D/A Converter Series for Electronic Adjustments

Standard 8bit

8ch Type D/A Converters

BH2226FV,BH2226F

No.09052EBT05

●Description

The BH2226FV,BH2226F is an 8bit R-2R-type D/A converter with 8 channels. The D/A converter output and

serial / parallel conversion function can be switched with one command, and a built-in RESET function

ensures that the output voltage at all channels is Low during power up. A broad power supply voltage

range (2.7V-5.5V) is available, providing design flexibility.

●Features

1) Integrated expansion port function

2) Built-in RESET function

3) High speed output response characteristics

4) 3-line-type serial interface

5) Broad power supply voltage range: 2.7V-5.5V

●Applications

DVCs, DSCs, DVDs, CD-Rs, CD-RWs

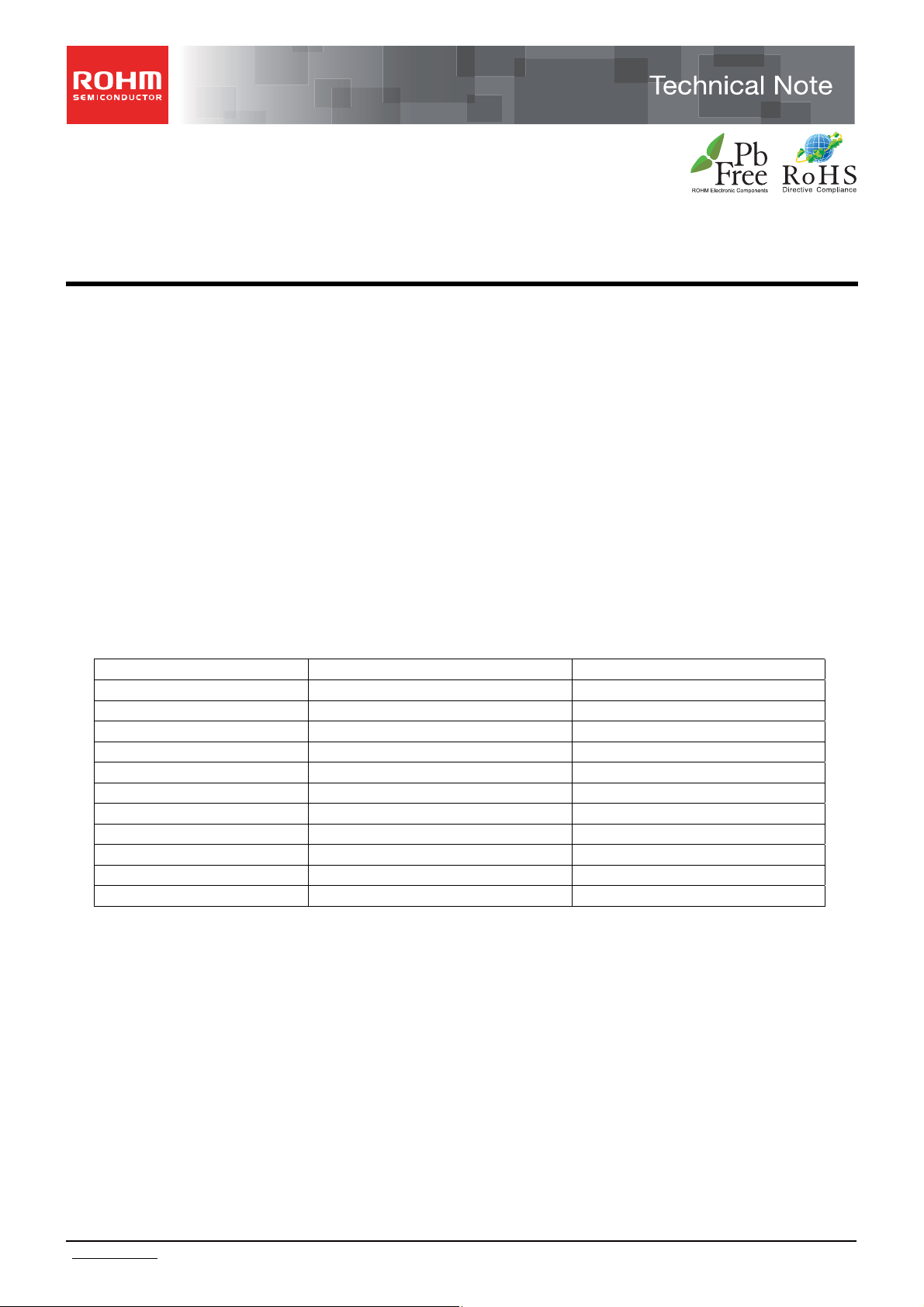

●Line up matrix

Parameter BH2226FV BH2226F

Power source voltage range 2.7~5.5V 2.7~5.5V

Number of channels 8ch 8ch

Current consumption 1.3 mA 1.3 mA

Differential non linearity error ±1.0LSB ±1.0LSB

Integral non linearity error ±1.5LSB ±1.5LSB

Output current performance ±1.0mA ±1.0mA

Settling time 100µs 100µs

Data transfer frequency 10MHz 10MHz

Input format CMOS CMOS

Data latch method CSB method CSB method

Package SSOP-B16 SOP16

www.rohm.com

1/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

BH2226FV,BH2226F

Technical Note

●Absolute Maximum Ratings

(Ta=25℃)

Parameter Symbol Limits Unit Remarks

Power source voltage VCC -0.3~7.0 V Terminal voltage VIN -0.3~VCC V -

Storage temperature ran ge

Power dissipation PD

TSTG -55~125 ℃ -

*1

mW BH2226FV

450

500*2 mW BH2226F

*1 Derated at 4.5mW/ ℃ at Ta>25℃

*2 Derated at 5.0mW/ ℃ at Ta>25℃

*3 Please note that this product is not robust against radiation.

●Recommended Operating Conditions

(Ta=25℃)

Parameter Symbol

MIN. TYP. MAX.

Limits

Unit Remarks

VCC power source voltage VCC 2.7 - 5.5 V Terminal input voltage range VIN 0 - VCC V Analog output current IO -1.0 - 1.0 mA Operating temperature range TOPR -20 - 85 ℃ Serial clock frequency FCLK - 1.0 10.0 MHz D/A output limit load capacity CL - - 0.1 µF -

●Electrical Characteristics

(Unless otherwise specified, VCC=3.0V, RL=OPEN, CL=0pF, Ta=25℃)

Parameter Symbol

MIN. TYP. MAX.

Limits

Unit Conditions

<Current consumption>

VCC system

ICC - 1.1 2.5 mA CLK=1MHz, 80H setting

ICCPD - 5 20 µA At power down setting

<Logic interface>

L input voltage VIL GND - 0.6 V VCC=5V

H input voltage VIH 2.4 - VCC V VCC=5V

Input current IIN -10 - 10 µA

L output voltage VOL - - 0.4 V IOH=2.5mA

H output voltage VOH VCC-0.4 - - V IOL=0.4mA

<Buffer amplifier>

Output zero scale voltage

Output full scale voltage

ZS1 GND - 0.1 V 00H setting, at no load

ZS3 GND - 0.3 V 00H setting, IOH=1.0mA

FS1 VCC-0.1 - VCC V FFH setting, at no load

FS3 VCC-0.3 - VCC V FFH setting, IOL=1.0mA

<D/A converter precision>

Differential non linearity error DNL -1.0 - 1.0 LSB Input code 02H~FDH

Integral non linearity error INL -1.5 - 1.5 LSB Input code 02H~FDH

VCC power source voltage rise

time

trVCC 100 - - µs VCC=0→2.7V

Power on reset release voltage VPOR - 1.9 - V

www.rohm.com

2/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

BH2226FV,BH2226F

●Timing Chart

(Unless otherwise specified, VCC=3.0V, RL=OPEN, CL=0pF, Ta=25℃)

Parameter Symbol

CLK L level time tCLKL 50 - - ns

CLK H level time tCLKH 50 - - ns

DI setup time tsDI 20 - - ns

DI hold time thDI 40 - - ns

Parallel input setup time tsPI 20 - - ns

Parallel input hold time thPI 40 - - ns

CSB setup time tsCSB 50 - - ns

CSB hold time thCSB 50 - - ns

CSB H level time tCSBH 50 - - ns

D/A output settling time tOUT - - 100 µs CL=50pF,RL=10kΩ

Parallel output delay time tpOUT - - 600 ns CL=50pF,RL=10kΩ

Serial output delay time tsOUT - - 350 ns CL=50pF,RL=10kΩ

MIN. TYP. MAX.

Limits

Fig.1

Unit Conditions

Technical Note

www.rohm.com

3/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

BH2226FV,BH2226F

●Terminal Description / Block Diagrams

(BH2226FV,BH2226F)

No.

Terminal

name

Function

1 DA1

2 DA2

3 DA3

4 DA4

5 DA5

Analog output terminal /

I/O input output terminal

6 DA6

7 DA7

8 DA8

9 VCC Power source terminal

10 RESETB Reset terminal

11 TEST Test terminal (normal connected to GND)

12 CSB Chip select signal input terminal

13 CLK Serial clock input terminal

14 DI Serial data input terminal

15 SO Serial data output terminal

16 GND Ground terminal

Technical Note

1

2

3

4

5

6

7

8

Serial

Interface

PowerOn

Reset

Fig.2

16

15

14

13

12

11

10

9

●Input-Output equivalence circuits

Terminal Equivalence Circuit Terminal Equivalence Circuit

DA1

DA2

DA3

DA4

DA5

DA6

DA7

DA8

DI

CLK

CSB

TEST

RESETB

SO

Fig.3 Input-Output equivalence circuits

www.rohm.com

4/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

BH2226FV,BH2226F

Technical Note

●Operation Description

・Command Transmission

The Control command consists of 3 lines of 12bit serial input data (MSB first).

DI data is read at the rising edge of the CLK, and becomes valid in the CSB Low area (before the CSB rise for 12bit data).

CSB

CLK

9 5

1 23467810 11 12

DI

D0 D1D2D3D4D5D6D7D8 D9 D10 D11 X X

Fig.4

Data Settings

D0 D1 D2 D3 D4 D5 D6 D7 Setting

0 0 0 0 0 0 0 0 At D/A setting:GND

1 0 0 0 0 0 0 0 At D/A setting:(VCC-GND)/256x1

0 1 0 0 0 0 0 0 At D/A setting:(VCC-GND)/256 x 2

1 1 0 0 0 0 0 0 At D/A setting:(VCC-GND)/256 x 3

0 0 1 0 0 0 0 0 At D/A setting:(VCC-GND)/256 x 4

~ ~

0 1 1 1 1 1 1 1 At D/A setting:(VCC-GND)/256 x 254

1 1 1 1 1 1 1 1 At D/A setting:(VCC-GND)/256 x 255

(Note) Default D[7:0]=00h

Channel Settings

D8 D9 D10 D11 Setting

0 0 0 0 Power down setting (default)

0 0 0 1 DA1

0 0 1 0 DA2

0 0 1 1 DA3

0 1 0 0 DA4

0 1 0 1 DA5

0 1 1 0 DA6

0 1 1 1 DA7

1 0 0 0 DA8

1 0 0 1 Power down release

1 0 1 0 Inconsequential

1 0 1 1 Inconsequential

1 1 0 0 I/O D/A select

1 1 0 1 I/O serial⇒Parallel

1 1 1 0 I/O parallel⇒Serial

1 1 1 1 I/O status setting

Input / Output D/A Selection settings :Each channel can be set for either I/O port or D/A converter output.

0: I/O mode (When I/O mode is selected, set the status as well.)

1: D/A mode (Set the I/O status to output mode.)

D0 D1 D2 D3 D4 D5 D6 D7 Description

DA1 DA2 DA3 DA4 DA5 DA6 DA7 DA8

Corresponding terminals for I/O or

D/A selection

I/O Status Setting : Set the status of the I/O input output terminal by D0 ~ D7.

0: input mode (High-Z status)

1: output mode

D0 D1 D2 D3 D4 D5 D6 D7 Description

DA1 DA2 DA3 DA4 DA5 DA6 DA7 DA8

Corresponding terminals for status

setting

www.rohm.com

5/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

BH2226FV,BH2226F

A

g

Technical Note

・Command Transmission Procedures

Carry out the following after power on and just after external reset:

(1) Power Down Release (2) I/O D/A Select (3) I/O Status Set

rbitrary settin

Power down release

I/O DAC select

Fig.5

I/O status setting

Note: When power is started, the power on reset is activated and the internal register initialized. However, as shown in the

figure above, in area (a), if CSB cannot be made High and noise is introduced in the control line an error may occur when

setting during the rising CSB signal.

In such a case, set the external RESETB terminal to Low and reset when CSB = High.

・Parallel - Serial Conversion

Parallel data {DA[8:1]} is taken in at the first CSB falling edge after setting the parallel serial command.

The data is then outputted in synch with the falling edge of the CLK in the next CSB = Low area, and output from 4CLK.

However, please note that the SCLK falling edge that occurs from CSB fall to the first SCLK rising edge is not counted.

Parallel data taking in

PS conversion command

Fig.6

・Serial - Parallel Conversion

DI serial data is taken in at the rising edge of the CLK.

The data is then output from the DA[8:1] terminal just after the CSB rising edge.

During that time the SO terminal output becomes undetermined (just previous address setting + data output).

Parallel data output

Fig.7

・D/A Converter Output Setting (Fig. 7)

DI serial data is taken in at the rising edge of the clock.

The D/A converter output is output from the DA[8:1] terminal just after the rising edge of the CSB.

During that time, the SO terminal output becomes undetermined (just previous address setting + data output).

DAC output

DA1 output

Fig.8

www.rohm.com

6/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

BH2226FV,BH2226F

A

A

]

●Electrical Characteristics Curves

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

CIRCUIT CURRENT:ICC[mA]

0.0

℃

85

25

℃

-20

℃

0123456

SUPPLY VOLTAGE:VCC[V]

Fig.9 Action current

consumption

0.4

0.3

0.2

0.1

0.0

-0.1

DNL [LSB]

-0.2

-0.3

-0.4

0 64 128 192 256

INPUT CODE [dec]

VCC=3.0V

16.0

14.0

12.0

10.0

8.0

6.0

4.0

2.0

CIRCUIT CURRENT:ICCPD[uA

0.0

85℃

25

℃

-20

℃

0123456

SUPPLY VOLTAGE:VCC[V]

Fig.10 Consumption current at

power down

1.0

0.8

0.6

0.4

0.2

0.0

-0.2

INL [LSB]

-0.4

-0.6

-0.8

-1.0

0 64 128 192 256

INPUT CODE [dec]

VCC=3.0V

Technical Note

3.0

VCC=3.0V

2.5

2.0

1.5

1.0

0.5

OUTPUT VOLTAGE:Vo[V]

0.0

0 64 128 192 256

INPUT CODE:[dec]

Fig.11 Output voltage

characteristic

0.25

0.20

0.15

0.10

DNL [LSB]

0.05

0.00

0.0 1.0 2.0 3.0 4.0 5.0 6.0

SUPPLY VOLTAGE:VCC[V]

Fig.12 Differential non linearity

error

0.45

0.40

0.35

0.30

0.25

0.20

INL [LSB]

0.15

0.10

0.05

0.00

0.0 1.0 2.0 3.0 4.0 5.0 6.0

SUPPLY VOLTAGE:VCC[V]

Fig.15 Power source voltage

vs. integral non linearity error

3.00

2.50

2.00

1.50

1.00

0.50

RESET VOLTAGE:VPOR[V]

0.00

-50 -25 0 25 50 75 100

TEMPARATURE:Ta[℃]

Fig.13 Integral non linearity

error

80.0

70.0

60.0

50.0

40.0

30.0

20.0

10.0

ZERO SCALE VOLTAGE:ZS[mV]

85℃

25

℃

-20

℃

0.0

0.0 1.0 2.0 3.0 4.0 5.0 6.0

IL=1.0m

SUPPLY VOLTAGE:VCC[V]

Fig.16 Output zero scale

voltage

100

80

-20

60

40

20

SETTLING TIME:tOUT[us]

0

℃

25

℃

85

℃

0.0 1.0 2.0 3.0 4.0 5.0 6.0

SUPPLY VOLTAGE:VCC[V]

Fig.14 Power source voltage

vs. differential non linearity

error

0

-20

-40

-60

-80

-20

-100

-120

FULL SCALE VOLTAGE:FS[mV]

-140

℃

25

℃

85

℃

0.0 1.0 2.0 3.0 4.0 5.0 6.0

IL=1.0m

SUPPLY VOLTAGE:VCC[V]

Fig.17 Output full scale

voltage

3.0

2.5

2.0

1.5

1.0

0.5

INPUT VOLTAGE:VIL,VIH[V]

0.0

0.0 1.0 2.0 3.0 4.0 5.0 6.0

VIH

VIL

SUPPLY VOLTAGE:VCC[V]

Fig.18 Reset release voltage

www.rohm.com

7/9

© 2009 ROHM Co., Ltd. All rights reserved.

Fig.19 Settling time

Fig.20 Input voltage

2009.07 - Rev.B

BH2226FV,BH2226F

●Operation Notes

(1) Numbers and data in entries are representative design values and are not guaranteed values of the items.

(2) Although we are confident in recommending the sample application circuits, carefully check their characteristics further

when using them. When modifying externally attached component constants before use, determine them so that they

have sufficient margins by taking into account variations in externally attached components and the Rohm LSI, not only

for static characteristics but also including transient characteristics.

(3) Absolute Maximum Ratings

Operating or testing the device over the maximum specifications may damage the part itself as well as peripheral

components. Therefore, please ensure that the specifications are not exceeded.

(4) GND potential

Ensure that the GND terminal is at the lowest potential under all operat ing conditions.

(5) Thermal design

Use a thermal design that allows for a sufficient margin regarding power dissipation (Pd) under actual operating conditions.

(6) Terminal sh orts and mis-mounting

Incorrect orientation or misalignment of the IC when mounting to the PCB may damage part. Short-circuits caused by

the introduction of foreign matter between the output terminals or across the output and power supply or GND may also

result in destruction.

Technical Note

(7) Operation in a strong magnetic field

Operation in a strong electromagnetic field may cause m alfunction.

(8) Reset Function

The power on reset circuit, which initializes internal settings, may malfunction during abrupt power ons. Therefore, set

the time constant so as to satisfy the power source rise time.

(9) After power on and after the external reset is in power down status, DA1 ~ DA8 will be in input mode (all terminals at

High-Z).

(10) In the case of condition changes in the DA1 ~ DA8 terminals (i.e. changes from D/A mode to serial-parallel mode, from

serial-parallel mode to parallel-serial mode, excluding D/A data and I/O data updates), change both analog and digital

settings of High-Z.

(11) Connect the RESETB terminal to VCC and set it to High, making sure that it becomes Low only at reset.

(12) Initialization of the serial interface shift register is carried out only by power on reset, or external reset, and is not reset

by CSB = High. Therefore, when a specified clock number (12CLK) is not attained during command setting,

interrupting processing, transfer regular data once again.

(13) The power down function restricts the consumption current in the internal analog circuit. Set it by command. At power

down, for channels set to D/A mode, "I/O D/A selection" is changed from "D/A mode" to "I/O mode". Therefore, when

the "I/O status setting" of the channel is in input mode, the terminal is in High-Z status and the input becomes unstable

and unnecessary current flows. Set the I/O status setting of channel to be in output mode, or set the terminal using

resistance.

(14) When shifting from PIO use status to D/A use status, a wait time in order to ensure D/A output stability is necessary.

Therefore wait for a maximum of 1ms after the "I/O D/A select" command is input.

If wait time is problematic, set the D/A setting code to 80hex and change it to the specified code setting.

www.rohm.com

8/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

BH2226FV,BH2226F

●Ordering part number

B H 2 2 2 6 F V - E 2

Part No. Part No.

SOP16

16

4.4± 0.2

6.2± 0.3

1

10± 0.2

(MAX 10.35 include BURR)

9

0.3MIN

8

0.15± 0.1

Package

FV: SSOP-B16

F: SOP16

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Packaging and forming specification

E2: Embossed tape and reel

(SSOP-B16/SOP16)

Technical Note

1.5± 0.1

0.11

SSOP-B16

6.4±0.3

1.15±0.1

1.27

0.10

0.4± 0.1

5.0±0.2

16

4.4±0.2

1

0.65

9

8

0.22±0.1

0.1

(Unit : mm)

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

0.3Min.

0.15±0.1

0.1

(Unit : mm)

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Direction of feed

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

www.rohm.com

9/9

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.B

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes ef forts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...