A

Audio Accessory ICs for Mobile Devices

Mixer & Selector ICs

with 16bit D/A Converter

BU7858KN,BU7893GU

●Description

This LSI is mounted with stereo 16bit D/A Converter and suitable for higher sound quality and miniaturization of cellular

phone with music play. BU7893GU has a 3D surround enhancement function and hence can play the wide-spreading

stereo sound from stereo speakers that are arranged nearby.

●Features

1) Mounted with Stereo 16bit audio D/A converter

2) Compatible with Stereo analogue interface

3) Stereo headphone amplifier (16Ω)

4) Low-band corrective circuit in headphone amplifier

5) Volume that can adjust the gain

6) Flexible mixing function

●Applications

Portable information & communication equipments such as cellular phone and PDA (Personal Digital Assistant) etc.

Cellular phone with music play

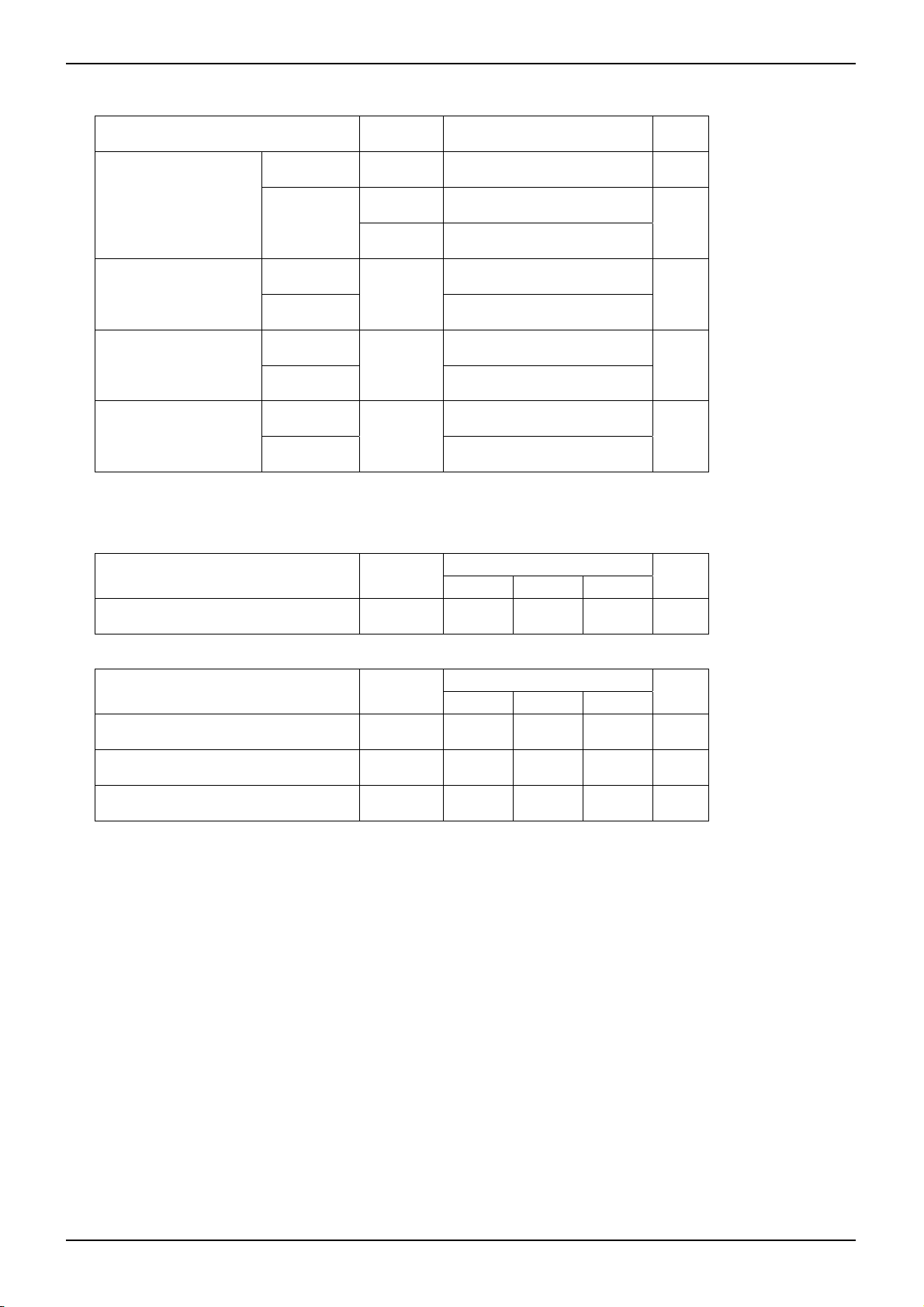

●Line up matrix

Function BU7858KN BU7893GU

No.10087EAT03

Stereo audio D/A converter 16bit 16bit

16bit Right justified

Stereo audio interface format

3D surround enhancement function No Yes

3 band equalizer No Yes

Stereo headphone amplifier 16Ω driver 16Ω driver

Line output (600Ω driver) Yes No

Headphone amplifier low-band correction function Built-in Built-in

Click noise reduction function

Package VQFN28 VCSP85H3

18bit Right justified

IIS

Yes

(headphone only)

16bit Left justified

16bit Right justified

IIS

Yes

www.rohm.com

1/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

●Absolute maximum ratings

Parameter Symbol Ratings Unit

Technical Note

BU7858KN VDD -0.3 ~ 4.5 V

Power-Supply Voltage

BU7893GU

DVDDIO

AVD D

-0.3 ~ 4.5

DVDDCO -0.3 ~ 2.5

*1

580

*2

Power Dissipation

Operating Temperature

BU7858KN

Pd

BU7893GU 700

BU7858KN

T

OPR

-20 ~ +85

BU7893GU -30 ~ +85

Storage Temperature

BU7858KN

T

STG

-55 ~ +125

BU7893GU -50 ~ +125

*1 : 5.8mW is decreased every 1℃ when using it over 25℃. (Mounted on the ROHM standard PCB )

*2: 7.0mW is decreased every 1℃ when using it over 25℃.

●Operating conditions

【BU7858KN】

Parameter Symbol

Min. Typ. Max.

Ratings

Power-Supply Voltage VDD 2.7 3.0 3.3 V

【BU7893GU】

Parameter Symbol

Min. Typ. Max.

Ratings

V

mW

℃

℃

Unit

Unit

Analog Power-Supply Voltage AVDD 2.6 2.8 3.3 V

Digital I/O Power-Supply Voltage DVDDIO DVDDCO 1.8 3.3 V

Digital Core Power-Supply Voltage DVDDCO 1.62 1.8 1.98 V

www.rohm.com

2/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

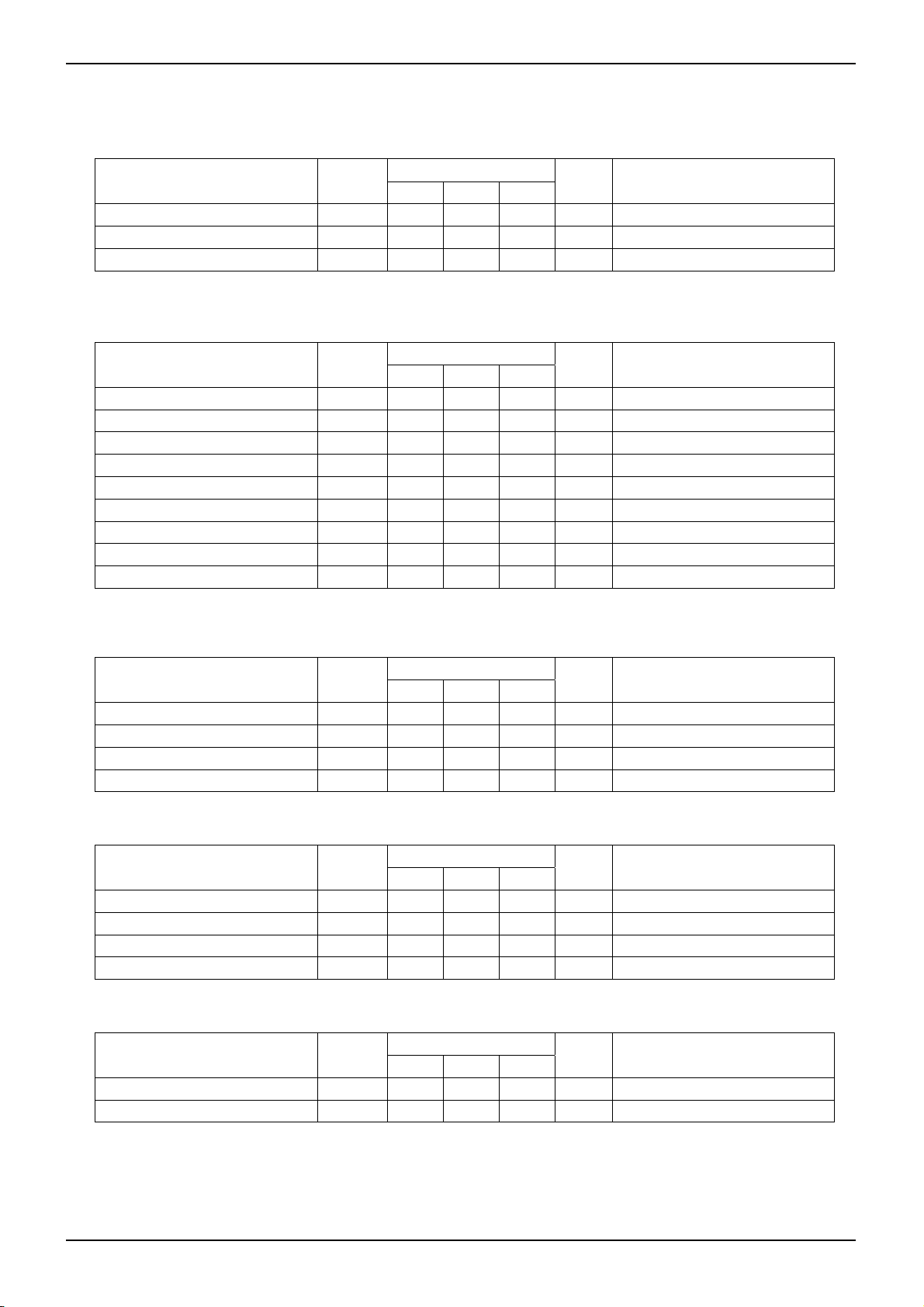

●Electrical characteristics

【BU7858KN】

Unless otherwise specified, Ta=25℃, AVDD=DVDD=3.0V

・Analog

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

Current Consumption Idd3 - 2.3 3.7 mA 16Ω driver part and no signal

Technical Note

DAC S/(N+D) SN+D - 85 - dB

DAC S/N SNR - 92 - dB

Headphone Amplifier

Total Harmonic Distortion

Headphone Amplifier

Maximum Output

Headphone Amplifier

Output Noise Voltage

THDhp - 0.05 0.5 %

PO - 10 - mW fin=1kHz, THD=10%, RL=16Ω

VNO - -94 -80 dBV A-weighted

SPO Maximum Output Level VOMAX1 2.0 - - V

EXTO Maximum Output Level VOMAX2 2.0 - - V

fs=44.1kHz, fin=1kHz, 20kHz

LPF, Vin=-0.5dBFS

fs=44.1kHz, fin=1kHz

, A-weighted, Vin=0dBFS

fin=1kHz, 20kHz LPF,

Vin=-10dBV

fin=1kHz, THD≦1%, 10kΩLoad

P-P

fin=1kHz, THD≦1%, 600ΩLoad

P-P

・Digital (DC)

Parameter Symbol

Min. Typ. Max.

Digital Input Voltage “L” VIL - -

Digital Input Voltage “H” VIH

0.8 x

DVDD

Limits

0.2 x

DVDD

Unit Conditions

V

- - V

Digital Output Voltage “L” VOL - - 0.5 V Iol=-500µA

Digital Output Voltage “H” VOH

DVDD

-0.5

- - V Ioh=500µA

Input Leakage Current 1 IIN1 - - ±2 µA at 0V, 3V

・Audio Interface

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

MCLKI Frequency fMCLK 4.096 - 18.432 MHz

MCLKI Duty Ratio dMCLK 45 - 55 %

LRCLK Frequency fs 16 - 48 kHz

LRCLK Duty Ratio dLR 45 - 55 %

BCLK Frequency fBCK 0.512 - 3.072 MHz

BCLK Duty Ratio dBCK 45 - 55 %

LRCLK edge to BCLK↑ Time tLRS 50 - - ns

BCLK↑ to LRCLK Edge Time tSLR 50 - - ns

Data Hold Time tSDH 50 - - ns

Data Set-up Time tSDS 50 - - ns

www.rohm.com

3/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

Technical Note

【BU7893GU】

・Whole Block

Unless otherwise specified, Ta=25℃, DVDD_CORE=1.8V, DVDD_IO=1.8V, AVDD=2.8V, Digital input terminal is fixed

with DVDD_IO “L” or “H” level, The gain settings of the audio paths are all 0dB, and no signal

Parameter Symbol

DVDD_CORE Stand-by Current

(Core logic block)

Min. Typ. Max.

ISTCO - - 10 µA standby,CLKI = DVSS

Limits

Unit Conditions

DVDD_IO Stand-by Current ISTIO - - 5 µA standby,CLKI = DVSS

AVDD Stand-by Current ISTA - - 5 µA standby

DVDD_CORE Operation Current IDDCO - 5 10 mA

DVDD_IO Operation Current IDDIO - 0.1 1 mA

AVDD Operation Current 1

(Analog melody)

AVDD Operation Current 2

(Digital melody)

IDDA1 - 1.6 2.8 mA

IDDA2 - 6.0 10.0 mA

BCLK,LRCLK = Input mode

MCLK = L output

ANAINL→MIX1→SPOL

ANAINR→MIX2→SPOR

SDI→MIX1→SPOL

SDI→MIX2→SPOR

TCXOI = 19.8MHz,fs = 44.1kHz

・DC Characteristic

Parameter Symbol Terminal

L Output Voltage

H Output Voltage

L Level Input Voltage1

L Level Input Voltage 2 CLKI

H Level Input Voltage 1

H Level Input Voltage 2 CLKI

L Level Input Current

H Level Input Current 1

H Level Input Current 2 CLKI

Output OFF Current

※1 : They also contain interactive terminals that are set output state.

※2 : They also contain interactive terminals that are set input state.

※3 : Please connect 100pF coupling capacitor and input 0.5V

(In address 15h CLKSEL1=0, CLKSEL0=1)

※4 : At interactive terminals of input state or three-state terminals of output-disable state

All output

terminal

All output

terminal

All input

terminal

All input

terminal

All input

terminal

All input

terminal

Hi-Z

terminal

※

※

※

3

※

Vild2 -0.3

※

3

※

Vihd2

※

※

3

※

Iihd2 -1 1 µA

※

Vold 0 0.30 V Iol=+0.8mA

1

Vohd

1

Vild1 -0.3 DVSS+0.5 V

2

Vihd1

2

Iild -1 1 µA

2

Iihd1 -1 1 µA

2

Iozd -10 10 µA

4

DVDD_IO

-0.30

DVDD_IO

or more when you input through coupling capacitor.

P-P

Limits

Min. Max.

Unit Conditions

DVDD_IO V Ioh=-0.8mA

3

-0.5

3

※

※

DVDD_IO

+0.3

DVDD_CORE

+0.3

V

V

V

Input terminal voltage is

DVSS

Input terminal voltage is

DVDD_IO

Input terminal voltage is

DVDD_CORE

・Audio Path(MIX)

Unless otherwise specified, Ta=25℃, AVDD=2.8V, reference input level=-6dBV, f=1kHz, A-weighted, path gain =0dB

Limits

Parameter Symbol

Unit Conditions

Min. Typ. Max.

ANAL_V Volume Setting G

ANAR_V Volume Setting G

-11 - +3 dB 1dB step

DACL

-11 - +3 dB 1dB step

DACR

www.rohm.com

4/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

Technical Note

・Audio Path (SP PREamp)

Unless otherwise specified,Ta=25℃,AVDD=2.8V, Reference input level =-6dBV, f=1kHz,

A-weighted, path gain =0dB, RL=33kΩ

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

THD+N THDSP - -70 -60 dB 20kHz LPF

Output Noise Voltage V

- -90 -80 dBV At no a signal

NOSP

Mute Level MLSP - -90 -80 dB 1kHz BPF

・Audio Path (HP amp)

Unless otherwise specified, Ta=25℃, AVDD=2.8V, reference input level =-6dBV, f=1kHz,

A-weighted, path gain =0dB, RL=16Ω

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

THD+N THDHP - -65 -55 dB 20kHz LPF

Output Noise Voltage V

The Maximum Output Power P

- -90 -80 dBV At no signal

NOHP

10 - - mW THD=10%,16Ω load

OHP

Channel Separation CSHP - -80 -70 dB Vo=-14dBV,1kHz BPF

Mute Level MLHP - -90 -80 dB 1kHz BPF

HPL_V Volume Setting 1 GA1

HPL_V Volume Setting 2 GA2

HPR_V Volume Setting 1 GA1

HPR_V Volume Setting 2 GA2

-48 - 0 dB 2dB step

HPL

-42 - +6 dB 2dB step

HPL

-48 - 0 dB 2dB step

HPR

-42 - +6 dB 2dB step

HPR

・3D Surround, Equalizer, and Audio DAC

Unless otherwise specified, Ta=25℃, AVDD=2.8V, BCLK=64fs, LRCLK=256fs, f=1kHz, path gain=0dB,

SPOL/SPOR output, SPOL/SPOR= no load, output=0dBFS

Parameter Symbol

Min. Typ. Max.

Full-scale Amplitude VMAX 1.40 1.68 2.00 V

S/N1 (A-Weighted) DAC

70 75 - dB

sn1

Limits

Unit Conditions

0.6×AVDD

P-P

THD+N1 (20kHz LPF) DACthd1 - -70 -60 dB fs=8,11.025kHz

THD+N2 (20kHz LPF) DACthd2 - -75 -65 dB fs=16,22.05,32,44.1,48kHz

・Audio I/F Format

Unless otherwise specified, Ta=25℃, DVDD_IO=1.62~3.3V, DVDD_CORE=1.62~1.98V

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

BCLK Output Frequency FBCKO 0.512 - 3.072 MHz 64fs

LRCLK Output Frequency FLRCKO 8 - 48 kHz

SDI Set-up Time tSDSU 100 - - nsec

SDI Hold Time tSDH 100 - - nsec

・PLL

Unless otherwise specified, Ta=25℃, AVDD=2.8V, BCLK = no load

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

PLL Lock-up Time Tlock1 - - 10 msec

PLL Jitter Tjitter1 - 200 - psec BCLK terminal,f

=65.536MHz

VCO

www.rohm.com

5/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

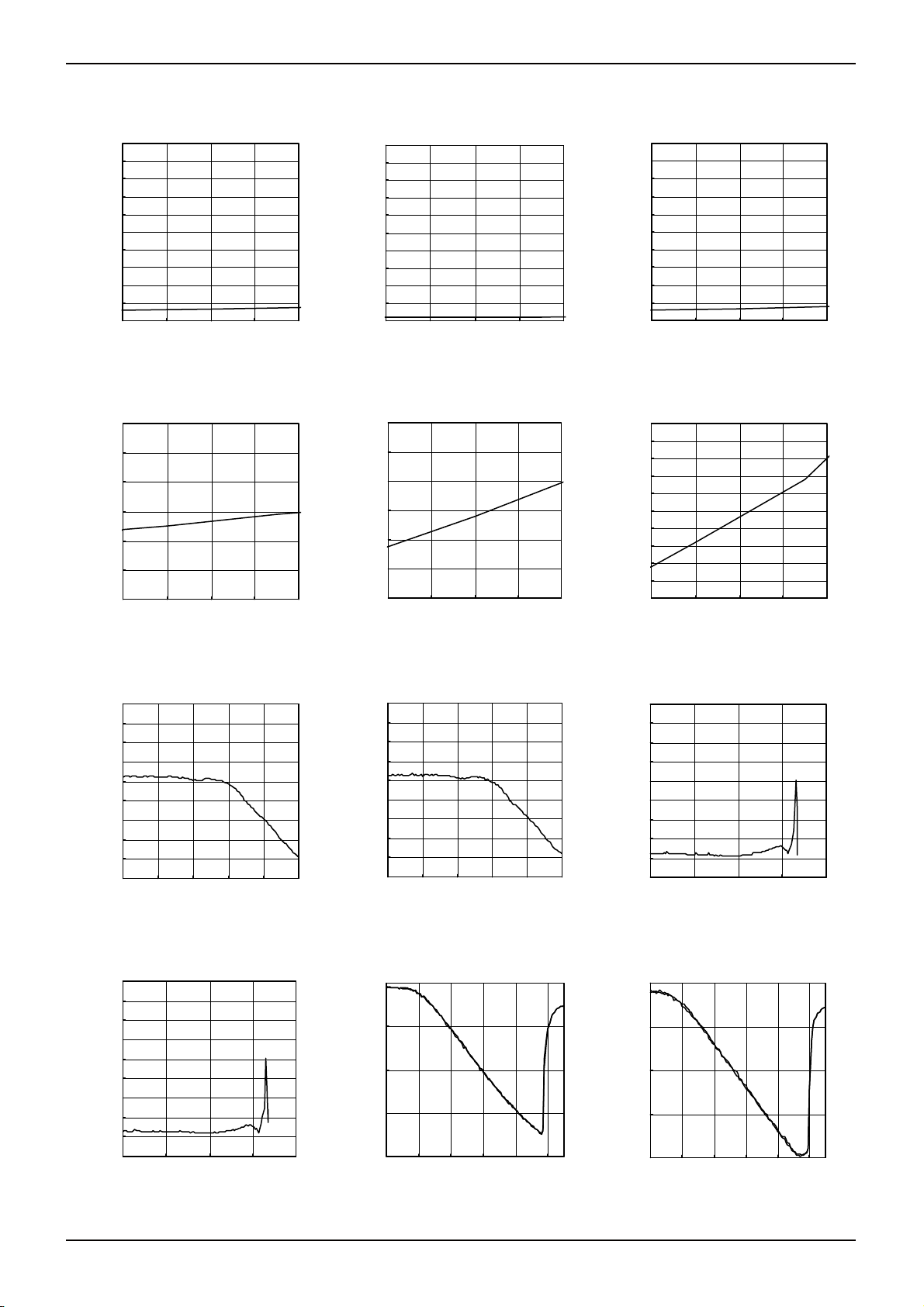

●Reference Data

【BU7858KN】

10.0

A)

μ

8.0

6.0

4.0

2.0

STAND BY CURRENT : ICC (

0.0

2.0 2.5 3.0 3.5 4.0 4.5

SUPLLY VOLTAGE : VD D( V)

Fig.1 Stand-by Current

-30

-40

-50

-60

-70

-80

THD+N ( dB)

-90

-100

-110

-120

-110 - 90 -70 - 50 -30 - 10

IN PUT LEVEL : VIN (dB FS)

Fig.4 16bit D/A Converter Total

Harmonic Distortion (Lch)

-30

-40

-50

-60

-70

-80

THD+N (dB)

-90

-100

-110

-120

10 100 1000 10000 100000

INPUT SIGNAL Fr eq : F IN( Hz)

Fig.7 16

bit D/A Converter

Total Harmonic Distortion (Rch)

100.00

10.00

1.00

THD+N (%)

0.10

0.01

-100 - 80 - 60 -40 - 20 0

INPU T LEVEL : VIN(dBV)

Fig.10 SPO

Total Harmonic Distortion

14.0

12.0

10.0

8.0

6.0

4.0

2.0

CIRCUIT CURRENT : ICC (mA)

0.0

2.0 2.5 3.0 3.5 4.0 4.5

SUPLLY VOLTAGE : VD D( V)

Fig.2 16bit D/A Converter

Operation Current

-30

-40

-50

-60

-70

-80

THD+N (dB)

-90

-100

-110

-120

-110 - 90 -70 - 50 - 30 - 10

INPU T LEVEL : VIN( dBFS)

Fig.5 16bit D/A Converter

Total Harmonic Distortion (Rch)

100.00

10.00

1.00

THD+N (%)

0.10

0.01

-100 - 80 -60 -40 - 20 0

IN PUT LEVEL : VIN (dBV)

Fig.8 Headphone Amplifier

Total Harmonic Distortion (HP_L)

100.00

10.00

1.00

THD+N (%)

0.10

0.01

-100 - 80 -60 - 40 -20 0

INPUT LEVEL : VIN (dB V)

Fig.11 EXTO

Total Harmonic Distortion

Technical Note

6.0

5.0

4.0

3.0

2.0

1.0

CIRCUIT CURRENT : ICC (mA)

0.0

2.0 2.5 3.0 3.5 4.0 4.5

SUPLLY VOLTAGE : VD D( V)

Fig.3 Headphone Amplifier

Operation Current

-3 0

-4 0

-5 0

-6 0

-7 0

-8 0

THD+N (dB)

-9 0

-100

-110

-120

10 100 1000 10000 100000

INPUT SIGNAL Freq : FIN(Hz)

Fig.6 16bit D/A Converter

Total Harmonic Distortion (Lch)

100.00

10.00

1.00

THD+N (%)

0.10

0.01

-100 - 80 -60 -40 - 20 0

INPUT LEVEL : VIN (dB V)

Fig.9 Headphone Amplifier

Total Harmonic Distortion (HP_R)

www.rohm.com

6/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

Technical Note

【BU7893GU】

5.0

4.5

A)

μ

4.0

3.5

3.0

2.5

2.0

1.5

1.0

STAND BY CURRENT : ICC (

0.5

0.0

1.6 1. 7 1.8 1.9 2.0

SUPLLY VOLTAGE : D VDD _COR E(V)

Fig.12 DVDD_CORE

Standby Current

5.0

4.5

A)

μ

4.0

3.5

3.0

2.5

2.0

1.5

1.0

STAND BY CURRENT : ICC (

0.5

0.0

2.6 2.8 3.0 3. 2 3.4

SUPLLY VOLT AGE : AVDD( V)

Fig.13 AVDD

Standby Current

5.0

4.5

A)

μ

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

CIRCUIT BY CURRENT : ICC (

0.0

1.6 1.7 1.8 1.9 2.0

SUPLLY VOLTAGE : DVDD_CORE(V)

Fig.14 DVDD_CORE

Operation Current (Analog melody)

2.0

1.9

1.8

1.7

1.6

1.5

CIRCUIT CURRENT : ICC (mA)

1.4

2.6 2. 8 3.0 3.2 3.4

SUPLLY VOLTAGE : AVDD (V)

Fig.15 AVDD

Operation Current (Analog melody)

5.0

4.5

4.0

3.5

3.0

2.5

CIRCUIT CURRENT : ICC (mA)

2.0

1.6 1.7 1.8 1.9 2.0

SUPLLY VOLT AGE : DVDD _CORE( V)

Fig.16 DVDD_CORE

Operation Current (digital melody)

4.0

3.9

3.8

3.7

3.6

3.5

3.4

3.3

3.2

CIRCUIT CURRENT : ICC (mA)

3.1

3.0

2.6 2. 8 3.0 3.2 3.4

SUPLLY VOLT AGE : AVDD( V)

Fig.17 AVDD

Operation Current (digital melody)

0.0

-10. 0

-20. 0

-30. 0

(dB)

-40. 0

-50. 0

THD+N

-60. 0

-70. 0

-80. 0

-90. 0

-100 - 80 -60 - 40 -20 0

INPU T LEVEL (dBF S)

Fig.18 16bit D/A Converter

Total Harmonic Distortion 1kHz (SPOL)

0.0

-10. 0

-20. 0

-30. 0

(dB)

-40. 0

-50. 0

THD+N

-60. 0

-70. 0

-80. 0

-90. 0

10 100 1000 10000 100000

INPUT SIGNAL FREQUENCY (Hz)

Fig.21 16bit D/A Converter

Total Harmonic Distortion (SPOR)

www.rohm.com

7/24

© 2010 ROHM Co., Ltd. All rights reserved.

0.0

-10.0

-20.0

-30.0

(dB)

-40.0

-50.0

THD+N

-60.0

-70.0

-80.0

-90.0

-100 - 80 - 60 -40 -20 0

INPU T LEVEL (dBFS)

ig.19 16bit D/A Converter

F

Total Harmonic Distortion 1kHz (SPOR)

100.00

10.00

(%)

1.00

THD+N

0.10

0.01

-100. 0 -80. 0 - 60.0 - 40.0 - 20.0 0.0

INPU T LEVEL (dBV)

Fig.22 Headphone Amplifier

Total Harmonic Distortion (HPOL / HPOR)

0.0

-10. 0

-20. 0

-30. 0

(dB)

-40. 0

-50. 0

THD+N

-60. 0

-70. 0

-80. 0

-90. 0

10 100 1000 10000 100000

INPU T SIGNA L FR EQU ENC Y (Hz )

Fig.20 16bit D/A Converter

Total Harmonic Distortion (SPOL)

100.0

10.0

(%)

1.0

THD+N

0.1

0.0

-100 - 80 -60 - 40 - 20 0

INPU T LEVEL (dBV)

Fig.23 Speaker Preamp

Total Harmonic Distortion (SPOL / SPOR)

2010.09 - Rev.

A

BU7858KN,BU7893GU

●Block diagram and pin assignment

【BU7858KN】

PLLC

MCLKO

PLL

RXI

RING

BCLK

MCLKI

BCLK

LRCLK

SDTI

MEL_R

MEL_L

EXTI

Digital

Audio

I/F

MEL_L

22

MEL_R

23

RING

24

RXI

25

PLLC

26

MCLKO

27

MCLKI

28

AVSSAVDDDVSSDVDD

MIX-

SEL1

SW1

+

ATT1

Digit

al

ATT

CVCOM

SW2

BIAS

16bit

DAC

16bit

DAC

LPF

LPF

ATT

ATT

NRST

Serial Control

SCLK

SDATA SCS

MIX-

SEL2

MIXSEL3

MIXSEL4

Fig.24 BU7858KN Block Diagram

21

EXTI

1

SDTI

SPO

20

2

LRCLK

19

EXTO

3

BCLK

AVDD

18

4

AVSS

HP_L

16

17

5

6

SCLK

DVSS

DVDD

Fig.25 BU7858KN Pin Assignment (TOP VIEW)

15

CA_L

7

ATT2

ATT3

ATT4

ATT5

SDATA

CSTEP

14

13

12

11

10

9

8

CSTART

CA_R

HP_R

CVCOM

CSTART

CSTEP

NRST

NCS

Technical Note

+

+

+

-

+

-

600Ω

16Ω

16Ω

SPO

EXTO

HP_R

CA_R

HP_L

CA_L

SP Amp

www.rohm.com

8/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

【BU7893GU】

0.1μF

CSTEP

Stereo Analog Interface

(From Melody LSI)

ANAINL

ANAINR

19.2MHz/

19.68MHz/

19.8MHz

CLKI

PLLC

Stereo PCM Interface

(MP3,AAC,etc)

MCLK

LRCLK

BCLK

SDI

1 2 3 4 5 6

1μF

PLL

DAI

VOL

VOL

CPOP

CPOP

Sonaptic

Serial I/F

SCLK

RSTB

Equalizer

3D

SIO

SO

SPI

DAC

DAC

CSB

-6dB

-6dB

-6dB

-6dB

COMOUT

VREF

+

+

Fig.26 BU7893GU Block diagram

1μF 1μF

COMIN

RX

EXT

DACL

DACR

RX

EXT

DACL

DACR

RX

EXT

DACL

DACR

RX

EXT

DACL

DACR

DVSS

DVDD_IO

DVDD_CORE

VOL

VOL

AVSS AVDD

Technical Note

CCL

HPOL

HPOR

CCR

SPOL

SP Amp

SPOR

SP Amp

6800p

6800p

8Ω

8Ω

100μ

+

100μ

+

16Ω

16Ω

A TEST3 HPOR HPOL CPOP SPOL TEST4

B CCR RSTB DVSS CCL SPOR COMIN

C SCLK SO

D SIO MCLK

CSTEP AVSS

COMOUT ANAINR

E CSB PLLC AVDD DVDD_CORE SDI ANAINL

F TEST2 CLKI DVDD_IO BCLK LRCLK TEST1

( TOP VIEW )

Fig.27 BU7893GU Ball Assignment

www.rohm.com

9/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

Technical Note

●Digital interface of 16 bit audio D/A converter

16bit audio D/A converter equipped with this series can be used with the following audio format.

【BU7858KN】

1) MSB first 16bit data (Right justified)

LRCLK(fs)

Lch

Rch

BCLK(64fs)

SDTI

0 1 2 15 14 13 12 11 4 3 2 0 1 Don’t Care Don’t Care

15

14

11 12 13

4

0 1 2 3

15:MSB, 0:LSB

2) MSB first 18bit data (Right justified)

LRCLK(fs)

Lch

Rch

BCLK(64fs)

17

SDTI

0 1 2 17 16 15 14 11 4 3 2 0 1 Don’t Care Don’t Care

16

11 14 15

4

0 1 2 3

17:MSB, 0:LSB

3) IIS mode 18bit data (Left justified)

LRCK(fs)

Lch

Rch

BCLK(64fs)

SDTI

Care

17 16 Don’t

4

2

3

Don’t Care

0 1

17

16

17:MSB, 0:LSB

4

3

0

2

1

Don’t Care

17 16

4) IIS mode 16bit data (BCLK=32fs)

LRCLK(fs)

Lch

Rch

BCLK(32fs)

15

14

12

13

SDTI

2

11

15:MSB, 0:LSB

0 1 2 3 6 7 8 9 10 0 1

0

2 3 6 7 8 9 10 15 14 13 12 11

15

1

14 13

Fig.28 AUDIO I/F FORMAT (BU7858KN)

BU7858KN is provided with a mode that generates MCLK (Master Clock) by using the built-in PLL, so it is possible to make

a D/A converter operate even if the clocks are only BCLK (64fs/32fs), LRCLK (fs).

The PLL generates MCLK (Master Clock), which is necessary for driving of D/A converter, from BCLK (Bit Clock).

Please connect a capacitor (PLLC) for the filter with DVSS. Moreover, please place the capacitor nearest DVSS of IC in

order to reduce the noise interference.

Then it is possible to monitor the master clock that is generated internally from MCLKO, which is after all the monitor

terminal, and hence does not guarantee drivability and phase-margin.

Please tie the MCLKI terminal to DVSS when PLL is used. And please tie the PLLC terminal to DVSS when PLL is not used.

Moreover, it is not necessary to set the “PLLPDN” and “SMPR” when PLL is not used.

www.rohm.com

10/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

【BU7893GU】

1. MSB first left justified format

Technical Note

LRCLK

BCLK

SDI

0 1 2 3 13 14 15 16 17 18 29 30 31 123 13

15 14 13 2 1 0 15 14 13 2 1 0

Don't care

Don't care Don't care Don't care

0

RchLch

14 15 16 17 18 29 30 31

0

15

2. MSB first right justified format

SDI

Don't care Don't careDon't care

15 14 13 2 1 0 2 1 015 14 13

Don't

care

3. IIS format

LRCLK

BCLK

SDI

0 1 2 3 4 141516171819 30 31 1 2 3 141516171819 30310 0

Don't

15 14 13 2 1 0

care

Don't care

Don't care Don't care

15 14 13 2 1 0

4

RchLch

Don't care

Fig.29 AUDIO I/F Format (BU7893GU)

●3D Surround enhancement function

【BU7893GU】

Even under the circumstances of adjacent arrangement of stereo speakers, the wide-spreading acoustic effect can be

achieved because of the output resulting from the digital audio input to which the 3D surround effect has been applied.

Moreover, the stereo sound at the time of audio recording can also be played truly. Please tell us about the parameter

setting when you use this function.

●Low-band corrective circuit

In the headphone output terminals (HP_L, HP_R or HPOL, HPOR), there is a low-band corrective circuit, which corrects the

low-band attenuation.

100kΩ

200kΩ

200kΩ

-

+

CHPx

C

HP_X

HPOX

CA_X

or

CCX

CL

+

or

OUTPUT

RL

Fig.30 BU7858KN & BU7893GU Headphone Output Equivalent Circuit

Low-band cut-off frequency fC= 1/(2・π・CL・RL)

Low-band boost frequency fBOOST = 1/(2・π・CCHPx・200kΩ)

Boost gain ABOOST = 20・log((200 kΩ+1/(2・π・f・CCHPx))/100 kΩ)

(the maximum low-band boost is 6dB)

For parameter setting, determine the output coupling capacitance CL and the headphone impedance R

before calculating

L

the low-band cut-off frequency fC. Then determine CCHPx so that the low-band cut-off frequency fC is roughly in

agreement with the low-band boost frequency fBOOST.

The recommended parameter setting of BU7858KN and BU7893GU is CCHPx = 6800pF at the time of CL = 100µF and

RL = 16Ω.

www.rohm.com

11/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

A

A

Technical Note

The frequency characteristic (theorical value) when the recommended constants are used is shown below.

10

5

0

-5

-10

-15

Gai n [ dB]

-20

-25

-30

-35

-40

1 10 100 1000 10000 100000

mplifier output

fter correction

Before correction

Fre quen cy [Hz]

Fig.31 Low-band corrective circuit Frequency characteristic

●CPU Interface

BU7858KN and BU7893GU can be controlled by using CPU interface.

【BU7858KN】

NCS

SCLK

SDATA

tcs

tds

A7

A6

tdh

A5

A4

tcyc

A3

A2

A1

A0

D7

D6 D5

D4 D3

D2 D1

tch

D0

Fig.32 CPU I/F Timing Chart 1 (BU7858KN)

After the falling edge of NCS, SDATA inputs are settled by 16 clock of SCLK, and data is written in the rising edge of NCS.

The data format is “16bit right justified”.

CPU interface is that 1Byte=16bit. It is absolutely necessary to insert the interval of NCS=”H” between first Byte and

Second Byte because it is not compatible with continuous data transmission. For the following th, please wait the time more

than 1 SCLK Clock. (th≧tcyc)

NCS

th

SCLK

SDATA

Fig.33 CPU I/F Timing Chart 2 (BU7858KN)

・AC Characteristics

Ta =2 5℃, AVDD=DVDD=3.0V

Parameter Symbol

SCLK Width

SDATA Input Hold Time

SDATA Input Set-up Time

NCS Set-up Time

NCS Hold Time

*It is recommended to use exclusive lines for CPU interface.

tcyc 250 - - ns

tdh 50 - - ns

tds 50 - - ns

tcs 50 - - ns

tch 50 - - ns

Min. Typ. Max.

Limits

Unit Conditions

www.rohm.com

12/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

A

A

A

A

T

A

A

A

A

A

A

A

A

A

A

【BU7893GU】

・Timing Chart

SCLK

Ts c

SIO

SEL

D[6]

Tscss

・Write Operation

SCLK

hc

D[5]

When direction is "1": Write operation

When direction is "0": Read operation

D[4]

D[0] Direction DT[7] DT[6]

Technical Note

DT[1]

DT[0]

SIO

SEL

D[6]

D[5]

D[4]

D[0]

Direction”H”

DT[7]

DT[6]

・Read Operation (mode 1): SO_ENABLE (bit0 at register address 14h)=0

SCLK

Ts d

SIO

SEL

D[6]

D[5]

D[4]

D[0]

Direction”L”

Hi-Z

DT[7]

・Read Operation (mode 2): SO_ENABLE (bit0 at register address 14h)=1

SCLK

Ts d

SIO

SO

Hi-Z

D[6]

D[5] AD[4] AD[0]

Direction”L”

DT[7] DT[6]

DT[1]

DT[6] DT[1]

Output data

DT[5]

DT[0]

DT[0]

DT[0] DT[1]

Hi-Z

SEL

Output data

Fig.34 CPU I/F Timing Chart (BU7893GU)

DVDD_IO=1.62~3.3V, Ta=-30~+85℃

Parameter Symbol

Min Typ Max

Limits

Unit Conditions

Bit Length Ncha 16 - - bit MSB first

SCLK Input Frequency FSCLK - - 15 MHz

SCLK ‘L’ Pulse Width Tlsclk 25 - - ns

SCLK ‘H’ Pulse Width Thsclk 25 - - ns

SCLK-SEL Set-up Time Tscss 10 - - ns

Data Set-up Time Tsc 10 - - ns

Data Hold Time Thc 10 - - ns

Delay Time of Data Output Tsd - - 30 ns

*It is recommended to use exclusive lines for CPU interface.

www.rohm.com

13/24

© 2010 ROHM Co., Ltd. All rights reserved.

SIO: Time from SCLK falling edge

SO : Time from SCLK rising edge

2010.09 - Rev.

A

BU7858KN,BU7893GU

Technical Note

●I2C Interface

【BU7893GU】

In the BU7893GU, the LSI can be controlled by using I

The device’s address (slave address) is "1100011(63h)". It is based on the Philips I

2

C interface.

2

C-BUS V2.1’s fast-mode, the

maximum transfer rate of a bit is 400kbps.

A7 A6 A5 A4 A3 A2 A1 W/R

1 1 0 0 0 1 1 0/1

I2C Slave addresses

・Bit Transfer

A data is transferred during the HIGH period of the clock . The data on the SIO line must be stable during this period.

The HIGH or LOW state of the data line can only change when the clock signal on the SCLK line is LOW. When SCL is

H and SDA changes, the START conditions or the STOP condition is generated, and it is interpreted as the control signal.

SIO

SCLK

SIO is stable.

Valid Data

SIO is possible

to change

・START & STOP Conditions

When SIO and SCLK are “H”, there is no data transfer performed on the I

2

C bus. A HIGH to LOW transition on the SIO

line while SCLK is HIGH is one such unique case. This situation indicates a START condition (S).

A LOW to HIGH transition on the SIO line while SCLK is HIGH defines a STOP condition (P).

SIO

SCL

START conditions

S P

STOP conditions

The consecutive START and STOP conditions are acceptable.

・Acknowledge

After START condition, 8 bits of data is transferred at a time. The transmitter releases the SIO line, and the receiver

returns the Acknowledge signal by assuming SIO to be “L”.

SIO output

by the transmitter

SIO output

by the receiver

Non-Acknowledge

Acknowledge

SCLK 1 2 8 9

S

START condition

Clock pulse

for Acknowledge

www.rohm.com

14/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

Technical Note

・Writing Protocol

The write protocol is shown below. The register address is transferred in a byte after the slave address and write

command are transferred. The third byte writes the data into the internal register that is indicated by the second byte.

After that, the register address is incremented on automatically (when the register address is between 00h and 16h).

However, when the register address reaches 16h, the register address does not change with the next byte transfer, rather,

it accesses the same register address (16h). The register address is incremented after transfer completion.

S A A A P

Data

R/W=0(Write)

from master to slave

from slave to master

A=Acknowledge

A=Non-Acknowledge

S=START condition

P=STOP condition

AD7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0A7 A6 A5 A4 A3 A2 A1 A01010 01 01

Register address

Increment

DataRegister addressSlave address

Register address

Increment

・Reading Protocol

It reads from the next byte after writing the slave address and R/W bit. The read register is the following address

accessed at the end. After that, the data of the address incremented is read out. The register addresses are

incremented after transfer completion.

101 0 0 1 1 D7D6D5D4D3D2D1D0 D7D6D5D4D3D2D1D0

Slave address

1S A P

Data

R/W=1(Read)

Register address

A A

Data

Register address

Increment

Increment

from master to slave

from slave to master

A=Acknowledge

A=Non-Acnkowledge

S=START condition

P=STOP condition

・Combined Reading Protocol

After specifying an internal address, it reads by generating resending start conditions and changing the direction of data

transfer. Afterwards, data from incremented addresses is read. The register addresses are incremented after transfer

completion. Compound writing is possible by writing R/W=0 after resending start condition.

S A A A

1010 0101

Slave address

R/W=0 ( Write)

D7 D6 D5 D4 D3 D2 D1 D0

from master to slave

from slave to master

www.rohm.com

15/24

© 2010 ROHM Co., Ltd. All rights reserved.

A7 A6 A5 A4 A3 A2 A1 A0

Register address

A

Data

Register address

Increment

Sr 1

1010 011

Slave address

R/W=1 ( Read)

D7 D6 D5 D4 D3 D2 D1 D0

Data

Register address

A=Acknowledge

=Non-acknowledge

A

S=START condition

P=STOP condition

Sr=Repeated START condition

Increment

P

A

2010.09 - Rev.

A

BU7858KN,BU7893GU

・Timing Diagram

(Repeated)

START

conditions

t

SU;STA

BIT 7 BIT 6

t

LOWtHIGH

1/f

SCLK

Acknowledge

STOP

condition

SCL

SIO

t

BUFtHD;STA

t

SU;DATtHD;DAT

2

Fig.35 I

C Timing Diagram

t

SU;STO

DVDD_IO=1.62~3.3V, Ta=-30~+85℃

Parameter Symbol

Hold Time at Start Condition t

SCLK “H” Level Time t

SCLK “L” Level Time t

Set-up Time for Repeated Start Condition t

Data Hold Time t

Data Set-up Time t

Set-up Time for Stop Condition t

Bus Release Time between Stop Condition

and Start Condition

Min Typ Max

0.6 - - µsec

HD;STA

0.6 - - µsec

HIGH

1.3 - - µsec

LOW

0.6 - - µsec

SU;STA

0 - 0.9 µsec

HD;DAT

100 - - nsec

SU;DAT

0.6 - - µsec

SU;STO

t

1.3 - - µsec

BUF

Limits

●Pin function

【BU7858KN】

No. Pin Name I/O Pin Function Power

Technical Note

Unit Conditions

Equivalent

Circuit

Diagram

1 SDTI I Audio DAC Serial Data Input DVDD A

2 LRCLK I Audio DAC LR Clock DVDD A

3 BCLK I Audio DAC BIT Clock DVDD A

4 DVDD - Digital Power Supply - -

5 DVSS - Digital Ground DVDD -

6 SCLK I Serial Clock for CPU Interface DVDD A

7 SDATA I Serial Data for CPU Interface DVDD A

8 NCS I Serial Chip Selection for CPU Interface DVDD A

9 NRST I Reset Input L: Reset DVDD A

10 CSTEP - Capacitor Connection Terminal for Pop Noise Reduction AVDD C

11 CSTART -

12 CVCOM -

Capacitor Connection Terminal for Pop Noise Reduction at

Start-up

Capacitor Connection Terminal for Internal Reference Voltage

Output

AVD D G

AVD D G

13 HP_R O Headphone Amplifier Output R-ch AVDD H

14 CA_R - Low-band Correction Capacitor for Headphone Amplifier R-ch AVDD C

www.rohm.com

16/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

No. Pin Name I/O Pin Function Power

15 CA_L - Low-band Correction Capacitor for Headphone Amplifier L-ch AVDD C

16 HP_L O Headphone Amplifier Output L-ch AVDD H

17 AVSS - Analog Ground - -

18 AVDD - Analog Power Supply - -

19 EXTO O 600Ω Driver Output AVDD H

20 SPO O Line Output for Speaker AVDD H

21 EXTI I External Input AVDD D

22 MEL_L I Melody Input L ch AVDD D

23 MEL_R I Melody Input R ch AVDD D

24 RING I RING Input AVDD E

Technical Note

Equivalent

Circuit

Diagram

25 RXI I RXI Input AVDD D

26 PLLC - Capacitor Connection Terminal for PLL Loop Filter DVDD C

27 MCLKO O Master Clock Output DVDD B

28 MCLKI I Master Clock Input DVDD A

PAD PAD PAD

BA

C

PAD

100kΩ

(TYP)

200kΩ

(TYP)

PADPAD

E

FD

PAD

PAD

GH

Fig.36 Equivalent Circuit Diagrams (BU7858KN)

www.rohm.com

17/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

r

【BU7893GU】

Matrix

No.

1 E3 AVDD - Analog Power Supply - AVDD -

2 C6 AVSS - Analog Ground - AVDD -

3 E6 ANAINL I DAC L-ch Input - AVDD G

4 D6 ANAINR I DAC R-ch Input - AVDD G

5 A3 HPOL O Headphone Amplifier Output L-ch Pull-down AVDD H

6 A2 HPOR O Headphone Amplifier Output R-ch Pull-down AVDD H

7 B4 CCL I

8 B1 CCR I

9 A5 SPOL O L-ch Line Output for Speaker Pull-down AVDD H

10 B5 SPOR O R-ch Line Output for Speaker Pull-down AVDD H

Pin Name I/O Pin Function

No.

Low-band Correction Capacito

for Headphone Amplifier L-ch

Low-band Correction Capacitor

for Headphone Amplifier R-ch

Terminal

Conditions

at Reset

Pull-down AVDD I

Pull-down AVDD I

Technical Note

Power

Equivalent

Circuit

Diagram

11 D5 COMOUT O Analog Reference Voltage Output Hi-Z AVDD J

12 B6 COMIN I Analog Reference Voltage Input Hi-Z AVDD K

13 A4 CPOP I/O

14 C5 CSTEP I/O

15 E2 PLLC I/O

16 E4 DVDD_CORE - Digital Core Power Supply - DVDD_CORE -

17 F3 DVDD_IO - Digital IO Power Supply - DVDD_IO -

18 B3 DVSS - Digital Ground -

19 F2 CLKI I

20 B2 RSTB I Reset Input L: Reset - DVDD_IO A

21 E1 CSB I

22 C1 SCLK I CPU Interface Clock - DVDD_IO A

23 D1 SIO I/O

24 C2 SO I/O

25 E5 SDI I Audio DAC Digital Data Input Hi-Z DVDD_IO C

Capacitor Connection Terminal

for Pop Noise Reduction

Capacitor Connection Terminal

for Noise Reduction during Volume Change

Capacitor Connection Terminal

for PLL Loop Filter

PLL Reference Clock Input

(19.2/19.68/19.8 MHz)

CPU Interface Select Pin

(L :CPU I/F DVDD_IO : I

CPU Interface Data Input/Output

(at Reset Input)

CPU Interface Data Output

(connected to DVSS when not in use)

2

C I/F)

Hi-Z AVDD L

Hi-Z AVDD L

- AVDD L

DVDD_IO,

DVDD_CORE

- DVDD_IO D

- DVDD_IO B

Hi-Z DVDD_IO F

Hi-Z DVDD_IO E

-

26 F4 BCLK I/O Audio DAC Bit Clock (Input State at Reset) Hi-Z DVDD_IO E

27 F5 LRCLK I/O Audio DAC LR Clock (Input State at Reset) Hi-Z DVDD_IO E

28 D2 MCLK I/O Audio DAC Master Clock (Input State at reset ) Hi-Z DVDD_IO E

29 F6 TEST1 I

30 F1 TEST2 I

31 A1 TEST3 I/O Test Pin (released during normal operation) - DVDD_IO E

32 A6 TEST4 I Test Pin (released during normal operation) - AVDD -

www.rohm.com

18/24

© 2010 ROHM Co., Ltd. All rights reserved.

Test Pin

(connected to DVSS during normal operation)

Test Pin

(connected to DVSS during normal operation)

Pull-down DVDD_IO C

Pull-down DVDD_IO C

2010.09 - Rev.

A

BU7858KN,BU7893GU

Schmitt Trigger

Technical Note

IN

PAD

A

B

IN

PAD

IN

PAD

C

Schmitt Trigger

IN

PAD

D

E

INOUT

PAD

PAD

INOUT

F

IN

PAD

-

+

OUT

PAD

IN

PAD

G

H

I

+

-

J

OUT

PAD

K

IN/OUT

PAD

L

IN/OUT

PAD

Fig.37 Equivalent Circuit Diagrams (BU7893GU)

www.rohm.com

19/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

●Recommended sequence

【BU7858KN】

Mode setting Flow

Power Supply ON

Reference Voltage ON

(VCOM=1)

Input Path Setting

Mixing Path Setting

Analog Power ON

(PDN=1)

PLL Setting

(PLLPDN=1)

(Using PLL)

DAC Setting

(Using DAC)

DAC MUTE OFF

(Using DAC)

HPAMP RESET Lifting

(Using HPAMP)

*1 : When the analog path setting is not changed (Repeated play)

*2 : When the power supply OFF, after playing

Power Supply OFF

Stand-by mode

RESET

NRST=0 or

PLLPDN=0, VCOM=0

*1

*1

Play

HPAMP RESET

(HPRST=0)

Analog Power OFF

(PDN=0)

PLL OFF

(PLLPDN=0)

(Using PLL)

DAC MUTE ON

(Using DAC)

HPAMP MUTE ON

(Using HPAMP)

Fig.38 BU7858KN Recommended Sequence Flow Chart

Technical Note

*2

www.rohm.com

20/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

【BU7893GU】

SAMPLE# AUDIO PATH+ AUDIO DAC BLOCK SETTING SEQUENCE

After powering up and canceling reset, set paths according to the sequence shown as below:

(1) Start up reference voltage

Start up the reference voltage in the REF_PWR register (00h).

To start up the VREF block fast, set the REF_ON bit (bit-0) and BST_ON bit (bit-1) to "1" simultaneously. After

starting up the reference voltage startup, set just the BST_ON bit (bit-1) to "0".

(2) Start up Audio DAC

When using Audio DAC

(2-1) Enable PLL block clock input and start up PLL

Start up the power supply of the PLL and enable clock input to the PLL in the PLL_PWR register (16h).

Set REF1_ON (bit-1) and PLL_ON (bit-0) to "1" simultaneously.

(2-2) Caution concerning interim between starting up PLL block and starting up Audio DAC block

After starting up the power supply of the PLL in the PLL_PWR register (16h), wait 10 msec before starting up the

Audio DAC.

(2-3) Start up Audio DAC block

Start up the power supply of the Audio DAC in the DAC SET4 register (13h).

Set DAC_ON (bit-5) and DAC_RSTB (Bit-4) to "1".

(2-4) Set 3D surround and Equalyzer parameter

Please tell us about the parameter setting when you use this function.

(3) Start up analog input amplifier to use

Start up the power supply of the input amplifier and input volume in the IAMP_PWR register (01h).

(4) Set input volume

Set the input volume in the IVR_1 register (09h).

(5) Set mixing path

Make mixing path settings in the MIX1 register (02h), MIX2 register (03h), MIX3 register (04h), and MIX4 register (05h).

(6) Set startup noise reduction sequence

Set the sequence time in the POP_TM register (07h).

(7) Set click noise reduction sequence

Set the sequence time in the OVR_TM register (0Ah).

(8) Set output path

Enable the relevant output path in the PATH_CNT register (06h).

(9) Set output volume

Set output volume values =0x18(-48dB) in the OVR_1 register (0Bh).

(10) Ramp up output driver amplifier

Ramp up the output driver amplifier in the DRV_PWR register (08h).

(11) Caution concerning interim between ramping up output driver amplifier and canceling mute

After setting the DRV_PWR register (08h), wait the sequence time set in the POP_TM register (07h) before canceling

mute.

(12) Cancel mute

Cancel mute state of the output driver amplifier in the DRV_MT register (0Ch).

(13) Caution concerning interim between canceling mute and setting output volume

After setting the DRV_MT register (0Ch), wait the sequence time that is set in the OVR_TM register (0Ah) before

subsequently setting output volume.

(14) Set output volume

Set output volume values in the OVR_1 register (0Bh).

Technical Note

www.rohm.com

21/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

Path Modification Sequence

(1) Set output mute

Put the output driver amplifier in a mute state by setting the DRV_MT register (0Ch).

(2) Caution concerning interim between setting mute and ramping down output driver amplifier

After setting the DRV_MT register (0Ch), wait the sequence time that is set in the OVR_TM register (0Ah) before

subsequently ramping down the output driver amplifier.

(3) Ramp down output driver amplifier

Ramp down the output driver amplifier by setting the DRV_PWR register (08h).

(4) Set AUDIO DAC (Refer to P.20)

(5) Modify input path, mixing path, output path (Refer to P.20)

(6) Ramp up output driver amplifier

Ramp up output driver amplifier in the DRV_PWR register (08h)

After ramping down output driver at (3), wait the sequence time that is set in the POP_TM register (07h) before

subsequently ramping up.

(7) Caution concerning interim between ramping up output driver amplifier and canceling mute

After setting the DRV_PWR register (08h) at (6), wait the sequence time that is set in the POP_TM register (07h)

before subsequently canceling mute.

(8) Cancel mute

Cancel output mute in the DRV_MT register (0Ch).

Power-Down Sequence

(1) Set output volume

Set output volume values =0x18(-48dB) in the OVR_1 register (0Bh).

(2) Caution concerning interim between setting output volume and setting mute

After setting the OVR_1 register (0Bh), wait the sequence time that is set in the DRV_MT register (0Ch) before

subsequently setting mute.

(3) Put the output driver amplifier in a mute state by using the DRV_MT register (0Ch).

(4) Caution concerning interim between setting mute and ramping down output driver amplifier

After setting the DRV_MT register (0Ch), wait the sequence time that is set in the OVR_TM register (0Ah) before

subsequently ramping down the output driver amplifier.

(5) Ramp down output driver amplifier

Ramp down the output driver amplifier in the DRV_PWR register (08h).

(6) Power down AUDIO DAC

When using AUDIO DAC

(6-1) Power down AUDIO DAC block

Power down the AUDIO DAC according to the DAC SET4 register (13h).

Set DAC_ON (bit-5) and DAC_RSTB (Bit-4) to "0".

(6-2) Mask clock input and power down PLL block

Power down the PLL and mask clock input to the PLL according to the PLL_PWR register (16h).

Set REF_ON (bit-1) and PLL_ON (bit-0) to "0" simultaneously.

(7) Input reset

Put a reset state by using RSTB pin input.

(8) Power down

Technical Note

www.rohm.com

22/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

●Notes for use

1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can

break down the devices, thus making impossible to identify breaking mode such as a short circuit or an open circuit. If

any special mode exceeding the absolute maximum ratings is assumed, consideration should be given to take physical

safety measures including the use of fuses, etc.

2) Operating conditions

These conditions represent a range within which characteristics can be provided approximately as expected. The

electrical characteristics are guaranteed under the conditions of each parameter.

3) Reverse connection of power supply connector

The reverse connection of power supply connector can break down ICs. Take protective measures against the

breakdown due to the reverse connection, such as mounting an external diode between the power supply and the IC’s

power supply terminal.

4) Power supply line

Design PCB pattern to provide low impedance for the wiring between the power supply and the GND lines. In this regard,

for the digital block power supply and the analog block power supply, even though these power supplies has the same

level of potential, separate the power supply pattern for the digital block from that for the analog block, thus suppressing

the diffraction of digital noises to the analog block power supply resulting from impedance common to the wiring patterns.

For the GND line, give consideration to design the patterns in a similar manner.

Furthermore, for all power supply terminals to ICs, mount a capacitor between the power supply and the GND terminal.

At the same time, in order to use an electrolytic capacitor, thoroughly check to be sure the characteristics of the capacitor

to be used present no problem including the occurrence of capacity dropout at a low temperature, thus determining the

constant.

5) GND voltage

Make setting of the potential of the GND terminal so that it will be maintained at the minimum in any operating state.

Furthermore, check to be sure no terminals are at a potential lower than the GND voltage including an actual electric

transient.

6) Short circuit between terminals and erroneous mounting

In order mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs, Erroneous mounting can

break down the ICs. Furthermore, if a shout circuit occurs due to foreign matters entering between terminals or between

the terminal and the power supply or the GND terminal, the ICs can break down.

7) Operation in a strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

8) Inspection with set PCB

On the inspection with the set PCB, if a capacitor is connected to a low-impedance IC terminal, the IC can suffer stress.

Therefore, be sure to discharge from the set PCB by each process. Furthermore, in order to mount or dismount the set

PCB to/from the jig for the inspection process, be sure to turn OFF the power supply and then mount the set PCB to the

jig. After the completion of the inspection, be sure to turn OFF the power supply and then dismount it from the jig. In

addition, for protection against static electricity, establish a ground for the assembly process and pay thorough attention

to the transportation and the storage of the set PCB.

9) Input terminals

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the

parasitic element can cause interference with circuit operation, thus resulting in a malfunction and then breakdown of the

input terminal. Therefore, pay thorough attention not to handle the input terminals, such as to apply to the input terminals

a voltage lower than the GND respectively, so that any parasitic element will operate. Furthermore, do not apply a voltage

to the input terminals when no power supply voltage is applied to the IC. In addition, even if the power supply voltage is

applied, apply to the input terminals, a voltage lower than the power supply voltage or within the guaranteed value of

electrical characteristics.

10) Ground wiring pattern

If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND

pattern from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that

resistance to the wiring pattern and voltage fluctuations due to a large curr

small-signal GND. Pay attention not to cause fluctuations in the GND wiring pattern of external parts as well.

11) External capacitor

In order to use a ceramic capacitor as the external capacitor, determine the constant with consideration given to a

degradation in the normal capacitance due to DC bias and changes in the capacitance due to temperature, etc.

12) No Connecting input terminals

In terms of extremely high impedance of CMOS gate, to open the input terminals causes unstable state. And unstable

state brings the inside gate voltage of p-channel or n-channel transistor into active. As a result, battery current may

increase. And unstable state can also causes unexpected operation of IC. So unless otherwise specified, input terminals

not being used should be connected to the power supply or GND line.

ent will cause no fluctuations in voltages of the

Technical Note

www.rohm.com

23/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

A

BU7858KN,BU7893GU

●Ordering part number

B U 7 8 5 8 K N - E 2

Technical Note

Part No. Part No.

Package

7858

7893

VQFN28

(1.1)

22 14

5.0±0.1

5.2±0.1

28

0.22±0.05

0.22±0.05

+0.1

0.6

−0.3

(0.5)

5.2±0.1

5.0±0.1

21

15

0.05

<Tape and Reel information>

8

71

M

+0.03

−0.02

0.95MAX

0.02

0.05

3−(0.35)

Notice :

(0.22)

Do not use the dotted line area

0.5

for soldering

(Unit : mm)

VCSP85H3

(BU7893GU)

1PIN MARK

<Tape and Reel information>

3.5±0.1

32-φ0.30±0.05

0.05

BA

0.5±0.1

F

E

D

C

B

A

123456

P=0.5× 5

(φ0.15)INDEX POST

0.08 S

A

3.5±0.1

1.0MAX

0.25±0.1

S

0.5±0.1

B

P=0.5× 5

(Unit : mm)

KN: VQFN28

GU: VCSP85H3

Quantity

Direction

of feed

Quantity

Direction

of feed

Packaging and forming specification

E2: Embossed tape and reel

Embossed carrier tape (with dry pack)Tape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Embossed carrier tapeTape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

Direction of feed

www.rohm.com

24/24

© 2010 ROHM Co., Ltd. All rights reserved.

2010.09 - Rev.

Notes

No copying or reproduction of this document, in par t or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injur y (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

http://www.rohm.com/contact/

R1010

A

Loading...

Loading...