at

zero. Resetting to zero can be done by

pressing touch for this counter (4) .

Page indicating working time (total belt

operating time) since being brought into

service. It is not possible to reset this counter

to zero.

Client :

-----------------------Surface : 10.0 Ha

Time : 0010 H 25min

P 20) Press on the pushbutton which is to be found on the upper FPD lid

in order to give ticket print-off order.

The printing settings are as follows:

- The surface area worked since last zero reset of the part-hour

counter.

- Time in service since last reset to zero on the hour gauge

Page which indicates in metres the total belt

travel distances since it was last reset to

zero by pressing on touch(4)

- It isn’t possible to print a ticket if you’re on the main

page.

Manual mode:

Manual mode is activated by changeover from the 2nd switch (6) to

« manual », but there is then no speed adjustment. The hydraulic block can be

varied by the intervention potentiometer which will alter the current which

can alter the current from 0 to the highest factory setting.

Ticket Printing (Option) :

Stop mode :

Stop mode is reached by centring the switch (6), which causes a ceasing of adjustment.

Notice originale : Français NT0002 V –p – 03/2014

20

OR

OR

4- Commissioning

Trailer hitching :

Hitched trailer speeds should not exceed 25 km/h or 40 km/h (according to model). The

attachment is assured via a standardised ring (all hitching types can be secured by using a

bracket, flange and pin).

PROCEDURE

Ensure that the tractor used can tolerate the weight burden

imposed by the trailer.

After hitching the trailer to the tractor, check that the cup plate is

properly positioned and secured in the locked -on position.

Before commissioning, check that all applicable points have been

greased (see the maintenance chapter)

Adjustable tractor hitching (automatic bracket or collector) :

Reverse slowly, with tow bar lowered and ring and tow pole married up.

Once in position, raise the towing apparatus (the ring will automatically find its own level).

Lockt he device in place.

Re-introduce the hydraulic or mechanical stand.

Attelage tracteur fixe (ringbolts, tow plate, hitch bar) :

Place the stand in position (ring above the ringplates or at tow plate level, or at the

hitching bar level).

Adjust hitching devices (tractor and machine) :

the ringbolt and then move down ring (the ring will automatically find

its own level).

Tow plate

Hitch bar

Manoeuvre tractor into position where necessary

Place the stand support in position and lock the stand.

Connect all hydraulic cables (tyres optional).

Wire up the lighting.

Tyres :

At the time of vehicle commission, it is vital to check and adjust pressure in line with the

tyre’s load-bearing capacity and the conditions under which the vehicle is to be used.

Notice originale : Français NT0002 V –p – 03/2014

21

Flexible

marking/tagging

Function

Flexible

marking/tagging

Function

Braking

Belt pressure

(DE)

Belt return

(DE)

Funnel closing

(DE)

Funnel opening

(DE)

Load transfer

(SE)

Axle locking

(SE)

Axle locking

(DE)

Hatch opening

(DE)

Hatch closing

(DE)

Hydraulic boom

cylinder output

(DE)

Hydraulic boom

cylinder return(DE)

Hydractive

suspension pressure

(DE or SE)

Hydractive

suspension return

(DE or free return )

Passive suspension

pressure (SE)

Passive drain

suspension

(Free return)

*SE : Simple Effect distributor

(pressure/ floating position)

*DE : Double Effect distributor

Connecting the pressure lines :

Connections can be made when the motor is turned off, when hydraulic

pressure has been released, and with the contact key taken out.

Notice originale : Français NT0002 V –p – 03/2014

22

Repère

Element

Function

1

Brake drums

Ensures braking

2

Brake jacks

Activate the braking pins when in motion .

3

Brake cable

Makes the connection between the handbrake

and the braking pins

4

Pipes (connected to the tractor)

Lubricates the braking jacks

5

Stationary brake

Hand brake

6

Trailer release cord (attache to a fixed

tractor point)

Puts on the hand brake in the event of trailer

separaration

Breaking circuit :

Spreaders come equipped with three braking systems, each of which ensures precise

operating.

When stationary, the hand brake should be used (manual). When moving, it’s the hydraulic

or pneumatic brake which is used. The third system is a back-up systyem in the event of

trailer separation (cord between the hand brake and and a fixed point in the tractor).

Connect the security cord in the event of trailer separation; this activates the parking brake.

Check for good cable tension to the connecting rods at the outset of each journey.

PROCEDURES

Any trailer whose load bearing weight PTAC exceeds 1.5 tonnes is

automatically equipped with assisted braking. This can be connected to

the tractor’s braking system.

Hydraulic braking circuit :

Install red hose (4) on the pressure outlet « BRAKES» on the tractor.

Ensure full functioning of the command box and the absence of leaks from the couplings.

Braking pressure : 100 to 130 bars.

Notice originale : Français NT0002 V –p – 03/2014

23

Element

Function

Illustration

Emergency relay valve

(ERV)

Ensures proper service braking as

well as automatic trailer braking in

the event of the trailer braking or the

lowering of pressure from the feed

pipes.

Static corrector

(optional)

For regulating braking pressure, and

therefore braking power, in

accordance with the vehicle’s state.

Relay valve

(optional)

Allows constant piloting of the

command circuit.

Brake release valve

Allows the release of the trailer

service brake after loosening the

automatic brake caused by

uncoupling the connecting pipes.

Reservoir + purge

Air supply tank under pressure.

Opening it allows moisture in the

circuit to be released.

Command coupler head

(yellow )

Allows braking commands between

the tractor and trailer.

Command coupler head

feed (red)

Ensures a constant feed between the

tractor and trailer.

Tank

Ensures service braking at the front,

and stationary braking at the back

through the double spring.

Pressure points

Allows circuit pressure to be

controlled

Pneumatic braking circuit

N.B : Braking can also be mixed( pneumatic hybrid hydraulic assembly) (Assembly

prohibited above 40 km/h)

Notice originale : Français NT0002 V –p – 03/2014

24

Pneumatic braking on two axles at (example) (40 km/h)

Installation of the drive shaft:

PROCEDURE

. All transmissions should be covered by a protector in a good state of

repair

. Any protector found below these standards should be replaced

immediately

Do not forget to install protectors and to fasten them by their chains.

Never start up power take-off without the required protectors being in

place.

. Wearing loose fiting clothing can be a source of accident.

. At the time of first use, it may prove necessary to adjust transmission length. To do

this :

Ensure the correct length of drive shaft tubing.

The tubes must not hit against the crossbeams during extreme turning manoeuvres

Minimum tube casing 500mm

There are several types of security on the tubes; traction bolt shearing or cam shaft security.

In the event of track bolt shearing the bolt must be replaced with the same type and quality as

the original one. Replacement with a more solid bolt will cause the vehicle to deteriorate.

N.B : For starting off en route, the use and maintenance of (primary and secondary)

transmission) please refer to the specific notices supplied with the machine by the

manufacturer.

Notice originale : Français NT0002 V –p – 03/2014

25

(Not used)

Left Flasher

Right Flasher

Mass

Left light

Right Light

Stop

(**)

Tab slit

A

Pin slit

B

Flat

Electrical Connections :

1- LIGHTING

The vehicles have a regulatory and standardized lighting system. It is mandatory to connect it

to the electrical system of the tractor.

PROCEDURE

. Never start without having checked the functioning of vehicle lighting

system: your safety and that of others depend on that. Do not leave wires

pending near the transmission.

Connect the multi-spindle socket (A) without forcing and in correct direction, the tab

should be in the slit.

(**) Attention : Our mounting system respects the standard in force regarding the

independency between the right and left lights. Depending on the compliance of tractor, a

bypass on front socket might be necessary.

If this is the case : Rolland can’t be held liable for the failure of lighting circuit and the

eventual consequences. This bypass is of client’s responsibility.

2- OPTIONAL EQUIPMENTS

Connect the 3-pin plug (B) without forcing, the direction is indicated by flat pin.

This plug is present in all the equipped machines: electronic boxes, weighing and

Notice originale : Français NT0002 V –p – 03/2014

centralized greasing system, or even in control of door opening, for example.

26

18

180

Axle of boom/ jig ring

Clevis fixed on

tractor

Installation of the auto-pilot system:

The auto-pilot axle requires the installation of a pilot cylinder. According to your trailer, you

may have to mount one or two clevis mountings in your tractor. These clevis mountings aren´t

warranted by ROLLAND. According to the brand and model of the tractor the positions of

clevis mountings may vary.

For one auto-pilot axle For two auto-pilot axles

When the tractor is fully blocked, check that there is approximately

20mm margin at the piston rods of rolling i.e. they are not completely in

or out.

Mounting the clevis:

The axle of the ball cylinder must have a minimum distance of :

180 mm for a simple cylinder mounting

120 mm / 160 mm for a double cylinder mounting

The ball cylinder´s axle must be remote:

18 mm of the boom/jib´s axle.

Notice originale : Français NT0002 V –p – 03/2014

27

160

120

Rear axle´s command cylinder

Front axle´s

command cylinder

120

Boom/Jib´s

cylinder

160

18

Installation of the cylinder:

To do this operation, we can´t have any pressure in the circuit. If your machine has only one

cylinder, the automatic lock system enables its easy implementation. Simply attach the

cylinder to the tractor and slowly steer for blocking. However, if your vehicle has the two

cylinders on the jib, put cylinders up manually.

The adjustment should be made with the tractor and trailer hitched

aligned, straight wheels, cylinder attached. It is recommended to drive

straight ahead for about 10 meters. Make sure the handbrake of the

tractor is pulled.

PROCEDURE

Close the selector valve of the circuit

Open the isolating valves of the different circuits.

Using the manual pump, increase the pressure of the circuits

Between 20 and 35 bars maximum for mounting of a simple cylinder with a diameter of

40/80(the manual pump’s valve must be closed)

Between 20 et 35 bars maximum for the mounting of a double cylinder

When the pressure stabilizes (it is tolerated a deviation of 5 bars) close the valves of the

circuits.

To re-use the hydraulic jack, simply re-open the selector valve. (make sure the auto-pilot

valves are closed)

To decrease the pressure in the circuit, you must close the selector valve of the circuit,

open the valves of different circuits and open the valve on the hand pump. The oil then

returns to the pump.

Notice originale : Français NT0002 V –p – 03/2014

28

Fixing axle

between jacking

pad – tractor

clevis

About steering and auto-pilot axles

Every auto-pilot can be used in a steering mode. To do this, simply place the cylinder on the

side of the jib in the space provided for this purpose. The fixing axis of tractor cylinder-clevis

is used to lock the cylinders. The pressure in the circuit must be removed (check the

manometers). To lock the steering axle, a pipe marked in yellow-green colour is placed in

the nose of the pipe holder.

In the auto-pilot (or forced) mode, it is forbidden to use the flexible

locking of the steering axle because it may cause strong damage to the

hydraulic system. So it is highly recommended that in auto-pilot mode,

you don´t connect this flexible hose (marked by a striped yellow and

green mark) to the tractor to avoid any risk of error. Before to steer ensure that

nothing is blocking the wheels.

The axle’s hydraulic circuit should be totally free of air.

Do not exceed recommended pressures during the circuit pressurizing process because the

membranes of nitrogen balls may be damaged and no longer fulfill their function.

Regarding the tracking axles, a flexible pipe marked in yellow-green colour is placed in

the nose of flexible pipes holder.

. On the road with tracking, it is recommended to block the axles in

order to avoid any accident linked to an offset of the trailer, particularly

when your vehicle is charging.

Notice originale : Français NT0002 V –p – 03/2014

29

5- Normal Use + Counter-Indications

Above, representation of explicit pictograms present in the vehicles representing the

different risks (risk of crushing, risk of falling, etc…)

Parking:

When it comes to park the vehicle, the respect for certain rules is mandatory for the user

safety as well as for having a vehicle ready to use when necessary.

It is recommended to store the vehicle in a covered place

Vehicle must be empty on his stand

Brakes are tightened

Parking surface must be flat (slope of 10º as maximum) and stabilized

Hydraulic plugs reconnected to the flexible holder

Greasing is done (see chapter maintenance)

Greasing of the exit cylinder rods

Notice originale : Français NT0002 V –p – 03/2014

30

Tyre Designation

Circumference

Diameter

Correction Value

18/22.5 (445 65 R 22.5)

3505

1130

1.26

500 60 R 22.5

3705

1180

1.33

550 60 R 22.5

3862

1230

1.38

600 55 R 26.5

4176

1330

1.5

Loading:

Any damage due to an overloading would in no case been covered by the manufacturer’s

warranty.

. Never exceed the vehicle loading capacity.

. Verify there is a good distribution of the load in the vehicle.

. Verify load balance, its stability as well as vehicle manœuvrability.

. Take care that during loading, no hard body (stone, pieces of wood,

steel, etc.) is loaded in spreader, it might cause damages.

. When used during the freezing period, verify the mobility of conveyor

rods before loading.

Transport

The spreaders are conceived for circulating at 25 km/h or 40 km/h. They are

approved for the road.

Respect the Highway Code.

. Never leave without having checked the vehicle lighting system: your

safety and others’ one depend on that.

. Verify tyre inflation (see chapter Maintenance). Hillside moving of

spreader can be dangerous. As far as possible, move on the direction of slope. Otherwise,

avoid moving with a loading up to 50% of nominal load.

For a maximum safety, it is crucial not to exceed a gradient of 15% (obstacle, rut, and

ditch).

Option of mileage indicator (odometer).

This odometer is configured for a tyre, type 305 70 R 19.5. If your vehicle is equipped with

different tyres, a correction of odometer display is necessary in order to obtain a correct and

exact distance.

Examples of corection values :

Real Value = read value x correction value

For any other dimension, please see on page 40.

Notice originale : Français NT0002 V –p – 03/2014

31

1

EACH INTERVENTION IN THE REGULATOR

(REGULATION OF MANUAL MAINTENANCE FOR

EXAMPLE) SHOULD BE DONE WITH MACHINE

ABSOLUTELY STOPPED. (TRACTOR ENGINE

TURNED, KEY OUT OF IGNITION). FOR RESTART,

CHECK §1-2 page 3).

SAME INSTRUCTIONS TO BE APPLIED IN CASE OF

MANUAL REGULATOR (SEE PAGE 12). IN

ADDICTION THE REAR GLASS OF THE TRACTOR

CABINET SHOULD BE IN CLOSED POSITION

DURING THE MACHINE OPERATION.( SEE

GENERAL SAFETY INSTRUCTIONS ON PAGE 3)

Spreading

Put the Power Take- Off moving without accelerating and bring it to normal speed of 1000

rot. / min.

Every spreaders ROLLAND are studied to operate in this way except in particular case (540

rot. /mn). In every cases, the scheme to be used is specified in a stitcher in the pipe holder

nose in the front of vehicle.

If the quality of spreading is not satisfactory, many things might be the cause: look for

the cause in the following points:

Adapt the settings in relation to manure.

The loading (irregular, not homogeneous).

The power of your tractor (too weak).

The rotation speed of the Power Take-Off (too slow – control the scheme) Check the

flow.

In case of tamping of manifold or table, invert the advance of moving background to get free

the manifold, consign the machine (see § 1-1 on page 3) and manually remove material

blocking the machine from the rear (see page 32). To do this handling, the use of Individual

Protection Equipment is mandatory. (gloves, glasses, helmet,…)

Regulator can also be used in manual mode in case of breakdown. To turn into manual mode,

you should turn the thumb wheel clockwise. Since the tightening of thumb wheel, the

regulator goes to manual mode, then it is just necessary to adjust the settings according to

needs.

To return to electric mode, you should only loosen as much as possible the thumb wheel.

If there is a failure of distributor or control box, you can connect the flexible pipes that come

out of distributor directly to the tractor.

Notice originale : Français NT0002 V –p – 03/2014

32

6- Adjustements

Preamble: Any adjustment must be made with machine unplugged (see §1-1 on page 3)

Adjustments of mechanic jib:

The jib adjustment enables to have a right box in accordance with the coupling height and to

have a greater flexibility as well as a maximum load transfer to the rear axle of the tractor.

Note: For the first operation, the concessionaire will carry on the jib adjustment.

PROCEDURE FOR ROLLMAX

. Handle it with the vehicle empty.

. Operate on horizontal and stable ground.

. Make sure the parking brakes are tightened. (tractor and trailer).

. Install the safety pin above the tractor coupling ring

Put the machine in a levelling space with a jack (lifting capacity: 5T) placed in front of

chassis.

Lay down jib adjustment axle. (signal B).

Position the jib in a way that spreader is horizontal when he is coupled to tractor.

The jib position will be adjusted into the nearest upper hole. Thus, the spreader will be

slightly pitched up.

Put again the axle in place as well as its pin.

Remove the jack.

The upper hole is used for big diameter wheels; the distance between each hole being of 7cm.

Jack 5T

Notice originale : Français NT0002 V –p – 03/2014

33

PROCEDURE FOR ROLLFORCE

. Handle it with the vehicle empty.

. Operate on horizontal and stable ground.

. Make sure the parking brakes are tightened. (tractor and trailer).

. Install the safety pin above the tractor coupling ring

Put the machine in a levelling space with a jack (lifting capacity: 5T) placed in front of

chassis.

Lay down jib adjustment axle (reference 280814).

Position the jib in a way that spreader is horizontal when he is coupled to tractor.

The jib position will be adjusted into the nearest lower hole. Thus, the spreader will be

slightly pitched up.

Put again the 4 axles in their place as well as their tightening pins.

Remove the jack.

Note: if there is a need to change the stiffness of jib suspension, the pre-stressed spring can be

changed by screwing or unscrewing the nut which is threaded into the end of the rod through

the spring.

Notice originale : Français NT0002 V –p – 03/2014

34

7- Servicing and maintenance

In order to execute the servicing operations in good conditions, please respect the

following safety rules:

Block the wheels.

Tighten the mechanic brake.

Remove the vehicle from its loading.

1. Verifying of the braking system (every 6 months)

a- Parking and rupture brake

Verify the good tension of parking/ rupture brake.

The parking brake lever should not be able to evolve in the last ¼ of its stroke. If this is

not the case, re-stretch the cable.

Procedure for cable stretching :

Put the lever of parking brake in rest position and be sure of the vehicle

immobilization by blocking it in the front and in the back of the wheels.

Unfasten the rope clamps from one side

Re- stretch the cable

Fasten again the rope clamps

Do again a test

If the brake rod (see fig1 on next page ) require too much angle in order to

enable an efficient braking, allow for sealing compensation in the trimmings

(see next point : b)

b- Service Brake

Verify the good condition of brakes cylinders, make sure they are not full-stroke and

control their fixation as well as the one of the retracting springs (the cylinders should not

get off more than two thirds of their maximum stroke, that’s to say: 100mm

If it is not the case, we must allow for sealing compensation in the brake trimmings.

To do so :

Put the lever of parking brake in rest position and be sure of the vehicle

immobilization by blocking it in the front and in the back of the wheels.

Remove the circlips on end cam brake (see fig1 on next page)

Detach the link rod cam.

With a pin spanner for example, make a couple in the brake cam to simulate a

braking movement.

Reposition the link rod cam in this position.

Reposition the circlips.

N.B: If your vehicle is equipped with brake cylinders with automatic sealing

compensation, the operation of trimmings sealing compensation will be

carried out automatically.

Notice originale : Français NT0002 V –p – 03/2014

35

Hole for viewing

trimmings

Brake cylinder

Brake Cam

Circlips

Control the wearing of trimmings through the hole provided for

this purpose.

If trimmings are out of use or unreliable, contact your seller ROLLAND.

Fig. 2

Fig. 1

c- Checking wheel hub bearings:

Bearings are wearing pieces, their lifetime depend on their work, their loading, their speed and

above all on their adjustments and their greasing.

To control the set of wheel hub bearings, you have to lift the axle (vehicle stopped (see §1-1

on page 3) and empty) in a way that the wheel doesn’t touch the ground anymore (need of a

5 T capacity jack with plumb under the axle) and grab the wheel in right and left sides

trying to make it move.

Control after the first operation.

Every two years, provide for the control of conic bearings adjustments. An excess of

backlash can deteriorate the bearings seats and braking devices.

d- Control of hub caps :

For fitted caps, visually control that they are well pressed to the bottom in the hubs.

For the screwed caps, verify that they are in correct place in the hub front side.

2. Maintenance of Baring :

The maintenance operations on bearings should be done by a qualified and competent

staff, with adequate tools and in a specialized workshop authorized by the vehicle

manufacturer.

Notice originale : Français NT0002 V –p – 03/2014

36

Greasing

Greasing

Tightening

1

2

3

4

14 greasing points along this axle

General Verifying

Rolling ½ tandems case, rods tandem

Verify and tighten all the nuts of axles coupling flange and the lifting rods if there are any

(following the order on sketch 2)

Grease the different articulating axles as well as the spring ends in their slide conveyor.

(Sketch 1).

Scheme 1 Scheme 2

Case of balance rolling or Rollfast

Check there is no backlash in the balance axle.

Grease the different points (14 for each balance axle or Rollfast)

Notice originale : Français NT0002 V –p – 03/2014

37

3. Cleaning and lubrication:

Proceed with profound cleaning of the spreader after each use. Then continue with a general

lubrication of the body (spray oil) and check the brakes. Check the machine for all cleaning

and lubricating operations (see §1-1 on page 3)

Each 10 hours:

-Greasing of the rug AV and AR nuts

- Lubrication of the Power Take-Off transmission

Each 50 hours:

- Lubrication of rolling, jib and bearings of the shaft 1-3 times / year (following

utilization)

- Lubrication of the scraper bearings (on the right of TCE, up on the vertical (in the upper

crankcase)). Provide adequate means of access (Cf. p.32)

-Lubrication of the bearings of transmission shaft

The lubrication points are represented by red dots on the diagram below. The oil of different

mechanical housings (gear reducers, gearbox and bevel gears) should be replaced every year

or every 200 hours in accordance with the amounts shown in the "maintenance of mechanical

housings." The recommended oil is SAE 140.

Notice originale : Français NT0002 V –p – 03/2014

38

Instructions for cleaning

Caution, this operation requires special precautions in addition to those mentioned throughout

this document (pages 3, 17, 20 and 26 in particular) and in this chapter.

You should:

Ensure that the machine is stopped until the emptying of the device is complete.

Use the side ladder for this purpose

Attention, it isn´t a mean of access to the interior of the vehicle.

If, however, an intervention in the interior of the body is necessary, an apparatus (not

supplied), of a scaffolding kind, must be implemented to access with railings and

other precautions. In general, all the interventions above the ground must be made

with the appropriate means of access.

All interventions, in the rear of the machine, must be done with machine stopped,

power disconnected and using individual protection equipment (glasses, gloves etc..)

recommended for the use of specific tools by their manufacturer, by example:

The pressurized water spear for washing the screws and bearings

A cutting tool to cut the strings

Etc.

The rotation of the rug as well as all other functions (door, hood) is sometimes necessary.

All our machines allow these functions independently of the Power Take- Off rotation.

This ensures the non-rotation of the moving parts especially with the "independent central"

option. Indeed, in this latter case, a connections kit comes with the machine (see pages 10-

13) to allow a supply of rug directly by tractor oil.

Notice originale : Français NT0002 V –p – 03/2014

39

A

B

A

B

A

B

Side tensioners

(in Rollforce and Rollmax)

Middle tensioners

(only in Rollmax)

4. Adjusting the rug tension/voltage:

This adjustment must be performed every 50 hours of use and checked every 10 hours (see

NOTE below). It prevents premature component wear and contributes to the maintenance of

the chains. To perform tension of the 2 chains (Rollforce) there are 2 tensioners (A) located

outside of the box. To tension the rug 4 chains (RollMax) there are 2 tensioners (A) outside

and two other tensioners (B) in the middle.

Loosen the lock nut A

The tension of the rug is made by compression of the spring by turning the nut B

A proper tension translates into a space of 5 to 10 mm between the rug first bar and the

guide plates under the spreader (rear).

Tension control to be performed in first using, after 10 spreaders,

after 50 spreaders, then every 10 hours (make the tension if needed)

Notice originale : Français NT0002 V –p – 03/2014

40

Coupling Bar

Counter- nuts

Cap nut

Counter-nuts

5. Steering axle (Rollmax option) :

Checking and adjusting the parallelism

Stop the vehicle, the steering axle must be aligned, the locking cylinders back on a flat

horizontal surface.

Measure the distance between the front and rear wheels and the steering axle. We need to

find the same value.

If this is not the case unlock the 2 lock nuts of the coupling bar and rotate it in order to find

the same distance to the front and to the rear.

Strongly lock the lock nuts.

Adjustment of the locking cylinders

Regularly check the lock nut against the blind and nut. After the parallelism, adjust locking

cylinder as follows:

Loosen the lock nuts

Lock the blind nuts.

Apply pressure in the cylinders and maintain it.

Unscrew the lock nuts to put them into abutments

Screw vigorously against the screw nuts to lock the adjustment.

Notice originale : Français NT0002 V –p – 03/2014

41

ALL WORK AT EACH ELEMENT OF

TRANSMISSION (SHAFT, UNIVERSAL JOINTS,

BEARINGS,...) MUST BE MADE WITH THE

MACHINE COMPLETELY STOPPED (STOP THE

TRANSMISSION AND ENGINE TRACTOR).

REMOVE THE KEY.

6. Regulator and hydraulic central maintenance:

Stop the vehicle (see §1-1 on page 3)

Check the oil and seal the reservoir. Think about draining the oil and change the filter

regulator every year. To change the filter, unscrew the bowl guard (red). Clean the inside

of the bowl with a cleaning agent (do not use cloth or paper towels), replace the filter and

then put the bowl.

Check the multiplier housing oil level. Perform a first emptying after 50 hours of use and

every year minimum.

Check the condition of the hose.

7. Rug Control :

Stop the vehicle (see §1-1 on page 3)

Check the wear nuts and bearings, lubrication is required (greasing).

Check the condition and attachment of the rug bars.

8. Transmission maintenance:

The maintenance of this organ is essential for your safety.

Stop the vehicle (see §1-1 on page 3)

Check as often as possible the protection of the gimbal.

Lubricate the various components of the Power Take-Off and the bearings of the shaft

(periodicity page 31).

Check the wear wedges and greasing on the transmission shaft.

Also grease the Power Take-Off at the ends of angle transmissions.

To optimize the operation in direct tractor, free return without brake (push-pull) is

recommended.

- Direct tractor output approximately 60L/min for a manual adjustment, MTKA

type, if not there is an overheating risk and possibility of engine breakage.

- Tractor output approximately 80L/min for a proportional adjustment with

electric command on cabinet.

- Every year, draining the oil from the plant, change the filter regulator and change

the strainer pot of the central.

Notice originale : Français NT0002 V –p – 03/2014

42

Element

Quantity (per scraper or per disk)

wearing pin disk

3

Shovel in stainless steel

C8

15

C10

19

C11

20

C12

20

C13

22

C22

21

C23

19

V17

21

V21

27

V25

34

TCE

15

2

2

2 types of shovels: left and right

Wearing cam

Rollmax

Wearing cam

Rollforce

9. Replacement of wearing parts:

Spreaders frameworks are provided with wear parts that must be replaced regularly, there is

no specific duration of lifetime for these parts as they wear out faster or slower depending on

the type of manure or as settings made by the user.

Notice originale : Français NT0002 V –p – 03/2014

43

Element

Quantity

Outer wear piece of left table TCEI EDT

1

Inner wear piece table TCEI EDT

1

Outer wear piece of TCEI table right EDT

1

Attention to mounting direction

The TCEi spreading tables can have an EDT finishing:

- Base thickness of table 10mm

- Rounded table and removable reinforced boxes

- Equipped with 3 removable pale enhanced

Notice originale : Français NT0002 V –p – 03/2014

44

Setting

Box

( for when in operation )

Oil Quantity (in litres)

V17

Middle

1.2

Left

2.2

Right

2.2

V21

Middle

1.2

Left

2.2

Right

2.2

V25

Middle

1.2

Left

2.2

Right

2.2

TCE

Middle

1.2

Left

2.5

Right

2.2

External angular gear

1.2

Cog wheel (x2)

0.8

TCEI

Middle

1.8

Left

1.5

Right

1.8

External angular gear

1

Cog wheel (x2)

0.7

Belt

Belt gear box

(right or right and left)

2.8

Central hydraulics

Gearbox pump box

0.3

Visco 400

10. Maintenance of gear boxes :

Record machine details (see §1-1 of page 3)

Replace the oil in the différent mechanical gear boxes annually or after every 200

hours service making use of SAE 140 in respect of the following quantities :

Notice originale : Français NT0002 V –p – 03/2014

45

11. Wheels and tyres :

Regularly check wheel clamps and tyre pressure

Inflation

Correct tyre pressure gives optimum traction, comfort and performance.Furthermore the tyres

will have a longer active life and surfaces with which they come into contact will suffer less

damage.

We strongly advise against :

-Under-inflation of tyres which can deform the shape and entail the vehicle being put

out of service.

-Over-inflation, which lowers surface contact leading to a loss of traction. In addition the

tyre body is more easily susceptible to bumps.

Assembly

Assemble the tyres on the rims intended for their positioning.

Use only clean rims in a good state of repair, and work on clean surfaces.

Use only appropriate tools for tyres and rims.

To facilitate assembly and disassembly, lubricate the bases (green) and the raised edges

(black) with a suitable product, following the outline below.

Fill a new tyre tube with new air. Use an inner tube in keeping with the spread of the tyre .

After mounting a tyre, ensure it is properly centred on the rim : if this is not the case, then

inflate, deflate and reinflate the tyre until exact centring has been achieved. Always bear in

mind the maximum tyre bead installation pressure on the rims of 2.5bars (35 p.s.i)

pressure.Then adjust to service or out of service pressure.

When transporting engines by road, rail or ship, it is necessary to inflate tyres to 2.5 bars

(35 p.s.i) in order not to negatively impact mooring systems.

Notice originale : Français NT0002 V –p – 03/2014

46

Type

Service

Pressure

Max.load at

40km/h*

Dimensions

Correction

value of the

hubometer

18 4/30 A324 Alliance

3.2

4080

1550x467

1.68

18 4/34 A324 Alliance

4.2

4200

1632x467

1.77

18 4/38 A356 Alliance

4.8

6270

1733x516

1.88

23 1 R26 Prostor

2.8

5000

1605x587

1.74

23 1/26 A347 Alliance

2.8

5030

1605x587

1.74

620/75 R26 A375 Alliance

3.8

6325

1595x625

1.73

650/60 R 34 Els Nokian

4

9400

1644x650

1.78

650/65 R 30.5 A380 Alliance

4

9660

1623x650

1.76

620/75 R 30 Michelin

4

5600

1710x604

1.85

650/75 R 32 A360 Alliance

3.9

7245

1793x645

1.94

650/65 R 26.5 A360 Alliance

4

9110

1520x650

1.65

580/70 R 38 A370 Alliance

3.3

5950

1817x577

1.97

650/65 R 30.5 Michelin Cargo

4

9660

1623x662

1.76

650/65 R 34 Els Nokian

4

9400

1645x650

1.78

650/65 R 26.5 A380 Alliance

4

9110

1520x650

1.65

710/50 R 30.5 Michelin Cargo

4

8840

1495x728

1.62

Type

Service

Pressure

Max.load at

40km/h*

Dimensions

Correction

value of the

hubometer

550/60 22.5 Diagonal/Divers

3

5300

1360x645

1.48

560/60 22.5 A380 Alliance

4

6710

1245x554

1.35

560/60 R 22.5 Nokian country

4

6300

1244x560

1.35

560/60 R 22.5 Michelin cargo

4

6290

1250x560

1.36

580/65 R 22.5 Nokian

Country

4

7250

1300x580

1.41

600/55 26.5 16PL

4

6390

1348x626

1.46

600/55 R26.5 Michelin Cargo

4

6390

1348x626

1.46

620/60 R26.5 Nokian Country

4

7900

1400x620

1.52

600/55 R26.5 A380 Alliance

4

7450

1350x620

1.46

650/55 R26.5 A380 Alliance

4

7900

1360x645

1.48

Characteristics of tyres available with Rollforce :

Available tyre qualities for Rollmax

*not all vehicles are set at 40 km/h ; there are also versions at 40km/h ou 25 km/h. In order to find out which

setting your vehicle has : check the sticker on the rear left of the vehicle or the gallery sheet .

Notice originale : Français NT0002 V –p – 03/2014

47

1 4 2

2

3

Bench

mark

function

colours

1

Number plate lighting

White

2

Lighting + stop

Red

3

indicators

Orange

4

Rear reflector

Red

12. Lighting :

When replacing a bulb, monitor the power level required and the filament connections.

N.B. : There is an option which exists to allow for protection of the lights against exhaust

fume spirals. This way the lights remain in good condition and visible to those behind the

vehicle on public highways. The principal is the following : protection is actively engaged as

soon as the trailer is in motion.

ALWAYS ENSURE THERE ARE NO THIRD PARTIES PRESENT AT THE

TIME WITHIN THE PERMITTED ZONE OF DEPLOYMENT.

Notice originale : Français NT0002 V –p – 03/2014

48

8- Assembly

Flashing light assembly :

The flashing light can be fed by the pilot lights, in certain cases it can be fed independently

with the help of a 3-way contact.

If there is a pilot light feed connection: maximum flashlight power should be 21 watts.

Notice originale : Français NT0002 V –p – 03/2014

49

Means of access example for silo

equipment assembly

Equipment Assembly ( ROLLMAX Options)°:

These operations are in the hands of the dealer since he alone is trained and

skilled in them. Means of access to the vehicle must be in place to guarantee

the absence of risk, most notably with the chute.

PROCEDURE

Having already grease coated them, instal the rear piles. Greasing makes assembly and

disassembly easier since adjustments are optimised to ensure watertight assembly . On the

rear mounted and installed piles , screw down the sheet metal on the rear-mounted piles

(on the inside of the trailer box).

Notice originale : Français NT0002 V –p – 03/2014

50

Assemble rear sockets and middle piles and then affix in place using the screws provided, .

Notice originale : Français NT0002 V –p – 03/2014

51

Assemble rear sockets having followed the piles in front, and then secure them using the

screws provided.

Notice originale : Français NT0002 V –p – 03/2014

52

Bolting points for handling the

spreader frame.

Framework support optional

Procedure for silage door assembly (A Rollmax option)

Before installing your silage door, you will need to remove the framework tool from the

your spreader. This operation is to be carried out by your ROLLAND dealer, who is the only

trained and skilled operative who has the requisite tools.

Procedure for disassembly of the tool framework

Disconnect the secondary transmission.

With the aid of slings, fasten the framework to an overhead bridge crane (minimum

capacity minimum 2,5 Tonnes for the slings and the bridge). Attachment points are

outlined in the following diagramme. The weight of all sub-assembly sections is stated

on stickers supplied.

Unscrew and remove all framework support fasteners on the box.

Remove the framework using the overhead bridge crane and rest it on its supports. Fix

it to its support using the nuts and strap(s) supplied, after having checked the clamps in

order to lift off the slings.

In the absence of framework support, place the framework flat on the floor on the

hatch side.

Silage panels

Having lubricated them with grease, assemble the piles. Greasing makes assembly and

disassembly easier since settings are adjusted in order to ensure assembly

watertightness. Attach to the spreader box with the screws supplied.

Then install the basket (mass of around 80 Kg) using a hoist or loader. Bolt together

using locking pins supplied.

Notice originale : Français NT0002 V –p – 03/2014

53

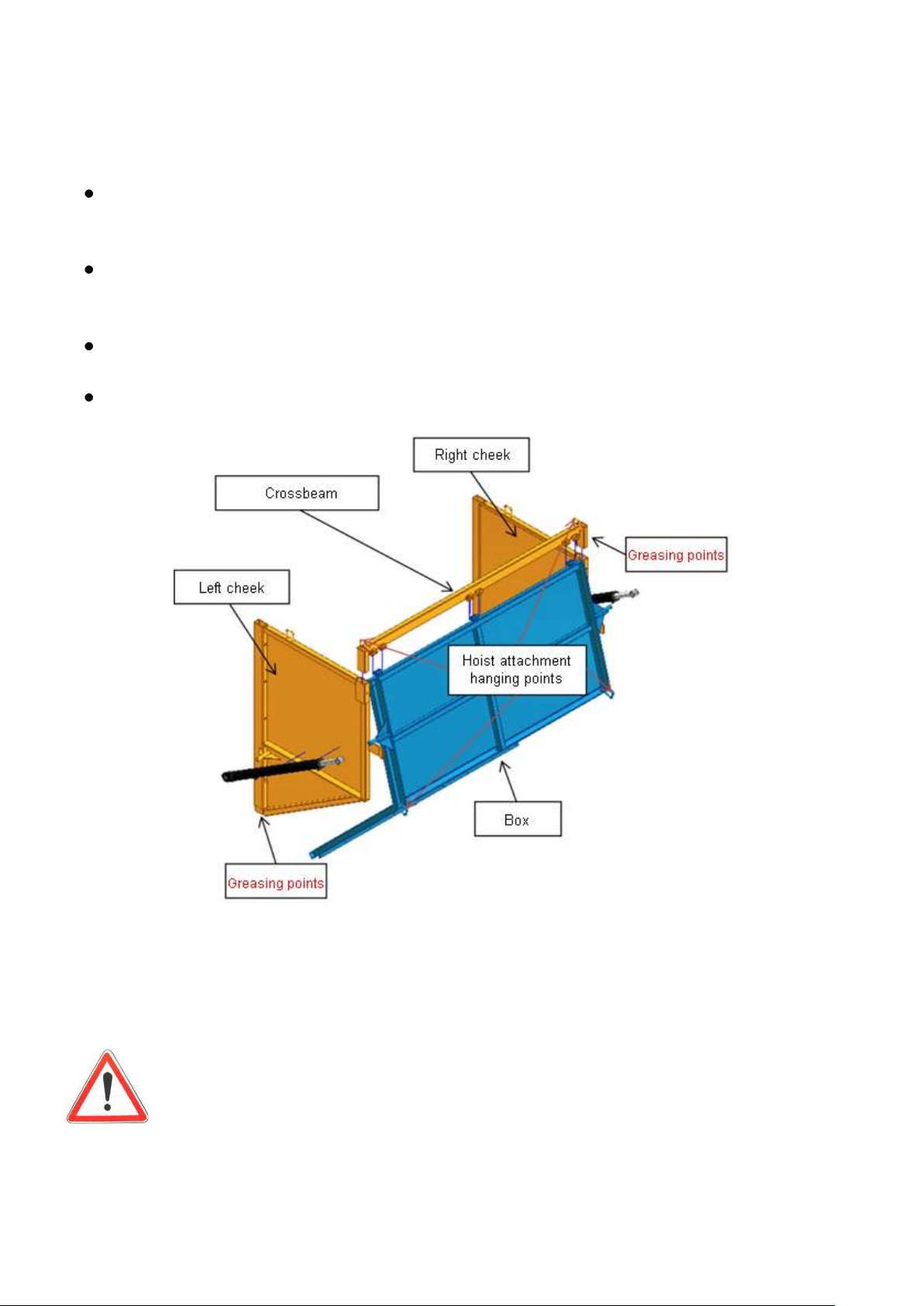

« LOULOU » Hatch

Having lubricated them with grease, assemble the cheeks. Greasing makes assembly

and disassembly easier since settings are adjusted in order to ensure assembly

watertightness. Attach to the spreader box with the screws supplied.

On the ground, assemble the box with the cross section higher using the spindles

supplied Make sure to put the locking pins in position in order to tighten up the

assembled set section.

By means of an overhead bridge crane, a hoist or a loader, put the box set in place with

the crossbeam. Attach to the cheeks with the screws supplied.

Finish by placing the jacks in position, the barrel being on the box side.

All operations carried out at height should be done using a suitable type of scaffolding

which is in compliance with regulations currently in force and set out for this kind of product

(body protectors, etc…).

The hatch opening jack « LOULOU » come equipped with double-pilot

valves. Pay attention to any potential residual pressure that there might be

between the valve and the jack.

Notice originale : Français NT0002 V –p – 03/2014

54

Component

Quantity

Illustration

Suspension jack

2

Suspension block with

tiller fitted with two

membrane accumulators

1

Jib 1

9-APPENDICES

APPENDIX 1

NOTES FOR SUSPENSION USE OF THE HYDRAULIC JIB

1- SYSTEM PRESENTATION

All trailer tillers are classed as hydraulic suspension jibs when they come fitted with

absorption systems which are powered by hydraulic technology rather than by parabolic

springs.

The system is governed by the tractor. The user can correct the height of his tiller trailer

in real time.

2- OPERATING PRINCIPLES

The system mainly comprises the following elements :

The different elements are assembled according to the following outline:

Notice originale : Français NT0002 V –p – 03/2014

55

3- SETTINGS IMPLEMENTATION AND USAGE

The jib should be set in such a way as to keep the trailer in a horizontal position.

It should however rest on the jackpin to deaden powerful bumps ( 3cm)

2 methods of use are envisaged:

It may be that the user wants a predefined trailer height setting valid throughout. In this

case the feed tubes on the circuit are not connecterd to the tractor. It is to be noted thst

the tiller functions in closed circuit , i.e, when the dumper is loaded, it can knock itself

over, and when going spreading, the jacks can be deployed and no corrective action is

possible.

This method of use is strongly advised against, despite the potential

benefits of having a distributor on the tractor.

Should the user leave pipes permanently attached to the tractor, he will thus be able to

alter the tiller height in real time and catch at will any jack oscillation due to any

variation of load in the vehicle.

This is the »normal» use of the system.

Operating this way gives maximum suspension supplety.

N.B : 2 or 3 adjustments are possible at the height attachment jack. The process for

attachment height procedure is the same as for the spring rest (see page 28)

Notice originale : Français NT0002 V –p – 03/2014

56

Compoennt

Quantity

Illustration

Suspension jack

4 suspension jacks for a 2axle vehicle

(6 for a 3-axle vehicle).

Passive suspension block B

1

Nitrogen ballholders

2

APPENDIX 2

USE NOTICE FOR PASSIVE SUSPENSION ON THE

UNDERCARRIAGE (Closed circuit ) ( ROLLMAX option)

1- SYSTEM PRESENTATION

Inactive, or even closed circuit suspension on train undercarriages comes equipped

with an autonomous shock absorption system.

The circuit is completely independent of the tractor.Suspension is regulated once and

for all (whilst still remaining alterable on occasions where necessary).Adjustment is made in

such a way that there is an optimum maximum articulation of the load .A jack stroke being

at 200mm, optimum articulatuion will be about ± 100mm.

The user cannot rectify the height of his vehicle in real time.

2- OPERATING PRINCIPLES

The system mainly comprises the following elements :

4 suspension jacks for a 2-axle vehicle (6 for a 3-axle vehicle)

1 hydraulic suspension management block

2 pistons accumulators

The system mainly comprises the following elements:

Notice originale : Français NT0002 V –p – 03/2014

57

External faucets

Middle

Manonometer

2 remarks :

There is a system in place during assembly intended to counter vehicle roll. Oil will never

just flow to where it is « easiest » Loads will be consistently equal on all 4 wheels, which in

turn provides hopper stability.

The pressure limit gauge is intended to even out abnormal peak pressure demands (violent

powerful bumps).

3- SETTING AND USE RECOMMENDATIONS

a. To increase the height of the suspension (raise the box) :

To add oil to the suspension circuit (if the height is deemed insufficient for example), it

is necessary to go ahead in the following manner :

Passive suspension block :

Attach the pipe marked by a spot to the tractor (the long green one ).

Open the two external block valves (see photo).The middle valve must be closed

Feed the oil circuit via the tube attached to the tractor until the desired level is attained A.

Reclose the two external valves and open the middle valve.

Release the residual pressure present in the pipe, whilst setting the tractor distributor to

"float".

Disconnect the (long green) tractor pipe.

Only the (short green) drain return pipe should remain connected.

ATTENTION: Be aware that spreader height may vary dependent on the

internal load.

Notice originale : Français NT0002 V –p – 03/2014

58

b.To increase the height of the suspension (raise the box):

To remove oil from the suspension circuit (where height is deemed too important for

example), it is necessary to go ahead as follows :

Attach the connector marked by a spot (the long green one) to the tractor.

Open the 2 external block valves (see photo).The middle valve should be closed

Set the relevant tractor distributor to "float" position until the required height is attained.

Reclose the 2 external valves and open the middle valve.

Release the residual pressure present in the pipe, whilst setting the tractor distributor to

"float".

Disconnect the (long green) tractor pipe.

Only the (short green) (vert court) drain return pipe should remain connected.

RECOMMENDATIONS FOR USE :

The tube which serves to regulate the height of the hopper must only be connected in

suspension interventions. In normal operations, this pipe must be attached tto the pipe box

door nose.

On the other hand, the "drain" pipe (oil return in the event of high excess pressure) must

remain permanenetly attached to the tractor.

AXLE OPTIONS BEFORE PRESSURE ABSORPTION (with 3 axles) :

A basic pipe (in a brown sheath like with the load transfer function) allows axle

command before absorption. In normal operating conditions (3-axle suspension), it is vital to

set the tractor distributor to "float".

This option is not recommended for 2-axle vehicles since it is incompatible with rear

steering axles. The combination of these two options would lead to vehicle instability.

Notice originale : Français NT0002 V –p – 03/2014

59

Date

Operation

Remarks

Visa

- Check wheel tightness

Every 50 km then twice yearly or at

he beginning of each season

- Check tyre inflation

pressure

Twice a year or at the beginning of

each season.

- Check for axle tightness or

the axle fulcrum

Twice a year or at the beginning of

each season.

- Grease points indicated in

the handbook

Check before each use

Actions to be carried out

prior to use by the

repurchaser

- Check for proper service

brake tightness, for

breakages and stationary

positioning

Make up for any defects found as

necessary

Operations to carry out before start-up

(by the DEALER)

9- Maintenance Log

Notice originale : Français NT0002 V –p – 03/2014

60

Date

Operation

Remarks

Maintenance Log

Notice originale : Français NT0002 V –p – 03/2014

61

11- CE Conformity Declaration for machines

(According to Annex IIA of Machines Directive 2006/42/CE)

Manufacturer: Ets ROLLAND

Address: Z.A des Landes 29800 TREFLEVENEZ

Name and address of the person authorised to elaborate technical dossier:

Name : Béatrice LE GALL

Address : Z.A des Landes 29800 TREFLEVENEZ

Through this document, we declare that

The machine:

- Brand: ROLLAND

- Commercial Designation:

- Type:

- Serial Number:

is in accordance with the relevant disposals of Machines Directives (2006/42/CE).

In addition, we declare that

(parts / articles ) compliant with the following European standardised standards were

applied.

-EN ISO 12100-1 & 12100-2

Done at TREFLEVENEZ, on

Name and title of signatory

Béatrice LE GALL

General Director

Notice originale : Français NT0002 V –p – 03/2014

62

12- WARRANTY CERTIFICATE – DECLARATION OF

START-UP OPERATION

Examples in this instance

USER

Name : ………………………………………………………………………………………………….

Address : ………………………………………………………………………………………………

Post Code : …………………City: …………………………..Country………………………………..

Landline : ……………………………… Mobile …………………………………

Fax : ………………………… Email : ……………………………………………………………….

VEHICLE

Type of vehicle : …………………………………………………………………….………………

Series N° (on the invoice or on the disc plate) : ………………………………………………….

Purchase date : ………………………………………………………………………………………….

Delivery date : …………………………………………………………………….……………….

GUARANTEE

Our vehicles are guaranteed for one year starting from the delivery date.Conditions of use are stipulated in the