1/4

Structure Silicon Monolithic Integrated Circuit

Product Name Audio Interface for Cellular Phone

Product No. BU7843AGU

Features Audio Interface

6x6 keyscan circuit

o

○Absolute Maximum Ratings(Ta=25

Parameter Symbol Rating Unit Remarks

Analog supply voltage AVD D

Digital supply voltage DVDD

Power supply voltage PVDD

Analog input voltage V

Digital input voltage V

Input current IIN

Allowable dissipation Pd 310(*1) mW

Operating temperature range T

Storage temperature range T

(*1) When Ta is above 25oC, reduce 3.1mW per 1oC.

○Recommended operating conditions(Ta =2 5

Parameter Symbol

Analog operation voltage AVDD 2.7 2.8 3.1 V (*2)

Digital operation voltage DVDD 1.65 1.8 3.1

Power operation voltage PVDD 2.7 2.8 3.1

(*2) AVDD and PVDD are internally connected in the IC and use the same potential.

This chip is not designed to protect itself against radioactive rays.

C)

AIN

DIN

OPR

STG

-0.3~4.5

-0.3~4.5

-0.3~4.5

AVSS-0.3~AVDD+0.3

DVSS-0.3~DVDD+0.3

-10~+10

o

-30~+85

-55~+125

C)

Rating

Min. Typ. Max.

V

V

V

V

V

mA

o

C

o

C

Unit Remarks

V

V

REV. B

2/4

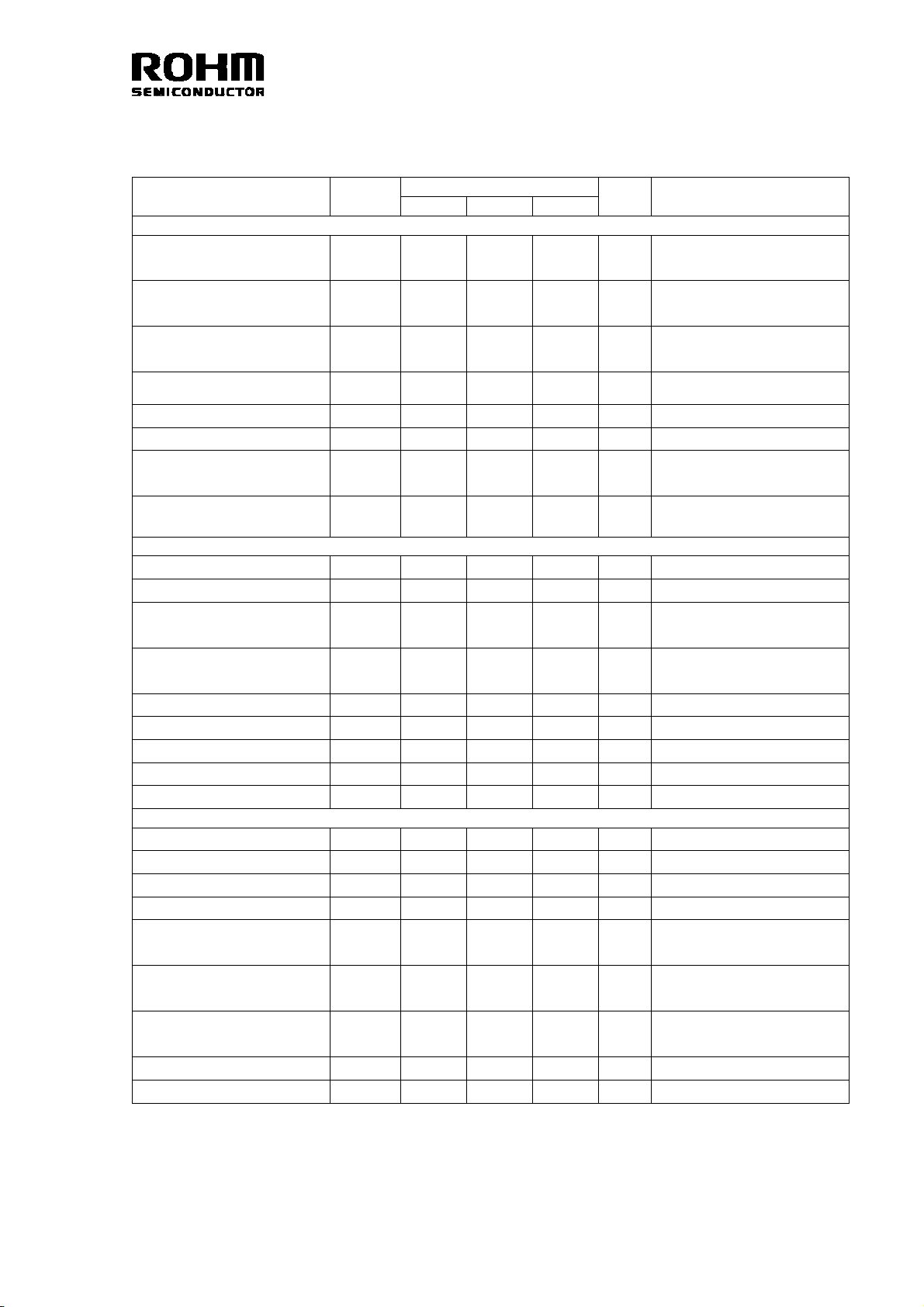

○Electrical Characteristics

(Unless otherwise noted, Ta = 25oC AVSS=DVSS=PVSS=0.0V ATT is set at 0)

Parameter Symbol

Min. Typ. Max.

Digital DC characteristics

Digital high level input

voltage 1

Digital high level input

voltage 2

Digital low level input voltage

1

Digital low level input voltage

2

V

IH1

V

IH2

V

V

Digital high level input current IIH

Digital low level input current IIL

Digital high level output

voltage

Digital low level output

voltage

VOH

V

IL1

IL2

OL

0.8

DVDD

DVDD

-0.4

- - 0.2

- - 0.4 V

- - 1

- - 1

DVDD

-0.5

- - 0.5 V

Digital AC characteristics

SCL clock frequency f

Bus free time t

(Iterative) start condition

setup time

(Iterative) start condition hold

time

SCL low time t

SCL high time t

Data setup time t

Data hold time t

Stop condition setup time t

- - 400 kHz

SCL

1.3 - - μs

BUF

t

0.6 - - μs

SU;STA

t

0.6 - - μs

HD;STA

1.3 - - μs

LOW

0.6 - - μs

HIGH

100 - - ns

SU;DAT

0 - - ns

HD;DAT

0.6 - - μs

SU;STO

Current consumption AVDD=DVDD=PVDD=2.8V input signal = no signal.

Standby current IST - - 3 μA

TX_OUT path current I

HF_OUT path current I

BT_OUT path current I

Reciever path current I

Headphone path current I

Speaker path current I

Full operation current I

Microphone bias current I

- 1.3 2.2 mA

DD1

- 1.4 2.4 mA

DD2

- 1.3 2.2 mA

DD3

- 2.5 4.2 mA

DD4

- 3.5 5.9 mA

DD5

- 1.9 3.2 mA

DD6

- 8.5 13.5 mA

DD9

- 250 430 μA

DD8

Rating

- - V

- - V

DVDD

- - V

Unit Condition

DVDD=3.0V

DVDD=1.8V

DVDD=3.0V

V

DVDD=1.8V

VIH=DVDD

μA

VIL=DVSS

μA

IOH=-1mA

IOL=1mA

After a reset

MIC1_IN→MIX6→TX_OUT

RX_IN→MIX2→HF_OUT

RX_IN→MIX2→BT_OUT

RX_IN→MIX2→RCVP_OUT、

RCVN_OUT

DACL_IN→MIX2→HPL_OUT

DACR_IN→MIX3→HPR_OUT

DACL_IN→MIX4→SPL_OUT

DACR_IN→MIX5→SPR_OUT

All paths are ON

BIAS_ON=!

REV. B

3/4

○External measure and View ○Pin layout diagram

BU78

43AGU

LOT No

VBGA063T050 (Unit: mm)

○Block diagram

Pin

NO.

Pin name

Pin

NO.

Pin name

Pin

NO.

Pin name

A1 N.C. F4 KB0 C8 RCVP_OUT

C3 MIC1_IN H4 DVDD C7 CPOP

C2 MIC2_IN G5 DVSS B8 N.C.

D2 MIC3_IN F5 KB1 B7 N.C.

C1 AUX1_IN H5 KB2 A8 N.C.

D3 DACR_IN E5 KB3 A7 N.C.

D1 AUX2_IN H6 KB4 C6 SPL_OUT

E2 DACL_IN G6 KB5 B6 SPR_OUT

E3 RX_IN H7 N.C. B5 HF_OUT

E1 SDA G7 N.C. A6 BT_OUT

E4 SDL H8 N.C. C5 TX_OUT

F1 KBR0 G8 N.C. A5 COMOUT

F2 KBR1 F6 IRQ B4 COMIN

G1 N.C. F7 RSTB C4 AVDD

G2 N.C. F8 HPR_OUT A4 AVSS

H1 N.C. E6 HPL_OUT D4 CBIAS

H2 N.C. E8 CHPL A3 MIC1_OUT

F3 KBR2 D7 PVSS B3 MICB

G3 KBR3 D6 PVDD A2 N.C.

G4 KBR4 D8 RCVN_OUT B3 N.C.

H3 KBR5 D5 CSTEP

MIC1_IN

MIC2_IN

MIC3_IN

AUX1_IN

DACR_IN

AUX2_IN

DACL_IN

RX_IN

KBR0

KBR1

N.C.

63

64

B2

1

A1

N.C.

3

-

C3

+

MIC AMP

4

C2

5

D2

6

AUX1_V

C1

-11~ +3dB/1dB

7

DACR_V

D3

-11~ +3dB/1dB

8

AUX2_V

D1

-11~ +3dB/1dB

9

DACL_V

E2

-11~ +3dB/1dB

10

RX_V

E3

-11~ +3dB/1dB

11

E1

SDA

12

SCL

13

14

15

N.C.

16

N.C.

I2C BUS I/FKEYSCAN

E4

DVDD

30k

F1

DVDD

30k

F2

G1

G2

6

H1

17

18

N.C.

61

62

B3

A2

MIC_BIAS AVDD / AVSS VREF

SW

SW

SW

DVDD

DVDD

30k

F3

H2

19

20

N.C.

KBR2

A3

MIC_V

-20~ +3 0dB/2dB

30k

G3

KBR3

59

60

D4

+

MIX1

+

MIX2

+

MIX3

+

MIX5

+

MIX4

DVDD

DVDD

30k

G4

21

22

KBR4

57

58

A4

C4

30k

F4

H3

23

24

KB0

KBR5

B4

DVDD / DVSS

H4

DVDD

56

A5

G5

25

55

MIX6

+

AVDD/PVDD is connected at internal ,

and they are connected analog portion .

26

DVSS

53

54

A6

C5

TX_V

BT_V

-26~ +4dB/2dB

-26~ +4dB/2dB

F5

H5

27

28

KB1

KB2

B5

600OSingle

HF_V

-26~ +4dB/2dB

E5

KB3

52

RCV_V

-26~ +4dB/2dB

HPL_V

-26~ +4dB/2dB

HPR_V

-26~ +4dB/2dB

29

51

B6

SPR_V

-26~ +12dB/2dB

H6

30

KB4

C6

SPL_V

G6

50

-26~ + 12dB/2dB

6

6

31

KB5

49

A8

A7

MUTE

ANTI-POP

32OBTL

AVDD / AVSS

16OSingle

16OSingle

KEYSCAN

BU7843AGU

H7

G7

32

N.C.

N.C.

B7

48

N.C.

B8

47

CPOP

C7

46

RCVP_OUT

C8

45

CSTEP

D5

44

RCVN_OUT

D8

43

PVDD

D6

42

PVSS

D7

41

CHPL

E8

40

HPL_OUT

E6

39

HPR_OUT

F8

38

CHPR

E7

37

RSTB

F7

36

IRQ

F6

35

N.C.

G8

34

N.C.

H8

33

N.C.

N.C.

N.C.

SPL_OUT

SPR_OUT

HF_OUT

BT_OUT

TX_OUT

COMOUT

COMIN

AVDD

AVSS

CBIAS

MIC1_OUT

MICB

N.C.

REV. B

4/4

Cautions on use

○

(1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc.,

can break down devices, thus making impossible to identify breaking mode such as a short circuit or an open circuit. If

any special mode exceeding the absolute maximum ratings is assumed, consideration should be given to take physical

safety measures including the use of fuses, etc.

(2) Operating conditions

These conditions represent a range within which characteristics can be provided approximately as expected. The

electrical characteristics are guaranteed under the conditions of each parameter.

(3) Reverse connection of power supply connector

The reverse connection of power supply connector can break down ICs. Take protective measures against the

breakdown due to the reverse connection, such as mounting an external diode between the power supply and the

IC’s power supply terminal.

(4) Power supply line

Design PCB pattern to provide low impedance for the wiring between the power supply and the GND lines.In this

regard, for the digital block power supply and the analog block power supply, even though these power supplies has the

same level of potential, separate the power supply pattern for the digital block from that for the analog block, thus

suppressing the diffraction of digital noises to the analog block power supply resulting from impedance common to the

wiring patterns. For the GND line, give consideration to design the patterns in a similar manner.

Furthermore, for all power supply terminals to ICs, mount a capacitor between the power supply and the GND terminal.

At the same time, in order to use an electrolytic capacitor, thoroughly check to be sure the characteristics of the

capacitor to be used present no problem including the occurrence of capacity dropout at a low temperature, thus

determining the constant.

(5) GND voltage

Make setting of the potential of the GND terminal so that it will be maintained at the minimum in any operating state.

Furthermore, check to be sure no terminals are at a potential lower than the GND voltage including an actual electric

transient.

(6) Short circuit between terminals and erroneous mounting

In order to mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs. Erroneous mounting

can break down the ICs. Furthermore, if a short circuit occurs due to foreign matters entering between terminals or

between the terminal and the power supply or the GND terminal, the ICs can break down.

(7) Operation in strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

(8) Inspection with set PCB

On the inspection with the set PCB, if a capacitor is connected to a low-impedance IC terminal, the IC can suffer

stress. Therefore, be sure to discharge from the set PCB by each process. Furthermore, in order to mount or

dismount the set PCB to/from the jig for the inspection process, be sure to turn OFF the power supply and then mount

the set PCB to the jig. After the completion of the inspection, be sure to turn OFF the power supply and then dismount

it from the jig. In addition, for protection against static electricity, establish a ground for the assembly process and pay

thorough attention to the transportation and the storage of the set PCB.

(9) Input terminals

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the

parasitic element can cause interference with circuit operation, thus resulting in a malfunction and then breakdown of

the input terminal. Therefore, pay thorough attention not to handle the input terminals, such as to apply to the input

terminals a voltage lower than the GND respectively, so that any parasitic element will operate. Furthermore, do not

apply a voltage to the input terminals when no power supply voltage is applied to the IC. In addition, even if the power

supply voltage is applied, apply to the input terminals a voltage lower than the power supply voltage or within the

guaranteed value of electrical characteristics.

(10) Ground wiring pattern

If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND

pattern from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that

resistance to the wiring pattern and voltage fluctuations due to a large current will cause no fluctuations in voltages of

the small-signal GND. Pay attention not to cause fluctuations in the GND wiring pattern of external parts as well.

(11) External capacitor

In order to use a ceramic capacitor as the external capacitor, determine the constant with consideration given to a

degradation in the nominal capacitance due to DC bias and changes in the capacitance due to temperature, etc.

(12) Others

In case of use this LSI, please peruse some other detail documents, we called ,Technical note, Functinal description,

Application note.

REV. B

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, of ce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes effor ts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injur y, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...