Rointe KYROS Installation Manual

KYROS

Digital Electric Water Heater

Wall-hung Unvented

INSTALLATION

MANUAL

02

03

WELCOME

Dear Customer,

Thank you for choosing the KYROS electric water heater, with an exclusive electronic temperature

programmer and made with the highest quality materials.

The KYROS water heaters have exceeded the most stringent quality controls in order to comply with the

most rigorous requirements for safety.

Thanks to its exclusive ROINTE Fuzzy Logic Energy Control technology, the electric water heater

achieves the maximum energy saving.

Before using the electric water heater we recommend you read this manual carefully in order to obtain

proper operating information.

IMPORTANT

THIS MANUAL SHOULD BE LEFT WITH THE UNIT AFTER INSTALLATION

04

TABLE OF CONTENTS

1. Introduction ....................................................................................................................................... 05

2. Technical Specifications ................................................................................................................... 05

3. General Requirements ...................................................................................................................... 06

4. Plumbing Installation ........................................................................................................................ 07

5. Electrical Installation ........................................................................................................................ 11

6. Filling and Commissioning ............................................................................................................... 12

7. Servicing and Maintenance ............................................................................................................... 12

8. Fault Finding ..................................................................................................................................... 13

9. User Instructions .............................................................................................................................. 14

10. Guarantee .......................................................................................................................................... 19

11. Installation, Commissioning and Service Record ............................................................................ 21

05

1. INTRODUCTION

The “RD TFT Series” is a high quality unvented enamelled steel domestic hot water cylinder suitable for

domestic hot water systems where the cold mains water supply has a maximum supply pressure of 0.9

MPa. Reduced performance is available at lower pressures but the units are not suitable for pressures

lower than 0.15 MPa and flow rate of 20 litres per minute.

Rointe offers the possibility to acquire all the necessary safety equipment to comply with legislation

governing the installation of such systems.

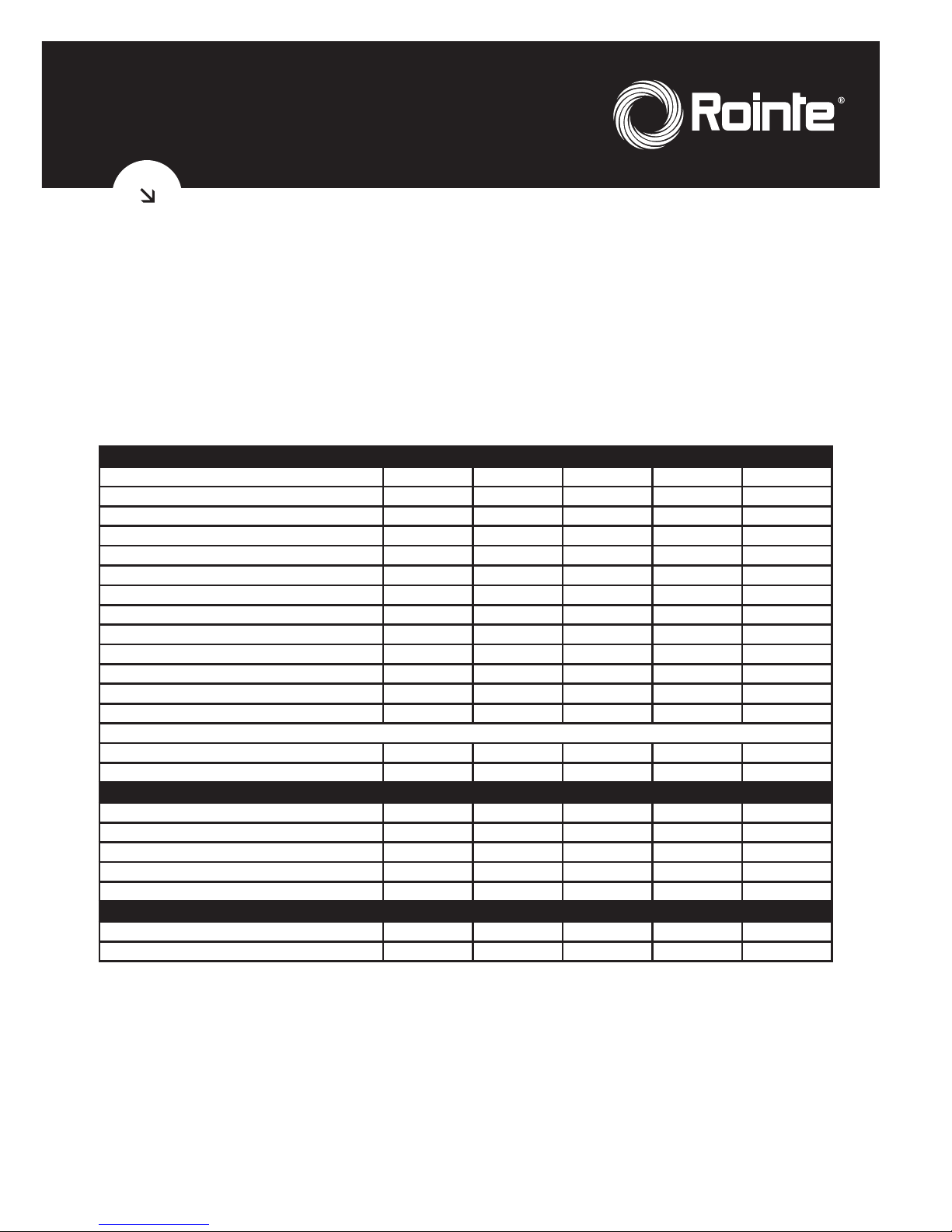

2. TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS

MODEL NUMBER

KWI050DHW2 KWI075DHW2 KWI100DHW2 KWI150DHW2 KWI200DHW2

Storage capacity (l) 50 75 100 150 200

Power (W) 2,400 2,400 2,400 2,400 2,400

Depth (mm) 404 404 404

580 580

Width (mm) 404 404 404 580 580

Overall height incl T/P valve 785 1,035 1,270 1,160 1,220

Height excl T/P valve 685 935 1,170 960 1,120

Weight when full (kg) 68 100 132 194 256

Cold feed/hot draw off connections (mm) 15 15 15 22 22

Maximum water supply pressure (MPa) 0.9 0.9 0.9 0.9 0.9

System operating pressure (pre-set) (MPa) 0.6 0.6 0.6 0.6 0.6

Expansion vessel charge pressure (MPa) 0.15 0.15 0.3 0.3 0.3

Expansion relief valve set pressure (MPa) 0.6 0.6 0.6 0.6 0.6

Temperature and pressure relief valve settings:

Lift pressure (MPa) 0.7 0.7 0.7 0.7 0.7

Lift temperature (ºC) 90 90 90 90 90

INSTALLATION KIT (OPTIONAL)

0.3 MPa pressure reducing valve • • • • •

0.6 MPa expansion relief valve • • • • •

Expansion vessel ltr 8 8 12 12 18

15mm to 22mm Tundish • • • • •

Isolation valve • • • • •

PERFORMANCE

Heat up time 15 to 65 ºC (min) 73 110 117 175 235

Reheat time for 70% of contents (min) 51 77 82 123 165

2.1. Component Check List

The KYROS water heater comes with the following components, please check through the

components supplied and ensure that all parts are present:

• Water Heater with sheathed heating elements, digital thermostat, TFT screen and manual

reset thermal cut-out

• T/P valve 0.7 MPa 90ºC and electrolytic fittings

• Installation and user manual

Please contact our customer service department to know how to acquire the safety fittings.

06

3. GENERAL REQUIREMENTS

3.1. The KYROS domestic hot water cylinder MUST be installed by a competent person in accordance

with section G3 of the current Building Regulations.

3.2. Important - It is important that the installer reads and understands these instructions, unpacks

and familiarises themselves with the equipment before commencing the installation. Failure to

observe these installation instructions could invalidate the warranty.

3.3. Water supply – The water supply to the cylinder should be potable water direct from a public

mains water supply with any water treatment equipment functioning correctly.

For optimum performance the unit should be fed via a 15 mm or 22 mm diameter supply pipe direct

from the mains water entry point to the property with supplies a maximum pressure of 0.9 MPa.

The unit can operate with a minimum supply pressure of 0.15 MPa and a flow rate of at least 20

litres per minute, but flow from the outlets will be low if several outlets are used simultaneously.

The cylinder control equipment is factory set to limit the system operating pressure to 0.3 MPa. The

maximum supply pressure into the pressure-reducing valve is 0.9 MPa.

3.4. Taps and fittings - All taps and fittings incorporated in the unvented system should have a

rated operating pressure of 0.7 MPa or above.

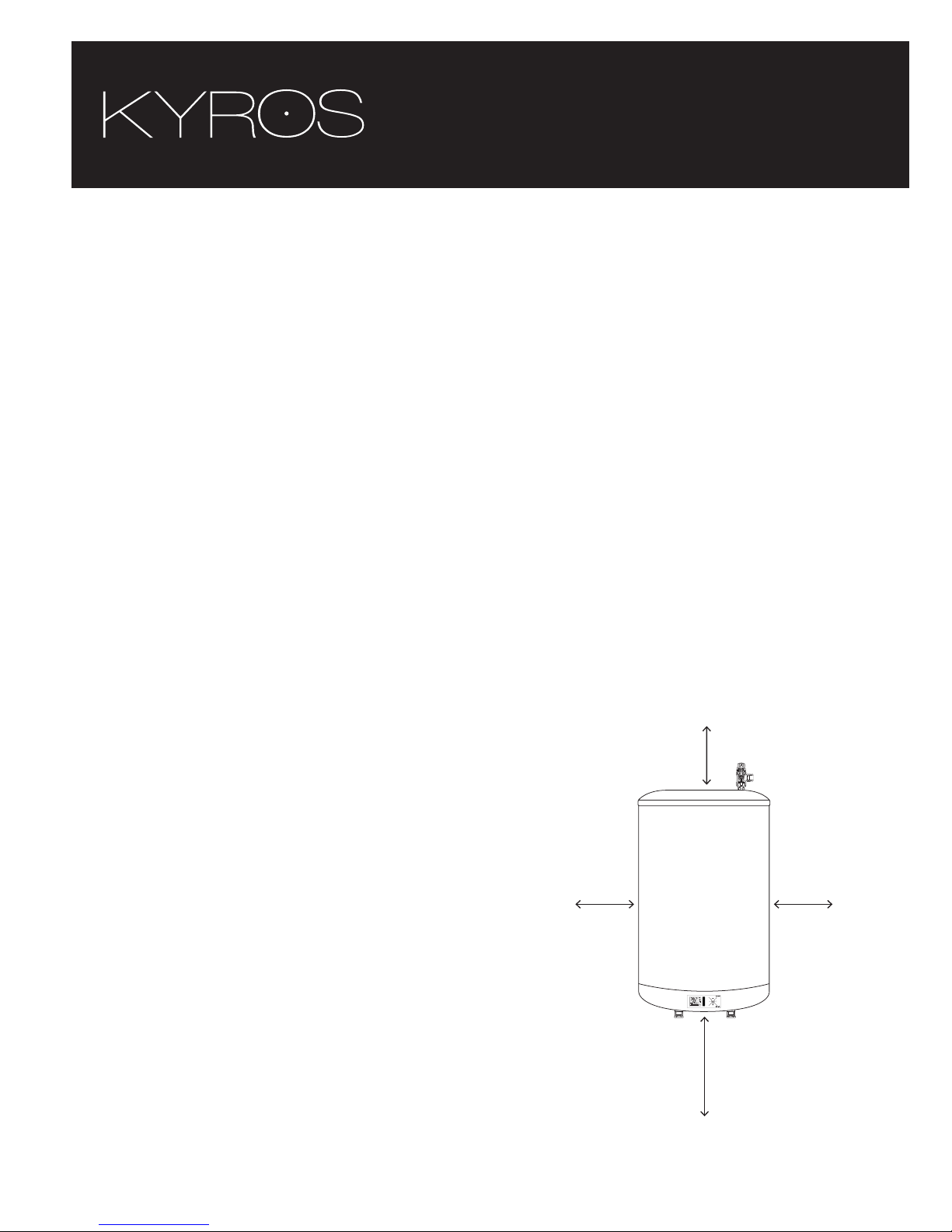

3.5. Location – The unit is designed to be vertically wall mounted, indoors, in a frost-free

environment. When choosing a suitable location for the cylinder, consideration should be given

to the routing of the discharge pipe to a convenient point and also the availability of an adequate

power supply for connecting the sheathed heating elements.

The wall onto which the cylinder is mounted should

be of good sound masonry construction capable of

holding the weight of the cylinder when full of water

(see

technical specifications

for weights).

The position of the cylinder should be such that easy

access is provided for servicing the controls and

replacing the sheathed heating element should the

need arise.

Pipe runs should be made as short as possible and

lagged to prevent heat loss.

To allow for servicing and repairs the unit must be

mounted at least 540 mm above any surface or object,

so that access can be gained to electric connectors

and the heating elements may be removed (see Fig 1).

The unit should be mounted close to an external wall

so that the discharge pipe D2 can be routed to a safe

visible place.

The tundish should be mounted in a visible location so

that it may easily be inspected.

Fig 1 - Minimum margins for servicing and repairs.

150 mm

100 mm 100 mm

540 mm

07

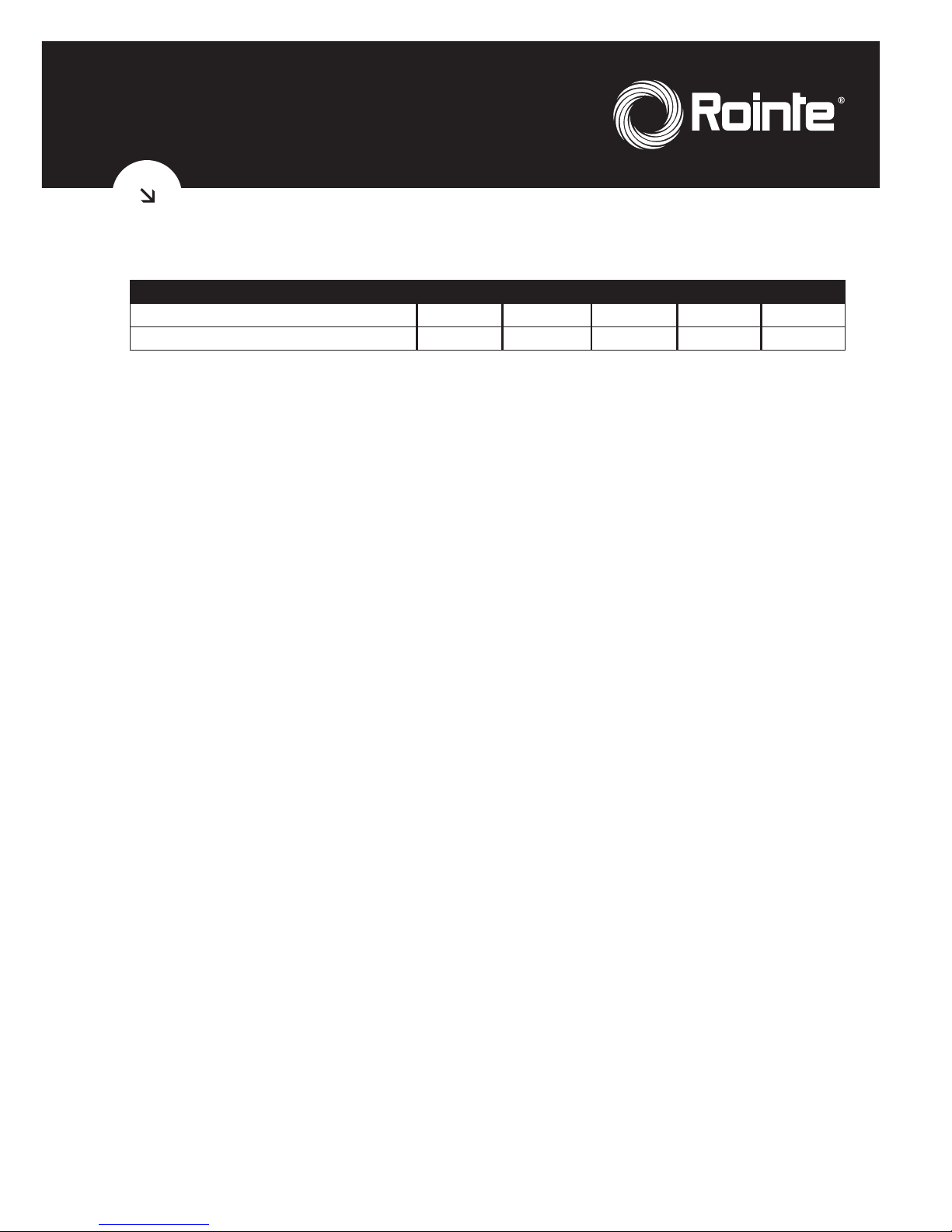

The distance between holes for the wall mounting depends on the model, see the following table

for reference:

Model

KWI050DHW2 KWI075DHW2 KWI100DHW2 KWI150DHW2 KWI200DHW2

Horizontal width between holes 350 mm 350 mm 350 mm 350 mm 350 mm

Height between upper and lower holes 340 mm 573 mm 768 mm 490 mm 670 mm

3.6. Storage and handling – If the cylinder is not being installed immediately, it should remain in its

box with all pipe end protective caps in situ to prevent damage. We recommend that the cylinder be

transported to its installation position with the outer box in place.

3.7. Pipework connections – All pipework connections to the cylinder MUST be made in accordance

with Fig 2.

3.8. Safety – This product is not intended to be used by persons (including children) with reduced

physical, sensory, or mental capacities, or have no experience or knowledge of the product, except if

they are supervised or instructed in the use of the product by a person who is responsible for his or

her safety. Children must be supervised at all times to ensure that they do not play with the product.

4. PLUMBING INSTALLATION

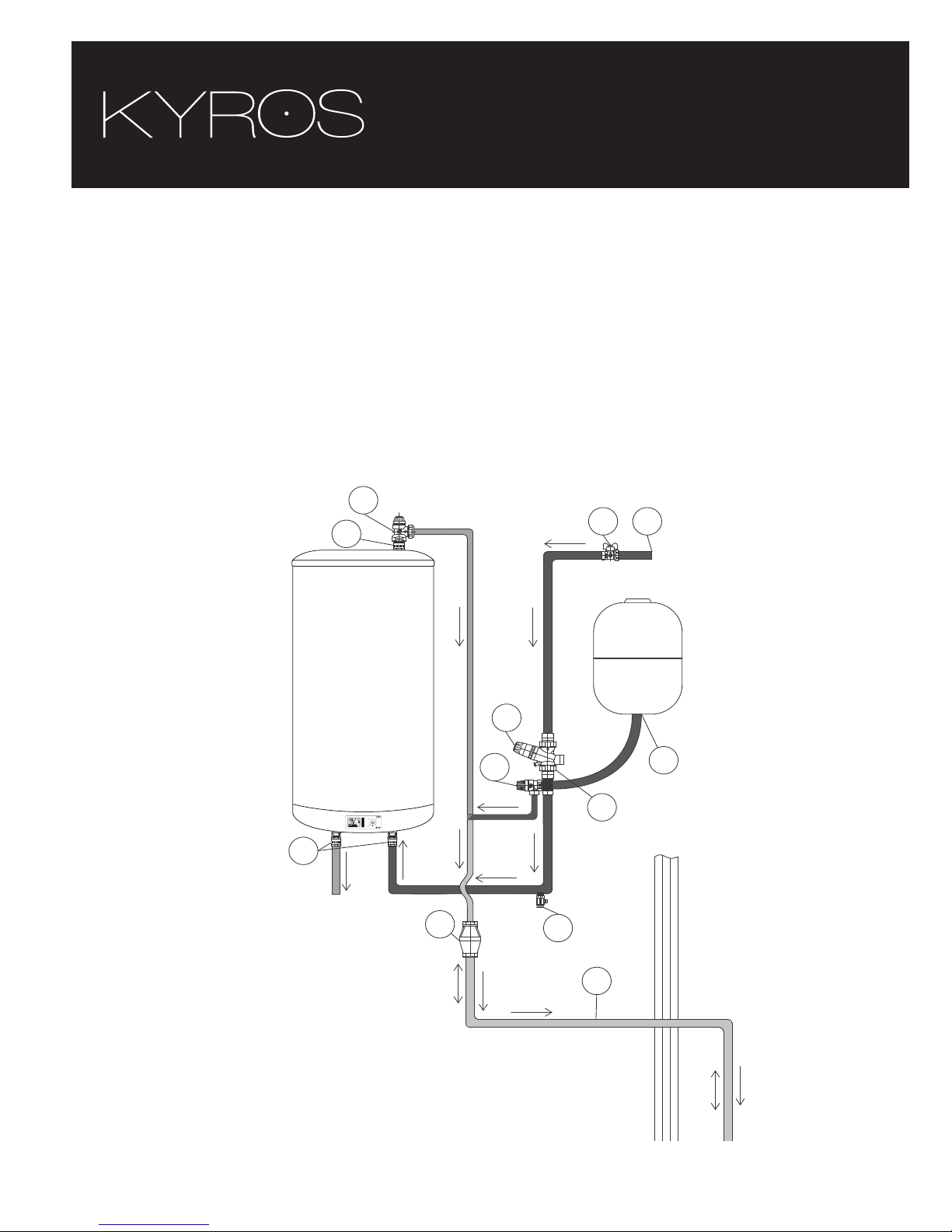

4.1. Connections. Connections MUST be made to the cylinder in accordance with Fig 1, and Fig 2.

A drain cock (not supplied) should be fitted in the position shown in Fig 2 to facilitate draining of

the cylinder.

4.2. Electrolytic fittings – It is a must for the electrolytic fittings to be fitted with the water heater.

If not, the guarantee will be void. Check the T/P Valve to see if it is connected with the electrolytic

fittings . If not, please contact us.

4.3. Cold water supply – For best results, the cylinder should be fed by an uninterrupted supply

pipe into the pressure reducing valve (PRV) with a maximum supply pressure of 0.9 MPa. The

cylinder should not be used on any system with a supply pressure below 0.15 MPa and a flow rate

of less than 20 litres per minute.

4.4. Temperature and pressure relief valve – The temperature and pressure relief valve (T/P Valve)

is supplied. Once the T/P valve is fitted should not be removed from the cylinder or tampered with

in any way. The valve is pre calibrated to lift at 0.7 MPa or 90 degrees centigrade and any attempt to

adjust it will invalidate the warranty and could affect the safety performance of the unit.

The outlet of the T/P valve should be routed in 15 mm copper piping in a downward direction

alongside the water heating unit to the tundish in a frost-free environment. The outlet of the

expansion relief valve must be T’d into this pipe before the tundish so that any water exiting either

valve can be seen draining through the tundish– see figure 2 and 3.

4.5. Pressure reducing valve – The pressure reducing valve should be installed in the cold water

supply to the water heating unit with the arrow pointing in the direction of water flow as shown in

figure 2. This can be connected to a maximum supply pressure of 0.9 MPa.

4.6. Expansion relief valve – This must be installed between the pressure reducing valve and the

water heating unit in accordance with Figure 2. No other valve should be fitted between this valve

and the cylinder. The expansion relief valve contains a non return valve.

08

4.7. Expansion vessel – A suitable expansion vessel with a pre-charge pressure of 0.15 or 0.3 MPa

is available in an optional kit for fitting to all water heating units in the range. The expansion vessel

MUST be fitted to the safety group. The expansion vessel MUST be positioned with the entry point

at the bottom – see Figure 2.

IMPORTANT: Regular checks must be carried out to ensure that the expansion vessel is correctly

pressurised to 0.15 or 0.3 MPa at all times. – see Figure 2.

4.8. Tundish – The tundish must not be positioned above or in close proximity of any electrical

current carrying devices or wiring. The installation should conform with the requirements of item

4.10 below.

4.9. Connection arrangement for TFT KYROS Cylinder

Water Flow

To tap

CW

to tap

Cold

water

inlet

Hot water

Outlet

12

5

3

4

300 MIN

100 MAX

6

9

8

7

10

11

11

1 Mains cold water supply

2 Stop cock (not supplied)

3 Pressure reducing valve *

4 Check valve *

5 Expansion relief valve *

6 Discharge pipe 22 mm

7 Drain cock (not supplied)

8 Tundish *

9 Expansion vessel *

10 T/P relief valve (included)

11 Electrolytic fittings (included)

Figure 2

* Available in optional Installation Kit

Loading...

Loading...