A

l

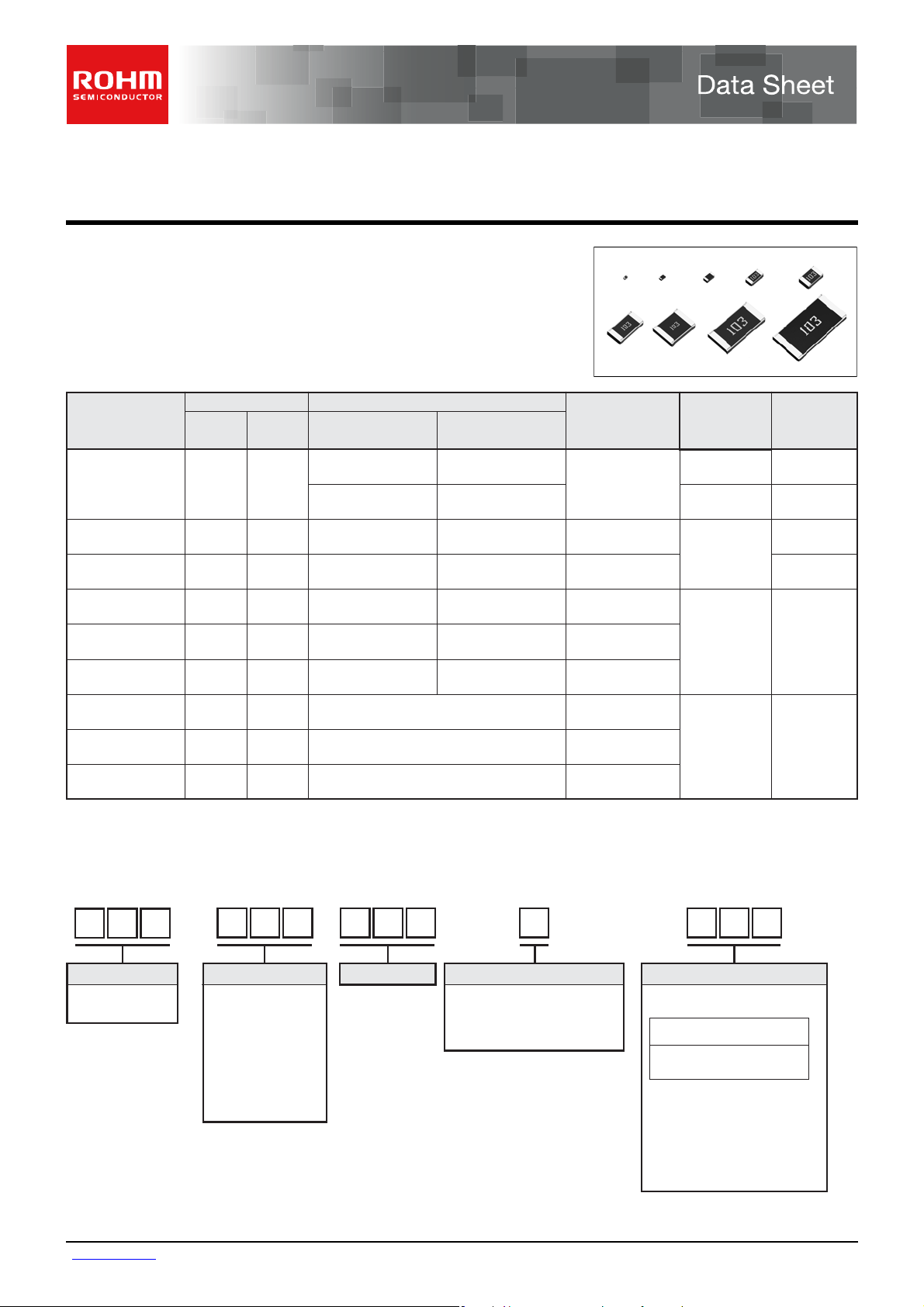

Thick Film Chip Resistors

MCR Series

Features

1) Full line up from ultra small size (01005) to 2512 with jumper type.

2) High reliability metal glazed thick film.

3) ROHM resistors have obtained ISO9001/ISO/TS16949 certification.

4) "Automotive" product is AEC-Q200 compliant.

Part No.

MCR004

(mm)

0402

Size

(inch)

01005 10Ω to 3MΩ

GENERAL PURPOSE

Type Code

AUTOMOTIVE

∗Corresponds to

AEC−Q200

YZP 15,000

RZP

Resistance Range

−

−

Packing

Specification

Paper tape

(2mm pitch)

Embossed tape

(1mm pitch)

Quantity / Ree

40,000

MCR006

MCR01

MCR03

MCR10

MCR18

MCR25

MCR50

MCR100

0603

1005

1608

2012

3216

3225

5025

6432

0201

0402

0603

0805

1206

1210 JZH

2010

2512

YRT

MRT

ERT

ERT

ERT

JZH

JZH

YZP

MZP

EZP

EZP

EZP

∗Please contact us for status of AEC-Q200 on "General purpose" products.

Part Number Description

06

CMR

Part No.

MCR

(Micro chip resistors)

Size

004 (0402 [01005])

006 (0603 [0201])

01 (1005 [0402])

03 (1608 [0603])

10 (2012 [0805])

18 (3216 [1206])

25 (3225 [1210])

50 (5025 [2010])

100 (6432 [2512])

0 YTR

(mm [inch])

Type Code

Resistance Tolerance Nominal Resistance

D ( ±0.5% )

F ( ±1% )

FX ( ±1% )

J ( ±5% )

∗Only MCR03EZP

(Including jumper type)

1Ω to 10MΩ

1Ω to 10MΩ

1Ω to 10MΩ

1Ω to 10MΩ

1Ω to 10MΩ

1Ω to 3.3MΩ

1Ω to 560kΩ

1Ω to 100kΩ

Paper tape

(2mm pitch)

Paper tape

(4mm pitch)

Embossed tape

(4mm pitch)

J01 0

Resistance code, 3 or 4 digits.

000 denotes jumper type.

Resistance

tolerance

D,FJ::4 digits

Ex.)

1Ω = 1R0 ( ±5% )

9.1 Ω = 9R1 ( ±5%

10 Ω = 10R0 ( ±0.5%,±1% )

100 ( ±5% )

2.2M Ω = 2204 ( ±1% )

225 ( ±5% )

Resistance

code

3 digits

15,000

10,000

5,000

4,000

)

www.rohm.com

1/11

c

○

2012 ROHM Co., Ltd. All rights reserved.

2012.03 - Rev.

A

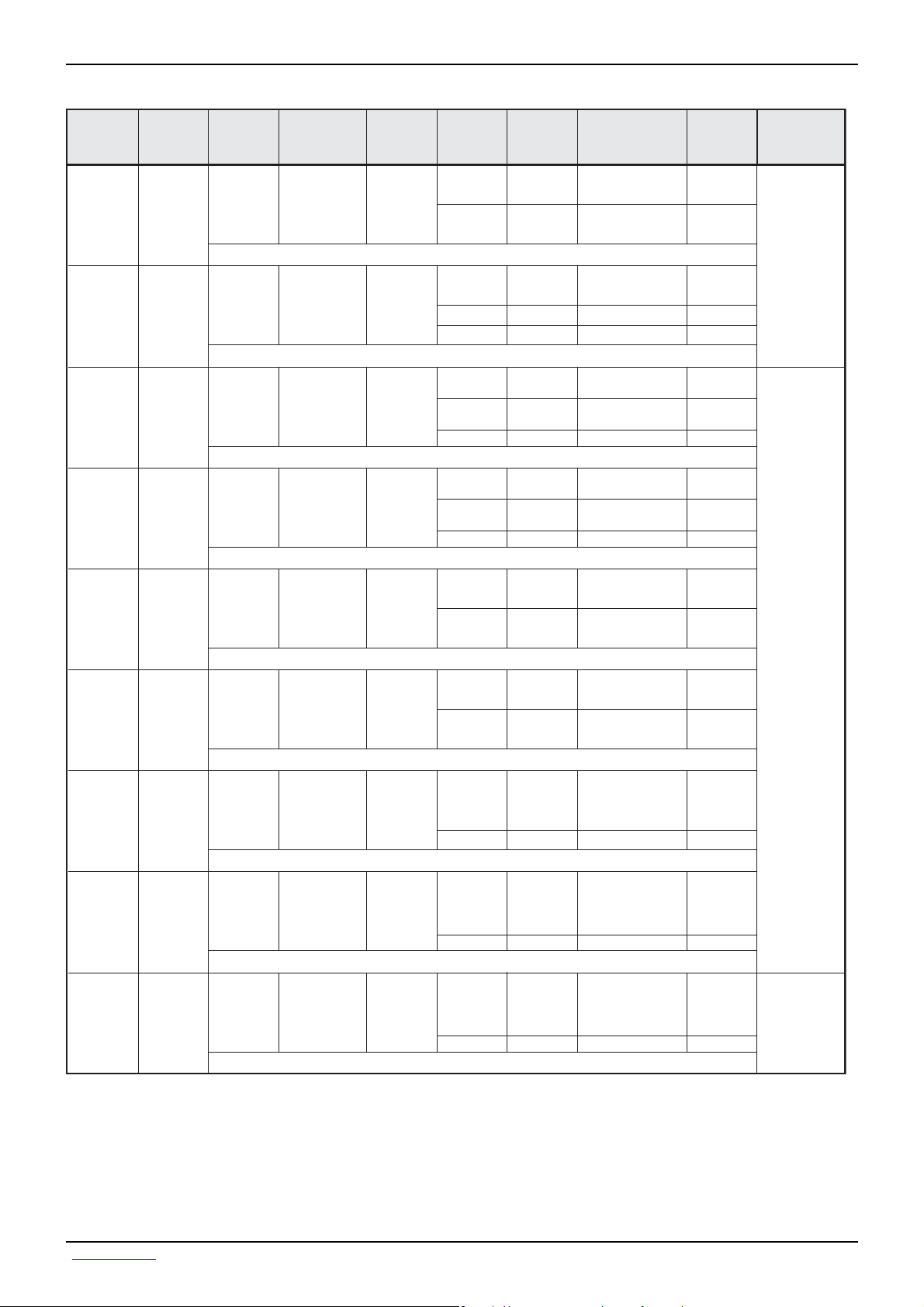

Data Sheet MCR series < General Purpose >

Products List

MCR004

Type Code

YZP,

RZP

Rated Power

(70

Limiting Element

°C)

(W)

0.031 15

Voltage

(V)

Maximum

Overload

Voltage

(V)

−

Temperature

Coefficient

(ppm / °C)

±300

±250

±300

±250

Resistance

Tolerance

(%)

J(±5%)

F(±1%)

Resistance Range SeriesPart No.

10Ω to 91Ω

100Ω to 3MΩ

10Ω to 91Ω

100Ω to 3MΩ

E24

E24

E24

E24

Jumper type : Rmax = 50m Ω / Imax. = 0.5A

MCR006 YRT

0.05

25

−

±600 / −200

±250

±250

±200

J(±5%)

F(±1%)

D(±0.5%)

1.0Ω to 9.1Ω

10Ω to 10MΩ

10Ω to 10MΩ

10Ω to 1MΩ

E24

E24

E24

E24

Jumper type : Rmax = 50m Ω / Imax. = 0.5A

MCR01

MRT

0.063

50

−

+500 / −250

±200

±100

±200

±100

J(±5%)

F(±1%)

D(±0.5%)

1.0Ω to 9.1Ω

10Ω to 10MΩ

10Ω to 976kΩ

1MΩ to 2.2MΩ

10Ω to 1MΩ

E24

E24

E24,E96

E24,E96

E24

Jumper type : Rmax = 50m Ω / Imax. = 1A

E24

E24

E24,E96

E24,E96

E24,E96

MCR03

ERT

0.1

50

100

±400

±200

±100

±200

±100

J(±5%)

F(±1%)

D(±0.5%)

1.0Ω to 9.1Ω

10Ω to 10MΩ

10Ω to 976kΩ

1MΩ to 10MΩ

10Ω to 1MΩ

Jumper type : Rmax = 50m Ω / Imax. = 1A

E24

E24

E24,E96

E24,E96

MCR10

ERT

0.125

150

200

±400

±200

±100

±200

J(±5%)

F(±1%)

1.0Ω to 9.1Ω

10Ω to 10MΩ

10Ω to 976kΩ

1MΩ to 2.2MΩ

Jumper type : Rmax = 50m Ω / Imax. = 2A

E24

E24

E24,E96

E24,E96

MCR18

ERT

0.25

200

400

±400

±200

±100

±200

J(±5%)

F(±1%)

1.0Ω to 9.1Ω

10Ω to 10MΩ

10Ω to 976kΩ

1MΩ to 2.2MΩ

Jumper type : Rmax = 50m Ω / Imax. = 2A

E24

E24

E24

E24,E96

MCR25

JZH

0.25

200

400

500±350

±500

±200

±100

J(±5%)

F(±1%)

1.0Ω to 2.0Ω

2.2Ω to 5.1Ω

5.6Ω to 3.3MΩ

10Ω to 1MΩ

Jumper type : Rmax = 50m Ω / Imax. = 2A

MCR50

JZH

0.5

200

400

500±350

±500

±200

±350

±100

J(±5%)

F(±1%)

1.0Ω to 2.0Ω

2.2Ω to 9.1Ω

10Ω to 330kΩ

360kΩ to 560kΩ

10Ω to 180kΩ

E24

E24

E24

E24

E24,E96

Jumper type : Rmax = 50m Ω / Imax. = 3A

MCR100

JZH

500±350

±500

1

200 400

±350

±200

±100

J(±5%)

F(±1%)

1.0Ω to 2.0Ω

2.2Ω to 9.1Ω

10Ω to 22Ω

24Ω to 100kΩ

10Ω to 82kΩ

E24

E24

E24

E24

E24,E96

Jumper type : Rmax = 50m Ω / Imax. = 4A

∗Design and specifications are subject to change without notice. Carefully check the specification sheet supplied with the product

before using or ordering it.

Operating

Temperature

Range

(°C)

−55 to +125

−55 to +155

−55 to +125

www.rohm.com

2/11

c

○

2012 ROHM Co., Ltd. All rights reserved.

2012.03 - Rev.

A

M

e

S

S

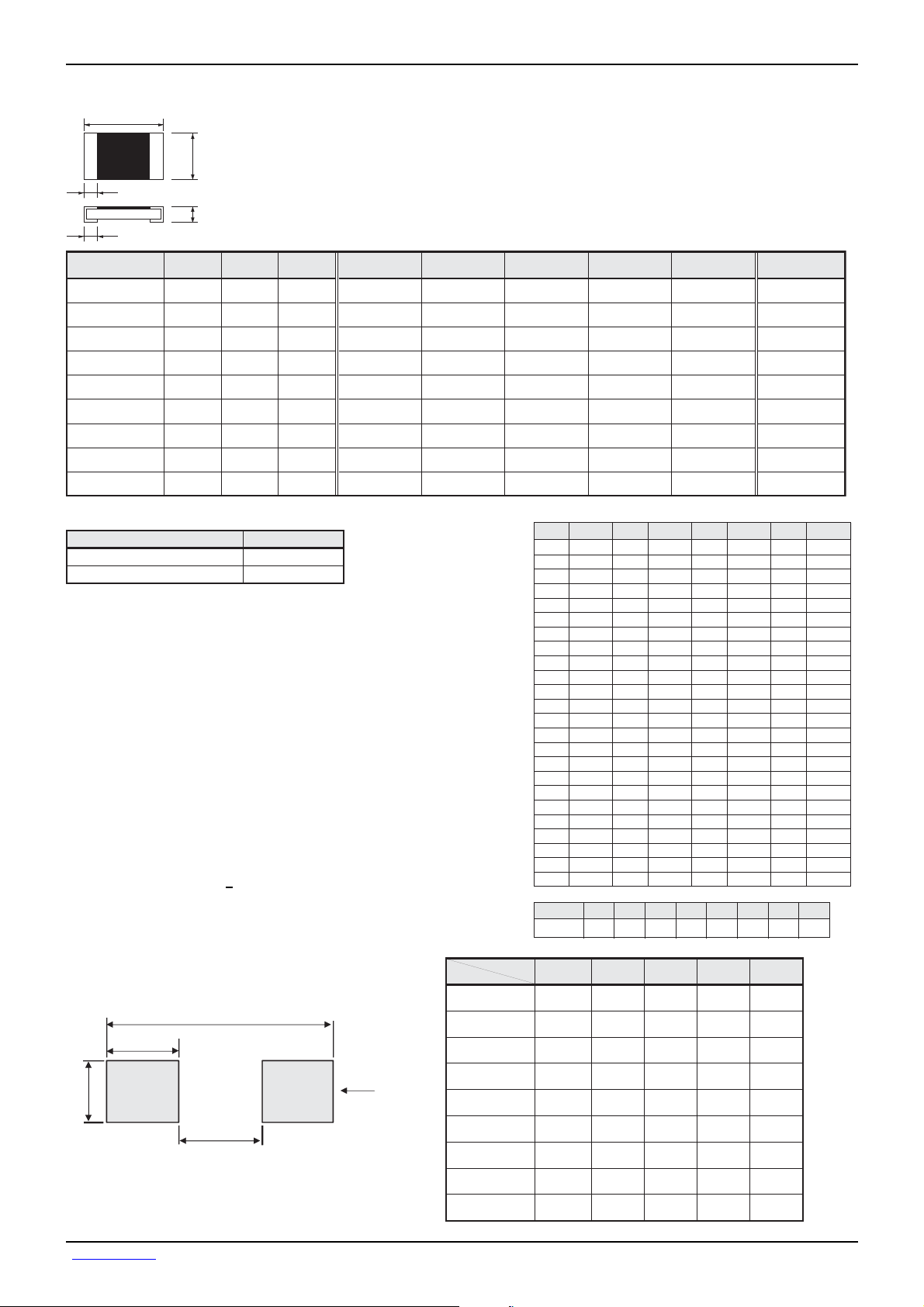

(Unit : mm)

Chip Resistor Dimensions and Markings

<Marking method>

There are three or four digits used for the calculation number

according to IEC code and “R”is used for the decimal point.

a

b

Jumper type

MCR004 / 006 / 01 / 25 / 50 / 100

MCR03 / 10 / 18

Marking method of MCR03

The description of markings on the chip resistor are as shown below.

①

The nominal resistance is expressed in by E-24series 3 digits.

The first 2 digits apply to the resistance value and the last one indicates

the number of zeros to follow. The R is used as a decimal point.

Example:100k= 104

②

・

For the resistance value contained in E96 series.

The nominal resistance is expressed in 3 digits. The first 2 digits is

symbol to the resistance value and the last one is symbol to multipliers.

Example : 100k= 01d (01d100×10

Example : 3.01k= 47b

・

For the resistance value not contained in E96 series and contained

in E-24 series.

The marking is expressed by E-24 series in 3 digits and one short bar

under the last marking letter.

Example : 390= 391

C

L

103

W

t

Part No. Type Code (mm) (inch) L W t a b

MCR004

MCR006

MCR01

MCR03

MCR10

MCR18

MCR25

MCR50

MCR100

YZP,RZP 0402 01005

YRT 0603 0201

MRT 1005 0402

ERT 1608 0603

ERT 2012 0805

ERT 3216 1206

JZH 3225 1210

JZH 5025 2010

JZH 6432 2512

arking method of jumper type

Marking method (J class):

Marking method (F/D class):

Land pattern Example

B

D

A

Marking existenc

No

Yes

(47b301×101 = 3010= 3.01k)

0.4±0.02 0.2±0.02 0.13±0.02 0.1±0.03 0.1±0.03

0.6±0.03 0.3±0.03 0.23±0.03 0.15±0.05 0.15±0.05

1.0±0.05 0.5±0.05 0.35±0.05 0.2±0.1

1.6±0.1 0.8±0.1 0.45±0.1 0.3±0.2 0.3±0.2

2.0±0.1 1.25±0.1 0.5±0.1 0.35±0.2 0.35±0.2

3.05±0.15 1.55±0.15 0.55±0.1 0.45±0.25 0.35±0.25

3.2±0.15 2.5±0.15 0.55±0.15 0.5±0.25 0.5±0.25

5.0±0.15 2.5±0.15 0.55±0.15 0.6±0.25 0.6±0.25

6.3±0.15 3.2±0.15 0.55±0.15 0.6±0.25 0.6±0.25

3

= 100,000= 100k)

Part No.

MCR004

MCR006

MCR01

MCR03

Dimensions

ymbol for E96 Series nominal resistance value

Symbol E96 Symbol E96 Symbol E96 Symbol E96

25

100

01

102

02

105

03

107

04

110

05

113

06

115

07

118

08

121

09

124

10

127

11

130

12

133

13

137

14

140

15

143

16

147

17

150

18

154

19

158

20

162

21

165

22

169

23

174

24

ymbol for multipliers

Symbol A b C d E F X Y

multipliers 10

010110210310410510−110−2

Type Code A

YZP,RZP 0.2

YRT

MRT

ERT

0.3

0.5

0.5

178

26

182

27

187

28

191

29

196

30

200

31

205

32

210

33

215

34

221

35

226

36

232

37

237

38

243

39

249

40

255

41

261

42

267

43

274

44

280

45

287

46

294

47

301

48

309

B

0.4

0.84

1.3

1.3

Land

MCR10

MCR18

MCR25

MCR50

MCR100

ERT

ERT

JZH

JZH

JZH

1.2

2.2

2.2

3.8

5.1

2.6

4.0

4.0

6.0

8.1

(Unit : mm)

+0.05

0.25

−0.1

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

0.16

1.15

0.3

0.5

0.5

1.5

2.3

2.3

3.0

Data Sheet MCR series < General Purpose >

Marking

existence

No

No

No

Yes ∗

Yes

Yes

Yes

Yes

Yes

73

316

74

324

75

332

76

340

77

348

78

357

79

365

80

374

81

383

82

392

83

402

84

412

85

422

86

432

87

442

88

453

89

464

90

475

91

487

92

499

93

511

94

523

95

536

96

549

C

D

0.1

0.27

0.4

0.4

0.7

0.9

0.9

1.1

1.5

562

576

590

604

619

634

649

665

681

698

715

732

750

768

787

806

825

845

866

887

909

931

953

976

www.rohm.com

3/11

c

○

2012 ROHM Co., Ltd. All rights reserved.

2012.03 - Rev.

A

8

8

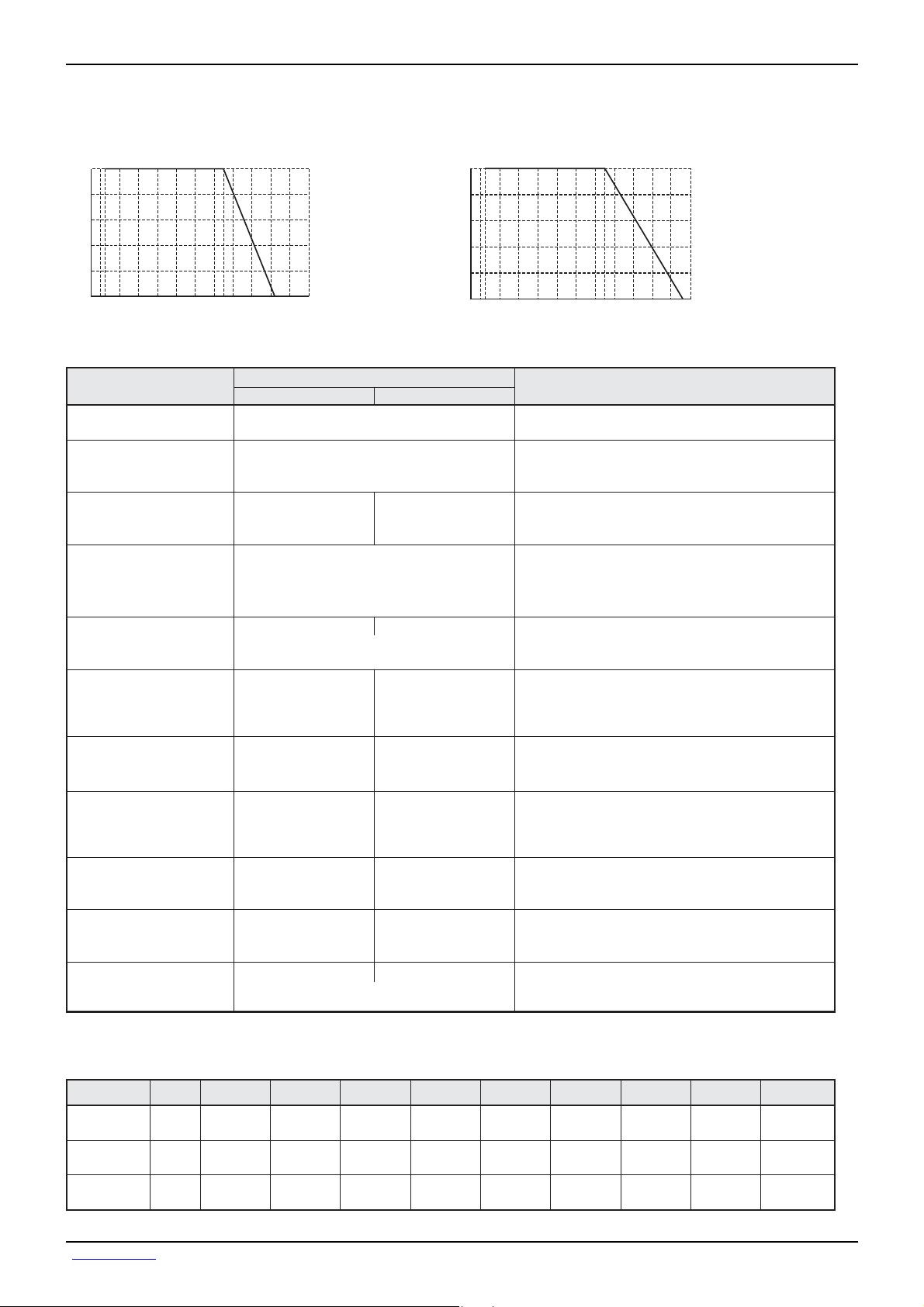

Derating Curve

When the ambient temperature exceeds 70°C, power dissipation must be adjusted according to the derating curves below.

MCR004 / 006 / 100

100

80

60

40

20

PERCENT RATED POWER (%)

0

−55 0 70 100 125

AMBIENT TEMPERATURE (°C)

Characteristics

Test Items Test Conditions

Guaranteed Value

Resistor Type

MCR01 / 03 / 10 / 18 / 25 / 50

100

80

60

40

20

PERCENT RATED POWER (%)

0

Jumper Type

−55 0 70 100 155

AMBIENT TEMPERATURE (°C)

Data Sheet MCR series < General Purpose >

Resistance

Variation of resistance

with temperature

Overload

Solderability

Resistance to

soldering heat

Rapid change of

temperature

Damp heat, steady state

Endurance at 70°C

Endurance

See P.1

See P.1

± (2.0%+0.1Ω) Max. 50mΩ

A new uniform coating of minimum of

95% of the surface being immersed

and no soldering damage.

± (1.0%+0.05Ω)

Max. 50mΩ

No remarkable abnormality on the appearance.

± (1.0%+0.05Ω)

± (3.0%+0.1Ω)

± (3.0%+0.1Ω)

± (3.0%+0.1Ω)

Max. 50mΩ

Max. 100mΩ

Max. 100mΩ

Max. 100mΩ

°C

20

Measurement : +20 / −55 / +20 / +125°C

Rated voltage (current) ×2.5, 2s.

Limiting element voltage ×2 : (See P.1)

Rosin·Ethanol (25%WT)

Soldering condition : 235±5

°C

Duration of immersion : 2.0±0.5s

Soldering condition : 260±5

°C

Duration of immersion : 10±1s

Test temp.

−55

°C

to +125°C 100cyc (MCR004 / 006)

°C

to +125°C 300cyc (MCR01)

−55

°C

to +125°C 5cyc (MCR03 / 10 / 18 / 25 / 50 / 100)

−55

40°C, 93%RH

Test time : 1,000h to 1,048h

70°C

Rated voltage (current)

1.5h : ON − 0.5h : OFF

Test time : 1,000h to 1,048h

125°C (MCR004 / 006 / 25 / 50 / 100)

155°C (MCR01 / 03 / 10 / 18)

Test time : 1,000h to 1,048h

23±5

°C

Resistance to solvent

Bend strength of

the end face plating

± (1.0%+0.05Ω)

± (1.0%+0.05Ω)

Max. 50mΩ

Max. 50mΩ

Without mechanical damage such as breaks.

, Immersion cleaning, 5±0.5min

Solvent : 2−propanol

−

Compliance Standard(s) : IEC60115−

JISC 5201−

Technical data

Parameter Unit

Insulation

resistance

Failure rate

Weight

mg/pc

MCR004

YZP / RZP

MΩ−

Fit

0.0038

0.04

MCR006

YRT

1000 1000 1000 1000

0.0185

0.150

MCR01

MRT

0.0185

0.565

MCR03

ERT

0.0185

2.03

MCR10

ERT

0.0185

4.73

MCR18

ERT

1000

0.0185

8.56

MCR25

JZH

1000

0.0203

16.5

MCR50

JZH

1000

0.0201

25.8

MCR100

JZH

1000

0.0586

42.0

www.rohm.com

4/11

c

○

2012 ROHM Co., Ltd. All rights reserved.

2012.03 - Rev.

Loading...

Loading...