Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Specifications

Rated Voltage:

Ripple Current Multipliers:

Complies with the EU Directive

2002/95/ EC req ui re men t

restricting the use of Lead (Pb),

Mercury (Hg), Cadmium (Cd),

Hexavalent chromium (Cr(VI)),

PolyBrominated Biphenyls (PBB)

and PolyBrominated Diphenyl

Ethers (PBDE).

Operating Temperature:

Capacitance:

Capacitance Tolerance:

DCLeakage Current:

Cold Impedence:

The Ultimate in Cold Performance and ESR

The Type 101C is the wide-temperature, low voltage version of the

Type 550C. It is ideal for high-ripple current military and industrial

applications that need full performance to –40 ºC and solid performance to –55 ºC. It also excels as apower-supply output capacitor

because of its exceptionally low ESR. The extended cathode foil of

the 101C assures heat flow from the capacitor element to the can in

all mounting orientations.

Highlights

5,000 hour load life

•

Ripple Current to > 100 amps @ 55 °C

•

ESRs to 2.5 mΩ

•

> 90% capacitance at –40 ºC

•

Thermal-Pak™ extended cathode construction

•

–55 °C to +105 °C

7.5 to 250 Vdc

290 µF to 1.5 F

7.5 to 150 Vdc: –10% +75%, 200 & 250 Vdc: 10 +50%

≤1.5√CV µA

–55 °C multiple of 25 °C Z ≤ 3

Ambient Temperature

45 °C 55 °C 65 °C 75 °C 85 °C 95 ºC 105 ºC

1.66 1.52 1.37 1.20 1.00 0.75 0.36

Frequency

1 3/8” & 1 3/4” Diameters

7.5 to 150 V 0.91 0.93 1.00 1.06 1.08 1.09 1.09

200 & 250 V 0.82 0.86 1.00 1.14 1.20 1.23 1.23

2” & 2 1/2” Diameters

7.5 to 150 V 0.92 0.94 1.00 1.05 1.07 1.08 1.08

200 & 250 V 0.82 0.86 1.00 1.14 1.20 1.23 1.27

3” Diameters

7.5 to 150 V 0.95 0.96 1.00 1.03 1.04 1.05 1.05

200 & 250 V 0.85 0.88 1.00 1.1

(4mA max. 5 minutes)

50 Hz 60 Hz 120 Hz

10 kHz

360 Hz 1 kHz 5 kHz & up

1 1.15 1.18 1.18

EIA Ripple Life:

5,000 h at full load @ 85 °C per EIA IS-749

∆Capacitance ±20%

ESR 200% of limit

DCL 100% of limit

Life Test:

2,000 h at 105 °C and rated voltage

∆Capacitance ±20%

ESR 200% of limit

DCL 100% of limit

Shelf Life:

500 h @ 105 °C, Capacitance, ESR and DCL, initial

requirements.

Vibration:

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

10 to 55 Hz, 0.06” and 10 g max, 1.5 h ea. of 2 axis

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

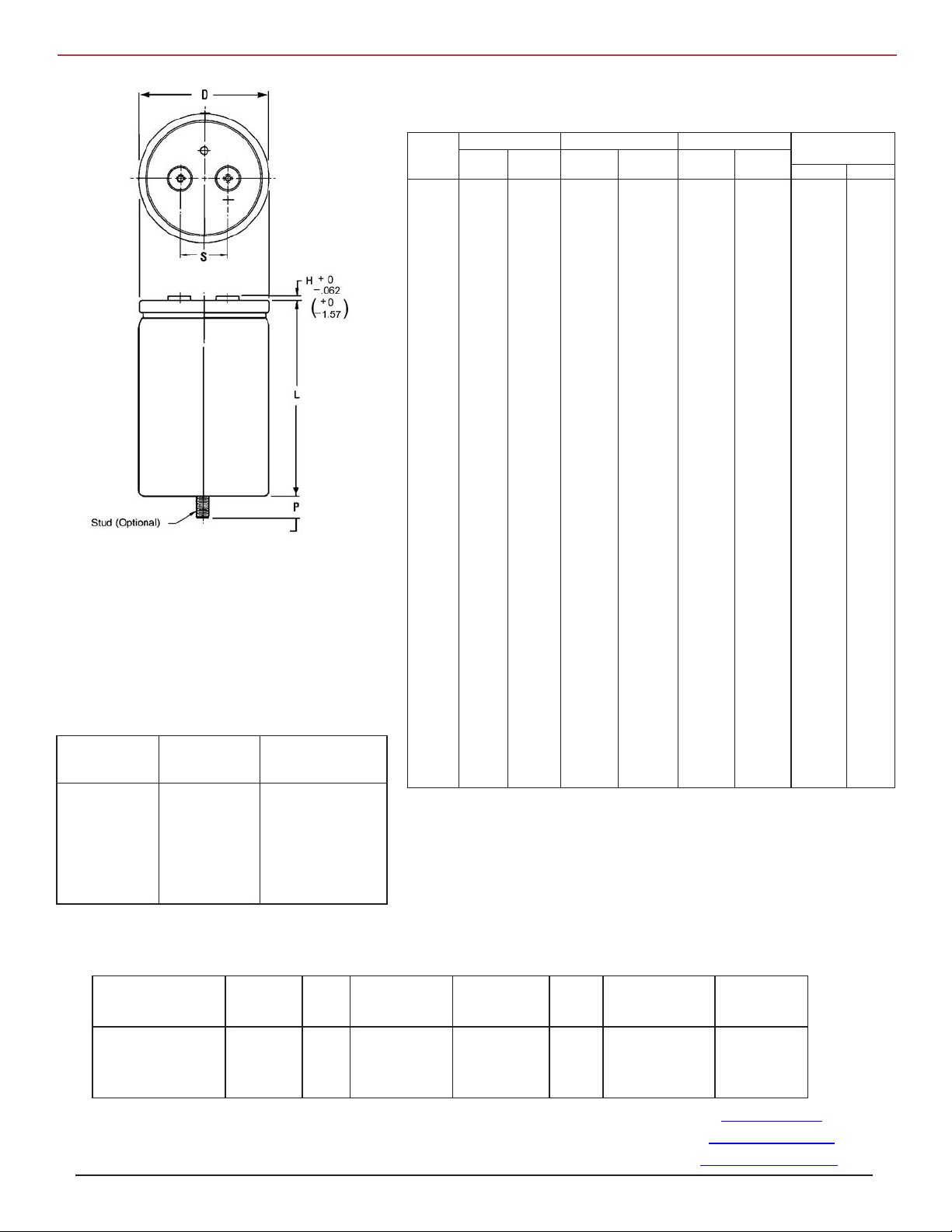

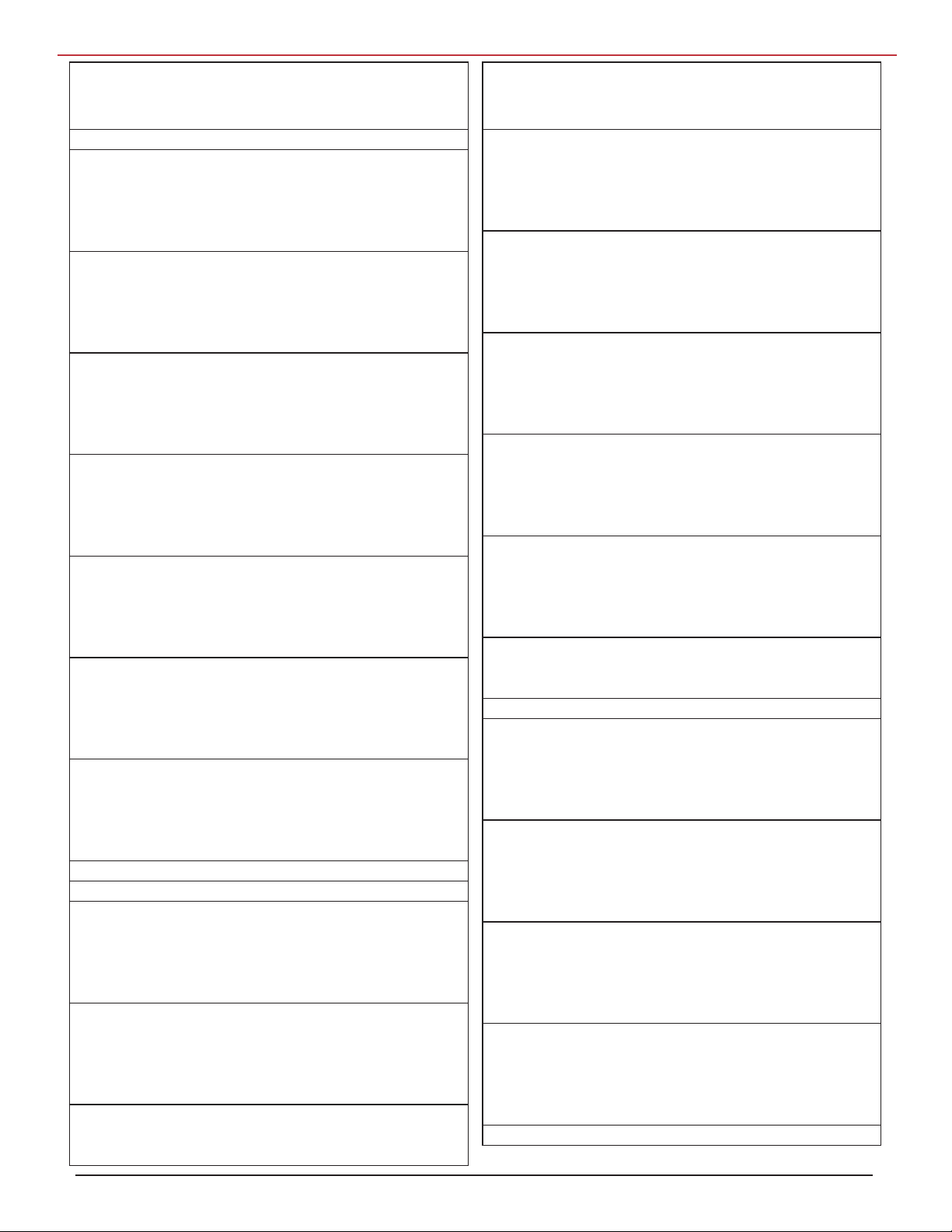

Outline Drawing

For insulated case, add 0.024”(0.610 mm) to “D”and 0.030”(0.762 mm) to height.

NOTE:With the stud-mount feature, a thermally-conductive disk can be inserted in the

bottom flush with the outer insulating sleeve.

This reduces the thermal resistance through

the can bottom by 0.3 °C/W. Can Style P.

Stud Dimensions

P±0.039”

Case Diam. Stud Thread

1.38 M8 0.470” (12.0)

1.75 M8 0.470” (12.0)

2.00 M12 0.630” (16.0)

2.50 M12 0.630” (16.0)

3.00 M12 0.630” (16.0)

(±1.0 mm)

Case Dimensions

Uninsulated Case Dimensions

Case ±.031 ±.78 ±.062 ±1.57 ±0.015 ±.38 T

Code Inches mm Inches mm Inches mm oz g

AK 1.375 34.93 1.625 41.28 0.50 12.70 1.9 54

AA 1.375 34.93 2.125 53.98 0.50 12.70 2.0 57

AH 1.375 34.93 2.625 66.68 0.50 12.70 2.7 77

AB 1.375 34.93 3.125 79.38 0.50 12.70 3.3 94

AJ 1.375 34.93 3.625 92.08 0.50 12.70 3.8 108

AC 1.375 34.93 4.125 104.78 0.50 12.70 4.4 125

AD 1.375 34.93 4.625 1

AE 1.375 34.93 5.125 130.18 0.50 12.70 6.8 193

AF 1.375 34.93 5.625 142.88 0.50 12.70 8.1 230

EA 1.750 44.45 2.125 53.98 0.75 19.05 2.7 76

EH 1.750 44.45 2.625 66.68 0.75 19.05 3.8 108

EB 1.750 44.45 3.125 79.38 0.75 19.05 5.1 145

EJ 1.750 44.45 3.625 92.08 0.75 19.05 6.8 193

EC 1.750 44.45 4.125 104.78 0.75 19.05 8.1 230

ED 1.750 44.45 4.625 1

EE 1.750 44.45 5.125 130.18 0.75 19.05 9.5 269

EF 1.750 44.45 5.625 142.88 0.75 19.05 10.5 298

BA 2.000 50.80 2.125 53.98 0.75 22.23 5.4 153

BH 2.000 50.80 2.625 66.68 0.75 22.23 6.1 173

BB 2.000 50.80 3.125 79.38 0.75 22.23 6.8 193

BJ 2.000 50.80 3.625 92.08 0.75 22.23 8.2 232

BC 2.000 50.80 4.125 104.78 0.75 22.23 9.5 269

BD 2.000 50.80 4.625 1

BE 2.000 50.80 5.125 130.18 0.75 22.23 10.7 303

BF 2.000 50.80 5.625 142.88 0.75 22.23 13.0 369

CH 2.500 63.50 2.625 66.68 1.25 28.58 9.2 261

CB 2.500 63.50 3.125 79.38 1.25 28.58 10.4 295

CJ 2.500 63.50 3.625 92.08 1.25 28.58 12.7 361

CC 2.500 63.50 4.125 104.78 1.25 28.58 15.0 425

CD 2.500 63.50 4.625 1

CE 2.500 63.50 5.125 130.18 1.25 28.58 19.3 547

CF 2.500 63.50 5.625 142.88 1.25 28.58 21.4 607

DB 3.000 76.20 3.125 79.38 1.25 31.75 16.7 473

DJ 3.000 76.20 3.625 92.08 1.25 31.75 20.0 567

DC 3.000 76.20 4.125 104.78 1.25 31.75 22.2 629

DD 3.000 76.20 4.625 1

DE 3.000 76.20 5.125 130.18 1.25 31.75 30.0 850

DF 3.000 76.20 5.625 142.88 1.25 31.75 31.9 904

DP 3.000 76.20 5.875 149.23 1.25 31.75 32.8 931

DN 3.000 76.20 7.625 193.68 1.25 31.75 39.5 1

DG 3.000 76.20 8.625 219.08 1.25 31.75 43.3 1227

Diam. (D) Length (L) Terminals (S)

ypical Weight

17.48 0.50 12.70 5.1 145

17.48 0.75 19.05 9.0 255

17.48 0.75 22.23 10.3 292

17.48 1.25 28.58 17.2 488

17.48 1.25 31.75 25.5 723

119

Terminal Dimensions

For Case Post Diameter H max min Full Thread Torque

Terminal Style Diameters Code in mm in mm Thread in mm in·lb N·m

Low Post 1⅜ to 3 A 0.314 8.0 0.094 2.4 10–32 0.218 5.5 25 2.82

High Post 1⅜ to 3 B 0.314 8.0 0.281 7.1 10–32 0.375 9.5 25 2.82

High Current, Med 2½ & 3 D 0.434 1

1.0 0.190 4.8 ¼–28 0.312 7.9 50 5.65

Click here to

see Hardware &

Mounting Options

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Part Numbering System

101C 183 T 250 DG 2 D S

Type Capacitance Tolerance Voltage Case Code Insulation Terminal Can Style

100 = 10 µF

101 = 100 µF

183 = 18,000 µF

M = ±20%

U = –10%+75%

T = –10%+50%

7R5 = 7.5 Vdc

063 = 63 Vdc

100 = 100 Vdc

0= None

1= Polyester

2= PVC

Standard insulation is 0.008-in PVC sleeve with 0.01-in polypropylene end disk.

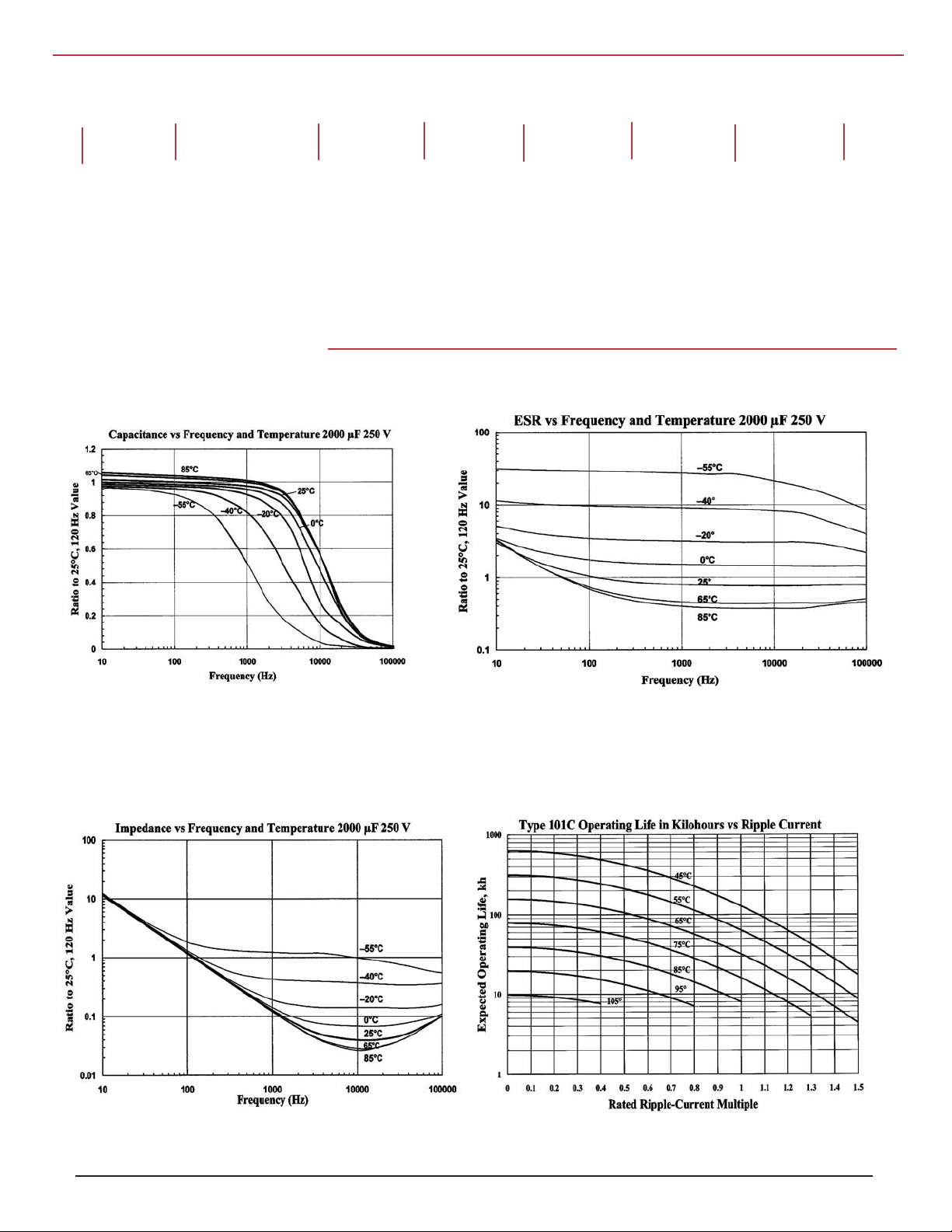

Typical Performance Curves

A = Low Post

B = High Post

D = High Current

Blank=

Standard

Can

S= Stud

Bottom

P= Stud

with

Thermal

Pad

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Ratings

Cap.

(µF)

28000 101C283U7R5AK2B 38.2 6.1 1 3/8 x 1 5/8 89000 101C893U010AJ2B 12.5 16.4 1 3/8 x 3 5/8

47000 101C473U7R5AA2B 25.0 8.7 1 3/8 x 2 1/8 99000 101C993U010EH2B 16.6 14.6 1 3/4 x 2 5/8

66000 101C663U7R5AH2B 19.0 1

79000 101C793U7R5BA2B 18.3 14.0 2 x 2 1/8 1

84000 101C843U7R5EA2B 22.6 1

84000 101C843U7R5AB2B 15.4 13.8 1 3/8 x 3 1/8 130000 101C134U010EB2B 13.2 17.4 1 3/4 x 3 1/8

100000 101C104U7R5AJ2B 13.2 15.9 1 3/8 x 3 5/8 140000 101C144U010AE2B 9.4 21.4 1 3/8 x 5 1/8

120000 101C124U7R5EH2B 16.5 14.7 1 3/4 x 2 5/8 150000 101C154U010BB2B 8.1 24.2 2 x 3 1/8

120000 101C124U7R5BH2B 12.4 18.3 2 x 2 5/8 160000 101C164U010EJ2B 1

120000 101C124U7R5AC2B 12.1 17.4 1 3/8 x 4 1/8 160000 101C164U010AF2B 8.7 23.1 1 3/8 x 5 5/8

140000 101C144U7R5AD2B 10.8 19.2 1 3/8 x 4 5/8 180000 101C184U010CH2B 9.2 24.5 2 1/2 x 2 5/8

160000 101C164U7R5EB2B 13.2 17.5 1 3/4 x 3 1/8 180000 101C184U010BJ2B 7.4 26.5 2 x 3 5/8

160000 101C164U7R5AE2B 9.9 20.9 1 3/8 x 5 1/8 190000 101C194U010EC2B 8.2 24.4 1 3/4 x 4 1/8

170000 101C174U7R5BB2B 8.5 23.6 2 x 3 1/8 220000 101C224U010ED2B 8.7 24.7 1 3/4 x 4 5/8

180000 101C184U7R5AF2B 9.1 22.6 1 3/8 x 5 5/8 230000 101C234U010BC2B 5.7 31.7 2 x 4 1/8

200000 101C204U7R5EJ2B 1

210000 101C214U7R5CH2B 9.4 24.2 2 1/2 x 2 5/8 250000 101C254U010EE2B 8.0 26.7 1 3/4 x 5 1/8

220000 101C224U7R5EC2B 8.2 24.4 1 3/4 x 4 1/8 260000 101C264U010BD2B 5.5 33.5 2 x 4 5/8

220000 101C224U7R5BJ2B 7.6 26.2 2 x 3 5/8 280000 101C284U010EF2B 7.4 28.7 1 3/4 x 5 5/8

260000 101C264U7R5BC2B 6.0 31.0 2 x 4 1/8 300000 101C304U010CJ2D 5.7 34.6 2 1/2 x 3 5/8

270000 101C274U7R5ED2B 8.7 24.7 1 3/4 x 4 5/8 300000 101C304U010BE2B 5.0 36.5 2 x 5 1/8

280000 101C284U7R5CB2B 7.2 29.4 2 1/2 x 3 1/8 340000 101C344U010BF2B 4.7 38.9 2 x 5 5/8

300000 101C304U7R5BD2B 5.7 32.9 2 x 4 5/8 360000 101C364U010DB2D 7.0 33.4 3 x 3 1/8

310000 101C314U7R5EE2B 7.9 26.8 1 3/4 x 5 1/8 370000 101C374U010CC2D 4.0 43.0 2 1/2 x 4 1/8

350000 101C354U7R5EF2B 7.4 28.8 1 3/4 x 5 5/8 430000 101C434U010CD2D 4.3 43.5 2 1/2 x 4 5/8

350000 101C354U7R5BE2B 5.2 35.9 2 x 5 1/8 450000 101C454U010DJ2D 5.7 38.8 3 x 3 5/8

360000 101C364U7R5CJ2D 5.9 34.2 2 1/2 x 3 5/8 500000 101C504U010CE2D 3.8 47.5 2 1/2 x 5 1/8

390000 101C394U7R5DB2D 7.1 33.1 3 x 3 1/8 550000 101C554U010DC2D 4.5 45.5 3 x 4 1/8

390000 101C394U7R5BF2B 4.9 38.2 2 x 5 5/8 560000 101C564U010CF2D 3.3 53.0 2 1/2 x 5 5/8

430000 101C434U7R5CC2D 4.2 42.4 2 1/2 x 4 1/8 640000 101C644U010DD2D 4.0 50.4 3 x 4 5/8

490000 101C494U7R5DJ2D 5.8 38.5 3 x 3 5/8 740000 101C744U010DE2D 3.7 54.0 3 x 5 1/8

490000 101C494U7R5CD2D 4.4 42.8 2 1/2 x 4 5/8 840000 101C844U010DF2D 3.3 58.2 3 x 5 5/8

570000 101C574U7R5CE2D 4.0 46.7 2 1/2 x 5 1/8 880000 101C884U010DP2D 3.3 59.2 3 x 5 7/8

610000 101C614U7R5DC2D 4.6 45.2 3 x 4 1/8 1200000 101C125U010DN2D 2.8 70.7 3 x 7 5/8

640000 101C644U7R5CF2D 3.4 52.1 2 1/2 x 5 5/8 1400000 101C145U010DG2D 2.5 76.9 3 x 8 5/8

700000 101C704U7R5DD2D 4.0 50.0 3 x 4 5/8 16 Vdc (25 Vdc Surge)

810000 101C814U7R5DE2D 3.7 53.6 3 x 5 1/8 16000 101C163U016AK2B 39.2 6.0 1 3/8 x 1 5/8

910000 101C914U7R5DF2D 3.4 57.8 3 x 5 5/8 27000 101C273U016AA2B 26.0 8.5 1 3/8 x 2 1/8

960000 101C964U7R5DP2D 3.4 58.8 3 x 5 7/8 38000 101C383U016AH2B 20.0 1

1300000 101C135U7R5DN2D 2.8 70.2 3 x 7 5/8 45000 101C453U016BA2B 19.1 13.7 2 x 2 1/8

1500000 101C155U7R5DG2D 2.5 76.4 3 x 8 5/8 46000 101C463U016EA2B 24.3 1

25000 101C253U010AK2B 36.0 6.2 1 3/8 x 1 5/8 59000 101C593U016AJ2B 13.5 15.7 1 3/8 x 3 5/8

41000 101C413U010AA2B 23.9 8.9 1 3/8 x 2 1/8 66000 101C663U016EH2B 17.7 14.2 1 3/4 x 2 5/8

58000 101C583U010AH2B 18.1 1

68000 101C683U010BA2B 17.8 14.2 2 x 2 1/8 73000 101C733U016AC2B 12.2 17.4 1 3/8 x 4 1/8

69000 101C693U010EA2B 22.8 1

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

7.5 Vdc (10 Vdc Surge) 74000 101C743U010AB2B 14.6 14.2 1 3/8 x 3 1/8

1.1 20.1 1 3/4 x 3 5/8 240000 101C244U010CB2B 7.0 29.7 2 1/2 x 3 1/8

10 Vdc (15 Vdc Surge) 49000 101C493U016AB2B 15.9 13.6 1 3/8 x 3 1/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

1.4 1 3/8 x 2 5/8 110000 101C114U010BH2B 12.1 18.6 2 x 2 5/8

1.6 1 3/4 x 2 1/8 120000 101C124U010AD2B 10.3 19.7 1 3/8 x 4 5/8

1.7 1 3/8 x 2 5/8 71000 101C713U016BH2B 13.0 18.0 2 x 2 5/8

1.6 1 3/4 x 2 1/8 82000 101C823U016AD2B 11.1 19.0 1 3/8 x 4 5/8

D x L

(inches)

Cap.

(µF)

10000 101C114U010AC2B 11.3 18.1 1 3/8 x 4 1/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

1.1 20.0 1 3/4 x 3 5/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

1.1 1 3/8 x 2 5/8

1.2 1 3/4 x 2 1/8

(inches)

D x L

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Cap.

(µF)

86000 101C863U016EB2B 14.1 16.9 1 3/4 x 3 1/8 94000 101C943U020BJ2B 8.0 25.7 2 x 3 5/8

93000 101C933U016AE2B 10.1 20.6 1 3/8 x 5 1/8 98000 101C983U020EC2B 8.6 23.8 1 3/4 x 4 1/8

100000 101C104U016BB2B 8.6 23.4 2 x 3 1/8 1

110000 101C114U016EJ2B 11.8 19.4 1 3/4 x 3 5/8 120000 101C124U020CB2B 7.5 28.9 2 1/2 x 3 1/8

1

10000 101C114U016AF2B 9.3 22.3 1 3/8 x 5 5/8 120000 101C124U020BC2B 6.0 30.9 2 x 4 1/8

120000 101C124U016CH2B 9.8 23.7 2 1/2 x 2 5/8 130000 101C134U020EE2B 8.4 26.0 1 3/4 x 5 1/8

120000 101C124U016BJ2B 8.0 25.7 2 x 3 5/8 130000 101C134U020BD2B 5.9 32.5 2 x 4 5/8

130000 101C134U016EC2B 8.6 23.8 1 3/4 x 4 1/8 140000 101C144U020EF2B 7.8 28.0 1 3/4 x 5 5/8

150000 101C154U016ED2B 9.2 24.0 1 3/4 x 4 5/8 150000 101C154U020CJ2D 6.1 33.6 2 1/2 x 3 5/8

160000 101C164U016CB2B 7.5 28.9 2 1/2 x 3 1/8 150000 101C154U020BE2B 5.3 35.4 2 x 5 1/8

160000 101C164U016BC2B 6.0 30.9 2 x 4 1/8 180000 101C184U020DB2D 7.3 32.7 3 x 3 1/8

170000 101C174U016EE2B 8.4 26.0 1 3/4 x 5 1/8 180000 101C184U020BF2B 4.9 38.0 2 x 5 5/8

170000 101C174U016BD2B 5.9 32.5 2 x 4 5/8 190000 101C194U020CC2D 4.3 41.9 2 1/2 x 4 1/8

190000 101C194U016EF2B 7.8 28.0 1 3/4 x 5 5/8 220000 101C224U020CD2D 4.5 42.3 2 1/2 x 4 5/8

200000 101C204U016CJ2D 6.1 33.6 2 1/2 x 3 5/8 230000 101C234U020DJ2D 5.9 38.1 3 x 3 5/8

200000 101C204U016BE2B 5.3 35.4 2 x 5 1/8 250000 101C254U020CE2D 4.0 46.2 2 1/2 x 5 1/8

230000 101C234U016BF2B 4.9 38.0 2 x 5 5/8 280000 101C284U020DC2D 4.7 44.6 3 x 4 1/8

240000 101C244U016DB2D 7.3 32.7 3 x 3 1/8 280000 101C284U020CF2D 3.4 51.6 2 1/2 x 5 5/8

250000 101C254U016CC2D 4.3 41.9 2 1/2 x 4 1/8 330000 101C334U020DD2D 4.1 49.5 3 x 4 5/8

290000 101C294U016CD2D 4.5 42.3 2 1/2 x 4 5/8 380000 101C384U020DE2D 3.8 53.0 3 x 5 1/8

300000 101C304U016DJ2D 5.9 38.1 3 x 3 5/8 420000 101C424U020DF2D 3.5 57.2 3 x 5 5/8

330000 101C334U016CE2D 4.0 46.2 2 1/2 x 5 1/8 450000 101C454U020DP2D 3.4 58.2 3 x 5 7/8

360000 101C364U016DC2D 4.7 44.6 3 x 4 1/8 610000 101C614U020DN2D 2.9 69.4 3 x 7 5/8

370000 101C374U016CF2D 3.4 51.6 2 1/2 x 5 5/8 710000 101C714U020DG2D 2.6 75.5 3 x 8 5/8

430000 101C434U016DD2D 4.1 49.5 3 x 4 5/8 25 Vdc (40 Vdc Surge)

490000 101C494U016DE2D 3.8 53.0 3 x 5 1/8 9900 101C992U025AK2B 42.6 5.7 1 3/8 x 1 5/8

560000 101C564U016DF2D 3.5 57.2 3 x 5 5/8 16000 101C163U025AA2B 28.2 8.2 1 3/8 x 2 1/8

590000 101C594U016DP2D 3.4 58.2 3 x 5 7/8 23000 101C233U025AH2B 20.9 10.8 1 3/8 x 2 5/8

800000 101C804U016DN2D 2.9 69.6 3 x 7 5/8 27000 101C273U025EA2B 25.1 1

920000 101C924U016DG2D 2.6 75.8 3 x 8 5/8 27000 101C273U025BA2B 19.9 13.5 2 x 2 1/8

13000 101C133U020AK2B 39.2 6.0 1 3/8 x 1 5/8 35000 101C353U025AJ2B 14.2 15.4 1 3/8 x 3 5/8

21000 101C213U020AA2B 26.0 8.5 1 3/8 x 2 1/8 39000 101C393U025EH2B 18.3 13.9 1 3/4 x 2 5/8

29000 101C293U020AH2B 20.0 1

34000 101C343U020BA2B 19.1 13.7 2 x 2 1/8 43000 101C433U025AC2B 12.7 17.0 1 3/8 x 4 1/8

35000 101C353U020EA2B 24.3 1

38000 101C383U020AB2B 15.9 13.6 1 3/8 x 3 1/8 52000 101C523U025EB2B 14.5 16.6 1 3/4 x 3 1/8

45000 101C453U020AJ2B 13.5 15.7 1 3/8 x 3 5/8 56000 101C563U025AE2B 10.6 20.2 1 3/8 x 5 1/8

50000 101C503U020EH2B 17.7 14.2 1 3/4 x 2 5/8 60000 101C603U025BB2B 9.0 22.9 2 x 3 1/8

54000 101C543U020BH2B 13.0 18.0 2 x 2 5/8 63000 101C633U025AF2B 9.7 21.9 1 3/8 x 5 5/8

55000 101C553U020AC2B 12.2 17.4 1 3/8 x 4 1/8 64000 101C643U025EJ2B 12.2 19.1 1 3/4 x 3 5/8

62000 101C623U020AD2B 1

66000 101C663U020EB2B 14.1 16.9 1 3/4 x 3 1/8 73000 101C733U025BJ2B 8.3 25.2 2 x 3 5/8

71000 101C713U020AE2B 10.1 20.6 1 3/8 x 5 1/8 77000 101C773U025EC2B 9.9 22.2 1 3/4 x 4 1/8

77000 101C773U020BB2B 8.6 23.4 2 x 3 1/8 88000 101C883U025ED2B 9.5 23.6 1 3/4 x 4 5/8

80000 101C803U020AF2B 9.3 22.3 1 3/8 x 5 5/8 90000 101C903U025BC2B 6.4 30.0 2 x 4 1/8

81000 101C813U020EJ2B 1

89000 101C893U020CH2B 9.8 23.7 2 1/2 x 2 5/8 100000 101C104U025EE2B 8.6 25.7 1 3/4 x 5 1/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

20 Vdc (30 Vdc Surge) 30000 101C303U025AB2B 16.6 13.3 1 3/8 x 3 1/8

1.1 19.0 1 3/8 x 4 5/8 70000 101C703U025CH2B 10.1 23.3 2 1/2 x 2 5/8

1.8 19.4 1 3/4 x 3 5/8 95000 101C953U025CB2B 7.7 28.4 2 1/2 x 3 1/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

1.1 1 3/8 x 2 5/8 42000 101C423U025BH2B 13.5 17.6 2 x 2 5/8

1.2 1 3/4 x 2 1/8 49000 101C493U025AD2B 11.6 18.6 1 3/8 x 4 5/8

D x L

(inches)

Cap.

(µF)

10000 101C114U020ED2B 9.2 24.0 1 3/4 x 4 5/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

1.0 1 3/4 x 2 1/8

D x L

(inches)

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Cap.

(µF)

100000 101C104U025BD2B 6.1 31.9 2 x 4 5/8 120000 101C124U030CC2D 4.7 40.0 2 1/2 x 4 1/8

10000 101C114U025EF2B 8.0 27.6 1 3/4 x 5 5/8 150000 101C154U030DJ2D 5.7 38.7 3 x 3 5/8

1

120000 101C124U025CJ2D 6.3 33.1 2 1/2 x 3 5/8 150000 101C154U030CD2D 4.3 43.4 2 1/2 x 4 5/8

120000 101C124U025BE2B 5.5 34.8 2 x 5 1/8 170000 101C174U030CE2D 3.8 47.4 2 1/2 x 5 1/8

140000 101C144U025DB2D 7.4 32.4 3 x 3 1/8 180000 101C184U030DC2D 4.8 43.9 3 x 4 1/8

140000 101C144U025BF2B 5.1 37.4 2 x 5 5/8 190000 101C194U030CF2D 3.5 51.2 2 1/2 x 5 5/8

150000 101C154U025CC2D 4.5 40.6 2 1/2 x 4 1/8 220000 101C224U030DD2D 4.3 48.5 3 x 4 5/8

170000 101C174U025CD2D 4.7 41.6 2 1/2 x 4 5/8 250000 101C254U030DE2D 3.8 52.8 3 x 5 1/8

180000 101C184U025DJ2D 6.0 37.7 3 x 3 5/8 280000 101C284U030DF2D 3.5 56.9 3 x 5 5/8

200000 101C204U025CE2D 4.2 45.5 2 1/2 x 5 1/8 300000 101C304U030DP2D 3.4 58.8 3 x 5 7/8

220000 101C224U025DC2D 4.8 44.1 3 x 4 1/8 410000 101C414U030DN2D 2.9 69.5 3 x 7 5/8

220000 101C224U025CF2D 3.6 50.3 2 1/2 x 5 5/8 470000 101C474U030DG2D 2.6 75.8 3 x 8 5/8

260000 101C264U025DD2D 4.5 47.3 3 x 4 5/8 40 Vdc (55 Vdc Surge)

290000 101C294U025DE2D 4.0 51.6 3 x 5 1/8 5400 101C542U040AK2B 47.6 5.4 1 3/8 x 1 5/8

330000 101C334U025DF2D 3.5 56.7 3 x 5 5/8 9000 101C902U040AA2B 32.3 7.6 1 3/8 x 2 1/8

350000 101C354U025DP2D 3.5 57.7 3 x 5 7/8 13000 101C133U040AH2B 23.1 10.3 1 3/8 x 2 5/8

480000 101C484U025DN2D 2.9 69.0 3 x 7 5/8 16000 101C163U040EA2B 26.6 10.7 1 3/4 x 2 1/8

550000 101C554U025DG2D 2.6 75.2 3 x 8 5/8 16000 101C163U040BA2B 21.2 13.0 2 x 2 1/8

5400 101C542U030AK2B 43.9 5.6 1 3/8 x 1 5/8 21000 101C213U040AJ2B 15.2 14.8 1 3/8 x 3 5/8

13000 101C133U030AA2B 29.8 8.0 1 3/8 x 2 1/8 23000 101C233U040EH2B 19.3 13.5 1 3/4 x 2 5/8

19000 101C193U030AH2B 21.4 10.7 1 3/8 x 2 5/8 25000 101C253U040BH2B 14.3 17.1 2 x 2 5/8

23000 101C233U030EA2B 23.1 1

23000 101C233U030BA2B 18.8 13.8 2 x 2 1/8 29000 101C293U040AD2B 12.4 17.9 1 3/8 x 4 5/8

24000 101C243U030AB2B 16.0 13.6 1 3/8 x 3 1/8 30000 101C303U040EB2B 15.4 16.2 1 3/4 x 3 1/8

30000 101C303U030AJ2B 14.1 15.4 1 3/8 x 3 5/8 33000 101C333U040AE2B 1

33000 101C333U030EH2B 16.9 14.5 1 3/4 x 2 5/8 34000 101C343U040BB2B 9.8 22.0 2 x 3 1/8

36000 101C363U030AC2B 13.0 16.8 1 3/8 x 4 1/8 37000 101C373U040EJ2B 12.9 18.6 1 3/4 x 3 5/8

36000 101C363U030BH2B 12.8 18.1 2 x 2 5/8 37000 101C373U040AF2B 10.4 21.1 1 3/8 x 5 5/8

41000 101C413U030AD2B 1

44000 101C443U030EB2B 13.4 17.3 1 3/4 x 3 1/8 43000 101C433U040BJ2B 8.8 24.4 2 x 3 5/8

47000 101C473U030AE2B 10.6 20.2 1 3/8 x 5 1/8 45000 101C453U040EC2B 10.5 21.6 1 3/4 x 4 1/8

49000 101C493U030BB2B 8.7 23.3 2 x 3 1/8 52000 101C523U040ED2B 9.5 23.6 1 3/4 x 4 5/8

53000 101C533U030AF2B 9.8 21.8 1 3/8 x 5 5/8 52000 101C523U040BC2B 7.1 28.5 2 x 4 1/8

54000 101C543U030EJ2B 1

59000 101C593U030CH2B 9.3 24.4 2 1/2 x 2 5/8 59000 101C593U040EE2B 8.9 25.4 1 3/4 x 5 1/8

62000 101C623U030BJ2B 7.8 25.8 2 x 3 5/8 61000 101C613U040BD2B 6.5 31.0 2 x 4 5/8

64000 101C643U030EC2B 9.2 23.0 1 3/4 x 4 1/8 66000 101C663U040EF2B 8.4 26.9 1 3/4 x 5 5/8

75000 101C753U030ED2B 8.4 25.1 1 3/4 x 4 5/8 70000 101C703U040BE2B 5.8 33.8 2 x 5 1/8

75000 101C753U030BC2B 6.3 30.1 2 x 4 1/8 71000 101C713U040CJ2D 6.6 32.2 2 1/2 x 3 5/8

81000 101C813U030CB2B 7.1 29.7 2 1/2 x 3 1/8 79000 101C793U040BF2B 5.3 36.5 2 x 5 5/8

85000 101C853U030EE2B 7.9 26.9 1 3/4 x 5 1/8 83000 101C833U040DB2D 8.6 30.1 3 x 3 1/8

88000 101C883U030BD2B 5.8 32.7 2 x 4 5/8 86000 101C863U040CC2D 5.4 37.3 2 1/2 x 4 1/8

95000 101C953U030EF2B 7.5 28.5 1 3/4 x 5 5/8 100000 101C104U040CD2D 4.9 40.6 2 1/2 x 4 5/8

100000 101C104U030CJ2D 5.7 34.6 2 1/2 x 3 5/8 1

100000 101C104U030BE2B 5.2 35.6 2 x 5 1/8 120000 101C124U040CE2D 4.4 44.4 2 1/2 x 5 1/8

1

10000 101C114U030BF2B 4.8 38.4 2 x 5 5/8 130000 101C134U040DC2D 5.3 41.9 3 x 4 1/8

120000 101C124U030DB2D 7.0 33.3 3 x 3 1/8 130000 101C134U040CF2D 4.0 48.0 2 1/2 x 5 5/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

30 Vdc (45 Vdc Surge) 17000 101C173U040AB2B 17.3 13.1 1 3/8 x 3 1/8

1.6 18.6 1 3/8 x 4 5/8 41000 101C413U040CH2B 10.7 22.7 2 1/2 x 2 5/8

1.3 19.9 1 3/4 x 3 5/8 56000 101C563U040CB2B 8.1 27.6 2 1/2 x 3 1/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

1.5 1 3/4 x 2 1/8 25000 101C253U040AC2B 14.0 16.2 1 3/8 x 4 1/8

D x L

(inches)

Cap.

(µF)

10000 101C114U040DJ2D 7.0 35.1 3 x 3 5/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

1.3 19.6 1 3/8 x 5 1/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

D x L

(inches)

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Cap.

(µF)

10000 101C114U063DF2D 4.5 50.2 3 x 5 5/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

1.0 20.5 1 3/8 x 5 5/8

1.0 21.1 1 3/4 x 4 1/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

D x L

(inches)

(A)

Nominal Size

(inches)

D x L

Cap.

(µF)

150000 101C154U040DD2D 5.2 44.0 3 x 4 5/8 63 Vdc (85 Vdc Surge)

170000 101C174U040DE2D 4.6 48.1 3 x 5 1/8 2800 101C282U063AK2B 57.9 4.9 1 3/8 x 1 5/8

190000 101C194U040DF2D 4.2 51.9 3 x 5 5/8 5000 101C502U063AA2B 35.5 7.3 1 3/8 x 2 1/8

210000 101C214U040DP2D 4.0 53.8 3 x 5 7/8 7200 101C722U063AH2B 25.8 9.8 1 3/8 x 2 5/8

280000 101C284U040DN2D 3.4 63.9 3 x 7 5/8 8800 101C882U063BA2B 22.8 12.6 2 x 2 1/8

330000 101C334U040DG2D 3.0 69.9 3 x 8 5/8 8900 101C892U063EA2B 28.0 10.4 1 3/4 x 2 1/8

3800 101C382U050AK2B 48.4 5.4 1 3/8 x 1 5/8 12000 101C123U063AJ2B 17.1 14.0 1 3/8 x 3 5/8

7000 101C702U050AA2B 30.8 7.8 1 3/8 x 2 1/8 13000 101C133U063EH2B 20.4 13.2 1 3/4 x 2 5/8

10000 101C103U050AH2B 22.0 10.5 1 3/8 x 2 5/8 14000 101C143U063BH2B 15.4 16.5 2 x 2 5/8

12000 101C123U050EA2B 26.5 10.7 1 3/4 x 2 1/8 14000 101C143U063AC2B 14.8 15.8 1 3/8 x 4 1/8

12000 101C123U050BA2B 20.8 13.2 2 x 2 1/8 16000 101C163U063AD2B 13.2 17.4 1 3/8 x 4 5/8

13000 101C133U050AB2B 17.5 13.0 1 3/8 x 3 1/8 17000 101C173U063EB2B 16.1 15.8 1 3/4 x 3 1/8

16000 101C163U050AJ2B 14.6 15.2 1 3/8 x 3 5/8 18000 101C183U063AE2B 12.0 19.0 1 3/8 x 5 1/8

18000 101C183U050EH2B 19.3 13.6 1 3/4 x 2 5/8 19000 101C193U063BB2B 10.2 21.5 2 x 3 1/8

19000 101C193U050BH2B 14.1 17.2 2 x 2 5/8 20000 101C203U063AF2B 1

19000 101C193U050AC2B 13.4 16.6 1 3/8 x 4 1/8 21000 101C213U063EJ2B 13.5 18.2 1 3/4 x 3 5/8

22000 101C223U050AD2B 1

24000 101C243U050EB2B 15.3 16.2 1 3/4 x 3 1/8 24000 101C243U063BJ2B 9.6 23.4 2 x 3 5/8

25000 101C253U050AE2B 10.8 20.0 1 3/8 x 5 1/8 25000 101C253U063EC2B 1

27000 101C273U050BB2B 9.6 22.2 2 x 3 1/8 29000 101C293U063ED2B 10.0 23.0 1 3/4 x 4 5/8

29000 101C293U050EJ2B 12.8 18.6 1 3/4 x 3 5/8 29000 101C293U063BC2B 8.2 26.4 2 x 4 1/8

29000 101C293U050AF2B 10.0 21.5 1 3/8 x 5 5/8 31000 101C313U063CB2B 8.6 26.9 2 1/2 x 3 1/8

32000 101C323U050CH2B 9.6 24.0 2 1/2 x 2 5/8 33000 101C333U063EE2B 9.3 24.8 1 3/4 x 5 1/8

34000 101C343U050BJ2B 8.6 24.6 2 x 3 5/8 34000 101C343U063BD2B 7.2 29.3 2 x 4 5/8

35000 101C353U050EC2B 10.5 21.6 1 3/4 x 4 1/8 37000 101C373U063EF2B 8.8 26.3 1 3/4 x 5 5/8

40000 101C403U050ED2B 9.5 23.6 1 3/4 x 4 5/8 39000 101C393U063BE2B 6.5 32.0 2 x 5 1/8

41000 101C413U050BC2B 7.2 28.2 2 x 4 1/8 40000 101C403U063CJ2D 7.0 31.4 2 1/2 x 3 5/8

44000 101C443U050CB2B 8.2 27.6 2 1/2 x 3 1/8 44000 101C443U063BF2B 5.9 34.6 2 x 5 5/8

46000 101C463U050EE2B 8.8 25.4 1 3/4 x 5 1/8 47000 101C473U063DB2B 9.3 29.0 3 x 3 1/8

48000 101C483U050BD2B 6.3 31.2 2 x 4 5/8 48000 101C483U063CC2D 5.6 36.4 2 1/2 x 4 1/8

52000 101C523U050EF2B 8.4 27.0 1 3/4 x 5 5/8 56000 101C563U063CD2D 5.2 39.5 2 1/2 x 4 5/8

55000 101C553U050CJ2D 6.6 32.2 2 1/2 x 3 5/8 59000 101C593U063DJ2D 7.5 33.8 3 x 3 5/8

55000 101C553U050BE2B 5.7 34.1 2 x 5 1/8 65000 101C653U063CE2D 4.6 43.3 2 1/2 x 5 1/8

62000 101C623U050BF2B 5.2 36.8 2 x 5 5/8 72000 101C723U063DC2D 6.0 39.5 3 x 4 1/8

65000 101C653U050DB2B 8.9 29.5 3 x 3 1/8 73000 101C733U063CF2D 4.2 46.8 2 1/2 x 5 5/8

67000 101C673U050CC2D 5.4 37.3 2 1/2 x 4 1/8 84000 101C843U063DD2D 5.6 42.5 3 x 4 5/8

79000 101C793U050CD2D 4.9 40.5 2 1/2 x 4 5/8 97000 101C973U063DE2D 5.0 46.5 3 x 5 1/8

83000 101C833U050DJ2D 7.3 34.4 3 x 3 5/8 1

90000 101C903U050CE2D 4.4 44.3 2 1/2 x 5 1/8 120000 101C124U063DP2D 4.3 52.0 3 x 5 7/8

100000 101C104U050DC2D 5.5 41.1 3 x 4 1/8 160000 101C164U063DN2D 3.6 62.2 3 x 7 5/8

100000 101C104U050CF2D 4.0 47.9 2 1/2 x 5 5/8 180000 101C184U063DG2D 3.2 68.2 3 x 8 5/8

120000 101C124U050DD2D 5.4 43.2 3 x 4 5/8 75 Vdc (100 Vdc Surge)

130000 101C134U050DE2D 4.8 47.2 3 x 5 1/8 2100 101C212U075AK2B 97.3 3.8 1 3/8 x 1 5/8

150000 101C154U050DF2D 4.4 51.0 3 x 5 5/8 3600 101C362U075AA2B 67.2 5.3 1 3/8 x 2 1/8

160000 101C164U050DP2D 4.2 52.9 3 x 5 7/8 5200 101C522U075AH2B 50.0 7.0 1 3/8 x 2 5/8

220000 101C224U050DN2D 3.5 63.0 3 x 7 5/8 6400 101C642U075BA2B 40.7 9.4 2 x 2 1/8

260000 101C264U050DG2D 3.1 69.0 3 x 8 5/8 6500 101C652U075EA2B 47.5 8.0 1 3/4 x 2 1/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

50 Vdc (75 Vdc Surge) 9400 101C942U063AB2B 20.4 12.0 1 3/8 x 3 1/8

1.9 18.3 1 3/8 x 4 5/8 23000 101C233U063CH2B 11.3 22.1 2 1/2 x 2 5/8

Ripple Max.

@ 85°C

120 Hz

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Cap.

(µF)

6800 101C682U075AB2B 39.3 8.7 1 3/8 x 3 1/8 9600 101C962U100AF2B 23.4 14.1 1 3/8 x 5 5/8

8400 101C842U075AJ2B 32.5 10.1 1 3/8 x 3 5/8 9800 101C982U100EJ2B 25.8 13.2 1 3/4 x 3 5/8

9400 101C942U075EH2B 34.2 10.2 1 3/4 x 2 5/8 1

10000 101C103U075AC2B 27.9 1

10000 101C103U075BH2B 27.4 12.4 2 x 2 5/8 12000 101C123U100EC2B 20.7 15.4 1 3/4 x 4 1/8

12000 101C123U075EB2B 27.0 12.2 1 3/4 x 3 1/8 14000 101C143U100ED2B 18.6 16.9 1 3/4 x 4 5/8

12000 101C123U075AD2B 24.5 12.8 1 3/8 x 4 5/8 14000 101C143U100BC2B 14.8 19.7 2 x 4 1/8

13000 101C133U075AE2B 22.0 14.0 1 3/8 x 5 1/8 15000 101C153U100EE2B 17.0 18.3 1 3/4 x 5 1/8

14000 101C143U075BB2B 18.0 16.2 2 x 3 1/8 15000 101C153U100CB2B 16.5 19.4 2 1/2 x 3 1/8

15000 101C153U075EJ2B 22.4 14.1 1 3/4 x 3 5/8 16000 101C163U100BD2B 14.3 20.8 2 x 4 5/8

15000 101C153U075AF2B 20.0 15.2 1 3/8 x 5 5/8 17000 101C173U100EF2B 15.9 19.6 1 3/4 x 5 5/8

17000 101C173U075CH2B 18.9 17.1 2 1/2 x 2 5/8 18000 101C183U100BE2B 12.7 22.9 2 x 5 1/8

17000 101C173U075BJ2B 16.8 17.7 2 x 3 5/8 19000 101C193U100CJ2B 13.3 22.7 2 1/2 x 3 5/8

18000 101C183U075EC2B 18.0 16.5 1 3/4 x 4 1/8 21000 101C213U100BF2B 1

21000 101C213U075ED2B 16.2 18.1 1 3/4 x 4 5/8 22000 101C223U100DB2B 13.8 23.8 3 x 3 1/8

21000 101C213U075BC2B 12.7 21.2 2 x 4 1/8 22000 101C223U100CC2B 10.0 27.4 2 1/2 x 4 1/8

23000 101C233U075CB2B 14.3 20.8 2 1/2 x 3 1/8 26000 101C263U100CD2B 9.7 28.9 2 1/2 x 4 5/8

24000 101C243U075EE2B 14.8 19.6 1 3/4 x 5 1/8 28000 101C283U100DJ2B 1

25000 101C253U075BD2B 12.3 22.4 2 x 4 5/8 30000 101C303U100CE2D 8.6 31.7 2 1/2 x 5 1/8

27000 101C273U075EF2B 13.9 20.9 1 3/4 x 5 5/8 34000 101C343U100DC2D 8.5 33.2 3 x 4 1/8

28000 101C283U075BE2B 1

29000 101C293U075CJ2B 1

32000 101C323U075BF2B 9.9 26.7 2 x 5 5/8 45000 101C453U100DE2D 6.5 40.5 3 x 5 1/8

34000 101C343U075DB2B 13.3 24.2 3 x 3 1/8 51000 101C513U100DF2D 6.0 43.5 3 x 5 5/8

35000 101C353U075CC2B 8.7 29.4 2 1/2 x 4 1/8 54000 101C543U100DP2D 6.0 44.1 3 x 5 7/8

41000 101C413U075CD2D 8.4 30.9 2 1/2 x 4 5/8 74000 101C743U100DN2D 4.8 54.0 3 x 7 5/8

43000 101C433U075DJ2B 10.8 28.2 3 x 3 5/8 85000 101C853U100DG2D 4.2 59.2 3 x 8 5/8

47000 101C473U075CE2D 7.5 34.0 2 1/2 x 5 1/8 150 Vdc (200 Vdc Surge)

52000 101C523U075DC2D 7.6 35.0 3 x 4 1/8 490 101C491U150AK2B 433.0 2.1 1 3/8 x 1 5/8

53000 101C533U075CF2D 6.7 36.9 2 1/2 x 5 5/8 880 101C881U150AA2B 241.0 3.1 1 3/8 x 2 1/8

61000 101C613U075DD2D 7.9 35.7 3 x 4 5/8 1200 101C122U150EA2B 199.0 3.9 1 3/4 x 2 1/8

70000 101C703U075DE2D 6.1 42.0 3 x 5 1/8 1300 101C132U150AH2B 163.0 4.0 1 3/8 x 2 5/8

79000 101C793U075DF2D 6.0 43.5 3 x 5 5/8 1500 101C152U150BA2B 159.0 4.8 2 x 2 1/8

83000 101C833U075DP2D 5.7 45.1 3 x 5 7/8 1700 101C172U150AB2B 125.0 4.9 1 3/8 x 3 1/8

1

10000 101C114U075DN2D 4.7 54.7 3 x 7 5/8 1800 101C182U150EH2B 133.0 5.2 1 3/4 x 2 5/8

130000 101C134U075DG2D 4.1 60.3 3 x 8 5/8 1900 101C192U150AJ2B 1

1300 101C132U100AK2B 1

2300 101C232U100AA2B 79.9 4.9 1 3/8 x 2 1/8 2500 101C252U150AC2B 84.9 6.6 1 3/8 x 4 1/8

3400 101C342U100AH2B 59.4 6.4 1 3/8 x 2 5/8 2700 101C272U150AD2B 80.1 7.1 1 3/8 x 4 5/8

4100 101C412U100BA2B 47.6 8.7 2 x 2 1/8 3100 101C312U150AE2B 74.0 7.6 1 3/8 x 5 1/8

4200 101C422U100EA2B 55.0 7.4 1 3/4 x 2 1/8 3200 101C322U150EJ2B 74.6 7.7 1 3/4 x 3 5/8

4400 101C442U100AB2B 46.6 8.0 1 3/8 x 3 1/8 3400 101C342U150BB2B 54.6 9.3 2 x 3 1/8

5400 101C542U100AJ2B 38.5 9.3 1 3/8 x 3 5/8 3600 101C362U150AF2B 66.3 8.4 1 3/8 x 5 5/8

6100 101C612U100EH2B 39.6 9.5 1 3/4 x 2 5/8 3800 101C382U150CH2B 62.8 9.4 2 1/2 x 2 5/8

6500 101C652U100AC2B 32.9 10.6 1 3/8 x 4 1/8 4000 101C402U150BJ2B 59.7 9.4 2 x 3 5/8

6500 101C652U100BH2B 32.0 1

7500 101C752U100AD2B 28.9 1

7900 101C792U100EB2B 31.1 1

8500 101C852U100AE2B 25.8 12.9 1 3/8 x 5 1/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

75 Vdc (100 Vdc Surge) 8900 101C892U100BB2B 21.0 15.0 2 x 3 1/8

1.0 24.6 2 x 5 1/8 34000 101C343U100CF2D 7.7 34.5 2 1/2 x 5 5/8

1.5 24.4 2 1/2 x 3 5/8 39000 101C393U100DD2D 7.9 35.7 3 x 4 5/8

100 Vdc (150 Vdc Surge) 2300 101C232U150BH2B 104.0 6.3 2 x 2 5/8

16.0 3.5 1 3/8 x 1 5/8 2500 101C252U150EB2B 95.5 6.5 1 3/4 x 3 1/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

1.5 1 3/8 x 4 1/8 11000 101C113U100BJ2B 19.5 16.4 2 x 3 5/8

1.4 2 x 2 5/8 4400 101C442U150EC2B 54.3 9.5 1 3/4 x 4 1/8

1.8 1 3/8 x 4 5/8 4500 101C452U150ED2B 53.1 10.0 1 3/4 x 4 5/8

1.4 1 3/4 x 3 1/8 5200 101C522U150EE2B 45.9 11.1 1 3/4 x 5 1/8

D x L

(inches)

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Cap.

(µF)

1000 101C113U100CH2B 20.7 16.3 2 1/2 x 2 5/8

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

1.4 24.9 2 x 5 5/8

1.2 27.7 3 x 3 5/8

12.0 5.5 1 3/8 x 3 5/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

D x L

(inches)

Type 101C –55 °C to 105 °C Low-ESR, Wide-Temperature Grade

Cap.

(µF)

5200 101C522U150CB2B 45.9 11.6 2 1/2 x 3 1/8 8300 101C832T200CE2B 24.0 19.0 2 1/2 x 5 1/8

5200 101C522U150BC2B 45.0 1

5700 101C572U150BD2B 41.9 12.2 2 x 4 5/8 10000 101C103T200CF2B 21.2 20.8 2 1/2 x 5 5/8

5800 101C582U150EF2B 41.2 12.2 1 3/4 x 5 5/8 1

6600 101C662U150BE2B 36.2 13.6 2 x 5 1/8 13000 101C133T200DB2B 17.8 20.9 3 x 3 1/8

6600 101C662U150CJ2B 36.2 13.8 2 1/2 x 3 5/8 13000 101C133T200DE2B 17.8 24.5 3 x 5 1/8

7800 101C782U150DB2B 35.7 14.8 3 x 3 1/8 14000 101C143T200DF2B 16.9 25.9 3 x 5 5/8

7900 101C792U150BF2B 30.2 15.3 2 x 5 5/8 15000 101C153T200DP2B 15.9 27.1 3 x 5 7/8

8500 101C852U150CC2B 28.1 16.3 2 1/2 x 4 1/8 20000 101C203T200DN2D 12.5 33.9 3 x 7 5/8

9400 101C942U150CD2B 25.4 17.8 2 1/2 x 4 5/8 23000 101C233T200DG2D 10.4 37.8 3 x 8 5/8

9900 101C992U150DJ2B 28.1 17.5 3 x 3 5/8 250 Vdc (350 Vdc Surge)

11000 101C1

12000 101C123U150DC2B 23.2 20.1 3 x 4 1/8 530 101C531T250AA2B 300.0 2.7 1 3/8 x 2 1/8

13000 101C133U150CF2B 18.4 22.3 2 1/2 x 5 5/8 700 101C701T250EA2B 227.0 3.7 1 3/4 x 2 1/8

14000 101C143U150DD2B 19.9 22.5 3 x 4 5/8 760 101C761T250AH2B 209.0 3.5 1 3/8 x 2 5/8

16000 101C163U150DE2B 17.4 24.8 3 x 5 1/8 890 101C891T250BA2B 164.0 4.7 2 x 2 1/8

18000 101C183U150DF2B 15.5 27.1 3 x 5 5/8 990 101C991T250AB2B 161.0 4.3 1 3/8 x 3 1/8

19000 101C193U150DP2B 14.7 28.2 3 x 5 7/8 1

26000 101C263U150DN2D 1

30000 101C303U150DG2D 9.3 40.0 3 x 8 5/8 1400 101C142T250BH2B 104.0 6.3 2 x 2 5/8

380 101C381T200AK2B 454.0 2.0 1 3/8 x 1 5/8 1500 101C152T250EB2B 106.0 6.2 1 3/4 x 3 1/8

680 101C681T200AA2B 254.0 3.0 1 3/8 x 2 1/8 1700 101C172T250AD2B 101.0 6.3 1 3/8 x 4 5/8

890 101C891T200EA2B 224.0 3.7 1 3/4 x 2 1/8 1900 101C192T250AE2B 90.7 6.9 1 3/8 x 5 1/8

980 101C981T200AH2B 176.0 3.9 1 3/8 x 2 5/8 1900 101C192T250EJ2B 83.8 7.3 1 3/4 x 3 5/8

100 101C112T200BA2B 181.0 4.5 2 x 2 1/8 1900 101C192T250BB2B 69.8 8.2 2 x 3 1/8

1

1300 101C132T200AB2B 133.0 4.8 1 3/8 x 3 1/8 2200 101C222T250AF2B 84.4 7.4 1 3/8 x 5 5/8

1400 101C142T200EH2B 142.0 5.0 1 3/4 x 2 5/8 2300 101C232T250CH2B 75.0 8.6 2 1/2 x 2 5/8

1600 101C162T200AJ2B 108.0 5.6 1 3/8 x 3 5/8 2300 101C232T250EC2B 69.2 8.4 1 3/4 x 4 1/8

1800 101C182T200BH2B 1

1900 101C192T200EB2B 105.0 6.2 1 3/4 x 3 1/8 2700 101C272T250ED2B 58.9 9.5 1 3/4 x 4 5/8

1900 101C192T200AC2B 88.9 6.4 1 3/8 x 4 1/8 2900 101C292T250BC2B 50.3 10.7 2 x 4 1/8

2200 101C222T200AD2B 90.4 6.7 1 3/8 x 4 5/8 3100 101C312T250CB2B 55.6 10.6 2 1/2 x 3 1/8

2400 101C242T200EJ2B 82.9 7.3 1 3/4 x 3 5/8 3100 101C312T250EE2B 51.3 10.5 1 3/4 x 5 1/8

2400 101C242T200BB2B 82.9 7.5 2 x 3 1/8 3400 101C342T250BD2B 45.6 1

2500 101C252T200AE2B 79.6 7.4 1 3/8 x 5 1/8 3500 101C352T250EF2B 45.5 1

2800 101C282T200AF2B 71.0 8.1 1 3/8 x 5 5/8 3900 101C392T250BE2B 42.0 12.6 2 x 5 1/8

3100 101C312T200BJ2B 64.2 9.0 2 x 3 5/8 4000 101C402T250CJ2B 43.1 12.6 2 1/2 x 3 5/8

3400 101C342T200EC2B 58.5 9.1 1 3/4 x 4 1/8 4500 101C452T250BF2B 38.3 13.6 2 x 5 5/8

3500 101C352T200ED2B 56.8 9.7 1 3/4 x 4 5/8 4700 101C472T250DB2B 42.3 13.6 3 x 3 1/8

4000 101C402T200EE2B 49.7 10.7 1 3/4 x 5 1/8 5100 101C512T250CC2B 30.6 15.6 2 1/2 x 4 1/8

4000 101C402T200CB2B 49.7 1

4000 101C402T200BC2B 43.1 1

4400 101C442T200BD2B 45.2 1

4500 101C452T200EF2B 44.2 1

5000 101C502T200BE2B 39.8 12.9 2 x 5 1/8 7700 101C772T250CF2B 24.1 19.5 2 1/2 x 5 5/8

5100 101C512T200CJ2B 39.0 13.3 2 1/2 x 3 5/8 8500 101C852T250DD2B 23.4 20.7 3 x 4 5/8

6100 101C612T200BF2B 32.6 14.7 2 x 5 5/8 9700 101C972T250DE2B 20.5 22.8 3 x 5 1/8

6500 101C652T200CC2B 26.3 16.9 2 1/2 x 4 1/8 1

7200 101C722T200CD2B 27.6 17.1 2 1/2 x 4 5/8 12000 101C123T250DP2B 16.6 26.5 3 x 5 7/8

7600 101C762T200DJ2B 29.7 17.0 3 x 3 5/8 16000 101C163T250DN2D 13.4 32.8 3 x 7 5/8

Catalog

Part Number

13U150CE2B 21.7 19.9 2 1/2 x 5 1/8 290 101C291T250AK2B 549.0 1.8 1 3/8 x 1 5/8

200 Vdc (275 Vdc Surge) 1500 101C152T250AC2B 106.0 5.9 1 3/8 x 4 1/8

ESR Max.

@ 25 °C

120 Hz

(mΩ)

1.3 35.7 3 x 7 5/8 1200 101C122T250AJ2B 133.0 5.0 1 3/8 x 3 5/8

11.0 6.1 2 x 2 5/8 2400 101C242T250BJ2B 58.0 9.5 2 x 3 5/8

Ripple Max.

@ 85°C

120 Hz

Nominal Size

(A)

1.3 2 x 4 1/8 9300 101C932T200DC2B 21.4 20.9 3 x 4 1/8

1.2 2 1/2 x 3 1/8 5700 101C572T250CD2B 28.9 16.7 2 1/2 x 4 5/8

1.5 2 x 4 1/8 5900 101C592T250DJ2B 33.7 16.0 3 x 3 5/8

1.7 2 x 4 5/8 6500 101C652T250CE2B 26.6 18.0 2 1/2 x 5 1/8

1.7 1 3/4 x 5 5/8 7200 101C722T250DC2B 27.6 18.4 3 x 4 1/8

D x L

(inches)

Cap.

(µF)

1000 101C113T200DD2B 20.5 22.1 3 x 4 5/8

100 101C112T250EH2B 145.0 5.0 1 3/4 x 2 5/8

1000 101C113T250DF2B 18.1 25.0 3 x 5 5/8

18000 101C183T250DG2D 1

Catalog

Part Number

ESR Max.

@ 25 °C

120 Hz

(mΩ)

1.1 36.7 3 x 8 5/8

Ripple Max.

@ 85°C

120 Hz

(A)

1.7 2 x 4 5/8

1.6 1 3/4 x 5 5/8

Nominal Size

D x L

(inches)

CDM Cornell Dubilier • 140 Technology Place • Liberty, SC 29657 • Phone: (864)843-2277 • Fax: (864)843-3800 • www.cde.com

Loading...

Loading...