Compact Video Driver Series for DSCs and Portable Devices

Ultra-compact Waferlevel

Chip Size Packeage

Output Capacitor-less

Single Output Video Drivers

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

No. 09064EAT01

●Description

Due to a built-in charge pump circuit, this video driver does not require the large capacity tantalum capacitor at the video

output pin that is essential in conventional video drivers. Features such as a built-in LPF that has bands suited to mobile

equipment, current consumption of 0 A at standby, and low voltage operation from as low as 2.5 V make it optimal for

digital still cameras, mobile phones, and other equipment in which high density mounting is demanded.

●Features

1) WLCSP ultra-compact package (1.6 mm x 1.6 mm x 0.75 mm)

2) Improved noise characteristics over BH768xxFVM series

3) Four video driver amplifier gains in lineup: 6 dB, 9 dB, 12 dB, 16.5 dB

4) Large output video driver of maximum output voltage 5.2 Vpp. Ample operation margin for supporting even low

voltage operation

5) Output coupling capacitor not needed, contributing to compact design

6) Built-in standby function and circuit current of 0 A (typ) at standby

7) Clear image playback made possible by built-in 8

8) Due to use of bias input format, supports not only video signals but also chroma signals and RGB signals

9) Due to built-in output pin shunt switch, video output pin can be used as video input pin (BH76706GU)

●Applications

Mobile phone, digital still camera, digital video camera, hand-held game, portable media player

●Line up matrix

Product Name Video Driver Amplifier Gain

BH76906GU 6dB 1Vpp

BH76909GU 9dB 0.7Vpp

BH76912GU 12dB 0.5Vpp

BH76916GU 16.5dB 0.3Vpp

th

-order 4.5 MHz LPF

Recommended

Input Level

Video Output Pin Shunt Function

―

BH76706GU 6dB 1Vpp ○

●Absolute Maximum Ratings (T

Parameter Symbol Rating Unit

Supply voltage Vcc 3.55 V

Power dissipation Pd 580 mW

Operating temperature range Topr -40~+85 ℃

Storage temperature range Tstg

* When mounted on a 50 mm×58 mm×1.6 mm glass epoxy board, reduce by 5.8mW/°C above Ta=+25°C.

www.rohm.com

1/16

© 2009 ROHM Co., Ltd. All rights reserved.

a = 25 °C)

-55~+125 ℃

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

Technical Note

●Operating Range

Parameter Symbol Min. Typ. Max. Unit

Supply voltage Vcc 2.5 3.0 3.45 V

●Electrical Characteristics

[Unless otherwise specified, Typ. : Ta = 25 °C, VCC = 3V]

Typical Values

Parameter Symbol

Circuit current 1-1 I

BH76906

15.0 mA In active mode (No signal)

CC1-1

GU

BH76909

GU

BH76912

GU

BH76916

GU

BH76706

GU

Unit Measurement Conditions

In active mode

Circuit current 1-2 I

17.0 mA

CC1-2

(Outputting NTSC color bar

signal)

Circuit current 2 I

Circuit current 3 I

Standby switch input current

High Level

Standby switch switching voltage

High Level

Standby switch switching voltage

Low Level

Standby switch outflow current

High Level

Standby switch outflow current

Middle Level

Standby switch outflow current

Low Level

Mode switching voltage

High Level

Mode switching voltage

Middle Level

Mode switching voltage

low Level

0.0 A In standby mode

CC2

- 100 A

CC3

45

I

thH1

1.2V min V Active mode

V

thH1

0.45Vmax V Standby mode

V

thL1

I

thH2

I

thM2

I

thL2

-

V

thH2

V

thM2

V

thL2

-

0

8

23

VCC

-0.2

(MIN.)

VCC/2

(TYP.)

0.2

(MAX.)

In input mode (Applying B3 =

1.5 V)

A Applying B3 = 3.0 V

A Applying B3 = 3.0 V

A Applying B3 = 1.5 V

A Applying B3 = 0 V

V Standby mode

V Input mode

V Active mode

Voltage gain GV 6.0 9.0 12.0 16.5 6.0 dB Vo=100kHz, 1.0Vpp

Maximum output level Vomv 5.2 Vpp f=10kHz,THD=1%

Frequency characteristic 1 Gf1 -0.2 -0.2 dB f=4.5MHz/100KHz

Frequency characteristic 2 Gf2 -1.5 -1.4 dB f=8.0MHz/100KHz

Frequency characteristic 3 Gf3 -26 -28 dB f=18MHz/100KHz

Frequency characteristic 4 Gf4 -44 -48 dB f=23.5MHz/100KHz

V

o=1.0Vp-p

Differential gain DG 0.5 %

Inputting standard staircase

Signal

V

o=1.0Vp-p

Differential phase DP 1.0 deg

Inputting standard staircase

signal

z~6MHz band

Y signal to noise ratio SNY +74 +73 +70 +70 +74 dB

C AM signal to noise ratio SNCA +77 +76 +75 +75 +77 dB

C PM signal to noise ratio SNCP +65 dB

Current able to flow into output pin lextin 30 mA

Output DC offset Voff ±50max mV

Input impedance Rin 150 k

Output pin shunt switch

on resistance

Ron - 3

100 kH

Inputting 100% white video signal

100~500 kHz band

Inputting 100% chroma video signal

100~500 kHz band

Inputting 100% chroma video signal

Applying 4.5 V to output pin

through 150 Ω

With no signal

Voff = (Vout pin voltage) ÷ 2

Measure inflowing current when

applying A3 = 1 V

www.rohm.com

2/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

A

V

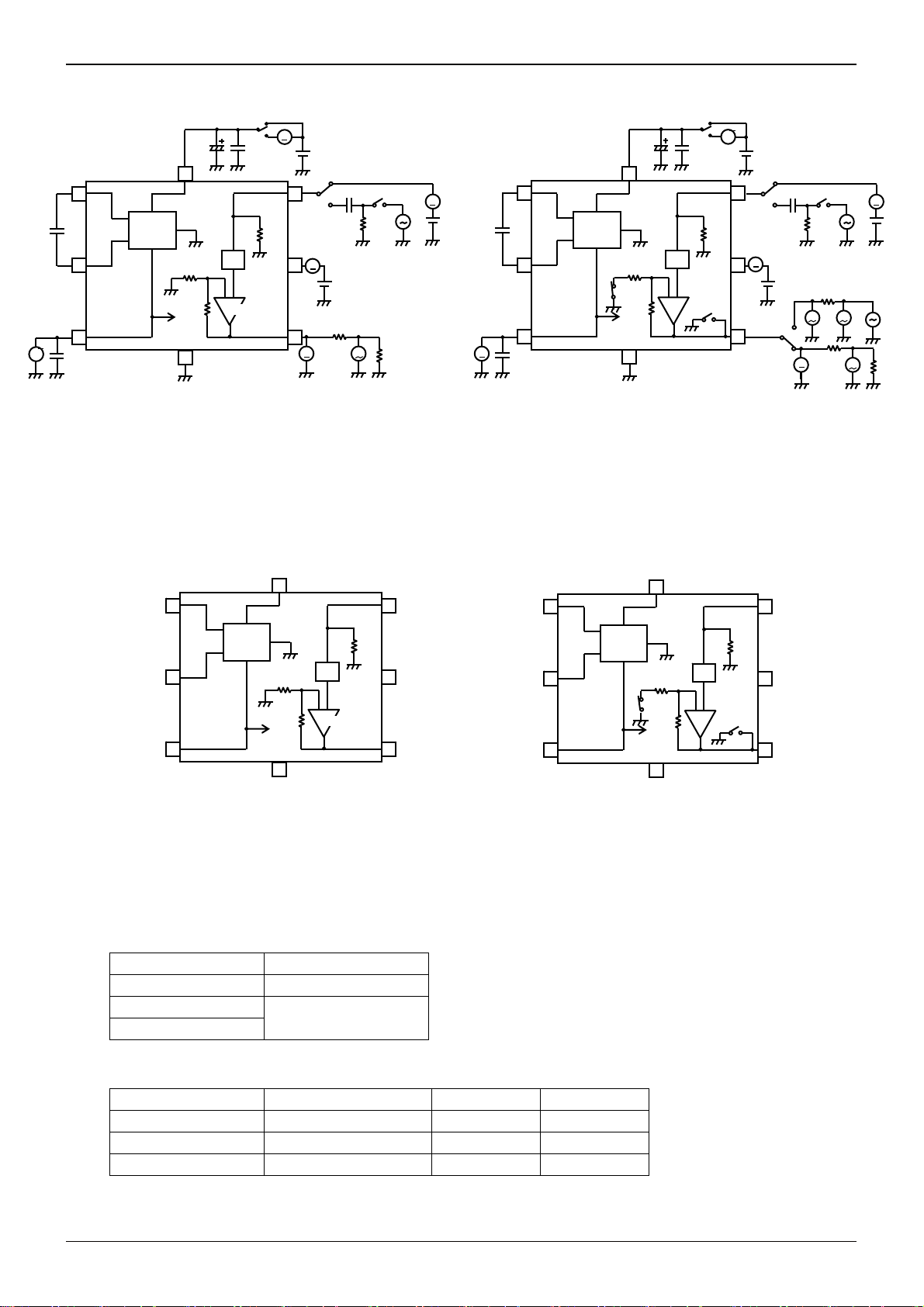

●Test Circuit Diagram

1.0uF

V

C_PLUS

C_MINUS

NVCC

1.0uF

10u

VCC

A2

A1

B1

C1

IN

CHARGE

PUMP

OUT

NVCC

LPF

6/9/12/16.5dB

GND

C2

0.01u

150k

A

(VCC)

1.0uF

V

C_PLUS

C_MINUS

NVCC

A1

B1

C1

1.0uF

VIN

A3

STBY

B3

VOUT

C3

0.1u

50Ω

A

75Ω

V

V

A

75Ω

(a) BH76906/09/12/16GU (b) BH76706GU

Fig. 1

CHARGE

PUMP

OUT

NVCC

Technical Note

A

0.01u

10u

VCC

A2

IN

150k

LPF

SW2

6dB

SW1

C2

GND

VIN

A3

STBY

B3

VOUT

C3

A

(VCC)

0.1u

50Ω

A

100Ω

V

75Ω

V

V

75Ω

※ A test circuit is a circuit for shipment inspection and differs from an application circuit example.

●Block Diagram

C_PLUS

A1

B1

C_MINUS

NVCC

C1

●Operation Logic

BH769xxGU

STBY Pin Logic Operating Mode

OPEN

BH76706GU

STBY Pin Logic Operating Mode SW1 SW2

※Use of the BH76706GU with the STBY pin OPEN is inappropriate

VCC

A2

IN

CHARGE

PUMP

OUT

NVCC

LPF

6/9/12/16.5dB

GND

C2

(a) BH76906/09/12/16GU

150k

VIN

A3

STBY

B3

VOUT

C3

C_PLUS

A1

B1

C_MINUS

NVCC

C1

VCC

A2

IN

CHARGE

PUMP

OUT

SW2

NVCC

6dB

C2

GND

(b) BH76706GU

LPF

Fig. 2

H Active

L

Standby

H Standby OFF OFF

M Input (Record) ON OFF

L Active (Playback) OFF ON

SW1

150k

VIN

A3

STBY

B3

VOUT

C3

www.rohm.com

3/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

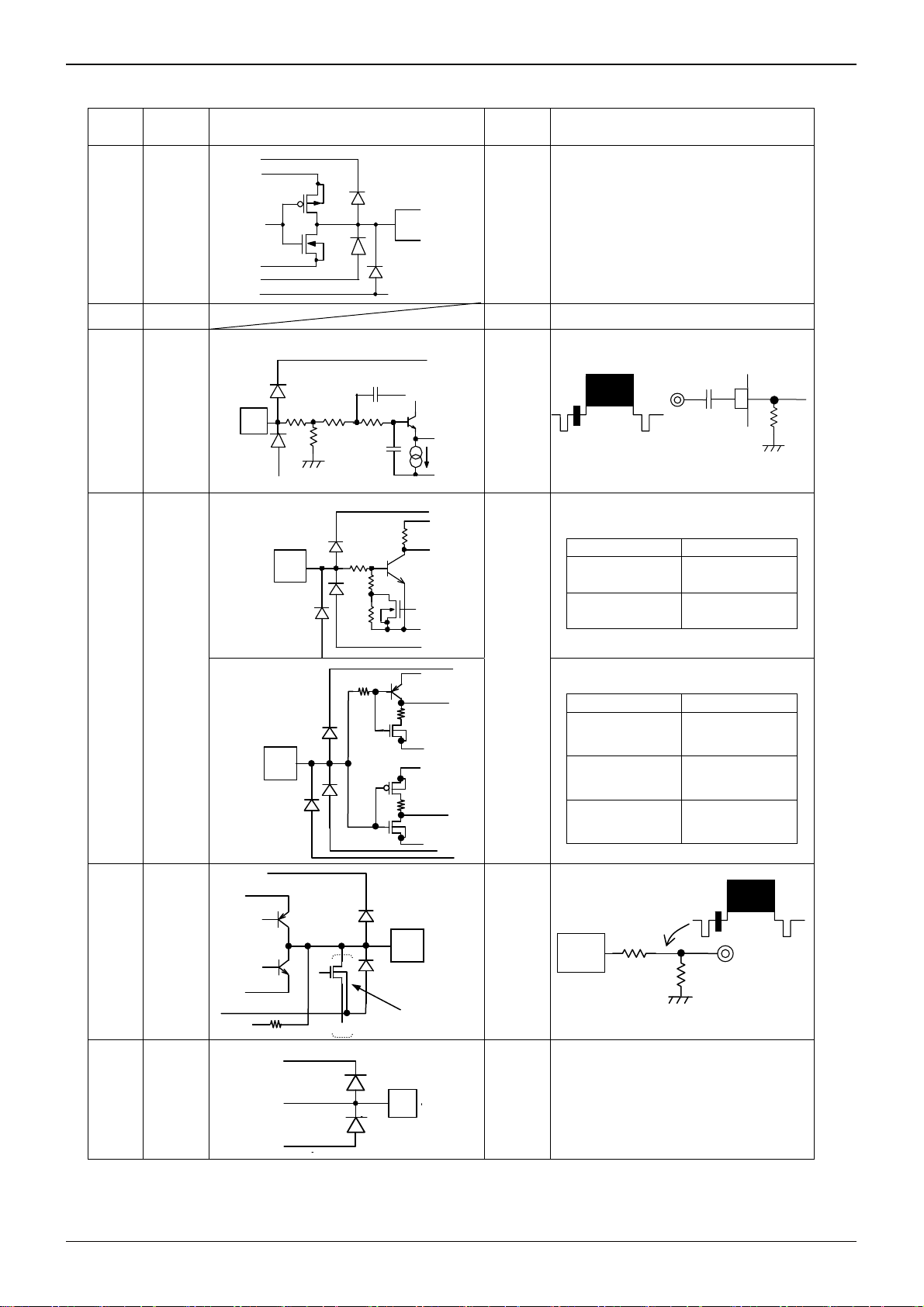

●Pin Descriptions

Ball

A1

Pin

Name

C_PLUS

Pin Internal Equivalent Circuit Diagram

VCC

VCC

C_PLUS

C1

DC

Voltage

+VCC

↑↓

Functional Description

Flying capacitor “+” pin

See functional descriptions of 7pin,

0V

GND

GND

NVCC

100

3.9k

4.1k

150K

VCC

3.9k

4.1k

VCC VCC pin

0V

Video signal input pin

Suitable input signals include

NV

composite video signals,

A2 VCC

A3 VIN

VIN

chroma signals, R.G.B. signals

50K

250K

200K

100K

VCC

VCC

vcc

200K

GND

GND

vcc

VCC

to

0V

ACTIVE/STANBY switching pin

Pin Voltage

1.2 V~VCC

( H )

0 V~0.45 V

( L )

MODE switching pin

Pin Voltage

B3 STBY

BH769xxGU

STBY

BH76706GU

2.8 V~VCC

STBY

GND

vcc

( H )

1.3 V~1.7 V

(M)

200K

GND

GND

NVCC

VCC

VCC

0 V~0.2 V

(L)

Video signal output pin

8pin

VIN

1μF

ACTIVE

STANBY

STANBY

GND (Record)

ACTIVE

(Playback)

Technical Note

150k

MODE

MODE

C3

VOUT

C2 GND

NVCC

NVCC

1K

VCC

NVCC

GND

VOUT

BH76706GU only

GND

0V

0V

VOUT

GND pin

75Ω

75Ω

Note 1) DC voltages in the figure are those when VCC = 3.0 V. Moreover, these values are reference values which are

not guaranteed.

Note 2) Numeric values in the figure are settings which do not guarantee ratings.

www.rohm.com

4/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

Technical Note

Flying capacitor “-“ pin (8pin)

C1

C2

NVC

0V

NVC

C1 NVCC

B1

C_MINUS

VCC

GND

GND

VCC

VCC

VCC

C_MINUS

C2

-VCC

(-2.75 V)

0V

↑↓

NVCC

-VCC

(-2.75 V)

Negative voltage pin (7pin)

Note 1) DC voltages in the figure are those when VCC = 3.0 V. Moreover, these values are reference values which are

not guaranteed.

Note 2) Numeric values in the figure are settings which do not guarantee ratings.

●Description of Operation

1) Principles of output coupling capacitorless video drivers

Single-supply amplifier

VCC

1000μF

1/2 VCC bias

Output capacitor required since DC

voltage is occurring at output pin

75Ω

75Ω

Dual-supply amplifier

VCC

-VCC

Output capacitor not required since

DC voltage does not occur at output

pin

75Ω

75Ω

Fig.3 Fig.4

For an amplifier operated from a single power supply (single-supply), since the operating point has a potential of

approximately 1/2 Vcc, a coupling capacitor is required for preventing direct current in the output. Moreover, since the

load resistance is 150 (75 + 75 ) for the video driver, the capacity of the coupling capacitor must be on the order of

1000 F if you take into account the low band passband. (Fig.3)

For an amplifier operated from dual power supplies (+ supply), since the operating point can be at GND level, a coupling

capacitor for preventing output of direct current is not needed.

Moreover, since a coupling capacitor is not needed, in principle, there is no lowering of the low band characteristic at the

output stage. (Fig.4)

2) Occurrence of negative voltage due to charge pump circuit

A charge pump, as shown in Fig. 5, consists of a pair of switches (SW1, SW2) and a pair of capacitors (flying capacitor,

anchor capacitor). Switching the pair of switches as shown in Fig. 5 causes a negative voltage to occur by shifting the

charge in the flying capacitor to the anchor capacitor as in a bucket relay.

In this IC, by applying a voltage of +3 V, a negative voltage of approximately -2.8 V is obtained.

www.rohm.com

5/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

V

V

Technical Note

cc +3V

SW1 SW2

Charge current

+

-

Flying capacitor

Anchor

Capacitor

Vcc +3V

Charge current

SW1

+

Charge current

Flying capacitor

SW2

-

Vcc occurs

-

-

Anchor Capacitor

+

cc +3V

Charging mode

-

+

Charge shi fting mode

-

+

+

-Vcc

-

occurs

Fig.5 Principles of Charge Pump Circuit

3) Configuration of BH769xxGU and BH76706GU

As shown in Fig. 6, a BH769xxGU or BH76706GU is a dual-supply amplifier and charge pump circuit integrated in one IC.

Accordingly, while there is +3 V single-supply operation, since a dual-supply operation amplifier is used, an output

coupling capacitor is not needed.

1μF

AMP

VCC

Dual-supply amplifier

75Ω

150k

VCC

75Ω

1-chip integration

Although single-supply,

output capacitor is not needed.

Charge pump

-VCC

1μF

Charge pump

1μF

Fig.6 Configuration Diagram of BH769xxGU or BH76706GU

4) Input pin format and sag characteristic

While a BH769xxGU or BH76706GU is a low voltage operation video driver, since it has a large dynamic range of

approximately 5.2 Vpp, a resistance termination method that is compatible regardless of signal form (termination by 150

k) is used, and not a clamp method that is an input method exclusively for video signals.

Therefore, since a BH769xxGU or BH76706GU operates normally even if there is no synchronization signal in the input

signal, it is compatible with not only normal video signals but also chroma signals and R.G.B. signals and has a wide

application range.

Moreover, concerning sag (lowering of low band frequency) that occurs at the input pin and becomes a problem for the

resistance termination method, since the input termination resistor is a high 150 k, even if it is combined with a small

capacity input capacitor, a sag characteristic that is not a problem in actual use is obtained.

In evaluating the sag characteristic, it is recommended that you use an H-bar signal in which sag readily stands out. (Fig.

8 to Fig. 10)

www.rohm.com

6/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

Technical Note

Input capacitor and input impedance cutoff frequency

is the same as when output capacitor in generic 75

driver is made 1000 F.

(Input pin time constant) (Output pin time constant)

1 F x 150 k = 1000 F x 150

a) Video signal without sag (TG-7/1 output, H-bar)

b) BH769xxGU or BH76706GU output (Input = 1.0 F, TG-7/1 output, H-bar)

c) 1000 F + 150 sag waveform (TG-7/1 output, H-bar)

Sag is determined

by input capacitor

and input resistor

only.

1μF

150k

Fig. 7

Fig. 8

TG-7/1

Fig. 9

Fig. 10

75Ω+75Ω=150Ω

Sag occurs

TV screen output image of

H-bar signal

Monitor

1μF

150k

BH769xxGU・BH76706GU

Nearly identical sag

75Ω

TG-7/1

75Ω

Monitor

1000μF

75Ω

75Ω

www.rohm.com

7/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

A

Technical Note

●Application Circuit Example

C_PLUS

C1=1.0uF C1=1.0uF

C_MINUS

NVCC

C2=1.0uF

t playback (Active mode) Recording (Input mode) BH76706GU only

NVCC

2.5~3.45V

Vcc

A2

SW2

C2

GND

LPF

6dB

C4=3.3uF

150k

SW1

A1

B1

C1

CHARGE

PUMP

NVCC

2.5~3.45V

Vcc

A2

SW2

C2

GND

C4=3.3uF

LPF

6/9/12/16.5dB

150k

SW1

C2=1.0uF

C_PLUS

A1

CHARGE

PUMP

B1

C_MINUS

NVCC

C1

C3=1.0uF C3=1.0uF

VIN

A3

VIDEO IN

STBY

B3

Video

monitor

CIRCUIT

CURREN

C3

VOUT

VIDEO OUT

R2=75Ω

VOUT

VIN

A3

STBY

B3

C3

VIDEO IN

R2=75Ω

VIDEO IN

75Ω

*SW1 and SW2 are built-in BH76706GU only See page 3/16 for STBY pin logic in each mode

Fig.11

※ We are confident in recommending the above application circuit example, but we ask that

you carefully check not just the static characteristics but also transient characteristics of this

circuit before using it.

●Caution on use

1. Wiring from the decoupling capacitor C4 to the IC should be kept as short as possible.

Moreover, this capacitor's capacitance value may have ripple effects on the IC, and may affect the S-N ratio for signals, so

we recommend using as large a decoupling capacitor as possible. (Recommended C4: 3.3 µF, B characteristics, 6.3 V

or higher maximum voltage)

Make mount board patterns follow the layout example shown on page 10 as closely as possible.

2. Capacitors to use

In view of the temperature characteristics, etc., we recommend a ceramic capacitor with B characteristics.

3. The NVCC (C1 pin) terminal generates a voltage that is used within the IC, so it should never be connected to a load

unless absolutely necessary. Moreover, this capacitor (C2) has a large capacitance value but very little negative voltage

ripple.

(Recommended C2: 1.0 F, B characteristic, 6.3 V or higher maximum voltage)

4. Capacitors C1 and C4 should be placed as close as possible to the IC. If the wiring to the capacitor is too long, it can

lead to intrusion of switching noise. (Recommended C1: 1.0 µF, B characteristics, 6.3 V or higher maximum voltage)

5. The HPF consists of input coupling capacitor C3 and 150 k of internal input impedance.

Be sure to check for video signal sag before determining the C3 value.

The cut-off frequency fc can be calculated using the following formula.

fc = 1/(2π×C3×150kΩ) (Recommended C3: 1.0 F, B characteristic, 6.3 V or higher maximum voltage)

6. The output resistor R2 should be placed close to the IC.

7. If the IC is mounted in the wrong direction, there is a risk of damage due to problems such as inverting VCC and GND.

Be careful when mounting it.

8. A large current transition occurs in the power supply pin when the charge pump circuit is switched. If this affects other

ICs (via the power supply line), insert a resistor (approximately 10 ) in the VCC line to improve the power supply's ripple

effects. Although inserting a 10

resistor lowers the voltage by about 0.2 V, this IC has a wide margin for low-voltage

operation, so dynamic range problems or other problems should not occur. (See Figures 12 to 14.)

www.rohm.com

8/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

Technical Note

1. Current ripple due to charge pump

circuit affects power supply Vcc pin

Vcc

Ω

10

1uF 3.3uF

2. Current ripple affects

DAC or other

Vcc pin

DAC

or

Other

1uF

V

IN

VIDEO

AMP

Ω

150k

V

OUT

-Vcc

75

Ω

75

Ω

Chrarge Pump

1uF

Fig.12 Effects of Charge Pump Circuit Current Ripple on External Circuit

1) Decoupling capacitor only

1) Decoupling capacitor only

Waveform of current between

power supply and capacitor (A)

10 mA/div

Waveform of current between

capacitor and IC (B)

10 mA/div

A

B

A

Fig.13

Vcc

2) Decoupling capacitor + 10 resistor

2) Decoupling capacitor + 10 resistor

Waveform of current between

power supply and capacitor (A)

10 mA/div

Waveform of current between

resistor and capacitor (B)

10 mA/div

Waveform of current between

capacitor and IC (C)

10 mA/div

10

Ω

A

A

B

A

C

Vcc

Fig.14

www.rohm.com

9/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

Vcc

A

Vcc

A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

●Evaluation Board Pattern Diagram (Double-sided, 2 layers)

Parts List

Symbol Function Recommended Value Remarks

C1 Flying capacitor 1μF B characteristic recommended

C2 Tank capacitor 1μF B characteristic recommended

C3 Input coupling capacitor

C4 Decoupling capacitor 3.3μF B characteristic recommended

R1 Input termination resistor 75Ω Needed when connected to video signal measurement set

R2 Output resistor 75Ω ―

R3 Output termination resistor 75Ω

Input connector BNC

Output connector RCA (Pin jack)

Fig.15

1μF

B characteristic recommended

Not needed when connected to TV or video signal

measurement set

Layer 1 wiring + Silkscreen legend

Layer 2 wiring

Solder pattern

Technical Note

www.rohm.com

10/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

g

Technical Note

●Reference Data

BH76906GU

30

25

20

15

10

CIRCUIT CURRENT [mA]

5

0

01234

STANDBY CURRENT [uA]

POWER SUPPLY VOLTAGE [V]

Fig. 16 Circuit Current vs Supply

Volta

BH76906GU

0.4

0.3

0.2

0.1

0

Ta= 2 5℃

e

VCC=3V

-0.1

-80 -40 0 40 80 120

Fig. 19 Standby Circuit Current

TEMPERATURE [℃]

vs Ambient Temperature

5

BH76906GU

Ta= 2 5℃

0

-5

-10

VOUT DC OFFSET [mV]

-15

2 2.5 3 3.5 4

POWER SUPPLY VOLTAGE [V]

Fig. 22 VOUT Pin Output DC Offset

vs Supply Voltage

BH76906GU

25

20

15

10

CIRCUIT CURRENT [mA]

5

-80 -40 0 40 80 120

TEMPERATURE [℃]

Fig. 17 Circuit Current

vs Ambient Temperature

BH76706GU

200

150

100

50

CIRCUIT CURRENT [μA] CIRCUIT CURRENT [μA]

0

22.533.54

POWER SUPPLY VOLTAGE

[V]

Ta= 2 5℃

Fig. 20 GND Mode Circuit Current

vs Supply Voltage

BH76906GU

5

0

-5

-10

VOUT DC OFFSET [mV]

-15

-80 -40 0 40 80 120

TEMPERATURE [℃]

Fig. 23 VOUT Pin Output DC Offset

vs Ambient Temperature

VCC=3V

VCC=3V

BH76906GU

0.4

0.3

0.2

0.1

0

STANDBY CURRENT [uA]

-0.1

22.533.54

POWER SUPPLY VOLTAGE [V]

Fig. 18 Standby Circuit Current

vs Supply Voltage

BH76706GU

200

150

100

50

CIRCUIT CURRENT [μA]

0

-80 -40 0 40 80 120

BH76906GU

10

0

-10

-20

-30

-40

-50

VOLTAGE GAIN [dB]

-60

-70

-80

1.E+06 1.E+07 1.E+08

TEMPERATURE [℃]

VCC=3V Ta=25℃

FREQUENCY [Hz]

Fig. 24 Frequency Characteristic

Ta= 2 5℃

VCC=3V

BH76706GU

10

0

-10

-20

-30

-40

-50

VOLTAGE GAIN [dB]

-60

-70

-80

1.E+06 1.E+07 1.E+08

FREQUENCY [Hz]

VCC=3V Ta=25℃

Fig. 25 Frequency Characteristic

www.rohm.com

11/16

© 2009 ROHM Co., Ltd. All rights reserved.

BH76906GU

6.2

6.1

6

5.9

VOLTAGE GAIN [dB]

5.8

22.533.54

POWER SUPPLY VOLTAGE [V]

Fig. 26 Voltage Gain vs Supply Voltage

Ta= 2 5℃

VOLTAGE GAIN [dB]

Fig. 27 Voltage Gainvs Ambient Temperature

BH76906GU

6.2

6.1

6

5.9

5.8

-80 -40 0 40 80 120

TEMPERATURE [℃]

VCC=3V

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

VCC=3V

0.4

BH76906GU

Ta= 2 5℃

BH76906GU

0.4

0.2

0

f=4.5MHz/100kHz

0.2

0

f=4.5MHz/100kHz

BH76906GU

-1

-2

-3

Technical Note

Ta= 2 5℃

f=8MHz/100kHz

-0.2

FREQUENCY RESPONSE1:Gf1[dB]

-0.4

22.533.54

POWER SUPPLY VOLTAGE

[V]

Fig. 28 Frequency Characteristic 1

vs Supply Voltage

BH76906GU

-1

-2

-3

-4

FREQUENCY RESPONSE2:Gf2[dB]

-5

-80 -40 0 40 80 120

TEMPERATURE [℃]

VCC=3V

f=8MHz/100kHz

Fig. 31 Frequency Characteristic 2

vs Ambient Temperature

-0.2

FREQUENCY RESPONSE1:Gf1[dB]

-0.4

-80 -40 0 40 80 120

TEMPARATURE [℃]

Fig. 29 Frequency Characteristic 1

vs Ambient Temperature

BH76906GU

-20

-25

-30

-35

FREQUENCY RESPONSE3:Gf3[dB]

22.533.54

POWER SUPPLY VOLTAGE [V]

f=18MHz/100kHz

f=18MHz/100kHz

Ta= 2 5℃

Fig.32 Frequency Characteristic 3

vs Supply Voltage

-4

FREQUENCY RESPONSE2:Gf2[dB]

-5

22.533.54

POWER SUPPLY VOLTAGE [V]

Fig. 30 Frequency Characteristic 2

vs Supply Voltage

BH76906GU

-20

f=18MHz/100kHz

-25

-30

-35

FREQUENCY RESPONSE3:Gf3[dB]

-80 -40 0 40 80 120

TEMPERATURE [℃]

VCC=3V

BH76906GU

-35

-40

-45

f=23.5MHz/100k

FREQUENCY RESPONSE4:Gf4[dB]

-50

22.533.54

POWER SUPPLY VOLTAGE [V]

Hz

Fig. 34 Frequency Characteristic4

vs Supply Voltage

BH76906GU

6

5.8

5.6

5.4

5.2

MAX OUTPUT VOLTAGE [Vpp]

Ta= 2 5℃

VCC=3V

BH76906GU

-35

-40

-45

f=23.5MHz/100k

FREQUENCY RESPONSE4:Gf4[dB]

-50

-80 -40 0 40 80 1 20

TEMPERATURE [℃]

Hz

Fig. 35 Frequency Characteristic 4

vs Ambient Temperature

3

2

1

6dB

0

9dB

12dB

16.5dB

-1

OUTPUT DC VOLTAGE [V]

-2

VCC=3V Ta =2 5 ℃

VCC=3V

BH76906GU

7

6

5

4

MAX OUTPUT VOLTAGE [Vpp]

3

22.533.54

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

5

-80 -40 0 40 80 120

TEMPARATURE [℃]

Fig. 37 Max. Output Level vs Ambient Temperature

www.rohm.com

12/16

© 2009 ROHM Co., Ltd. All rights reserved.

-3

-1.5 -1.0 -0.5 0.0 0.5 1.0 1.5

INPUT DC VOLTAGE [V]

Fig. 38 DC I/O Characteristic

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

Technical Note

CHARGEPUMP OSC FREQUENCY [KHz]

BH76906GU

230

225

220

215

210

205

200

22.533.54

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

Fig. 39 Charge Pump Oscillation Frequency

vs Supply Voltage

BH76906GU

-1

-1.5

-2

-2.5

-3

-3.5

CHARGEPUMP OUTPUT VOLTAGE [V]

-4

22.533.54

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

Fig. 41 Charge Pump Output Voltage

vs Supply Voltage

BH76906GU

230

225

220

215

210

CHARGEPUMP OSC FREQUENCY [KHz]

205

-80 -40 0 40 80 120

TEMPERATURE [℃]

VCC=3V

Fig. 40 Charge Pump Oscillation Frequency

vs Ambient Temperature

BH76906GU

-1.0

-1.5

-2.0

-2.5

CHARGEPUMP OUTPUT VOLTAGE [V]

-3.0

0.0 10.0 20.0 30.0 40.0

LOAD CURRENT [mA]

VCC=3V Ta=25℃

Fig. 42 Charge Pump Load Regulation

BH76912GU

1.2

1.1

1

0.9

DIFFERENTIAL PHASE [Deg]

0.8

22.533.54

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

DIFFERENTIAL PHASE [Deg]

BH76912GU

1.2

1.1

1

0.9

0.8

-80 -40 0 40 80 120

TEMPERATURE [℃]

VCC=3V

Fig. 43 Differential Phase

vs Supply Voltage

BH76912GU BH76912GU

0.8

0.6

0.4

0.2

DIFFERENTIAL GAIN [%]

Ta= 2 5℃

0.8

0.6

0.4

0.2

DIFFERENTIAL GAIN [%]

VCC=3V

0

22.533.54

POWER SUPPLY VOLTAGE [V]

Fig. 45 Differential Gain

vs Supply Voltage

www.rohm.com

13/16

© 2009 ROHM Co., Ltd. All rights reserved.

0

-80 -40 0 40 80 120

TEMPERATURE [℃]

Fig. 46 Differential Gain

vs Ambient Temperature

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

BH76906GU BH76906GU

79

Ta= 2 5℃

79

Technical Note

VCC=3V

78.5

78

Y S/N [dB]

77.5

77

2 2 .5 3 3 .5 4

POWER SUPPLY VOLTAGE [V]

Fig. 47 Y S/N vs Supply Voltage

BH76906GU

80

78

76

74

CHROMA S/N (AM) [dB]

72

70

2 2.5 3 3.5 4

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

Fig. 49 C AM S/N vs Supply Voltage

78.5

78

Y S/N [dB]

77.5

77

-80 -40 0 40 80 120

TEMPERATURE [℃]

Fig.48 Y S/N vs Ambient Temperature

BH76906GU

80

78

76

74

CHROMA S/N (AM) [dB]

72

70

-80 -40 0 40 80 120

TEMPERATURE [℃]

VCC=3V

Fig. 50 C AM S/N vs Ambient Temperature

BH76906GU

70

68

66

64

CHROMA S/N (PM) [dB]

62

60

22.5 33.54

POWER SUPPLY VOLTAGE [V]

Ta= 2 5℃

Fig. 51 C PM S/N vs Supply Voltage

BH76906GU

180

165

150

135

INPUT IMPEDANCE [kΩ]

Ta= 2 5℃

BH76906GU

70

68

66

64

CHROMA S/N (PM) [dB]

62

60

-80 -40 0 40 80 120

TEMPERATURE [℃]

VCC=3V

Fig. 52 C PM S/N vs Ambient Temperature

BH76906GU

165

150

135

INPUT IMPEDANCE [kΩ]

VCC=3V

120

22.533.54

POWER SUPPLY VOLTAGE [V]

Fig. 53 Input Impedance vs Supply Voltage

www.rohm.com

14/16

© 2009 ROHM Co., Ltd. All rights reserved.

120

-80 -40 0 40 80 120

TEMPERATURE [℃]

Fig. 54 Input Impedance vs Ambient Temperature

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

BH76906GU

20

VCC=3V Ta=25℃

BH76706GU

20

Technical Note

VCC=3V Ta=25℃

16

12

8

4

CIRCUIT CURRENT [mA]

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0

CTL TERMINAL VOLTAGE [V]

Fig. 55 Control Pin Characteristic

16

12

8

CIRCUIT CURRENT [mA]

4

0

0 0.5 1 1.5 2 2.5 3

CTL TERMINAL VOLTAGE [V]

Fig. 56 Control Pin Characteristic

5

BH76706GU

Ta= 2 5℃

BH76706GU

5

VCC=3V

4

4

3

3

2

ON RESISTANCE [Ω]

2

ON RESISTANCE [Ω]

1

22.5 33.5 4

POWER SUPPLY VOLTAGE [V]

1

-80 -40 0 40 80 120

POWER SUPPLY VOLTAGE [V]

Fig. 57 Output Pin Shunt Switch On Resistance

vs Supply Voltage

Fig. 58 Output Pin Shunt Switch On Resistance

vs Ambient Temperature

● Performing separate electrostatic damage countermeasures

When adding an externally attached electrostatic countermeasure element to the output pin, connect a varistor in the

position shown in Fig. 59 (if connected directly to the output pin, the IC could oscillate depending on the capacity of the

varistor). For this IC, since the output waveform is GND-referenced and swings positive and negative, a normal Zener

diode cannot be used.

ESD or surge

VOUT

75Ω

75Ω

Fig.59 Using Externally Attached Varistor

www.rohm.com

15/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

BH76906GU, BH76909GU, BH76912GU, BH76916GU, BH76706GU

●Selection of order type

VCSP85H1

<Dimension>

B H 7 6 9 0 E 2

Part. No.

BH76906GU

BH76909GU

BH76912GU

BH76916GU

BH76706GU

Tape Embossed carrier tape

Quantity 3000pcs

Direction

of feed

(Unit:mm)

6

E2

(The direction is the 1pin of product is at the upper left when you hold

reel on the left hand and you pull out the tape on the right hand)

1234 1234 1234 1234 1234 1234

Reel

G U

1pin

※When you order , please order in times the amount of package quantity.

Technical Note

Tape and Reel information

Direction of feed

www.rohm.com

16/16

© 2009 ROHM Co., Ltd. All rights reserved.

2009.03 - Rev.A

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machiner y, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...