Page 1

Original:

___________________________________________________________________________

16.01.2014

Assembly- and Operating Instructions:

2-jaw parallel grippers, pneumatically actuated

RPP/ RPP-A

Description Page

Comparison: RPP/ RPP-A 2

Overview: RPP/ RPP-A 4

Safety Precautions and Guidelines for Use 6

Description of the Parallel Grippers: RPP 9

Description of the Parallel Grippers: RPP-A 17

Installation, Commissioning: RPP/ RPP-A 25

Maintenance, Repair: RPP/ RPP-A 32

Accessories: RPP/ RPP-A 35

Manufacturer's Declaration: RPP/ RPP-A 37

Date of issue: Dillingen, 16.01.2014

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 1 of 37

Page 2

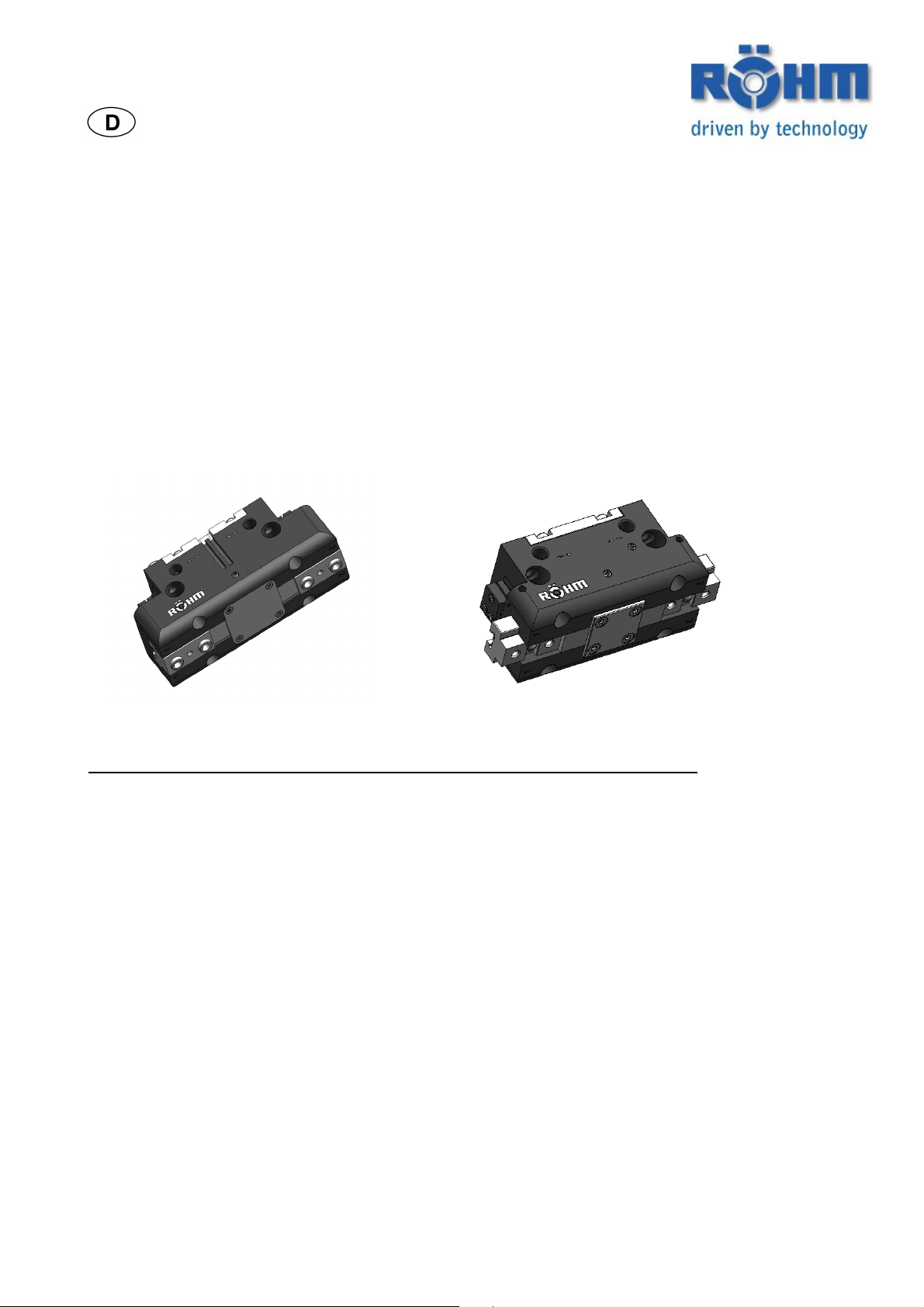

Comparison: RPP; RPP-A

2-jaw parallel grippers

___________________________________________________________________________

2-jaw parallel grippers, pneumatically actuated

RPP

Functional principle

• Tried-and-tested T-slots for gripping under maximum load

• Quick and efficient gripping

• Centrical gripping of round and angular workpieces

• Universal use by using different clamping jaws

• Optimum use in series production

• All sizes are available with two stroke lengths

• Clamping force regulation by means of pressure change

• Constant clamping force at the same pressure, and therefore high clamping precision

• Compact, ergonomic form

• Purge port to prevent contamination

• Grippers can be installed on two gripper sides

• Position polling possible by means of inductive and magnetic sensors

• Compressed air port via screw connection or direct port

• Gripping force lock for outer or inner gripping as extra type

• Base jaw / top jaw interface with centring sleeves

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 2 of 37

Page 3

Comparison: RPP; RPP-A

2-jaw parallel grippers

___________________________________________________________________________

2-jaw parallel grippers, pneumatically actuated

RPP-A

Functional principle

• Tried-and-tested T-slots for gripping under maximum load

• Quick and efficient gripping

• Centrical gripping of round and angular workpieces

• Universal use by using different clamping jaws

• Optimum use in series production

• All sizes are available with two stroke lengths

• Clamping force regulation by means of pressure change

• Constant clamping force at the same pressure, and therefore high clamping precision

• Compact, ergonomic form

• Purge port to prevent contamination

• Grippers can be installed on two gripper sides

• Position polling possible by means of inductive sensors

• Compressed air port via screw connection or direct port

• Gripping force lock for outer or inner gripping as extra type

• Base jaw / top jaw interface with T-slot, positioning pin and positioning hole

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 3 of 37

Page 4

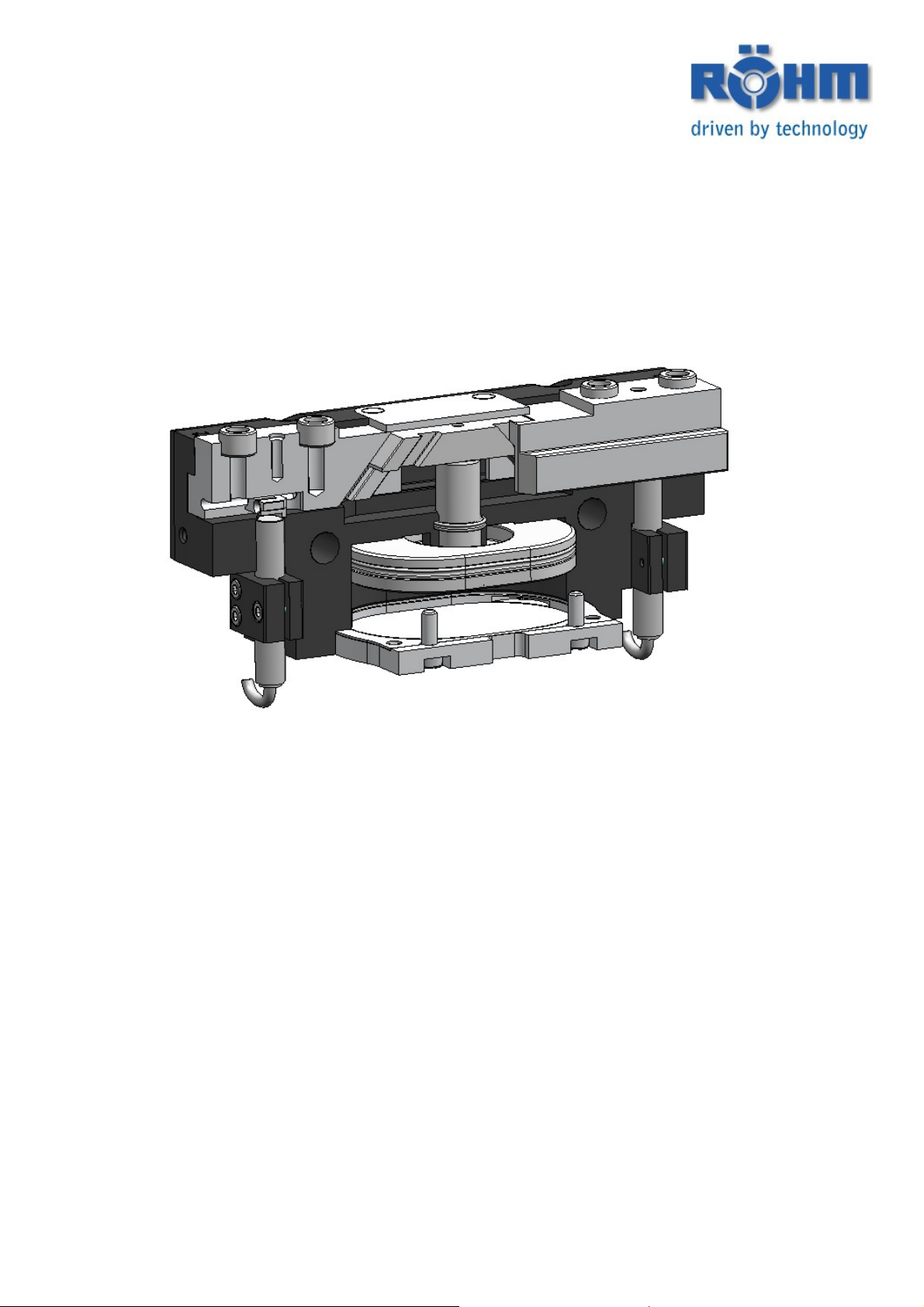

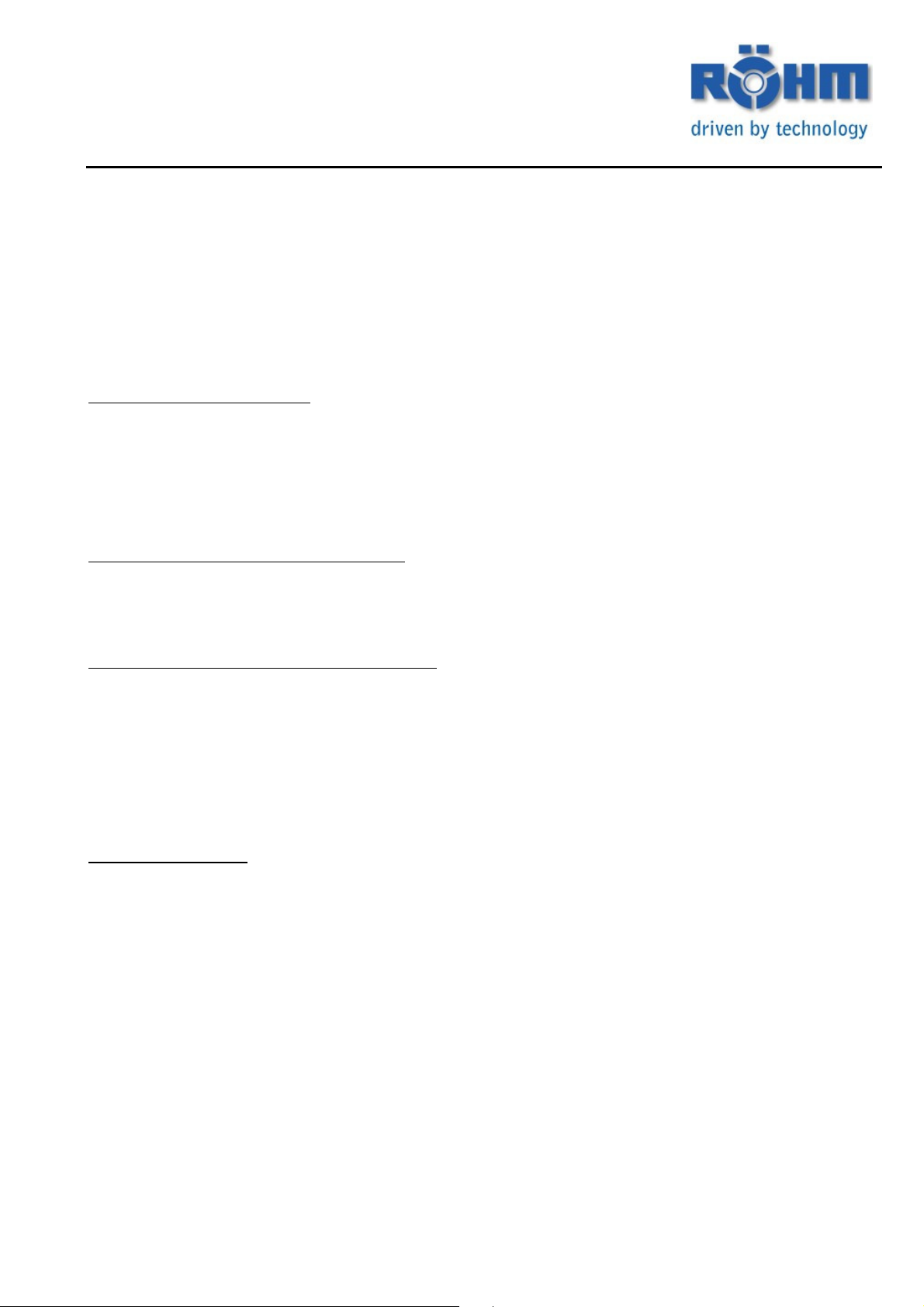

Overview: RPP; RPP-A

2-jaw parallel grippers

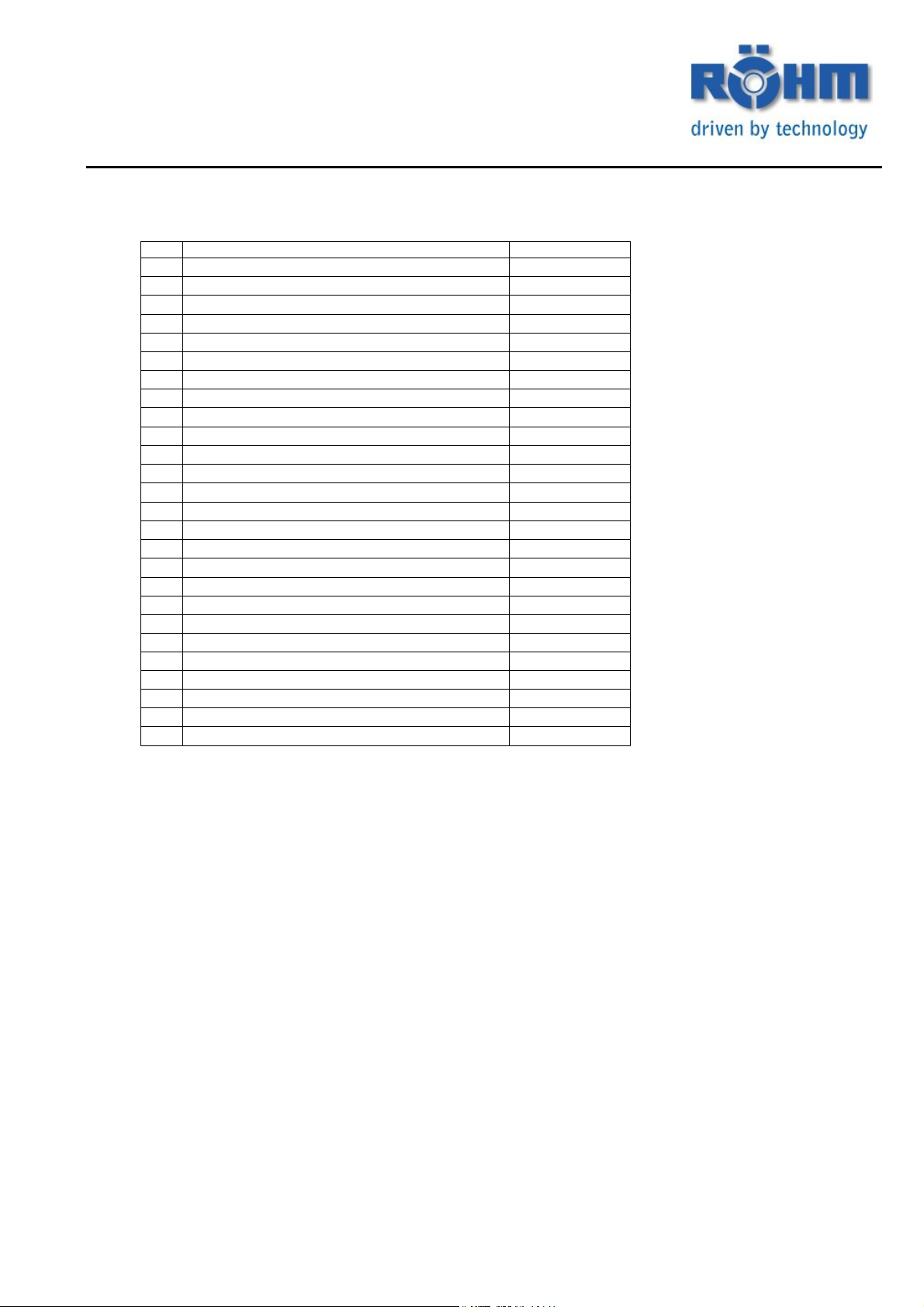

Overview:

Designation

Type

RPP 50

RPP

Total stroke

[mm]

1 2 1 2 1 2

8 4 180 350 0,7 1,45

Max. possible gripping

force

[N]

Recommended workpiece

weight

[kg]

RPP 64

RPP 80

RPP 100

RPP 125

RPP 160

RPP 200

RPP 240

RPP 300

RPP type:

1 Large jaw stroke, normal gripping force

2 Normal jaw stroke, high gripping force

GA Gripping force lock for outer gripping with integrated springs for increased gripping forces

GI Gripping force lock for inner gripping with integrated springs for increased gripping forces

12 6 300 600 1,5 3

16 8 450 860 2,2 4,3

20 10 700 1400 3,5 7

26 12 1200 2400 6 12

32 16 1850 3400 9 17

50 28 2800 4800 14 24

60 34 4200 7000 21 35

70 40 6200 10300 31 52

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 4 of 37

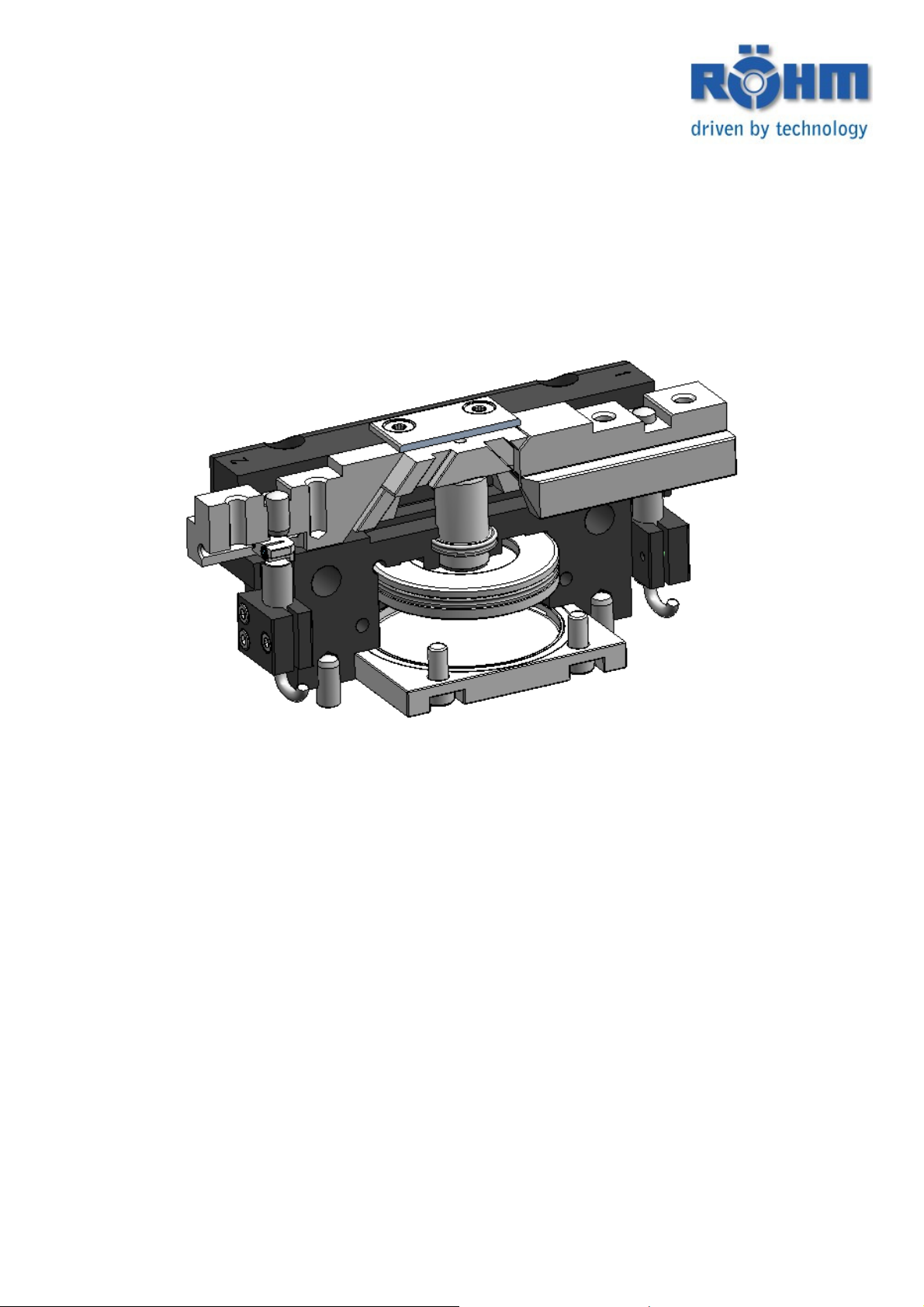

Page 5

Overview: RPP; RPP-A

2-jaw parallel grippers

Overview:

Designation

Type

RPP-A

Total stroke

[mm]

1 2 1 2 1 2

Max. possible gripping

force

[N]

Recommended workpiece

weight

[kg]

RPP-A 64

RPP-A 80

RPP-A 100

RPP-A 125

RPP-A 160

12 6 240 450 1,2 2,2

16 8 380 700 1,9 3,5

20 10 600 1160 3,0 5,5

26 12 950 1900 4,5 9,5

32 16 1300 2500 6,5 12,5

RPP-A type:

1 Large jaw stroke, normal gripping force

2 Normal jaw stroke, high gripping force

GA Gripping force lock for outer gripping with integrated springs for increased gripping forces

GI Gripping force lock for inner gripping with integrated springs for increased gripping forces

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 5 of 37

Page 6

Safety Precautions and Guidelines for Use

2-jaw parallel grippers

I. Qualifications of the operator

Persons with no experience in working with gripping installations are exposed to particular danger due to incorrect

behaviour, particularly during set-up work due to the gripping movements and forces occurring.

Gripping installations may therefore only be operated, adjusted or repaired by persons specifically qualified or

trained for this work, or who have many years of experience in this work.

II. Risk of injury

For technical reasons, this unit may consist partly of sharp-edged individual parts. Particular care must therefore be

taken to avoid injury when working on these parts!

1. Installed energy accumulators

Moving parts preloaded with compression springs, tension springs of other springs or with other elastic elements

represent a hazard potential due to their stored energy. Underestimating this potential can result in serious injuries

due to projectile-like individual parts flying around uncontrolled. This stored energy must be relieved before further

work can be carried out. Gripping installations to be dismantled must therefore be examined for such potential

sources of danger using the corresponding assembly drawings.

If the relief of this stored energy cannot be carried out without danger, the dismantling may only be carried out by

authorised personnel.

2. Calculation of the necessary gripping forces

If this gripping installation is intended to hold or clamp the workpiece against machining forces exerted from the

outside, the machining forces involved in a given machining process must be determined and provided with a safety

allowance commensurate with the calculation method and the machining operation. The gripping installation must

then be able to generate at least the gripping forces calculated in this way.

3. Use of other/further clamping inserts/workpieces

The necessary minimum clamping force must always be determined when using other clamping inserts or

workpieces.

1.Clamping of other/further workpieces

If special clamping sets are provided for this gripping installation (jaws, clamping inserts, systems, alignment

elements, position fixators, tips, etc.), only the workpieces for which the clamping sets were designed may be

clamped in the intended manner using these clamping sets. If this is not observed, insufficient clamping forces or

unfavourable clamping positions may result in material damage or personal injury.

If further or similar workpieces are to be clamped with the same clamping set, written approval must therefore be

obtained from the manufacturer.

4. Gripping force check

Gripping force check (general)

In accordance with standard EN 1550 § 6.2 No. d) for rotating work holding chucks which can also be applied to

stationary clamping installations in this one point, static gripping force measuring instruments should be used to

inspect the maintenance condition at regular intervals in accordance with the maintenance manual. This prescribes

that a gripping force check should be performed after approx. 40 operating hours, irrespective of the clamping

frequency.

If necessary, special clamping force measuring jaws or instruments (load cells) must be used for this.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 6 of 37

Page 7

Safety Precautions and Guidelines for Use

2-jaw parallel grippers

5. Strength of the workpiece to be clamped

In order to ensure reliable gripping of the workpiece with the applied load forces, the clamped material must be

strong enough to withstand the gripping force.

Non-metallic materials such as plastic or rubber, etc. may only be clamped after testing and under particular

observation!

6. Installation and adjustment work

During clamping or alignment movements, etc., short distances are travelled in short times, in some cases with high

forces.

The drive system provided for the gripper actuation must therefore always be switched off during installation and

adjustment work. If the clamping movements are essential during set-up mode, however, then for clamping strokes

longer than 4 mm

- A fixed or temporarily installed workpiece holder must be installed on the device, or

- An independently actuated holding device must be installed,

or

- A workpiece loading aid must be provided,

or

- The set-up operations must be performed in hydraulic, pneumatic or electric jog mode (corresponding control

must be possible!).

The type of this set-up aid depends fundamentally on the machine tool employed and may have to be procured

separately!

The machine owner must ensure that during the whole clamping process, any danger to persons from the

movements of the clamping means is ruled out. For this reason, either 2-hand controls for actuation of the clamping

movement or - even better - corresponding guards must be provided.

7. Tightening and replacement of bolts

If bolts are replaced or loosened, faulty replacement or tightening may result in dangers for persons and materials.

For this reason, the tightening torque recommended by the bolt manufacturer and corresponding to the bolt grade

must always be used for al mounting bolts unless expressly specified otherwise.

The following tightening torque table applies for all the standard sizes M5 - M24 for grades 8.8, 10.9 and 12.9:

If replacing the original bolts, always use bolt grade 12.9 in case of doubt. The grade 12.9 must always be used for

the mounting bolts of clamping inserts, top jaws, fixed stops, cylinder covers and comparable elements.

All mounting bolts which due to their intended use have to be frequently loosened and tightened again (e.g. due to

tooling work) must be coated with lubricant (grease paste) every six months in the thread area and on the head

contact surface.

Grade M5 M6 M8 M10 M12 M14 M16 M18 M20 M22 M24

8.8 5,5 9,5 23 46 80 130 190 270 380 510 670 Nm

10.9 8,1 13 33 65 110 180 270 380 530 720 960 Nm

12.9 9,5 16 39 78 140 220 330 450 640 860 1120 Nm

All figures in Nm

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 7 of 37

Page 8

Safety Precautions and Guidelines for Use

2-jaw parallel grippers

III. Environmental hazards

A very wide variety of different media are currently required for lubrication, cooling, etc. during operation of a

clamping or gripping installation. These are generally connected to the clamping installation by pipes or hoses. The

most frequently used are hydraulic oil, lubricating oil/grease and coolants. Particular attention must be paid to these

media when working with the clamping installation to ensure that they do not get into the ground or water. Caution!

Environmental hazard!

This applies in particular:

During installation/removal as there may still be residues in the pipework, piston chambers or oil drain plugs,

To porous, defective or not correctly installed gaskets,

To lubricants that for design reasons escape or are slung out of the clamping installation during operation.

These escaping substances should therefore be collected and recycled or disposed of in accordance with the

applicable regulations.

IV. Safety engineering demands on power-actuated gripping installations:

1. The gripping installation may only be moved when the clamping pressure in the gripper has been built up

and clamping can be carried out in the admissible working range.

2. Clamping may only be released when the gripping installation has come to a standstill.

3. In the event of a failure of the clamping energy, a signal must be given that immediately stops the machine.

4. In the event of a failure of the clamping energy, the workpiece must remain firmly clamped.

5. In the event of an electric power failure and return, it must not be possible for the momentary switching

position to change.

V. Safety precautions:

1. Do not move parts by hand when the power supply is connected and switched on.

2. Do not reach into the open mechanical elements or between the clamping jaws.

3. Disconnect the energy supplies during installation, retooling, maintenance and adjustment

operations.

4. Carry out maintenance, retooling or attachment outside the danger zone.

5. During installation, connection, adjustment, commissioning and testing, measures must be

taken to ensure that accidental actuation of the unit by the fitter or other persons is not

possible.

6. When using all handling modules, protective guards in accordance with the EC Machinery

Directive must be fitted.

7.

Dangers are posed by objects falling or being slung out. Measures must be taken to prevent

such falling or slinging out.

8. The service and maintenance intervals must be observed.

9.

Grippers which clamp under spring load or which have a gripping force lock with springs are

under spring tension. The resilient pressing star is also under spring tension. Particular care is

therefore necessary during dismantling.

10. Particularly on grippers with gripping force maintenance, top jaws must be designed such that

in pressure-free state, a gripper reaches one of the end positions so that no residual energy is

released during changing of the top jaws.

In addition, the admissible active clearances from the corresponding tables must be observed.

Furthermore, the safety and accident prevention regulations applicable at the place of

operation must be observed.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 8 of 37

Page 9

Description of the RPP Parallel Grippers

2-jaw parallel grippers

2-jaw parallel grippers, pneumatically actuated

RPP

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 9 of 37

Page 10

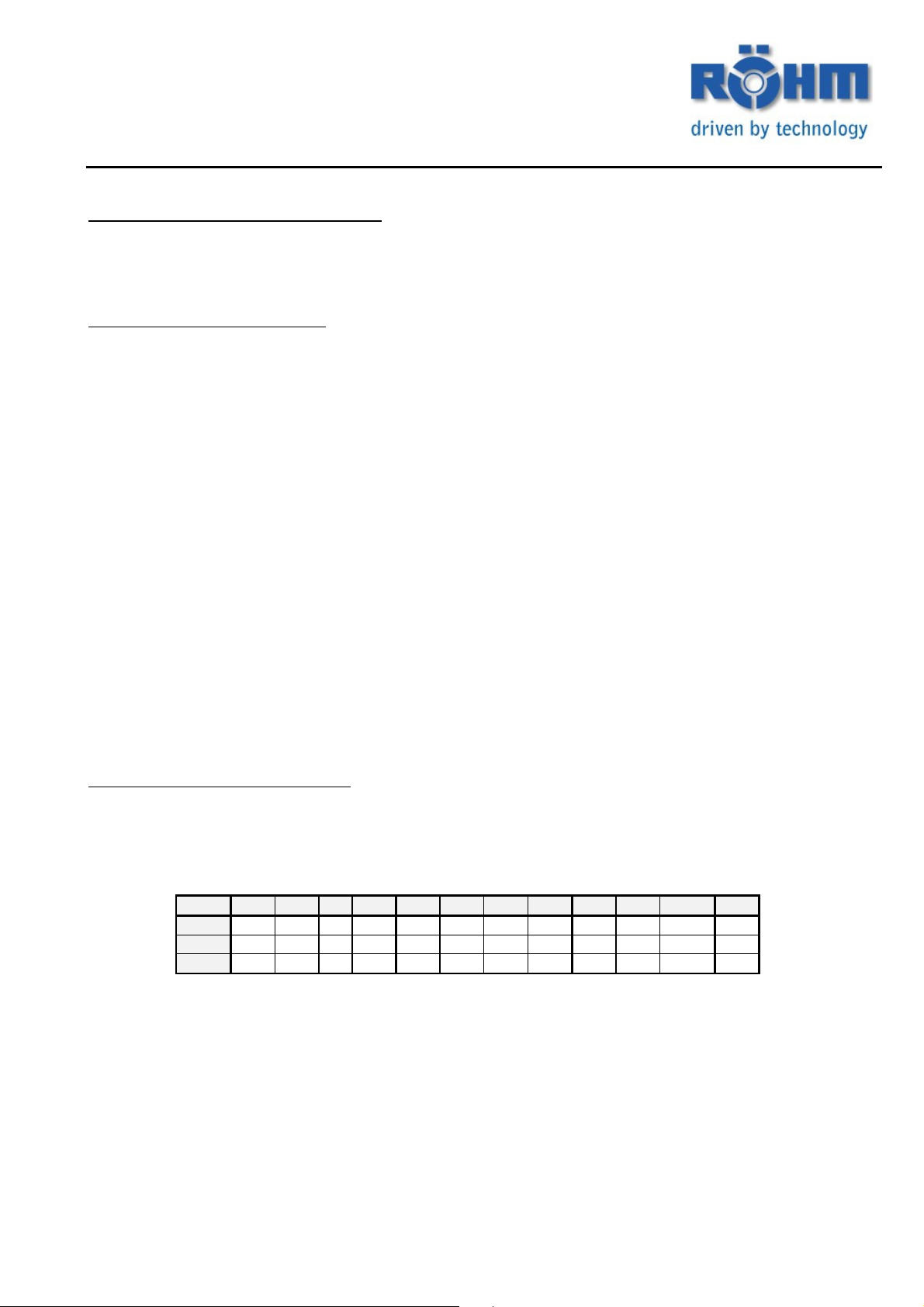

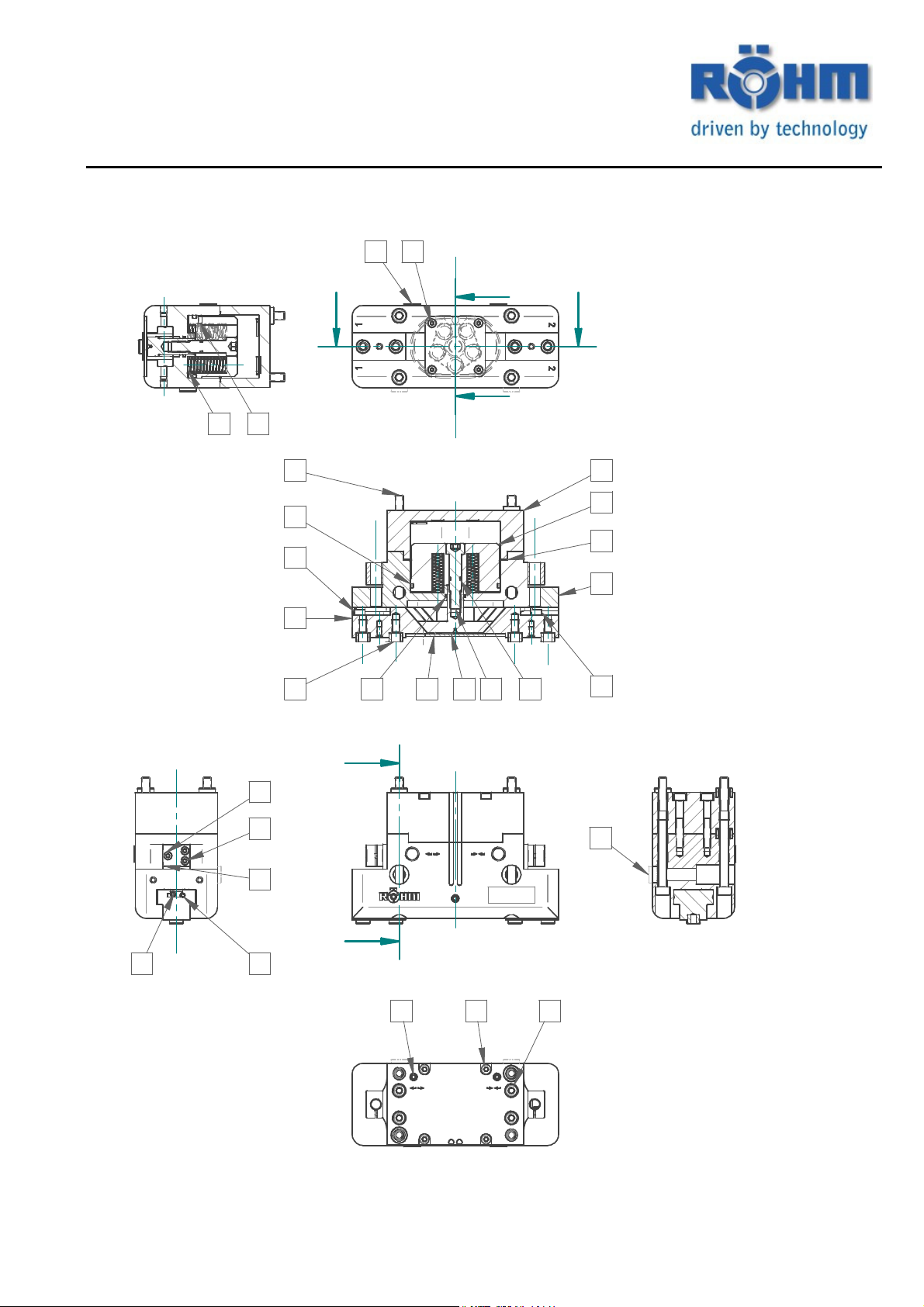

Description of the RPP Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP xxx-x

Schnitt A-A

33

Schnitt B-B

27

1

9

31

B

4

6

28 8

A

B

A

24

19

13

7

10

12

30

11

20

32

21

2 3

12

5

25

22

XXX

26

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 10 of 37

Page 11

Description of the RPP Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP xxx-x

Item Designation

1 Gripper body

2 Base jaw

3 Wedge piston

4 Piston disc

5 Lower cover

6 Upper cover

7 Gasket

8 Countersunk-head locating screw

9 Shifting block 1

10 Shifting block 2

11 Adjustment spindle

12 Centering sleeve

13 Centering sleeve

19 Mounting bolt

20 Mounting bolt

21 Mounting bolt

22 Mounting bolt

24 Mounting bolt

25 Grub screw DIN 913

26 Grub screw DIN 913

27 Quad-Ring

28 Quad-Ring

30 Clamping bolt

31 Protective plug

32 Sensor holder

33 Round magnet

Wear part

x

x

x

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 11 of 37

Page 12

Description of the RPP Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP xxx- x /GA

2431

Schnitt C-C

C

B

B

34 33

23

22

19

27

9

2

12

C

Schnitt B-B

35

8 2928

A

6

4

7

1

10

Schnitt A-A

13

32

1130

A

XXX

25 21 20

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 12 of 37

Page 13

Description of the RPP Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP xxx- x /GA

Item Designation

1 Gripper body

2 Base jaw

3 Wedge piston

4 Piston

5 Lower cover

6 Spring housing

7 Gasket

8 Locating screw

9 Shifting block 1

10 Shifting block 2

11 Adjustment spindle

12 Centering sleeve

13 Centering sleeve

19 Mounting bolt

Mounting bolt

20

Mounting bolt

21

Mounting bolt

22

Mounting bolt

23

24 Mounting bolt

25 Grub screw DIN 913

27 Quad-Ring

28 Quad-Ring

29 O-ring

30 Clamping bolt

31 Protective plug

32 Sensor holder

33 Round magnet

34 Compression spring

Wear part

x

x

x

x

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 13 of 37

Page 14

Description of the RPP Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP xxx- x /GI

Schnitt C-C

34

33

19

27

9

2

12

24

31

C

B

B

C

Schnitt B-B

35

8 2928

6

4

7

1

10

Schnitt A-A

A

23

XXX

22

32

1130

A

13

25 21 20

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 14 of 37

Page 15

Description of the RPP Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP xxx- x /GI

Item Designation

1 Gripper body

2 Base jaw

3 Wedge piston

4 Piston

5 Lower cover

6 Spring housing

7 Gasket

8 Locating screw

9 Shifting block 1

10 Shifting block 2

11 Adjustment spindle

12 Centering sleeve

13 Centering sleeve

19 Mounting bolt

Mounting bolt

20

Mounting bolt

21

Mounting bolt

22

Mounting bolt

23

24 Mounting bolt

25 Grub screw DIN 913

27 Quad-Ring

28 Quad-Ring

29 O-ring

30 Clamping bolt

31 Protective plug

32 Sensor holder

33 Round magnet

34 Compression spring

Wear part

x

x

x

x

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 15 of 37

Page 16

Description of the RPP Parallel Grippers

2-jaw parallel grippers

Option: Dirt cover SA-RPP

XXX XXX

Abdeckung

62

70

66

68

Gew.-Stifte herausdrehen

61 63

71

Öffnung zum Einstellen

der Verstellklötze mittels der Verstellspindel

Öffnung zum Lösen und Sichern

der Verstellklötze mittels der Spannschraube

6765

Item Designation

61 Cover plate

62 Cover

63 Intermediate jaw

65 Centering sleeve

66 Mounting bolt

67 Mounting bolt

68 Mounting bolt

70 Grub screw DIN 913

71 Quad-Ring

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Wear part

x

Page 16 of 37

Page 17

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

2-jaw parallel grippers, pneumatically actuated

RPP-A

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 17 of 37

Page 18

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP-A xxx- x

5

26

45

B

Schnitt B-B

1 7

20

35

9

4

6298

B

42

10

2 3

36

40

41

44

22

21

30

31

A

XXX

Schnitt A-A

11

A

32

23

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 18 of 37

Page 19

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP-A xxx- x

Item Designation

1 Gripper body

2 Base jaw

3 Wedge piston

4 Piston disc

5 Lower cover

6 Upper cover

7 Gasket

8 Countersunk-head locating screw

9 Shifting block 1

10 Shifting block 2

11 Adjustment spindle

20 Mounting bolt

21 Mounting bolt

22 Mounting bolt

23 Mounting bolt

26 Mounting bolt

29 Clamping bolt

30 Grub screw DIN 913

31 Grub screw DIN 913

32 Grub screw DIN 913

35 Quad-Ring

36 Quad-Ring

40 Straight pin DIN 6325

41 Straight pin DIN 6325

42 Roll pin DIN 7346

44 Sensor holder

45 Protective plug

Wear part

x

x

x

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 19 of 37

Page 20

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP-A xxx- x /GA

B

Schnitt B-B

1

35

9

2

43

20

26

36

45

5

6 8

B

4

7

42

10

3

37

40

41

A

Schnitt A-A

44

22

31

23

11

XXX

29

A

32

21

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 20 of 37

Page 21

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP-A xxx- x /GA

Item Designation

1 Gripper body

2 Base jaw

3 Wedge piston

4 Piston disc GA

5 Lower cover

6 Spring housing

7 Gasket

8 Locating screw

9 Shifting block 1

10 Shifting block 2

11 Adjustment spindle

20 Mounting bolt

21 Mounting bolt

22 Mounting bolt

23 Mounting bolt

26 Mounting bolt

29 Clamping bolt

31 Grub screw DIN 913

32 Grub screw DIN 913

35 Quad-Ring

36 Quad-Ring

37 O-ring

40 Straight pin DIN 6325

41 Straight pin DIN 6325

42 Roll pin DIN 7346

43 Compression spring

44 Sensor holder

45 Protective plug

Wear part

x

x

x

x

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 21 of 37

Page 22

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP-A xxx- x /GI

B

Schnitt B-B

1

20 43

35

9

2

26

6 8

455

B

4 7

42

10

41

44

22

23

11

29

31

A

A

32 21

36

3

37

40

Schnitt A-A

XXX

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 22 of 37

Page 23

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

Description 2-jaw parallel grippers: RPP-A xxx- x /GI

Item Designation

1 Gripper body

2 Base jaw

3 Wedge piston

4 Piston disc GI

5 Lower cover

6 Spring housing

7 Gasket

8 Locating screw

9 Shifting block 1

10 Shifting block 2

11 Adjustment spindle

20 Mounting bolt

21 Mounting bolt

22 Mounting bolt

23 Mounting bolt

26 Mounting bolt

29 Clamping bolt

31 Grub screw DIN 913

32 Grub screw DIN 913

35 Quad-Ring

36 Quad-Ring

37 O-ring

40 Straight pin DIN 6325

41 Straight pin DIN 6325

42 Roll pin DIN 7346

43 Compression spring

44 Sensor holder

45 Protective plug

Wear part

x

x

x

x

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 23 of 37

Page 24

Description of the RPP-A Parallel Grippers

2-jaw parallel grippers

Option: Dirt cover SA-RPP-A

67 66

XXX

Gew.-Stifte herausdrehen

Item Designation

61 Cover plate

62 Cover

63 Intermediate jaw

64 Sealing plug size 2

65 Mounting bolt

66 Mounting bolt

67 Mounting bolt

68 Straight pin DIN 6325

69 Grub screw DIN 913

70 Quad-Ring

71 O-ring

72 Filter disc

Abdeckung

62

69

65

64

71

68

Öffnung zum Einstellen

der Verstellklötze mittels der Verstellspindel

Öffnung zum Lösen und Sichern

der Verstellklötze mittels der Spannschraube

bei Verwendung von Nährungsschaltern

Dichtbolzen POS.64 entfernen

72

61

70

63

Wear part

x

x

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 24 of 37

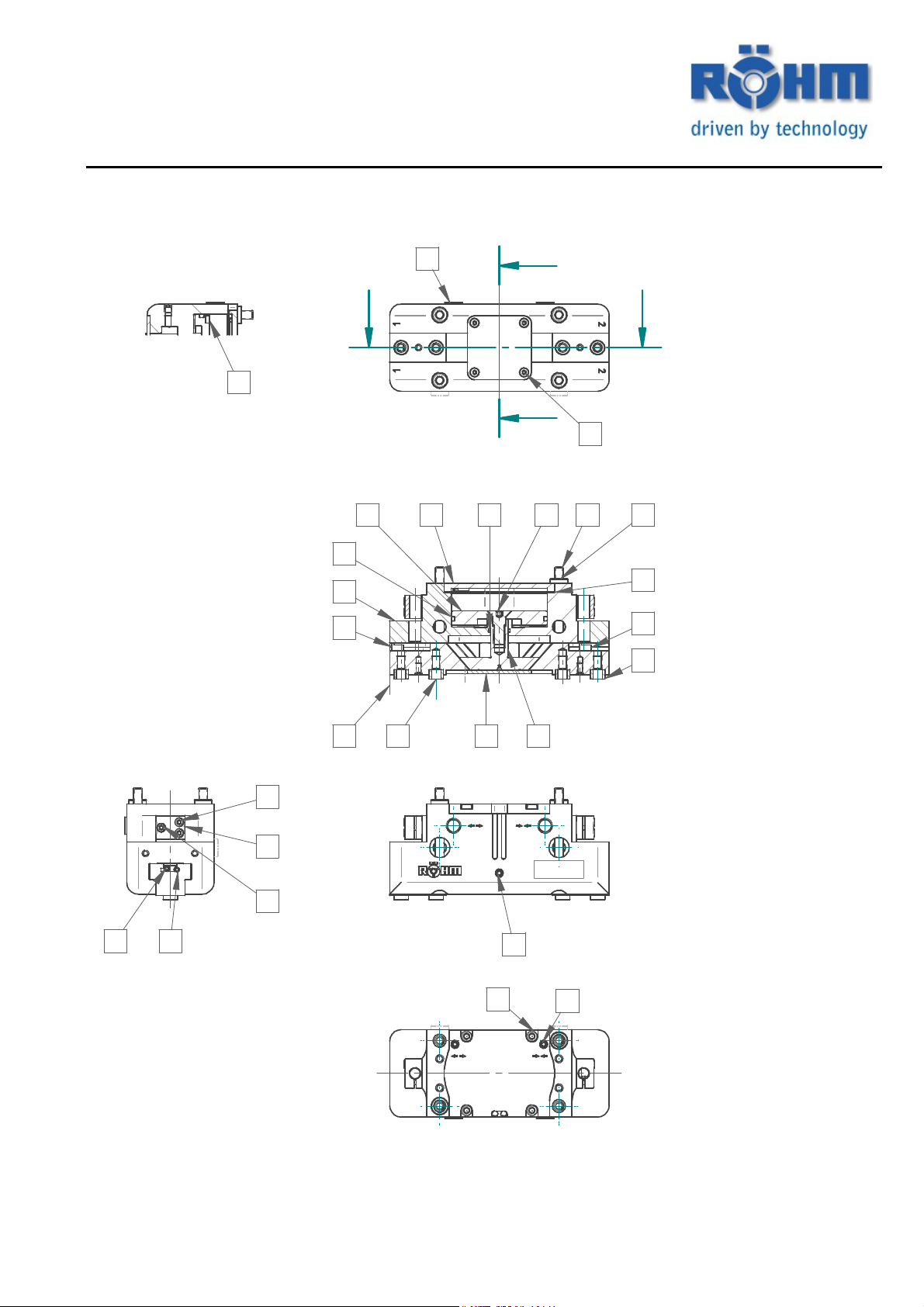

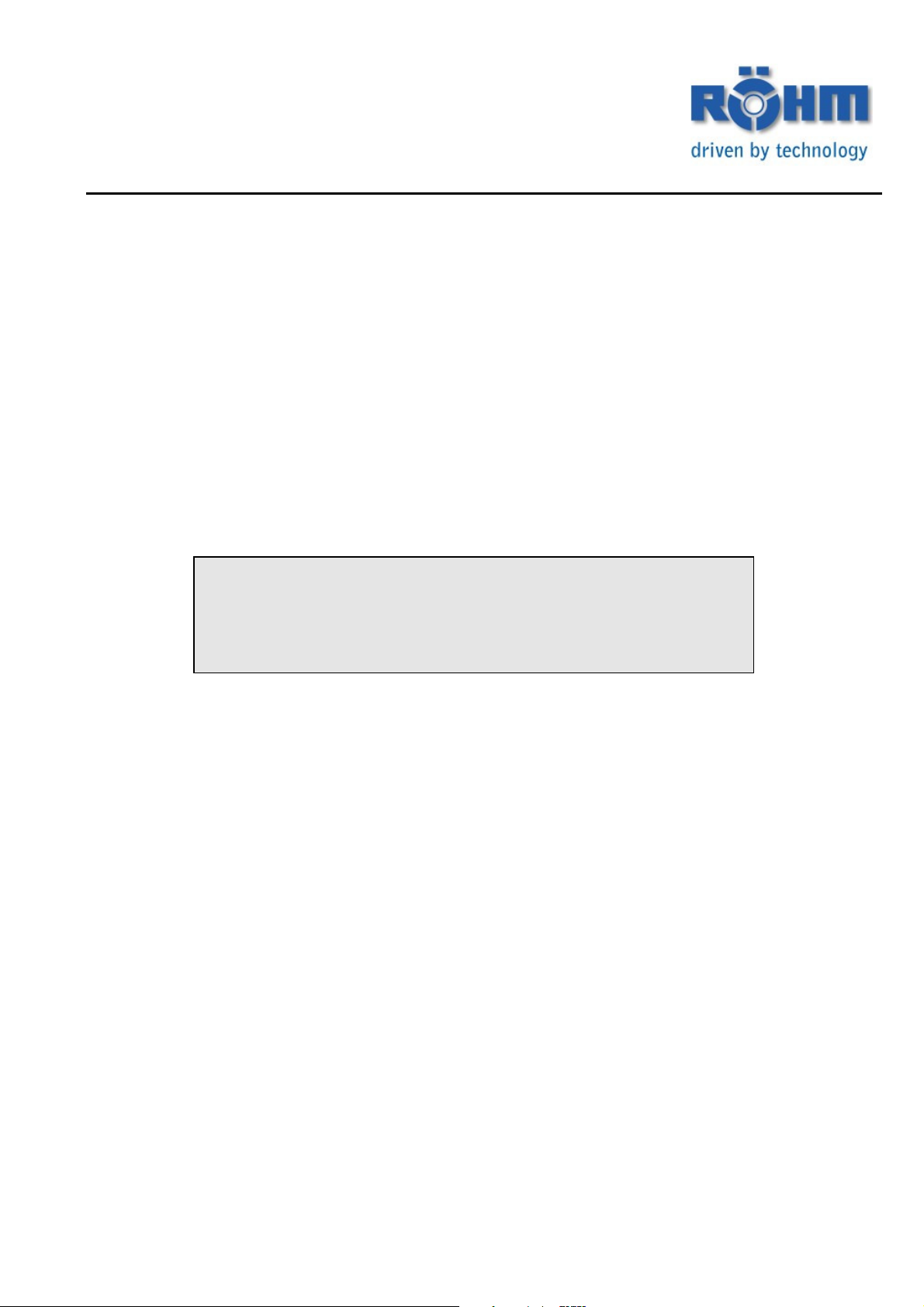

Page 25

Installation, Commissioning of Parallel Grippers

2-jaw parallel grippers

RPP

Zentrierhülse;

Gewindebohrung bzw.

Durchgangsbohrung für Anbau des

Greifers von unten.

M5; G1/8"; G1/4 - Gewinde für

Pneumatikanschluss

XXX

Anschraubflächen

Zentrierhülse;

Gewindebohrung bzw.

Durchgangsbohrung für

seitlichen Anbau des

Greifers.

Anschraubflächen

Sperrluftanschluss

Für schlauchlosen

Direktanschluss von unten

Caution:

also the safety precautions. Please refer to the catalogue for the connection dimensions of the

respective gripper size.

The energy supply must be switched off during installation of the gripper. Observe

Installation of Gripper RPP

1. Position the gripper using the centering sleeves contained in the accessories kit.

2. Bolt on the gripper from above using 4 mounting bolts supplied. If the gripper is mounted on

the side, the customer must provide mounting bolts.

Please observe the specified tightening torques.

3. With hoseless direct connection, pay attention to a clean connection surface. Use the

corresponding gaskets from the accessories kit.

4. During installation with compressed air screw fitting, pay attention to leak tightness of the

fitting.

Caution! When using hoseless direct connections, remove the grub screws and close off

the ports not used using suitable blind plugs.

5. Installation and adjustment of the polling sensors.

See "Installation of the proximity sensors and magnetic switches"

Function check

1. Actuate the gripper and test the stroke end positions of the jaws.

2. Check the sensor signal.

3. Check this function also with the workpiece.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 25 of 37

Page 26

Installation, Commissioning of Parallel Grippers

2-jaw parallel grippers

RPP-A

Zyl.-Stift, Gewindebohrung bzw.

Durchgangsbohrung für Anbau des

Greifers von unten.

M5; G1/8"; G1/4 - Gewinde für

Pneumatikanschluss

Anschraubflächen

Zentrierhülse;

Gewindebohrung bzw.

Durchgangsbohrung für

seitlichen Anbau des

Greifers.

Positionierung des Greifers

über Zyl.-Stift

Anschraubflächen

Sperrluftanschluss

Für schlauchlosen

Direktanschluss von unten

Caution:

The energy supply must be switched off during installation of the gripper. Observe also the

safety precautions. Please refer to the catalogue for the connection dimensions of the respective gripper

size.

Installation of Gripper RPP-A

1. Position the gripper using the two positioning pins contained in the accessories kit.

2. Bolt on the gripper from above using 4 mounting bolts supplied. If the gripper is mounted on

the side, the customer must provide mounting bolts.

Please observe the specified tightening torques.

3. With hoseless direct connection, pay attention to a clean connection surface. Use the

corresponding gaskets from the accessories kit.

4. During installation with compressed air screw fitting, pay attention to leak tightness of the

fitting.

Caution! When using hoseless direct connections, remove the grub screws and close off the

ports not used using suitable blind plugs.

5. Installation and adjustment of the polling sensors.

See "Mounting of the proximity switches"

Function check

1. Actuate the gripper and test the stroke end positions of the jaws.

2. Check the sensor signal.

3. Check this function also with the workpiece.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 26 of 37

Page 27

Installation, Commissioning of Parallel Grippers

2-jaw parallel grippers

RPP/ RPP-A

Backe 1 Backe 2

Klemmschraube

Ind. Nährungsschalter

Sensorhalter

Spannschraube

Verstellspindel

Nährungsschalter 1

Nährungsschalter 1

Installation of the inductive proximity switches

Poll: Gripper open

1) Push the proximity switch under jaw 2 into the sensor holder up to the stop and secure it with

the clamping screw.

2) Move the gripper to position "OPEN" and test the function. Works setting: "Signal". If no

signal appears, a fine adjustment of the shifting block can be carried out at the adjustment

spindle. The shifting block is fixed from the outside with a clamping screw. Use a screwdriver

T8 (Torx size 8) for loosening and tightening.

Axialer Sensoranschlag

Verschiebeklotz

The clamping position poll for inner gripping is adjusted to the respective workpiece using the

adjustment spindle.

Poll: Grippers closed

1) Push the proximity switch under jaw 2 into the sensor holder up to the stop and secure it with

the clamping screw.

2) Move the gripper to position "CLOSED" and test the function. Works setting: "Signal". If no

signal appears, a fine adjustment of the shifting block can be carried out at the adjustment

spindle. The shifting block is fixed from the outside with a clamping screw. Use a screwdriver

T8 (Torx size 8) for loosening and tightening.

The clamping position poll for inner gripping is adjusted to the respective workpiece using the

adjustment spindle.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 27 of 37

Page 28

Installation, Commissioning of Parallel Grippers

2-jaw parallel grippers

RPP/ RPP-A

Gew.-Stifte herausdrehen

Abdeckung

62

70

66

68

XXX

XXX

61 63

71

Öffnung zum Einstellen

der Verstellklötze mittels der Verstellspindel

Öffnung zum Lösen und Sichern

der Verstellklötze mittels der Spannschraube

6765

Adjustment of the sensor polling when using the dirt cover:

1) Remove the grub screws from the side cover

2) Loosen the (TORX ) clamping screw 1/2 turn in the bore: "RELEASE"

3) Adjustment possibility for shifting blocks 1 and 2 by turning the adjustment spindle (hex.

socket head screw) in bore: "ADJUST".

Caution:

The shifting blocks must not be adjusted beyond the outer edge of the base jaw as

otherwise they will collide. See assembly drawing

4) After adjustment, the shifting block must be secured with the (TORX) clamping screw by

turning 1/2 turn in bore: "SECURE".

5) Close off the bores in the covers with grub screws.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 28 of 37

Page 29

Installation, Commissioning of Parallel Grippers

2-jaw parallel grippers

RPP/ RPP-A

Backe 1

Magnetschalter

Id.1083570 Magnetfeld-Sensor mit

Id.1045770 Haltewinkel

Backe 2

Installation of the magnetic field sensors

Poll: Gripper open

1) Position the gripper in position "OPEN"

2) Push magnetic field sensor 1 with the mounting bracket to the front into the C-groove in

gripper body (item 1) up to the stop and then pull the sensor out again slowly until it switches.

3) Fix the magnetic switch in this position by clamping it by tightening the grub screw in the Cgroove. (max. 0.1 Nm)

Körper

1

Magnetfeldsenor 1

(Greifer geöffnet)

EINZELHEIT

Magnetfeldsenor 2

(Greifer geschlossen)

4) Test the function by opening and closing the gripper

Poll: Grippers closed

1) Position the gripper in position "CLOSED"

2) Push magnetic field sensor 2 with the mounting bracket to the front into the C-groove in

gripper body (item 1) up to the stop and then pull the sensor out again slowly until it switches.

3) Fix the magnetic switch in this position by clamping it by tightening the grub screw in the Cgroove. (max. 0.1 Nm)

4) Test the function by opening and closing the gripper

Poll: Workpiece gripped

Outer gripping

1) Clamp the part to be gripped

Proceed as described under "Gripper closed" from points 2-4.

Inner gripping

2) Clamp the part to be gripped

Proceed as described under "Gripper open" from points 2-4.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 29 of 37

Page 30

Installation, Commissioning of Parallel Grippers

2-jaw parallel grippers

RPP

XXX

XXX

Abdeckung

62

70

66

68

Gew.-Stifte herausdrehen

61 63

Öffnung zum Einstellen

der Verstellklötze mittels der Verstellspindel

Öffnung zum Lösen und Sichern

der Verstellklötze mittels der Spannschraube

71

6765

Installation of the RPP dirt cover

Caution: The energy supply must be switched off during installation of the dirt cover on the gripper.

Observe also the safety precautions. Please refer to the catalogue for the connection dimensions of the

respective gripper size.

1) Before installing the dirt cover on the RPP gripper, check that the upper edge of the

lower cover is at the same height as the gripper body. The lower cover must not protrude

beyond the edge of the gripper body (correct cover height, if necessary).

2) The connection surfaces must be clean and free from dirt.

3) Install the covers (item 62) on left and right on the end faces of the gripper and tighten

the mounting bolts slightly.

4) Now place the cover plate (item 61) into the gripper and bolt this with the hexagon head

bolts to the gripper and the side covers (item 62). Tighten all the mounting bolts.

5) Take the Quad-Ring supplied and place it into the groove of the cover plate.

6) Install the intermediate jaw on the base jaw. The intermediate jaw is centered on the

base jaw by means of the centering sleeves. Pay attention to the clearances of the wiper

surfaces on the intermediate jaw – surfaces may have different lengths. The

intermediate jaw must protrude by the same amount on both sides after positioning.

When the gripper is open, the overhang corresponds to the jaw stroke of the gripper.

Fasten the intermediate jaw to the base jaw using cylinder screw (item 67). After

installing the intermediate jaws, check the free movement of the jaws.

7) Install the centering sleeves on the intermediate jaw.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 30 of 37

Page 31

Installation, Commissioning of Parallel Grippers

2-jaw parallel grippers

RPP-A

Gew.-Stifte herausdrehen

Abdeckung

62

69

Installation of the RPP-A dirt cover

67 66

bei Verwendung von Nährungsschaltern

65

Dichtbolzen POS.64 entfernen

64

71

63

68

Öffnung zum Einstellen

der Verstellklötze mittels der Verstellspindel

Öffnung zum Lösen und Sichern

der Verstellklötze mittels der Spannschraube

61

XXX

72

70

Caution: The energy supply must be switched off during installation of the dirt cover on the gripper.

Observe also the safety precautions. Please refer to the catalogue for the connection dimensions of the

respective gripper size.

1) Before installing the dirt cover on the RPP-A gripper, the lower cover must be loosened and

removed from the gripper.

2) The connection surfaces must be clean and free from dirt.

3) Install the covers (item 62) on left and right on the end faces of the gripper and tighten the

mounting bolts slightly.

4) Now place the cover plate (item 61) into the gripper and bolt this with the hexagon head bolts to

the gripper and the side covers (item 62). Tighten all the mounting bolts.

5) Take the Quad-Ring supplied and place it into the groove of the cover plate.

6) Install the intermediate jaw on the base jaw. The intermediate jaw is positioned on the base jaw

by means of the roll pin and T-slot. Pay attention to the clearances of the wiper surfaces on the

intermediate jaw – surfaces may have different lengths. The intermediate jaw must protrude by

the same amount on both sides after positioning. When the gripper is open, the overhang

corresponds to the jaw stroke of the gripper. After installing the intermediate jaws, check the

free movement of the jaws.

7) Install the roll pins on the intermediate jaw.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 31 of 37

Page 32

Maintenance, Repair of the Parallel Grippers

2-jaw parallel grippers

Maintenance and service life

The maintenance condition of the gripper is crucial for its function, clamping force, precision and service

life.

The gripper is lubricated at the factory with a basic lubrication of special grease, ID 1096752 Klueberplex

BEM 41-132.

We recommend Klueberplex BEM 41-132 for relubrication.

Service life with normal use without preventive maintenance: 5 million cycles

Service life with normal use with preventive maintenance: 10 million cycles

Recommendation for preventive maintenance:

For normal use:

Lubrication / cleaning: Every 2 million cycles or 1x per year

For heavy-duty use:

Lubrication / cleaning: Every 1 million cycles or every 6 months with grease nipple

If no grease nipple is fitted, a grease nipple should be fitted to the purge port and the gripper lubricated here.

We recommend Klueberplex BEM 41-132 for relubrication.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 32 of 37

Page 33

Maintenance, Repair of the Parallel Grippers

2-jaw parallel grippers

Dismantling and assembly of a gripper:

Caution: Be sure to observe the safety precautions.

1) Disconnect the pressure lines

2) Loosen the bolts and remove the lower cover (item 5).

3) Unscrew the bolts and remove the upper cover (item 6).

4) Loosen the bolt (item 8) and remove the piston disc (item 4).

(Item 8 is secured with Loctite)

5) Press the wedge piston (item 3) up out of the gripper body (item 1).

6) Pull the base jaws (item 2) out of the gripper body (item 1).

7) Remove all gaskets

8) Clean all parts thoroughly and inspect the parts for wear

or defects.

9) Renew all gaskets

The gripper is reassembled in the reverse order.

Pay attention to the correct numbering and position of the components. Unless otherwise prescribed, all bolts

must be secured with Loctite 222 and tightened to a torque as specified in the DIN standard (see point II/7).

Type GA or GI with gripping force lock:

Caution! Particular dangers exist here! Be sure to pay attention to the assembly drawing!

Gripper body, spring housing, piston disc and piston may be under spring pressure. The spring load on

the piston disc (GA type) or spring housing (GI type) must be countered by appropriate means.

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 33 of 37

Page 34

Maintenance, Repair of the Parallel Grippers

2-jaw parallel grippers

Maintenance:

Extensive maintenance work only becomes necessary at fairly long intervals (approx. every 5 million

gripping cycles). As soon as the gripper starts to bind and lose its gripping force, however, it must be

removed from the machine and subjected to a general cleaning.

The gripper is thereby dismantled into its individual parts, inspected for wear, cleaned and after repairing

any damaged parts reassembled and recoated with special grease. We recommend that the sealing

elements subjected to dynamic loads, in particular, are replaced at this point. One set of the wear parts

and sealing elements marked in the parts list should therefore always be in stock for this purpose.

During assembly of the gripper, pay careful attention that marked parts are installed in their correct

positions again.

We should point out that only OEM spare parts or installation parts from authorised suppliers should be

used. No warranty claims will be accepted for any damaged caused by the use of parts from third parties.

Note: For smooth ordering of spare parts or individual parts, always

quote the 6-digit identification number engraved on the

component and – if possible – also the serial number. The serial

number consists of a letter followed by 2 numbers and possibly a

consecutive number stamped either on the rating plate or in the

immediate vicinity of the identification number.

Manufacturer's address: .

Röhm GmbH Dillingen Works

Röhmstr. 6

89407 Dillingen/Donau

GERMANY

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 34 of 37

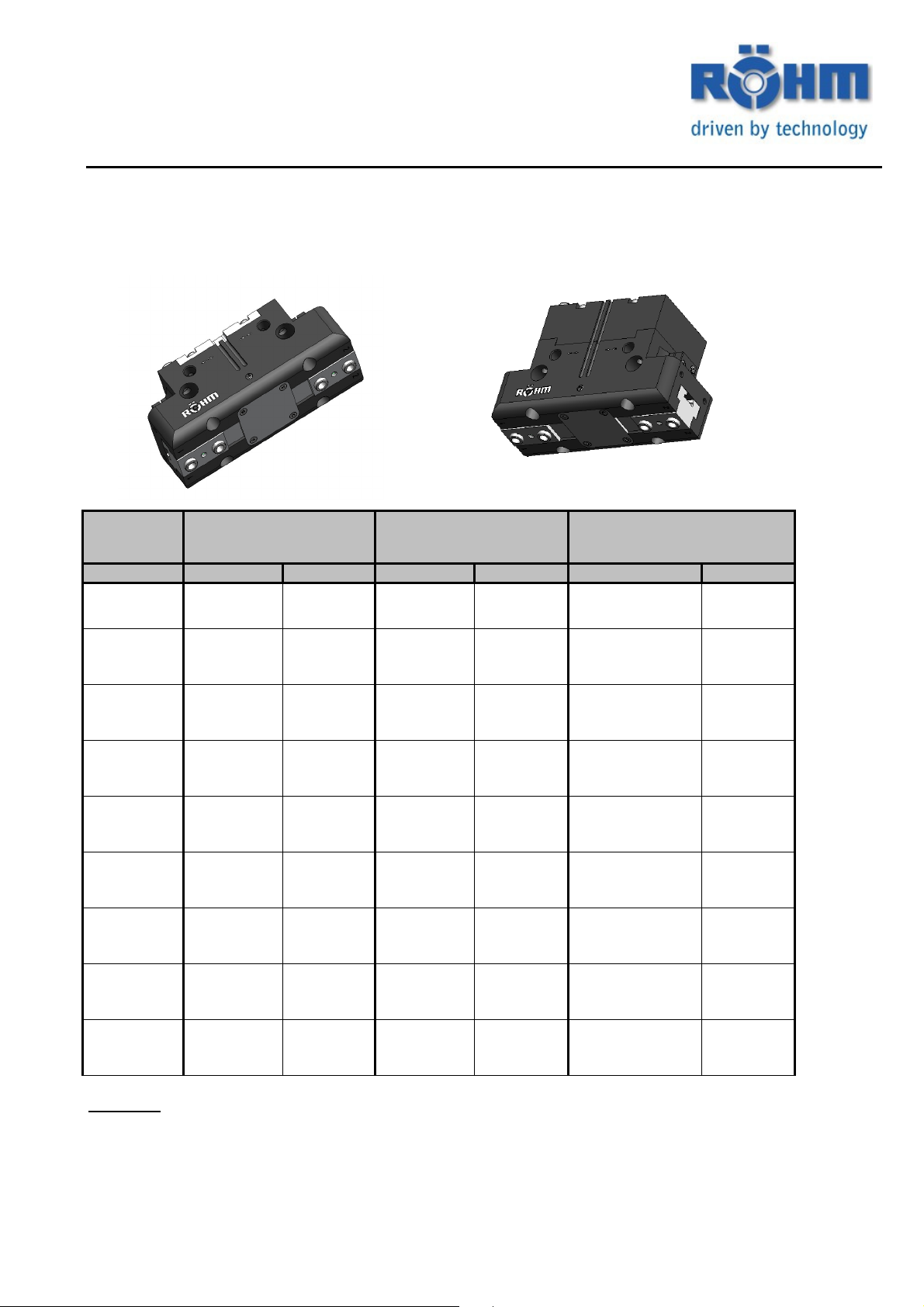

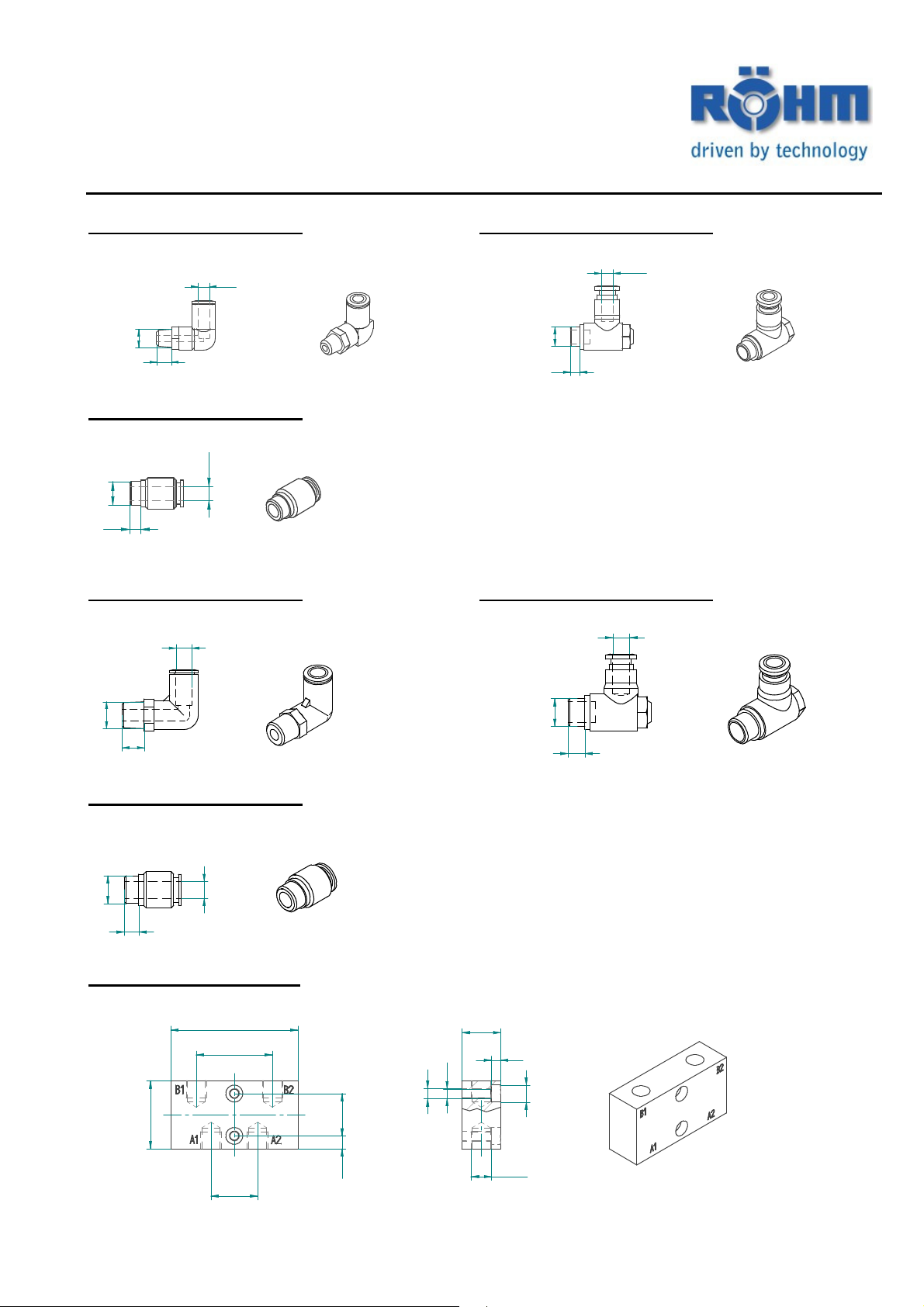

Page 35

Accessories (not included in scope of supply)

2-jaw parallel grippers

Sensors

Inductive proximity switch Inductive proximity switch

Order No. ID 229114 Order No. ID 389661

with 3 m cable (without plug) with 3 m cable (without plug)

30,5

M8 x 1

46,5 M8 x 1

Magnetic field sensor

Order No. ID 1083570

with 3 m cable (without plug)

Id.1045770 Haltewinkel

Id.1083570 Magnetfeld-Sensor

3

2,7

6,5 21,6

Kabel

4,6

3,6

Pneumatic connections

Screw connection M5

Order No. ID 1004281 Order No. ID 476077

5M

4

O

3

Screw connection M5

Order No. ID 476989

5M

3,5

4

O

Throttle check valve M5

4

O

5M

3,65

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 35 of 37

Page 36

Accessories (not included in scope of supply)

2-jaw parallel grippers

Screw connection G1/8"

Order No. ID 477025 Order No. ID 499260

6

O

G1/8"

8

Screw connection G1/8"

Order No. ID 1111010

6

O

G1/8"

4,6

Screw connection G1/4"

Order No. ID 1002453 Order No. ID 1201067

8

O

Throttle check valve G1/8”

6

O

G1/8"

4,9

Throttle check valve G1/4”

8

O

G1/4"

11

Screw connection G1/4"

Order No. ID 1028900

8

G1/4"

6,6

O

Pressure relief valve

Order No. ID 1078823

60

36

32,2

4,5

M5

O

18,2

G1/4"

8

1:1

4,4

8

O

6,1 20

22

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

G1/8 (4x)

Page 36 of 37

Page 37

2-jaw parallel grippers

ID 1104573 Operating Manual RPP; RPP-A

Röhm GmbH, Dillingen Works Röhmstr. 6, 89407 Dillingen/Donau, GERMANY, Tel. (49)9071/508-0

Page 37 of 37

Loading...

Loading...