High-performance Clock Generator Series

DVD-video Reference

Clock Generators for A/V Equipments

BU2280FV, BU2360FV, BU2362FV

●Description

These clock generators are an IC generating three types of clocks - VIDEO, AUIDIO and SYSTEM clocks – necessary for

DVD player systems, with a single chip through making use of the PLL technology. Particularly, the AUDIO clock is a

DVD-Video reference and yet achieves high C/N characteristics to provide a low level of distortion factor.

●Features

1) Connecting a crystal oscillator generates multiple clock signals with a built-in PLL.

2) AUDIO clock of high C/N characteristics providing a low level of distortion factor

3) The AUDIO clock provides switching selection outputs.

4) Single power supply of 3.3 V

●Applications

DVD players

●Lineup

Part name BU2280FV BU2360FV BU2362FV

Power source voltage [V] 3.0 ~ 3.6 2.7 ~ 3.6 2.7 ~ 3.6

Reference frequency [MHz] 27.0000 27.0000 27.0000

2 - - -

No.12005EBT04

DVD VIDEO

Output frequency

[MHz]

Jitter 1σ [psec] 70 70 70

Long-term-Jitter p-p [nsec] 8.0 2.5 5.0

Package SSOP-B24 SSOP-B16 SSOP-B16

DVD AUDIO, CD

(Switching outputs)

SYSTEM

768 (48k type) - - 36.8640

768 (44.1k type) 33.8688 33.8688 33.8688

384 (44.1k type) - - 16.9344

1 27.0000 27.0000 27.0000

1/2 - - -

768fs

512fs

384fs

256fs - - -

other - -

36.8640

/33.8688

24.5760

/22.5792

18.4320

/16.9344

- -

24.5760

/22.5792

- -

24.5760

/22.5792

36.8640

/16.9344

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

1/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

Technical Note

●Absolute Maximum Ratings (Ta=25℃)

Parameter Symbol BU2280FV BU2360FV BU2362FV Unit

Supply voltage

Input voltage

Storage temperature range

Power dissipation

*1 In the case of exceeding Ta = 25℃, 6.3mW to be reduced per 1℃

*2 In the case of exceeding Ta = 25℃, 4.5mW to be reduced per 1℃

*Operating is not guaranteed.

*The radiation-resistance design is not carried out.

*Power dissipation is measured when the IC is mounted to the printed circuit board.

VDD -0.5 ~ +7.0 -0.5 ~ +7.0 -0.5 ~ +7.0 V

VIN -0.5~VDD+0.5 -0.5~VDD+0.5 -0.5~VDD+0.5 V

Tstg

PD 630

-30 ~ +125 -30 ~ +125 -30 ~ +125 ℃

*1

450

*2

450

*2

●Recommended Operating Range

Parameter Symbol BU2280FV BU2360FV BU2362FV Unit

Parameter VDD 3.0 ~ 3.6 2.7 ~ 3.6 2.7 ~ 3.6 V

Supply voltage VIH 0.8VDD~VDD 0.8VDD~VDD 0.8VDD~VDD V

mW

Input “H” Voltage VIL

0.0 ~ 0.2VDD 0.0 ~ 0.2VDD 0.0 ~ 0.2VDD V

Input “L” Voltage Topr -5 ~ +70 -25 ~ +85 -25 ~ +85 ℃

Operating temperature CL 15 15 15 pF

Output load CL_27M1 - 40 (CLK27M1) - pF

27M output load 1 CL_27M2 - 25 (CLK27M2) - pF

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

2/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

Technical Note

●Electrical characteristics

◎BU2280FV(VDD=3.3V, Ta=25℃, Crystal frequency 27.0000MHz, unless otherwise specified.)

Parameter

Symbol

Min. Typ. Max.

Limits

Unit Conditions

Output L voltage VOL - - 0.4 V IOL=4.0mA

Output H voltage VOH 2.4 - - V IOH=-4.0mA

Consumption current IDD - 30 50 mA At no load

CLK768FS

CLK512FS

CLK384FS

CLK768-44 - 33.8688 - MHz At FSEL=L, XTAL×3136 / 625 / 4

CLK768-48 - 36.8640 - MHz At FSEL=H, XTAL×2048 / 375 / 4

CLK512-44 - 22.5792 - MHz At FSEL=L, XTAL×3136 / 625 / 6

CLK512-48 - 24.5760 - MHz At FSEL=H, XTAL×2048 / 375 / 6

CLK384-44 - 16.9344 - MHz At FSEL=L, XTAL×3136 / 625 / 8

CLK384-48 - 18.4320 - MHz At FSEL=H, XTAL×2048 / 375 / 8

CLK33M CLK33M - 33.8688 - MHz XTAL×147 / 40 / 4

CLK16M CLK16M - 16.9344 - MHz XTAL×147 / 40 / 8

Duty Duty 45 50 55 % Measured at a voltage of 1/2 of VDD

Period-Jitter 1σ P-J 1σ - 70 - psec *1

Period-Jitter MIN-MAX

Rise Time Tr - 2.5 - nsec

Fall Time Tf - 2.5 - nsec

P-J

MIN-MAX

- 420 - psec *2

Period of transition time required for the

output reach 80% from 20% of VDD.

Period of transition time required for the

output reach 20% from 80% of VDD.

Output Lock-Time Tlock - - 1 msec *3

Note) The output frequency is determined by the arithmetic (frequency division) expression of a frequency input to XTALIN.

If the input frequency is set to 27.0000MHz, the output frequency will be as listed above.

◎BU2360FV(VDD=3.3V, Ta=25℃, Crystal frequency 27.0000MHz, unless otherwise specified.)

Parameter

Symbol

Min. Typ. Max.

Limits

Unit Conditions

Output L voltage VOL - - 0.4 V IOL=4.0mA

Output H voltage VOH 2.4 - - V IOH=-4.0mA

FSEL input VthL VthL 0.2VDD - - V *4

FSEL input VthH VthH - - 0.8VDD V *4

Hysteresis range Vhys 0.2 - - V Vhys = VthH - VthL *4

Action circuit current IDD - 27.0 40.5 mA At no load

CLK27M CLK27M - 27.0000 - MHz XTAL direct out

CLK33M CLK33M - 33.8688 - MHz XTAL×3136 / 625 / 4

CLK512FS

CLK512_48 - 24.5760 - MHz At FSEL=H, XTAL×2048 / 375 / 6

CLK512_44 - 22.5792 - MHz At FSEL=L, XTAL×3136 / 625 / 6

Duty Duty 45 50 55 % Measured at a voltage of 1/2 of VDD

Period-Jitter 1σ P-J 1σ - 70 - psec *1

Period-Jitter MIN-MAX

Rise Time Tr - 2.5 - nsec

Fall Time Tf - 2.5 - nsec

P-J

MIN-MAX

- 420 - psec *2

Period of transition time required for the

output reach 80% from 20% of VDD.

Period of transition time required for the

output reach 20% from 80% of VDD.

Output Lock-Time Tlock - - 1 msec *3

Note) The output frequency is determined by the arithmetic (frequency division) expression of a frequency input to XTALIN.

If the input frequency is set to 27.0000MHz, the output frequency will be as listed above.

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

3/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

Technical Note

◎BU2362FV(VDD=3.3V, Ta=25℃, Crystal frequency 27.0000MHz, unless otherwise specified.)

Parameter Symbol

Min. Typ. Max.

Limits

Unit Conditions

Output L voltage VOH 2.4 - - V IOH=-4.0mA

Output H voltage VOL - - 0.4 V IOL=4.0mA

Action circuit current IDD - 35 45 mA At no load

CLK512FS

CLKA

CLK512-44 - 22.5792 - MHz At FSEL1=OPEN XTAL*3136/625/6

CLK512-48 - 24.5760 - MHz At FSEL1=L XTAL*2048/375/6

CLKA-A - 16.9344 - MHz At FSEL1=OPEN XTAL*3136/625/8

CLKA-B - 36.8640 - MHz At FSEL1=L XTAL*2048/375/8

CLK36M CLK36M - 36.8640 - MHz XTAL*2048/375/4

CLK33M CLK33M - 33.8688 - MHz XTAL*3136/625/4

CLK16M CLK16M - 16.9344 - MHz XTAL*3136/625/8

CLK27M CLK27M - 27.0000 - MHz XTAL direct out

Duty Duty 45 50 55 % Measured at a voltage of 1/2 of VDD

Period-Jitter 1σ P-J 1σ - 70 - psec *1

Period-Jitter MIN-MAX

Rise Time Tr - 2.5 - nsec

Fall Time Tf - 2.5 - nsec

P-J

MIN-MAX

- 420 - psec *2

Period of transition time required for the

output reach 80% from 20% of VDD.

Period of transition time required for the

output reach 20% from 80% of VDD.

Output Lock-Time Tlock - - 1 msec *3

Note) The output frequency is determined by the arithmetic (frequency division) expression of a frequency input to XTALIN.

If the input frequency is set to 27.0000MHz, the output frequency will be as listed above.

Common to BU2280FV, BU2360FV and BU2362FV:

*1 Period-Jitter 1σ

This parameter represents standard deviation (1 ) on cycle distribution data at the time when the output clock cycles

are sampled 1000 times consecutively with the TDS7104 Digital Phosphor Oscilloscope of Tektronix Japan, Ltd.

*2 Period-Jitter MIN-MAX

This parameter represents a maximum distribution width on cycle distribution data at the time when the output clock

cycles are sampled 1000 times consecutively with the TDS7104 Digital Phosphor Oscilloscope of Tektronix Japan, Ltd.

*3 Output Lock-Time

The Lock-Time represents elapsed time after power supply turns ON to reach a 3.0V voltage, after the system is

switched from Power-Down state to normal operation state, or after the output frequency is switched, until it is stabilized

at a specified frequency, respectively.

BU2360FV

4 This parameter represents lower and upper limit voltages at the Schmitt trigger input PIN having hysteresis

characteristics shown in figure below. The width requested by these differences is assumed to be a hysteresis width.

0.2VDD 0.8VDD

hys

V

Output Voltage [V]

0

VthLV

Input Voltage [V]

th

H

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

4/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2280FV basic data)

Technical Note

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.1 33.9MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

5.0nsec/div

Fig.4 36.9MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.2 33.9MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.5 36.9MHz Period-Jitter

VDD=3.3V, at CL=15pF

10dB/div

10kHz/div

Fig.3 33.9MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

10dB/div

10kHz/div

Fig.6 36.9MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.7 22.6MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

5.0nsec/div

Fig.10 24.6MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.8 22.6MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.11 24.6MHz Period-Jitter

VDD=3.3V, at CL=15pF

10dB/div

10kHz/div

Fig.9 22.6MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

10kHz/div

Fig.12 24.6MHz Spectrum

VDD=3.3V, at CL=15pF

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

5/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2280FV basic data)

Technical Note

RBW=1kHz

VBW=100Hz

1.0V/div

10.0nsec/div

Fig.13 16.9MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

10.0nsec/div

Fig.16 18.4MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.14 16.9MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.17 18.4MHz Period-Jitter

VDD=3.3V, at CL=15pF

10dB/div

10kHz/div

Fig.15 16.9MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

10dB/div

10kHz/div

Fig.18 18.4MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.19 27MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

LT Jitter 6.2nsec LT Jitter 8.1nsec

2.0nsec/div

Fig.22 24.6MHz LT Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.20 27MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

2.0nsec/div

Fig.23 22.6MHz LT Jitter

VDD=3.3V, at CL=15pF

10dB/div

10kHz/div

Fig.21 27MHz Spectrum

VDD=3.3V, at CL=15pF

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

6/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

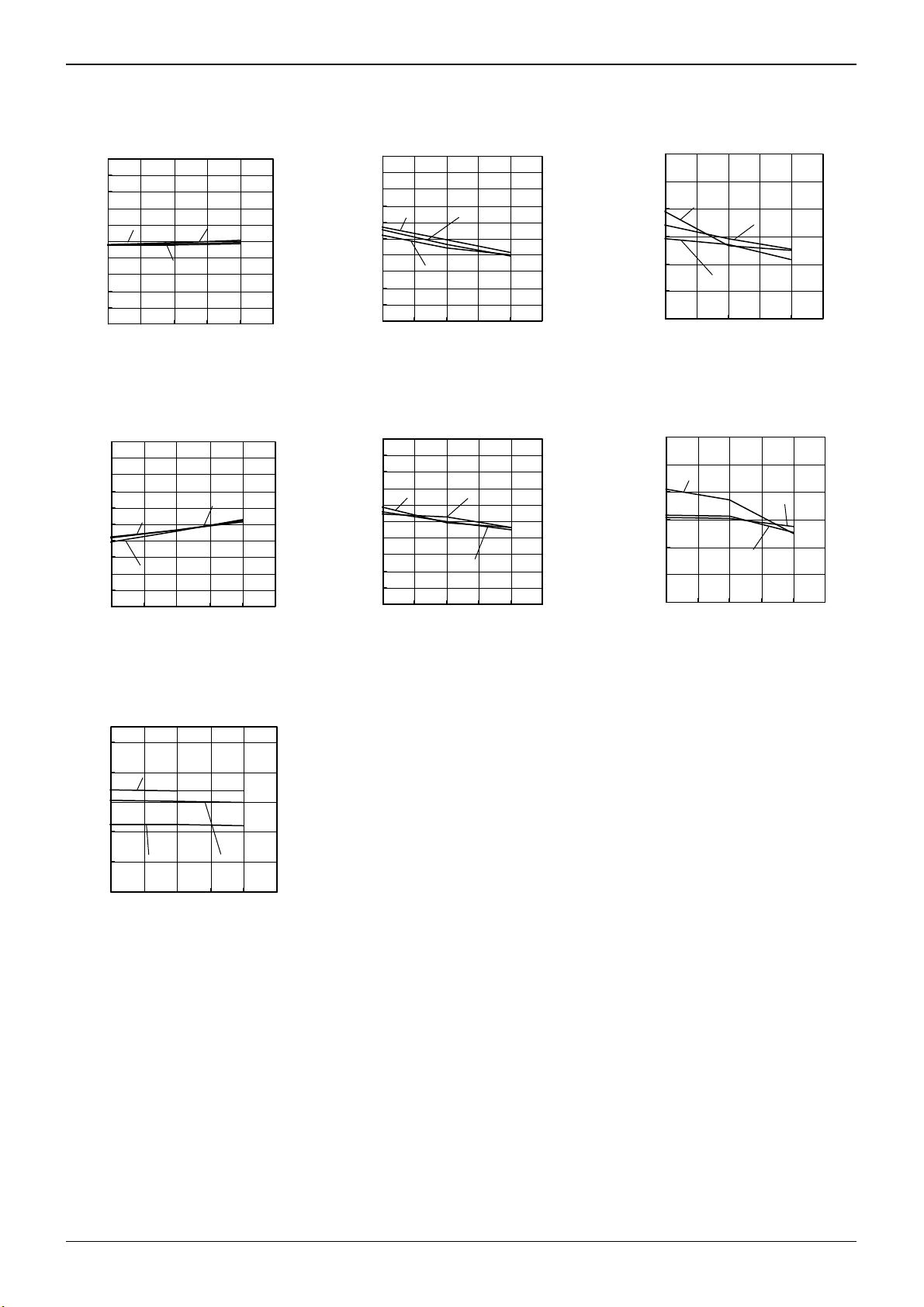

55

●Reference data (BU2280FV Temperature and Supply voltage variations data)

55

54

53

52

51

50

Duty[%]

:

49

48

Duty

47

46

45

VDD=3.7V

-25 0 25 50 75 100

Fig.24 33.9MHz

Temperature-Duty

55

54

53

Duty[%]

:

Duty

52

51

50

49

48

47

46

45

VDD=2.9V

VDD=3.7V

-25 0 25 50 75 100

Fig.27 36.9MHz

Temperature-Duty

55

54

53

52

51

50

Duty[%]

:

49

VDD=3.3V

48

Duty

47

46

45

-25 0 25 50 75 100

Fig.30 22.6MHz

Temperature-Duty

55

54

53

52

VDD=2.9V

51

50

Duty[%]

:

49

48

Duty

47

46

45

-25 0 25 50 75 100

Fig.33 24.6MHz

Temperature-Duty

VDD=3.3V

Temperature:T[℃]

Temperature:T[℃]

VDD=3.7V

Temperature:T[℃]

VDD=3.3V

VDD=3.7V

Temperature:T[℃]

VDD=2.9V

VDD=3.3V

VDD=2.9V

100

90

PJ-1σ[psec]

:

Period-jitter1σ

80

70

60

50

40

30

20

10

VDD=3.3V

0

-25 0 25 50 75 100

Temperature:T[℃]

VDD=2.9V

VDD=3.7V

Fig.25 33.9MHz

Temperature-Period-Jitter 1σ

100

90

80

70

60

PJ-1σ[psec]

:

50

40

30

20

Period-jitter1σ

10

0

VDD=3.3V

-25 0 25 50 75 100

Temperature:T[℃]

VDD=2.9V

VDD=3.7V

Fig.28 36.9MHz

Temperature-Period-Jitter 1σ

100

90

80

70

60

PJ-1σ[psec]

:

50

40

30

20

Period-jitter1σ

10

0

VDD=3.7V

VDD=2.9V

-25 0 25 50 75 100

Temperature:T[℃]

VDD=3.3V

Fig.31 22.6MHz

Temperature-Period-Jitter 1σ

100

90

80

VDD=2.9V

70

60

PJ-1σ[psec]

:

50

40

30

20

Period-jitter1σ

10

0

-25 0 25 50 75 100

VDD=3.3V

VDD=3.7V

Temperature:T[℃]

Fig.34 24.6MHz

Temperature-Period-Jitter 1σ

Technical Note

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

Temperature r-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

Temperature-Period-Jitter MIN-MAX

VDD=3.3V

VDD=3.7V

Temperature:T[℃]

Fig.26 33.9MHz

VDD=3.7V

VDD=3.3V

Temperature:T[℃]

Fig.29 36.9MHz

VDD=3.7V

VDD=2.9V

Temperature:T[℃]

Fig.32 22.6MHz

VDD=3.7V

VDD=3.3V

VDD=2.9V

Temperature:T[℃]

Fig.35 24.6MHz

VDD=2.9V

VDD=2.9V

VDD=3.3V

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

7/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2280FV Temperature and Supply voltage variations data)

55

54

53

Duty[%]

:

Duty

Duty[%]

:

Duty

Duty[%]

:

Duty

52

51

50

49

48

47

46

45

55

54

53

52

51

50

49

48

47

46

45

55

54

53

52

51

50

49

48

47

46

45

VDD=2.9V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.36 16.9MHz

Temperature-Duty

VDD=2.9V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.39 18.4MHz

Temperature-Duty

VDD=3.7V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.42 27MHz

Temperature-Duty

VDD=3.7V

VDD=3.3V

VDD=3.7V

VDD=3.3V

VDD=3.3V

VDD=2.9V

100

90

80

70

VDD=3.7V

60

PJ-1σ[psec]

:

50

40

30

VDD=2.9V

20

10

Period-jitter1σ

0

-25 0 25 50 75 100

Temperature:T[℃]

VDD=3.3V

Fig.37 16.9MHz

Temperature-Period-Jitter 1σ

100

90

80

70

60

PJ-1σ[psec]

:

50

40

30

20

10

Period-jitter1σ

0

-25 0 25 50 75 100

VDD=2.9V

Temperature:T[℃]

VDD=3.7V

VDD=3.3V

Fig.40 18.4MHz

Temperature-Period-Jitter 1σ

100

90

PJ-1σ[psec]

:

Period-jitter1σ

80

70

60

50

40

30

20

10

VDD=2.9V

0

-25 0 25 50 75 100

Temperature:T[℃]

VDD=3.3V

VDD=3.7V

Fig.43 27MHz

Temperature-Period-Jitter 1σ

50

40

IDD[mA]

:

30

20

10

Circuit Current

0

VDD=3.7V

VDD=2.9V

-25 0 25 50 75 100

Temperature:T[℃]

VDD=3.3V

Fig.45 Action circuit current

(with maximum output load)

Temperature-Consumption current

Technical Note

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

VDD=3.7V

Temperature:T[℃]

Fig.38 16.9MHz

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

VDD=2.9V

Temperature:T[℃]

Fig.41 18.4MHz

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

VDD=2.9V

VDD=3.7V

0

-25 0 25 50 75 100

Temperature:T[℃]

Fig.44 27MHz

Temperature-Period-Jitter MIN-MAX

VDD=2.9V

VDD=3.3V

=

VDD=3.3V

VDD=3.3V

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

8/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2360FV basic data)

Technical Note

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.46 27MHz output waveform

VDD=3.3V, at CL=40pF

1.0V/div

5.0nsec/div

Fig.49 27MHz output waveform

VDD=3.3V, at CL=25pF

1.0V/div

500psec/div

Fig.47 27MHz Period-Jitter

VDD=3.3V, at CL=40pF

1.0V/div

500psec/div

Fig.50 27MHz Period-Jitter

VDD=3.3V, at CL=25pF

10dB/div

10kHz/div

Fig.48 27MHz Spectrum

VDD=3.3V, at CL=40pF

RBW=1kHz

VBW=100Hz

10dB/div

10kHz/div

Fig.51 27MHz Spectrum

VDD=3.3V, at CL=25pF

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.52 33.9MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

5.0nsec/div

Fig.55 24.6MHz output waveform

VDD=3.3V, at CL=15pF

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

1.0V/div

500psec/div

Fig.53 33.9MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.56 24.6MHz Period-Jitter

VDD=3.3V, at CL=15pF

9/23

10dB/div

10kHz/div

Fig.54 33.9MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

10dB/div

10kHz/div

Fig.57 24.6MHz Spectrum

VDD=3.3V, at CL=15pF

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2360FV basic data)

Technical Note

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.58 22.6MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.59 22.6MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

1.0nsec/div

Fig61. 24.6MHz LT Jitter

VDD=3.3V, at CL=15pF

LT Jitter 2.3nsec

1.0V/div

LT Jitter 2.5nsec

1.0nsec/div

Fig62. 22.6MHz LT Jitter

VDD=3.3V, at CL=15pF

●Reference data (BU2360FV Temperature and Supply voltage variations data)

55

54

53

52

Duty[%]

:

Duty

Duty[%]

:

Duty

51

50

49

48

47

46

45

55

54

53

52

51

50

49

48

47

46

45

VDD=3.7V

VDD=2.4V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.63 27MHz (40pF)

Temperature-Duty

VDD=3.7V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.66 27MHz (25pF)

Temperature-Duty

VDD=3.3V

VDD=2.4V

VDD=3.3V

100

90

80

70

60

PJ-1σ[psec]

:

50

40

30

20

10

Period-jitter1σ

0

-25 0 25 50 75 100

VDD=2.4V

VDD=3.7V

VDD=3.3V

Temperature:T[℃]

Fig.64 27MHz (40pF)

Temperature-Period-Jitter 1σ

100

90

80

70

60

PJ-1σ[psec]

:

50

40

30

20

Period-jitter1σ

10

0

-25 0 25 50 75 100

VDD=2.4V

VDD=3.7V

Temperature:T[℃]

Fig.67 27MHz (25pF)

Temperature-Period-Jitter 1σ

VDD=3.3V

10dB/div

10kHz/div

Fig.60 22.6MHz Spectrum

VDD=3.3V, at CL=15pF

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

VDD=3.3V

Temperature:T[℃]

VDD=2.4V

VDD=3.7V

Fig.65 27MHz (40pF)

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

VDD=2.4V

VDD=3.7V

Temperature:T[℃]

VDD=3.3V

Fig.68 27MHz (25pF)

Temperature-Period-Jitter MIN-MAX

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

10/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2360FV Temperature and Supply voltage variations data)

55

54

53

52

51

50

Duty[%]

:

49

48

Duty

47

46

45

-25 0 25 50 75 100

55

54

53

52

51

50

Duty[%]

:

49

48

Duty

47

46

45

-25 0 25 50 75 100

VDD=2.4V

VDD=3.7V

Temperature:T[℃]

Fig.69 33.9MHz

Temperature-Duty

VDD=3.3V

Temperature:T[℃]

Fig.72 24.6MHz

Temperature-Duty

VDD=3.3V

VDD=2.4V

VDD=3.7V

100

90

80

70

60

PJ-1σ[psec]

:

50

40

30

20

10

Period-jitter1σ

0

-25 0 25 50 75 100

VDD=2.4V

VDD=3.7V

Temperature:T[℃]

Fig.70 33.9MHz

Temperature-Period-Jitter 1σ

100

90

80

70

60

PJ-1σ[psec]

:

50

VDD=3.3V

40

30

20

Period-jitter1σ

10

0

-25 0 25 50 75 100

Temperature:T[℃]

VDD=3.7V

VDD=2.4V

Fig.73 24.6MHz

Temperature-Period-Jitter 1σ

VDD=3.3V

55

54

53

]

52

%

Duty[

:

Duty

VDD=2.4V

51

50

49

48

47

46

45

-25 0 25 50 75 100

Fig.75 22.6MHz

Temperature-Duty

50

40

IDD[mA]

:

30

VDD=3.3V

VDD=3.7V

Temperature:T[℃]

VDD=3.7V

VDD=3.3V

100

90

VDD=3.7V

80

70

60

PJ-1σ[psec]

:

50

40

VDD=2.4V

30

20

10

Period-jitter1σ

0

-25 0 25 50 75 100

VDD=3.3V

Temperature:T[℃]

Fig.76 22.6MHz

Temperature-Period-Jitter 1σ

20

10

Circuit Current

0

Temperature-Consumption current

VDD=2.4V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.78 Action circuit current

(with maximum output load)

Technical Note

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

VDD=2.4V

VDD=3.7V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.71 33.9MHz

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

VDD=3.3V

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

-25 0 25 50 75 100

Temperature:T[℃]

Fig.74 24.6MHz

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

VDD=3.7V

VDD=2.4V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.77 22.6MHz

Temperature-Period-Jitter MIN-MAX

VDD=3.3V

VDD=2.4V

VDD=3.7V

VDD=3.3V

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

11/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data(BU2362FV basic data)

Technical Note

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.79 33.9MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

5.0nsec/div

Fig.82 36.9MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.80 33.9MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.83 36.9MHz Period-Jitter

VDD=3.3V, at CL=15pF

10dB/div

10kHz/div

Fig.81 33.9MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

10dB/div

10kHz/div

Fig.84 36.9MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.85. 22.6MHz output waveform

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

VDD=3.3V, at CL=15pF

1.0V/div

5.0nsec/div

Fig.88 24.6MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.86 22.6MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.89 24.6MHz Period-Jitter

VDD=3.3V, at CL=15pF

12/23

10dB/div

10kHz/div

Fig.87 22.6MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

10dB/div

Fig.90 24.6MHz Spectrum

VDD=3.3V, at CL=15pF

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data(BU2362FV basic data)

Technical Note

RBW=1kHz

VBW=100Hz

1.0V/div

5.0nsec/div

Fig.91 16.9MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

5.0nsec/div

Fig.94 27MHz output waveform

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.92 16.9MHz Period-Jitter

VDD=3.3V, at CL=15pF

1.0V/div

500psec/div

Fig.95 27MHz Period-Jitter

VDD=3.3V, at CL=15pF

10dB/div

10kHz/div

Fig.93 16.9MHz Spectrum

VDD=3.3V, at CL=15pF

RBW=1kHz

VBW=100Hz

10dB/div

10kHz/div

Fig.96 27MHz Spectrum

VDD=3.3V, at CL=15pF

1.0V/div

LT Jitter 4.8nsec

2.0nsec/div

Fig.97 24.6MHz LT Jitter

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

VDD=3.3V, at CL=15pF

1.0V/div

2.0nsec/div

Fig.98 22.6MHz LT Jitter

VDD=3.3V, at CL=15pF

13/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2362FV Temperature and Supply voltage variations data)

55

54

53

52

51

50

Duty[%]

:

49

48

Duty

47

46

45

-25 0 25 50 75 100

55

54

53

52

51

50

Duty[%]

:

49

48

Duty

47

46

45

-25 0 25 50 75 100

55

54

53

]

52

%

51

50

Duty[

:

49

48

Duty

47

46

45

-25 0 25 50 75 100

55

54

53

52

51

50

Duty[%]

:

49

48

Duty

47

46

45

-25 0 25 50 75 100

VDD=3.3V

VDD=2.4V

Temperature:T[℃]

Fig.99 33.9MHz

Temperature-Duty

VDD=2.4V

VDD=3.3V

VDD=3.7V

Temperature:T[℃]

Fig.102 36.9MHz

Temperature-Duty

VDD=2.4V

VDD=3.3V

VDD=3.7V

Tem per atu re:T[℃]

Fig.105 22.6MHz

Temperature-Duty

VDD=2.4V

VDD=3.3V

Temperature:T[℃]

Fig.108 24.6MHz

Temperature-Duty

VDD=3.7V

VDD=3.7V

100

90

80

70

VDD=2.4V

60

PJ-1σ[psec]

:

50

40

30

20

10

Period-jitter1σ

0

-25 0 25 50 75 100

VDD=3.7V

VDD=3.3V

Temperature:T[℃]

Fig.100 33.9MHz

Temperature-Period-Jitter 1σ

100

90

80

PJ-1σ[psec]

:

Period-jitter1σ

70

60

50

40

30

20

10

VDD=2.4V

0

-25 0 25 50 75 100

VDD=3.7V

VDD=3.3V

Temperature:T[℃]

Fig.103 36.9MHz

Temperature-Period-Jitter 1σ

100

90

80

70

60

PJ-1σ[psec]

:

50

40

30

20

10

Period-jitter1σ

0

-25 0 25 50 75 100

VDD=3.7V

VDD=3.3V

Temperature:T[℃]

Fig.106 22.6MHz

Temperature-Period-Jitter 1σ

100

90

80

VDD=2.4V

70

60

PJ-1σ[psec]

:

50

40

30

20

Period-jitter1σ

10

VDD=3.3V

0

-25 0 25 50 75 100

Temperature:T[℃]

Fig.109 24.6MHz

Temperature-Period-Jitter 1σ

VDD=2.4V

VDD=3.7V

Technical Note

100

90

80

70

60

PJ-1σ[psec]

:

Period-jitter1σ

VDD=2.4V

50

40

30

20

10

0

-25 0 25 50 75 100

Temperature:T[℃]

Fig.101 33.9MHz

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

VDD=2.4V

0

-25 0 25 50 75 100

Temperature:T[℃]

Fig.104 36.9MHz

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

VDD=3.7V

VDD=3.3V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.107 22.6MHz

Temperature-Period-Jitter MIN-MAX

600

500

:

400

300

200

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

100

0

VDD=3.7V

-25 0 25 50 75 100

Temperature:T[℃]

Fig.110 24.6MHz

Temperature-Period-Jitter MIN-MAX

VDD=3.3V

VDD=3.7V

VDD=3.7V

VDD=3.3V

VDD=2.4V

VDD=2.4V

VDD=3.3V

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

14/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Reference data (BU2362FV Temperature and Supply voltage variations data)

55

54

53

52

Duty[%]

:

Duty

VDD=2.4V

51

50

49

48

47

46

45

-25 0 25 50 75 100

Temperature:T[℃]

Fig.111 16.9MHz

Temperature-Duty

VDD=3.7V

VDD=3.3V

100

90

80

70

VDD=3.7V

60

PJ-1σ[psec]

:

50

40

30

20

Period-jitter1σ

10

VDD=3.3V

0

-25 0 25 50 75 100

VDD=2.4V

Temperature:T[℃]

Fig.112 16.9MHz

Temperature-Period-Jitter 1σ

55

54

53

52

51

Duty[%]

:

Duty

VDD=3.3V

50

49

48

VDD=2.4V

47

46

45

-25 0 25 50 75 100

Temperature:T[℃]

Fig.114 27MHz

Temperature-Duty

VDD=3.7V

100

90

80

70

VDD=3.3V

60

PJ-1σ[psec]

:

50

40

30

20

Period-jitter1σ

10

0

-25 0 25 50 75 100

VDD=2.4V

VDD=3.7V

Temperature:T[℃]

Fig.115 27MHz

Temperature-Period-Jitter 1σ

50

40

IDD[mA]

:

30

VDD=3.7V

20

VDD=3.7V

VDD=2.4V

10

Circuit Current

0

-25 0 25 50 75 100

Fig.117 Action circuit current

(with maximum output load)

Temperature-Consumption current

VDD=3.3V

Temperature:T[℃]

Technical Note

600

500

:

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

Temperature-Period-Jitter MIN-MAX

:

PJ-MIN-MAX[psec]

Period-jitterMIN-MAX

Temperature-Period-Jitter MIN-MAX

VDD=3.7V

400

300

200

100

0

-250 255075100

VDD=3.3V

VDD=2.4V

Temperature:T[℃]

Fig.113 16.9MHz)

600

500

VDD=2.4V

400

300

200

100

0

-25 0 25 50 75 100

Temperature:T[℃]

VDD=3.3V

VDD=3.7V

Fig.116 27MHz

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

15/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

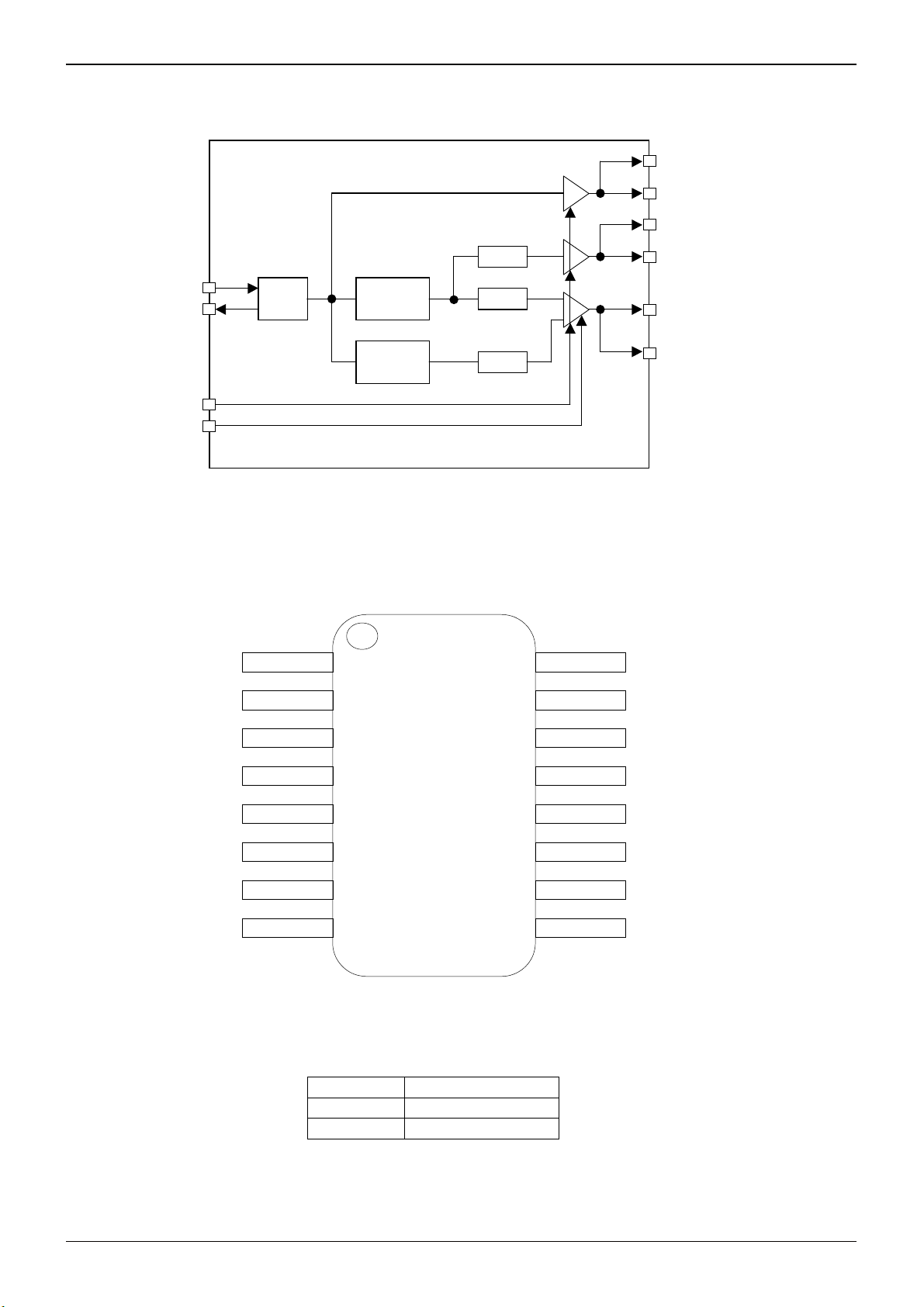

●Block diagram, Pin assignment

◎BU2280FV

8:XTALIN

9:XTALOUT

XTALIN=27.0000MHz

XTAL

OSC

21:OE

23:CTRLFS

(FSEL=OPEN:48.0kHz type

FSEL=L :44.1kHz type)

1:VDD1 24:CLK27M3

2:VSS1 23:CTRLFS

3:CLK27M1 22:CLK768FS

4:CLK27M2 21:OE

5:AVDD 20:CLK384FS

6:AVDD 19:DVDD

7:AVSS 18:DVSS

8:XTALIN 17:DVSS

9:XTALOUT 16:CLK512FS1

10:VSS2 15:CLK512FS2

11:VDD2 14:VDD2

12:CLK33M 13:VSS2

CTRLFS CLK384FS CLK512FS CLK768FS

L 16.9344MHz 22.5792MHz 33.8688MHz

OPEN 18.4320MHz 24.5760MHz 36.8640MHz

PLL1

PLL2

1/4

1/6

1/8

1/4

1/6

1/8

Fig.118

BU2280FV

BU2280FV

Fig.119

Technical Note

3:CLK27M1

(27.0000MHz)

4:CLK27M2

(27.0000MHz)

24:CLK27M3

(27.0000MHz)

12:CLK33M

(33.8688MHz)

22:CLK768FS

(CTRLFS=OPEN:36.8640MHz

CTRLFS=L :33.8688MHz)

16:CLK512FS1

(CTRLFS=OPEN:24.5760MHz

CTRLFS=L :22.5792MHz)

15:CLK512FS2

(CTRLFS=OPEN:24.5760MHz

CTRLFS=L :22.5792MHz)

20:CLK384FS

(CTRLFS=OPEN:18.4320MHz

CTRLFS=L :16.9344MHz)

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

16/23

2012.02 - Rev.B

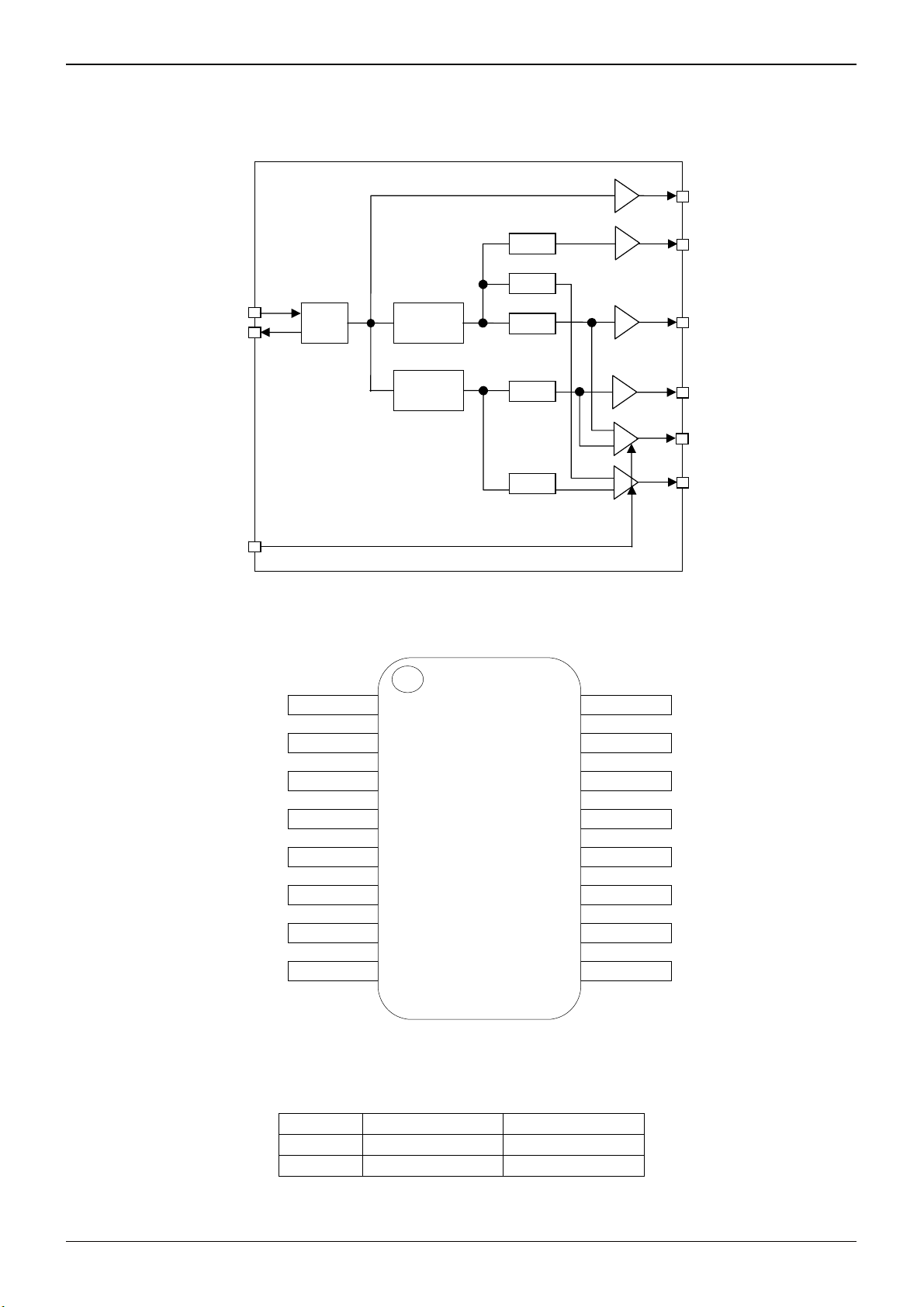

BU2280FV, BU2360FV, BU2362FV

●Block diagram, Pin assignment

◎BU2360FV

XTALIN=27.0000MHz

7:XTALIN

8:XTALOUT

16:OE

14:FSEL

(FSEL=OPEN:48.0kHz type

FSEL=L :44.1kHz type)

XTAL

OSC

PLL1

PLL2

1/4

1/6

1/6

Technical Note

3:CLK27M

(27.0000MHz)

4:CLK27M

(27.0000MHz)

15:CLK33M1

(33.8688MHz)

13:CLK33M2

(33.8688MHz)

10:CLK512FS1

(FSEL=OPEN:24.5760MHz

FSEL=L :22.5792MHz)

9:CLK512FS2

(FSEL=OPEN:24.5760MHz

FSEL=L :22.5792MHz)

Fig.120

1:VDD2 16:OE

2:VSS2 15:CLK33M1

3:CLK27M1 14:FSEL

4:CLK27M2 13:CLK33M2

5:AVDD 12:DVDD

6:AVSS 11:DVSS

7:XTALIN 10:CLK512FS1

8:XTALOUT 9:CLK512FS2

BU2360FV

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

Fig.121

FSEL CLK512FS1 / 2

L 22.5792MHz

OPEN 24.5760MHz

17/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

3:C

5

6

SS

SS

8

S

9:C

●Block diagram, Pin assignment

◎BU2362FV

8:XTALIN

7:XTALOUT

XTALIN=27.0000MHz

XTAL

OSC

14:FSEL1

1:VDD2 16:CLK36M

2:VSS2 15:CLK33M

LK27M 14:FSEL1

4:TEST 13:CLK16M

:AVDD

:AV

7:XTALOUT

:XTALIN

FSEL1 CLK512FS CLKA

OPEN 22.5792MHz 16.9344MHz

L 24.5760MHz 36.8640MHz

PLL1

PLL2

1/4

1/6

1/8

1/4

1/6

Fig.122

BU2362FV

12:DVDD

11: DV

10:CLK512F

LKA

Fig.123

Technical Note

3:CLK27M

(27.0000MHz)

15:CLK33M

(33.8688MHz)

13:CLK16M

(16.9344MHz)

16:CLK36M

(36.8640MHz)

9:CLKA

(FSE=OPEN:16.9344MHz

FSEL=L :36.8640MHz)

10:CLK512FS

(FSE=OPEN:22.5792MHz

FSEL=L :24.5760MHz)

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

18/23

2012.02 - Rev.B

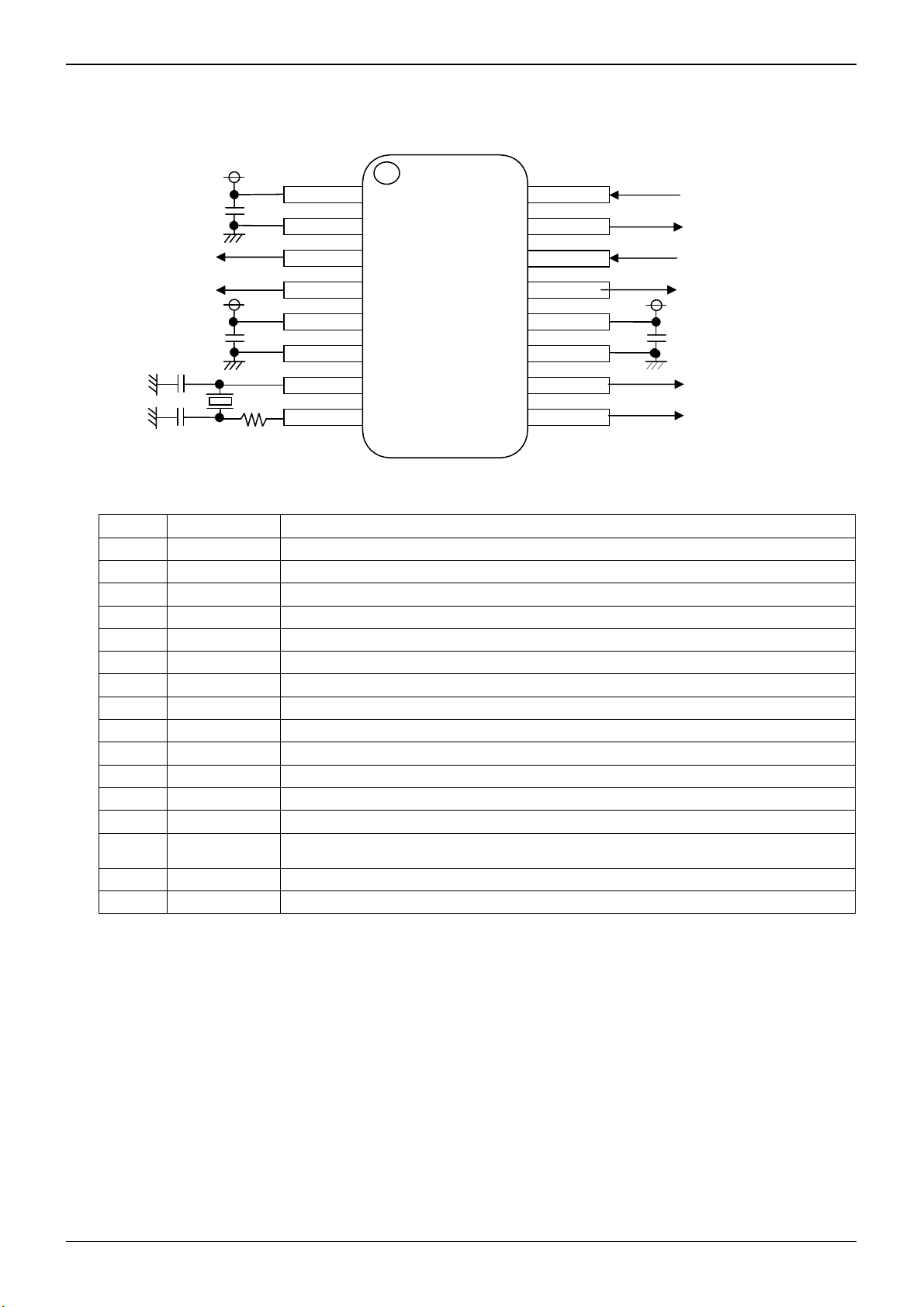

BU2280FV, BU2360FV, BU2362FV

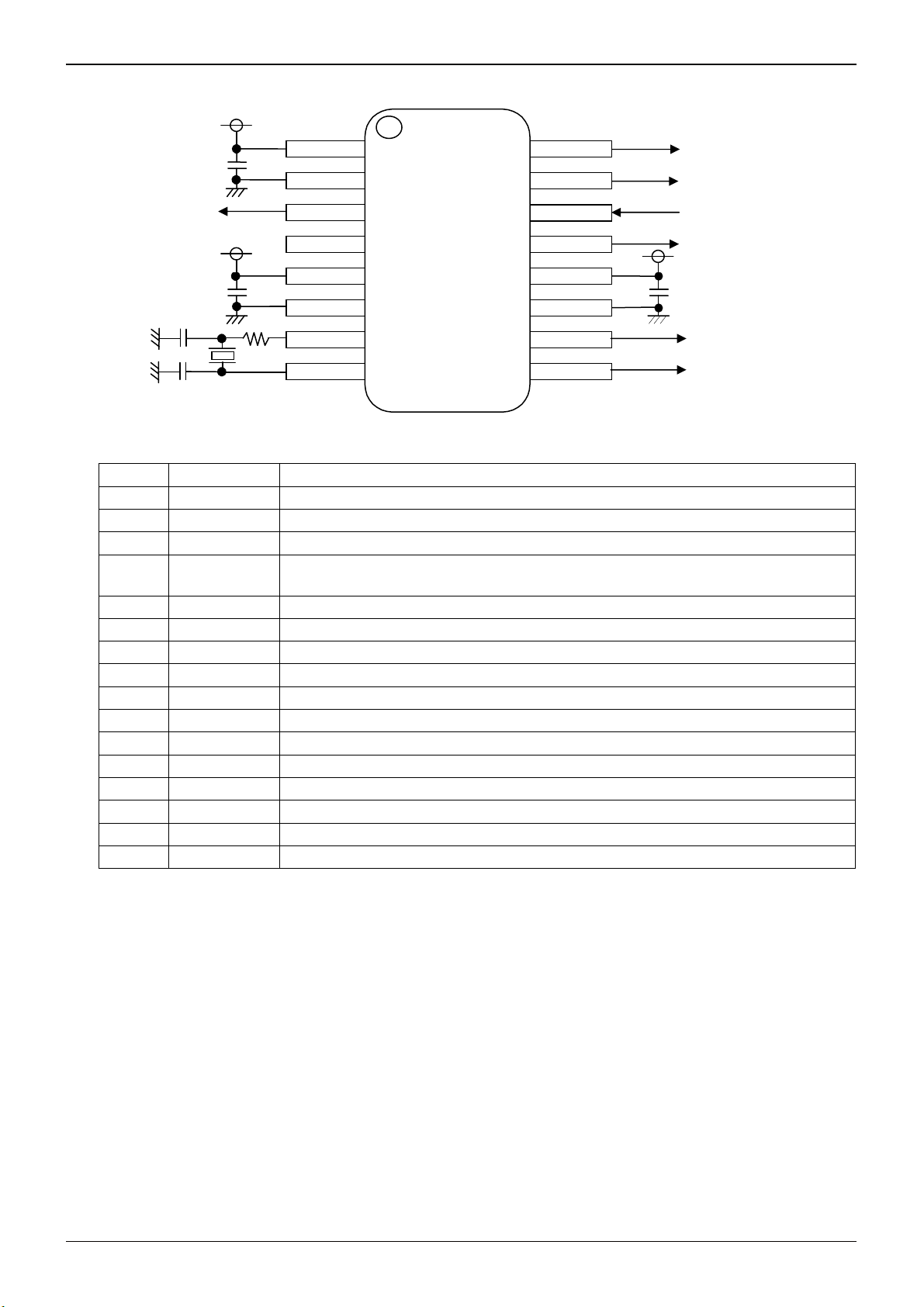

●Example of application circuit

◎BU2280FV

0.1µF

27.0000MHz

27.0000MHz

0.1µF

33.8688MHz

0.1µF

1:VDD1

2:VSS1

3:CLK27M1

4:CLK27M2

5:AVDD

6:AVDD

7:AVSS

8:XTALIN

9:XTALOUT

10:VSS2

11: VDD 2

12:CLK33M

BU2280FV

Fig.124

Description of terminal

PIN No. PIN Name PIN Function

1 VDD1 Power supply for 27MHz

2 VSS1 GND for 27MHz

3 CLK27M1 27.0000MHz Clock output terminal 1

4 CLK27M2 27.0000MHz Clock output terminal 2

5 AVDD Power supply for Analog block

6 AVDD Power supply for Analog block

7 AVSS GND for Analog block

8 XTALIN Crystal input terminal

9 XTALOUT Crystal output terminal

10 VSS2 GND for 33MHz

11 VDD2 Power supply for 33MHz

12 CLK33M 33.8688MHz Clock output terminal

13 VSS2 GND for 33MHz

14 VDD2 Power supply for 33MHz

15 CLK512FS2 CTRLFS=OPEN:24.5760MHz, CTRLFS=L:22.5792MHz

16 CLK512FS1 CTRLFS=OPEN:24.5760MHz, CTRLFS=L:22.5792MHz

17 DVSS GND for Digital block

18 DVSS GND for Digital block

19 DVDD Power supply for Digital block

20 CLK384FS CTRLFS=OPEN:18.4320MHz, CTRLFS=L:16.9344MHz

21 OE Output enable (with pull-up), OPEN:enable, L:disable

22 CLK768FS CTRLFS=OPEN:36.8640MHz, CTRLFS=L:33.8688MHz

15, 16, 20, 22PIN output selection (with pull-up)

23 CTRLFS

OPEN:24.5760MHz(15PIN, 16PIN), 18.4320MHz(20PIN), 36.8640MHz(22PIN)

L:22.5792MHz(15PIN, 16PIN), 16.9344MHz(20PIN), 33.8688MHz(22PIN)

24 CLK27M3 27.0000MHz Clock output terminal 3

Note) Basically, mount ICs to the printed circuit board for use.

(If the ICs are not mounted to the printed circuit board, the characteristics of ICs may not be fully demonstrated.)

Mount 0.1F capacitors in the vicinity of the IC PINs between 1PIN (VDD1) and 2PIN (VSS1), 5PIN-6PIN (AVDD) and 7PIN (AVSS), 10PIN (VSS2) and

11PIN (VDD2), 13PIN(VSS2) and 14PIN (VDD2), 17PIN-18PIN (DVSS) and 19PIN(DVDD), respectively.

Depending on the conditions of the printed circuit board, mount an additional electrolytic capacitor between the power supply and GND terminal.

For EMI protection, it is effective to put ferrite beads in the origin of power supply to be fed to BU2280FV from the printed circuit board or to insert a

capacitor (of 1 or less), which bypasses high frequency desired, between the power supply and the GND terminal.

24:CLK27M3

23:CTRLFS

22:CLK768FS

21:OE

20:CLK384FS

19:DVDD

18:DVSS

17:DVSS

16:CLK512FS1

15:CLK512FS2

14:VDD2

13:VSS2

27.0000MHz

OPEN:48.0kHz type

L:44.1kHz type

36.8640MHz

or 33.8688MHz

OPEN:Enable

L:Disable

18.4320MHz

or 16.9344MHz

0.1µF

24.5760MHz

or 22.5792MHz

24.5760MHz

or 22.5792MHz

0.1µF

Technical Note

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

19/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Example of application circuit

◎BU2360FV

0.1µF

27.0000MHz

27.0000MHz

0.1µF

1:VDD2

2:VSS2

3:CLK27M1

4: CLK27M2

5:AVDD

6:AVSS 11:DVSS

BU2360FV

7:XTALIN

8:XTALOUT

Fig.125

Description of terminal

PIN No. PIN name PIN function

1 VDD2 Power supply for 27MHz

2 VSS2 GND for 27MHz

3 CLK27M1 27.0000MHz Clock output terminal 1 (CL=40pF)

4 CLK27M2 27.0000MHz Clock output terminal 2 (CL=25pF)

5 AVDD Power supply for Analog block

6 AVSS GND for Analog block

7 XTALIN Crystal input terminal

8 XTALOUT Crystal output terminal

9 CLK512FS2 FSEL=OPEN:24.5760MHz, FSEL=L:22.5792MHz

10 CLK512FS1 FSEL=OPEN:24.5760MHz, FSEL=L:22.5792MHz

11 DVSS GND for Digital block

12 DVDD Power supply for Digital block

13 CLK33M2 33.8688MHz Clock output terminal 2

14 FSEL

9, 10PIN output selection (with pull-up)

OPEN:24.5760MHz(9, 10PIN), L:22.5792MHz(9, 10PIN)

15 CLK33M1 33.8688MHz Clock output terminal 1

16 OE Output enable (with pull-up), OPEN:enable, L:disable

Note) Basically, mount ICs to the printed circuit board for use.

(If the ICs are not mounted to the printed circuit board, the characteristics of ICs may not be fully demonstrated.)

Mount 0.1F capacitors in the vicinity of the IC PINs between 1PIN (VDD2) and 2PIN (VSS2), 5PIN (AVDD) and 6PIN (AVSS), 11PIN (DVSS) and 12PIN

(DVDD), respectively.

Depending on the conditions of the printed circuit board, mount an additional electrolytic capacitor between the power supply and GND terminal.

For EMI protection, it is effective to put ferrite beads in the origin of power supply to be fed to BU2360FV from the printed circuit board or to insert a

capacitor (of 1 or less), which bypasses high frequency desired, between the power supply and the GND terminal.

16:OE

15:CLK33M1

14:FSEL

13:CLK32M2

12:DVDD

10:CLK512FS1

9:CLK512FS2

Technical Note

OPEN:Enable

L:Disable

33.8688MHz

OPEN:48.0kHz type

L:44.1kHz type

33.8688MHz

0.1µF

24.5760MHz

or 22.5792MHz

24.5760MHz

or 22.5792MHz

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

20/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

Technical Note

●Example of application circuit

◎BU2362FV

1:VDD2

16:CLK36M

36.8640MHz

2:VSS2

BU2362FV

27.0000MHz

27.0000MHz

3:CLK27M

4:TEST

5:AVDD

6:AVSS

7:XTALOUT

8:XTALIN

15:CLK33M

14:FSEL1

13:CLK16M

12:DVDD

11:DVSS

10:CLK512FS1

9:CLKA

33.8688MHz

H:44.1kHz mode

L:48kHz mode

16.9344MHz

22.5792MHz

or 24.5670MHz

16.9344MHz

or 36.8640MHz

Fig.126

Description of terminal

Pin No. PIN NAME Function

1 VDD2 Power supply for CLK27, CLK36M

2 VSS2 GND for CLK27, CLK36M

3 CLK27M 27MHz Clock output terminal

4 TEST

Input pin for TEST : with pull-down

(Please set ”L” or OPEN, normally)

5 AVDD Power supply for Analog block

6 AVSS GND for Analog block

7 XTALOUT Crystal output terminal

8 XTALIN Crystal input terminal

9 CLKA CLKA output terminal (16.9344MHz or 36.8640MHz)

10 CLK512FS 512fs Clock output terminal (22.5792MHz or 24.5760MHz)

11 DVSS Power supply for Digital block

12 DVDD GND for Digital block

13 CLK16M 16.9344MHz Clock output terminal

14 FSEL1 CLKA or CLK512FS pin output select : with pull-up

15 CLK33M 33.8688MHz Clock output terminal

16 CLK36M 36.8640MHz Clock output terminal

●Notes for use (BU2362FV)

Basically, mount ICs to the printed circuit board for use. (If the ICs are not mounted to the printed circuit board, the

characteristics of ICs may not be fully demonstrated.)

Mount 0.1F capacitors in the vicinity of the IC PINs between 1PIN (VDD2) and 2PIN (VSS2), 5PIN (AVDD) and 6PIN

(AVSS), 11PIN (DVSS) and 12PIN (DVDD), respectively.

For the fine-tuning of frequencies, insert several numbers of pF in the 7PIN and 8PIN to GND.

Depending on the conditions of the printed circuit board, mount an additional electrolytic capacitor between the power supply

and GND terminal.

For EMI protection, it is effective to put ferrite beads in the origin of power supply to be fed to BU2362FV from the printed

circuit board or to insert a capacitor (of 1Ω or less), which bypasses high frequency desired, between the power supply and

the GND terminal.

*Even though we believe that the example of recommended circuit is worth of a recommendation, please be sure to thoroughly recheck the characteristics

before use.

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

21/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Notes for use

1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as applied voltage (VDD or VIN), operating temperature range (Topr),

etc., can break down devices, thus making impossible to identify breaking mode such as a short circuit or an open circuit.

If any special mode exceeding the absolute maximum ratings is assumed, consideration should be given to take physical

safety measures including the use of fuses, etc.

2) Recommended operating conditions

These conditions represent a range within which characteristics can be provided approximately as expected. The

electrical characteristics are guaranteed under the conditions of each parameter.

3) Reverse connection of power supply connector

The reverse connection of power supply connector can break down ICs. Take protective measures against the breakdown

due to the reverse connection, such as mounting an external diode between the power supply and the IC’s power supply

terminal.

4) Power supply line

Design PCB pattern to provide low impedance for the wiring between the power supply and the GND lines.

In this regard, for the digital block power supply and the analog block power supply, even though these power supplies has

the same level of potential, separate the power supply pattern for the digital block from that for the analog block, thus

suppressing the diffraction of digital noises to the analog block power supply resulting from impedance common to the

wiring patterns. For the GND line, give consideration to design the patterns in a similar manner.

Furthermore, for all power supply terminals to ICs, mount a capacitor between the power supply and the GND terminal. At

the same time, in order to use an electrolytic capacitor, thoroughly check to be sure the characteristics of the capacitor to be

used present no problem including the occurrence of capacity dropout at a low temperature, thus determining the constant.

5) GND voltage

Make setting of the potential of the GND terminal so that it will be maintained at the minimum in any operating state.

Furthermore, check to be sure no terminals are at a potential lower than the GND voltage including an actual electric

transient.

6) Short circuit between terminals and erroneous mounting

In order to mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs. Erroneous mounting can

break down the ICs. Furthermore, if a short circuit occurs due to foreign matters entering between terminals or between

the terminal and the power supply or the GND terminal, the ICs can break down.

7) Operation in strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

8) Inspection with set PCB

On the inspection with the set PCB, if a capacitor is connected to a low-impedance IC terminal, the IC can suffer stress.

Therefore, be sure to discharge from the set PCB by each process. Furthermore, in order to mount or dismount the set

PCB to/from the jig for the inspection process, be sure to turn OFF the power supply and then mount the set PCB to the jig.

After the completion of the inspection, be sure to turn OFF the power supply and then dismount it from the jig. In addition,

for protection against static electricity, establish a ground for the assembly process and pay thorough attention to the

transportation and the storage of the set PCB.

9) Input terminals

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the

parasitic element can cause interference with circuit operation, thus resulting in a malfunction and then breakdown of the

input terminal. Therefore, pay thorough attention not to handle the input terminals, such as to apply to the input terminals a

voltage lower than the GND respectively, so that any parasitic element will operate. Furthermore, do not apply a voltage to

the input terminals when no power supply voltage is applied to the IC. In addition, even if the power supply voltage is

applied, apply to the input terminals a voltage lower than the power supply voltage or within the guaranteed value of

electrical characteristics.

10) Ground wiring pattern

If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND

pattern from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that

resistance to the wiring pattern and voltage fluctuations due to a large current will cause no fluctuations in voltages of the

small-signal GND. Pay attention not to caus

11) External capacitor

In order to use a ceramic capacitor as the external capacitor, determine the constant with consideration given to a

degradation in the nominal capacitance due to DC bias and changes in the capacitance due to temperature, etc.

e fluctuations in the GND wiring pattern of external parts as well.

Technical Note

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

22/23

2012.02 - Rev.B

BU2280FV, BU2360FV, BU2362FV

●Ordering part number

B U 2 2 8 0 F V - E 2

Part No. Part No.

SSOP-B24

7.8 ± 0.2

(MAX 8.15 include BURR)

24

7.6 ± 0.3

5.6 ± 0.2

1

2280

2360,2362

13

0.3Min.

12

0.15 ± 0.1

Package

FV:SSOP-B24

FV:SSOP-B16

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Packaging and forming specification

E2: Embossed tape and reel

Technical Note

1.15 ± 0.1

0.1

SSOP-B16

6.4±0.3

1.15±0.1

0.10

9

8

0.22±0.1

0.1

Direction of feed

(Unit : mm)

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

0.3Min.

0.15±0.1

0.1

(Unit : mm)

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Direction of feed

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

0.65

0.22 ± 0.1

5.0±0.2

16

4.4±0.2

1

0.65

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

23/23

2012.02 - Rev.B

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...