Rok RC Symsteer User Manual

Symsteer instruction manual:

©2012 www.ROKrc.com.au All rights reserved for all images and text copy in this manual.

Foreword:

Thank you for purchasing a genuine SYMSTEER by Rok rc.

Symsteer has been designed to improve steering performance and add new braking dimension to your HPI baja. Symsteer's

push/pull symmetrical design uses the equilibrium of push/pull force to improve steering performance by a large degree. The

push/pull servo saver is not a new concept, it has been used incredibly successfully by large-scale cars in Europe for many

years but the way it has been incorporated into Symsteer's uniquely accessible, plug-in design is a first. The ‘race-orientated’

design is the first complete s t eer ing and braking system of its type for hpi Baja that a general user can install with minimal

expertise and no chassis modification.

It is designed to be used with or without front brakes. Rear brakes are now controlled by the opposite side servo than the

throttle servo.

If you choose to install front hydraulic brakes, Symsteer's dual brake servo positions will lend themselves to work with a

number of different hydraulic master cylinder positions. cable front brakes are also possible but all styles are not entirely

supported by Symsteer desig n and t he u s e r will b e required to assess their suitability or improvise their own cable pull

mounting connection that will work with the Symsteer throttle/brake servo. If you are considering front brakes after

purchasing Symsteer please no t e: We highly recommend hydraulic front b r akes for off road use as they are less problematic in

themselves and require far less continual adjustment. Brake balance and modulation of left and right wheel braking force is

much better controlled with hydraulic calipers and most users with front cable brakes find them almost impossible to use

reliably in race condit i ons.

Rear cable pull lay-shaft brake on the other hand is very reliable and does not suffer the left/right balance i ssue because it

works evenly through the transmission using one calliper. Cable pull rear brakes are as simple as using a solid connecting rod.

Symsteer chooses to mount the rear brake servo on the opposite side to the throttle servo and uses a heavy duty cable

arrangement to achieve the off-centre pull to the rear brake cam lever. Our testing has proven that rear brake performance is

better than a standard arrangement because it does not suffer from the usual radio box movement during braking because the

pulling force is encapsulated within the cable system therefore adding zero pull force on the Symsteer chassis mounting points.

Opposite side rear brake servo was chosen for our design because most of all available hydraulic front brake systems for HPI

baja mount the master cylinder on the throttle side. To utilize effective brake bias a nd mixing steering input with front brakes

you must utilize another servo on a different radio channel. This is why we put the rear b r ake servo on the opposit e side of

throttle. Brake mixing and bias adjustment will minimize under-steer during heavy braking entering a corner. It is the only way

to get complete benefit from front brakes. To understand more abou t this please see our Website and YouTube vid eos.

If you do not use front brakes you will also appreciate the redundancy of using a separate brake servo and an isolated throttle

servo. It is a well-known fact that braking force is what what shortens the life of the throttle/brake servo in a conventional

system. By isolating the throttle you will rar ely ne ed t o replace the throttle servo because it is u nder very little load from

throttle duties alone. T hi s coul d b e the dif ference between finishing a rac e or g e tting a DNF result. Even if you don't race, the

redundancy advantage of two servos is a bonus. With front brakes the advantage is obvious. Three individ ual servos is

far superior than trying to do three jobs ( throttle, rear brake, and front brake) all with one servo. At best, the idea of using

one servo for three jobs is ambitious, at worst, you will destroy servos regularly a nd never achieve the full benefit of fro nt and

rear braking potential.

It is also possible to use the throttle servo to do rear braking by flipping the top plate over and using the cable and throttle on

the throttle side. A double throttle rod servo post and some modification to the roll cage front cross-member will be required to

do this successfully. This option might also allow the use of front brakes on the opposing side to the throttle servo in order to

use them as line lockers for drag racing.

THIS INSTRUCTION MANUAL WILL ATTEMPT TO SHOW YOU A BASIC REAR BRAKE ONLY SETUP WITH PUSH/PULL STEERING

SERVO SAVER. for front and rear brake setup we recommend at least a three channel radio with mixing capabi lity in ord er to

fully utilize symsteers brake mixing and brake bias ability through radio adjustment. Two channel radio is possible with a ‘y’

splitter but you will need to so u rce a servo reversing lead in order to revers e t h e b r a ke servo in relation to the throttle servo.

For more tips on installation please visit ROK rc’s YouTube channel. Just search "Rok rc Symsteer". Or “rokr ctu be ” t o f ind our

video channel.

Installation:

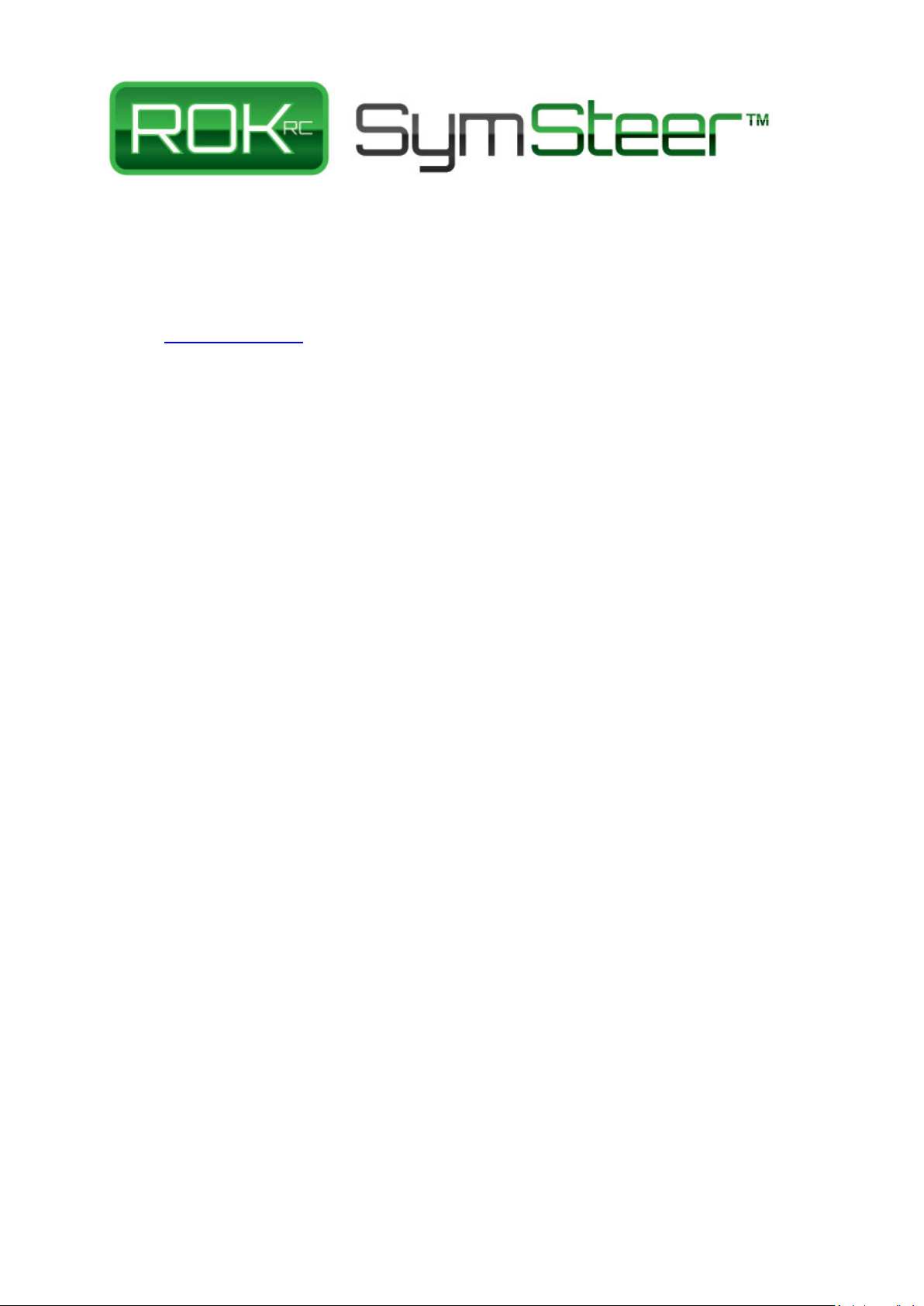

Your Basic Symsteer comprises of the following parts:

Top plate, Bottom plate, b atter y tr ay and straps, radio box and antenna rod, front and rear standoffs, rear

brake cable and brake blocks, large stainles s ste e l steering turnbuckle connecting rods for wheel hub to servo

saver (6mm ball ends not supplied, user should re -use ball ends from their Hpi b aj a or replace if the y are in

poor condition), stainless steel se rv o tur nbuckle with ball ends throttle linkages and ball ends, collets, scre ws,

nylock nuts and chassis captured nuts.

Optional purchases are; servo saver (different styles available), full length servo horn for HPI (quarter scale

futaba) style steering servo or Hitec (R hino ) large scale steering servo. You may also purchase a master

cylinder linkage rod assembly if you have front brakes.

Step 1.

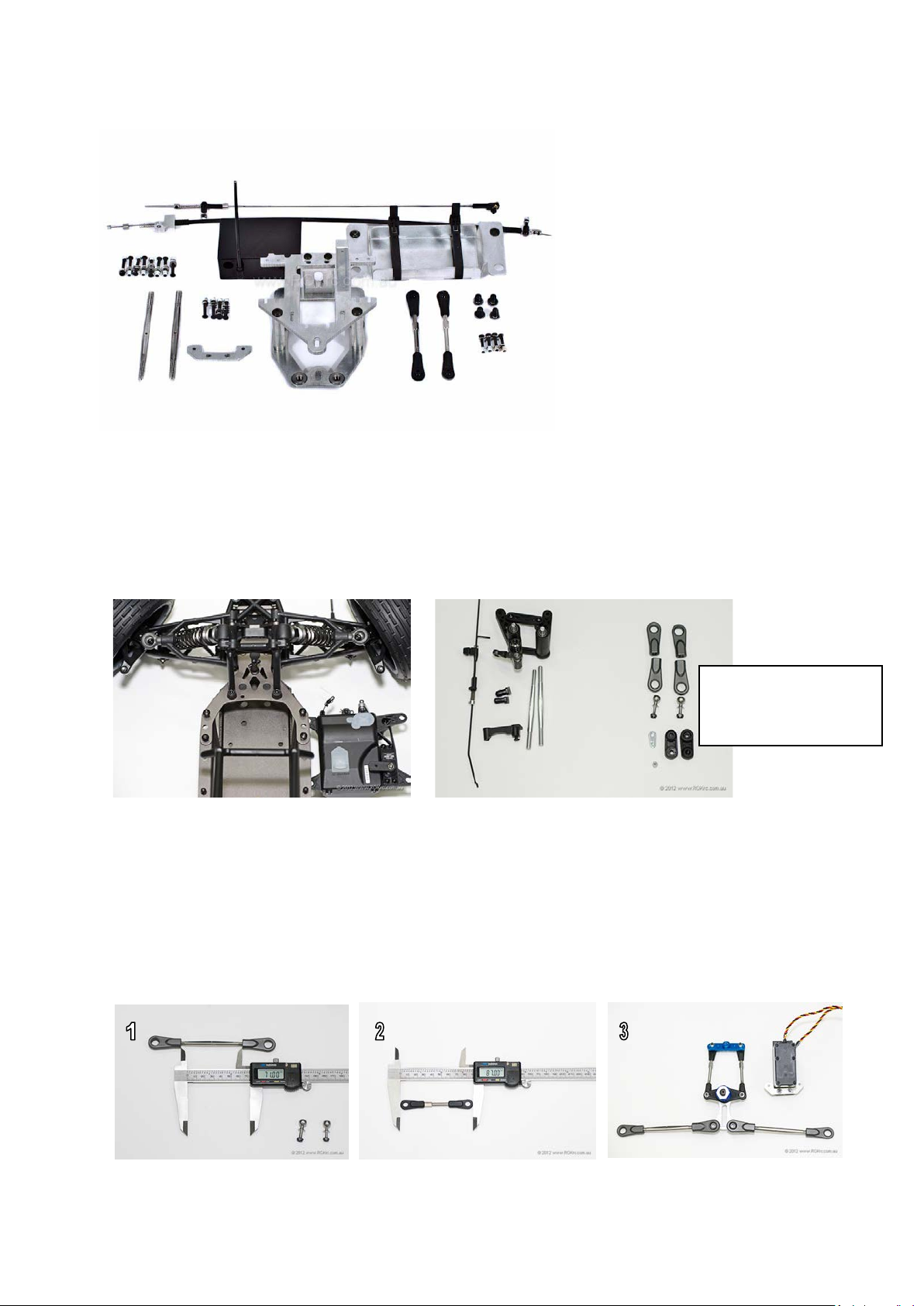

Remove existing radio box and servo saver from your HPI Baja.

Keep existing rod ends and balls whic h conne c t yo ur exis ting steering tie rods to the wheel hub and old servo

saver. The old Tie rod s will not b e used. Just the ball ends and pivot balls on the wheel hubs and servo saver.

Step two:

- Assemble new heavy duty stainless steel (long er) tie rod s with yo ur rod ends to suit Symsteer

approximate length of 71 mm between the plastic ends. Ball ends not supplied. Pic 1.

- Make up new stainless steel heavy duty servo tie rods to exact 87mm overall (some minor adjustment

may be required once steering servo is fitted, adjus t both rod s evenly). 7mm plastic ball ends and

balls are supplied. Pic 2.

- Connect rod balls and rod ends to servo horn. Ensure screw heads face down so that thread po ints up

and does not bind on chassis. Pic. 3.

Re-use rod ends, pivot balls,

shock tower retaining lugs and

throttle lever.

Step 3:

4mm shim at top of servo saver.

Install servos as per image. Note: 2 x Sticky plas tic cab l e guides are now supplie d for underside of servos. You

can also apply strong tape or hot glue or Zap goo II to wires on underside of throttle and brake servos to dire c t

servo wires rearward toward the radio box. This ensures they do not get ta ng led in yo ur steering linkages.

(Race tip 1: Do not over -tighten servo screws. they should be just snug to allo w some flex on their r ubb er

grommets supplied with the servo. This will les s e n the chance of servo case mounts c racking. ) Spline on

throttle and brake servos are closest to the front of the car . Steering servo requires cross-member to be fitted

as shown. Spline of the steering servo is closest to the rear of the car. Screws connecting cross-member to the

servo should be left loose until the servo is fitted to the under s ide of the top plate. For longer servos like

standard HPI and Futaba ¼ scale servos, the cross-member and top plate beco me sandw ic he d betwe e n the

servo screws. For shorter servos like Hitec h and Rhino Dig i4 slide the crossmember backward and screw servo

retaining through the cross-member as shown.

Step 4.

Install rear brake cable stop block on top plate shown in pics above. Two M4 screws from underside of top

plate as shown on photos above. Cable end caps are plastic and can be threaded into the cable stop with a pair

of plyers. Ensure they seat all the way in.

Step 5.

Install servo saver on the centre position of the triple position hole in the top and bottom plate. Other

positions are generally there for non-typic a l servo s avers and Ackerman angle adjustment if clearance allows

it. For the time being, do not be concerned with these alternate positio ns a nd install it on the middle hole.

Highly important! Ensure that you fit the shims supplied for your

servo saver in the positions shown in the pic. These shim washer/s ensure a

smooth rotation of the servo saver. If you do not fit them in the exact position shown you will likely

experience binding of your servo saver as the centre housing of the servo saver pivots on the

hardened centre pos t and must have shims to enabl e free movement at the top and/or bottom

plate. These shims may require replacing after considerable use. At the first sign that they might be

worn from the pivoting friction please replace them to ensure smooth operation of your steering. It

is a small price to pay for perfectly smooth steering.

Note: Elcon Competition Servo saver requires shims at the top and bottom between the servo saver

and the top and bottom plate. FG competition servo saver requires only one shim at the to p

between the servo saver and the top plate. Shims are specific size for top and bottom. The size of

these shims is absol utely critical. Please don’t mix them up or use plai n was he rs. We do not provide

warranty for servos so please ensure that the servo saver always pivots freely.

ELCON Competition Servo Saver:

Under top plate.

5mm Shim at base

Ensure compression nut is below top of brass

centre post so it does not touch with top plate.

You should also Loctite this nut to be sure!

Loading...

Loading...