Page 1

KD2002-DF10A

Printheads

Compact medium speed thick film

thermal printhead (8 dots / mm)

KD2002-DF10A

Using its expertise in LSI technolo gy , R OHM has developed new high density driver ch ips for use in the KD2002-DF10A .

Capable of being employed for bot h thermal and therm al transfer pr inting, with a print speed of 25 0mm/s, the resulti ng

print heads are the fastest in their c lass. This high-speed and high-density printing answers the needs of POS, ATM,

KIOSK and ticket printing devices, which are increasingly being called upon to produce graphical output.

zApplications

POS printers

ATM printers

KIOSK printers

Ticket printers

zFeatures

1) The use of a special partial glaze and the latest heating elemen t structure, along w ith new high-de nsity driver chip s that

can accept big current, has allowed ROHM to achieve print speeds of 250mm/s with using thermal history control, the

fastest in its class.

2) Standard printheads in the line up are capable of 203 or 300 dpi. They achieve the high resolution needed for graphics

and other complex print patterns.

3) One rank resistance value of 650Ω ± 3% eliminates the inconvenience of rank selection.

4) The required driving voltage of 3.15 to 5.25V allows wide range of power supply voltage setting. This also allows

multiple choice of electronic co mponents fo r printers.

5) 2-inch, 3-inch and 4-inch series are available.

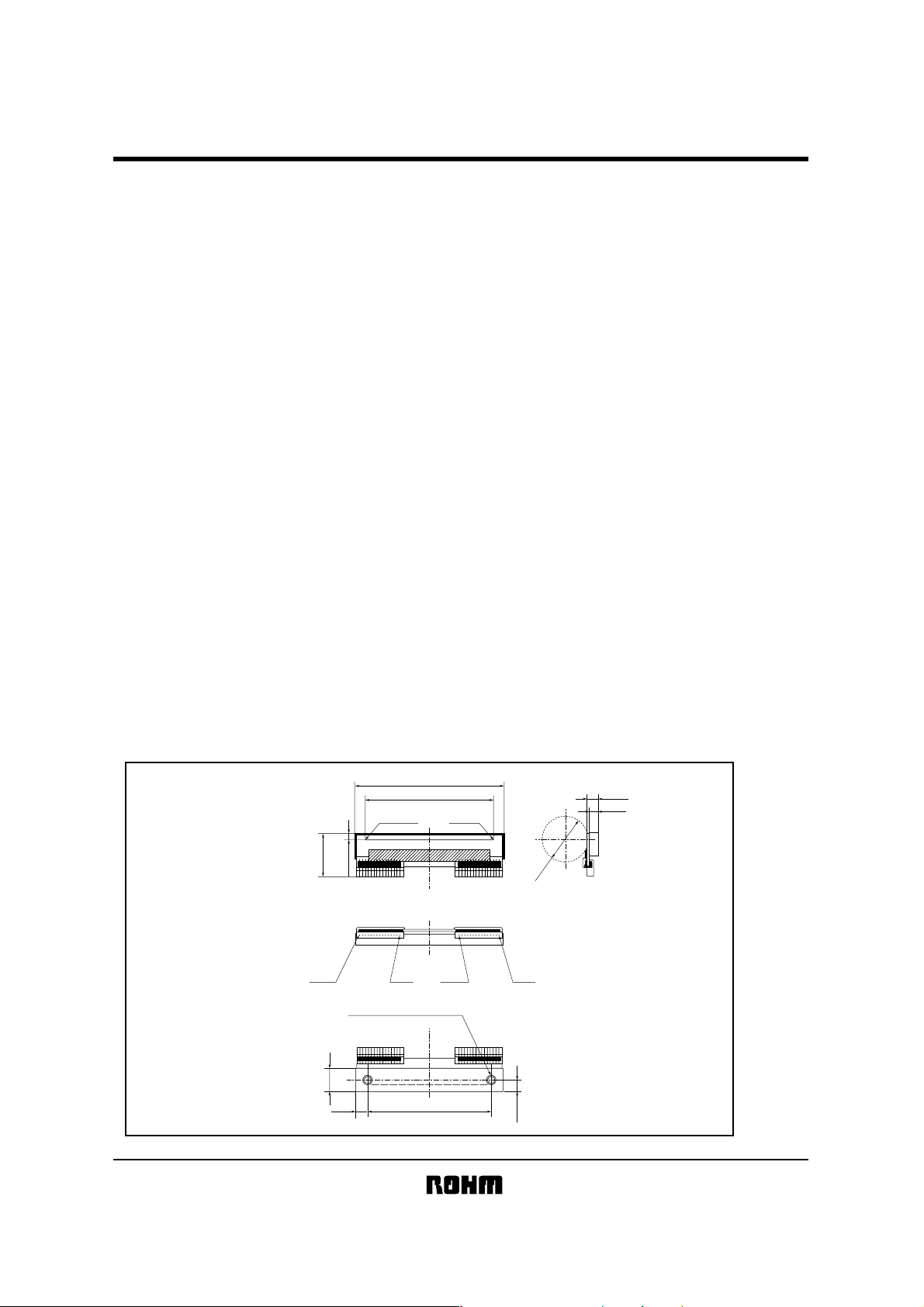

zDimensions (Unit : mm)

DOT #448

65

DOT #1

55±0.2

56 (EFFECTIVE PRINT WIDTH)

Max.20

2.6±0.1

NO.15 NO.1 NO.1NO.15

CONNECTOR B CONNECTOR A

2−M3 (EFFECTIVE DEPTH 3)

(10.2)

5±0.2

φ20.0

5.1±0.1

5.1±0.4

4±0.2

Rev.A 1/4

Page 2

KD2002-DF10A

r

Printheads

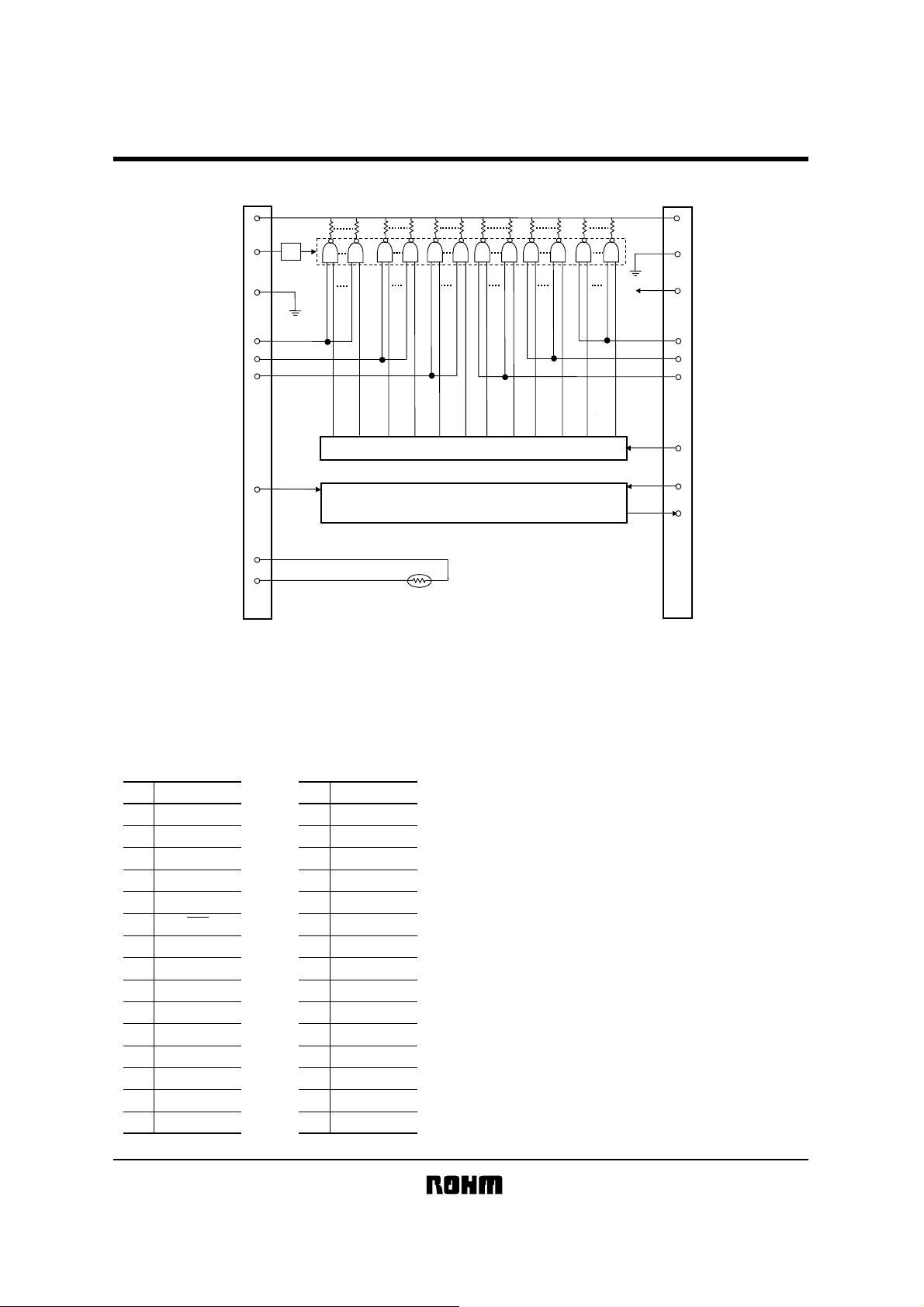

zEquivalent circuit

Dot#448

V

H

V

SF

L/S

448 385

384 321 320 257 192 129

256 193

GND

STB6

STB5

STB4

Latc h Reg ist er

DI

Shift Register

TM

TM

VH: Print Voltage

Connector B

VSF: Driver Output Voltage

STB: Strobe (High active)

/LAT: Latch

CLK: Clock

DI: Data in

DO: Data out

GND: Ground

TM: Thermisto

Thermisto r

30KΩ B: 3950K

VSF : Usually VSF and VH are connected.

When measuring R value of Heat-

element, V

separated (Page4, 7.(4)).

and VH should be

SF

zPin assignments

CONNECTOR A CONNECTOR B

No.

Circuit

1VH

2

3

4

5

6

7

8

9

10

11

12

13

14

15

VH

VH

VH

DO

LAT

CLK

V

DD

STB1

STB2

STB3

GND

GND

GND

GND

No.

10

11

12

13

14

15

Circuit

1 GND

2

3

4

5

6

7

8

9

GND

GND

GND

GND

TM

TM

STB4

STB5

STB6

DI

VSF

VH

VH

VH

Rev.A 2/4

Dot#1

1

128

Connector A

V

GND

V

DD

STB1

STB2

STB3

/LAT

CLK

DO

H

Page 3

Printheads

zTiming chart

CLK(Clock)

tsetup DI thold DI

DI(Data in)

"High" :Black

"Low" :White

DO(Data out)

"High" :Black

"Low" :White

/LAT(Latch)

"High" : Hold

"Low":Through

STB(Strobe)

DRIVER OUT

*If delay time for Driver Out can not be secured enough, there is a poss ibility that VH would fluctuate

greatly. Please design the circuit so that V

zCharacteristics

Parameter

Effective printing width

Dot pitch

Total dot number

Average resistance value

Applied voltage

Applied power

Print cycle

Pulse width

Maximum number of dots energized simultaneously

Maximum clock frequency

Maximum roller diameter

Running life / pulse life

Operating temperature

tw CLK

td DO

tsetup LAT

thold LAT

tw LAT tsetup STB

tdo tdo

does not exceed peak voltage (Vp).

H

Symbol Typical Unit

−

−

−

Rave

H

V

P

O

SLT

ON

T

−

−

−

−

−

56.0

0.125

448

650

24

0.79

0.5

0.19

448

16

φ20.0

50/5×10

5 to 45

7

mm

mm

dots

Ω

V

W/dot

ms

ms

dots

MHz

mm

km/pulses

°C

KD2002-DF10A

min.10µsec*

Rev.A 3/4

Page 4

Printheads

zElectrical characteristic curves

0.8

0.7

0.6

0.5

mJ/dot)

0.4

0.3

ENERGY (

0.2

0.1

0

012345

SCANNING LINE TIME (

Fig.3 Adaptive speed chart

180

160

140

120

100

80

60

RESISTANCE : (kΩ)

40

20

0

−20 −10 10 30 50 700204060

Fig.6 Thermistor curve

Paper : KF50-HDA (OJI)

ms/line)

TEMPERATURE : (°C)

1.8

1.6

1.4

1.2

1.0

0.8

0.6

OPTICAL DENSITY

0.4

0.2

0.0

0.00 0.05 0.10 0.15 0.20 0.25 0.30

ENERGY (

SLT : 1.25ms/line

mJ/dot)

Fig.4 Representative density curve

KD2002-DF10A

0.8

0.7

0.6

0.5

mJ/dot)

0.4

0.3

ENERGY (

0.2

0.1

0

012345

SCANNING LINE TIME (

Fig.5 Maximum energy curve

ms/line)

Rev.A 4/4

Page 5

Appendix

Notes

No technical content pages of this document may be reproduced in any form or transmitted by any

means without prior permission of ROHM CO.,LTD.

The contents described herein are subject to change without notice. The specifications for the

product described in this document are for reference only. Upon actual use, therefore, please request

that specifications to be separately delivered.

Application circuit diagrams and circuit constants contained herein are shown as examples of standard

use and operation. Please pay careful attention to the peripheral conditions when designing circuits

and deciding upon circuit constants in the set.

Any data, including, but not limited to application circuit diagrams information, described herein

are intended only as illustrations of such devices and not as the specifications for such devices. ROHM

CO.,LTD. disclaims any warranty that any use of such devices shall be free from infringement of any

third party's intellectual property rights or other proprietary rights, and further, assumes no liability of

whatsoever nature in the event of any such infringement, or arising from or connected with or related

to the use of such devices.

Upon the sale of any such devices, other than for buyer's right to use such devices itself, resell or

otherwise dispose of the same, no express or implied right or license to practice or commercially

exploit any intellectual property rights or other proprietary rights owned or controlled by

ROHM CO., LTD. is granted to any such buyer.

Products listed in this document are no antiradiation design.

The products listed in this document are designed to be used with ordinary electronic equipment or devices

(such as audio visual equipment, office-automation equipment, communications devices, electrical

appliances and electronic toys).

Should you intend to use these products with equipment or devices which require an extremely high level

of reliability and the malfunction of which would directly endanger human life (such as medical

instruments, transportation equipment, aerospace machinery, nuclear-reactor controllers, fuel controllers

and other safety devices), please be sure to consult with our sales representative in advance.

It is our top priority to supply products with the utmost quality and reliability. However, there is always a chance

of failure due to unexpected factors. Therefore, please take into account the derating characteristics and allow

for sufficient safety features, such as extra margin, anti-flammability, and fail-safe measures when designing in

order to prevent possible accidents that may result in bodily harm or fire caused by component failure. ROHM

cannot be held responsible for any damages arising from the use of the products under conditions out of the

range of the specifications or due to non-compliance with the NOTES specified in this catalog.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact your nearest sales office.

ROHM Customer Support System

www.rohm.com

THE AMERICAS / EUPOPE / ASIA / JAPAN

Contact us : webmaster@ rohm.co. jp

Copyright © 2007 ROHM CO.,LTD.

21, Saiin Mizosaki-cho, Ukyo-ku, Kyoto 615-8585, Japan

TEL : +81-75-311-2121

FAX : +81-75-315-0172

Appendix1-Rev2.0

Loading...

Loading...