High-performance Video Driver Series

Output Capacitor-less

Video Drivers

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

No.09064EAT02

●Description

The BH768xx series video drivers are the optimum solution for high density integration systems such as, digital still

cameras, mobile phones, and portable video devices. A built-in charge pump circuit eliminates the need for a large output

coupling capacitor. Features include: a built-in LPF, low-voltage (2.5 V) operation, and 0 µA current consumption during

standby mode.

●Features

1) Select from four video driver amp gain settings: 6 dB, 9 dB, 12 dB, and 16 dB

2) Large-output video driver with maximum output voltage of 5.2 Vpp.

Supports wide and low-voltage operation range.

3) No output coupling capacitor is needed, which makes for a more compact design

4) Built-in standby function sets circuit current to 0 µA (typ.) during standby mode

5) Clear image reproduction by on-chip 8-order 4.5-MH

6) Bias input method is used to support chroma, video, and RGB signals.

7) MSOP8 compact package

●Applications

Mobile telephones, DSCs (digital still cameras), DVCs (digital video cameras), portable game systems,

portable media players, etc.

●Line up matrix

Part No. Video driver amp gain Recommended input level

z LPF (Low Pass Filter)

BH76806FVM 6dB 1Vpp

BH76809FVM 9dB 0.7Vpp

BH76812FVM 12dB 0.5Vpp

BH76816FVM 16.5dB 0.3Vpp

Absolute maximum ratings (T

Parameter Symbol Ratings Unit

Supply voltage Vcc 3.55 V

Power dissipation Pd 470 mW

Operating temperature range Topr

Storage temperature range Tstg -55~+125 ℃

* Reduce by 4.7 mW/C over 25C, when mounted on a 70mm×70mm×1.6mm PCB board.

a=25℃)

-40~+85 ℃

www.rohm.com

1/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Operating range (Ta=25℃)

Parameter Symbol Min. TYP. Max. Unit

Supply voltage Vcc 2.5 3.0 3.45 V

Electrical characteristics (Unless otherwise noted, Typ.: T

a=25℃, VCC=3V)

Typical value

Parameter Symbol

BH76806

FVM

BH76809

FVM

BH76812

FVM

BH76816

Technical Note

Unit Conditions

FVM

Circuit current 1 I

Circuit current 2 I

Standby SW input current

High-Level

Standby switching voltage

High-Level

Standby Switching voltage

Low-Level

16 15 mA No signal

CC1

0.0 A Standby mode

CC2

I

45 A When 3.0 V is applied to 4pin

thH

V

1.2V min V standby OFF

thH

V

0.45Vmax V standby ON

thL

Voltage gain GV 6.0 9.0 12.0 16.5 dB Vo=100KHz, 1.0Vpp

Maximum output level Vomv 5.2 Vpp f=1KHz,THD=1%

Frequency characteristic 1 Gf1 -0.45 dB f=4.5MHz/100KHz

Frequency characteristic 2 Gf2 -3.0 dB f=8.0MHz/100KHz

Frequency characteristic 3 Gf3 -32 dB f=18MHz/100KHz

Frequency characteristic 4 Gf4 -51 dB f=23.5MHz/100KHz

Differential Gain DG 0.5 %

Differential Phase DP 1.0 deg

Vo=1.0Vp-p

Standard stair step signal

V

o=1.0Vp-p

Standard stair step signal

Band = 100 kHz to 6 MH

Y signal output S/N SNY +74 +73 +70 +70 dB

75 termination

100% chroma video signal

Band = 100~500KHz

C signal output S/N (AM) SNCA +77 +76 +75 +75 dB

75Ωtermination

100%chroma video signal

Band = 100~500KH

C signal output S/N (PM) SNCP +65 dB

75Ωtermination

100%chroma video signal

Output pin source current lextin 30 mA

±50

Output DC offset voltage Voff

max

4.5 V applied via 150 to

output pin

75 termination

mV

z

z

www.rohm.com

2/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Measurement circuit

1. 0u F

1

A

V2

(VCC)

OSC1

1

2

SW3

SW2

10u

50

0. 1u

V4

2

0. 1u

3

4

IN OUT

CHARGE PUMP

GND

6d B/9d B/

LPF

150K

12d B/1 6. 5d B

※ Test circuit is intended for shipment inspections, and differs from application circuit.

Fig. 1

Control pin settings

Parameter States Note

NVCC

Technical Note

8

7

6

5

4. 7u

1. 0u F

75

V

75

V

Block diagram

Standby(4pin)

C1

C1

VCC

VCC

Vin

Vin

STBY

STBY

H Active

L Standby

OPEN Standby

1

IN OUT

2

3

CHARGE PUMP

LPF

GND

NVC C

6dB/9dB/

12dB /1 6.5dB

8

7

6

C2

C2

NVCC

NVCC

GND

GN D

AMP

150K

4

5

Vout

Vout

Fig.2

www.rohm.com

3/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

T

Pin descriptions

Pin

No.

1

Pin

name

C1

equivalent circuit

VCC

VCC

DC

voltage

+VCC

↑↓

0V

C1

GND

GND

NVCC

2 VCC

VCC

Technical Note

Functions

Flying capacitor "+" pin

See function description for pins 7

and 8

VCC Pin

3 VIN

4 STBY

5

VOUT

VCC

4.1k

4.1k

VIN

100

150K

NV

0V

Video signal input pin

Adaptive input signal

Composite video signal/

VIN

1μF

chroma signal/RGB signal, etc.

STBY

VCC

VCC

50K

250K

200K

VCC

VCC

GND

GND

VOU

VCC

to

0V

0V

ACTIVE/STANBY Switching Pin

1.2V~VCC

0V~0.45V

Terminal

Votage

( H )

( L )

MODE

ACTIVE

STANBY

Video signal output pin

VOUT

NVCC

NVCC

1K

75Ω

75Ω

150k

VCC

6 GND

GND

0V

GND Pin

NVCC

*1 The DC voltage in the figure is VCC = 3.0 V. These values are for reference only and are not guaranteed.

*2 These values are for reference only and are not guaranteed.

www.rohm.com

4/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Technical Note

●Pin descriptions

7 NVCC

VCC

GND

VCC

-VCC

C2

(-2.75V)

Flying capacitor “-”pin

(8pin)

C1

C2

NVC

Load voltage pins (7 pins)

NVC

8 C2

GND

VCC

VCC

NVCC

0V

↑↓

-VCC

(-2.75V)

*1 The DC voltage in the figure is VCC = 3.0 V. These values are for reference only and are not guaranteed.

*2 These values are for reference only and are not guaranteed.

Description of operations

1) Principles of video driver with no output coupling capacitor

Amp (Single power supply)

Amp (Dual power supply)

VCC

1/2VCC Bias

Fig.3 Fig.4

When the amplifier operates using single voltage power supply, the operating potential point is approximately 1/2 Vcc.

Therefore, a coupling capacitor is required to prevent DC output. For the video driver, the load resistance is 150 (75

+ 75 ). Therefore, the coupling capacitor should be about 1000 µF when a low bandwidth for transmission is considered.

(See Figure 3.)

When the amplifier operates using a dual (±) power supply, the operating point can be set at GND level, and therefore,

there is no need for a coupling capacitor to prevent DC output.

Since a coupling capacitor is not needed, there is no sagging of low-frequency characteristics in output stage. (See Figure

4.)

2) Generation of negative voltage by charge pump circuit

As is shown in Figure 5, the charge pump consists of a pair of switches (SW1 and SW2) and a pair of capacitors (flying

capacitor and load capacitor), generating a negative voltage. When +3 V is applied to this IC, approximately -2.83 V of

negative voltage is obtained.

Output capacitor is required due to DC

voltage at output pin

75Ω

1000μF

75Ω

VCC

-VCC

Output capacitor is not required since

DC voltage is not applied to output pin

75Ω

75Ω

VCC

0V

www.rohm.com

5/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

ア

Technical Note

Vcc +3V

charge current

+

SW1 SW2

Flying capacitor

Vcc +3V

charge current

SW1 SW2

-

Load capacitor

+

-

charge current

Flying capacitor

-Vcc is generated

-

Load capacitor

+

Vcc +3V

charge current

+

-

charge transfer mode

-

+

+

-

-Vcc is generated

Fig. 5 Principles of Charge Pump Circuit

1) Configuration of BH768xxFVM Series

As is shown in Figure 6, in the BH768xxFVM Series, a dual power supply amplifier is integrated with a charge pump circuit

in the same IC. This enables operation using a + 3V single power supply while also using a dual power supply amplifier,

which eliminates the need for an output coupling capacitor.

1μF

AMP

VCC

Dual power supply amp

ンプ H768xxFVM

75Ω

150k

VCC

75Ω

Single chip

integration

Output capacitor not required

for single power supply either.

Charge Pump

-VCC

3.3μF

Charge pump

768xxFVM

1μF

Fig. 6 BH768xxFVM Configuration Diagram

2) Input terminal type and sag characteristics

BH768xxFVM Series devices provide both a low-voltage video driver and a large dynamic range (approximately 5.2 Vpp).

A resistance termination method (150 k termination) is used instead of the clamp method, which only supports video

signals, since it supports various signal types.

The BH768xxFVM series supports a wide range of devices such as, video signals, chroma signals, and RGB signals that

can operate normally even without a synchronization signal.

In addition, input terminating resistance (150 k) can use a small input capacitor without reducing the sag low-band

It is recommended to use a H-bar signal when evaluating sag characteristics, since it makes sag more noticeable. (See

Figures 7 to 10.)

www.rohm.com

6/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Technical Note

Cut-off frequency for input capacitor and input impedance is

the same as when the output capacitor is set at 1000 µF with

an ordinary 75 driver.

(Input terminal time constant) (Output terminal time constant)

a) Sag-free video signal (TG-7/1 output, H-bar)

b) BH768xxFVM output (input = 1.0 µF, TG-7/1 output, H-bar)

c) 1000 uF + 150 sag waveform (TG-7/1 output, H-bar)

1 F X 150 K = 1000 F X 150

Sag is determined

by input capacitor

and input

resistance only.

1μF

150k

Fig. 7

Fig. 8

TG-7/1

Fig. 9

Fig. 10

75Ω+75Ω=150Ω

Sag

H-bar signal's TV screen

output image

75Ω

Monitor

1μF

150k

BH768xxFVM

Nearly identical sag characteristics

75Ω

TG-7/1

Monitor

1000μF

75Ω

75Ω

75Ω

www.rohm.com

7/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Application circuit

1.0μF(C18)

Technical Note

1

OUT

6dB/9dB/

12dB/16.5dB

NVCC

150k

IN

CHARGE PUNP

LPF

GND

Fig. 11

※

10Ω(R2)

2

3.3μF

(C2)

VIDEO IN

1.0μF(C3)

L:Standby

High Active

Open Standby

Low Standby

3

4

※Although ROHM is confident that the example application circuit reflects the best possible

recommendations, be sure to verify circuit characteristics for your particular application.

8

7

6

75Ω(R5)

5

1.0μF(C7)

VIDEO OUT

www.rohm.com

8/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

c

c

1.Effects of charge pump

circuit’s current ripple

Vcc

10Ω

1μF

DAC etc.

2.Current ripple affects DAC, etc.

1μF

V

IN

Vcc pin

VIDEO

AMP

150kΩ

Charge Pump

Fig. 12 Effect of Charge Pump Circuit's Current Ripple on External Circuit

1) Decoupling capacitor only

Current waveform (A) between single

power supply and capacitor

10mA/div

Current waveform (B)

between capacitor and IC

10mA/div

Fig.13

2) Decoupling capacitor + Resistance 10Ω

Current waveform (A) between single

power supply and capacitor

10mA/div

Current waveform (B)between single

power supply and capacitor

10mA/div

Current waveform (C)between single

power supply and capacitor

10mA/div

Fig.14

3.3μF

V

-Vcc

A

OUT

Technical Note

75Ω

75Ω

1μF

Vc

A

A

B

A

Vc c

Vc

10

Ω

A

C

Vc c

A

B

A

www.rohm.com

9/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

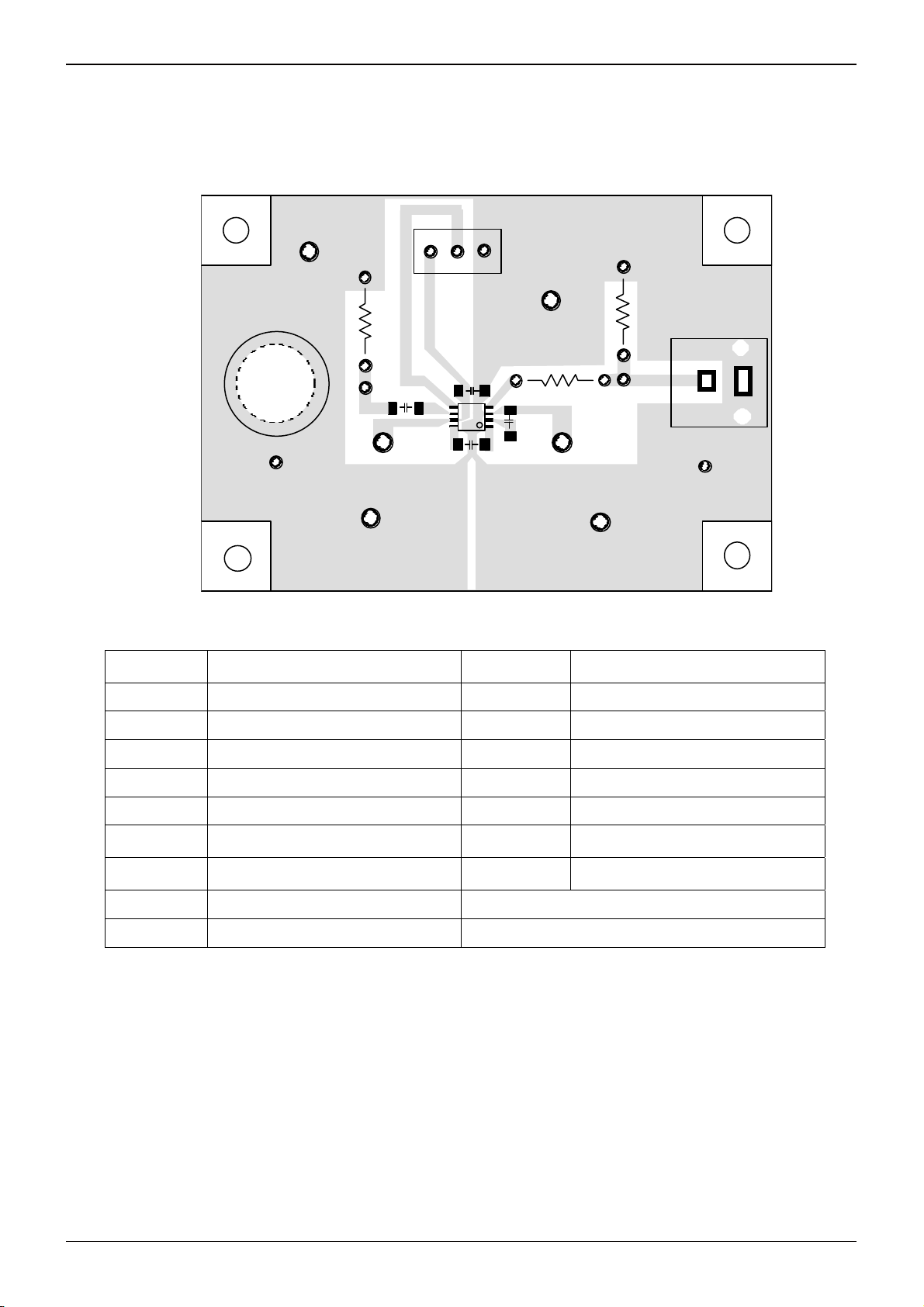

Pattern diagram of evaluation board

GND

STBY

ACT

VIN

R3

GND

C3

C4

R1

C2

GND

VCC

C1

GND

GND

ROHM BH76806/09/12/16FVM

List of external components

Fig. 15

Symbol Function

Recommended

value

C1 Flying capacitor 1μF B characteristics are recommended

C2 Tank capacitor

C3 Input coupling capacitor

1μF

1μF

Technical Note

R2

GND

B characteristics are recommended

B characteristics are recommended

VOUT

GND

Remark

C4 Decoupling capacitor 3.3μF B characteristics are recommended

R1 Output resistor

R2 Output terminating resistance 75Ω

R3 Input terminating resistance 75Ω

Input connector BNC

Output connector RCA (pin jack)

75Ω -

Not required when connecting to TV

or video signal test equipment.

Required when connecting to video

signal test equipment.

www.rohm.com

10/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Technical Note

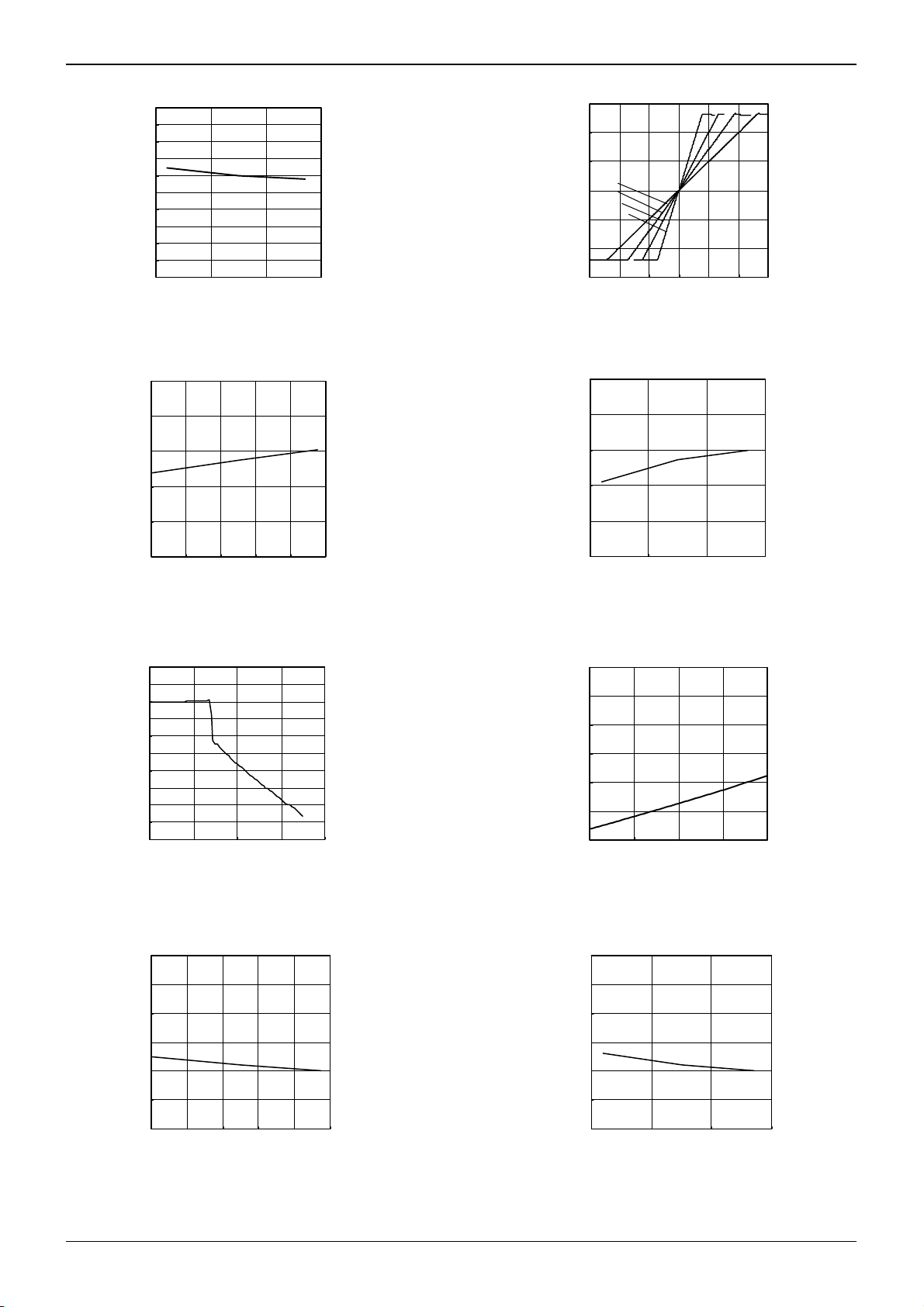

Reference data

BH76812FVM

30

25

20

15

10

CIRCUIT CURRENT [mA]

5

0

01234

POWER SUPPLY VOLTAGE [V]

Fig. 16 Circuit current vs. Supply voltage

BH76812FVM

20

18

16

14

12

CIRCUIT CURRENT [mA]

10

-50 0 50 100

TEMPERATURE [℃]

Fig. 18 Circuit current vs. Temperature

BH76812FVM

50

25

Ta= 2 5℃

VCC=3V

Ta= 2 5℃

BH76812FVM

1

0.8

0.6

0.4

0.2

STANDBY CURRENT [uA]

0

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE [V]

Ta= 2 5

℃

Fig. 17 Circuit Current (Standby) vs. Supply Voltage

STANDBY CURRENT [uA]

BH76812FVM

1

0.8

0.6

0.4

0.2

0

-50 0

TEMPERATURE [

VCC=3V

50 100

℃]

Fig. 19 Circuit Current (Standby) vs. Temperature

BH76812FVM

50

25

VCC=3V

0

-25

VOUT DC OFFSET [mV]

-50

2.5

2.7 2.9 3.1

POWER SUPPLY VOLTAGE [V]

Fig. 20 V

out DC offset voltage

3.3 3.5

vs. Supply voltage

VOLTAGE GAIN [dB]

BH76812FVM

5

-5

-15

-25

-35

-45

-55

-65

-75

0.1

VCC=3V Ta=25

1

FREQUENCY [MHz]

10

Fig. 22 Frequency characteristic

℃

100

0

-25

VOUT DC OFFSET [mV]

-50

-50 0 50 100

Fig. 21 V

TEMPERATURE [

out DC offset voltage

℃]

vs. Temperature

BH76812FVM

12.5

12.4

12.3

12.2

12.1

12

11.9

11.8

VOLTAGE GAIN [dB]

11.7

11.6

11.5

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE [V]

Ta= 2 5

℃

Fig. 23 Voltage gain vs. Supply voltage

www.rohm.com

11/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Technical Note

BH76812FVM

12.5

12.4

12.3

12.2

12.1

12

11.9

11.8

VOLTAGE GAIN [dB]

11.7

11.6

11.5

-50 0 50 100

TEMPERATURE [

Fig. 24 Voltage gain vs. Temperature

BH76812FVM

1

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

FREQUENCY RESPONSE1:Gf1[dB]

-1

-50 0 50 100

f=4. 5MHz/100kHz

TEMPERATURE[℃]

VCC=3V

℃]

VCC=3V

Fig. 26 Frequency response 1 vs. Temperature

BH76812FVM

0

-1

-2

-3

-4

-5

FREQUENCY RESPONSE2:Gf2[dB]

-6

-50 0 50 100

TEMPERATURE [

VCC=3V

f=8MHz/100kHz

℃]

BH76812FVM

1

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

FREQENCY RESPONSE1:Gf1[dB]

-1

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE:Vcc[V]

f=4. 5MHz/100kHz

Ta= 2 5

℃

Fig. 25 Frequency response 1 vs. Supply voltage

BH76812FVM

0

-1

-2

-3

-4

-5

FREQUENCY RESPONSE2:Gf2[dB]

-6

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE: Vcc [V]

Ta= 2 5℃

f=8MHz/100kHz

Fig. 27 Frequency response 2 vs. Supply voltage

BH76812FVM

-40

-45

-50

-55

-60

-65

FREQUENCY RESPONSE4:Gf4[dB]

-70

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE:Vcc[V]

f=23.5MHz/100kHz

Ta= 2 5

℃

Fig. 28 Frequency response 2 vs. Temperature

BH76812FVM

-40

-45

-50

-55

-60

-65

FREQUENCY RESPONSE4:Gf4[dB]

-70

-50 0 50 100

TEMPERATURE [℃]

f=23.5MHz/100kHz

TEMPERATURE [Deg]

VCC=3V

Fig. 30 Frequency response 4 vs. Temperature

www.rohm.com

12/16

© 2009 ROHM Co., Ltd. All rights reserved.

Fig.29 Frequency response 4 vs. Supply voltage

BH76812FVM

7

6

5

4

3

2

1

MAX OUTPUT VOLTAGE [Vpp]

0

2.52.72.93.13.33.5

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

Fig. 31 Maximum output voltage level vs. Supply voltage

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Technical Note

Fig. 32 Maximum output level vs. Temperature

BH76812FVM

6

5.8

5.6

5.4

5.2

5

4.8

4.6

4.4

4.2

MAXIMUM OUTPUT LEVEL:Vomv[Vpp]

4

-50 0 50 100

TEMPERATURE[V]

VCC=3V

300

BH76812FVM

Ta= 2 5℃

260

220

180

140

CHARGEPUMP OSC FREQUENCY [KHz]

100

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE [V]

Fig. 34 Charge pump oscillation frequency

vs. Supply voltage

BH76812FVM

1.0

0.5

0.0

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

-3.5

CHARGEPUMP OUTPUT VOLTAGE [V]

-4.0

0.01.02.03.04.0

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

Fig. 36 Charge pump output voltage

vs. Supply voltage

BH76812FVM

3

2

1

6dB

0

9dB

12dB

16.5dB

-1

OUTPUT DC VOLTAGE [V]

-2

-3

-1.5 -1.0 -0.5 0.0 0.5 1.0 1.5

INPUT DC VOLTAGE [V]

VCC=3V Ta =2 5 ℃

Fig. 33 Output DC voltage – Input DC voltage

BH76812FVM

300

260

220

180

140

100

CHARGEPUMP OSC FREQUENCY [KHz]

-50 0 50 100

TEMPERATURE [

VCC=3V

℃]

Fig. 35 Charge pump oscillation frequency

vs. Temperature

BH76812FVM

0

-0.5

-1

-1.5

-2

-2.5

CHARGEPUMP OUTPUT VOLTAGE [V]

-3

0 10203040

LOAD CURRENT [mA]

VCC=3V Ta=25℃

Fig. 37 Charge pump load regulation

BH76812FVM BH76812FVM

3

2.5

2

1.5

1

0.5

DIFFERENTIAL PHASE [Deg]

0

2.5 2.7 2.9 3.1 3. 3 3.5

POWER SUPPLY VOLTAGE [V]

Fig. 38 Differential phase vs. Supply voltage

www.rohm.com

13/16

© 2009 ROHM Co., Ltd. All rights reserved.

Ta= 2 5℃

3

2.5

2

1.5

1

0.5

DIFFERENTIAL PHASE [Deg]

0

-50 0 50 100

TEMPERATURE [℃]

Fig. 39 Differential phase vs. Temperature

VCC=3V

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Technical Note

BH76812FVM BH76812FVM

3

2.5

2

1.5

1

DIFFERENTIAL GAIN [%]

0.5

0

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE [V]

Fig. 40 Differential gain vs. Supply voltage

BH76812FVM

80

75

70

Y S/N [dB]

65

60

2.5 2.7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE [V]

Fig. 42 S/N(Y) vs. Supply Voltage

BH76812FVM

80

75

70

65

CHROMA S/N (AM) [dB]

60

2.5 2.7 2.9 3. 1 3.3 3.5

POWER SUPPLY VOLTAGE [V]

Fig. 44 S/N(C-AM) vs. Supply Voltage

BH76812FVM

70

68

66

64

62

60

58

56

54

C SYSTEM PM S/N:SNcp[dB]

52

50

2.5 2. 7 2.9 3.1 3.3 3.5

POWER SUPPLY VOLTAGE: Vcc[V]

Ta= 2 5℃

Ta= 2 5℃

Ta= 2 5℃

Ta= 2 5

3

2.5

2

1.5

1

DIFFERENTIAL GAIN [%]

0.5

0

-50 0 50 100

TEMPERATURE [℃]

VCC=3V

Fig. 41 Differential gain vs. Temperature

BH76812FVM

80

75

70

Y S/N [dB]

65

60

-50 0 50 100

TEMPERATURE [℃]

VCC=3V

Fig.43 S/N(Y) vs. Temperature

BH76812FVM

80

75

70

65

CHROMA S/N (AM) [dB]

60

-50 0 50 100

TEMPERATURE [

VCC=3V

℃]

Fig. 45 S/N(C-AM) vs. Temperature

℃

BH76812FVM

70

65

60

55

CHROMA S/N (PM) [dB]

50

-50 0 50 100

TEMPERATURE [℃]

VCC=3V

Fig. 46 S/N(C-PM) vs. Supply Voltage

www.rohm.com

14/16

© 2009 ROHM Co., Ltd. All rights reserved.

Fig. 47 S/N(C-PM) vs. Temperature

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

Technical Note

BH76812FVM

20

VCC=3V Ta=25℃

15

10

5

CIRCUIT CURRENT [mA]

Fig. 48 Circuit current vs. CTL terminal voltage

0

0.0 0.5 1.0 1.5 2.0

CTL TERMINAL VOLTAGE [V]

Cautions on use

1. Numbers and data in entries are representative design values and are not guaranteed values of the items.

2. Although ROHM is confident that the example application circuit reflects the best possible recommendations, be sure

to verify circuit characteristics for your particular application. Modification of constants for other externally connected

circuits may cause variations in both static and transient characteristics for external components as well as this Rohm

IC. Allow for sufficient margins when determining circuit constants.

3. Absolute maximum ratings

Use of the IC in excess of absolute maximum ratings, such as the applied voltage or operating temperature range

(Topr), may result in IC damage. Assumptions should not be made regarding the state of the IC (short mode or

open mode) when such damage is suffered. A physical safety measure, such as a fuse, should be implemented

when using the IC at times where the absolute maximum ratings may be exceeded.

4. Thermal design

Perform thermal design, in which there are adequate margins, by taking into account the permissible dissipation

(Pd) in actual states of use.

5. Short circuit between terminals and erroneous mounting

Pay attention to the assembly direction of the ICs. Wrong mounting direction or shorts between terminals, GND, or other

components on the circuits, can damage the IC.

6. Operation in strong electromagnetic field

Using the ICs in a strong electromagnetic field can cause operation malfunction.

7. Wiring from the decoupling capacitor C2 to the IC should be kept as short as possible.

This capacitance value may have ripple effects on the IC, and may affect the S-N ratio. It is recommended to use

as large a decoupling capacitor as possible. (Recommendations: 3.3 µF, B characteristics, 6.3 V or higher)

8. Target capacitor

It is recommended to use a ceramic capacitor with good temperature characteristics (B).

9. The NVCC (7 pin) terminal generates a voltage that is used within the IC, so it should not be connected to a load

unless necessary. This capacitor (C7) has a large capacitance value with low negative voltage ripple.

10. Capacitors C18 and C2 should be placed as close as possible to the IC. If the wire length to the capacitor is too

long, it can lead to switching noise. (Recommended C18: 1.0 µF; C2: 3.3 µF, B characteristics, 6.3 V or higher

maximum voltage)

11. The HPF consists of input coupling capacitor C3 and 150 k of the internal input.

Be sure to check for video signal sag before determining the C3 value.

The cut-off frequency fc can be calculated using the following formula.

fc = 1/(2π× C3 × 150 k) (Recommendations: 1.0 µF, B characteristics, 6.3 V or higher maximum voltage)

12. The output resistor R5 should be placed close to the IC.

13. Improper mounting may damage the IC.

14. A large current transition occurs in the power supply pin when the charge pump circuit is switched. If this affects

other ICs (via the power supply line), insert a resistor (approximately 10 ) in the VCC line to improve the power

supply's ripple effects. Although inserting a 10 resistor lowers the voltage by about 0.2 V, this IC has a wide margin

for low-voltage operation, so dynamic range problems or other problems should not occur. (See Figures 12 to 14.)

www.rohm.com

15/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76806FVM, BH76809FVM, BH76812FVM, BH76816FVM

p

Selection of order type

B

H 7 6

8

0

6

F

Part. No.

BH76806FVM

BH76809FVM

BH76812FVM

BH76816FVM

MSOP8

<Dimension>

4.0 ± 0.2

0.475

0.9Max.

0.75 ± 0.05

0.1

±

2.8

2.9 ± 0.1

0.65

0.08 ± 0.05

<Tape and Reel information>

Tape

Quantity

58

0.6 ± 0.2

0.29 ± 0.15

41

0.22

+0.05

−0.04

0.08 S

0.145

+0.05

−0.03

0.08

M

Direction

of feed

Embossed carrier tape

cs

3000

TR

(Correct direction: 1pin of product should be at the upper left when you

hold reel on the left hand, and you pull out the tape on the right hand)

XX

X

X X

X

X

XX

X

X X

X

X

(Unit:mm)

Reel

V

X

1Pin

M

XX

X X

X

X

X X

X

X X

X

X

Direction of feed

※Orders are available in complete units only.

X X

X

X X

X

Technical Note

T R

Tape and Reel

information

X

www.rohm.com

16/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...