Page 1

t

(

)

(

)

r

r

p

g

g

p

(

A

)

V

Multifunction LCD Segment Driver

BU97930MUV MAX 108 segments (SEG27×COM4)

●Features

Integrated RAM for display data (DDRAM):

27 x 4 bit (Max 108 Segment)

LCD drive output:

4 Common output, Max 27 Segment output

Integrated 1ch LED driver circuit

Segment /GPO(Max 4port) output mode selectable

Support PWM generation from ext. or internal clock

(Resolution: 8bit)

Support standby mode

Integrated Power-on-Reset circuit (POR)

Integrated Oscillator circuit

No external component

Low power consumption design

Independent power supply for LCD driving

Support Blink function

(Blink frequency 1.6, 2.0, 2.6, 4.0Hz selectable)

●Applications

Telephone

FAX

Portable equipment (POS, ECR, PDA etc.)

DSC

DVC

Car audio

Home electrical appliance

Meter equipment

etc.

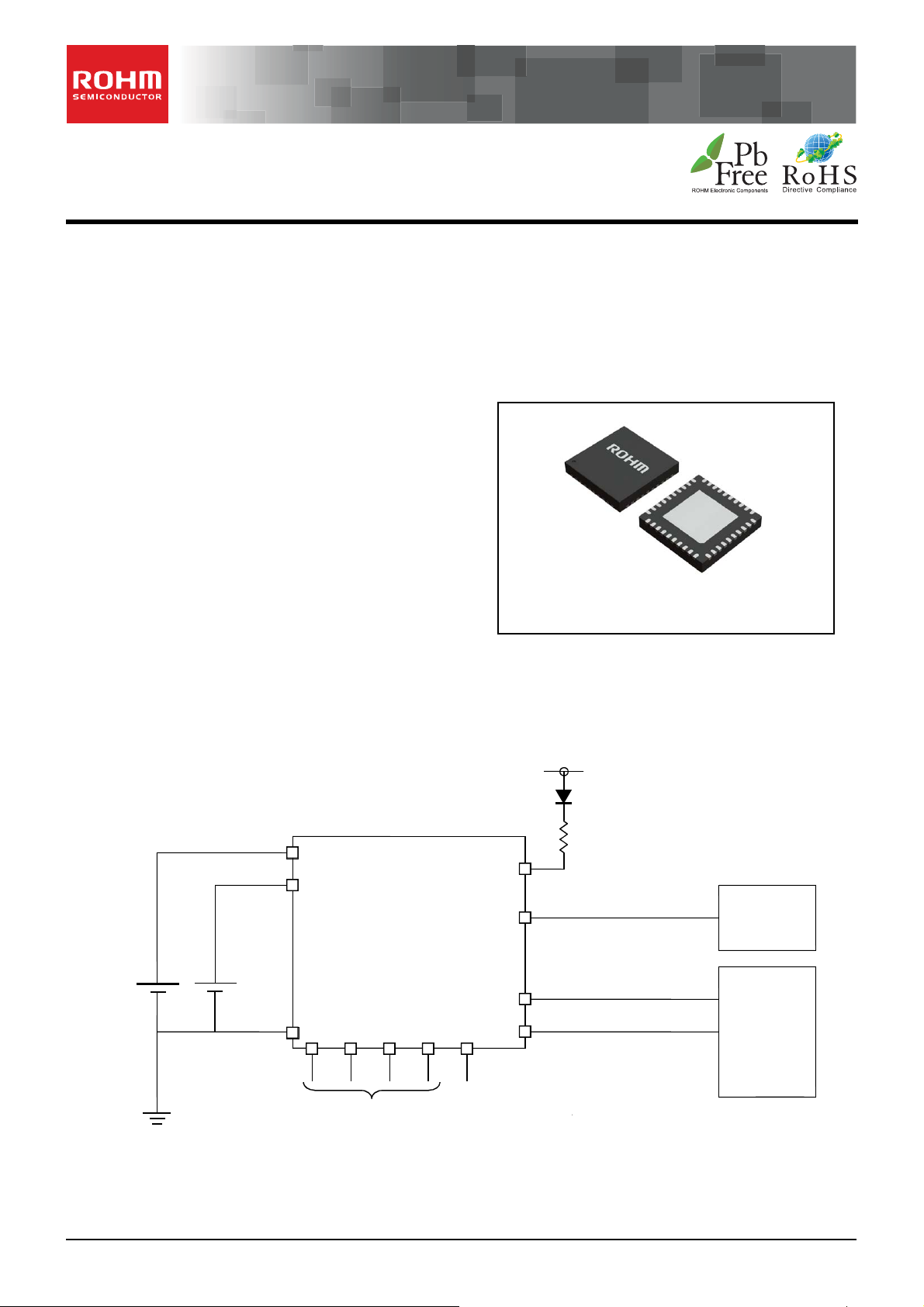

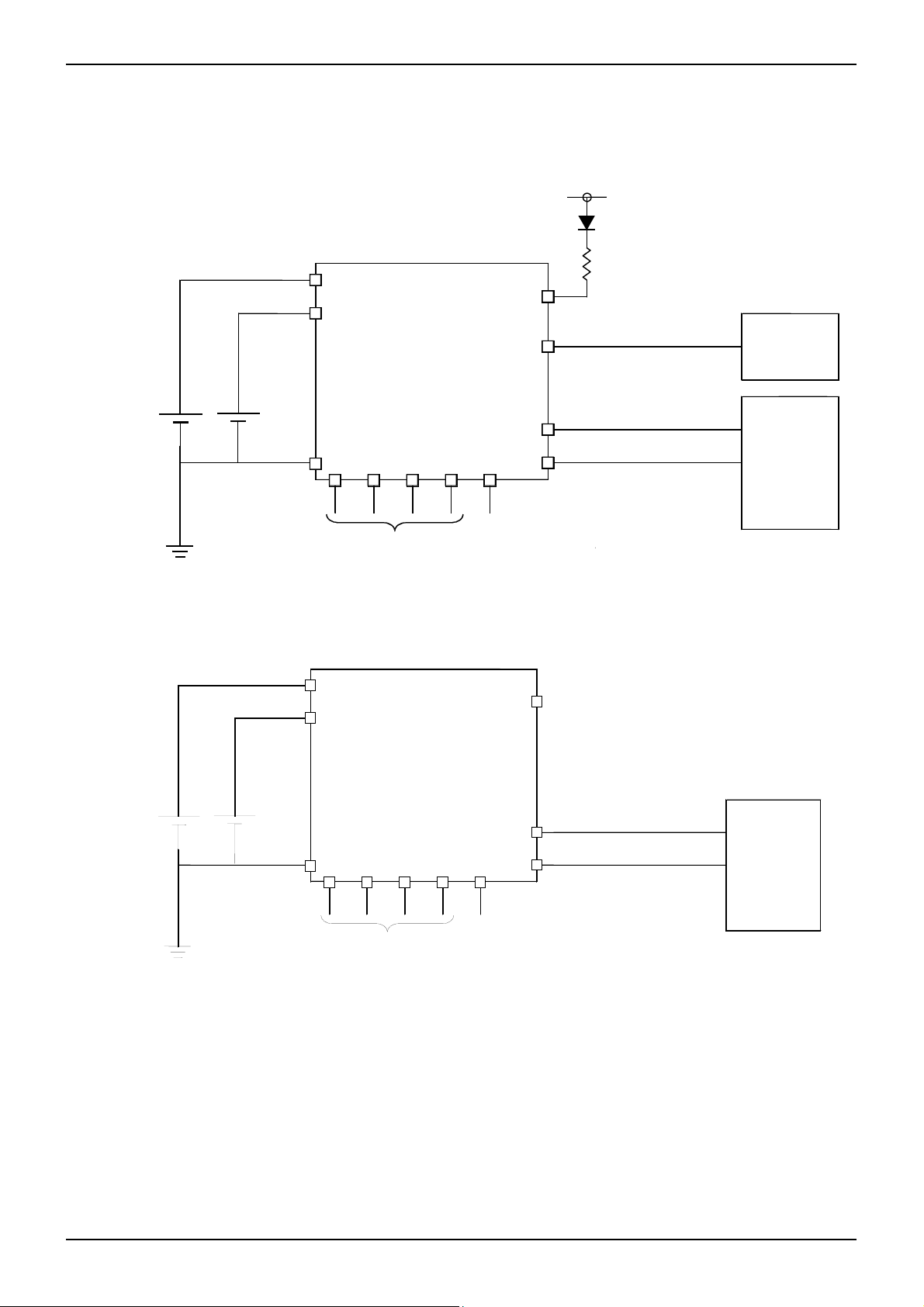

●Ty pical A pplication Circuit

LED/GPO using case

5.0V

3.3V

VSS

VLCD

VDD

BU97930MUV

Input signal from controlle

INHb

●Key Specifications

■ Supply Voltage Range: +1.8V to +3.6V

■ LCD drive power supply Range: +2.7V to +5.5V

■ Operating Temperature Range: -40°C to +85°C

■ Max Segments: 108 Segments

■ Display Duty: Static, 1/3, 1/4 selectable

■ Bias: Static, 1/3

■ Interface: 3wire serial interface

●Package W (Typ.) x D (Typ.) x H (Max.)

QFN040V6060

6.00mm x 6.00mm x 1.00mm

VLED=5.0V

arding resistor value

*Re

Please detect the value accordin

ut current value

in

LED

SEG26

GPO1

to

GPO4

SEG23

to

to

SEG

COM3

22

CLKINCSB SD SCL

CLKIN

*

External CLK input terminal

If not in use, , connect to VSS or o

SEG0

COM0

Datashee

to

current MAX = 20m

Othe

device

LCD

en .

Figure 1. T ypical application circuit

○Product structure:Silicon monolithic integrated circuit ○This product is not designed for protection against radioactive rays.

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・14・001

1/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 2

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

r

r

(typ=40.96

12345678910302928272625242322

21

Datasheet

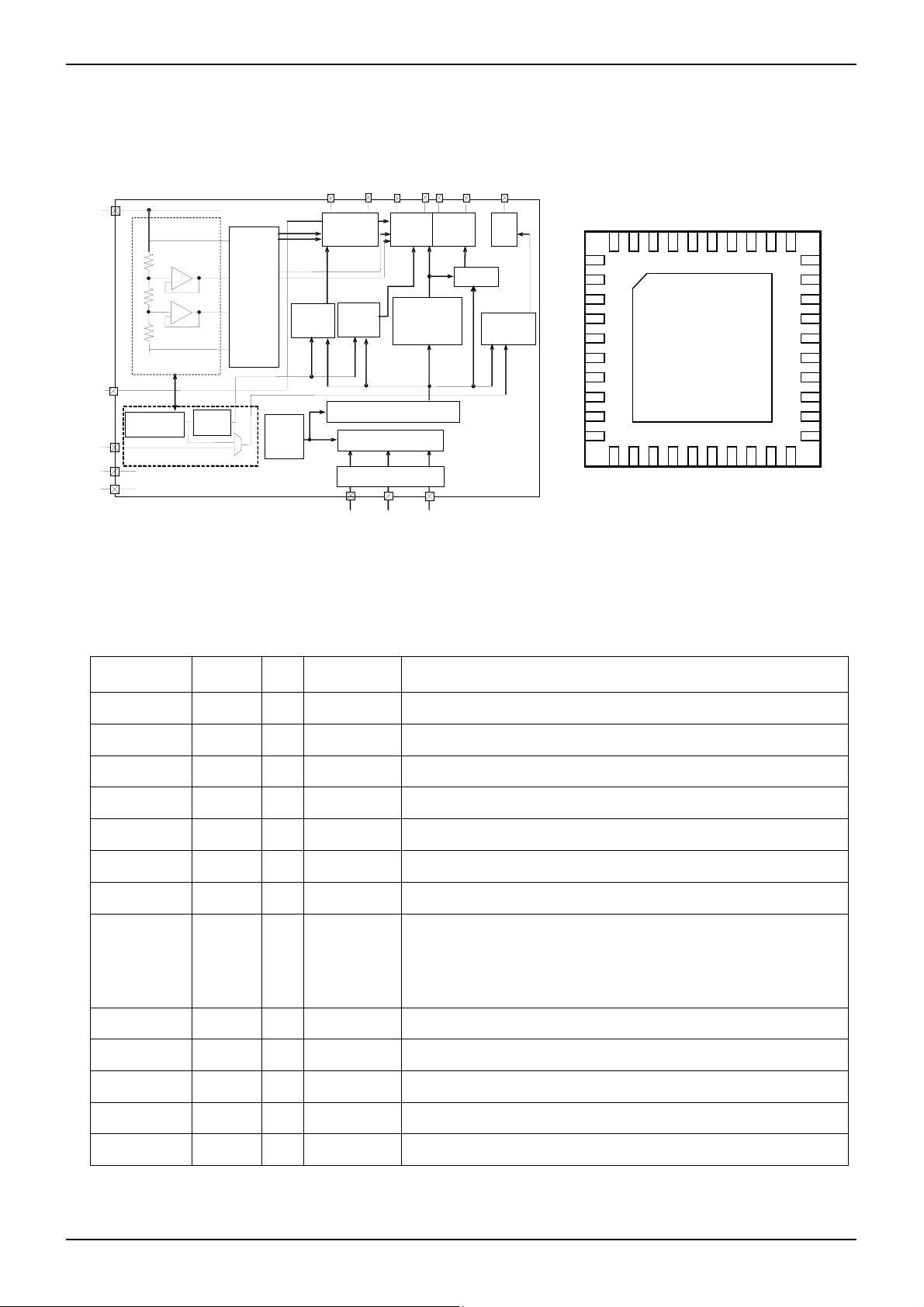

●Block Diagram / Pin Configuration / Pin Description

VLCD

LCD voltage

G enerator

COM0……COM3

common

drive

SEG0 …...22 SEG23...26

Segment

driver

LCD

BIAS

SELECTOR

common

counter

blink timing

generator

GPO data latch

divider

(Div.2)

Command

Data

CSB

Decoder

serial inter face

IF FILTER

SD

Power On

Reset

INHb

CLKIN

VDD

VSS

VSS

CR O

OS C block

kHz

DDRAM

SCL

Segment

driver/GPO

Controlle

GPO

LED

LED

drive

PWM

Generator

CSB

SCL

SD

VDD

INHb

CLKIN

VLCD

COM0

COM1

COM2

40

VSS COM3

39

LED SEG0

38

SEG26 SEG1

37

SEG25 SEG2

36

SEG24 SEG3

35

SEG23 SEG4

34

SEG22 SEG5

33

SEG21 SEG6

32

SEG20 SEG7

31

SEG19 SEG8

SEG18

SEG17

SEG16

EXT-PAD

SEG15

SEG14

SEG13

SEG12

SEG11

11

12

13

14

15

16

17

18

19

20

SEG10

SEG9

Figure 2. Block Diagram Figure 3. Pin Configuration (BOTTOM VIEW)

Table 1 Pin Description

Terminal

CSB 1 I - Chip select: "L" active

SCL 2 I - Serial data transfer clock

SD 3 I - Input serial data

VDD 4 - - Power supply for LOGIC

CLKIN 6 I OPEN / VSS

VSS 40 - - GND

VLCD 7 - - Power supply for LCD

INHb 5 I VDD

COM0 to 3 8 to 11 O OPEN COMMON output for LCD

Terminal

number

I/O unused case Function

External clock input terminal (for display/PWM using selectable);

Support Hi-Z input mode at internal clock mode

Display turning on/off select terminal

H: turning on display, L: turning off display

INHb = “L”: All SEG/COM terminals : output VSS level

GPO terminal : output VSS level

LED drive terminal : output Hi-Z

SEG0 to 22 12 to 34 O OPEN SEGMENT output for LCD

SEG23 to 26 35 to 38 O OPEN SEGMENT output for LCD/GPO

LED 39 O OPEN LED driver output

EXT-PAD - - VSS substrate

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

2/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 3

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Absolute Maximum Ratings (VSS=0V)

Parameter Symbol Ratings Unit Remarks

Power supply voltage 1 VDD -0.3 to +4.5 V Power supply

Power supply voltage 2 VLCD -0.5 to +7.0 V Power supply for LCD

Power Dissipation Pd 0.8*

Input voltage range VIN -0.5 to VDD+0.5 V

Operational temperature range Topr -40 to +85 ℃

Storage temperature range Tstg -55 to +125 ℃

Iout1 5 mA SEG output

Output current

*1 When operated higher than Ta=25℃, subtract 8.0mW per degree. (using ROHM standard board)

(board size: 74.2mm×74.2mm×1.6mm material: FR4 board copper foil: land pattern only).

●Recommended Operating Ratings(Ta=-40°C to +85°C,VSS=0V)

Parameter Symbol

Power supply voltage 1 VDD 1.8 - 3.6 V Power supply

Power supply voltage 2 VLCD 2.7 - 5.5 V Power supply for LCD

Output current Iout4 - - 20 mA Per LED port 1ch

●Electrical Characteristics

DC characteristics (Ta=-40°C to +85°C, VDD=1.8V to 3.6V, VLCD=2.7V to 5.5V, VSS=0)

Parameter Symbol

“H” level input voltage VIH 0.8VDD - VDD V SD, SCL, CSB, CLKIN, INHb

“L” level input voltage VIL VSS - 0.2VDD V SD, SCL, CSB, CLKIN, INHb

Hysteresis width VH - 0.2 - V SCL, INHb, VDD=3.3V, Ta=25°C

“H” level input current IIH1 - - 5 µA

“L” level input current IIL1 -5 - - µA

VOH1

“H” level output voltage

(*2)

“L” level output voltage

(*2)

Current consumption

(*1)

*1 Power save mode 1 and frame inversion setting *2 Iload: In this case, load current from only one port

VOH2

VOH3

VOL1 - - 0.4 V

VOL2 - - 0.4 V

VOL3 - - 0.5 V

VOL4 - 0.11 0.5 V

IstVDD - 3 10 µA

IstVLCD - 0.5 5 µA

IVDD1 - 8 15 µA

IVDD2 - 30 45 µA

IVLCD1 - 10 15 µA

IVLCD2 - 30 48 µA

Iout2 5 mA COM output

Iout3 10 mA GPO output

Iout4 50 mA LED output

Ratings

MIN TYP MAX

Limit

MIN TYP MAX

VLCD

-0.4

VLCD

-0.4

VLCD

-0.6

- - V

- - V

- - V

1

Unit Remarks

Unit Condition

W

SD, SCL, CSB, CLKIN,

INHb, VI=3.6V

SD, SCL, CSB, CLKIN,

INHb, VI=0V

Iload=-50µA, VLCD=5.0V

SEG0 to SEG26

Iload=-50µA, VLCD=5.0V,

COM0 to COM3

Iload=-1mA,VLCD=5.0V,

SEG23 to SEG26(GPO mode)

Iload= 50µA, VLCD=5.0V,

SEG0 to SEG26

Iload= 50µA, VLCD=5.0V,

COM0 to COM3

Iload=1mA, VLCD=5.0V,

SEG23 to SEG26(GPO mode)

Iload=20mA, VLCD=5.0V,

LED

Input terminal ALL’L’,

Display off, Oscillation off

Input terminal ALL’L’,

Display off, Oscillation off

VDD=3.3V, Ta=25°C, 1/3bias, fFR=64Hz,

PWM generate off, All output pin open

VDD=3.3V, Ta=25°C, 1/3bias, fFR=64Hz,

PWM Frequency=500Hz setting,

All output pin open

VLCD=5.0V, Ta=25°C, 1/3bias, fFR=64Hz,

LED generate off, All output pin open

VLCD=5.0V , Ta=25℃, 1/3bias, fFR=64Hz,

PWM Frequency=500Hz setting,

All output pin open

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

3/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 4

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

W

f

●Electrical Characteristics – continued

Oscillation Frequency Characteristics (Ta=-40°C to +85°C, VDD=1.8V to 3.6V, VLCD=2.7V to 5.5V, VSS=0)

Parameter Symbol

Frame frequency 1 fFR1 57.6 64 70.4 Hz

Frame frequency 2 fFR2 51.2 64 73.0 Hz

Frame frequency 3 fFR3 45.0 - 64 Hz

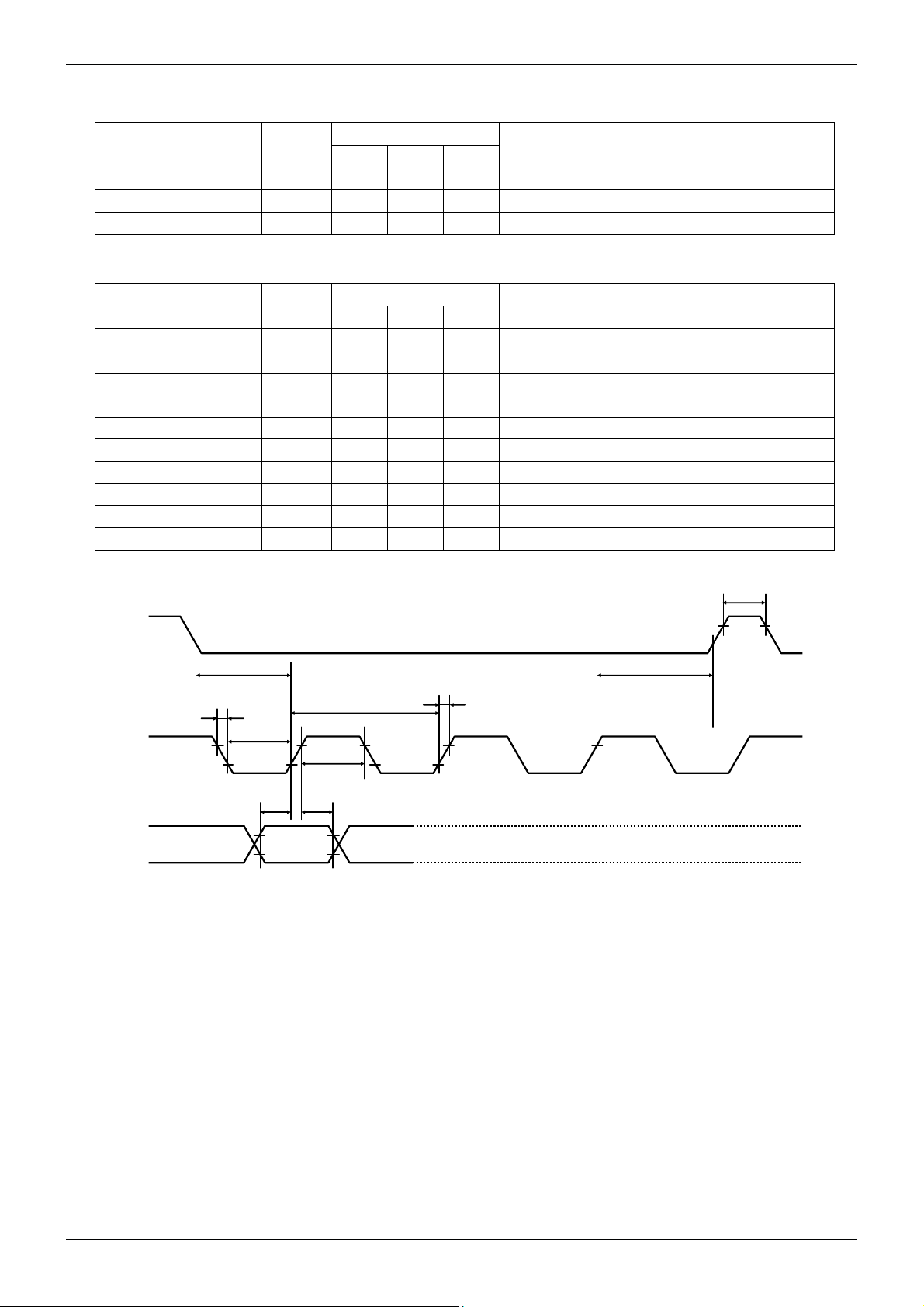

MPU interface Characteristics (Ta=-40°C to +85°C, VDD=1.8V to 3.6V, VLCD=2.7V to 5.5V, VSS=0)

Parameter Symbol

Input rise time tr - - 50 ns

Input fall time tf - - 50 ns

SCL cycle time tSCYC 250 - - ns

“H” SCL pulse width tSHW 50 - - ns

“L” SCL pulse width tSLW 50 - - ns

SD setup time tSDS 50 - - ns

SD hold time tSDH 50 - - ns

CSB setup time tCSS 50 - - ns

CSB hold time tCSH 50 - - ns

“H” CSB pulse width tCHW 50 - - ns

CSB

SCL

SD

tCSS

t

tSL

tSDS tSDH

MIN MIN MIN

MIN TYP MAX

tSCYC

tSHW

Limit

Limit

Unit Condition

VDD=3.3V, Ta=25°C, fFR=64Hz setting

VDD=2.5 to 3.6V fFR=64Hz setting

VDD=1.8 to 2.5V fFR=64Hz setting

unit Condition

tCSH

tr

Datasheet

tCHW

Figure 4. Serial interface timing

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

4/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 5

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

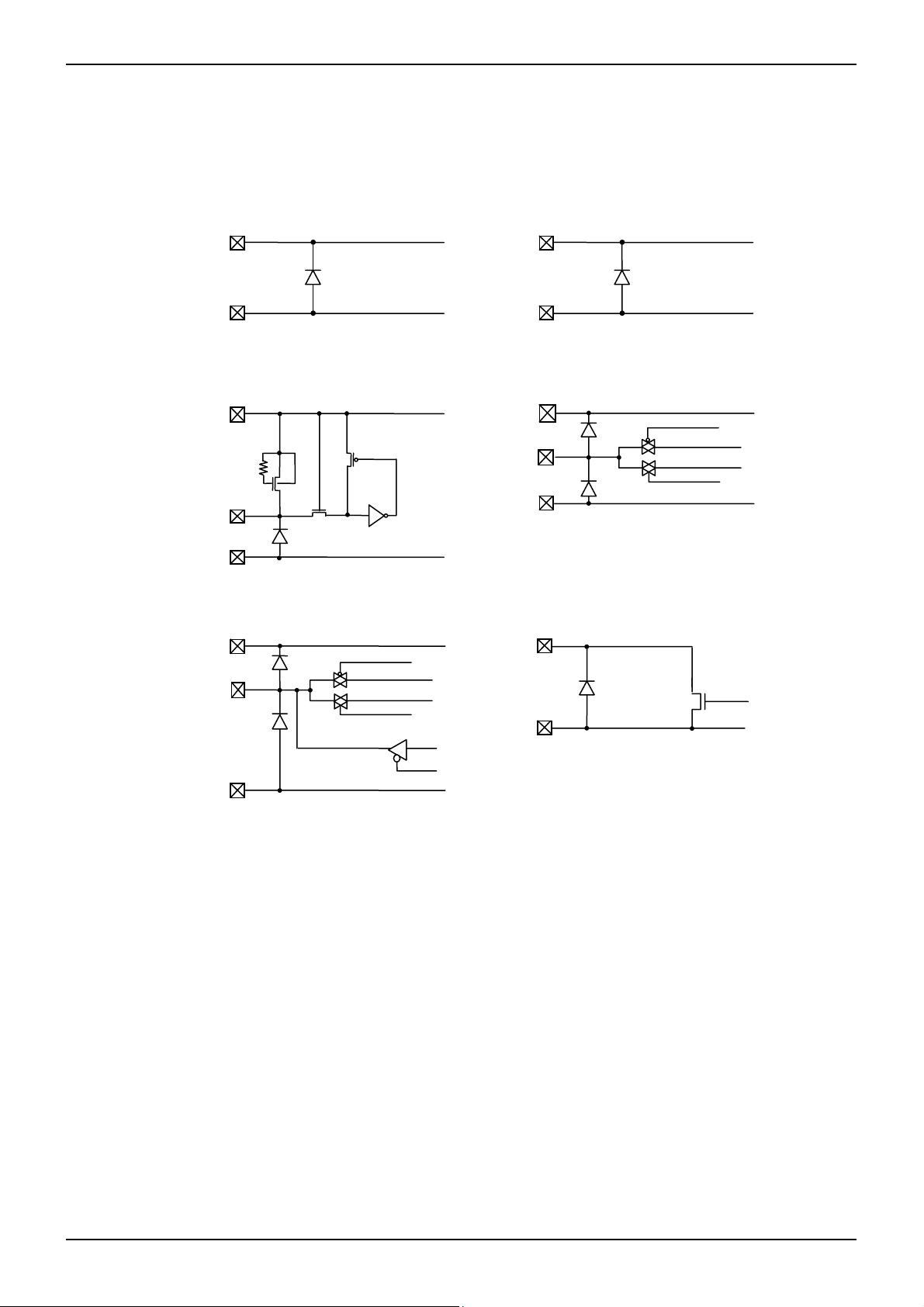

●I/O equivalent circuit

VLCD

VSS

VDD

CSB, SD,

SCL,INHb

CLKIN

VSS

VLCD

SEG23-26

VSS

VDD

VSS

VLCD

SEG0-22

COM0-3

VSS

LED

VSS

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

Figure 5. I/O equivalent circuit

5/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 6

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

r

r

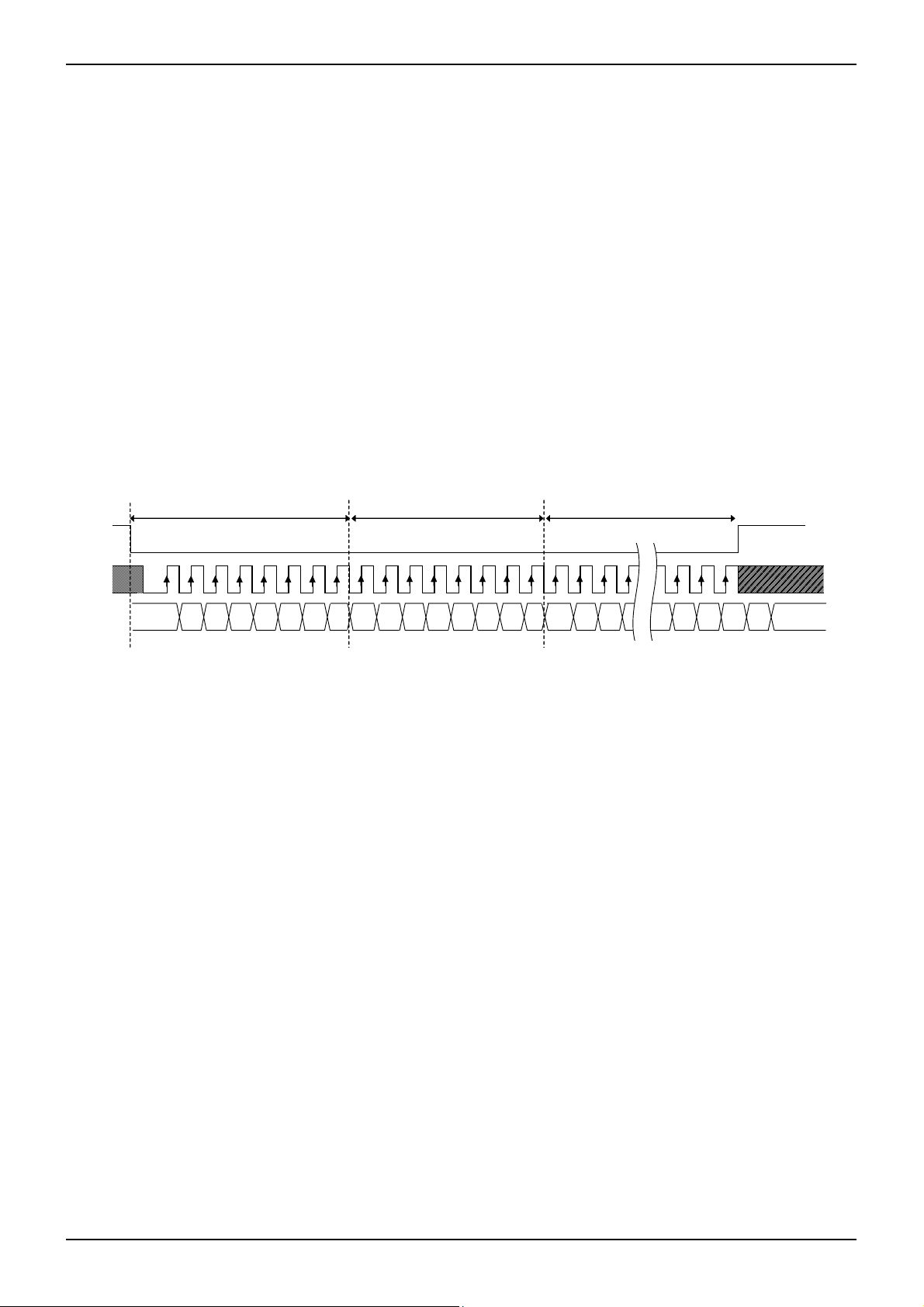

●Example of recommended circuit

1) LED/GPO operation

2) SEG output only operation

5.0 V

3. 3V

VSS

VLCD

VDD

BU97930MUV

Input signal from controlle

INHb

LED

CLKINCSB SD SCL

CLKIN

*

External CLK input terminal

In case being unused, connect to VSS

VLED =5. 0V

*Regarding resistor value

Please detect the value according to

input current value (

SEG26(GPO

to

SEG0

COM0 to COM3

1)

SEG23( GPO 4)

SEG22

to

Datasheet

current MAX = 20mA)

Othe

device

LCD

or be opened

.

VLCD

LED

VDD

OPEN if unused

BU97930MUV

5.0V 3.3V

VSS

Input signal from controller

INHb

CLKINCSB SD SCL

CLKIN

*

External CLK input terminal

connect to VSS or open. If unused

SEG0

COM0toCOM3

Figure 6. Example of Recommended Circuit

to

SEG26

LCD

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

6/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 7

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

CD/C

3

0

4D6D5

2

Datasheet

●Function description

○Command and data transfer method

○3-SPI (3-wire serial interface)

This device is controlled by a 3-wire signal (CSB, SCL, and SD).

First, Interface counter is initialized with CSB=“H".

Setting CSB=”L”, enables SD and SCL inputs.

The protocol of 3-SPI transfer is as follows.

Each command starts with Command or Data judgment bit (D/C) as MSB data,

followed by data D6 to D0 (this is when CSB =”L”).

(Internal data is latched at the rising edge of SCL, serial data is converted to an 8-bit parallel data at the falling edge of

the 8th CLK.)

When CSB changes from “L” to “H”, and at this time serial commands are less than 8 bits, command and data transfers

are cancelled. To start sending command again, please set CSB=”L" and send command continuously.

After sending RAMWR or BLKWR or GPOSET command, this device is in the RAM data input mode. Under this mode,

device can not accept new commands.

In this case, execute a “H” to “L” transition at CSB, after this sequence, the device is released from RAM data input mode,

and can accept new command.

CSB

1st byte Command 2nd byte Command

3rd byte Command

SCL

SD

D/C

D3 D6D0 D0

D

D2

D/

D1 D

D5

D6D5D4D

D/CD4 D3 D2 D1

D1 D

D6

Figure 7. 3-SPI Data transfer Format

* 8-bit data, sending after RAMWR command, are display RAM data

* 8-bit data, sending after BLKWR command, are blink RAM data

* SCL and SD can be set to “H” or cleared to “L” during CSB=”H”.

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

7/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 8

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

A

A

A

A

j

Datasheet

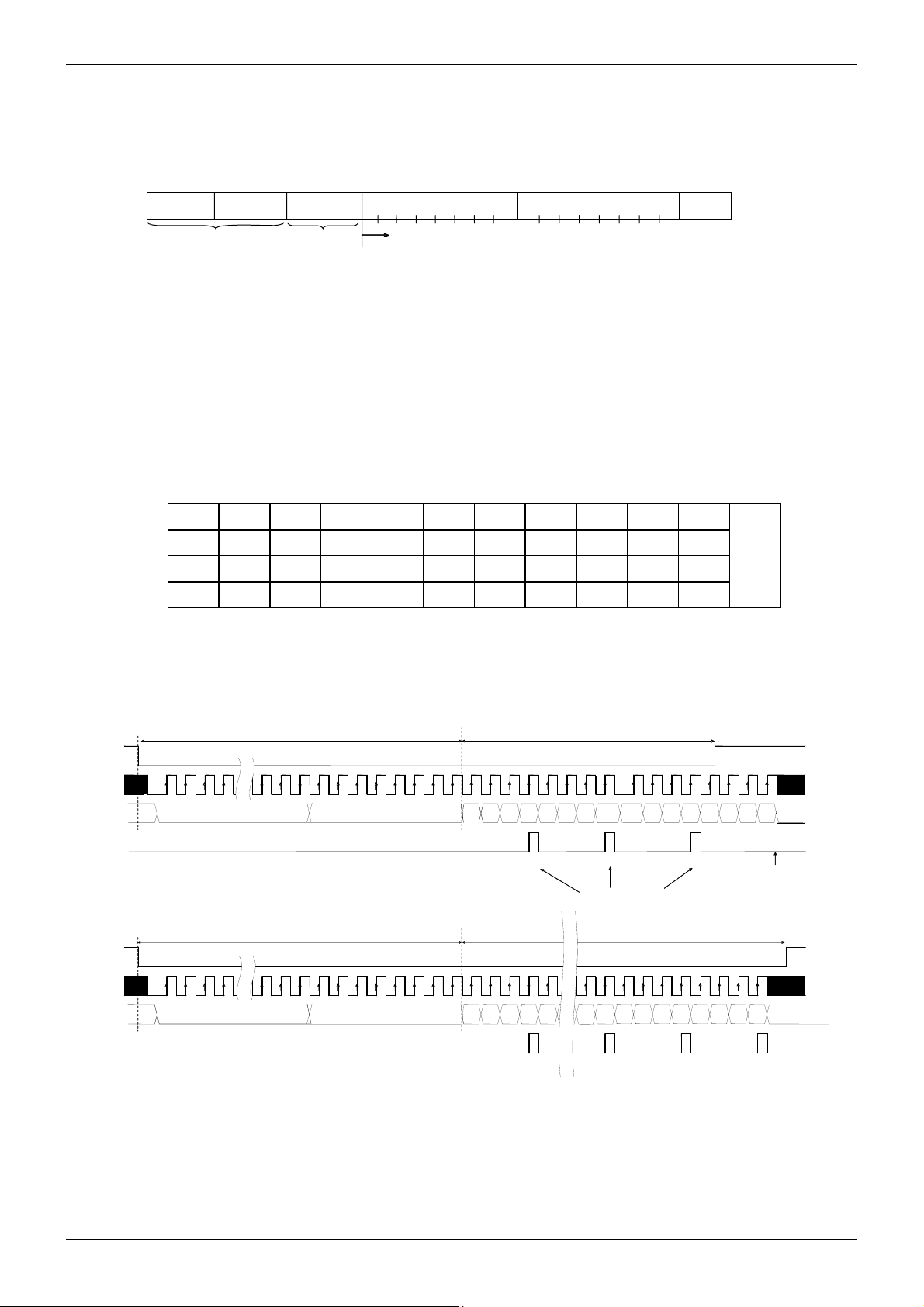

○Write display data and transfer method

This device has Display Data RAM (DDRAM) of 28×4=112bit.

The relationship between data input and display data, DDRAM data and address are as follows.

Command

1st Byte

10000011

ddress set

2nd Byte

Command

00000000

Command

10100000

RAM Write

a

b

Display RAM data

c

de

g

h

f

i

kl m

no

…

p

According to this command, an 8-bit binary data will be written to the DDRAM. The starting address of the DDRAM where

data will be written is specified by “ADSET” command, and is automatically incremented for every 4 bits of data received..

Writing data to DDRAM can be done by continuously sending data.

(In case data is sent continuously after write date at 1Ah (SEG26), RAM data will be written to 1Bh (dummy address)

and return to address 00h (SEG0) automatically.)

In case SEG port assigned to GPO port by OUTSET command, corresponding SEG address do not change and used as

dummy address.

DDRAM address

00 01 02 03 04 05 06 07

・・・

0 a e i m

1 b f j n

2 c g k o

BIT

3 d h l p

SEG

SEG

0

1

SEG

2

SEG

3

SEG4SEG5SEG6SEG

・・・

7

19h 1Ah 1Bh

SEG

25

SEG

26

ADDRESS

DUMMY

Display data write to DDRAM every 4 bits.

In case CSB changes from ”L” to ”H” before 4 bits of data transfer was finished, RAM write is cancelled.

Command

Display data

CSB

1st byte Command / 2nd byte Command

COM0

COM1

COM2

COM3

SCL

SD D2 D5 D4 D3 D2 D1 D0

Internal

signal

RAM write

Address set command RAMWR command

Command

RAMWR command

CSB

SCL

Internal

signal

RAM write

1st byte Command / 2nd byte Command

Address set command

D6 D5 D4 D3D7 D1

ddress 00h

D7 D6SD

D4 D3 D2 D0

Address 00h

ddress 01h

RAM write every 4bit

Address 30h

D0 D7

D6

ddress 02h

Display data

D7

Address 31h

data lower than 4bit case

RAM write is canceled

D5

D5 D6

D4D4 D2 D1D5 D3

Addres00h

Auto increment

Return to address 00h

Figure 8. Display Data Transfer Method

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

8/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 9

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

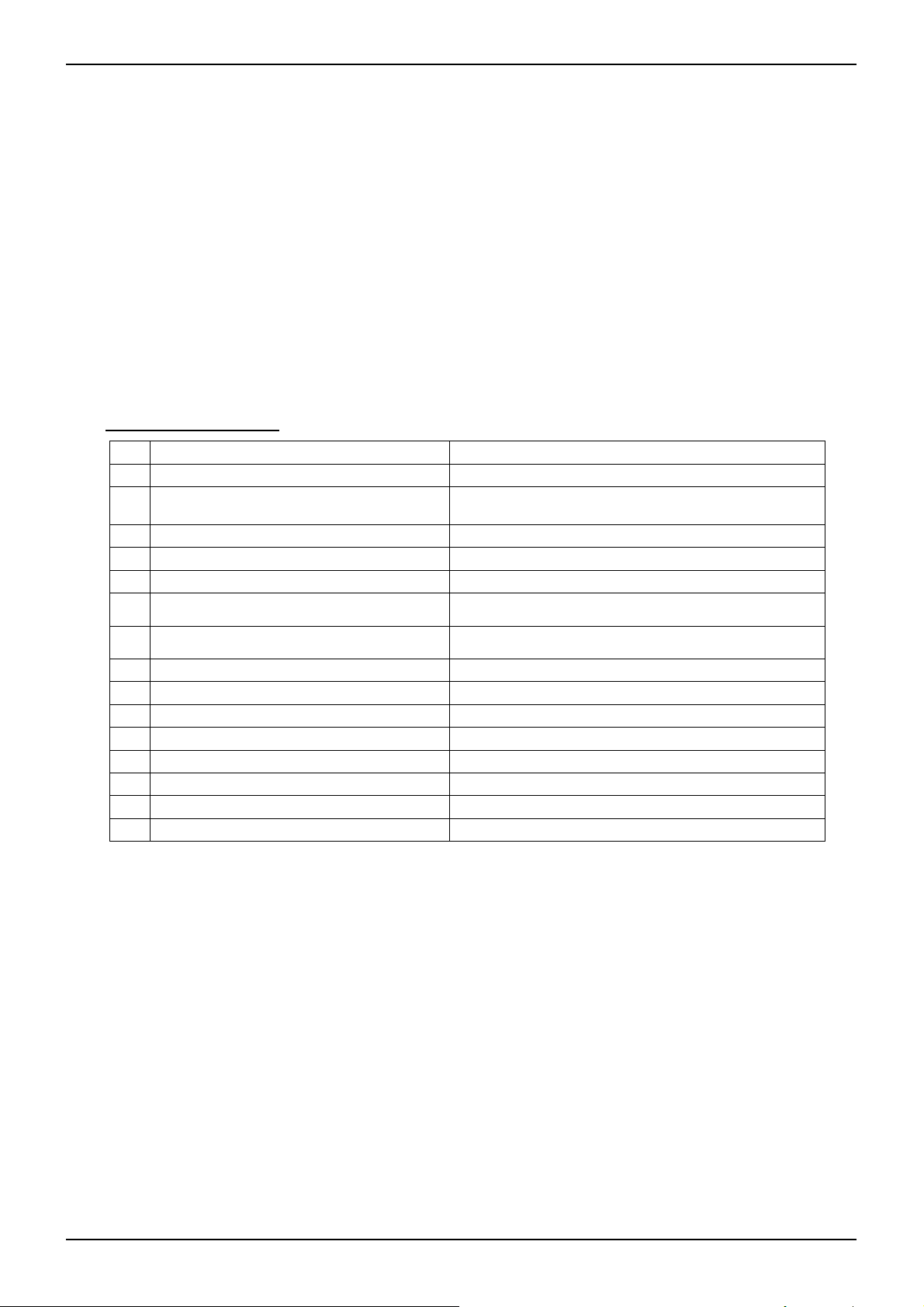

○Blink function

This device has Blink function. Blink function can set each segment port individually.

Blink ON/OFF and Blink frequency are set by the BLKSET command.

Blink frequency varies according to fCLK characteristics.

Blink setup of each segment is controlled by BLKWR command.

The write start address is specified by “BLKADSET” command. And this address will automatically increment every 4 bits

of blink data received. The relation of BLKWR command, blink ram data, and blinking segment port is below.

In case data is “1”, segment will blink, on the other hand when data is “0”, segment will not blink.

(In case data is written continuously after write data at 1Ah (SEG26), RAM data will be written to 1Bh (dummy address)

and return to address 00h (SEG0) automatically.)

Please refer to the following figures about Blink operation of each segment.

In case SEG port assigned to GPO port by OUTSET command, corresponding SEG address does not change and used

as dummy address.

1st Byte

Command

10000100

Command

Blink set

2nd Byte

00000011

1st Byte

Command

10000111

2nd Byte

Command

00000000

Blink Address set

Command

11000000

Blink

RAMWR

a

b

d

c

Blink RAM data

g

f

e

h i

j

k

m

n o

l

Blink RAM address

00 01 02 03 04 05 06 07

0 a e i m

・・・

19h 1Ah 1Bh

ADDRESS

DUMMY

1 b f j n COM1

2 c g k o COM2

BIT

3 d h l p COM3

SEG 0 SEG 1 SEG 2 SEG 3 SEG4 SEG5 SEG6 SEG

7

SEG

25

SEG

26

Datasheet

…

p

COM0

DDRAM data

SEG A SEG B SEG C SEG D

Blink RAM data

SEG A SEG B SEG C SEG D

Segment output

SEG A SEG B SEG C SEG D SEG A SEG B SEG C SEG D SEG A SEG B SEG C SEG D SEG A SEG B SEG C SEG D

under the 2Hz stting segment output will blink every 0.5 second (ON->OFF->ON)

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

Blink frequency

Figure 9. Blink Operation

9/28

SEGA/B is blink

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 10

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○LCD Driver Bias/Duty Circuit

BU97930MUV generates LCD driving voltage using an on-chip Buffer AMP.

Also, it can drive LCD with low power consumption

*Line and frame inversion can be set by MODESET command.

*1/4duty, 1/3duty and static mode can be set by DISCTL command.

About each LCD driving waveform, please refer to “LCD driving waveform” descriptions.

○Initial state

Initial state after SWRST command input

○Display off

○All command register values are in Reset state.

○DDRAM address data and Blink address data are initialized

(DDRAM data and Blink RAM data are not initializing.

Please write DDRAM data and Blink RAM data before Display on.)

●Command / Function list

Function description table

NO Command Function

1 Mode Set (MODESET) Sets LCD drive mode (display on/off, current mode)

2 Display control (DISCTL)

3 Address set (ADSET)

4 Blink set (BLKSET)

5 Blink address set (BLKADSET)

SEG/GPO port change

6

(OUTSET)

LED drive control (PWMSET)

7

(H piece adjustment of PWM)

8 RAM WRITE (RAMWR) Writes display data to display data RAM

9 Blink RAM WRITE (BLKWR) Writes Blink data to BLINK data RAM

10 All Pixel ON (APON) Sets all Pixel display on

11 All Pixel OFF (APOFF) Sets all Pixel display off

12 All Pixel On/Off mode off (NORON)

13 Software Reset (SWRST) Software Reset

14

OSC external input (OSCSET)

15 GPO output set (GPOSET) Sets GPO output data

Sets LCD drive mode

(frame freq., line/frame inversion)

Sets display data RAM address for RAMWR command

Sets Blink mode on/off

Sets Blink data RAM address for BLKWR command

Selects segment output/general purpose output (GPO)

Sets PWM1 signal “H” width for LED driving

Sets normal display mode (APON/APOFF cancel)

Enables External clock input

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

10/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 11

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Command Descriptions

D/C, Data / Command judgment bit (MSB)

For more details, please refer to 3wire serial I/F

○Mode Set (MODESET)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte command 1 0 0 0 0 0 0 1 81h 2nd byte command 0 0 0 0 P3 P2 P1 P0 - 00h

Display Set

Condition P3 Reset state

Display OFF 0 ○

Display ON 1

Display OFF : No LCD driving mode (Output: VSS Level)

Turn off OSC circuit and LCD power supply circuit. (Synchronized with frame freq)

Display ON : LCD driving mode

Turn on OSC circuit and LCD power supply circuit.

Read data from DDRAM and display to LCD.

LED port and GPO port output states are not affected by a Display on/off state

Output state is determined by command setup (OUTSET GPOSET, PWMSET) and INHb terminal state,

respectively. For more details, please refer to each command description.

LCD drive mode set

Condition P2 Reset state

Frame inversion 0 ○

Line inversion 1

Current mode set

Condition P1 P0 Reset state

Power save mode1 0 0 ○

Power save mode2 0 1

Normal mode 1 0

High power mode 1 1

* Please supply the VLCD voltage larger than 3V at High power mode.

(Reference data of consumption current)

Condition Current consumption

Power save mode 1 ×1.0

Power save mode 2 ×1.7

Normal mode ×2.7

High power mode ×5.0

* The value changes according to the panel load.

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

11/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 12

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○Display control (DISCTL)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 0 0 0 1 0 82h 2nd byte Command 0 0 0 0 P3 P2 P1 P0 - 02h

Duty set

Condition P3 P2 Reset state

1/4duty (1/3bias) 0 0 ○

1/3duty (1/3bias) 0 1

Static (1/1bias) 1 *

*: Don’t care

In 1/3 duty, Display data and Blink data of COM3 are ineffective.

COM1 and COM3 output are same data.

Please be careful in transmitting display data and blink data.

The examples of SEG/COM output waveform, under each Bias/Duty set up, are sho wn at "LCD Driver Bias/Duty

Circuit" description.

Frame frequency set

Condition

(1/4,1/3,1/1duty)

(128Hz, 130Hz, 128Hz) 0 0

(85Hz, 86hz, 64Hz) 0 1

(64Hz, 65Hz, 48Hz) 1 0 ○

(51Hz, 52Hz, 32Hz) 1 1

Relation table, between Frame frequencies (FR), integrated oscillator circuit (OSC) and Divide number.

DISCTL

(P1,P0)

(0,0) 160 156 160 128 131.3 128

(0,1) 240 237 320 85.3 86.4 64

(1,0) 320 315 428 64 65 47.9

(1,1) 400 393 640 51.2 52.1 32

*1: FR is frame frequency, in case OSC frequency = 20.48KHz (typ).

The Formula, to calculate OSC frequency from Frame frequency is shown below.

“ OSC frequency = Frame frequency (measurement value) x Divide number ”

Divide number:Please determine by using the value of Frame Frequency Set (P1,P0) and duty setting (P3,P2).

Ex) (P1,P0) = (0,1) ,(P3,P2) = (0,1) => Divide number= 237

(0,0)

1/4duty

P1 P0 Reset state

Divide FR [Hz] (*1)

Duty set (P3,P2) Duty set (P3,P2)

(0,1)

1/3duty

(1,*)

1/1duty

(0,0)

1/4duty

(0,1)

1/3duty

Datasheet

(1,*)

1/1duty

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

12/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 13

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○Address set (ADSET)

MSB LSB

MSB D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 0 0 0 1 1 83h 2nd byte Command 0 0 0 P4 P3 P2 P1 P0 - 00h

Set start address to write DDRAM data.

The address can be set from 00h to 1Ah. (Address 1Bh is used at dummy address)

Do not set other addresses. (Except 00h to 1Bh address is not acceptable.)

In case writing data to DDRAM, make sure to send RAMWR command.

○Blink set (BLKSET)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 0 0 1 0 0 84h 2nd byte Command 0 0 0 0 0 P2 P1 P0 - 00h

Set Blink ON/OFF.

For more details, please refer to "Blink function".

Blink set

Blink mode(Hz) P2 P1 P0 Reset state

OFF 0 0 / * 0 / * ○

1.6 1 0 0

2.0 1 0 1

2.6 1 1 0

4.0 1 1 1

*: Don’t care

○Blink address set (BLKADSET)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 0 0 1 1 1 87h 2nd byte Command 0 0 0 P4 P3 P2 P1 P0 - 00h

Set Blink data RAM start write address.

The address can be set from 00h to 1Ah. (Address 1Bh is used at dummy address)

Do not set other addresses. (Except 00h to 1Bh address is not acceptable.)

In case writing data to Blink RAM, make sure to send BLKWR command

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

13/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 14

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○SEG/GPO port change (OUTSET)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 0 1 0 0 0 88h 2nd byte Command 0 0 0 0 0 P2 P1 * - 00h

Set output mode, Segment output or GPO output.

P2 to P0: Select changing port number. (SEG23 to SEG26 ports are SEG mode/GPO mode selectable)

In case GPO output is selected, Terminal output data is set by GPOSET command.

Ex) In case SEG 26 port assigned to GPO,

If GPO1 data is "H", GPO1 (SEG26) port outputs "H" (VLCD Level).

If GPO1 data is "L", GPO1 (SEG26) port outputs "L" (VSS level).

Output terminal state under the P2 to P0 set condition is listed below

Output Terminal state

Condition SEG Terminal state (SEG output/GPO output)

P2 P1 P0 SEG23 port SEG24 port SEG25 port SEG26 port

0 0 * SEG23 SEG24 SEG25 SEG26

0 1 0 SEG23 SEG24 SEG25 GPO1

0 1 1 SEG23 SEG24 GPO2 GPO1

1 0 0 SEG23 GPO3 GPO2 GPO1

1 0 1 GPO4 GPO3 GPO2 GPO1

1 1 * (OUTSET command will be canceled)

In case SEG port is switched to the GPO port, DDRAM address and Blink RAM address do not change.

In this case DDRAM address and Blink RAM address, selected GPO output mode is dummy address.

The output state of GPO and LED port under the INHb H/L, display on/off, and RESET state are listed below.

Control port

INHb DISPLAY

H L ON OFF

Datasheet

RESET state

According to

GPO

LED

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

GPOSET

command

According to

PWMSET

command

Low Fix

Hi-Z

14/28

According to

GPOSET

command

According to

PWMSET

command

According to

GPOSET

command

According to

PWMSET

command

GPO unselected

(All SEG output)

LED unselected

(All SEG output)

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 15

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○LED drive-control (PWM “H” width control) command (PWMSET)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 0 1 0 1 0 8Ah 2nd byte Command 0 0 0 0 0 0 P7 P6 - 00h

3rd byte Command 0 0 P5 P4 P3 P2 P1 P0 - 00h

2nd and 3rd byte command data are able to set from 00h to 3Fh (described as 8bit binary data).

In case other value is selected, sending command is ignored, and 2nd and 3rd byte command data is set to 3Fh.

In default state, 2nd and 3rd byte command data are set to 00h.

In case command is less than 3 bytes, sending command is cancelled.

According to PWMSET command, LED driving signal is adjustable. PWM “H” width is adjustable by 8-bit resolution.

Explanation about P7 to P6 data of 2nd byte command and P5 to P0 data of 3rd byte command are as follows:

(The 2nd byte data are used as upper 2bit, and 3rd byte data are used as lower 6 bits.)

8bit mode: P7 data is used as MSB of 8 bits, and P0 data is used LSB.

LED driving period is decided by the “H” width of PWM signal, generated by PWM generator circuit (resolution: 8 bits).

Ex)

In case, external PWM clock 125KHz, parameter setting value is 127 ( 7Fh )

1-bit resolution: 8us

ALL HI set: PWM signal frequency about 500Hz, H width about 2.00msec

ALL LOW set: PWM signal frequency about 500Hz, H width 0usec (in case 8-bit resolution)

This command is reflected, synchronizing with a next PWM frame head.

And, LED port output is as follows. LED port operation does not affect Display ON/OFF state.

(*) About the PWM frequency and PWM “H” width calculation.

PWM cycle and PWM “H” width, decided by PWM clock cycle are described as follows:

(PWM clock cycle is a minimum unit of PWM “H” width)

In case PWM is generated from internal clock, the PWM cycle varies according to OSC frequency.

PWM (ALL HI)

PWM (ALL Low)

PWM frequency = PWM clock cycle × (Number of the steps (8bit =256) - 1 )

PWM H width = PWM clock cycle × Parameter set value (8bit: 0 to 255)

PWM Duty = PWM H width/PWM cycle = Parameter set value / Number of the steps

Duty shift

FFh

(H width : wide)

00h

(H width: narrow)

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

15/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 16

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○RAM WRITE (RAMWR)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 1 0 0 0 0 0 A0h 2nd byte Command Display data Random

….

n byte Command Display data Random

Input data, sending after 1st byte command, are used as Display data. And display data are sent every 4 bits. Please set

this command after the ADSET command.

○Blink RAM WRITE (BLKWR)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 1 0 0 0 0 0 0 C0h 2nd byte Command Blink data Random

….

n byte Command Blink data Rand om

Input data, sending after 1st byte command, are used as Display data. And display data are sent every 4 bits.

Please set this command after the BLKADSET command.

○All Pixel ON (APON)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 1 0 0 0 1 91h -

After sending the command, all SEG outputs set display on state regardless of the DDRAM data.

(This command affects the SEG output terminals only (except GPO and LED output)

○All Pixel OFF (APOFF)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 1 0 0 0 0 90h -

After sending the command, all SEG outputs set display off state regardless of the DDRAM data.

(This command affects the SEG output terminals only (except GPO and LED output)

○All Pixel ON/OFF mode off (NORON)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 1 0 0 1 1 93h -

After sending the command, all SEG outputs are released from APON/APOFF state.

And SEG port output signal follows DDRAM data.

(This command affects the SEG output terminals only (except GPO and LED output)

After reset sequence or SWRESET, all outputs set NORON state.

○Software Reset (SWRST)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 1 0 0 1 0 92h -

After sending the command, device is set to default state.

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

16/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 17

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○OSC external input command (OSCSET)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 1 1 0 0 0 98h 2nd byte Command 0 0 0 0 0 P2 P1 P0 - 00h

Sets the type of clock mode. There are 4 selectable modes including external clock input mode.

Details of this command function are as follows.

Condition P2 P1 P0 Reset state

Internal CLK (PWM generation OFF) 0 0 0 ○

External CLK input for PWM (PWM generation OFF) 0 0 1

Internal CLK (PWM generation ON) 0 1 0

External CLK input for PWM (PWM generation ON) 0 1 1

External CLK input for Display (ROHM use only) 1 * *

(P2,P1,P0)=(0,0,1) : External PWM input mode

CLKIN:external PWM input available.

PWMOUT: “L” Output

*under the (P2,P1,P0)=(0,0,0) condition PWMOUT into same state

(P2,P1,P0)=(0,1,0) : PWM is generated from an internal oscillating frequency

(P2,P1,P0)=(0,1,1) : PWM is generated from an External CLK input CLKIN

PWM width is set by PWMSET command.

The relation of OSC function control by each command is as follows:

CLKIN terminal

External clock

External PWM

Integrated OSC

OSCSET

command

PWM

generation

PWMSET

command

Datasheet

(*: Don’t care)

LED

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

Figure 10. OSC External Input

17/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 18

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

○GPO output set command (GPOSET)

MSB LSB

D/C D6 D5 D4 D3 D2 D1 D0 Hex Reset

1st byte Command 1 0 0 1 1 0 1 0 9Ah 2nd byte Command 0 0 0 P4 P3 P2 P1 0 - 00h

(*: Don’t care)

Set GPO output data. The relation between SEG port (GPO port) and data is shown below.

GPOSET data GPO port SEG port

P1 GPO1 SEG26

P2 GPO2 SEG25

P3 GPO3 SEG24

P4 GPO4 SEG23

GPO data output is asynchronous from frame cycle.

In case INHb=”H”, GPO output signal follows GPOSET data, on the other hand, in case INHb=”L” GPO output is

GND level. GPO output is not affected by Display ON/OFF state.

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

18/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 19

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

A

A

A

A

●LCD driving waveform

1/4Duty

Line inversion Frame inversion

SEGn SEGn+1

SEGn+2

SEGn+3

SEGn

SEGn+1

SEGn+2

SEGn+3

Datasheet

state

COM0

COM1

COM2

COM3

Vreg

COM0 COM0

VSS

Vreg

COM1 COM1

VSS

Vreg

COM2 COM2

VSS

Vreg

COM3 COM3

VSS

Vreg

SEGn

SEGn

VSS

Vreg

SEGn+1

SEGn+1

VSS

Vreg

SEGn+2

SEGn+2

VSS

Vreg

SEGn+3

SEGn+3

VSS

Vreg

stateB

1frame 1frame

COM0 state

COM1 stateB

COM2

COM3

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

state

(COM0-SEGn) (COM0-SEGn)

-Vreg

Vreg

stateB stateB

(COM1-SEGn)

(COM1-SEGn)

-Vreg

state

-Vreg

Vreg

-Vreg

Figure 11. Waveform of Line Inversion Figure12. Waveform of Frame Inversion

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

19/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 20

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

A

A

A

A

1/3Duty

Line inversion Frame inversion

SEGn SEGn+1

state

COM0

COM1

stateB

SEGn+2

SEGn+3

SEGn SEGn+1

COM0 state

COM1 stateB

Datasheet

SEGn+2 SEGn+3

COM2

COM3

Vreg

COM0 COM0

VSS

Vreg

COM1 COM1

VSS

Vreg

COM2 COM2

VSS

Vreg

COM3 COM3

VSS

Vreg

SEGn SEGn

VSS

Vreg

When

1/3duty

COM3 and COM1 is same

1frame 1frame

When 1/3duty

COM3 and COM1

is same

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

COM2

COM3

When 1/3duty

COM3 and COM1 is same

SEGn+1 SEGn+1

VSS

Vreg

SEGn+2

SEGn+2

VSS

Vreg

SEGn+3

SEGn+3

VSS

Vreg

state

(COM0-SEGn) (COM0-SEGn)

-Vreg

Vreg

stateB stateB

(COM1-SEGn) (COM1-SEGn)

-Vreg

state

VSS

Vreg

VSS

Vreg

VSS

Vreg

-Vreg

Vreg

-Vreg

Figure 13. Waveform of Line Inversion Figure 14. Waveform of Frame Inversion

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

20/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 21

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

A

A

A

A

1/1Duty (Static)

Line inversion Frame inversion

SEGn SEGn+1

Datasheet

SEGn SEGn+1SEGn+2 SEGn+3

SEGn+2 SEGn+3

stateB stateB

state

COM0

COM1

COM2

COM3

Vreg

COM0 COM0

VSS

Vreg

COM1 COM1

VSS

Vreg

COM2 COM2

VSS

Vreg

COM3 COM3

VSS

Vreg

When 1/1duty (Static)

COM1 / COM0 is same

waveform

COM2 / COM0 is same

1frame 1frame

waveform

When 1/1duty

(Static)

COM1 / COM0

is same

waveform

COM2 / COM0

is same

waveform

COM3 / COM0

is same

waveform

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

COM0 state

COM1

COM2

COM3

When 1/1duty (Static)

COM1 / COM0 is same

waveform

COM2 / COM0 is same

waveform

SEGn SEGn

VSS

Vreg

SEGn+1 SEGn+1

VSS

Vreg

SEGn+2 SEGn+2

VSS

Vreg

SEGn+3 SEGn+3

VSS

Vreg

state

-Vreg

Vreg

stateB stateB

state

VSS

Vreg

VSS

Vreg

VSS

Vreg

VSS

Vreg

-Vreg

Vreg

-Vreg

-Vreg

Figure 15. Waveform of Line Inversion Figure 16. Waveform of Frame Inversion

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

21/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 22

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Initialize Sequence

Recommended input sequence is listed below, before starting LCD driving.

(Refer to Power ON/OFF sequence)

Input voltage supply

↓

CSB ‘H’ …interface initializing

↓

CSB ‘L’ …interface command sending

↓

SWRESET …software reset

↓

MODESET …Display off

↓

Various commands setting

↓

RAM WRITE

↓

Blink RAM WRITE

↓

MODESET …Display on

↓

Start LCD driving

*Before initializing sequence, DDRAM address, DDRAM data, Blink address and Blink data are random.

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

22/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 23

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Cautions on Power-On/ Power-Off condition

○POR circuit

BU97930MUV has “P.O.R” (Power-On Reset) circuit and Software Reset function.

Please follow the recommended Power-On conditions in order to power up properly.

1, Please set power up conditions, follow the recommended tR, tF, tOFF, and Vbot specification below in order to

ensure P.O.R operation.

(*The detection voltage of POR varies because of environment, etc. To operate POR, please satisfy

Vbot lower than 0.5V condition.)

VDD

VDET

tOFF

tR

Recommended condition of tR, tF, tOFF, Vbot

tR tOFF Vbot VDET

Vbot

less than

10ms

* VDET : POR detect level

Over

1ms

less than

0.5V

Figure 17. Power ON/OFF Waveform

Datasheet

TYP

1.2V

2, If it is difficult to meet the above conditions, execute the following sequence after Power-On.

(1) CSB=”L”→”H” condition

(2) After CSB”H”→“L”, execute SWRST command.

In addition, in order to the SWRST command certainly, please wait 1ms after a VDD level reaches to 90% and

CSB=”L”→”H”.

*Before SWRST command, input device will be in unstable state, since SWRST command does not operate

perfect substitution of a POR function.

VDD

CSB

Min 1ms

Min 50ns

SWRST

Command

Figure 18. SWRST Command Sequence

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

23/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 24

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

Datasheet

●Power ON / OFF sequence

Display ON/OFF control by INHb terminal is not asynchronous with frame cycle.

In order to prevent display flickering under the power on/off sequence, please send MODESET command (Display off) and

set INHb terminal ="L"

VLCD

VDD

INHb

Command

±0ns No Limit

MODE SET

Display off

Various setupSWRST

REGSET RAM WRITE

Blink RAM

WRITE

MODE SET

Display on

MODE SET

Display off

±0ns No Limit

Figure 19. Power On/Off Sequence

●Notes on pull down resistor usage

Satisfy the following sequence if input terminals are pulled down by external resistors (In case MPU output Hi-Z).

Date transaction period with MPU

CSB

SD

SCL

Input "L"

period

Input"Hi-Z"

period

Figure 20. Recommended sequence when input ports are pulled down

BU97930MUV adopts a 5V tolerant I/O for the digital input. This circuit includes a bus-hold function to keep

HIGH level. A pull down resistor of below 10KΩshall be connected to the input terminals for transitions

from HIGH to LOW because the bus-hold transistor turns on during the input’s HIGH level. (Refer to the

Figure 5; I/O Equivalent Circuit)

A higher resistor than 10KΩ(approximate) causes input terminals being steady by intermediate potential between HIGH

and LOW level so unexpected current is consumed by the system.

The potential depends on the pull down resistance and bus-hold transistor’s resistance.

As the bus-hold transistor turns off upon the input level is cleared to LOW, a higher resistor can be used as a pull down

resistor if MPU sets SD and SCL lines to LOW before it releases the lines.

The LOW period preceding MPU’s bus release shall be at least 50ns as same as a minimum CLK width ( tSLW ).

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

24/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 25

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Operational Notes

(1) Absolute maximum ratings

Operating the IC over the absolute maximum ratings may damage the IC. The damage can e ither be a short circuit

between pins or an open circuit between pins. Therefore, it is important to consider circuit protection measures, such as

adding a fuse, in case the IC is operated over the absolute maximum ratings.

(2) Recommended operating conditions

These conditions represent a range within which the expected char acteristics of the IC can be approximately o btained.

The electrical characteristics are guaranteed under the conditions of each parameter.

(3) Reverse connection of power supply

Connecting the po wer supply in reverse polarity can damage the IC. Take precautions against reverse polarity when

connecting the power supply, such as mounting an external diode between the power supply and the IC’s power supply

terminals

(4) Power supply lines

Design the PCB layout pattern to provide low impedance ground and supply lines. Separate the ground and supply lines

of the digital and analog blocks to prevent noise in the ground an d supply lines of the digital block from affecting the

analog block. Furthermore, connect a capacitor to ground at all power supply pins. Consider the effect of temperature

and aging on the capacitance value when using electrolytic capacitors.

(5) Ground Voltage

The voltage of the ground pin must be the lowest voltage of all pins of the IC at all operating conditions. Ensure that no

pins are at a voltage below the ground pin at any time, even during transient condition.

Datasheet

(6) Short between pins and mounting errors

Be careful when mounting the IC on printed circuit boards. The IC may be damaged if it is mounted in a wrong

orientation or if pins are shorted together. Short circuit may be caused by conductive particles caught between the pins.

(7) Operation under strong electromagnetic field

Operating the IC in the presence of a strong electromagnetic field may cause the IC to malfunction.

(8) Testing on application boards

When testing the IC on an application board, connecting a c apacitor directly to a low-impedance output p in may subject

the IC to stress. Always discharge capacitors completely after each process or step. The IC’s power supply should

always be turned off completely before connecting or removing it from the test setup during the inspection process. To

prevent damage from static discharge, ground the IC during assembly and use similar precautions during transport and

storage.

(9) Regarding input pins of the IC

In the construction of this IC, P-N junctions are inevitably formed creating parasitic diodes or transistors. The operation

of these parasitic elements can result in mutual interference among circuits, operational faults, or physical damage.

Therefore, conditions which cause these parasitic elements to operate, such as applying a voltage to an input pin lower

than the GND voltage should be avoided. Furthermore, do not apply a v oltage to the input terminals when no power

supply voltage is applied to the IC. Even if the power supply voltage is applied, make sure that the in put terminals have

voltages within the values specified in the electrical characteristics of this IC.

(10) GND wiring pattern

When using both small-signal and large-current GND traces , the two ground traces should be routed separately but

connected to a single ground at the reference point of the applic ation board to avoid fluctuations in the small-signal

ground caused by large currents. Also ensure that the GND traces of external compone nts do not cause variations on

the GND voltage. The power supply and ground lines must be as short and thick as possible to reduce line impedance.

(11) External Capacitor

When using a ceramic capacitor, determine the dielectric constant considering the change of capacitance with

temperature and the decrease in nominal capacitance due to DC bias and others.

(12) Unused input terminals

Input terminals of an IC are often connected to the gate of a CMOS transistor. The gate has extremely high impeda nce

and extremely low capacitance. If left unconnected, the electric field from the outside can easily charge it. The small

charge acquired in this way is enough to produce a signific ant effect on the conduction through the transistor an d cause

unexpected operation of IC. So unless otherwise specified, input terminals not bei ng used should be connected to the

power supply or ground line.

(13) Rush current

When power is first supplied to the IC, rush current may flow instantaneously. It is possible that the charge current to the

parasitic capacitance of internal photo diode or the internal logic may be unstable. Therefore, give special consideration

to power coupling capacitance, power wiring, width of GND wiring, and routing of connections.

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

25/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 26

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Ordering Information

B U 9 7 9 3 0 M U V - E 2

Part Number

●Marking Diagram

VQFN040V6060 (TOP VIEW)

BU97930

MUV :VQFN040V6060

Part Number Marking

LOT Number

1PIN MARK

Package

Packaging and forming specification

E2: Embossed tape and reel

VQFN040V6060)

(

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

26/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 27

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Physical Dimension, Tape and Reel Information

Package Name VQFN040V6060

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

27/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 28

Datasheet

BU97930MUV MAX 108 segments (SEG27×COM4)

●Revision History

Date Revision Changes

14.Mar.2012 001 New Release

Improved the statement in all pages.

8.Jan.2013 002

Deleted “Status of this document” in page 26.

Changed format of Physical Dimension, Tape and Reel Information.

Datasheet

www.rohm.com

© 2013 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

28/28

TSZ02201-0A0A2D300060-1-2

8.Jan.2013 Rev.002

Page 29

Datasheet

Datasheet

Notice

●General Precaution

1) Before you use our Products, you are requested to carefully read this document and fully understand its contents.

ROHM shall not be in any way responsible or liable for failure, malfunction or accident arising from the use of a ny

ROHM’s Products against warning, caution or note contained in this document.

2) All information contained in this document is current as of the issuing date and subject to change without any prior

notice. Before purchasing or using ROHM’s Products, please confirm the latest information with a ROHM sales

representative.

●Precaution on using ROHM Products

1) Our Products are designed and manufactured for applicat ion in ordinar y el ectronic eq uipments (such as AV equipment,

OA equipment, telecommunication equipment, home electronic appliances, amusement equipment, etc.). If you

intend to use our Products in devices requiring extremely high reliability (such as medical equipment, transport

equipment, traffic equipment, aircraft/spacecraft, nuclear power controllers, fuel controllers, car equipment including car

accessories, safety devices, etc.) and whose malfunction or failure may cause loss of human life, bodily injury or

serious damage to property (“Specific Applications”), please consult with the ROHM sales representative in advance.

Unless otherwise agreed in writing by ROHM in advance, ROHM shall not be in any way respons ible or liable for any

damages, expenses or losses incurred by you or third parties arising from the use of any ROHM’s Products for Specific

Applications.

2) ROHM designs and manufactures its Products subject to strict quality control system. However, semiconductor

products can fail or malfunction at a certain rate. Please be sure to implement, at your own responsibilities, adequate

safety measures including but not limited to fail-safe design against the physical injury, damage to any propert y, which

a failure or malfunction of our Products may cause. The following are examples of safety measures:

[a] Installation of protection circuits or other protective devices to improve system safety

[b] Installation of redundant circuits to reduce the impact of single or multiple circuit failure

3) Our Products are designed and manufactured for use under standard conditions and not under any special or

extraordinary environments or conditions, as exemplified below. Accordingly, ROHM shall not be in any way

responsible or liable for any damages, expenses or losses arising from the use of any ROHM’s Products under any

special or extraordinary environments or conditions. If you intend to use our Products under any special or

extraordinary environments or conditions (as exemplified below), your independent verification and confirmation of

product performance, reliability, etc, prior to use, must be necessary:

[a] Use of our Products in any types of liquid, including water, oils, chemicals, and organic solvents

[b] Use of our Products outdoors or in places where the Products are exposed to direct sunlight or dust

[c] Use of our Products in places where the Products are exposed to sea wind or corrosive gases, including Cl

H

2S, NH3, SO2, and NO2

[d] Use of our Products in places where the Products are exposed to static electricity or electromagnetic waves

[e] Use of our Products in proximity to heat-producing components, plastic cords, or other flammable items

[f] Sealing or coating our Products with resin or other coating materials

[g] Use of our Products without cleaning residue of flux (even if you use no-clean type fluxes, cleaning residue of

flux is recommended); or Washing our Products by using water or water-solub le cleaning agents for cleaning

residue after soldering

[h] Use of the Products in places subject to dew condensation

4) The Products are not subject to radiation-proof design.

5) Please verify and confirm characteristics of the final or mou nted pro ducts in using the Products.

6) In particular, if a transient load (a large amount of load applied in a short per iod of time, such as pulse) is applied,

confirmation of performance characteristics after on-board mounting is strongly recomm ended. Avoid applying power

exceeding normal rated power; exceeding the power ratin g under steady-state loading condition may negatively affect

product performance and reliability.

7) De-rate Power Dissipation (Pd) dependi ng on Ambient temp erature (T a). When used i n sealed area, co nfirm the actual

ambient temperature.

8) Confirm that operati on temperature is within the specified range described in the product specification.

9) ROHM shall not be in any way responsible or liable for failure induced under deviant condition from what is defined in

this document.

2,

Notice - Rev.004

© 2013 ROHM Co., Ltd. All rights reserved.

Page 30

Datasheet

●Precaution for Mounting / Circuit board design

1) When a highly active halogenous (chlorine, bromine, etc.) flux is used, the residue of flux may negatively affect prod uct

performance and reliability.

2) In principle, the reflow soldering method must be used; if flow soldering method is pref erred, please consult with the

ROHM representative in advance.

For details, please refer to ROHM Mounting specification

●Precautions Regarding Application Examples and External Circuits

1) If change is made to th e constant of an external circuit, please allow a sufficient margin considering variatio ns of the

characteristics of the Products and external components, including transient characteristics, as well as static

characteristics.

2) You agr ee that application notes, reference designs, and associated data and in formation contained in this document

are presented only as guidance for Products use. Therefore, in case you use such information, you are solely

responsible for it and you must exercise your own independent verification and judgmen t in the use of such information

contained in this document. ROHM shall not be in any way responsible or liable for any damages, expenses or losses

incurred by you or third parties arising from the use of such information.

●Precaution for Electrostatic

This Product is electrostatic sensitive product, which may be damaged due to electrostatic discharge. Please take proper

caution in your manufacturing process and storage so that voltage exceeding the Products maximum rating will not be

applied to Products. Please take special care under dr y condition (e.g. Gro unding of human bod y / equipment / solder iron,

isolation from charged objects, setting of Ionizer, friction prevention and temperature / humidity control).

●Precaution for Storage / Transportation

1) Product performance and soldered connections may deteriorate if the Products are stored in the places where:

[a] the Products are exposed to sea winds or corrosive gases, including Cl2, H2S, NH3, SO2, and NO2

[b] the temperature or humidity exceeds those recommended by ROHM

[c] the Products are exposed to di rect sunshine or condensation

[d] the Products are exposed to high Electrostatic

2) Even under ROHM recommended storage condition, solderability of products out of recommended storage time perio d

may be degraded. It is strongly recommended to confirm solderabilit y before using Products of which storage time is

exceeding the recommended storage time period.

3) Store / transport cartons in the correct direction, which is indicated on a carton with a symbol. Otherwise bent leads

may occur due to excessive stress applied when dropping of a carton.

4) Use Products within the specified time after opening a humidity barrier bag. Baking is required before using Products of

which storage time is exceeding the recommended storage time period.

●Precaution for Product Label

QR code printed on ROHM Products label is for ROHM’s internal use only.

●Precaution for Disposition

When disposing Products please dispose them properly using an authorized industry waste company.

●Precaution for Foreign Exchange and Foreign Trade act

Since our Products might fall under controlled goods prescribed by the applicable foreign exchange and foreign trade act,

please consult with ROHM representative in case of export.

●Precaution Regarding Intellectual Property Rights

1) All information and data including but not limited to application example contain ed in this document is for reference

only. ROHM does not warrant that foregoing information or data will not infringe an y intellectual property rights or any

other rights of any third party regarding such information or data. ROHM shall not be in any way responsible or liable

for infringement of any intellectual property rights or other damages arising from use of such information or data.:

No license, expressly or implied, is granted hereby under any intellectual property rights or other rights of ROHM or any

2)

third parties with respect to the information contained in this document.

Datasheet

Notice - Rev.004

© 2013 ROHM Co., Ltd. All rights reserved.

Page 31

Datasheet

●Other Precaution

1) The information contained in this document is provided on an “as is” basis and ROHM does not warrant that all

information contained in this document is accurate and/or error-free. ROHM shall not be in any way responsible or

liable for any damages, expenses or losses incurred by you or third parties resulting from inaccuracy or errors of or

concerning such information.

2) This document may not be reprinted or reproduced, in whole or in part, without prior written consent of ROHM.

3) The Products may not be disassembled, converted, modified, reproduced or otherwise changed without prior written

consent of ROHM.

4) In no event shall you use in any way whatsoever the Products and the related technical information contained in the

Products or this document for any military purposes, including but not limited to, the development of mass-destruction

weapons.

5) The proper names of companies or products described in this document are trademarks or registered t rademarks of

ROHM, its affiliated companies or third parties.

Datasheet

Notice - Rev.004

© 2013 ROHM Co., Ltd. All rights reserved.

Loading...

Loading...