Page 1

A

Touch Screen Controller ICs

Resistive Type

Touch Screen Controller ICs

BU21023GUL, BU21023MUV, BU21024FV-M

●Description

Unlike most resistive touch screen controllers, the BU21023/ BU21024 4-wire resistive touch screen controllers enable

dual-touch detection and gesture recognition. These intelligent controllers expose a set of registers to a host processor and

are software configurable. The controllers can detect single point coordinates, dual coordinates, pinch, spread, rotate left

and rotate right gestures, enabling pan and zoom operations in applications that previously had to rely exclusively on

capacitive touch technology. Resistive touch does not require custom panel development which reduces development cost

and results in faster time to market across a family of products.

●Features

1) Enables single touch, dual touch & gesture recognition using standard 4-wire resistive touch panels

2) Adjustable touch detection threshold allows fine tuning of pressure sensitivity for an application

3) Enables measurement of single point touch pressure

4) SPI and I

5) Programmable interrupt polarity

6) 10-bit ADC provides sufficient resolution for finger or stylus inputs

7) Firmware for internal CPU may be downloaded from Host processor or from an EEPROM

8) Includes filtering options to eliminate false coordinates

9) Built in support for intelligent calibration

10) Easy to swap X & Y coordinates or adapt to different touch panel connections

11) Single 3V power supply

12) Available in a range of small package sizes and temperature ranges

13) Ideally suited for large volume automotive, consumer and industrial applications

●Application

・Products with a LCD that can benefit from pan and zoom operations.

・Smart phones, Digital Cameras, Video Cameras, GPS Receivers, Printers,

Copiers, automotive navigation panels, touch kiosks

・Tablet PCs , Notebook computers, LCD displays (with USB interface)

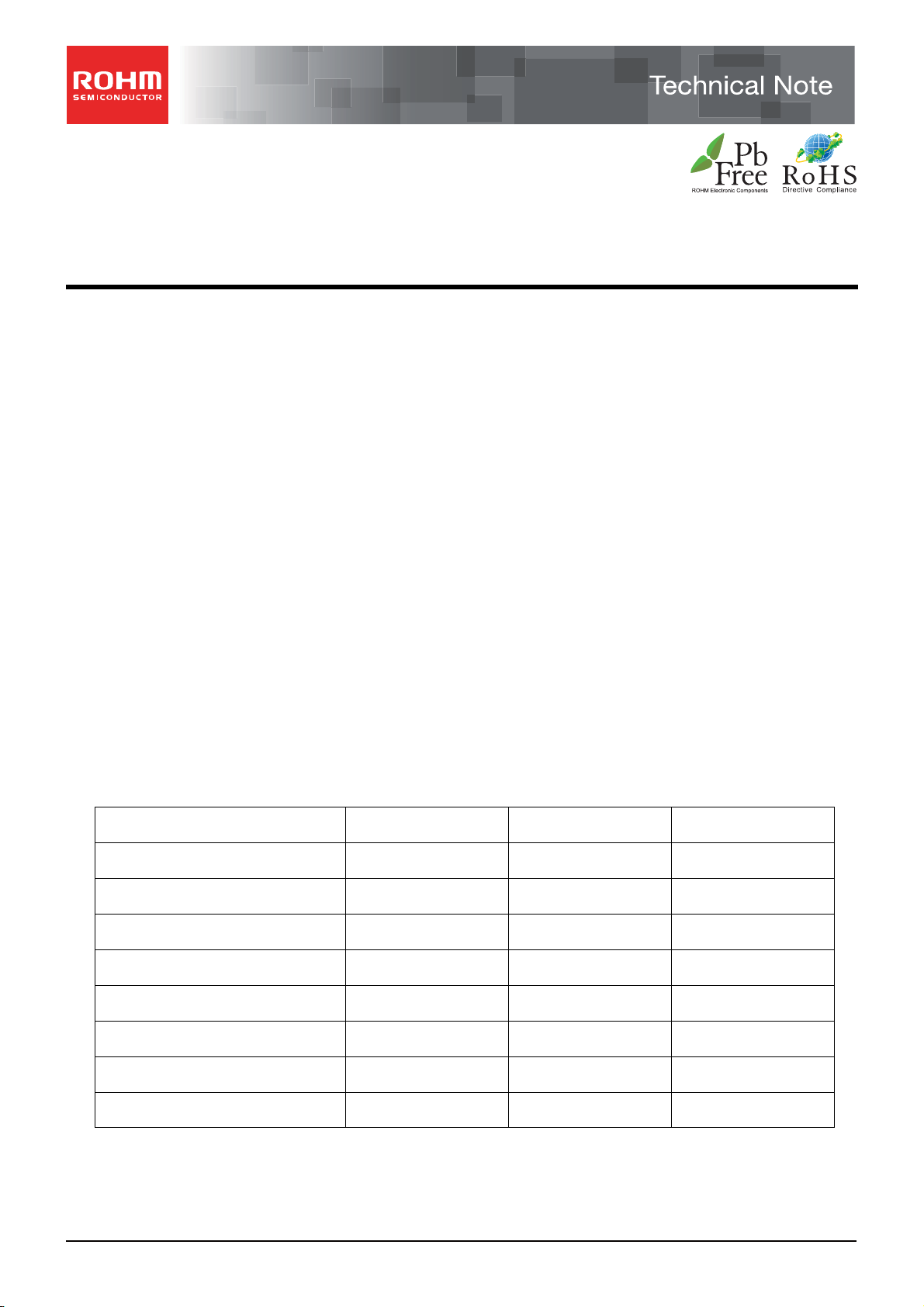

●Line up matrix

2

C like interface for interfacing to host processor

No.11105EAT01

Parameter BU21023GUL BU21023MUV BU21024FV-M

Screen

Maximum detection point

Integrated Filter process

Gesture Detection

Supplied Voltage Range(V)

Temperature Range(℃)

Host I/F

PKG

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

4-wire resistive

touch screen

2 2 2

Yes Ye s Yes

Yes Ye s Yes

2.7 - 3.6 2.7 - 3.6 2.7 - 3.6

-20 - 85 -20 - 85 -40 - 85

4-wire SPI

2-wire serial

VCSP50L2 VQFN028V5050 SSOP-B28

1/17

4-wire resistive

touch screen

4-wire SPI

2-wire serial

4-wire resistive

touch screens

4-wire SPI

2-wire serial

2011.08 - Rev.

Page 2

A

BU21023GUL,BU21023MUV,BU21024FV-M

●Absolute Maximum Ratings

Parameter Symbol Ratings Unit Condition

Power supply voltage VDD -0.3 ~ 4.5 V

Input voltage VIN VSS-0.3 ~ VDD+0.3 V

*1

BU21023GUL

mW

830

Technical Note

Power dissipation

BU21023MUV 704

Pd

BU21024FV-M 850

*2

mW

*3

mW

Storage temperature range Tstg -50 ~ 125 ℃

*1 Derate by 7.04 mW /℃ centigrade when ambient temperature exceeds 25℃. Measured using Epoxy-Glass PCB measuring 50x58x1.75 mm

*2 Derate by 8.30mW /℃ centigrade when ambient temperature exceeds 25℃. Measured using Epoxy-Glass PCB measuring 50x58x1.75mm

*3 Derate by 8.50mW /℃ centigrade when ambient temperature exceeds 25℃. Measured using Epoxy-Glass PCB measuring 50x58x1.75mm

●Recommended Operating Conditions

Parameter Symbol

Min. Typ. Max.

Ratings

Unit Condition

Power supply voltage VDD 2.70 3.00 3.60 V

Digital core power supply DVDD 1.62 1.80 1.98 V DVDD_EXT=H

BU21023GUL

Operating

temperature range

Note: The BU21023/BU21024 controllers can be operated with a single 3V VDD supply.

It is also possible to supply 1.8V DVDD from an external source if the DVDD_EXT pin is connected to logic high.

BU21023MUV

Topr

BU21024FV-M -40 25 85 ℃

-20 25 85 ℃

●Electrical Characteristics (Ta=25℃, VDD=3.00V)

Parameter Symbol

Min. Typ. Max.

Limits

Unit Condition

Low-level input voltage

High-level input voltage

Low-level output voltage

High-level output voltage

Standby current

Sleep current1

Sleep current2

Operating current

Oscillation frequency

Resolution

Differential non-linearity error

Integral non-linearity error

VIL VSS-0.5 - 0.2×VDD V

VIH 0.8×VDD - VDD+0.5 V

VOL - - VSS+0.4 V

VOH VDD-0.4 - - V

Ist - - 1 µA

Icc1 - 60 100 µA

Icc2 - 10 20 µA

Idd - 4 6 mA

Freq 18 20 22 MHz

Ad 1024×1024 Bit

DNL -3.0 - +3.0 LSB

INL -3.0 - +3.0 LSB

RSTB=L

DVDD_EXT=L

DVDD_EXT=H

No load

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

2/17

2011.08 - Rev.

Page 3

A

BU21023GUL,BU21023MUV,BU21024FV-M

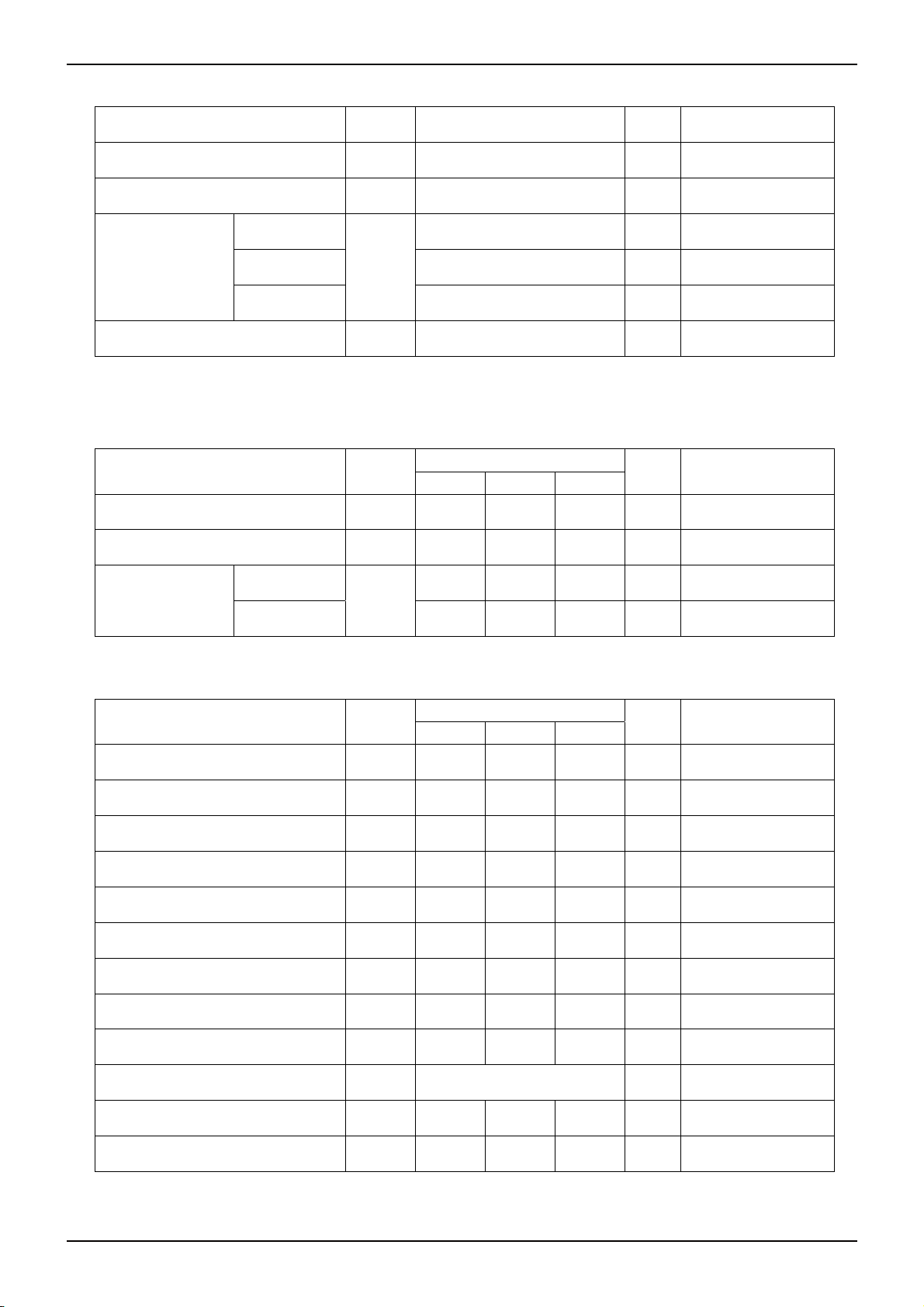

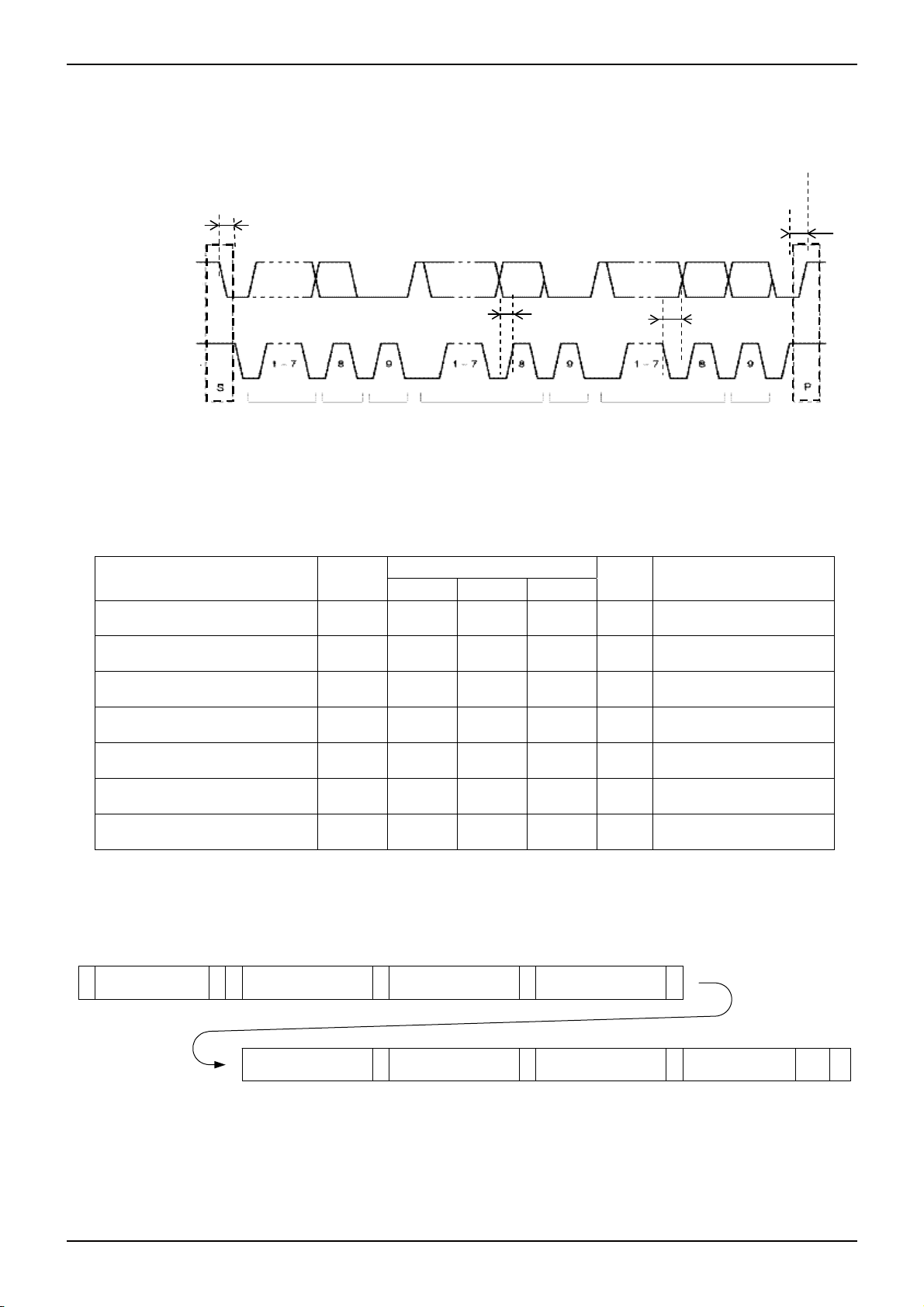

●HOST-I/F mode (4-wire SPI)

(SCK=SCL_SCK, SI=SDA_SI, CSB=SEL_CSB, SO=SO)

Technical Note

Condition : VDD = 3.0V Ta=25

Parameter Symbol

CSB setup time t1 30 - - ns

SCK "H" level period t2 30 - - ns

SCK "L" level period t3 30 - - ns

SI setup time t4 20 - - ns

SI holding time t5 20 - - ns

CSB holding time t6 20 - - ns

CSB "H" level time t7 50 - - ns

Data output delay time t8 - - 15 ns

SCK frequency t9 - - 15 MHz

Note: SPI interface is selected by tying IFSEL pin to logic low. IFSEL= logic high selects the 2-wire interface

℃

Limits

Min. Typ. Max.

Unit Condition

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

3/17

2011.08 - Rev.

Page 4

A

BU21023GUL,BU21023MUV,BU21024FV-M

Technical Note

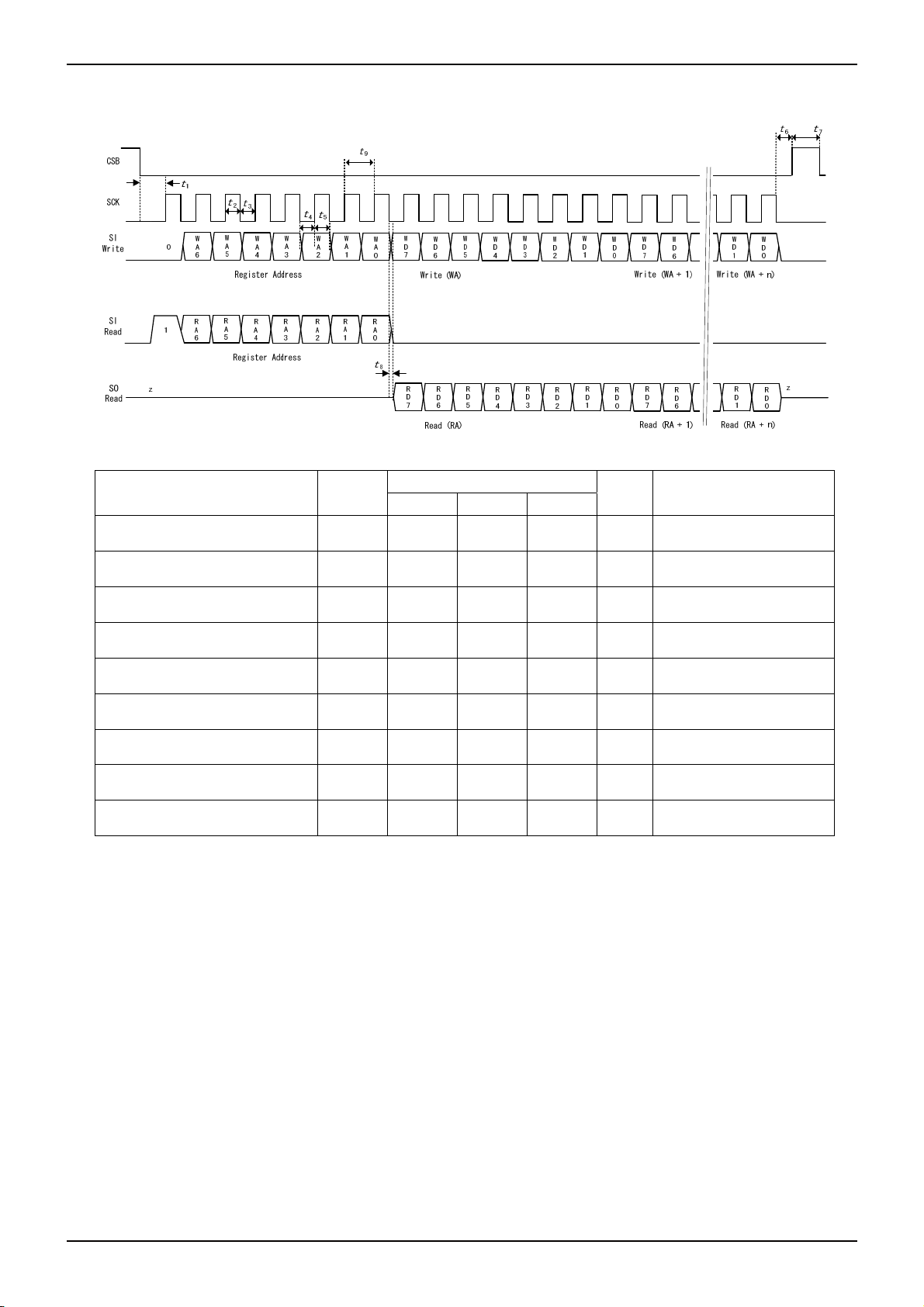

●HOST-I/F mode (2-wire serial)

(SCL=SCL_SCK, SDA=SDA_SI)

The 2-wire serial mode presents an I

conforming to the I

2

C specification. The BU21023MUV/ BU21023GUL / BU21024FV-M devices can co-exist with other I2C

2

C like interface for all practical purposes, but it is not a complete implementation

devices on the same bus. The slave address for 2-wire serial communication is 5Ch or 5Dh. This is determined by the

SEL_CSB pin.

SEL_CSB = “L” : Slave address = 5Ch

SEL_CSB = “H” : Slave address = 5Dh

t

SU;STO

SDA

SDA

SCL

SCL

t

HD;STA

t

SU;DAT

t

HD;DAT

Address ACK

Data Data

ACK

ACK

Parameter Symbol

SCL clock frequency

START condition hold time

SCL “L”

SCL “H”

Data hold time

Data setup time

STOP condition setup time

Min. Typ. Max.

f

0 - 400 kHz

SCL

t

0.6 - - µs

HD:STA

t

1.3 - - µs

LOW

t

0.6 - - µs

HIGH

t

0.1 - - µs

HD:DAT

t

0.1 - - µs

SU:DAT

t

0.6 - - µs

SU:STO

Limits

Unit Condition

・Write protocol

S SLAVE ADDRESS W

7bit = 5Ch or 5Dh 8bit 8bit

A

REGISTER

ADDRESS

A WRITE DATA AP

・Read protocol

S SLAVE ADDRESS W

7bit = 5Ch or 5Dh 8bit 7bit = 5Ch or 5Dh 8bit

from master to slave S = START condition

R = data direction READ (SDA HIGH)

W = data direction WRITE (SDA LOW)

A = acknowledge (SDA LOW)

N = not acknowledge (SDA HIGH)

from slave to master P = STOP condition

A

REGISTER

ADDRESS

A S SLAVE ADDRESS R A READ DATA N P

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

4/17

2011.08 - Rev.

Page 5

A

BU21023GUL,BU21023MUV,BU21024FV-M

A

A

A

A AAA A

A

A

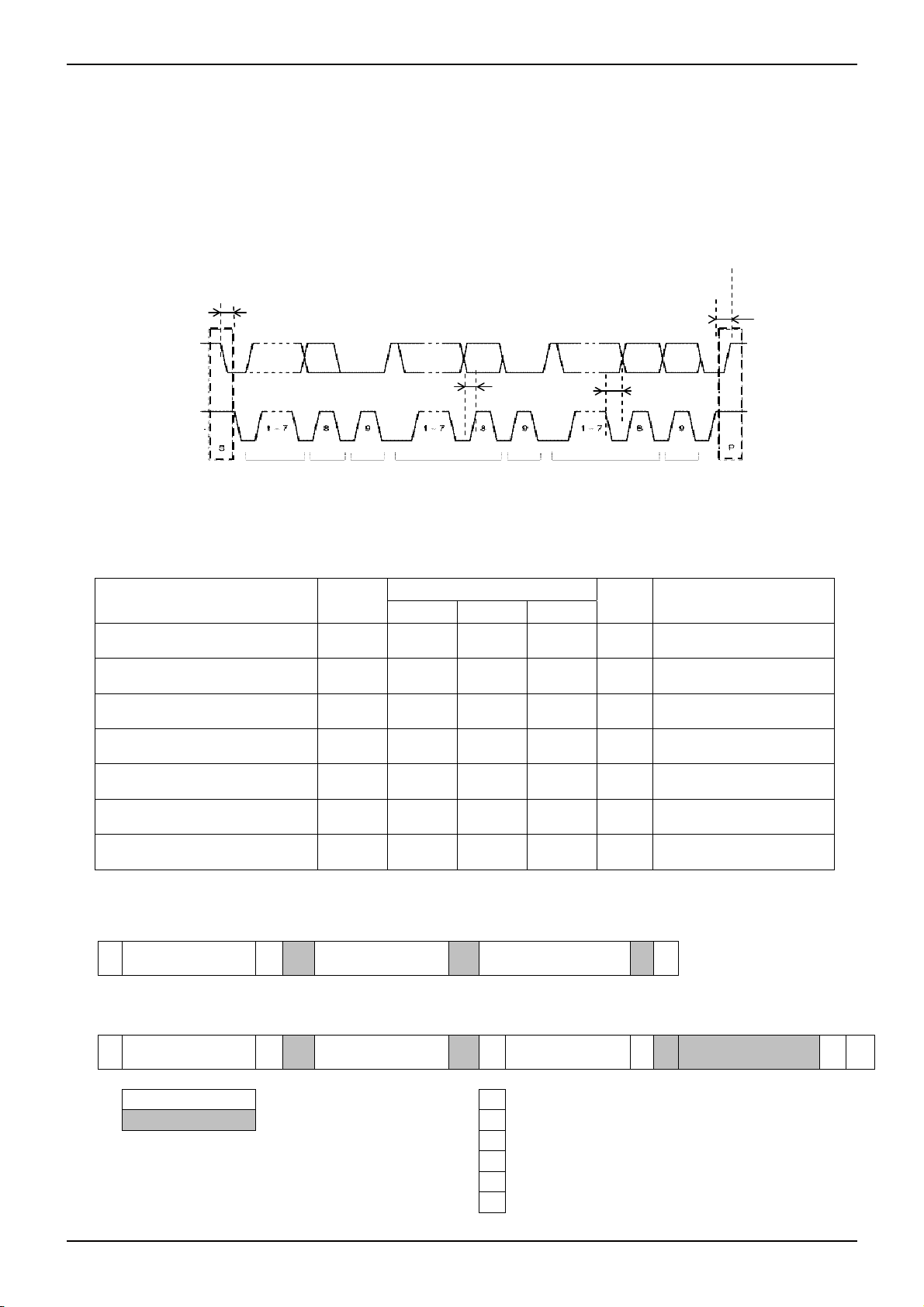

●EEPROM I/F

BU21023/BU21024 controllers include an EEPROM interface for firmware download.

Device address of EEPROM is set via register 0x51(EEPROM_ADDR).

Timing chart

t

HD;STA

SDA

t

SU;DAT

SCL

Technical Note

t

SU;STO

t

HD;DAT

SCL clock frequency

START hold time

SCL ”L” width

SCL ”H” width

Data hold time

Data setup time

STOP setup time

Protocol

*IC does not support the write command.

*IC supports the following read command.

Start

Address

Parameter Symbol

Read

/Write

ACK

Min. Typ. Max.

f

270 310 350 kHz

SCL

t

0.7 - 0.9 µs

HD:STA

t

1.4 - 1.8 µs

LOW

t

1.4 - 1.8 µs

HIGH

t

0.7 - 0.9 µs

HD:DAT

t

0.7 - 0.9 µs

SU:DAT

t

0.7 - 0.9 µs

SU:STO

Data Data

Limits

ACK

Unit Condition

ACK

S

SLAVE

DDRESS

W

1st WORD

DDRESS

DATA(n-3)

2nd WORD

DDRESS

DATA(n-2)

DATA(0)

DATA(n-1)

DATA(n) P

N

Stop

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

5/17

2011.08 - Rev.

Page 6

A

BU21023GUL,BU21023MUV,BU21024FV-M

●Background Information

A resistive touch panel is made up of a multilayer sandwich of resistive films and protective coatings all sitting on top of an

LCD display. Resistive touch panels work by direct contact of a stylus or a finger flexing a pair of resistive films, hence any

blunt pointing instrument or a gloved finger may be used.

Touch panel resolution

The resolution of a touch panel is typically measured in dots per inch (dpi) and is a function of the physical size of the touch

panel and the ADC used in the conversion circuitry. For example, a 3”x5” panel used with the BU21023/BU21024 devices

can provide a theoretical resolution of 1024 /5 = 204 dpi. In the case of resistive touch panels, the direct contact nature of its

operation and finger thickness often impose an upper limit on the effective system resolution that may be achieved,

regardless of the resolution of the ADC itself.

●Functional Description

The BU21023/BU21024 devices connect to a standard 4-wire resistive touch screen on one side and to a host processor on

the other side. The BU21024 includes four additional sense terminals allowing it to be used with either 4-wire or 8-wire

resistive touch screens. The BU21023/BU21024 include the analog and digital circuitry to process and provide dual touch

coordinate data and pinch, spread, rotate-right and rotate-left gesture information to the host CPU.

The BU21023/BU21024 devices include an internal CPU and provide a high degree of programmability by exposing a set of

registers that can be accessed by a host CPU through SPI or I

SPI or I

via registers. When an interrupt occurs, for example, due to touch detection, the host processor is required to read an

interrupt status register to determine the cause of the interrupt and take appropriate action.

The program memory of the internal CPU may be initialized via the host interface or via an external EEPROM. This is

selected by a register setting.

The BU21023/BU21024 devices support two sensing modes; continuous and interval sensing modes, that are register

selectable. In the continuous sensing mode, the embedded CPU reads Z, X & Y coordinates continuously when a touch is

detected. The interval sensing mode allows a delay to be inserted between each cycle. The continuous sensing mode is

used more often though the interval sensing mode minimizes power consumption. The continuous sensing mode typically

completes a sampling cycle consisting of Z, X & Y measurements in approximately 2.3 mS.

The BU21023/BU21024 devices enable optimization of touch detection threshold for a given panel. They also include

several sophisticated calibration algorithms.

This document includes a description of the registers followed by flow charts that describe specific steps that a host

processor must follow. Often, a flow chart requires other flow charts to explain the steps in finer detail.

The document also includes information on touch screen parameters that one should to look for while selecting resistive

touch panels for multi-touch.

2

C like interface is selected, The BU21023/BU21024 devices include an INT pin whose polarity can be programmed

2

C like serial interfaces. The IFSEL pin determines whether

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6/17

2011.08 - Rev.

Page 7

A

BU21023GUL,BU21023MUV,BU21024FV-M

r

A

A

y

r

r

K

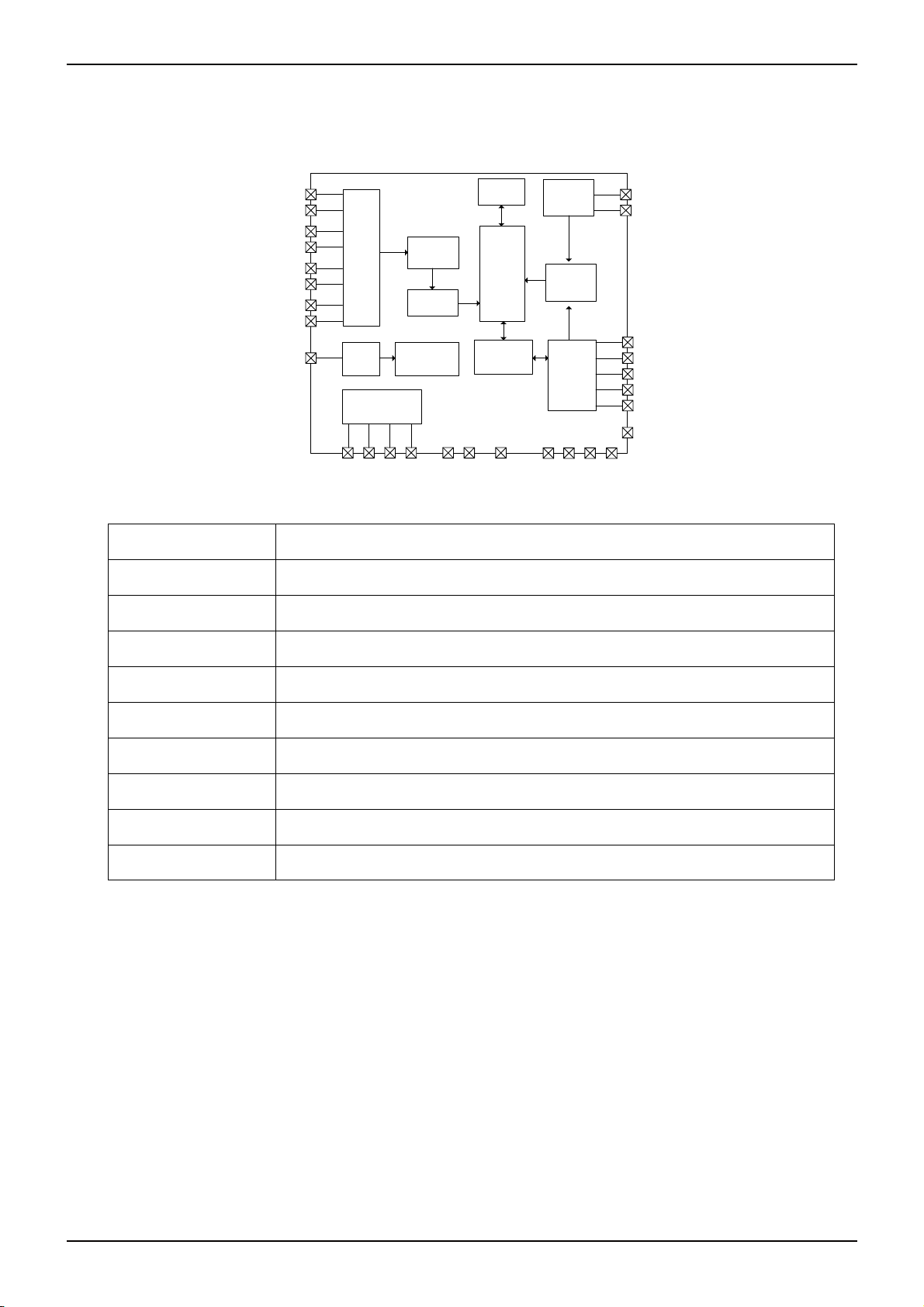

●Block Diagram / Description of each block

【BU21023GUL / BU21023MUV】

XP

Work

Memory

EEPROM

I/F

Technical Note

ECL

EDA

XN

YP

YN

CLK_EXT

Panel

I/F

OSC

PVDD

Regulato

VDD

Generato

DVDD

(10bit)

Filter

Clock

DVDD_EXT

DC

CPU

(8bit)

Registe

VSS

VDD

RSTB

Program

Memor

Host

I/F

T2

T1

SEL_CSB

SCL_SC

SDA_SI

SO

INT

IFSEL

T3

T4

Screen I/F 4-wire resistive touch screen interface

ADC 10bit A/D converter

OSC Internal 20MHz oscillator block with optional external clock input

Regulator

Internal regulator provides 1.8V DVDD supply. DVDD can also be supplied from an

external source if DVDD_EXT pin is tied high.

Clock Generator System clock and timing generation (10MHz CPU clock)

CPU Core For dual touch processing, programmability and host interface

Work memory Data memory for CPU

Program Memory

EEPROM I/F

Program memory for CPU. Code can be downloaded by host processor or from an

external EEPROM

To connect to external EEPROM if downloading program memory from EEPROM. Use

of external EEPROM is optional.

Host I/F 4-wire SPI or 2-wire I2C like interface provides access to registers

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

7/17

2011.08 - Rev.

Page 8

A

BU21023GUL,BU21023MUV,BU21024FV-M

【BU21024FV-M】

XP

XN

YP

YN

XPM

XNM

YPM

YNM

Panel

I/F

(10bit)

CLK_EXT

Osc

Clock

generator

Regulator

PVDD

AVDD

DVDD

DVDD_EXT

Screen I/F 4-wire or 8-wire resistive touch screen interface

ADC

Filter

Technical Note

Work

memory

CPU

(8bit)

register

VSS

VDD

EEPROM

I/F

Program

memory

Host

I/F

T1

RSTB

T2

ECL

EDA

SEL_CSB

SCL_SCK

SDA_SI

SO

INT

IFSEL

T3

T4

ADC 10bit A/D converter

OSC Internal 20MHz oscillator block with optional external clock input

Regulator

Internal regulator provides 1.8V DVDD supply. DVDD can also be supplied from an

external source if DVDD_EXT pin is tied high.

Clock Generator System clock and timing generation (10MHz CPU clock)

CPU Core For dual touch processing, programmability and host interface

Work memory Data memory for CPU

Program Memory

EEPROM I/F

Program memory for CPU. Code can be downloaded by host processor or from an

external EEPROM

To connect to external EEPROM if downloading program memory from EEPROM. Use

of external EEPROM is optional.

Host I/F 4-wire SPI or 2-wire I2C like interface provides access to registers

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

8/17

2011.08 - Rev.

Page 9

A

BU21023GUL,BU21023MUV,BU21024FV-M

Technical Note

●Pin Description

【BU21023GUL】

No. Pin name I/O Function Fig.

D1 YN I/O Panel interface E

C1 XN I/O Panel interface E

C2 YP I/O Panel interface E

B1 XP I/O Panel interface E

A1 T4 I/O Test pin E

A2 PVDD O Regulator output (for supply panel voltage) -

B3 AVDD O Regulator output (for supply analog block) -

A3 DVDD I/O

Regulator output (for supply digital block) or supply digital voltage

(DVDD_EXT="H")

B4 DVDD_EXT I Digital voltage enable (H=Hi-z , L=DVDD Enable) E

A4 VDD - Supply voltage -

A5 VSS - Ground -

C3 RSTB I H/W reset E

B5 CLK_EXT I Supply external clock for debug A

C4 T1 I Test pin A

C5 T2 I Test pin A

D4 T3 I Test pin A

D5 IFSEL I Intereface select pin (L=SPI, H=2wire serial) A

D3 SO O SPI Serila data output 2wire - F

E5 INT O Interrupt output C

D2 SEL_CSB I SPI Chip select 2wire Slave address select C

E4 SDA_SI I/O SPI Serial data input 2wire Serial data in-out C

E3 SCL_SCK I SPI Serial clock input 2wire Serial clock input C

E2 EDA I/O EEPROM SDA C

E1 ECL O EEPROM SCL C

1. Please use 1.0uF capacitors between AVDD and DVDD to GND, and leave PVDD terminal open.

2. If DVDD_EXT=”H “, the DVDD pin can be connected to an external 1.8V power source.

3. Please pull up the ECL, EDA, and INT pins using 10k ohm resistors as shown in the application diagram at the end of this document.

ECL and EDA pins may be directly connected to GND if an external EEPROM is not being used. Please connect a 0.1uF capacitor between T4 and GND.

T1, T2 & T3 pins should be connected to GND.

4. When using the 2 wire serial interface, please pull up the SCL_SCK, SDA_SI pins via 10k ohms and leave SO unconnected.

5. Please note that the values of resistors and capacitors mentioned here are only recommended values.

6. RSTB should be held low until supply voltage VDD has ramped up and has reached a stable level.

7. The polarity of INT pin is programmable via register 0x30

8. Connect CLK_EXT to GND for normal use

T4 PVDD DVDD VDD VSS

A

XP AVDD DVDD_EXT CLK_EXT

B

XN YP RSTB T1 T2

C

YN SEL_CSB SO T3 IFSEL

D

ECL EDA SCL_SCK SDA_SI INT

E

ECL EDA SCL_SCK SDA_SI IN T

E

YN SEL_CSB SO T3 IFSEL

D

XN YP RSTB T1 T2

C

XP AVDD DVDD_EXT CLK_EXT

B

T4 PVDD DVDD VDD VSS

A

-

12345

TOP VIEW (BALL SIDE DOWN)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

9/17

12345

BOTTOM VIEW (BALL SIDE UP)

2011.08 - Rev.

Page 10

A

BU21023GUL,BU21023MUV,BU21024FV-M

Technical Note

【BU21023MUV】

No. Pin name I/O Function fig

1 NC - - -

2 NC - - -

3 NC - - -

4 YN I/O Panel interface E

5 XN I/O Panel interface E

6 YP I/O Panel interface E

7 XP I/O Panel interface E

8 T4 I/O Test pin E

9 PVDD O Regulator output (for supply panel voltage) -

10 AVDD O Regulator output (for supply analog block) -

11 DVDD I/O

Regulator output (for supply digital block) or supply digital voltage

(DVDD_EXT="H")

12 DVDD_EXT I Digital voltage enable (H=Hi-Z , L=DVDD enable) E

13 VDD - Supply voltage -

14 VSS - Ground -

15 RSTB I H/W reset E

16 CLK_EXT I Supply external clock for debug A

17 T1 I Test pin A

18 T2 I Test pin A

19 T3 I Test pin A

20 IFSEL I Intereface select pin (L=SPI, H=2wire serial) A

21 SO O SPI Serila data output 2wire - F

22 INT O Interrupt output C

23 SEL_CSB I SPI Chip select 2wire Slave address select C

24 SDA_SI I/O SPI Serial data input 2wire Serial data in-out C

25 SCL_SCK I SPI Serial clock input 2wire Serial clock input C

26 EDA I/O EEPROM SDA C

27 ECL O EEPROM SCL C

28 NC - - -

1. Please use 1.0uF capacitors between AVDD and DVDD to GND, and leave PVDD terminal open.

2. If DVDD_EXT=”H “, the DVDD pin can be connected to an external 1.8V power source.

3. Please pull up the ECL, EDA, and INT pins using 10k ohm resistors as shown in the application diagram at the end of this document.

ECL and EDA pins may be directly connected to GND if an external EEPROM is not being used. Please connect a 0.1uF capacitor between

T4 and GND. T1, T2 & T3 pins should be connected to GND.

4. When using the 2 wire serial interface, please pull up the SCL_SCK, SDA_SI pins via 10k ohms and leave SO unconnected.

5. Please note that the values of resistors and capacitors mentioned here are only recommended values.

6. RSTB should be held low until supply voltage VDD has ramped up and has reached a stable level.

7. The polarity of INT pin is programmable via register 0x30

8. Connect CLK_EXT to GND for normal use

1

3

5T16

7

8

T4

9

PVDD

10

AVDD

11

DVDD

12

DVDD_EXT

13

VDD

14

VSS

SEL_CSB

SDA_SI

SCL_SCK

EDA

ECL

2

21 SO

20 I FSEL

19 T3

18 T2

17 T1

16 CLK_EXT

15 RSTB

22INT

23

24

25

26

27

NC

28

14 VSS

VDD

13

DVDD_EXT

12

DVDD

11

AVDD

10

PVDD

9

T4

8

ECL

EDA

SCL_SCK

SDA_SI

SEL_CSB

INT

28

NC

27

26

25

24

23

22

4

-

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

1NC

2NC

3NC

4YN

5XN

TOP VIEW (LEAD SIDE DOWN)

7XP

6YP

10/17

21 NC

20 NC

19 NC

18 YN

17 XN

16 YP

T3

SO

BOTTOM VIEW (LEAD SIDE UP)

T2

IFSEL

CLK_EXT

15 XP

RSTB

2011.08 - Rev.

Page 11

A

BU21023GUL,BU21023MUV,BU21024FV-M

Technical Note

【BU21024FV-M】

No. Pin name I/O Function fig

1 EDA I/O EEPROM SDA C

2 ECL O EEPROM SCL C

3 YNM I/O Panel interface (Test input) E

4 XNM I/O Panel interface (Test input) E

5 YPM I/O Panel interface (Test input) E

6 XPM I/O Panel interface (Test input) E

7 YN I/O Panel interface E

8 XN I/O Panel interface E

9 YP I/O Panel interface E

10 XP I/O Panel interface E

11 T4 I/O Test pin E

12 PVDD O Regulator output (for supply panel voltage) -

13 AVDD O Regulator output (for supply analog block) -

14 DVDD I/O

Regulator output (for supply digital block) or supply digital voltage

(DVDD_EXT="H")

15 DVDD_EXT I Digital voltage enable (H=Hi-Z , L=DVDD enable) E

16 VDD - Supply voltage -

17 VSS - Ground -

18 RSTB I H/W reset E

19 CLK_EXT I Supply external clock for debug A

20 T1 I Test pin A

21 T2 I Test pin A

22 T3 I Test pin A

23 IFSEL I Intereface select pin (L=SPI, H=2wire serial) A

24 SO O SPI Serila data output 2wire - F

25 INT O Interrupt output C

26 SEL_CSB I SPI Chip select 2wire Slave address select C

27 SDA_SI I/O SPI Serial data input 2wire Serial data in-out C

28 SCL_SCK I SPI Serial clock input 2wire Serial clock input C

1. Please use 1.0uF capacitors between AVDD and DVDD to GND, and leave PVDD terminal open.

2. If DVDD_EXT=”H “, the DVDD pin can be connected to an external 1.8V power source.

3. Please pull up the ECL, EDA, and INT pins using 10k ohm resistors as shown in the application diagram at the end of this document.

ECL and EDA pins may be directly connected to GND if an external EEPROM is not being used. Please connect a 0.1uF capacitor between

T4 and GND. T1, T2 & T3 pins should be connected to GND.

4. When using the 2 wire serial interface, please pull up the SCL_SCK, SDA_SI pins via 10k ohms and leave SO unconnected.

5. Please note that the values of resistors and capacitors mentioned here are only recommended values.

6. RSTB should be held low until supply voltage VDD has ramped up and has reached a stable level.

7. The polarity of INT pin is programmable via register 0x30

8. Connect CLK_EXT to GND for normal use

9. Please leave the XPM, XNM, YPM, YNM terminals open if using a 4-wire touch screen. These pins should be connected to the reference leads of an

8-wire touch screen if one is being used.

SCL_ SCK

SEL_ CSB

SDA _SI

28

27

26

SO

IFSEL

INT

25

24

23

T3

T2

T1

22

21

20

RSTB

VSS

VDD

CLK_EXT

19

18

17

DVDD_EXTDVDD

16

15

-

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

TOP VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ECL

EDA

YNM

YPM

XNM

YN

XPM

YP

XN

T4

XP

PVDD

AVDD

TOP VIEW

11/17

2011.08 - Rev.

Page 12

A

BU21023GUL,BU21023MUV,BU21024FV-M

PAD

Technical Note

PAD

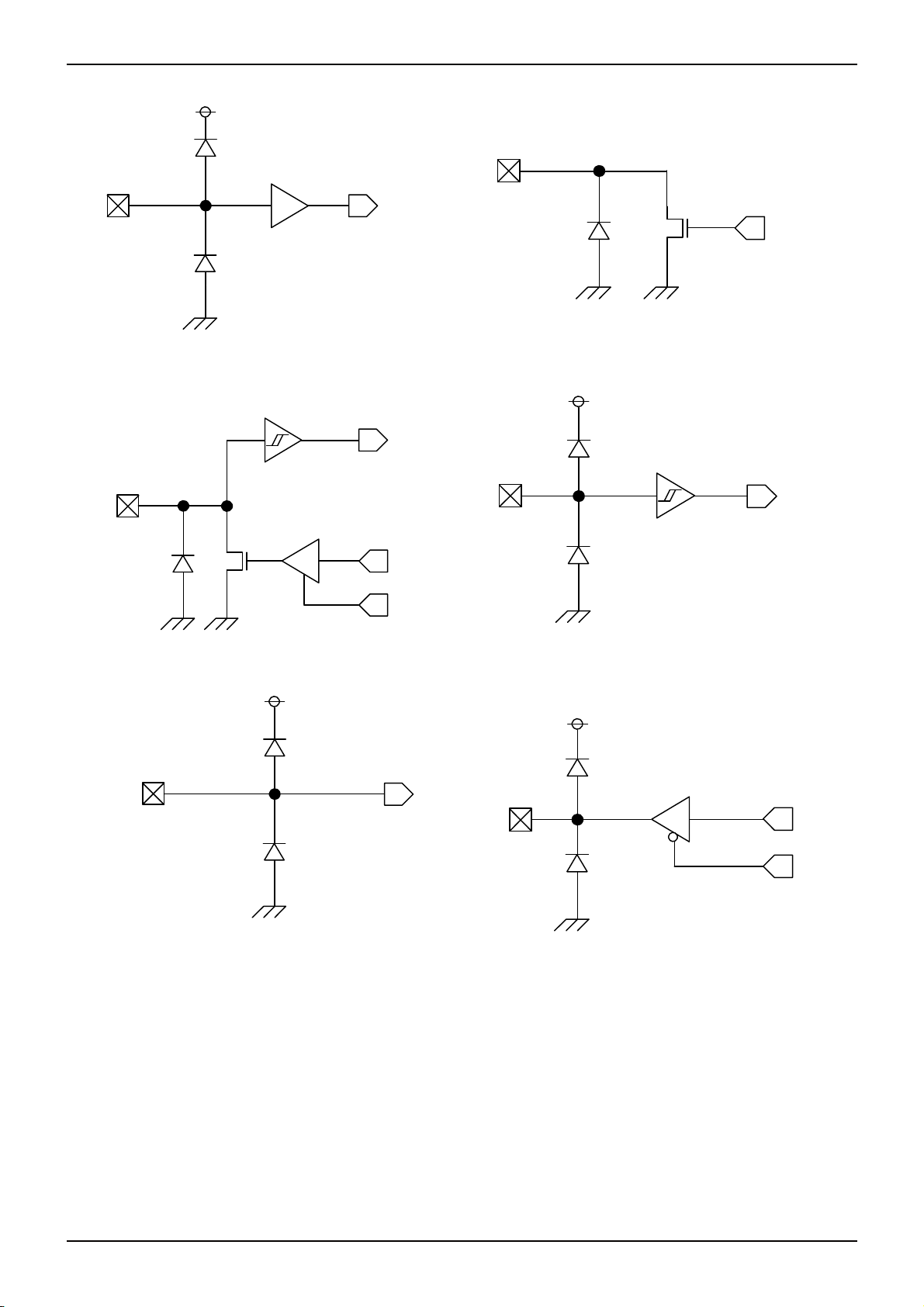

Fig. A

Fig. B

PAD

PAD

Fig. C

Fig. D

PAD

CIN

PAD

●Fig. BU21023GUL / BU21023MUV / BU21024FV-M I/O equivalent circuit

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Fig. E Fig. F

12/17

2011.08 - Rev.

Page 13

A

BU21023GUL,BU21023MUV,BU21024FV-M

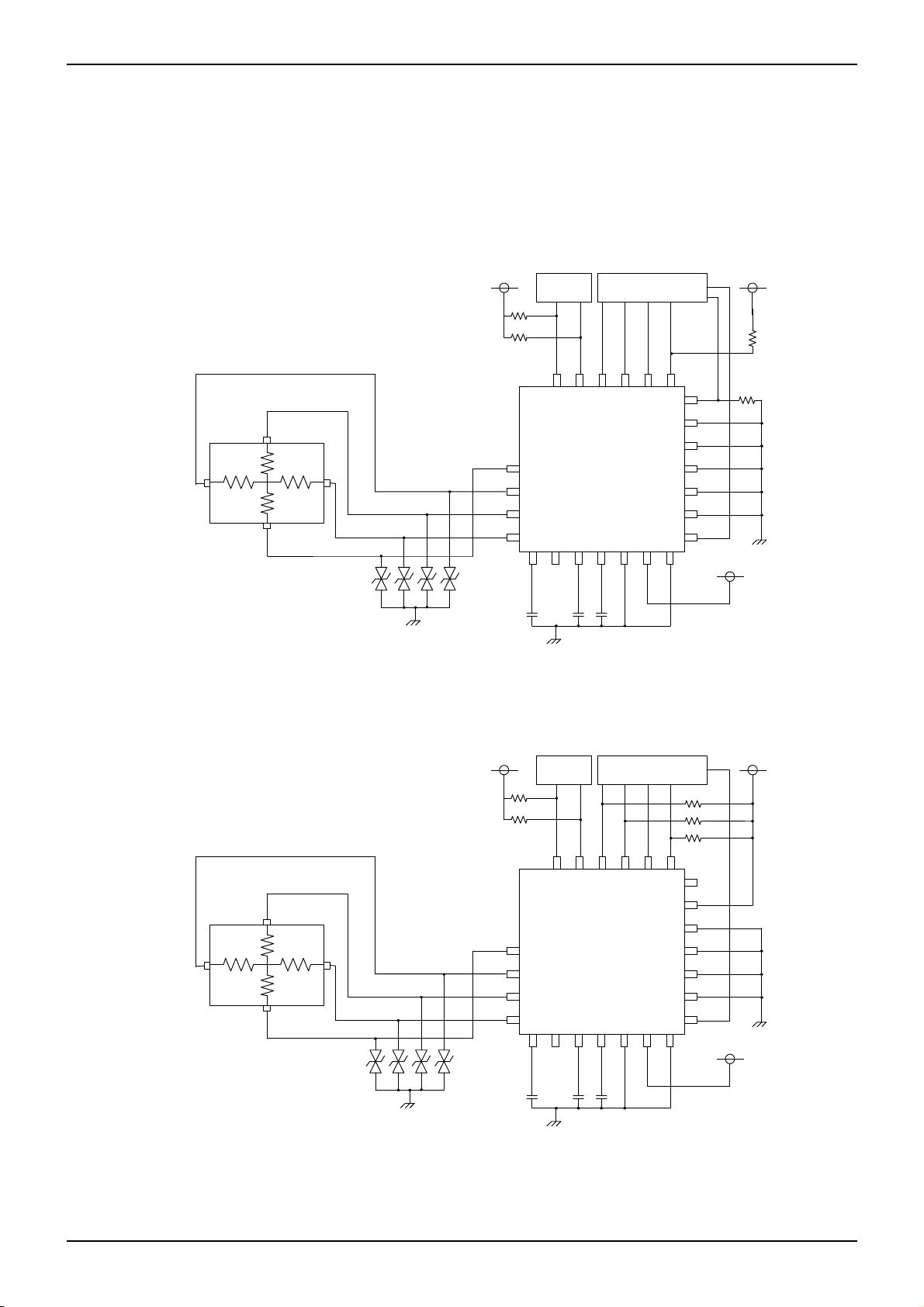

●Application Circuit

【BU21023GUL/BU21023MUV】

BU21023GUL/MUV support 2 host interfaces (4-wire SPI and 2-wire serial bus).

The figures below are shown application circuit when each interface is used.

(Although BU21023GUL is CSP package, it is shown in similar figure for comparing.)

*Please connect the terminal of ECL/EDA with VSS, when firmware is download form HOST.

*Please insert TVS diode each sensor line from the perspective that enhances resistance to ESD.

*In 4-wire SPI using case, pull up INT terminal to VDD or host IO voltage (max4.5V).

If no using, connect to GND.

VDD

EEPROM

10kohm

10kohm

EDA

ECL

panel

YN

XN

YP

XP

SCL_SCK

BU21023

SDA_SI

Host

SEL_CSB

Technical Note

VDD

10kohm

INT

(10kohm)

SO

IFSEL

T3

T2

T1

EXT_CLK

RSTB

TVS diode

T4

AVDD

PVDD

0.1uF 1.0uF 1.0uF

DVDD

Example 1 : BU21023GUL/MUV application circuit(4-wireSPI)

In 2-wire serial interface using case,

please pull up INT, SCL_SCK, SDA_SI terminal to VDD or host IO voltage(max4.5V).

VDD

EEPROM

10kohm

10kohm

EDA

ECL

panel

YN

XN

YP

XP

SCL_SCK

BU21023

VSS

VDD

DVDD_EXT

VDD

Host

10kohm

10kohm

10kohm

SDA_SI

SEL_CSB

INT

SO

IFSEL

T3

T2

T1

EXT_CLK

RSTB

VDD

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

TVS diode

T4

AVDD

PVDD

0.1uF 1.0uF 1.0uF

DVDD

DVDD_EXT

VSS

VDD

Example 2 : BU21023GUL/MUV application circuit(2-wire Serial bus)

13/17

VDD

2011.08 - Rev.

Page 14

A

BU21023GUL,BU21023MUV,BU21024FV-M

【BU21024FV-M】

BU21024FV-M support 2 host interfaces (4-wire SPI and 2-wire serial bus).

The figures below are shown Application Circuit when each interface is used.

(Although BU21023GUL is CSP package, it is shown in similar figure for comparing.)

*Please connect the terminal of ECL/EDA with VSS, when Firmware is download form HOST.

*Please insert TVS diode each sensor line from the perspective that enhances resistance to ESD.

*In 4-wire SPI using case, pull up INT terminal to VDD or host IO voltage(max4.5V).

If no using, connect to GND.

VDD

VDD

Technical Note

VDD

panel

TVS diode

EEPROM

10kohm 10kohm

0.1uF

1.0uF

1.0uF

EDA

1

ECL

2

YNM

3

XNM

4

YPM

5

XPM

6

YN

7

8

9

10

11

12

13

14

BU21024FV-M

XN

YP

XP

T4

PVDD

AVDD

SCL_SCK

SEL_CSB

CLK_EX T

DVDD_EXTDVDD

SDA_SI

IFSEL

RSTB

VSS

VDD

28

27

26

25

INT

SO

24

23

T3

22

T2

21

T1

20

19

18

17

16

15

10kohm

Host

(10kohm)

VDD

Example 3 : BU21024FV-M Application Circuit(4-wireSPI)

VDD

VDD

VDD

10kohm 10kohm

panel

TVS diode

EEPROM

0.1uF

1.0uF

1.0uF

EDA

1

ECL

2

YNM

3

XNM

4

YPM

5

XPM

6

YN

7

8

9

10

11

12

13

14

BU21024FV-M

XN

YP

XP

T4

PVDD

AVDD

SCL_SCK

SEL_CSB

CLK_E XT

DVDD_EXTDVDD

Example 4 : BU21024FV-M Application Circuit(2-wire Serial bus)

SDA_SI

IFSEL

RSTB

VSS

VDD

10kohm

28

27

26

25

INT

SO

24

23

T3

22

T2

21

T1

20

19

18

17

VDD

16

15

Host

VDD

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

14/17

2011.08 - Rev.

Page 15

A

BU21023GUL,BU21023MUV,BU21024FV-M

Technical Note

BU21024FV-M has the other pins for debug except for 4-wire resistive touch screen interface (XP, YP, XN, YN).

When debug, there are 4 monitor pins corresponding to four past terminals.

(In 4-wire, supply and detect voltage of screen on 4 pins. When debug, if this function is enable,

it is possible to supply voltage on past 4pins and detect voltage on 4 pins with **M separately. )

To remove the noise of Screen itself, the filter is composed of discrete circuit.

It is possible to ease the decrease of screen voltage's dynamic range, which is caused by wiring resistance on the PCB.

Note: These debug terminals are only for debug. So, please don’t use them in normal application using.

VDD

VDD

VDD

10kohm 10kohm

panel

TVS diode

EEPROM

10 ohm

10 ohm

10 ohm

EDA

1

ECL

2

YNM

3

1nF

XNM

4

1nF

1nF

1nF

0.1uF

1.0uF

1.0uF

YPM

5

XPM

6

YN

7

8

9

10

11

12

13

14

BU21024FV-M

XN

YP

XP

T4

PVDD

AVDD

SCL_SCK

SEL_CSB

CLK_EX T

DVDD_EXTDVDD

SDA_SI

IFSEL

RSTB

VSS

VDD

28

27

26

25

INT

SO

24

23

T3

22

T2

21

T1

20

19

18

17

16

15

Example 5 : BU21024FV-M Application Circuit(4-wireSPI with RC filter)

VDD

VDD

10kohm

Host

(10kohm)

VDD

VDD

panel

TVS diode

EEPROM

10kohm 10kohm

10 ohm

10 ohm

10 ohm

1nF

10 ohm

1nF

EDA

1

ECL

2

YNM

3

1nF

XNM

4

1nF

0.1uF

1.0uF

1.0uF

YPM

5

XPM

6

YN

7

8

9

10

11

12

13

14

BU21024FV-M

XN

YP

XP

T4

PVDD

AVDD

SCL_SCK

SEL_CSB

CLK_EX T

DVDD_EXTDVDD

SDA_SI

IFSEL

RSTB

VSS

VDD

28

27

26

25

INT

SO

24

23

T3

22

T2

21

T1

20

19

18

17

16

15

10kohm

VDD

Example 6 : BU21024FV-M Application Circuit(2-wire Serial bus with RC filter)

Host

VDD

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

15/17

2011.08 - Rev.

Page 16

A

BU21023GUL,BU21023MUV,BU21024FV-M

●Notes for use

(1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc.,

can break down devices thus making impossible to identify breaking mode such as a short circuit or an open circuit. If

any special mode exceeding the absolute maximum ratings is assumed, consideration should be given to take physical

safety measures including the use of fuses, etc.

(2) Operating conditions

These conditions represent a range within which characteristics can be provided approximately as expected. The

electrical characteristics are guaranteed under the conditions of each parameter.

(3) Reverse connection of power supply connector

The reverse connection of power supply connector can break down ICs. Take protective measures against

the breakdown due to the reverse connection, such as mounting an external diode between the power supply

and the IC's power supply terminal.

(4) Power supply line

Design PCB pattern to provide low impedance for the wiring between the power supply and the GND lines. In this regard,

for the digital block power supply and the analog block power supply, even though these power supplies has the same

level of potential, separate the power supply pattern for the digital block from that for the analog block, thus suppressing

the diffraction of digital noises to the analog block power supply resulting from impedance common to the wiring

patterns. For the GND line, give consideration to design the patterns in a similar manner. Furthermore, for all power

supply terminals to ICs, mount a capacitor between the power supply and the GND terminal. At the same time, in order

to use an electrolytic capacitor, thoroughly check to be sure the characteristics of the capacitor to be used present no

problem including the occurrence of capacity dropout at a low temperature, thus determining the constant.

(5) GND voltage

Make setting of the potential of the GND terminal so that it will be maintained at the minimum in any operating state.

Furthermore, check to be sure no terminals are at a potential lower than the GND voltage including an actual electric

transient.

(6) Short circuit between terminals and erroneous mounting

In order to mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs. Erroneous mounting

can break down the ICs. Furthermore, if a short circuit occurs due to foreign matters entering between terminals or

between the terminal and the power supply or the GND terminal, the ICs can break down.

(7) Operation in strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

(8) Inspection with set PCB

On the inspection with the set PCB, if a capacitor is connected to a low-impedance IC terminal, the IC can suffer stress.

Therefore, be sure to discharge from the set PCB by each process. Furthermore, in order to mount or dismount the set

PCB to/from the jig for the inspection process, be sure to turn OFF the power supply and then mount the set PCB to the

jig. After the completion of the inspection, be sure to turn OFF the power supply and then dismount it from the jig. In

addition, for protection against static electricity, establish a ground for the assembly process and pay thorough attention

to the transportation and the storage of the set PCB.

(9) Input terminals

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the

parasitic element can cause interference with circuit operation, thus resulting in a malfunction and then breakdown of

the input terminal. Therefore, pay thorough attention not to handle the input terminals, such as to apply to the input

terminals a voltage lower than the GND respectively, so that any parasitic element will operate. Furthermore, do not

apply a voltage to the input terminals when no power supply voltage is applied to the IC. In addition, even if the power

supply voltage is applied, apply to the input terminals a voltage lower than the power supply voltage or within the

guaranteed value of electrical characteristics.

(10) Ground wiring pattern

If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND

pattern from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that

resistance to the wiring pattern and voltage fluctuations due to a large current will cause no fluctuations in voltages of

the small-signal GND. Pay attention not to cause fluctuations in the GND wiring pattern of external parts as well.

(11) External capacitor

In order to use a ceramic capacitor as the external capacitor, determine the constant with consideration given to a

degradation in the nominal capacitance due to DC bias and changes in the capacitance due to temperature, etc.

(12) Rush current

The IC with some power supplies has a capable of rush current due to procedure and delay at power-on. Pay attention

to the capacitance of the coupling condensers and the wiring pattern width and routing of the power supply and the GND

lines.

(13) Others

In case of use this LSI, please peruse some other detail documents, we called, Technical note, Functional description,

Application note.

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

16/17

2011.08 - Rev.

Page 17

A

BU21023GUL,BU21023MUV,BU21024FV-M

Technical Note

●Ordering part number

B U 2 1 0 2 4 F V - M E 2

Part No. Part No.

UCSP50L1

(BD82103GWL)

1PIN MARK

11-φ0.2±0.05

0.05

(φ0.15)INDEX POST

VQFN028V5050

BA

0.3±0.05

5.0±0.1

1.0MAX

0.08 S

C0.2

28

22

0.4±0.1

21023

21024

1.8±0.05

0.08 S

A

B

A

2

3C1

P=0.4×3

5.0±0.1

1PIN MARK

2.7±0.1

17

1521

1.0 0.5 0.25

1.5±0.05

0.1±0.05

0.55MAX

S

0.35±0.05

B

4

P=0.4×2

(Unit : mm)

S

0.02

-

(0.22)

+0.03

0.02

8

2.7±0.1

14

+0.05

-0.04

(Unit : mm)

Package

GUL : VCSP50L2

MUV: VQFN028V5050

FV : SSOP-B28

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

<Tape and Reel information>

Quantity

Direction

of feed

3000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Embossed carrier tapeTape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Order quantity needs to be multiple of the minimum quantity.

∗

Packaging and forming specification

E2: Embossed tape and reel

Direction of feed

Direction of feed

SSOP-B28

10 ± 0.2

(MAX 10.35 include BURR)

28

5.6 ± 0.2

7.6 ± 0.3

1

1.15 ± 0.1

0.1

0.65

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

15

14

0.22 ± 0.1

0.1

0.3Min.

0.15 ± 0.1

(Unit : mm)

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

17/17

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

2011.08 - Rev.

Page 18

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...