Page 1

Hi-performance Regulator IC Series for PCs

FET Integrated

Switching Regulator for DDR-SDRAM Cores

BD95514MUV

●Description

BD95514MUV is a switching regulator capable of supplying high current output (up to 4A) at low output voltages (0.7V~5.0V)

over a broad range of input voltages (4.5V~28V). The regulator features an internal N-MOSFET power transistor for high

efficiency and low space consumption, while incorporating ROHM’s proprietary H

the industry’s fastest transient response time against load changes. SLLM (Simple Light Load Mode) technology is also

integrated to improve efficiency when powering lighter loads, as well as soft start, variable frequency, short-circuit protection

with timer latch, over-voltage protection, and REF tracking functions. This regulator is suited for PC applications.

●Features

1) I Internal low ON-resistance power N-MOSFET (typ:120m)

2) I Internal 5V linear voltage regulator (100mA)

3) Integrated H

4) Selectable Simple Light Load Mode (SLLM), Quiet Light Load Mode (QLLM) and forced continuous mode

5) Built-in thermal shutdown, low input, current overload, output over- and under-voltage protection circuitry

6) Soft start function to minimize rush current during startup

7) Adjustable switching frequency (f = 200 kHz ~ 1000 kHz:It changes depending on the setup condition.)

8) Built-in output discharge function

9) VQFN032V5050 power package

10) Tracking function

11) Internal bootstrap diode

●Applications

Mobile PCs, desktop PCs, LCD-TV, digital household electronics

3

RegTM DC/DC converter controller

3

Reg

TM

control mode technology, yielding

No.09030EBT16

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

1/15

2009.04 - Rev.B

Page 2

BD95514MUV

Technical Note

●Absolute Maximum Ratings (Ta=25°C)

Parameter Symbol Value Unit

Input Voltage 1 VCC 7 *1 V

Input Voltage 2 VDD 7

*1

V

Input Voltage 3 AVIN 30 *1

Input Voltage 4 VIN 30 *1 V

External VCC Voltage EXTVCC 7 *1 V

BOOT Voltage BOOT 35 V

BOOT-SW Voltage BOOT-SW 7 *1 V

Output Feedback Voltage FB VCC V

SS/FS/MODE Voltage SS/FS/MODE VCC V

VREG Voltage VREG VCC V

EN/CTL Input Voltage EN/CTL 7 *1 V

PGOOD Voltage PGOOD 7 *1 V

Output Current (Average) Isw 4 *1 A

Power Dissipation 1 Pd1 0.38*2 W

Power Dissipation 2 Pd2 0.88

Power Dissipation 3 Pd3 2.06

Power Dissipation 4 Pd4 4.56

*3*6

W

*4*6

W

*5*6

W

Operating Temperature Range Topr -10~+100 °C

Storage Temperature Range Tstg -55~+150 °C

Junction Temperature Tjmax +150 °C

*1 Do not exceed Pd.

*2 Ta≧25°C (IC only), power dissipated at 3.0mW / °C.

*3 Ta≧25°C (single-layer board, 20.2 mm

*4 Ta≧25°C (4-layer board, 10.29 mm

*5 Ta≧25°C (4-layer board, all layers with 5505 mm

*6 Values observed with chip backside soldered. When unsoldered, power dissipation is lower.

2

copper heat dissipation pad), power dissipated at 7.0mW / °C.

2

copper heat dissipation pad on top layer, 5505 mm2 pad on 2nd and 3rd layer), power dissipated at 16.5mW / °C.

2

copper heat dissipation pads), power dissipated at 36.5mW / °C.

●Operating Conditions (Ta=25°C)

Parameter Symbol Min Max Unit

Input Voltage 1 VCC 4.5 5.5 V

Input Voltage 2 VDD 4.5 5.5 V

Input Voltage 3 AVIN 4.5 28 V

Input Voltage 4 VIN 4.5 28 V

External VCC Voltage EXTVCC 4.5 5.5 V

BOOT Voltage BOOT 4.5 33 V

SW Voltage SW -0.7 28 V

BOOT-SW Voltage BOOT-SW 4.5 5.5 V

MODE Input Voltage MODE 0 5.5 V

EN/CTL Input Voltage EN/CTL 0 5.5 V

PGOOD Voltage PGOOD 0 5.5 V

Minimum On Time tonmin - 100 nsec

*This product is not designed for use in a radioactive environment.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

2/15

2009.04 - Rev.B

Page 3

BD95514MUV

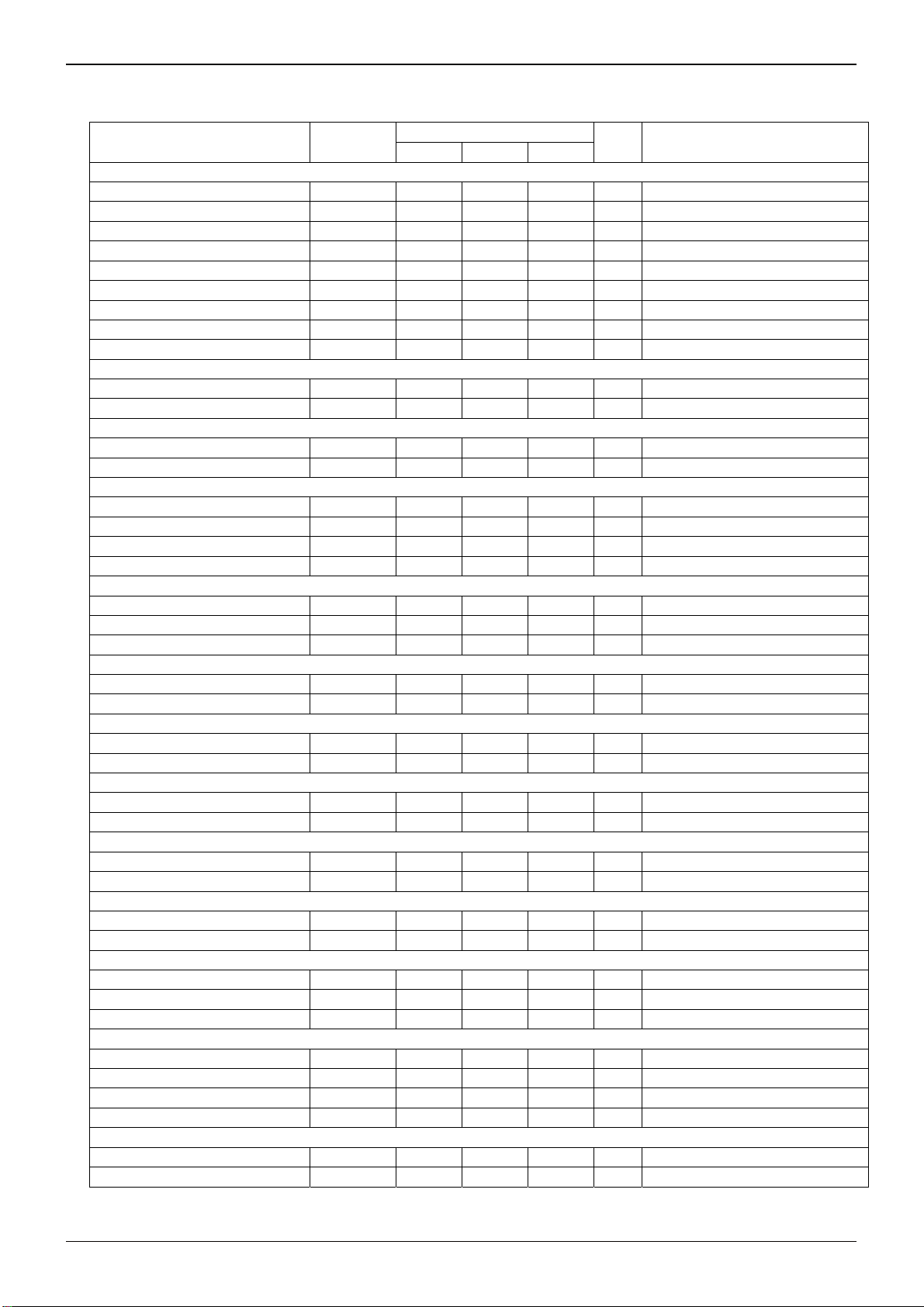

●ELECTRICAL CHARACTERISTICS

(unless otherwise noted, Ta=25℃, AVIN=12V, VCC=VDD=VREG, EN/CTL=5V, MODE=0V, RFS=180kΩ)

Parameter Symbol

[Whole Device block]

AVIN bias current 1 IIN1 - 1300 2000 A

AVIN bias current 2 IIN2 - 200 300 A EXTVCC=5V

AVN standby current IINstb - 0 10 A CTL=EN=0V

EN Low voltage ENlow GND - 0.8 V

EN High voltage ENhigh 2.3 - 5.5 V

EN bias current IEN - 12 20 A

CTL Low voltage CTLlow GND - 0.8 V

CTL High voltage CTLhigh 2.3 - 5.5 V

CTL bias current ICTL - 1 6 A

[5V Linear regulator block ]

VREG output voltage VREG 4.90 5.00 5.10 V AVIN=6.0 to 25VIREG=0 to 100mA

Maximum current IREG 200 - - mA

[5V switch block ]

EXTVCC input threshold voltage EVCC_UVLO 4.2 4.4 4.6 V EXTVCC:Sweep up

Switch resistance REVCC - 1.0 2.0

[Under Voltage Locked Out block ]

AVIN threshold voltage AVIN_ UVLO 4.1 4.3 4.5 V VCC:Sweep up

AVIN hysteresis voltage dAVIN_ UVLO 100 160 220 mV VCC:Sweep down

VREG threshold voltage VREG_ UVLO 4.1 4.3 4.5 V VREG:Sweep up

VREG hysteresis voltage dVREG_ UVLO 100 160 220 mV VREG:Sweep down

[H3RegTM block]

ON Time ton 400 500 600 nsec

MAX ON Time tonmax 5.0 11.0 22.0 sec

MIN OFF Time toffmin - 450 550 nsec

[FET Driver block]

High side ON resistance Ron_high - 120 200 m

Low side ON resistance Ron_low - 120 200 m

[SCP block]

SCP startup voltage VSCP 0.420 0.490 0.560 V VFB:30%down

Delay time tSCP 0.5 1 2 ms

[OVP block]

OVP setting voltage VOVP 0.800 0.840 0.880 V VFB:20%up

Delay time tOVP 0.5 1 2 ms

[Soft start block]

Charge current Iss 1.4 2.2 3.0 A

Standby voltage Vss_stb - - 100 mV

[Current Limit block]

High side FET output current limit IHOCP 4.5 6.0 7.5 A High peak detect

Low side FET output current limit ILOCP 3.0 4.0 5.0 A Low peak detect

[Output Voltage Sense block]

Feedback pin voltage 1 VFB1 0.693 0.700 0.707 V

Feedback pin voltage 2 VFB2 0.690 0.700 0.710 V Ta=-10℃ to 100℃,Iout=0A to 4A

Feedback pin bias current IFB -100 0 100 nA

[Mode block]

SLLM VthSLLM VCC-0.5 - VCC V SLLM(Maximum LG offtime:∞)

Forced continuous mode VthCONT GND - 0.5 V Continuous mode

QLLM VthQLLM 2.5 3.0 3.5 V QLLM(Maximum LG offtime:40usec)

Open voltage VMODE 1.5 - 3.0 V

[Power Good block]

VFB Power Good Low voltage VFB PL 0.605 0.630 0.655 V VFB:10%down

VFB Power Good High voltage VFB PH 0.745 0.770 0.795 V VFB:10%up

Standard Value

MIN TYP MAX

Unit Condition

Technical Note

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

3/15

2009.04 - Rev.B

Page 4

BD95514MUV

T

T

T

T

Technical Note

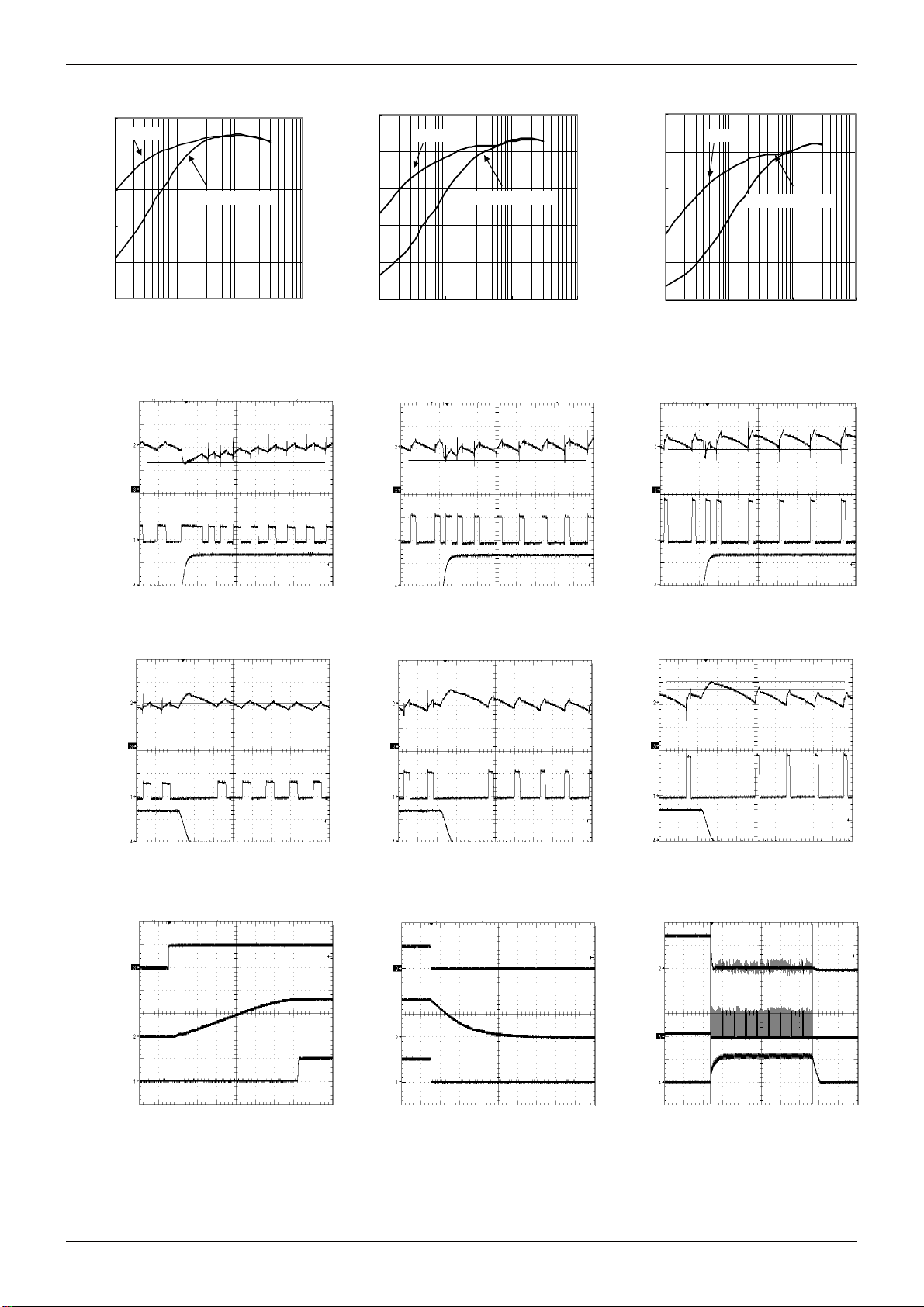

●Reference Data

100

[%]

SLLM

80

60

40

Continuous Mode

20

0

0.01 0.1 1 10

Fig.1 Io-Efficiency

IN=7V,VOUT=2.5V)

(V

Io [A]

(50mV/div)

VOU

2sec/div

SW

(10V/div)

IOUT

(2A/div)

Fig.4 Transient Response

IN=7V, VOUT=2.5V)

(V

(50mV/div)

VOU

2sec/div

SW

(10V/div)

IOUT

(2A/div)

Fig.7 Transient Response

IN=7V, VOUT=2.5V)

(V

200sec/div 2msec/div

EN

VOUT

2[V/div]

PGOOD PGOOD

Fig.10 PGOOD Rising

Waveform

100

SLLM SLLM

80

60

[%]

40

20

0

0. 01 0. 1 1 10

Continuous Mode

Io [A]

Fig.2 Io-Efficiency

(VIN=12V,VOUT=2.5V)

VOU

(50mV/div)

SW

(10V/div)

IOUT

(2A/div)

Fig.5 Transient Response

(VIN=12V, VOUT=2.5V)

VOUT

(50mV/div)

SW

(10V/div)

IOUT

(2A/div)

Fig.8 Transient Response

(V

IN=12V, VOUT=2.5V)

EN

OUT

V

2[V/div]

Fig.11 PGOOD Falling

Waveform

100

80

60

[%]

40

20

0

0.01 0.1 1 10

Continuous Mode

Io [A]

Fig.3 Io-Efficiency

(VIN=19V,VOUT=2.5V)

2sec/div 2sec/div

VOUT

(50mV/div)

SW

(10V/div)

IOUT

(2A/div)

Fig.6 Transient Response

IN=19V, VOUT=2.5V)

(V

2sec/div 2sec/div

VOU

(50mV/div)

SW

(10V/div)

IOUT

(2A/div)

Fig.9 Transient Response

(VIN=19V, VOUT=2.5V)

V

OUT

2[V/div]

SW

5[A/div]

I

L

200sec/div

Fig.12 SCP Timer Latch

Waveform

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

4/15

2009.04 - Rev.B

Page 5

BD95514MUV

k

A

A

●Reference Data

EN

REG

V

2[V/div]

OUT

V

2[V/div]

SW

Fig.13 EN wake up

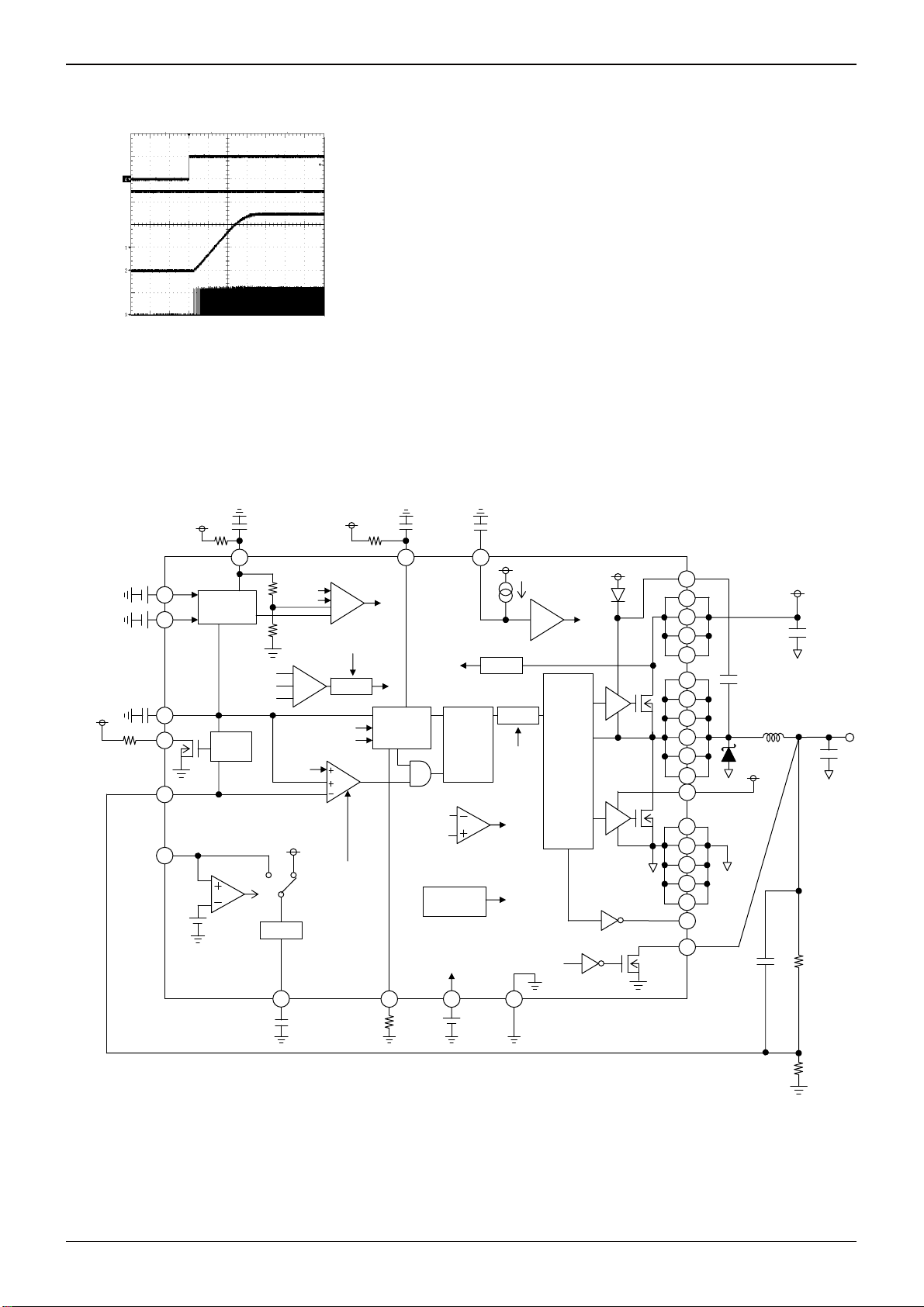

●Block Diagram

REG

V

EN

CTL

REF(0.7V)

PGOOD

FB

EXTV

10

8

17

6

18

CC

14

VREG

Reference

Block

400sec/div

13

VREF×0.85

V

SS×0.85

Power

Good

VCC

V

OUT

5V Reg

15

REG

AVIN

SS

VIN

REG

MODE

UVLO

ILIM

SCP

TSD

V

IN

OVP

Delay

EN

UVLOV

SCP

H3Reg

Controller

Bloc

11

VIN SS

7

ILIM

TM

REF×1.2

FB

Thermal

Protection

MODE

FS V

16

Soft Start

OCP

RSQ

912

MODE

OVP

TSD

MODE

GND MODE

Driver

Circuit

EN/UVLO

SS

Technical Note

DD

V

HG

LG

5

1

2

3

4

26

27

28

29

30

31

21

22

23

24

25

32

20

19

BOOT

V

IN

SW

DD

V

PGND

CE

OUT

V

VREG

VIN(4.5~28V)

OUT

V

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

5/15

2009.04 - Rev.B

Page 6

BD95514MUV

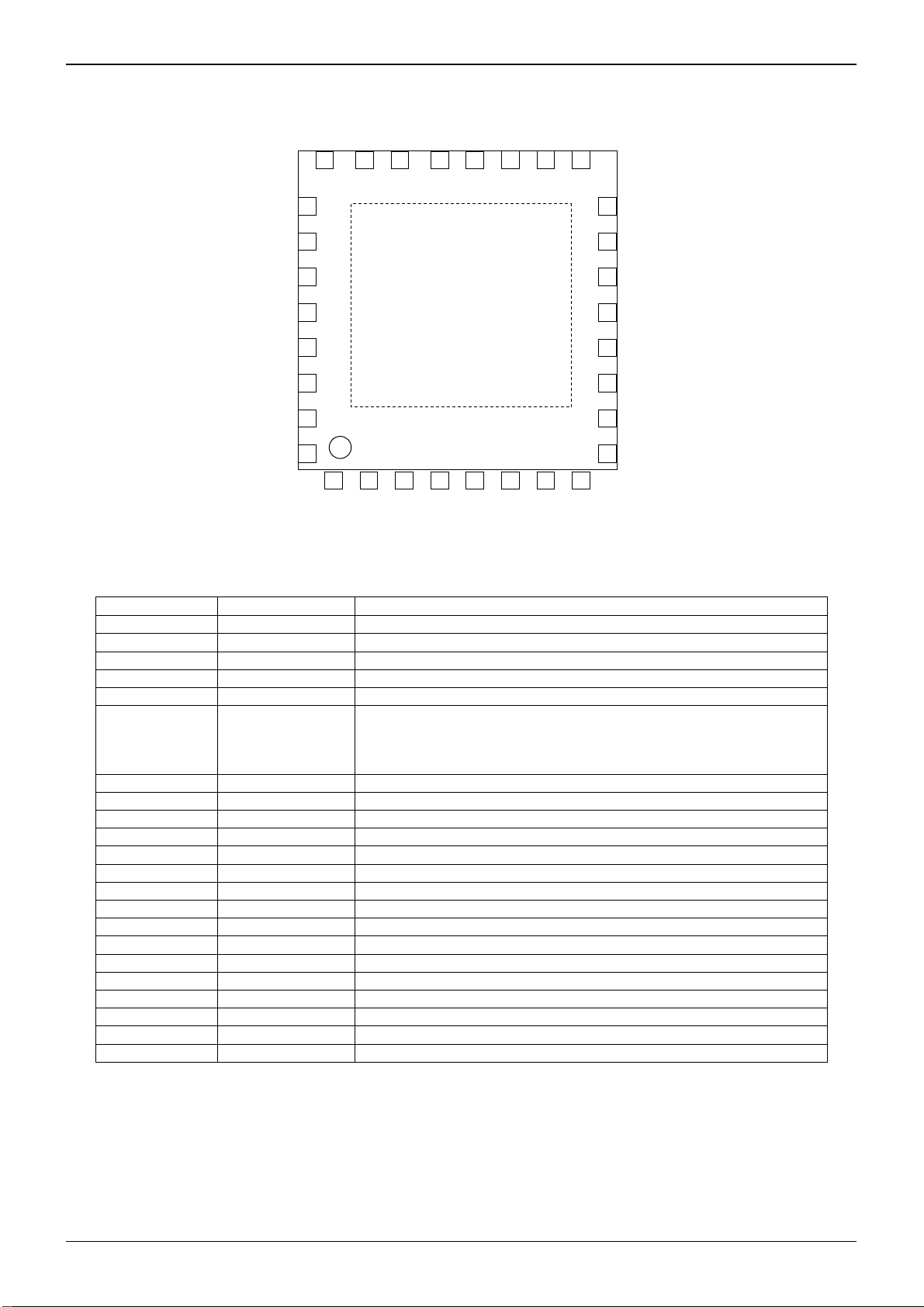

●Pin Configuration

PGND

SW

SW

25

26

27

22 21 20

23 24

22 21 20

23 24

19 18 17

19 18 17

16

15

14

SS

REG

V

EXTVcc

Technical Note

●Pin Function Table

PIN No. PIN Name PIN Function

1-4 VIN Battery voltage input (4.5 ~ 28 V)

5 BOOT HG driver power supply

6 PGOOD Power good output (high when output ±10% of regulation)

7 AVIN Battery voltage sense

8 CTL Linear regulator on/off (high = 5.0V, low = off)

9 MODE

10 EN Enable output (high when VOUT ON)

11 FS Switching frequency adjustment(RFS = 30 k ~ 300 k)

12 GND Sense ground

13 VCC Power supply input

14 EXTVCC External power supply input

15 VREG IC reference voltage (5.0V / 100mA)

16 SS Soft start condenser input

17 REF Output reference voltage (0.7 V)

18 FB Feedback input (0.7 V)

19 VOUT Voltage discharge output

20 CE Reversing HG output

21 VDD Power supply input (5 V)

22-25 PGND Power ground

26-31 SW Output to inductor

32 PGND Power ground

Underside FIN Substrate connection

28

SW

SW

29

SW

30

SW

31

PGND

32

1 2 3 4 5 6

V

IN VIN VIN VIN BOOT PGOOD

*Connect the underside (FIN) to the ground terminal

*Connect the underside (FIN) to the ground terminal

AV

Control mode selection

GND:Continuous Mode

3.0V:QLLM

VCC:SLLM

V

CC

13

GND

12

FS

11

EN

10

MODE

9

7

8

CTL

IN

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

6/15

2009.04 - Rev.B

Page 7

BD95514MUV

Technical Note

●Pin Descriptions

・VCC

This pin supplies power to the IC’s internal circuitry, excluding the FET driver. The input supply voltage range is 4.5 to 5.5 V.

This pin should be bypassed with either a power capacitor or RC filter.

・EN

Enables or disables the switching regulator. When the voltage on this pin reaches 2.3V or higher, the internal switching

regulator is turned on. At voltages less than 0.8V, the regulator is turned off.

DD

・V

This pin supplies power to the low side of the FET driver, as well as to the bootstrap diode. As the diode draws its peak

current when switching on or off, this pin should be bypassed with a capacitance of approximately 1µF.

REG

・V

Output pin from the 5V linear regulator. This pin also supplies power to the internal driver and control circuitry.

REG standby function is controlled by the CTL pin. The output supplies 5V at 100mA and should be bypassed to ground

V

using a 10 µF capacitor with a rating of X5R or X7R.

・EXTVCC

External power supply input for the linear regulator. When the voltage on the EXTVCC pin exceeds 4.4V, the regulator

uses it in conjunction with other power sources to supply V

REG. Connect the EXTVCC pin to GND when not in use.

・REF

Reference voltage output pin. The reference voltage is set internally by the IC to 0.7V, and the IC works to keep V

approximately equal to V

FB. Variations in voltage levels on this pin affect the output voltage, so the pin should be

bypassed with a 100pF ~ 0.1µF ceramic capacitor.

・SS

Soft start pin. When EN is set high, the capacitor between the internal current source(typ:2.2A) and SS-GND controls

the startup time of the IC. When the voltage on the SS pin is lower than the REF output voltage (0.7V), the output voltage

is held at the same voltage as the SS pin.

IN

・AV

The BD95514MUV controls the duty cycle and output voltage based upon the input voltage at this pin, so voltage

variations or oscillations on this line can cause operation to become unstable. This pin also acts as the voltage input for

the switching block, so insufficient coupling impedance can also cause operation to become unstable. Therefore, this line

should be bypassed with either a power capacitor or RC filter.

・FS

Frequency-adjusting resistance input pin. Attaching a resistance of 30k~300k adjusts the switching frequency from 200

kHz~1MHz (p.11).

・BOOT

This pin serves as the power source for the high side of the FET driver. A bootstrap diode is integrated within the IC.

The maximum voltage on this pin should not exceed +30V vs. GND or +7V vs. SW. When operating the switching

regulator, the operation of the bootstrap circuitry causes the BOOT voltage to swing from (V

IN + VDD) ~ VDD.

・PGOOD

Power good indicator. This open-drain output should be connected via a 100k pull-up resistor.

・MODE

Mode selection pin. When low, the IC functions in forced-continuous mode; at voltages from 0V ~ 3V, QLLM mode;

when high, SLLM mode.

・CTL

Linear regulator control pin. When voltage is 2.3V or higher, a logic HIGH is recognized and the internal regulator

REG = 5 V) is switched on. At voltages of 0.8V or lower, a logic LOW is recognized and the regulator is switched off.

(V

However, even if EN is logic HIGH, the switching regulator will not operate if CTL is logic LOW.

・FB

Output voltage feedback input. V

FB is held at 0.7V by the IC.

・SW

Output from the switching regulator to the inductor. This output swings from V

IN ~ GND. The trace from the output to

the inductor should be as short and wide as possible.

OUT

・V

Voltage output discharge pin. When EN is off, this output is pulled low.

IN

・V

Power supply input. The IC can accept any input from 4.5V to 28V. This pin should be bypassed directly to ground by a

power capacitor.

・PGND

Power ground terminal.

REF

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

7/15

2009.04 - Rev.B

Page 8

BD95514MUV

r

A

r

f

A

Technical Note

●Operation

The BD95514MUV is a switching regulator incorporating ROHM’s proprietary H3RegTM CONTROLLA control system.

When V

OUT drops suddenly due to changes in load, the system quickly restores the output voltage by extending the ton time

interval. This improves the regulator’s transient response. When light-load mode is activated, the IC employs the Simple

Light Load Mode (SLLM) controller, further improving system efficiency.

3

RegTM Control

H

(Normal Operation)

VFB

VREF

HG

LG

When VFB falls below the reference voltage (0.7V), the

3

H

RegTM CONTROLLA is activated;

t

ON

VREF

IN

V

×

1

f

[sec]・・・(1)

High gate output is determined by the above formula.

(Rapid Changes in Load)

VFB

VREF

Io

ON+α

t

When V

the voltage remains below V

preprogrammed t

system quickly restores V

thereby improving transient response.

drops due to a sudden change in load and

OUT

time interval has elapsed, the

ON

by extending the tON time,

OUT

after the

REF

HG

LG

Light Load Control

(SLLM Mode)

VREF

HG

LG

VFB

SLLM mode is enabled by setting the MODE pin to logic

high. When the low gate is off and the current through

the inductor is 0 (current flowing from V

to SW), the

OUT

SLLM function is activated, disabling high gate output.

falls below V

If V

FB

again, the high gate is switched

REF

back on, lowering the switching frequency of the regulato

and yielding higher efficiency when powering light loads.

0

(QLLM Mode)

VREF

VFB

HG

LG

0

QLLM mode is enabled by setting the MODE pin to HiZ o

middle voltage. When the lower gate is off and the

current through the inductor is 0 (current flowing from

VOUT to SW), QLLM mode is activated, disabling high

gate output.

If VFB falls below VREF within a programmed time

interval (typ. 40µs), the high gate is switched on, but i

VFB does not fall below VREF, the lower gate is forced

on, dropping VFB and switching the high gate back on.

The minimum switching frequency is set to 25 kHz (T=40

µS), which keeps the regulator’s frequency from entering

the audible spectrum but yields less efficient results than

SLLM mode.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

8/15

2009.04 - Rev.B

Page 9

BD95514MUV

f

T

●Timing Chart

・Soft Start Function

EN

tSS

SS

OU

V

IIN

・Timer Latch-type Short Circuit Protection

VREF×0.70

VOUT

1ms

SCP

EN/UVLO

・Output Over-Voltage Protection

REF×1.2

VOUT

V

HG

LG

Switching

Technical Note

The soft start function is enabled when the EN pin is set

high. Current control circuitry takes effect at startup,

yielding a moderate “ramping start” in output voltage.

Soft start timing and incoming current are given by

equation (2) and (3) below:

Soft start period:

REF×Css

V

=

t

SS

2.2A(typ)

Rush current:

OUT

IN(ON)=

I

Co×V

tss

(Css: soft start capacitor;

Co: All capacitors connected with VOUT)

When output voltage falls to V

output short circuit protection engages, turning the IC of

after a set period of time to prevent internal damage.

When EN is switched back on or when UVLO is cleared,

output continues. The time period before shutting off is

set internally at 1 ms.

When output reaches or exceeds V

over-voltage protection is engaged, turning the low-side

FET completely on to reduce the output (low gate on, high

gate off). When the output falls, it returns to standard

mode.

[sec]

・・・(2)

・・・(3)

[A]

REF x 0.70 or less, the

x 1.2, the output

REF

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

9/15

2009.04 - Rev.B

Page 10

BD95514MUV

A

r

[A]

[H]

t

(

)

[A]

Technical Note

●External Component Selection

1. Inductor (L) Selection

VIN

ΔIL

IL

OUT

V

L

Co

The inductor’s value directly influences the output ripple current.

s formula (4) indicates below, the greater the inductance o

switching frequency, the lower the ripple current:

(VIN-VOUT)×VOUT

ΔIL=

The proper output ripple current setting is about 30% of maximum output

current.

L×V

IN×f

・・・(4)

ΔIL=0.3×IOUTmax. [A]・・・(5)

(V

IN-VOUT)×VOUT

L=

(ΔI

L: output ripple current, f: switching frequency)

ΔI

L×VIN×f

・・・(6)

Output ripple current

※ Passing a current larger than the inductor’s rated current will cause magnetic saturation in the inductor and decrease

system efficiency. In selecting the inductor, be sure to allow enough margin to assure that peak current does not exceed

the inductor’s rated current value.

※ To minimize possible inductor damage and maximize efficiency, choose an inductor with a low DCR and ACR resistance.

V

OUT

)

O

When determining the proper output capacitor, be sure to factor in the equivalent

series resistance (ESR) and equivalent series inductance (ESL) required to se

the output ripple voltage at 20 mV or more.

When selecting the limit of the inductor, be sure to allow enough margin for the

output voltage. Output ripple voltage is determined by formula (7) below:

ΔV

OUT=ΔIL×ESR+ESL×ΔIL / TON・・・(7)

L: Ouput ripple current, ESR: equivalent series resistance,

(ΔI

ESL: equivalent series inductance)

2. Output Capacitor Selection (C

VIN

L

Output Capacitor

ESR

ESL

Co

Give special consideration to the conditions of formula (7) for output capacitance. Also, keep in mind that the output rise

time must be established within the soft start timeframe.

Co≦

tss×(I

V

limit-IOUT)

OUT

・・・(8)

tss: Soft start timeframe (see p. 10, equation (2))

I

: Maximum output current

limit

Choosing a capacitance that is too large can cause startup malfunctions, or in some cases, may engage the short circuit

protection.

3. Input Capacitor Selection (C

VIN

CIN

L

Co

)

IN

In order to prevent extreme over-current conditions, the input capacitor must

have a low enough ESR to fully support a large ripple in the output. The

formula for RMS ripple current (I

V

OUT

IRMS=IOUT×

√

IN

V

VIN-VOUT

VIN

) is given by equation (9) below:

RMS

・・・(9)

IOUT

When VIN=2×VOUT, IRMS=

2

Input Capacitor

A low-ESR capacitor is recommended to reduce ESR loss and maximize efficiency.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

10/15

2009.04 - Rev.B

Page 11

BD95514MUV

A

Technical Note

4. Frequency Adjustment

500

450

400

350

300

250

200

Frequency [kHz]

150

100

50

0

50 100 150 200 250 300

From top:VIN=

RFS[k]

5V

7V

12V

19V

25V

The resistance connected to the FS terminal adjusts the

on-time (t

the left. When t

) during normal operation as illustrated to

ON

, input voltage and VREF voltage are

ON

known, the switching frequency can be determined by

the following formula:

F=

・・・(10)

V

REF

IN×tON

V

However, real-life considerations (such as external

MOSFET gate capacitance and switching time) must be

factored in as they affect the overall switching rise and

fall time. This leads to an increase in t

ON

total frequency slightly.

dditionally, when output current lingers around 0A in

continuous mode, this “dead time” also has an effect

upon t

, further lowering the switching frequency.

ON

Confirm the switching frequency by measuring the

current through the coil (at the point where current does

not flow backwards) during normal operation.

The BD95514MUV operates by feeding the output voltage back through a resistive voltage divider. The output voltage is

set by the following equation (see schematic below):

Output Voltage = ×

R1+R2

R2

VREF (0.7V) + ×ΔIL×ESR・・・(11)

1

2

The switching frequency is also amplified by the same resistive voltage divider network:

sw = ×(frequency set by RFS) [Hz]・・・(12)

f

R1+R2

R2

REF(0.7V)

CONTROLLA

FB

VIN

H3RegTM

RQ

S

SLLM

SLLM

TM

Driver

Circuit

, lowering the

VIN

Output Voltage

ESR

R1

R2

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

11/1 5

2009.04 - Rev.B

Page 12

BD95514MUV

A

W

Technical Note

●Evaluation Board Circuit (Frequency=300kHz Continuous Mode/QLLM/SLLM Example Circuit)

SW

L1

VOUT

GND_VIN

VIN

VIN

D1

C14

PGOOD

VDD

R9

R4 R22

VDD

C7

SW3

VDD

SW1

C10

C11

C12

C8

C9

D

R17 SW2

VIN

VIN

VIN

VIN

BOOT

PGOOD

VIN

CTL REF

CTL

MODE

EN

SWSWSWSWSWS

PGND

MODE

EN

FS

GND

R6

VCC

GND

VCC

PGND

PGND

PGND

PGND

VDD

CE

VOUT

FB

EXTVCC

VREG

SS

C5C4R2C2C1

R1

VREG

C6 C19

R5

SS

R18

R7 C13

R8

VDD

GND PGND

VCC EXTVCC

●Evaluation Board Parts List

Designation Rating PART No. Company Designation Rating PART No. Company

R1 10 MCR03 ROHM C03 1F ceramic capacitor -

R2 0 MCR03 ROHM C04 1F ceramic capacitor -

R3 - - - C05 3300pF ceramic capacitor R4 10 MCR03 ROHM C06 0.1F ceramic capacitor R5 10K MCR03 ROHM C07 0.1F ceramic capacitor R6 270K MCR03 ROHM C08 - - R7 10k MCR03 ROHM C09 - - R8 3.07k MCR03 ROHM C10 - - R9 100K MCR03 ROHM C11 22F ceramic capacitor -

R10 - - - C12 0.1F ceramic capacitor R11 - - - C13 1000pF ceramic capacitor R12 - - - C14 220F 4TPE220MF SANYO

R13 - - - C15 - - R14 - - - C16 - - R15 0 MCR03 ROHM C17 - - R16 0 MCR03 ROHM C18 - - R17 0 MCR03 ROHM C19 470pF ceramic capacitor R18 0 MCR03 ROHM D1 - RSX501L-20 ROHM

R22 510k MCR03 ROHM D - TDZ5.1 ROHM

C01 1F ceramic capacitor - L1 3.2H CDEP105-3R2MC-50 Sumida

C02 - - - U1 - BD95514MUV ROHM

VOUT

GND_VOUT

GND_VDD

REF

VDD

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

12/15

2009.04 - Rev.B

Page 13

BD95514MUV

●Operation Notes

(1) Absolute maximum ratings

Exceeding the absolute maximum ratings (such as supply voltage, temperature range, etc.) may result in damage to the

device. In such cases, it may be impossible to identify problems such as open circuits or short circuits. If any

operational values are expected to exceed the maximum ratings for the device, consider adding protective circuitry

(such as fuses) to eliminate the risk of damaging the IC.

(2) Power supply polarity

Connecting the power supply in reverse polarity can cause damage to the IC. Take precautions when connecting the

power supply lines. An external power diode can be added.

(3) Power supply lines

The PCB layout pattern should be designed to provide the IC with low-impedance GND and supply lines. To minimize

noise on the supply and GND lines, ground and power supply lines of analog and digital blocks should be separated.

For all power lines supplying ICs, connect a bypass capacitor between the power supply and the GND terminal. If

using electrolytic capacitors, keep in mind that their capacitance is reduced at lower temperatures.

(4) GND voltage

The potential of the GND pin must be the minimum potential in the system in all operating conditions.

(5) Thermal design

Use thermal design techniques that allow for a sufficient margin for power dissipation in actual operating conditions.

(6) Inter-pin shorts and mounting errors

Use caution when positioning he IC for mounting on PCBs. The IC may be damaged if there are any connection errors

or if pins are shorted together.

(7) Operation in strong electromagnetic fields

Exercise caution when using the IC in the presence of strong electromagnetic fields as doing so may cause the IC to

malfunction.

(8) ASO

When using the IC, set the output transistor so that it does not exceed either absolute maximum ratings or ASO.

(9) Thermal shutdown circuit

The IC incorporates a built-in thermal shutdown circuit (TSD circuit), which is designed to shut down the IC only to

prevent thermal overloading. It is not designed to protect the IC or guarantee its operation. Do not continue to use

the IC if this circuit is activated, or in environments in which activation of this circuitry can be assumed.

(10) Testing on application boards

When testing the IC with application boards, connecting capacitors directly to low-impedance terminals can subject the

IC to stress. Always discharge capacitors completely after each process or step. The IC’s power supply should be

turned off completely before connecting it to or removing it from a jig or fixture during the evaluation process. To

prevent damage from static discharge, ground the IC during assembly and use similar precautions during transport and

storage.

TSD ON Temp. [°C] (typ.) Hysteresis Temp. [°C] (typ.)

BD95514MUV 175 15

Technical Note

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

13/15

2009.04 - Rev.B

Page 14

BD95514MUV

(11) Regarding IC input pins

This monolithic IC contains P+ isolation and P substrate layers between adjacent elements in order to keep them

isolated. PN junctions are formed at the intersection of these P layers with the N layers of other elements, creating

parasitic diodes and/or transistors. For example (refer to the figure below):

・When GND > Pin A and GND > Pin B, the PN junction operates as a parasitic diode

・When GND > Pin B, the PN junction operates as a parasitic transistor

Parasitic diodes occur inevitably in the structure of the IC, and the operation of these parasitic diodes can result in

mutual interference among circuits, operational faults, or physical damage. Accordingly, conditions that cause these

diodes to operate, such as applying a voltage lower than the GND voltage to an input pin (and thus to the P substrate)

should be avoided.

Resistance

Pin A

N

P+ P

P

Parasitic Element

GND

(12) (12) Ground wiring traces

When using both small-signal and large-current GND traces, the two ground traces should be routed separately but

connected to a single ground potential within the application in order to avoid variations in the small-signal ground

caused by large currents. Also ensure that the GND traces of external components do not cause variations on GND

voltage.

●Power Dissipation

5.5

5.0

④4.56W

4.5

4.0

3.5

3.0

2.5

③2.06W

Power Dissipation Pd [W]

2.0

1.5

②0.88W

1.0

①0.38W

0.5

0

0 20 40 60 80 100 120

Ambient Temperature Ta [°C]

Pin A

+

N N

P Substrate

VQFN032V5050

Pin B

N

P+

Parasitic Element

Parasitic Elements

Example of IC Structure

140

Technical Note

Transistor (NPN)

B

C

B

E

N

P

P+

N

P 基板

GND

GND

① IC Only

θ

= 328.9 °C/W

j-a

② IC mounted on 1-layer board (with 20.2 mm

= 142.0 °C/W

θ

j-a

③ IC mounted on 4-layer board (with 20.2 mm

5502 mm

2

pad on layers 2,3)

θ

= 60.7 °C/W

j-a

④ IC mounted on 4-layer board (with 5505mm

端子 B

B C

E

GND

Other Adjacent Elements

Parasitic Elements

2

copper thermal pad)

2

pad on top layer,

2

pad on all layers)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

14/15

2009.04 - Rev.B

Page 15

BD95514MUV

Technical Note

●Ordering part number

B D 9 5 5 1 4 M U V - E 2

Part No. Part No.

VQFN032V5050

5.0± 0.1

1.0MAX

0.08 S

0.75

C0.2

0.4± 0.1

32

25

5.0± 0.1

3.4± 0.1

24

0.5

17

1PIN MARK

+0.03

0.02

81

9

16

+0.05

0.25

-

0.04

0.02

-

3.4± 0.1

S

(0.22)

(Unit : mm)

Package

MUV : VQFN032V5050

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Packaging and forming specification

E2: Embossed tape and reel

Direction of feed

Order quantity needs to be multiple of the minimum quantity.

∗

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

15/15

2009.04 - Rev.B

Page 16

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...