Rointe DALIS, Dalis 200DHW4, Dalis 200DHWI4, Dalis 260DHW4, Dalis 260DHWI4 Instruction Manual

Page 1

INSTRUCTION MANUAL

Information, operation & installation

DALIS

Digital electric unvented heat pump

Page 2

Please read this instruction manual carefully to ensure correct installation and operation.

It is important that the installer reads and understands these instructions and unpacks and

familiarises themselves with the equipment before commencing the installation. Failure to

observe these instructions will make the guarantee invalid.

CONTENTS

1. Introduction ....................................................................................................................................... 2

2. Disclaimer ......................................................................................................................................... 3

3. Regulations ....................................................................................................................................... 3

4. Mandatory installation kits ............................................................................................................... 3

5. Safety information and warnings ..................................................................................................... 4

6. Technical information ....................................................................................................................... 6

7. Before installation ............................................................................................................................. 8

8. Installation ....................................................................................................................................... 12

9. Commissioning ............................................................................................................................... 24

10. Programming ................................................................................................................................. 25

11. Maintenance .................................................................................................................................. 39

12. Troubleshooting ..............................................................................................................................41

13. Product disposal .............................................................................................................................41

14. Guarantee conditions .................................................................................................................... 42

15. Commissioning record .................................................................................................................. 44

16. Guarantee certificate ..................................................................................................................... 45

17. Service record ............................................................................................................................... 47

1. Introduction

Thank you for choosing Rointe. The Dalis heat pump is designed to produce sanitary domestic hot

water, through the use of heat pump technology. This model consists of a compressor, evaporator,

condenser and a throttle valve. A liquid / refrigerant gas flows inside this product.

The product is manufactured from high quality components and meets all health and safety require-

ments. Before installing and / or using this product, carefully read this manual. This manual must be

kept with the product at all times, even if the ownership of the product changes.

If you have any questions on this product, please contact our Technical Support department by phon-

ing 0203 321 5929 or send an email to support@rointe.co.uk.

IMPORTANT: This product has been manufactured for domestic hot water as part of a pressur-

ised water heating system. Rointe will not take responsibility for safe operation of this product

outside of the scope of intended use.

The symbol represents important information or a warning. Please read these carefully.

2

Page 3

DALIS

Digital electric unvented heat pump

2. Disclaimer

This manual has been thoroughly verified, however in some instances non-compliance can occur.

Therefore we (Rointe) accept no liability for complete conformity.

We reserve the right to carry out modifications to the product’s construction, characteristics or its

data at any time. Therefore, we do not accept any liability claims attributable to instructions, figures,

drawings or descriptions, without prejudice to errors of any kind.

We will not be held responsible for damages attributable to incorrect installation, product misuse or

improper use, or as a consequence of unauthorised repairs, modifications or replacement.

3. Regulations

The equipment can only be installed and commissioned for use within domestic water closed heating

systems, according to the BS EN 12828 standard. It adheres to the following directives:

• Directive 2011/65/UE on use of hazardous substances in electronic equipment (RoHS).

• Directive 2014/30/UE Electromagnetic compatibility (EMC).

• Directive 2014/35/EU Low Voltage Directive (LVD).

• Directive 2009/125/CE Ecodesign requirements.

• Directive 2010/30/UE Energy labelling.

• Directive 2012/19/UE on waste electrical and electronic equipment (WEEE).

3.1. Protection degree

The product has a Protection Degree of IPX4.

3.2. Refrigerant/coolant used

The type of refrigerant used is: HFC-R134a. This device contains fluorinated greenhouse gases

included in the Kyoto protocol. Do not discard these gases into the environment. Maintenance and

disposal operations must be carried out by qualified personnel only.

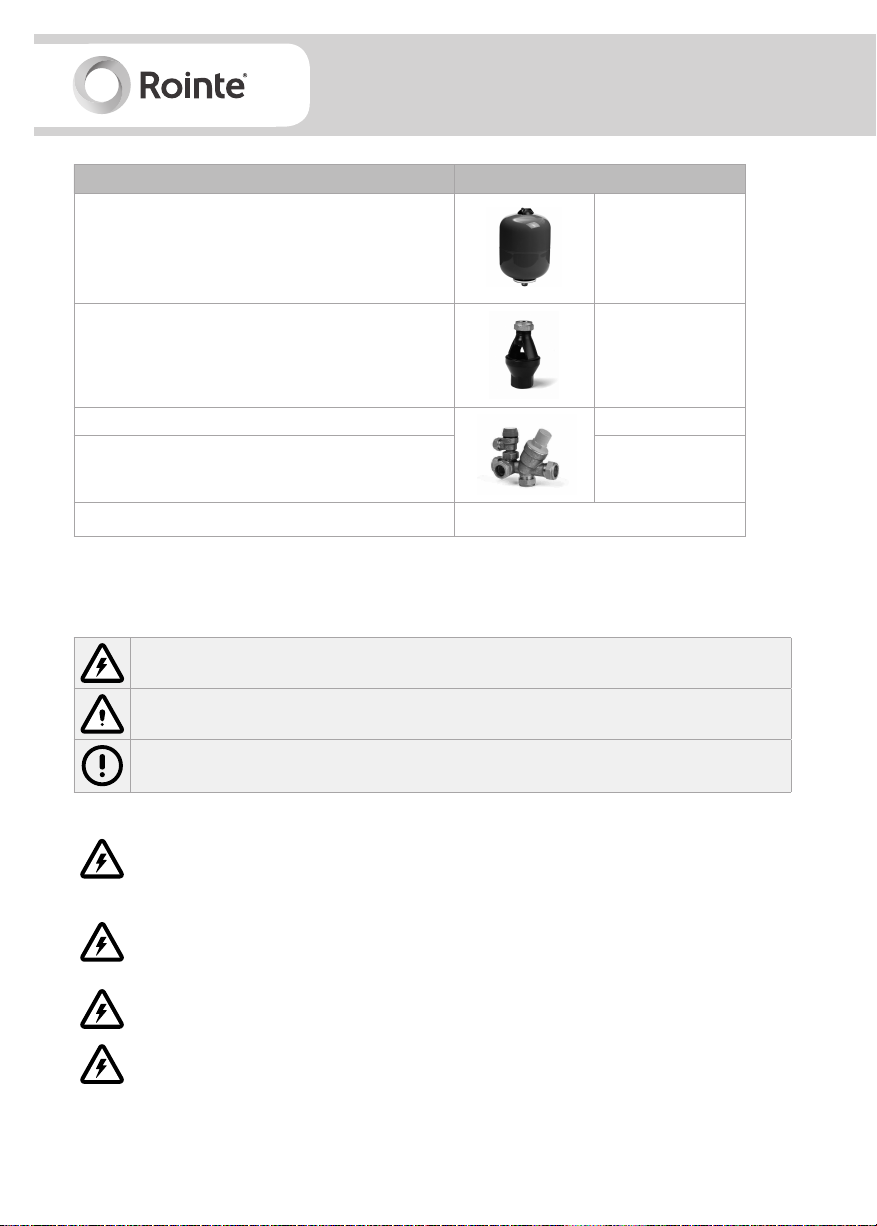

4. Mandatory installation kits

IMPORTANT

As this product is an unvented domestic hot water heater, it is mandatory that it be

installed using a Rointe installation kit and by a professional with a valid Unvented

Water Heater Installer certification. The installation kits are NOT supplied with this

product. They must be purchased separately. They comply with Building Regulations

Section G3.

Please contact us on 0203 321 5929 if you have not purchased an appropriate

installation kit for this product BEFORE installation.

The T/P valve is factory fitted with the product as standard.

3

Page 4

Fittings supplied with installation kit (sold separately) KITW03

Expansion vessel

Tundish 15 - 22 mm

Pressure reducing valve 0.35 Mpa

Safety relief valve 0.60 Mpa

EAN CODE 8436045914354

18 litres

(0.1 Mpa)

5. Safety information and warnings

Please read this information carefully. If you have any questions, please contact us.

This symbol indicates a safety warning or a hazard of an electrical nature.

This symbol indicates general warnings of actions that could result in damage to the

product or injury to the installer/user/person.

This symbol indicates information or advice for operation of the product.

Do not open or disassemble the product when it is connected to a power supply. Isolate

all electrical supplies from the product before commencing work. Danger of electric

shock!

The maintenance of this appliance must be carried out by suitable qualified persons

only. It is recommended to maintain the product on an annual basis. Isolate all power

supplies from the product before commencing work. Danger of electric shock!

It is important that the tundish is positioned away from any electrical components.

Means for electrical disconnection must be incorporated in the fixed wiring in

accordance with wiring rules.

4

Page 5

DALIS

Digital electric unvented heat pump

Before removing the cover from the product isolate the appliance using the isolating

switch. Danger of electrical shock! Only use suitable electrically insulated equipment

when working inside product housing.

Do not touch the equipment when barefoot or with wet or damp body parts.

This product must only be installed and operated by competent adults. Children must

not play with the product. The product must not be cleaned, nor any maintenance

made by children.

No isolating device may be fitted between the inlet group and the cold water inlet on

the cylinder, as by doing so impor tant safety devices could be isolated.

Do not sit on, rest anything on, move from an upright position or place anything inside

the product.

The cylinder must be filled with water before switching on. Failure to do so will damage

the heating element and the guarantee will be invalid.

The appliance should be installed in a place where it is not exposed to damp, frost or

ice and is not at risk of being splashed with water. Do not spray or pour water into the

product.

This product has not been designed, nor is it intended for use within hazardous

environments (due to the presence of potentially explosive atmospheres – according to

ATEX standards or with a requested IP level exceeding that of the product) or in

applications that require (fault-tolerant, fail-safe) safety characteristics such as in

circuit-breaking systems and/or technologies or in any other context in which the

malfunctioning of an application could cause death or injury to people or animals or

serious damage could be caused to objects or the environment.

If the product fails, it could cause damage to people or animals, or cause damage to

objects or the environment. If necessary, please provide an independent monitoring

system with alarm functions to avoid such damages.

We (Rointe) are not responsible, under any circumstances, if the product is used for

purposes other than those for which it is intended, or improper use of the product.

5

Page 6

6. Technical information

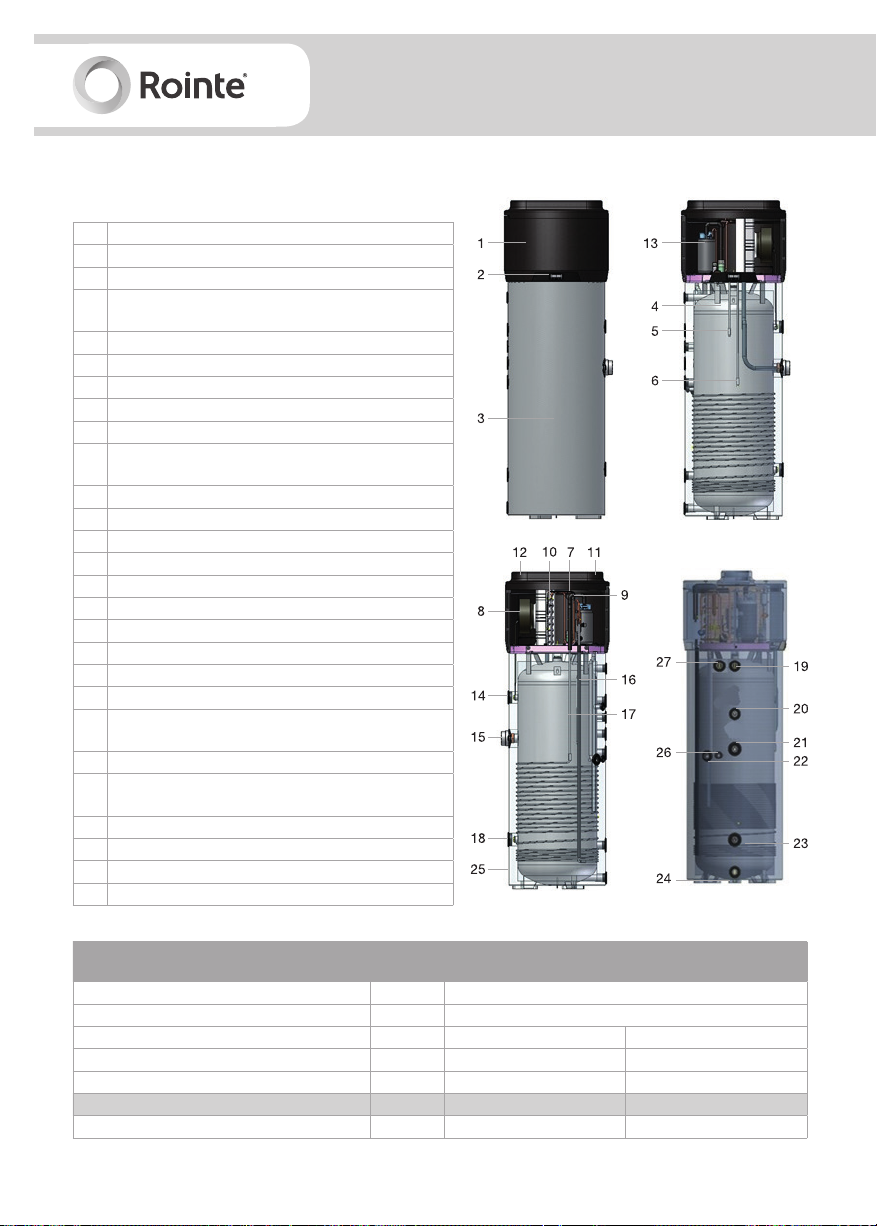

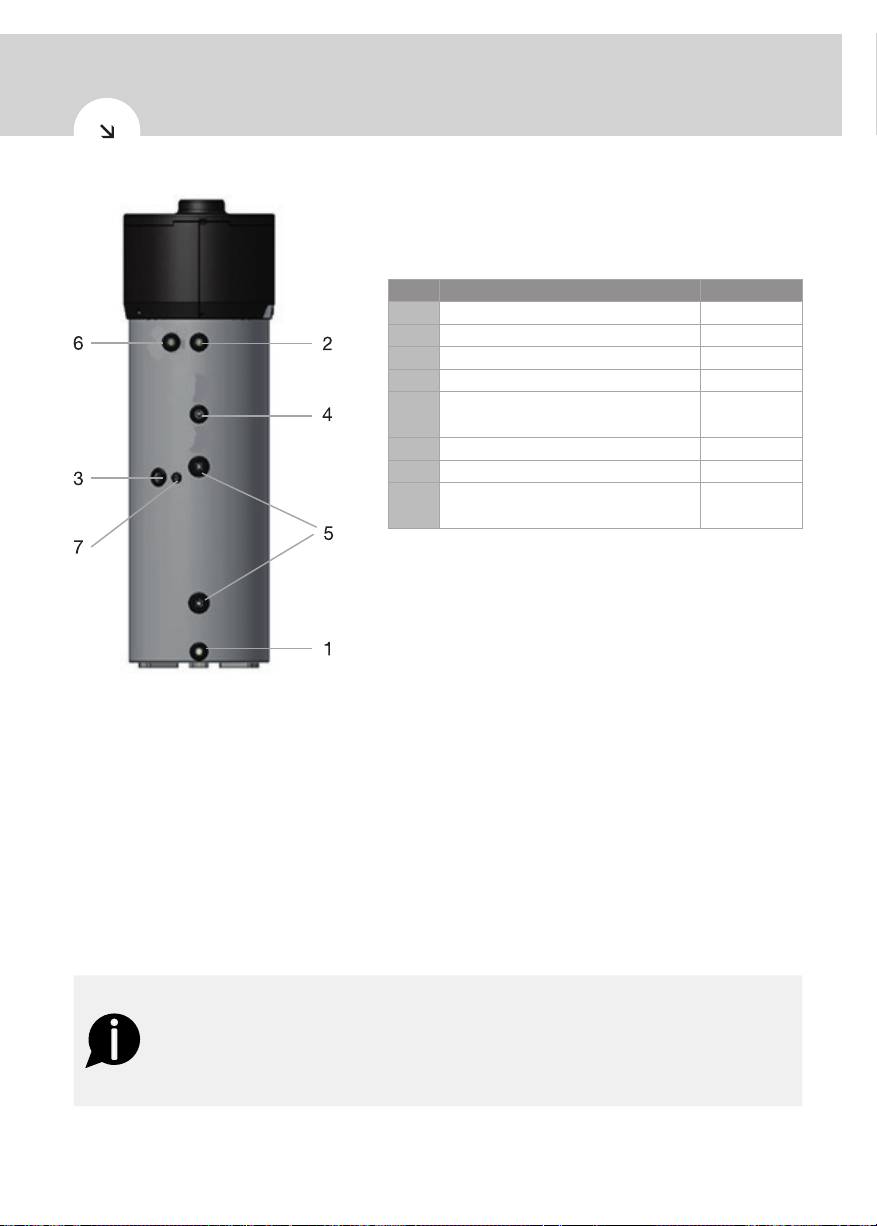

6.1. Construction characteristics

1 Heat pump 1.6 Kw

2 Control panel

3 ABS casing

Steel tank (water heater) enamelled according to EN

4

standards (capacity: 200 / 260 litres)

5 Upper probe

6 Lower probe

7 Refrigerant recharge

8 Air recirculation fan

9 Throttle valve with double capillary tube

High-efficiency finned evaporator coil. Volume of

10

liquid deposited is regulated by a thermostatic valve.

11 Air inlet (160 mm)

12 Air outlet (160 mm)

13 Hermetically-sealed rotary compressor

14 Replaceable magnesium anode

15 Electric heating element

16 Condensation pump discharge line

17 Condensation return

18 Replaceable magnesium anode

19 Hot water outlet connection joint (G 1”)

20 Recirculation mounting (G ¾”)

Input coil for solar thermal power system

21

(G 1”1/4; 1 m2 exchange surface)

22 Condensatation discharge pipe (G 1/2”)

Ouput coil for solar thermal power system

23

(G 1”1/4; 1 m2 surface)

24 Cold water inlet connection joint (G 1”)

25 50 mm polyurethane insulation

26 ½”G fitting for probe immersion sleeve

27 Pressure and temperature relief valve G1/2”

Description

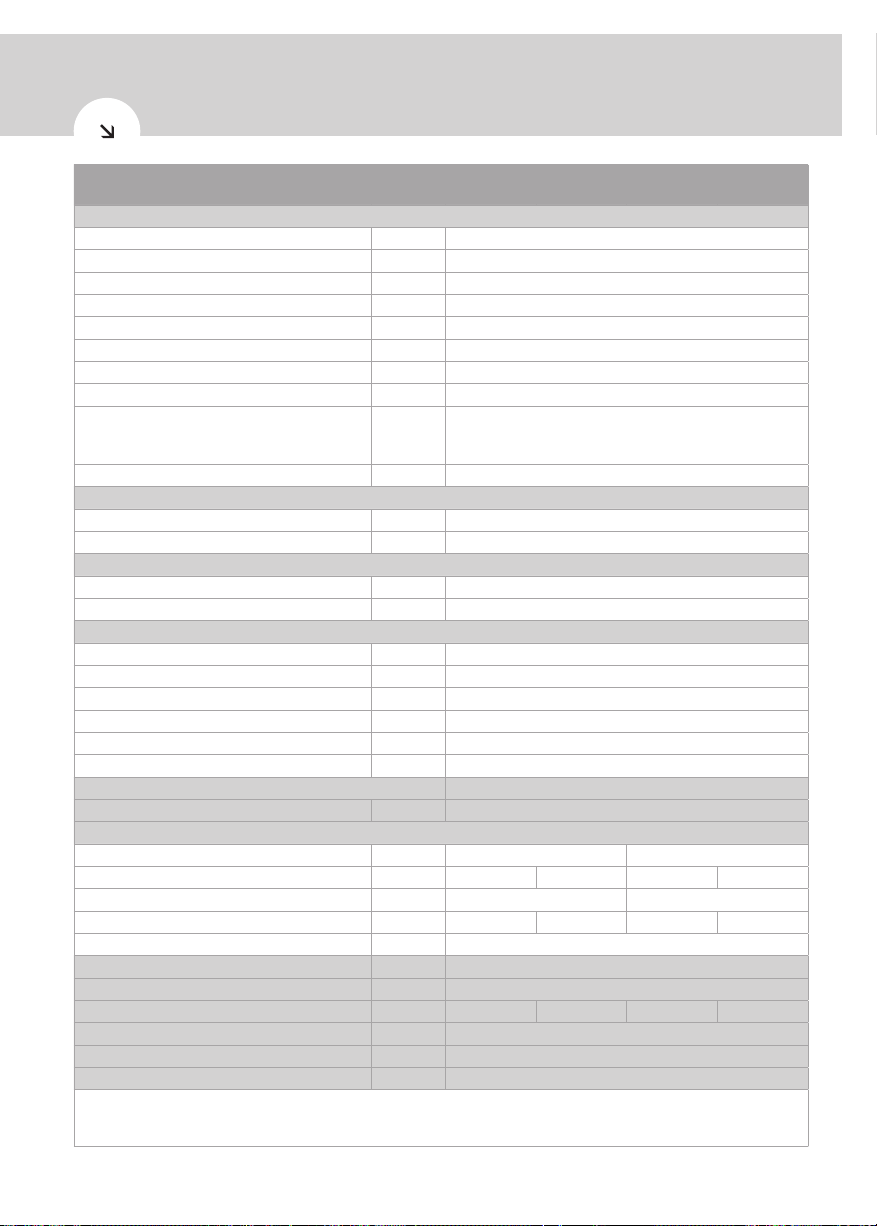

Thermal power yield kW 1.6

Total thermal power kW 3.1

Heating time (1) h:m 07:16 09:44

Heating time in BOOST mode (1) h:m 03:48 04:57

Thermal losses (2) W 105 76

Dimensions (diameter x height x depth)

Ø mm 650 650

6

Unit of

measure

mm 650 x 1,714 x 600 650 x 2,004 x 600

Dalis

200DHW4

Dalis

200DHWI4

Dalis

260DHW4

Dalis

260DHWI4

Page 7

DALIS

Digital electric unvented heat pump

Description

Unit of

measure

Dalis

200DHW4

Dalis

200DHWI4

Dalis

260DHW4

Dalis

260DHWI4

Electrical data

Power supply V 1/N/230

Frequency Hz 50

Degree of protection - IPX4

Max. absorption

Average power absorption kW

kW 0.50

0.37

Heating element + max. absorption kW 2

Power kW 1.5

Max. current A 2.3

16A T fuse / 16A automatic switch, characteristic C

Overload protection A

(to be expected during installation on power supply

systems

Internal protection - Single safety thermostat with manual reset

Functions

Temperature min. ÷ max. air intake 90% R.H. °C 4 ÷ 43

Min. ÷ max temperature installation site °C 4 ÷ 43

Working temperature

Max. programmable temperature - ECO °C 56

Max. programmable temperature - AUTO °C 70

Compressor (rotary) & fan (centrifugal)

Compressor protection - Thermal circuit breaker with automatic reset

Ejection outlet diameter mm 160

Revolutions per minute RPM 1,420

Nominal air capacity m3/h 350

Max. pressure head available Pa 100

Motor protection - Internal thermal circuit breaker with automatic reset

Condenser

Refrigerant R134a (load)

g 900

Wrapped externally, not in contact with water

Water storage

Capacity litres 200 260

Actual water storage capacity Vm litres 199 194 254 246

Max. volume hot water Vmax (3) litres 276 342

Connection coil solar thermal power system m2 n/a 0.9 m

2

n/a 0.9 m

Cathodic protection mm 2 x Mg anode Ø33 x 250; G1 1/4”

Insulation

Defrosting

Empty weight / when filled with water

- 50mm high density polyurethane foam

- Passive with air

Kg 81 / 280 92 / 286 93 / 347 110 / 356

Sound power indoors Lw(A) (4) dB (A) 59

Automatic anti-legionella cycle (5) - YES

Maximum working pressure

(1) temperature of incoming air supply 20°C (max.15°C), temperature of water heater storage environment 20°C, water heated from

10°C to 55°C, (according to EN 16147-2011). (2) measurements carried out according to EN 12897-2006. (3) measurements carried

out according to EN 16147-2011. (4) measurements carried out according to EN 12102-2013. (5) Automatic activation - 30 day cycle.

bar 7

2

7

Page 8

7. Before installation

IMPORTANT

Failure to observe these instructions will invalidate the guarantee. Handling / instal-

lation of this product is subject to the Health & Safety At Work act. This product must

be installed by a qualified professional that is certified for Unvented Water Heater

installation. Do not attempt to install this product yourself if you are not qualified.

7.1. Handling and transport

• You must not put any type of pressure on the upper part of the device, as it is not structural in

nature. The product must be transported and handled in the upright position only. The screen

should be facing the upper side. If tipped, the centre of gravity will shift. Please handle with care.

• The equipment can only be transpor ted horizontally during the last kilometre, taking care to

place some supports on the underside of the product in order not to lean against upper parts.

Positions allowed for transport/handling:

Positions NOT allowed for transport / handling:

8

Page 9

DALIS

Digital electric unvented heat pump

7.2 . P a cka g i ng

• If the product is not installed immediately, it should remain in its protective packaging with all

pipe/end caps in place to prevent damage or dir t deposits.

• The equipment is supplied in a cardboard box, fixed to a pallet with screws. When removing the

screws from underneath the pallet, DO NOT tilt the product.

• Use a forklift or pallet truck to unload the equipment: these should have a load capacity of at

least 250 kg. Do not drop or lower the product suddenly.

• Unpacking the product must be carried out with care so the product does not become damaged.

Ensure all the supplied fittings have been removed from the packaging.

• Keep packaging out of reach of children. Make sure that the appliance is intact and not damaged.

If in doubt, do not use or install the product and contact us.

7.3. Location

Please adhere to the following conditions when choosing a location to install the product:

• Must be installed in a damp, frost-free environment, with containment systems in case of serious

water leaks.

• Must have structural integrity that is sufficiently robust to support the product weight when the

tank is full of water, plus a flat and level surface on which to install the product.

• Must allow access to water mains supply, hot and cold water pipework and a suitable electrical

supply.

• Be readily available for connection to condensation discharge pipe.

• Be sufficiently ventilated and illuminated (if necessary) and in a space of at least 20m3.

Figure 2 - minimum installation space

9

Page 10

The product MUST NOT be installed in locations where:

• The air intake contains solvents, explosive matter, grease, dirt or dust/aerosol particles.

• It is outdoors, in rooms exposed to frost, ice or damp, or in rooms where there is a lot of steam/

vapour (e.g. a bathroom).

• It is sat on floor slabs containing wooden beams e.g. attics, to avoid mechanical vibrations.

• It is prohibited to connect vented exhaust hoods to ventilation systems.

Care must be taken when installing the product in a garage or outbuilding. All exposed pipework must

be sufficiently insulated to avoid frost or ice damage.

When installing the product, ensure that all labels are visible and pipework does not restrict any work

that needs to be carried out on the various components.

Ensure the product sits flat and level on a horizontal surface as shown in figure 2.

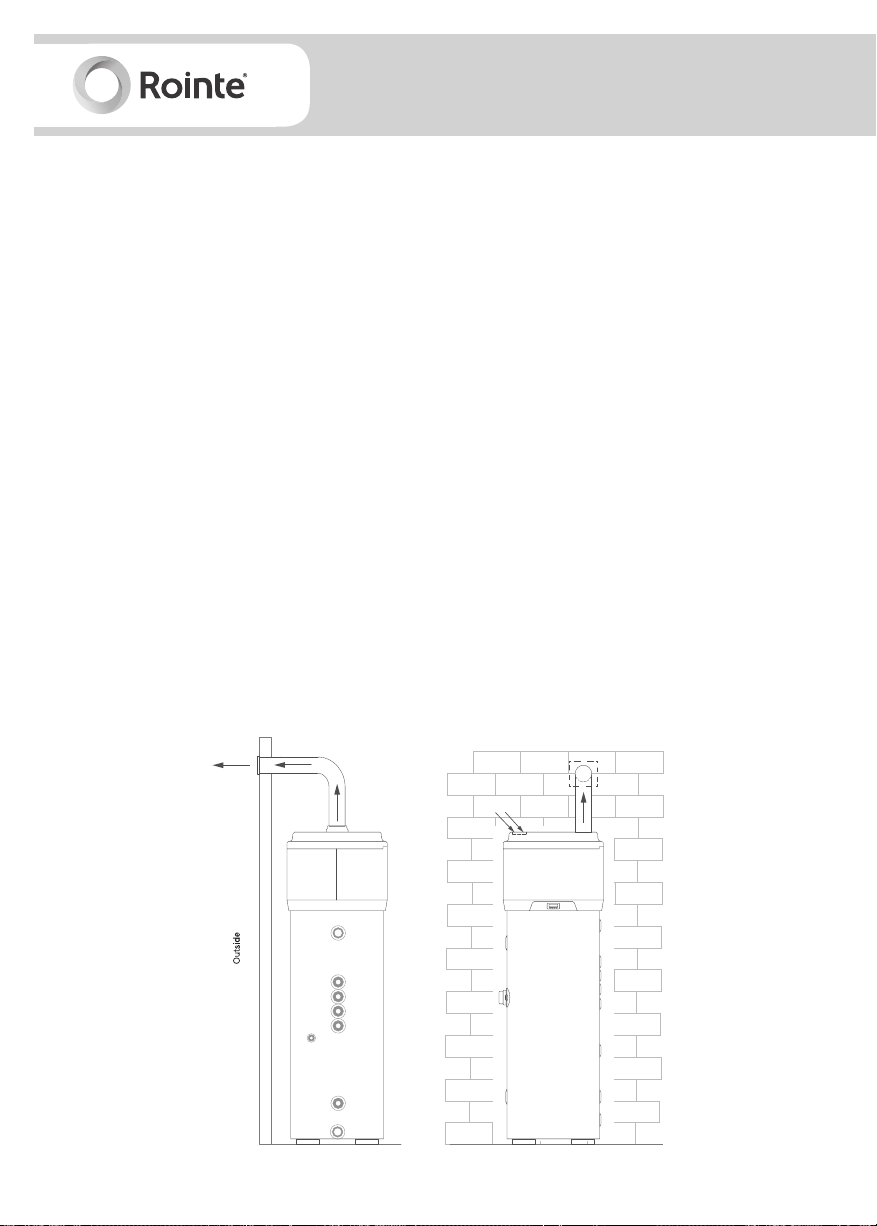

7.4. Ventilation

The product requires adequate ventilation (see figure 3). Install air ducts ensuring each one:

• Does not weigh down the product itself and allows for maintenance work.

• Is suitably protected to avoid foreign objects or materials getting inside the product.

• Does not exceed the recommended maximum length of 6 metres (with 2 x 90º elbow junctions).

• The total maximum allowable pressure drop for all components, including feed-throughs for

mounting on an external wall, in the pipe system does not exceed 100 Pa.

Figure 3 - Air duct for model with upper outlets

10

Page 11

DALIS

Digital electric unvented heat pump

• During operation, the heat pump tends to lower the ambient temperature if the external air duct

is not carried out.

• An appropriate protection grid must be installed in line with the discharge pipe conveying air

to the outside, with the aim of avoiding foreign bodies from entering the equipment. In order to

guarantee maximum device performance, the grid chosen must ensure low pressure loss.

• In order to avoid the formation of condensate, insulate the air discharge pipes and the air duct

cover connections with steam-tight thermal cladding of an adequate thickness.

• If it is considered necessary in order to prevent flow noise, sound mufflers can be mounted. Fit

the pipes and connections to the heat pump with vibration damping systems.

WARNING

The simultaneous operation of an open flue firebox (e.g. an open flue fireplace) or

combustion chamber together with the product will cause a dangerous drop in am-

bient pressure. This could cause the blackflow of exhaust gas into the environment

itself.

Do not use the product with an open flue firebox or combustion chamber. Use only

sealed (approved) chamber fireboxes or combustion chambers with a separate duct

for combustion air.

Keep the doors of the room closed and hermetically sealed if they do not have a

supply of combustion air in common with inhabited areas.

7.4.1. Ventilation accessories

Suitable ventilation accessories are available on the market, which are designed for simple and

efficient heat pump water connections. See below for ventilation accessories required for successful

and correct installation:

Item Part

1

Semi-rigid pipe - 160mm Ø lg 2m

2

90º insulated elbow - 160mm Ø

3

Collars for attaching to wall

4

Connectors for insulated pipe

5

Horizontal terminal for insulated pipe

11

Page 12

8. Installation

100 mm MAX

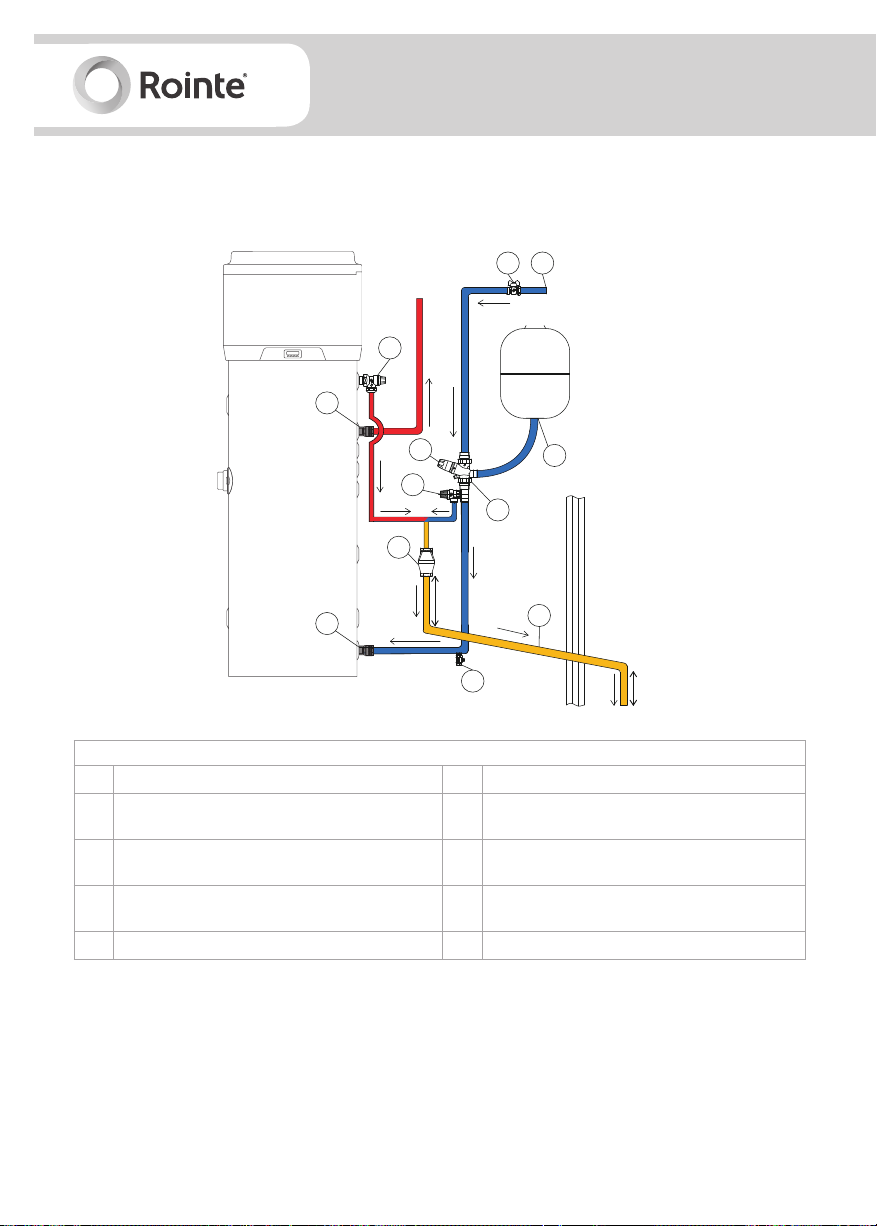

8.1. Installation diagram

Figure 5 - installation

11

Hot water outlet

2

1

Water flow

10

CW

3

5

8

to tap

9

4

11

Cold water inlet

300 mm MIN

7

6

DESCRIPTION OF INSTALLATION ITEMS

1

Mains cold water supply

2

Stop cock (not supplied)

Pressure reducing valve - (supplied in mandatory

3

installation kit, see section 4)

Check valve & expansion relief valve - (supplied

4-5

in mandatory installation kit, see section 4)

6

Discharge pipe 22 mm

7

Drain valve (not supplied)

Tundish - (supplied in mandatory installation kit,

8

see section 4)

Expansion vessel - (supplied in mandatory

9

installation kit, see section 4)

10 T/P relief valve (included)

11 Electrolytic fittings (included)

When carrying out the installation you must take care, so that:

• Extra pressure is not applied to the product e.g. by leaning on it.

• Foreign bodies and materials cannot enter inside the product.

• The selected pressure protection grid ensures low pressure loss.

• The air discharge pipes and roof connections are isolated with steam-tight thermal coating to

avoid condensation.

12

Page 13

DALIS

Digital electric unvented heat pump

8.2. Non-standard installations

One of the unique features of heat pump heating systems is that they create a considerable drop in

air temperature usually expelled outdoors. The expelled air, in addition to being colder than the air in

the environment, is also fully dehumidified. This means that the flow of air can be fed back inside the

building again to cool rooms or spaces during warmer months, such as the summer. A dual air outlet

pipe should be installed, with 2 dampers attached, so that the expelled air flow can be directed either

indoors or outdoors - see figure 6a and 6b.

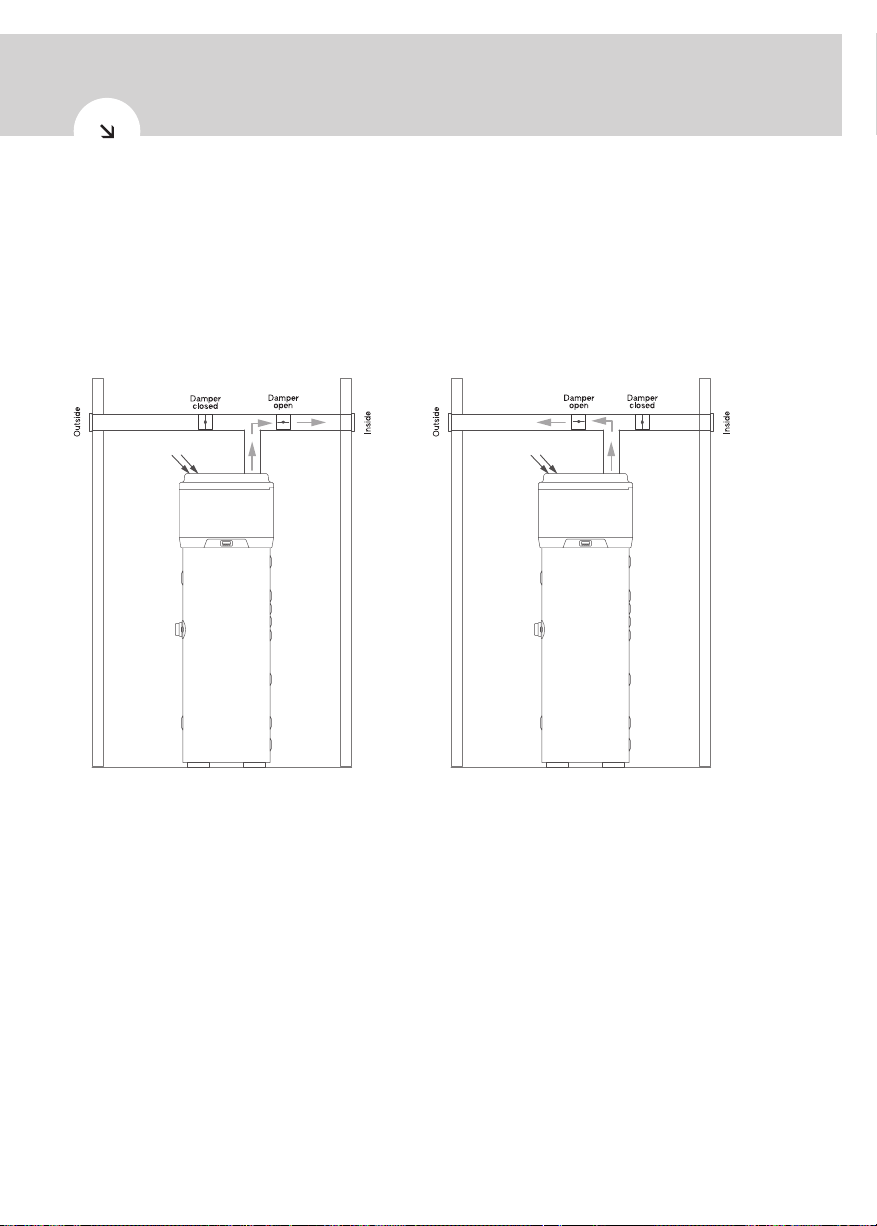

Figure 6a - installation in summer Figure 6b - installation in winter

8.3. Cold water supply

For safe per formance of the product, the tank should be directly fed by an uninterrupted supply pipe

that connects to the pressure reducing valve with a maximum supply pressure of 0.9 MPa - see figure

5. The product should not be used with a supply pressure below 0.15 MPa and a flow rate of less than

20 litres per minute. The following criteria must also be met:

• Cold water supply must come directly from the cold water mains after the mains stop valve to

the p rop e r t y.

• The inside diameter of the cold water pipework must be at least 19mm.

• Pipework should meet the water supply regulations for wholesome water.

13

Page 14

8.4. Connections

8.4.1. Overall dimensions

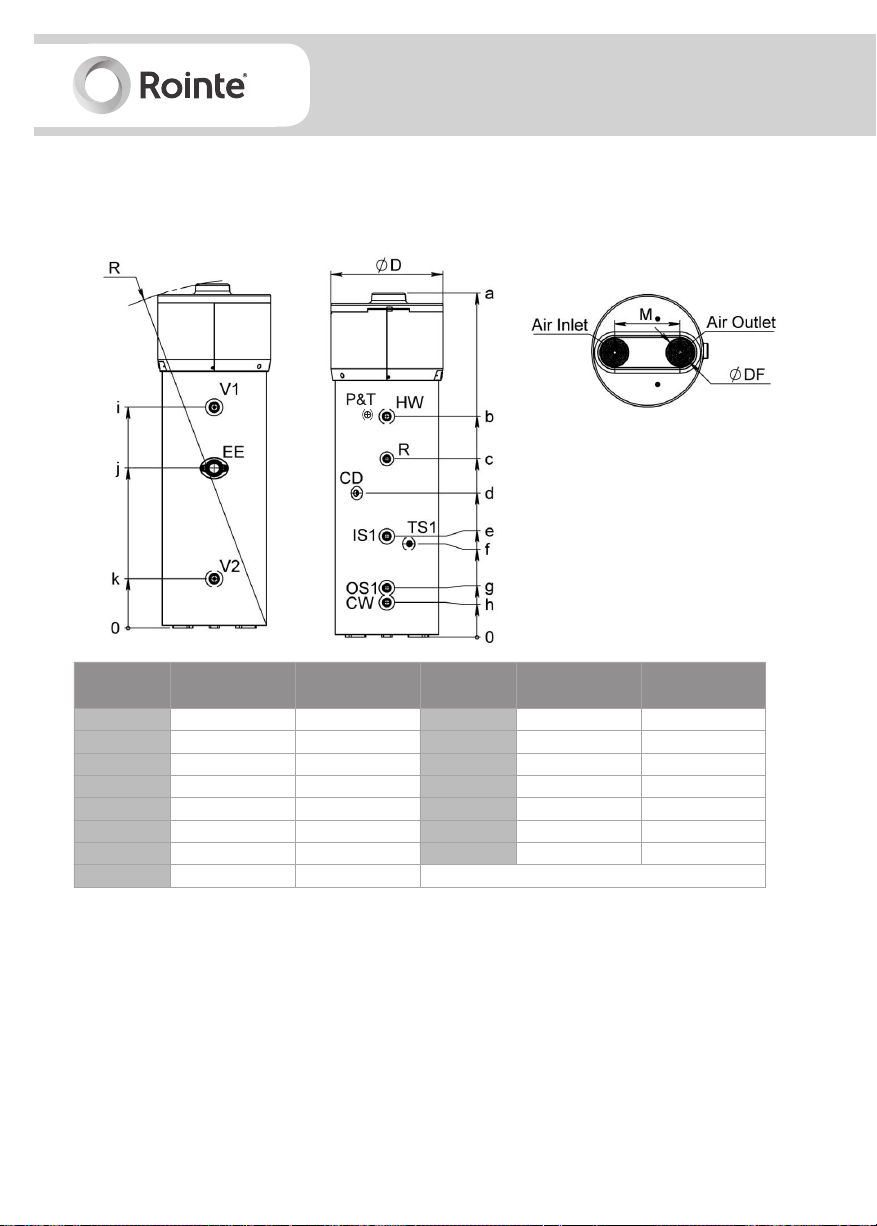

Figure 7 - overall dimensions

Dimensions

(+/- 5mm)

a

b

c

d

e

f

g

h

200 litres model 260 litres model

1,717 2,004

1,001 1,286

769 1,065

769 839

674 674

644 644

287 287

202 202

Dimensions

(+/- 5mm)

i

j

k

R

ØD

ØDF

M

200 litres model 260 litres model

1,000 1,286

716 931

287 287

1,751 2,025

650 650

160 160

380 380

8.4.2. Water supply connections

Connect the cold water inlet and outlet pipes to the appropriate connection points (see figure 8).

14

Page 15

Figure 8 - overall dimensions

DALIS

Digital electric unvented heat pump

No.

1

CW: cold water inlet pipe G1”

2

HW: hot water outlet pipe G1”

3

CD: condensation drain 1/2”

4

R: recirculation pipe G 3/4”

IS1: Solar thermal power inlet coil

5

OS1: Solar thermal power outlet coil

6

P&T: T/P valve G1/2”

7

TS1: immersion sleeve probe G 1/2”

V1 / V2: protective anodes

-

EE: Heating element

Description Connection

G1”

G1 1/4”

G1 1/2”

A dirt/impurities filter must be installed in the cold water pipe inlet. The product must not operate with

a water hardness below 12ºF or hardness above 25ºF. If this is the case, then a suitably calibrated and

monitored water softener must be used.

This product is equipped with a pressure and T/P valve that complies with the BS EN 1490:2000

standard. It is factory set to operate on 7 bars pressure and a temperature of 90ºC.

The T/P safety valve for protection against over pressure and temperature must be operated regularly

to remove lime scale deposits and check it is not blocked. For more information on the T/P valve

please see section 8.9.

In case an expansion vessel is not installed, make sure that the cold water intake does not contain

any non-return valves.

WARNING

This product is capable of producing domestic hot water over 60ºC. To protect

against burns, we recommend a thermostatic mixing valve (sold separately) be in-

stalled in the hot water pipe. Also ensure there is no human burn risk at drain pipe

connecting T/P valve.

See figures 9a and 9 b for an example of a water supply connection.

15

Page 16

Figure 9a - water supply connection

1

2

3

4 Heat pump

5

6

7

8

9

Water inlet pipe

Shut-off valve

Automatic thermostat mixing valve

Recirculation pump

Spring check valve

Hot water outlet pipe

Drain tap

Expansion vessel

Figure 9b - T/P safety valve to drainage

16

10

T/P safety valve

11

Inspectable end of discharge pipe

Page 17

8.4.3. Solar power system integration

Figure 10 - example of a solar power system integration

DALIS

Digital electric unvented heat pump

1

Cold water intake pipe

2

Solar power system pump and accessories

3

Solar collectors/panels

4 Heat pump

5

Recirculation pump

6

Spring check valve

7

Drain tap

8

Solar thermal power coil

9

Hot water outlet pipe

8.5. Pipework and taps

The pipe runs should be executed as short as possible. Unused pipework should be removed and all

remaining lagged in accordance with regulatory requirements to prevent heat loss and condensation.

All pipework connections must be made according to figure 5. A drain cock (not supplied) should be

fitted in the position shown in figure 5. All taps and fittings should have a rated operating pressure of

0.6 Mpa (bar) or above.

8.6. Pressure reducing valve

The pressure reducing valve should be installed in the cold water supply to the product, above the

tundish and pointing in the direction as shown in figure 5. The pressure reducing valve can be con-

nected to a maximum supply pressure of 0.9 Mpa.

17

Page 18

8.7. Expansion vessel

The expansion vessel is mandatory on this product and is available within the installation kit (sold

separately) described in section 2. It MUST be fitted to the safety group and positioned with the

entry point at the bottom (see figure 5). We recommend to mount the expansion vessel higher than

the water heater to avoid draining the water heater when maintaining and replacing the expansion

vessel. It is important to check the pre-charge pressure of the expansion vessel membrane before

filling the cylinder. The expansion vessel should be pressurised to 0.15 or 0.3 MPa at all times.

8.8. Expansion relief valve

The expansion relief valve must be installed between the pressure reducing valve and the product

(see figure 5). No other valve should be fitted between this valve and the cylinder. The expansion

relief valve contains a non return valve. The discharge pipework from the expansion relief valve must

be installed constantly falling to an open point of discharge. It is recommended to combine it with

the discharge of the T/P valve (see figure 5).

8.9. T/P valve

The T/P valve (temperature and pressure relief valve) is supplied factory fitted as part of the product,

to meet the requirements of the G3 building regulations. It complies with the BS EN 1490 standard.

The valve is pre-calibrated to lift at 0.7 MPa or 90ºC. The T/P valve should not be removed or modified

in any way and if done so, will render the guarantee invalid.

The outlet of the T/P valve should be routed in 15mm copper piping, in a downward direction along-

side the product to the tundish. The outlet of the expansion relief valve must be T’d into this pipe

before the tundish. This is so any water exiting either valve can drain through the tundish (see figure

11).

The T/P valve must be discharged directly or by way of a manifold via a short length of pipe (D1) into a

tundish. The discharge pipe must be installed in a continuous downward direction and in a frost free

environment. Water may drip from the discharge pipe and this pipe must be left open to the

atmosphere. The diameter of the discharge pipe (D1) should not be less than the nominal outlet size

of the safety device e.g. T/P valve.

Where a manifold is used it should be sized to accept and discharge the total discharge from all D1

discharge pipes connected.

8.10. Tundish

The tundish should be vertical and located in the same space as the product and clearly visible to

the user. It must be fitted in close proximity to the safety device and close to the electrical current

carrying the wiring. There should be no more than 600mm of pipe between the valve outlet and the

tundish (see figure 11).

18

Page 19

Figure 11 - tundish and discharge pipe

8.11. Discharge pipe arrangement (D2)

DALIS

Digital electric unvented heat pump

WARNING

Discharge will consist of scalding water and steam. Asphalt, roofing felt and

non-metallic rainwater goods may be damaged by such discharges.

Please see figure 11 for diagram of discharge (D2) pipe arrangement. The discharge pipe from the

tundish should:

• Terminate in a safe place, where there is no risk to persons in the vicinity of the discharge.

• Be manufactured of metal or other material that is clearly demonstrated to be capable of safely

withstanding temperatures of the water discharged.

• Be clearly and permanently labelled to identify the product and its performance standard.

• Be at least one size larger than the normal outlet size of the safety device, unless its total

hydraulic resistance exceeds that of a straight pipe 9m long, i.e. discharge pipes between 9m

and 18m equivalent resistance length should be at least two sizes larger than the normal outlet

size of the safety device, between 18m and 27m and at least three sizes larger and so on.

• Have a vertical section of pipe at least 300mm long below the tundish, before any elbows or

bends in the pipework and installed in a continuous fall.

• Have discharges visible at both the tundish and the final point of discharge. Where this is not

possible or practical, here are some examples of acceptable discharge arrangements:

- Ideally below a fixed grating and above the water seal in a trapped gully.

19

Page 20

- External surfaces such as car parks, hard standings, grassed areas etc. are acceptable

providing that where children play or humans/animals otherwise come into contact with

discharges, a wire cage or similar guard is positioned to prevent contact whilst maintaining

visibility.

- Discharge at high level, e.g. into a metal hopper and metal down pipe with the end of the

discharge pipe clearly visible (tundish visible or not) or onto a roof capable of withstanding

high temperature discharges of water and 3 m from any plastic guttering system that would

collect such discharges (tundish visible).

- Where a single pipe serves a number of discharges such as in blocks of flats, the number

served should be limited to not more than six systems so that any installation discharging

can be traced reasonably easily. The single common discharge pipe should be at least one

pipe size larger than the largest individual discharge pipe to be connected. If unvented hot

water storage systems are installed where discharges from safety devices may not be appar-

ent (i.e. in dwellings occupied by blind, or disabled people), consideration should be given to

the installation of an electrically operated device to warn when discharge takes place.

IMPORTANT

Rointe do not take responsibility for any damage caused from discharges.

Figure 12 - sizing table for copper discharge (D2) pipe for common temperature relief valve outlets

Valve outlet size

(diameter, inches)

G 1/2 15

G 3/4 22

Min. size of discharge pipe

before tundish (mm)

Min. size of discharge pipe

D2 after tundish (mm)

22 9

28 18

35 27

28 9

35 18

42 27

Max. allowed length of pipe

after tundish (m)

8.11.1. Calculated example

The example below is for a 1/2” diameter temperature relief valve with a discharge pipe (D2) having

4 x 22mm elbows and a length of 7m from the tundish to the point of discharge.

The maximum resistance allowed for a straight length of 22mm copper discharge pipe (D2) from a

1/2” diameter temperature relief valve is 9.0m. Subtract the resistance for 4 x no 22mm elbows at

0.8m each = 3.2m.

The maximum permitted length equates to: 5.8m, which is less than the actual length of 7m, there-

fore, calculate the next largest size.

Maximum resistance allowed for a straight length of 28mm pipe (D2) from a 1/2” diameter tempera-

ture relief valve equates to: 18m. Subtract the resistance for 4 x 28mm elbows at 1.0 each = 4m.

Therefore the maximum permitted length equates to: 14m. As the actual length is 7m, a 28mm

diameter copper pipe will be satisfactory.

20

Page 21

DALIS

Digital electric unvented heat pump

8.12. Drain valve

We recommend a drain valve is installed (not supplied) in the lowest point of the cold water feed to

the product. This allows the product to be drained in a controlled manner if necessary (see figure 5).

8.13. Condensation drain connections

Condensation formed during operation of the heat pump should flow through a purpose-built outlet

pipe (G 1/2”) that passes inside the insulating casing and emerges on the side of the appliance.

Connect it to a duct via a siphon so that the condensation should flow as it should.

Figure 13a - example of condensation discharge Figure 13b - example of condensation

pipe c on n e ct io n via a s ip h on dischar g e pipe c on n e ct io n via si ph o n

with a water shut-off valve

8.14. Electrical fittings

The product is supplied already wired for the mains power supply. It is powered through a flexible

cable and a socket/plug combination (figure 14). An earthed Type G socket (UK) with separate pro-

tection is needed for the connection to the mains power supply.

Figure 14 - type G socket and plug

21

Page 22

IMPORTANT

The power supply to which the product will be connected must be protected by an

adequate residual current circuit breaker.

The type of residual current circuit breaker must be chosen by evaluating the type

of electric equipment to be used on the entire system.

With reference to the connection to the mains power supply and the safety equip-

ment (e.g. residual current circuit breaker), it must comply with standard IEC 60364-

4- 41.

The power supply must comply with all regulations in the country of product instal-

lation, as well as IEE Wiring regulations.

IMPORTANT

If the power cable is damaged, please contact us on 0203 321 5929. Please do not

shorten, modify or alter the power cable or plug without authorisation from Rointe.

It will render your guarantee invalid.

8.14.1. Remote connections

The product can be connected to other remote energy systems (solar panels and solar thermal

power). The user interface has two digital inputs with the following functions:

• Digital 1

When a dry contact is closed between terminals 30 and 31 (brown/yellow cable wires) and the

water temperature as measured by NTC1 is greater than SP8, the product stops. The product

starts again when the contact is released and the time set under C13 is reached, or immediate-

ly if the lower probe temperature is below SP8.

• Digital 2

When a dry contact is closed between terminals 31 and 32 (green/white cable wires) and the

heat pump reaches the temperature set under SP5 (pre-set to 62ºC), the nominal hot water

temperature is increased by 7ºC. For example, if you want to increase the temperature from

62ºC to 75ºC, you can specify that by accessing parameter SP6 in the settings where there is

sufficient solar panel electrical energy. The increase in temperature from 62ºC to 75ºC should

be made using the electric heating element (if SP6 is equal to SP5, the resistor is never activat-

ed).

For connection to digital inputs, the product is provided with an additional 4-core cable that has al-

ready been linked to the circuit board of the user inter face (placed inside the equipment - figure 14).

The remote links to any energy systems must be carried out by a qualified installer (junction boxes,

terminals and connection cables).

22

Page 23

DALIS

Digital electric unvented heat pump

Figure 14 - remote connection cables

To access the 4-core cable for remote connection it is necessary to remove the upper cover of the

product (see section 11.1. - figure 16), and take the cable outside through the dedicated opening

that is already present on the back cover, as indicated in figure 14.

Figure 15 - example of a remote connection

23

Page 24

8.14.2. Wiring diagram

Figure 15 - wiring diagram

9. Set up - commissioning

IMPORTANT

Check the product is connected to the earth cable.

Check that the line voltage corresponds to that indicated on the product identifica-

tion label/plate.

The tank must be filled with water before the product is switched on or connected

to a power supply.

See below for step by step guide on commissioning:

1) Fill the boiler by opening the water inlet tap and check that there are no leaks from gaskets,

pipes, joins or connections. Tighten the bolts or connections where necessary.

2) Do not exceed the maximum permitted pressure indicated in section 6 (technical informa-

tion).

24

Page 25

Digital electric unvented heat pump

3) Check that the water circuit safety equipment is working.

4) Connect the plug to the power socket.

5) When the plug is inserted, the product will be in stand-by mode. The display will remain

switched of f and the power key will be illuminated.

6) Press the power key. The equipment starts up in “ECO” mode (default setting), 5 minutes

after pressing the key.

10. Programming

10.1. Control panel

Fi

DALIS

10.1.1. ON / Stand-by button

• Switches the product on. When the product is switched on, it shows the status it was in when it

was previously switched off.

• Switches the product into stand-by. In stand-by the product can switch on in certain time slots

and independently enable the anti-legionella and defrost functions.

10.1.2. SET button

• Confirms choices, parameters or values.

10.1.3. Down button

• Scrolls down list of various parameters.

• Reduces the value of a parameter e.g. temperature.

10.1.4. Up button

• Scrolls up list of various parameters.

• Increases the value of a parameter e.g. temperature.

25

Page 26

10.2. Display screen

10.2.1. Display screen information

Symbol Item Description

If this is lit, the compressor is active.

Compressor LED

Defrost LED If this is lit, defrosting is in progress.

MF LED If this is lit, the electric heating element is active.

Fan LED If this is lit, the fan is active.

Maintenance LED If this is lit, maintenance of the air filter is required (if present).

If this is flashing:

- The compressor start-up procedure is in progress.

- The modification of the operating set points is in progress.

If this is lit, check the list of alarms and follow the procedure indicated in this

manual.

If this is lit, the product is in stand-by mode.

If this is flashing, the product has been switched on/off manually during a

switching on/off period in a certain time slot.

Loc

dEFr

Anti

ObSt

ECO

Auto

Alarm LED

ºCelsius LED If this is lit, the temperature will be measured in degrees (ºC).

ºFahrenheit LED If this is lit, the temperature will be measured in fahrenheit (ºF).

ON / Stand-by LED

n/a Not used

The keyboard is locked.

The defrosting procedure is in progress and it is NOT possible to enable any other function.

The anti-legionella function cycle is in progress.

The overboost function is active.

The economy function is active.

The automatic function is active.

10.3. Operating modes

• AUTOMATIC mode

This mode mainly uses the renewable energy of the heat pump. As a suppor t measure the electric

heating elements can be enabled and are activated if the water temperature is below a certain level,

or in the event where a temperature exceeding 62°C is required.

26

Page 27

DALIS

Digital electric unvented heat pump

• ECONOMY mode

This mode only uses the renewable energy of the heat pump without activating the electric heating

elements. It takes longer to enable but has considerable energy saving characteristics.

• OVERBOOST mode

This mode heats the water quickly by the using both the heat pump and the electric heating elements.

This function can be activated manually when the water temperature in the tank is below 40°C. At the

end of the heating process, the function is automatically disabled and the product is automatically

reset to AUTOMATIC or ECONOMY mode depending on which of these two functions was previously

programmed.

• ANTI-LEGIONELLA mode

This function is used as an antibacterial treatment to eliminate harmful bacteria by increasing the

water temperature to 60ºC. This function is activated automatically every 30 days, regardless of the

current mode in use.

• DEFROSTING mode

This function is necessary in order to eliminate frost deposits, which prevent the transfer of heat. This

function is enabled automatically when the device is used at low ambient temperatures.

IMPORTANT

When the equipment is turned on for the first time, it is programmed by the manufac-

turer to operate in the economy mode, with a water temperature value of 55°C. This

ensures energy saving using the renewable energy sources of the heat pump only.

Please note that the use of this function enables the user to save an average energy

saving of approximately 70% compared to other standard electric water heaters.

10.4. Basic management

10.4.1. Switch on/off manually

Press the button. The on/stand-by LED light will switch on/off. The equipment can also be

switched on / off during certain time slots; see parameters HOn and HOf.

If switching on/off manually, this always has priority over programmed time intervals.

If the keypad has been locked or an advanced function is in progress, it will not be possible to switch

the product on/off.

Each time the product is turned on, a series of internal inspections will be carried out before activating

the heat pump. The compressor indicator light will blink as these inspections take place. Once

the verification period has passed (approximately 5 minutes), the indicator will remain lit meaning the

unit is on.

10.4.2. Setting the day and time

To set the day and time:

27

Page 28

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press and release the button. The screen will show the first available code.

• Press either the or button until “rtc” appears on the screen.

• You will now need to set the correct day of the week. Press and release the button. The

day is shown as 1 ... 7 (the number 1 is Monday). The screen will show “dd” followed by the two

numbers that represent the day.

• Use the or buttons within 15 seconds to select the correct day.

• You will now need to set the correct hour. Press and release the button. The screen will

show “hh” followed by the two numbers that represent the time. The time is displayed in 24-hour

format.

• Use the or buttons within 15 seconds to select the correct time.

• You will now need to set the correct minutes. Press and release the button. The display will

show “nn”, followed by the two numbers that represent the minutes.

• Use the or buttons within 15 seconds to select the correct minutes.

• Then press and release the button to save your settings, or do not carry out any other

operation for 15 seconds.

• To exit the procedure: press and release the button or do not carry out any operation for

60 seconds.

10.4.3. Programming the time slots for switching the product on / off

Before you can configure time slots for switch on/off, you must program the correct/current day and

time as described in section 10.4.2. previously.

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press and release the button. “SP1” will appear on the screen.

To program the first time interval:

• Press and release either the or button within 15 seconds to select “HOn1” (the first

time on) and / or “HOf1” (the first time off). Select “HOn2” and “HOf2” for the second on / off

time.

• Press and release the button.

• Press and release either the or button within 15 seconds.

• Press and release the button or do not carry out any other operation for 15 seconds.

To program a time slot on a specific day of the week:

• After the previous procedure has been carried out, press either the or button and then

release within 15 seconds to select “Hd1” (switch on time for day 1/Monday) and / or “Hd2. ..7“

(switching on time for days 2 to 7 / Tuesday to Sunday).

• Press and release the button.

28

Page 29

DALIS

Digital electric unvented heat pump

• Press either the or button within 15 seconds to select “1” (the first switch on / off time)

or “2” (the second switch on / off time).

• Press and release the button or do not carry out any other operation for 15 seconds.

• To exit the procedure before its completion: do not carry out any operation for 15 seconds or

press the button and then release it.

• When programming becomes active, the symbol will flash. Carefully evaluate enabling of

time slot operation in order to avoid malfunctions caused by users.

10.4.4. Lock / unlock the keypad

To lock the keypad:

• Make sure that no other advanced procedure is in progress.

• Press the and buttons together for 1 second. “Lock” will appear on the screen.

• If the keypad is locked, it will not be possible to carry out any kind of operation on the control

panel. If you press a key, “Lock” will appear on the screen.

To unlock the keypad:

• Press the and buttons together for 1 second. “UnL” will appear on the screen and you

can use the keypad again.

10.4.5. Changing the operating mode

AUTOMATIC mode

To start the AUTOMATIC mode manually:

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press the button. “Auto” starts flashing.

• Press the button to confirm and start the automatic operating mode.

• To exit the procedure: press the button without changing the mode.

ECONOMY mode

To start the ECONOMY mode manually:

• Make sure that the keypad is not locked, that no other advanced procedure is in progress and

that the equipment is not in OVERBOOST mode.

• Press the button. “ECO” starts flashing. Press the button to confirm and start the ECO

operating mode.

• To exit the procedure: press the button without changing the mode.

OVERBOOST mode

To start the OVERBOOST mode manually:

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

29

Page 30

• Press the button. “ECO” or “AUTO” starts flashing. Press either the or button until

“Obst” starts to flash on the screen.

• Press the button to confirm and start the OVERBOOST operating mode.

• To exit the procedure: press the button without changing the mode.

10.4.6. Temperature programming for ECO operating mode (SP1)

To set the temperature for ECONOMY mode:

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press and release the button. “SP1” will appear on the screen. Press and release the

button again. The compressor indicator light starts flashing.

• Press either the or button within 15 seconds to set the temperature. The parameters

r3, r4 and r5 will be visible.

• Press and release the button, or do not carry out any other operation for 15 seconds. The

compressor indicator light will disappear. Press and release the button.

• To exit the procedure before completion, do not carry out any operation for 15 seconds (all

changes made will be saved).

10.4.7. Temperature programming for AUTOMATIC operating mode (SP2)

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press and release the button. “SP1” will appear on the screen. Press either the or

button until “SP2” appears on the screen.

• Press and release the button again. The compressor indicator light starts flashing.

• Press either the or button within 15 seconds to set the temperature. The parameters

r1, r2 and r5 will be visible.

• Press and release the button, or do not carry out any other operation for 15 seconds. The

compressor indicator light will disappear. Press and release the button.

• To exit the procedure before completion, do not carry out any operation for 15 seconds (all

changes made will be saved).

10.4.8. Viewing the operation status

To view the current operating status:

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press the button . Either Auto, ECO, Obst or Anti will appear on the screen within 3 sec-

onds depending on the current active operating state.

10.5. Advanced management

The following instructions are reserved for specialised technical assistance personnel.

30

Page 31

DALIS

Digital electric unvented heat pump

10.5.1. Different operating mode start conditions

Each mode of operation must meet specific conditions to be activated:

• AUTOMATIC mode

The condition to activate this function is as follows: lower probe <SP2 - r0 (hysteresis).

• ECONOMY mode

The condition to activate this function is as follows: lower probe <SP1 - r0 (hysteresis).

• OVERBOOST mode

The condition to activate this function is as follows: lower probe <SP3 and upper probe <SP3. When

a temperature higher than SP3 is detected, the overboost operating mode is terminates and the pre-

viously established operating mode is restored.

10.5.2. Screen

If the product is “ON”, during normal operation the display will show the temperature set (parameter

P5):

• If P5 = 0, the display will show the temperature of the upper part of the tank.

• If P5 = 1, the display will show the active working set point.

• If P5 = 2, the display will show the temperature of the bottom of the tank.

• If P5 = 3, the display will show the evaporator temperature.

• If the equipment is in the “stand-by” state, the screen will turn off.

10.5.3. Alarms & errors

A “UtL” alarm (fan fault) will display on the screen and emit an audible signal that can be turned off

by pressing any button on the controller. If a “UtL” alarm occurs, you must contact our Technical

Support team on 0203 321 5929. An alarm is never cancelled unless the device is switched off or put

in stand-by mode. The heat pump operating mode is automatically disabled and the electric heating

elements enabled in order to ensure the continuity of the hot water supply.

Alarms:

Code Description

Minimum temperature alarm - the equipment will continue working normally.

Solution:

AL

AH

- Check the temperature associated with the alarm.

- Parameters displayed on the screen: A0, A1, A2 and A11.

Maximum temperature alarm - the equipment will continue working normally.

Solution:

- Check the temperature associated with the alarm.

- Parameters displayed on the screen: A3, A4, A5 and A11.

31

Page 32

Code Description

Digital input alarm - the compressor will shut off. Defrosting will not activate.

Solution:

id

iSd

FiL

UtL

- Check the causes that led to the activation of the inputs (possible short circuit in signal cables).

- See the parameters: i0; i1 and i2.

Blocked equipment alarm - the compressor will shut off. Defrosting will not activate.

Solution:

- Check the causes that led to the activation of the digital input.

- See the parameters: i0; i1; 18 and i9.

- Turn the product off, then on again or disconnect the product from the electrical network.

Ventilation filter verification alarm (if present)

Solution:

- Check how clean the filter is. To turn off the alarm message, press any button on the keypad.

Possible fan fault - the compressor and fan will turn off. Heating occurs through electric elements.

Solution:

- See parameters SP10 and C14.

- Check fan conditions.

Errors:

Code Description

Pr1

Pr2

Pr3

Top probe error - the product stops working.

Solution:

- Check that the type of probe conforms to the settings of parameter P0.

- Check that the probe is intact.

- Check the probe connection.

- Check the temperature of the upper part of the product.

Bottom probe error - the product stops working.

Solution:

- The same as in the previous situation, but with respect to the probe in the lower part of the

tank.

Evaporator probe error - the product stops working.

Solution:

- The same as in the previous situation, but with respect to the evaporator probe.

Once the cause of the alarm/error has been fixed, normal operation of the product will be restored.

10.5.4. Defrost mode

The defrost mode can be activated automatically when the evaporator temperature is lower than that

programmed in parameter d17 (only if P4 has a value other than 0).

In any case, between one defrosting procedure and another, the compressor must have been left on

for a period longer than or equal to the minutes d18, otherwise, the request to activate the defrosting

procedure will not be accepted.

32

Page 33

DALIS

Digital electric unvented heat pump

If P4 = 1, d2 represents the temperature of the evaporator above which the defrosting procedure is

completed. Vice versa, if P4 = 0 or P4 = 2, the parameter d2 is not taken into consideration.

If during the defrosting procedure the evaporator or the probe is higher than the set threshold by

means of parameters d2 and P4 = 1, the request to activate the defrosting procedure will not be

accepted.

The thawing procedure consists of three stages:

• Defrosting stage: the d3 parameter establishes the maximum length of the stage. Output status:

- The compressor is active if d1 = 1, otherwise it is switched off.

- The defrosting relay is active if d1 = 0 or d1 = 1, otherwise it is switched off.

- The fans are switched on if d1 = 2, otherwise they are switched off.

• Dripping stage: the d7 parameter establishes the length of the stage. Output status:

- The compressor is switched off.

- The defrosting relay is active if d1 = 0 or d1 = 1, otherwise it is switched off.

- The fans are switched off.

• Drying stage: the d16 parameter establishes the length of the stage. Output status:

- The compressor acts according to parameter d8.

- The defrosting relay is active if d1 = 0 or d1 = 1, otherwise it is switched off.

- The fans are switched off.

If the “anti-legionella” or “overboost” functions are in progress, the defrosting procedure will not be

activated.

10.5.5. Configuration parameter settings

To carry out the procedure:

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press and hold the buttons for 4 seconds. The screen will show “PA” (password).

• Press and release the button.

• Press either the or button within 15 seconds to set “-19” on the display screen.

• Press and release the button, or do not carry out any operation for 15 seconds.

• Press and hold the buttons for 4 seconds. The screen will show the “SP1” parameter.

To select a parameter:

• Press either the or button.

To change a parameter:

• Press and release the button.

• Press either the or button to increase or decrease the value of the parameter (within

15 seconds).

33

Page 34

• Press and release the button, or do not carry out any operations for 15 seconds.

To exit the procedure:

• Press and hold the buttons for 4 seconds. or do not carry out any operations for 60

seconds (any changes will be saved).

Switch the product off and then on again to make the changes made to the parameters effective/active.

10.5.6. Restore factory settings

To carry out the procedure:

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press and hold the buttons for 4 seconds. The screen will show “PA” (password).

• Press and release the button.

• Press either the or button within 15 seconds to set “149” on the display screen.

• Press and release the button, or do not carry out any operation for 15 seconds.

• Press and hold the buttons for 4 seconds. The screen will show the “dEF” parameter.

• Press and release the button.

• Press either the or button within 15 seconds to set “1”.

• Press and release the button, or do not carry out any operation for 15 seconds. The display

will show “dEF” flashing for 4 seconds, after which the product will exit this operation.

• Disconnect the product from the electrical network.

10.5.7. Compressor operating hours

The device is capable of memorizing up to 9,999 hours of compressor operation. If the number of

hours exceeds “9,999” it flashes. To display the operating hours of the compressor:

• Make sure that the keypad is not locked and that no other advanced procedure is in progress.

• Press and release the button. The screen will show “CH”.

• Press the button to see the hours.

• Press and release the button.

To exit the procedure:

• Keep the button pressed or do not carry out any operation for 60 seconds. Alternatively

press and release the button.

10.6. Specific operations

The product is provided with a verification system of the environmental conditions concerning the

temperatures of the external incoming air. The below is necessary to avoid the product working with

the heat pump mode out of specification, which may cause faults to the compressor and the conse-

quent interruption of the product’s functions.

34

Page 35

DALIS

Digital electric unvented heat pump

At each start up, the fan is activated for a time set up to 1 minute (parameter C12). After this time,

the system measures the incoming air temperature. If the temperature is equal to or lower than the

parameter SP9 (4ºC), the conditions for activation of the product are not met, therefore the electric

heating elements are activated. The heat up process continues with the help of the electrical heating

elements until the set point established with the ongoing active cycle is reached.

The system verifies every 120 minutes, the environmental conditions and activates the heat pump

mode only when conditions are adequate for its operation.

10.7. Product parameters

Description Code Unit Min. Max. Default Notes

Password PA 0

H20 set HOT eco

cycle

H20 set HOT auto

cycle

H20 set cold SP3 ºC / ºF 10.0 r2 45.0

H20 set for heat

pump stop

H20 set for enabling

of photovoltaic

systems

H20 set antifreeze SP7 ºC / ºF 0 40.0 10.0

Set point solar

thermal cycle

Set cold evaporator SP9 ºC / ºF -25.0 25.0 -4.0

Set damaged

evaporator

Upper probe

calibration

Lower probe

calibration

Evaporator probe

calibration

Type of probe PO ---- 0 1 1

Decimal point P1 ---- 0 1 1 1 = display decimal point per temp.

Unit of

measurement

Function

associated with

evaporator probe

SP1 ºC / ºF r3 r4 55.0

SP2 ºC / ºF r1 r2 55.0

SP5 ºC / ºF r1 SP2 56.0

SP6 ºC / ºF 40.0 100.0 75.0

SP8 ºC / ºF 0 100.0 40.0

SP10 ºC / ºF -50.0 25.0 -25.0

CA1 ºC / ºF -25.0 25.0 2.0

CA2 ºC / ºF -25.0 25.0 0.0

CA3 ºC / ºF -25.0 25.0 0

P2 ---- 0 1 0

P4 ---- 0 2 2

Function reserved for specialised

technical staff

0 = PTC

1 = NTC

2 = PT1000

0 = ºC

1 = ºF

0 = Disabled

1 = Defrosting start-stop

2 = Defrosting start

35

Page 36

Description Code Unit Min. Max. Default Notes

0 = Upper probe

Local display data P5 ---- 0 3 0

Remote display data P6 ---- 0 3 0

Display data refresh

time specified in

tenths of a second

Work set hysteresis r0 ºC / ºF 0.1 30.0 7.0

Minimum auto cycle

set point

Maximum auto cycle

set point

Minimum eco cycle

set point

Maximum eco cycle

set point

Work set change lock r5 ---- 0 1 0

Delay in equipment

start up

Delay as from last ON C1 min. 0 240 5

Delay as from last

OFF

Minimum ON time C3 sec 0 240 0

No. compressor

operating hours req.

for maintenance

Delay air temperature

sample taking for

cold evaporator test

Minimum delay

between fan start-up

and compressor activation for incoming

air temperature check

Timeout solar thermal

cycle

Delay for damaged

fan check

Defrosting type d1 ---- 0 2 2

P8 1/10 sec 0 250 5

r1 ºC / ºF 10.0 r2 40.0

r2 ºC / ºF r1 100.0 70.0

r3 ºC / ºF 10.0 r4 40.0

r4 ºC / ºF r3 100.0 56.0

C0 min. 0 240 5

C2 min. 0 240 5

C10 hour 0 9999 0 0 = function excluded

C11 min 0 999 120

C12 min 0 240 1

C13 min 0 240 20

C14 min -1 240 20 -1 = disabled function

1 = Operation setpoint

2 = Lower probe

3 = Evaporator probe

0 = Upper probe

1 = Operation set-point

2 = Lower probe

3 = Evaporator probe

1 = it is not possible to change the set

point; it can only be seen.

Compressor protections

0 = with heating element

1 = with hot gas

2 = with compressor stopped

36

Page 37

Digital electric unvented heat pump

Description Code Unit Min. Max. Default Notes

Evaporator temperature to conclude

defrosting procedure

(only if P4=1)

Maximum duration of

defrosting procedure

Automatic defrosting

start threshold (evaporator temperature)

Minimum compressor

start up time to start

deforsting procedure

Minimum level probe

alarm (only AL1

warning)

Minimum alarm set

(only AL1 warning)

Type of minimum

level alarm (only AL1

warning)

Maximum level

probe alarm (only AH

warning)

Maximum alarm set

(only AH warning)

Type of maximum

level alarm delay

(only AH warning)

Minimum level AL1

alarm delay due to

equipment start-up

(only warning)

AL1 and AH temperature alarm delays

(only warning)

Alarm hysteresis A11 min 0.1 30.0 2.0

Heating element start

up interval (antilegionella)

Anti-legionella

function set

Duration of antilegionella cycle

Solar thermal input

enabling (digital 1)

d2 ºC / ºF -50.0 50.0 3.0

d3 min 0 99 20

d17 ºC / ºF -50.0 50.0 -2.0

d18 min 0 240 60

A0 ---- 0 2 0

A1 ºC / ºF 0.0 50.0 10.0

A2 ---- 0 1 0

A3 ---- 0 2 0

A4 ºC / ºF 0.0 199.0 90.0

A5 ---- 0 1 0

A6 min 0 240 120

A7 min 0 240 15

H0 days 0 99 30

H1 ºC / ºF 10.00 199.0 60.0

H3 min 0 240 2

i0 ---- 0 2 2

0 = upper probe

1 = lower probe

2 = evaporator probe

0 = disabled

1 = absolute

0 = upper probe

1 = lower probe

2 = evaporator probe

0 = disabled

1 = absolute

0 = input disabled

1 = pressure input

2 = digital 1 input

DALIS

37

Page 38

Description Code Unit Min. Max. Default Notes

Type of solar thermal

input contact (digital 1)i1 ---- 0 1 0

High/low pressure

end compressor

protection

Photovoltaic input

enabling (digital 2)

Type of photovoltaic

input contact (digital 2)i4 ---- 0 1 0

Number of digital

input alarms per

equipment block

Time for digital input

alarm counter reset

Buzzer enabling u9 ---- 0 1 1

Switching on time for

Monday

Switching on time for

Tuesday

Switching on time for

Wednesday

Switching on time for

Thursday

Switching on time for

Friday

Switching on time for

Saturday

Switching on time for

Sunday

Time for first switch

on timeslot

Time for first switch

off timeslot

Time according to

timeslot switch on

Time according to

timeslot switch off

Equipment address LA ---- 1 247 247

Baud Rate Lb ---- 0 3 2

i2 min 0 120 0

i3 ---- 0 1 1

i8 ---- 0 15 0

i9 min 1 999 240

Hd1 ---- 1 2 1

Hd2 ---- 1 2 1

Hd3 ---- 1 2 1

Hd4 ---- 1 2 1

Hd5 ---- 1 2 1

Hd6 ---- 1 2 2

Hd7 ---- 1 2 2

HOn1 ---- 00:00 23.59 --:-- --:-- = function excluded

HOF1 ---- 00:00 23.59 --:-- --:-- = function excluded

HOn2 ---- 00:00 23.59 --:-- --:-- = function excluded

HOF2 ---- 00:00 23.59 --:-- --:-- = function excluded

0 = active if contact is closed

1 = active if contact is open

0 = input disabled

2 = input enabled

0 = active if contact closed

1 = active if contact open

0 = buzzer disabled

1 = buzzer enabled

1 = HOn1-HOF1

2 = HOn2-HOF2

1 = HOn1-HOF1

2 = HOn2-HOF2

1 = HOn1-HOF1

2 = HOn2-HOF2

1 = HOn1-HOF1

2 = HOn2-HOF2

1 = HOn1-HOF1

2 = HOn2-HOF2

1 = HOn1-HOF1

2 = HOn2-HOF2

1 = HOn1-HOF1

2 = HOn2-HOF2

0 = 2400

1 = 4800

2 = 9600

3 = 19200

38

Page 39

DALIS

Digital electric unvented heat pump

Description Code Unit Min. Max. Default Notes

Parity LP ---- 0 2 2

RESERVED E9 ---- 0 2 0

11. Maintenance

IMPORTANT

Any repair, replacement or modification of the product must be carried out by qualified personnel. Inadequate repairs can put the user and others in serious danger. If

your product needs to be repaired, please contact us.

Before carrying out any maintenance operation, make sure that the product is not

and cannot be accidentally connected to the mains. Disconnect the product from the

power source before performing any cleaning or maintenance operations.

11.1. Readjustment of safet y equipment

The product is equipped with a safety thermostat. With manual reset, the product switches off in case

of overheating. To restore protection it is necessary to:

• Disconnect the product from the electrical network and then remove the air ducts.

• Remove the top cover by loosening the respective fixing screws - see figure 16.

• Manually reset the safety thermostat activated from the top (figure 17). The central pin of the thermostat protrudes approximately 4 mm.

• Reassemble the top cover that has been previously removed.

0 = NONE

1 = ODD

2 = EVEN

IMPORTANT

Activation of the safety thermostat could be due to a fault associated with the control

panel or lack of water in the tank. Carrying out repair operations on parts that perform

safety functions endangers the safe operation of the product. Replace defective components with original spare parts only.

The intervention of the thermostat excludes the operation of the electric heating elements but not the

heat pump system within the permitted operating limits.

39

Page 40

Figure 16 - top cover removal Figure 17 - resetting the safety thermostat

Click

11.2. Inspections

Visual inspection of the general condition of the product and its systems, as well as inspection of the

absence of leaks and the ventilation filter is recommended on a quarterly basis. This must be con-

ducted by qualified professional. Inspection of the tightening of bolts, nuts, flanges and water supply

connections that may have been loosened by vibration, is recommended on an annual basis. This

must be conducted by a qualified professional. We also recommend to check the integrity status of all

magnesium anodes - see section 11.3. below.

11.3. Magnesium anodes

The magnesium anode (Mg), also called “sacrificial” anode, prevents any parasitic current generated in

the product, which can cause corrosion processes on the surface of the product.

In fact, magnesium is a metal with a lower electrochemical potential compared to the material that covers the inside of the water heater, therefore, it attracts the negative charges that are formed during the

heating of the water causing corrosion. Therefore, the anode “sacrifices” itself corroding in place of the

deposit. The water heater has two anodes; the first is mounted on the bottom and the second on the

top of the tank (the area most affected by corrosion).

The integrity of magnesium anodes should be checked at least once every two years (we recommend

the magnesium anodes are checked at least once per year). The operation must be carried out by qualified personnel. Before performing the inspection, you must:

• Close the cold water inlet. Empty water from the water heater (see paragraph 11.5).

• Loosen the upper anode and check its corrosion condition. If more than 30% of the anode surface

has suffered corrosion, it must be replaced.

• Carry out the same operation for the lower anode.

The anodes have adequate sealing joints to prevent water leakage. It is recommended to use anaerobic

sealant for compatible threads for use in sanitary and heating systems. The joints must be replaced

both in the case of an inspection and in the case of replacement of anodes with new joints.

40

Page 41

DALIS

Digital electric unvented heat pump

11.4. Emptying the water heater

It is advisable to drain the water from inside the water heater if it should remain unused for a certain

period of time, especially at low temperatures. It is sufficient to disconnect the water supply inlet connection. Alternatively, during the installation stage of the system, it is advisable to install a drain trap

with a connection to a hose. It is important to empty the system in order to avoid freezing water if the

product is unused for a period of time.

12. Troubleshooting

If you encounter problems, without the occurrence of any of the alarms or errors described in the

relative paragraphs, please check if the problem can be easily solved using the table below, BEFORE

requesting technical assistance.

Issue Possible cause

The heat pump does not work. Absence of electrical connection / there is no electricity.

The compressor and / or the fan do not work. The scheduled safety period has not ended.

The heat pump continuously switches on and off. Incorrect programming of parameters / set point and /

The heat pump remains continuously on and does not

switch off.

The electric heating element does not switch on. Please do not intervene. Please contact Technical

The plug is not inserted correctly in the outlet.

The programmed temperature has been reached.

or hysteresis values.

Incorrect programming of parameters / set point and /

or hysteresis values.

Support.

IMPORTANT

In the event that the user fails to solve the problem, turn off the equipment and contact us to request Technical Suppor t, specifying the model and serial number of the

purchased product.

13. Product disposal

IMPORTANT

This equipment contains fluorinated greenhouse gases. Maintenance and disposal

operations must only be carried out by qualified personnel.

Under the European Directive 2012/19/UE on Waste Electrical and Electronic Equipment (WEEE), the

product cannot be disposed of in the usual council bins and containers. They must be separated to

optimise the recover y and recycling of all of the components and materials and reducing the impact

to human health and the environment. The symbol of the container crossed out over a horizontal line

is marked on all of ROINTE products to remind the consumer of the obligation to separate them on

disposal. The consumer should contact the local authority or original point of sale to learn more about

the correct disposal of this product. The unauthorised removal of the device by the user may lead to

administrative sanctions imposed on the user by the applicable legislation.

41

Page 42

14. Rointe Product Guarantee

In this section, we hereby describe the guarantee conditions, which the buyer acquires, on buying this

product from ROINTE. These conditions comply with all the rights construed in the national legislation

in force, as well as any additional rights and guarantees, which are offered by ROINTE.

Any incident that you might detect in your ROINTE product can be sorted by the product seller or

quickly by the manufacturer. Please contact ROINTE by telephoning 0203 321 5929 fo r Technic a l

Suppor t. Alternatively, you can email ROINTE at support@rointe.co.uk, through which we will instruct

you on how to solve the incident.

You will need to state the product reference (located on the label indicating product features),

serial number, proof of purchase and the type of incident at hand when contacting us so that

we can check the guarantee. In addition, please at tach a copy of the product invoice.

14.1. ROINTE guarantees that there are no material defects of design or manufacture at the time of

original acquisition and guarantees the inner steel cylinder for a period of 60 months and any electronic

and electrical components for 24 months, provided that they have not been modified in any way.

14.2. If during the guarantee period, the product does not work correctly under normal use, and any

design, material or manufacturing defect is found, ROINTE will repair or substitute the product as it

may see fit, in accordance with the terms and conditions as follows:

14.2.1. The guarantee is only applicable if the original guarantee is issued by the seller and when the