LED Driver Series for LCD Backlight

Simple Structure Constant Current

Backlight Driver for LCD panels

(Non-step type)

BD9206EFV

No.09040EAT03

●Description

BD9206EFV is an IC with a built-in 6ch high-accuracy (absolute accuracy:±4%) constant-current driver.

Capable of lighting a maximum of 36 white LEDs with 6 rows×6 lines.

Due to the wide input voltage range (8V~30V), it can be widely used from a backlights of Note PC and PDA etc. to LED light

sources of Scanner and PPC etc.

Moreover, it restrain the generation of heat at the time of large current drive because of adoption of high-heat-radiation

package(HTSSOP-B20).

●Features

1) A wide input voltage range(8V~30V)

2) Capable of driving a maximum of 36 white LEDs of 6 series×6 parallel

3) Value of constant current is set by the VSET terminal

4) Due to the STBY terminal, the consumption current at the time of standby is low

5) PWM dimming is possible due to the clock input to the EN terminal

6) Built-in 5V regulator

7) High-heat-radiation package of HTSSOP-B20 6.4×6.5×0.85mm

●Applications

For use in LED light source of PPC and Scanner etc., LED lighting fixture, and LCD backlight lights of monitor

and note PC etc.

●Absolute maximum ratings(Ta=25℃)

Item Symbol Rating Unit

Power Supply Voltage Vcc 36 V

V

LED output voltage

Power Dissipation Pd 3.2

Operational Temperature Range

Storage Temperature Range Tstg -55~+150 ℃

LED Maximum Current

*1 Reduce with 25.6mW at 1℃ if Ta= 25℃ or above at the time of mounting a base-plate of glass

epoxy in 4 layer of 70mm×70mm×1.6mm.

*2 It is value per LED driver 1ch.

Please set inside the range which does not exceed the allowable loss value of the package.

LED 28 V

Topr -40~+85 ℃

I

LED 30

*1

W

*2

mA

www.rohm.com

1/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

●Recommended Operational condition(Ta=25℃)

Item

Power Supply Voltage

EN terminal clock input possible range VENCLK 100~10000 Hz

VSET input possible range VSET 0.6~3 V

Applied voltage range for LED terminal VLED 0.6~28 V

●Electrical Characteristics(Unless specified, Ta=25℃,Vcc=24V)

Item Symbol

【Whole】

Circuit electric current

when OFF

Circuit electric current

when stand by

Circuit electric current

when operating

【LED Driver 1~6】

IOFF - 17 28 μA STBY=L, EN=L, TEST=L

ST - 1.8 3.6 mA STBY=H, EN=L, TEST=L

I

ICC - 2.5 5.0 mA STBY=H, EN=H, TEST=L

Symbol Rating Unit

Vcc 8~30 V

Ratings

Min.

Typ.

Technical Note

Unit Conditions

Max.

Output current ILED 19.2 20.0 20.8 mA VSET=2.0V, VLED=1V

Leak electric current

when OFF

Influx electric current to

VSET terminal

【VREG】

Output voltage VREG 4.7 5.0 5.3 V Io=1mA

Output current IOMAX 10 30 - mA Vo=VREG×0.9

【UVLO】

Detection voltage VUVREG 2.4 2.9 3.4 V VREG fall down

Hysteresis voltage VUHYVREG 0.05 0.1 0.2 V VREG rise up

【STBY, EN, TEST】

Input Low level VIL -0.3 - 0.8 V

Input high level VIH 2.0 - Vcc V

Input current RPD 33 47 66 μA Vin=3V

It is not the radiation-proof design for this product.

ILEDLK - 0.0 5.0 μA VLED=26V

INVSET - -0.05 -0.10 μA VSET=2V

I

www.rohm.com

2/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

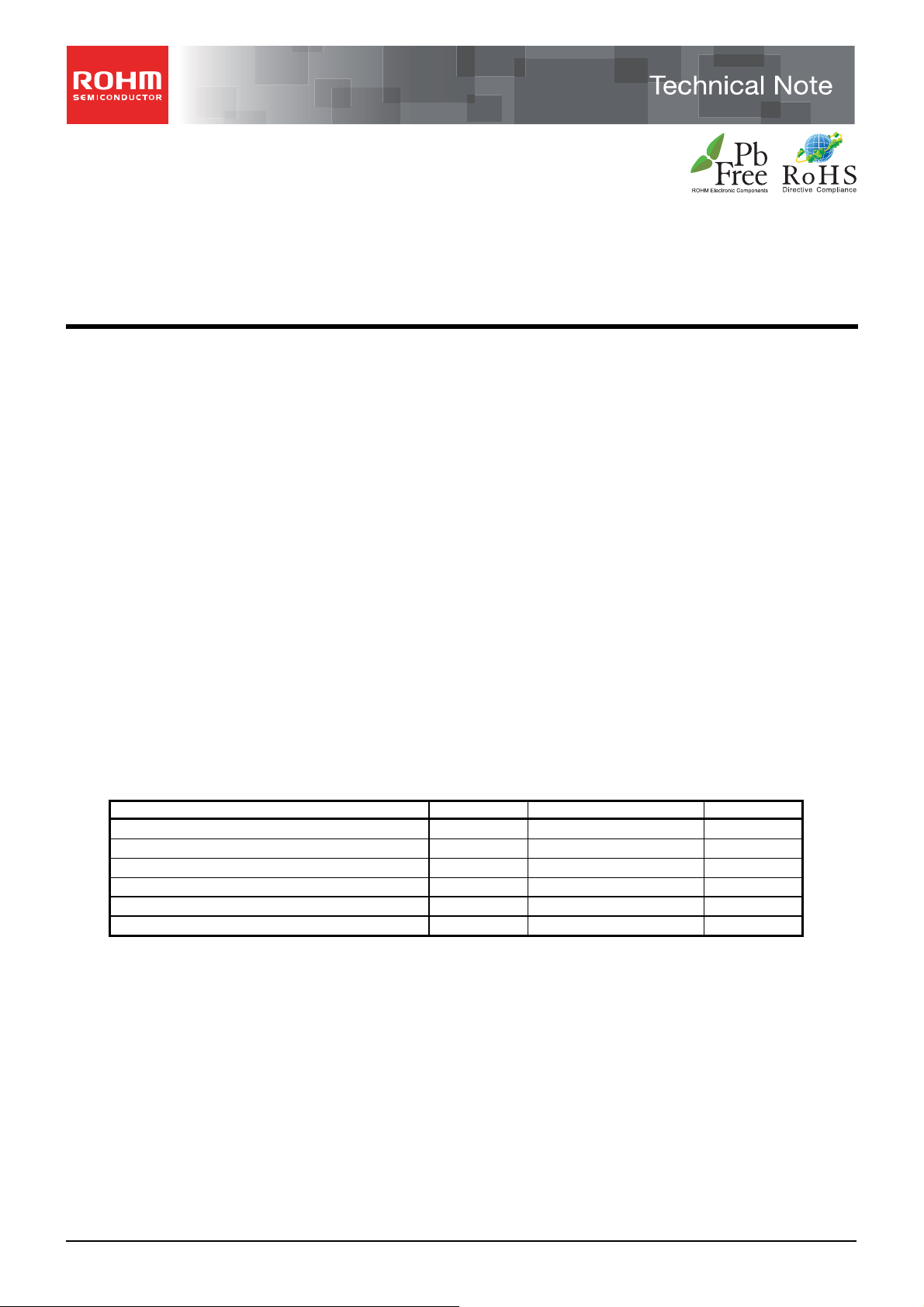

●Block diagram ●Package outline drawing

VCC

20

STBY

2

PREREG

AGND

100k

4

5VREG

Driver

Current

Setting

5VREG

EN

3

VSET

100k

PREREG

TSD

18

RSET

REF

5V

REG

UVLO

5VREG

ENH1

ISET1

5VREG

6

ISET2~5

4

Current

Driver

1

6

LED2~5

VREG

Vo

LED1

BD9206EFV

・・・・

ISET6

5VREG

・・・・ ・

LED6

15

PGND1~2

HTSSOP-B20(Unit:mm)

17

TEST

●Terminal placement diagram ●Terminal explanation

VREG

1

2

STBY

EN

3

4

AGND

5

PGND1

6

LED1

LED2

7

LED3

8

N.C.

9

N.C.

10

Fig..3

Fig..1 Fig..2

Terminal

VCC

20

19

N.C.

18

VSET

TEST

17

PGND2

16

15

LED6

LED5

14

13

LED4

12

N.C.

11

N.C.

number

Terminal

name

Function

Terminal

number

Terminal

name

1 VREG Power supply for internal circuit 11 N.C. (Not yet connected terminal)

2 STBY

Stand by terminal

(Low:OFF,High:stand by,

operation)

12 N.C. (Not yet connected terminal)

3 EN LED1~16 Enable terminal(Active:High) 13 LED4 Output terminal 4 for LED driver

4 AGND

GND for internal standard section 14 LED5 Output terminal 5 for LED driver

5 PGND1 POWER GND for LED driver 15 LED6 Output terminal 6 for LED driver

6 LED1

Output terminal 1 for LED driver 16 PGND2

7 LED2 Output terminal 2 for LED driver 17 TEST

8

9 N.C.

LED3 Output terminal 3 for LED driver 18 VSET

(Not yet connected terminal) 19 N.C. (Not yet connected terminal)

10 N.C. (Not yet connected terminal) 20 VCC Terminal of power supply

Technical Note

Lot No.

Function

Power GNDPOWER GND for LED

driver

Terminal for test mode shift

(Use at usual time:Low)

Standard voltage terminal for fixed

electric current setting

www.rohm.com

3/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

(

)

(

)

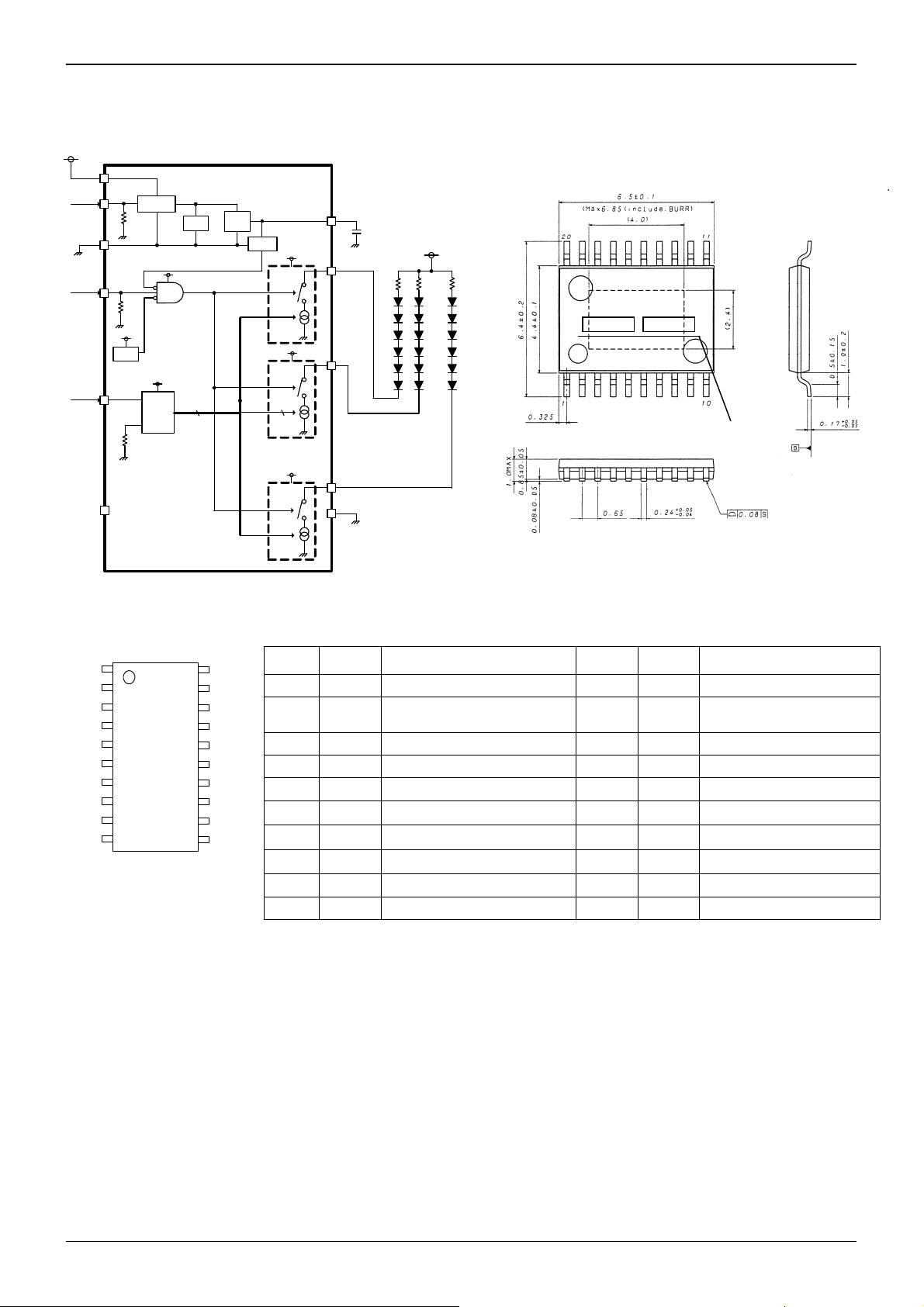

●Reference data(Unless specified,VCC=24V, Ta=25℃)

0.05

0.04

0.03

0.02

ICC [mA]

0.01

0.00

0 4 8 12162024283236

STBY=L

EN=L

VCC [V]

Fig..4-1 Circuit electric current

(at the time of OFF mode)

35

30

25

20

15

ILED [mA]

10

5

0

0 0.5 1 1.5 2 2.5 3 3.5

VSET [V]

Fig..4-4 VSET Constant electric

current Characteristics

10

9

8

7

6

5

4

VREG [V]

3

2

1

0

0 4 812162024283236

VCC [V]

Io=0mA

Fig..4-7 VREG_VCC characteristic

8

7

6

5

4

3

VRED [V]

2

1

0

0 0.5 1 1.5 2 2.5 3

VEN [V]

Fig..4-10 EN Threshold voltage

3.0

2.5

2.0

1.5

ICC [mA]

1.0

0.5

0.0

0 4 8 12 162024283236

Fig..4-2 Circuit electric current

at the time of stand bymode

32

28

24

20

16

12

ILED [mA]

8

4

0

0123456

Fig..4-5 VLED Dependency of ILED

5.5

5.4

5.3

5.2

5.1

5.0

4.9

VREG [V]

4.8

4.7

4.6

4.5

-40 -20 0 20 40 60 80 100

Fig..4-8 VREG temperature

VCC [V]

VSET [V]

TEMP [℃]

characteristic

Technical Note

5

STBY=H

EN=L

VSET=2V VSET=2V

Io=0mA

4

3

2

ICC [mA]

1

0

0 4 8 12162024283236

VCC [V ]

Fig..4-3 Circuit electric current

at the time of operatingmode

24

23

22

21

20

ILED [mA]

19

18

17

-40 -20 0 20 40 60 80 100

TEMP [℃]

Fig..4-6 Constant electric current

temperature characteristic

8

7

6

5

4

3

VREG [V]

2

1

0

0 0.5 1 1.5 2 2.5 3

VSTBY [V]

Fig..4-9 STBY Threshold voltage

STBY=H

EN=H

www.rohm.com

4/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

p

Technical Note

● Block functional descriptions

■PREREG, REF, 5VREG

PREREG is an circuit of constant voltage supplied to REF and 5VREG in which the voltage applied to VCC terminal is made

to be constant.

REF is a temperature-compensated reference voltage resource and used as reference voltage of TSD (Thermal Shutdown

Circuit).

5VREG is a 5V constant-voltage source and used as a power supply of constant-current driver.

The 5V constant voltage is output to VREG terminal. Moreover, it is recommended to attach a 1μF ceramic capacitor using

for phase correction, to VREG terminal.

■UVLO(Under Voltage Lock Out)

The LED driver is turned OFF when the VREG voltage is less than 2.9V(typ). The operation of lighting up is reset when

VREG becomes more than 3.0V(typ).

■ TSD(Thermal Shutdown Circuit)

TSD circuit protects the IC from thermo runaway or thermal damage.

TSD circuit detects the chip temperature and turns the circuit off if the chip temperature reaches 175℃. The hysteresis of

20℃ is set for TSD detection and release so as to prevent malfunction caused by temperature fluctuations.

■Current Driver(Constant-current driver), Driver Current Setting

Current Driver(Constant-current driver) is an circuit that generates a constant current for lighting of LED.

Constant-current circuit of BD9206EFV consists of the constant current setting part and the constant current driver part.

The constant-current driver part operates in such a manner that the voltage of Point a is equal to the voltage of point b

because the part serves as a buffer, the input of which is the voltage VX that is set by the constant current setting part.

Therefore, the current ILED that flows into the VLED terminal is as follows:

ILED = Vb/RSET = Va/RSET = VX/RSET = VSET*A/RSET = VSET*B

(A and B are numerical constants)

For BD9206EFV, the numerical constants inside the IC are set in such a way that the following formula is brought into

existence:

ILED(mA) = VSET *10 (VSET=0.6~3.0V)

If VSET is fixed, then the Vb is fixed, therefore the current ILED always flows independent of the fixed voltage of VLED.

However, the constant current operation is stopped if the voltage of VLED terminal is less than 0.6V, so please ensure

VLED>0.6V.

Vo

[Constant current driver part]

VSET

【定電流設定部】

[Constant current setting part]

VX=VSET*A

電圧

Voltage

shift circuit

変換

回路

VX

【定電流ドライバ部】

Condenser for phase

位相補償 用コンデンサ

com

ensation

a

+

-

EN

RSET

ILE D

VLED

b

Fig..5

www.rohm.com

5/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

● Rise time and Fall time of LED Driver’s constant current

In the state of STBY=H, the rise time of constant current at the time of EN=L→H and the fall time at the time of EN=H→L

are as shown in the following table.

As shown in Fig.5, the constant current driver is formed in such a way that the NMOS of the driver output is made to be

operated or stopped by the EN signal.

Therefore, the rise time for the second time or later is shorter than the one for the first time because the electrical ch arge

of the capacitor for phase compensation is reopened from the charged state.

First time Second time or later Remarks

The time interval between the

Rise time 2.9μs ± 7% 2.6μs ± 7%

Fall time 0.7μs ± 11% 0.7μs ± 11%

On the condition that VCC=Vo=24V, VF(LED)=3.2V 5-stage connection, RL=15Ω

■STBY, EN

At the time of STBY=L, it becomes the OFF mode, then only a portion of the circuit inside the IC is operating, so the circuit

current is restricted to 17μA (typ).

At the time of STBY=H, it becomes the Standby mode, then 5VREG is started and UVLO is released before the LED driver

gets into the state of Ready.

After that, if EN=L→H, then the current flows into the LED driver and the LED is lighted up.

Note: If STBY and EN are simultaneously made to be L→H, then the rising edge of the LED driver gets late because t he

starting time of 5VREG is necessary.

If it is used after PWM dimming, then please let STBY=H beforehand and input the CLK to EN before using.

●Operation logic of LED driver

●Logic of LED driver protection circuit

EN

STBY

L Stop Stop

H Stop Operation

L H

STBY

UVLO

TSD

moment of EN=L→H and the

moment at which the I

reaches 90% of the set value

The time interval between the

moment of EN=H→L and the

moment at which the I

reaches 10% of the set value

EN

active : High

Technical Note

LED

LED

LED

Driver

Function Stop Operation

UVLO VREG < 2.9V(typ) VREG > 3.0V(typ)

TSD Ta > 175℃ Ta < 155℃

■TEST terminal

TEST terminal is only used in ROHM’s testing process before delivery, so please use the IC with the terminal fixed at Low in

normal times.

www.rohm.com

6/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

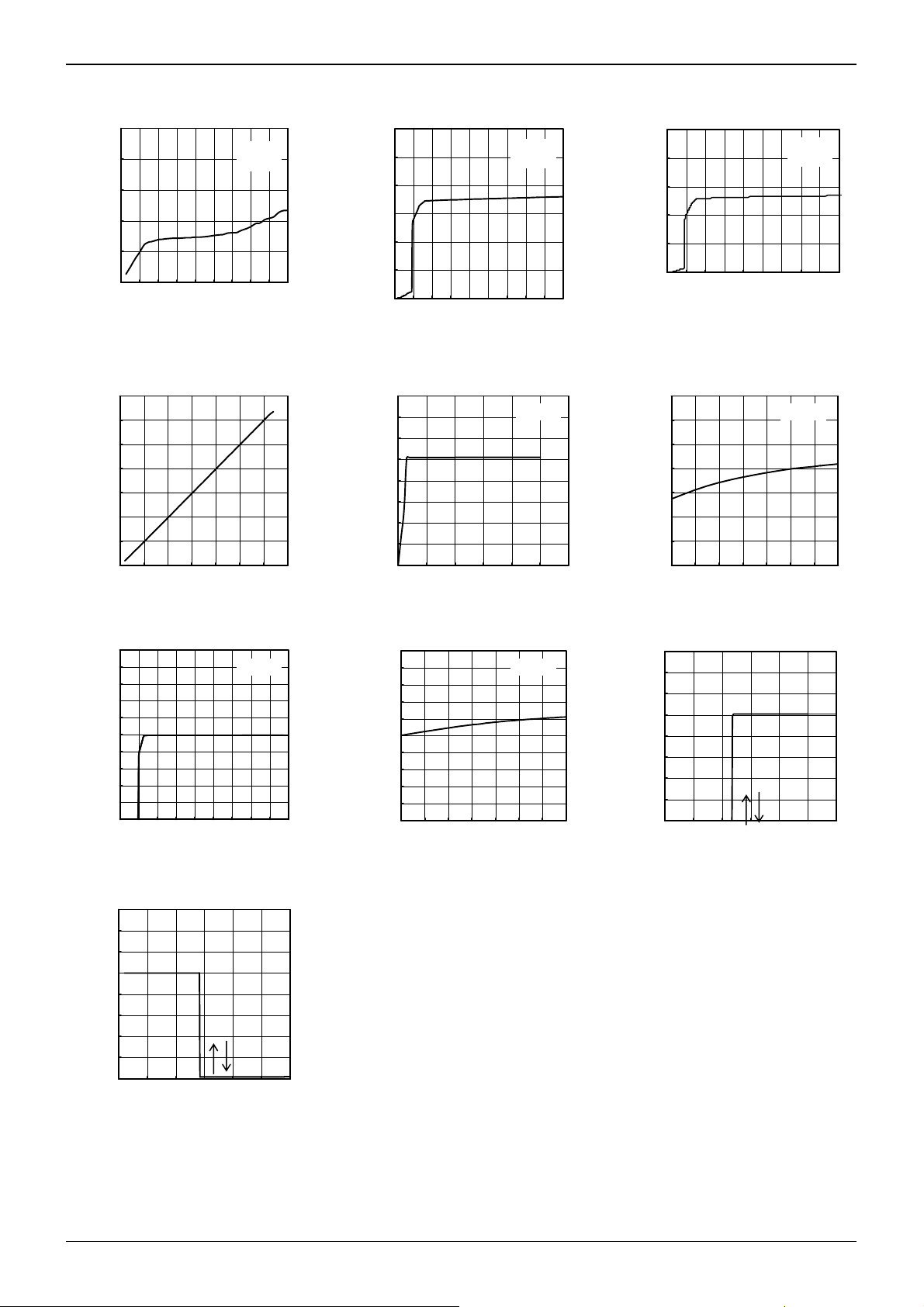

●Timing chart

VCC

VSET

STBY

EN

VREG

UVLO internal signal

UVLO( 内部信号)

TSD internal signal

TSD(内部信号)

I

LED

※Please be careful about a current flowing to the VCC side via the diode for electrostatic breakdown protection if a

voltage is applied to STBY terminal or EN terminal earlier than to VCC terminal.

3.0V

①②③④ ⑤ ⑥ ⑦ ⑧ ⑨ ⑩⑪

Fig..7

2.9V

Technical Note

① VCC input.

② VSET Setting

③ It moves to OFF mode due to STBY =

L -> H. 5VREG (VREG) start. Rising

time ms.

④ It becomes UVLO = H depending upon

VREG >3.0V, it moves to stand-by

mode. As for LED driver, it is ready

state.

⑤ LED Lighting with EN = L -> H .

⑥ LED lighting out with EN = H → L

⑦ it is same with ⑤

⑧ Detecting TSD with Ta > 175℃,

LED lighting out

⑨ Deleting TSD with Ta < 155℃,

LED lighting

⑩LED lighting out with STBY,EN=H→L

⑪Detecting UVLO=L with VREG<2.9V

www.rohm.com

7/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

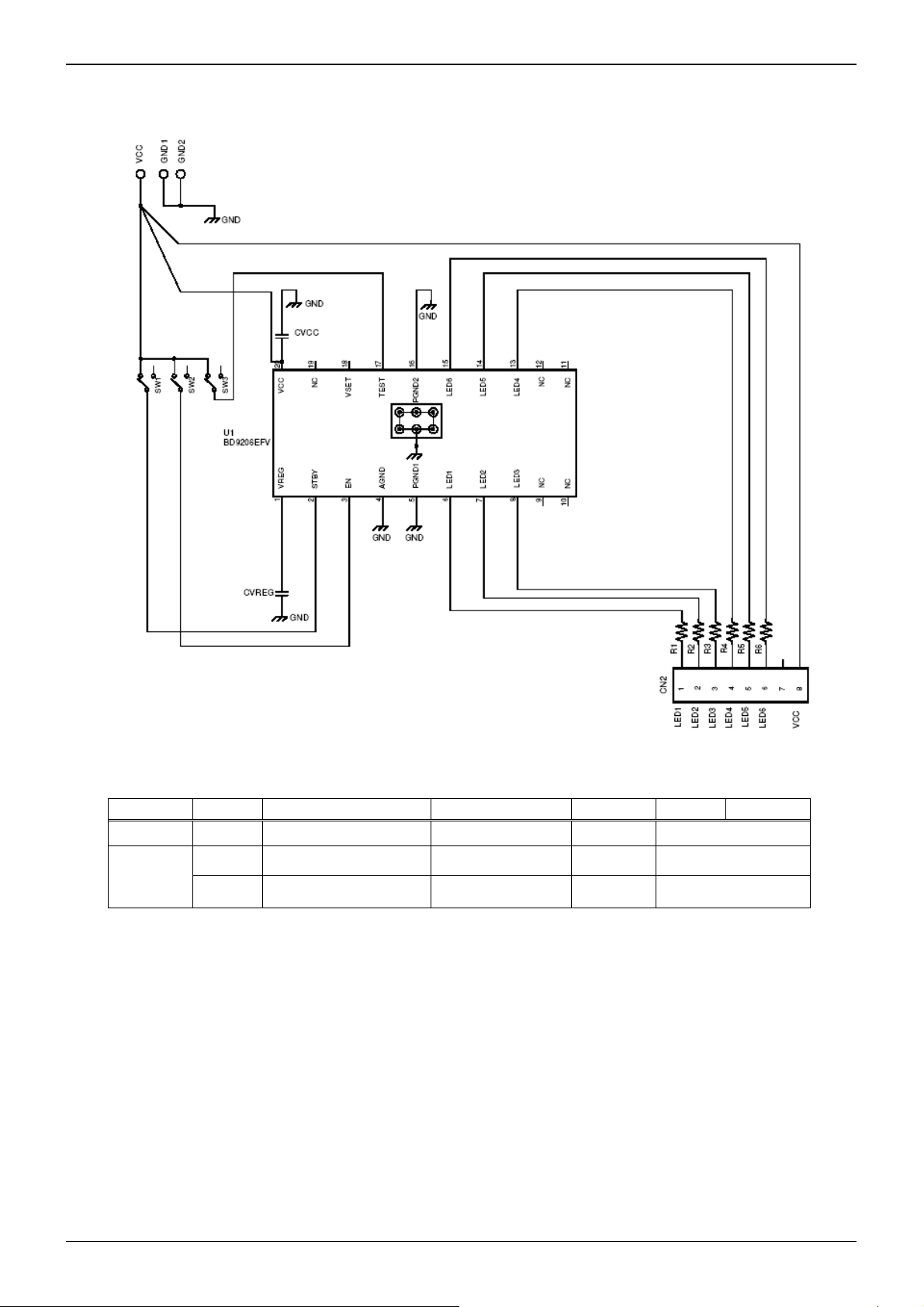

●Recommendation of Circuit figure

When you use VCC=24V ILED=20mA

Variety Symbol Usage Type Maker Value Unit

Resistance R1~R6 For reducing IC thermal loss MCR03Series15R0 ROHM 15Ω

Technical Note

Fig..8

capacitor

CVCC For input by-pass capacitor GMR55DB31H106 murata 10uF

CVREG For VREG phase compensation GMR188R71A105 murata 1uF

●The points of manufacturing substrate

For this IC, at the time of LED lighting, the temperature of the package increases due to heat generation of the constant

current driver.

Therefore, please bring the radiating fin on the back side of the package down to the GND with wide substrate pattern in

order to promote heat radiation.

In addition, the heat radiation can be further promoted by putting a thermal VIA in.

The heat radiation can be promoted similarly by connecting the unconnected terminals, TEST terminals and unused

terminals of LED1~6 to GND.

www.rohm.com

8/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

Technical Note

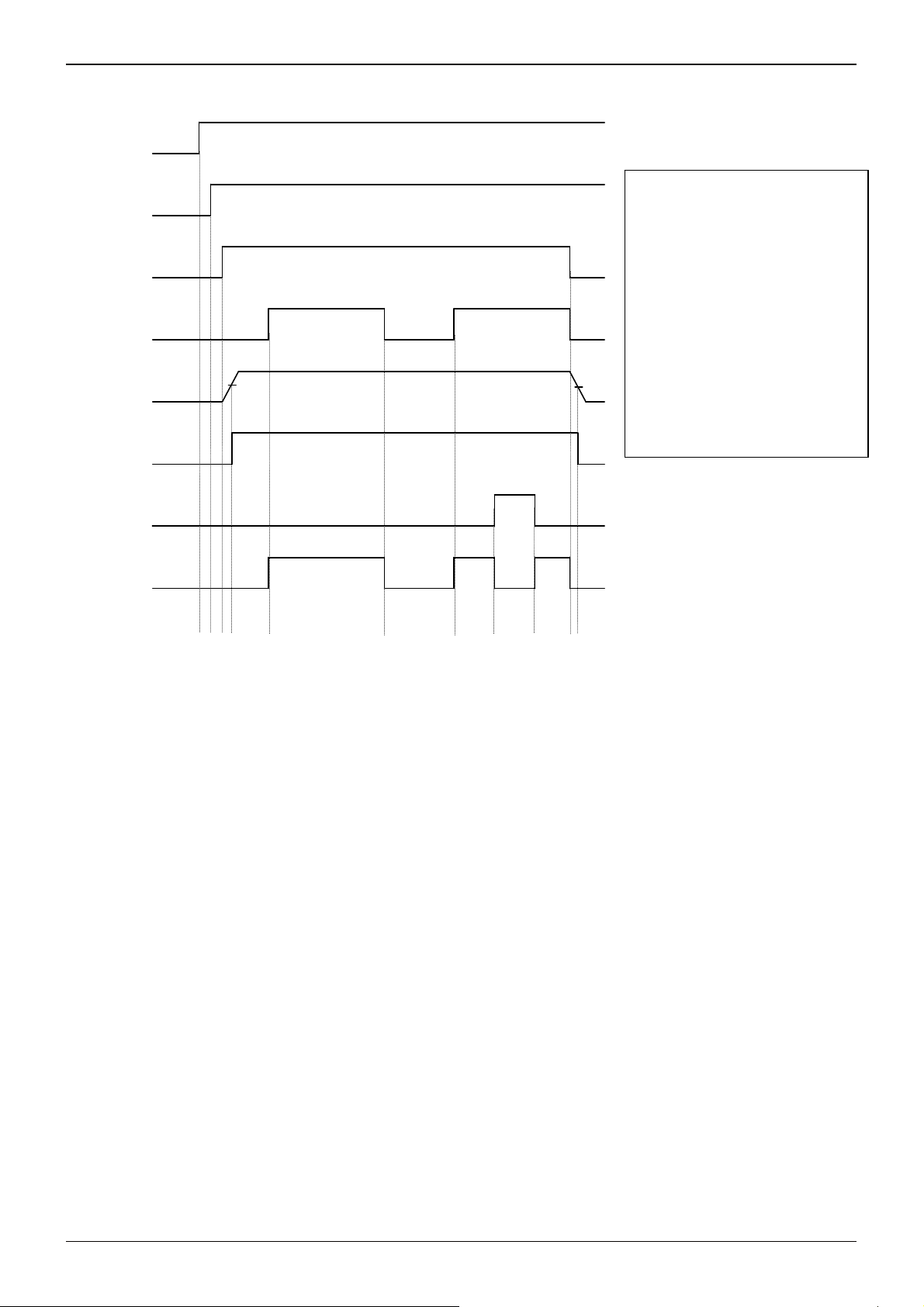

●The calculation of electric power consumption for IC and the deciding method of external resistance value

Electric power consumption of IC is decided with formula below.

P(N)=ICC*VCC+[(Vo-RL*ILED)-(Vf+⊿Vf+⊿VfT)*M]*N*ILED ・・・・①

ICC

VCC

Vf

⊿Vf

⊿VfT

M

N

ILED

Vo

IC Consumed electric

:

current

:

Input voltage

:

LED Vf voltage

:

(normal temperature typ)

:

LED Vf Variation

:

LED Vf Temperature

:

variation

Stage number around

:

LED 1 line

:

LED line number

:

LED Constant current

value

Voltage OF LED anode

Vo

RL

VF

*M

*N

ILED

side

RL

external resistance

(external loss)

Fig..9

Please insert the heat-radiation resistor RL in order to decrease the heat radiation at the IC.

If the value of RL is made to be larger, then the heat radiation of the IC is decreased, but if the terminal voltage VLED of the

LED driver is less than 0.6V, then the constant current operation becomes impossible, therefore please set the RL in such a way

that the following expression is met:

VLED=Vo-(Vf+⊿Vf+⊿VfT)*M-RL*ILED>0.6V

Please set the ILED and RL in such a way that the relational expressions ① & ② are met.

Moreover, the permissible loss of the package is as shown in the following graph.

HTSSOP-B20 Pd

4.0

3.5

3.0

2.5

2.0

1.5

許容損失Pd(W)

allowable loss

1.0

3.20

2.30

1.00

③

②

①1layer baseplate

①:1層基板

Heat dissipation

(

(表層放熱銅箔:

copper foil on surface

Omm2)

0mm2

②2layer base―plate

Heat dissipation

(

copper foil on Inside

②:2層基板

and outside layer:

(表裏層放熱銅箔:

4900mm2)

4900mm2)

:

①

0.5

0.0

0 25 50 75 100 125 150

Temperature around Ta(℃)

周囲温度Ta(℃)

③4layer base―plate

③:4層基板

(

Heat dissipation

(全層放熱銅箔:

copper foil on whole

layer:4900mm2)

4900mm2

Fig..10

www.rohm.com

9/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

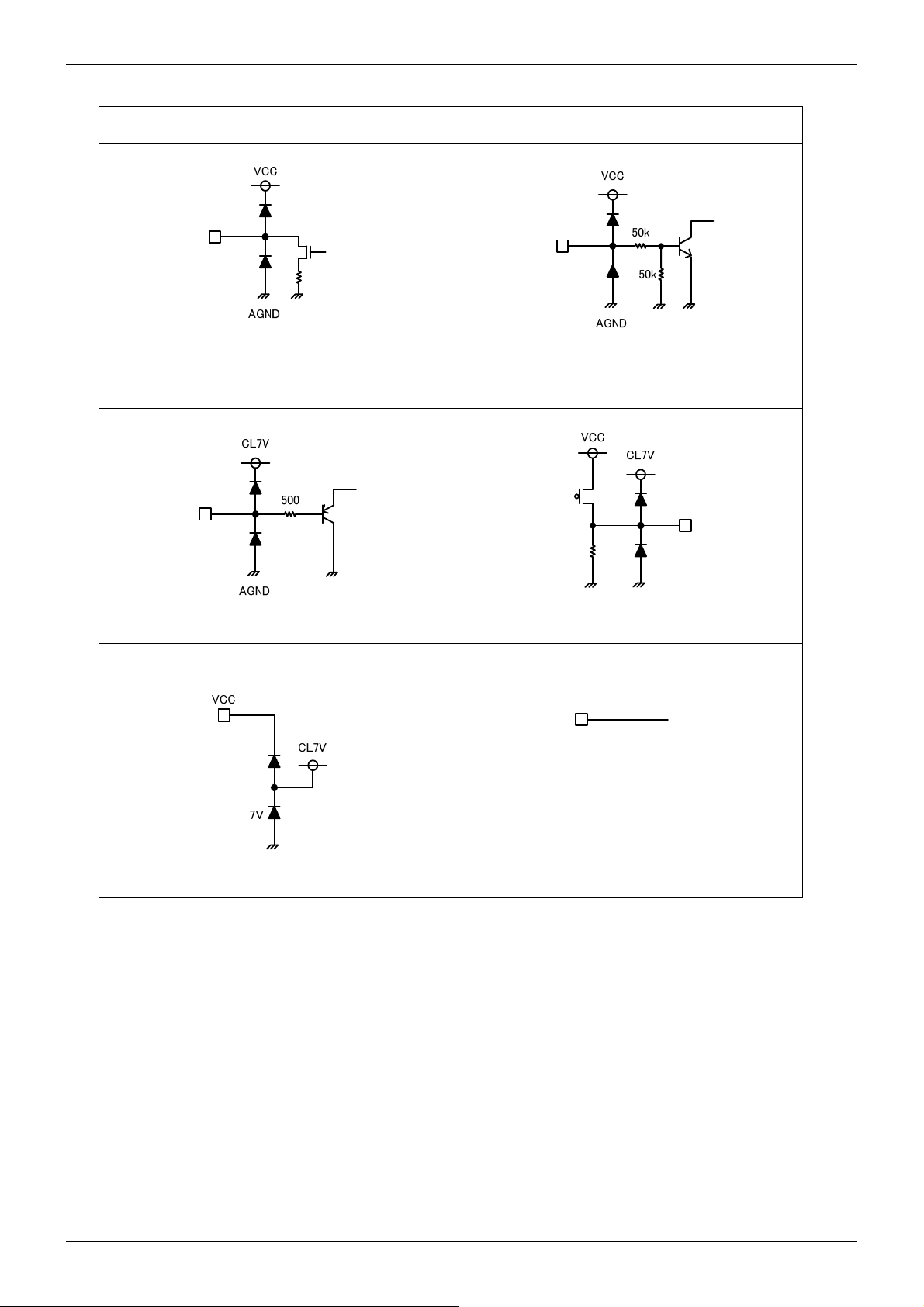

●Input/output equivalent circuit

6:LED1, 7:LED2, 8:LED3,

13:LED4, 14:LED5, 15:LED6

18:VSET 1:VREG

Technical Note

2:STBY

3:EN, 17:TEST

CL7V 9, 10, 11, 12, 19:N.C.

※The voltage clamp element of 7V is connected to CL7V.

N.C. pin is not connected

www.rohm.com

10/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

子

Technical Note

●Notes for use

1.) The absolute maximum ratings

We pay sufficient attention for quality control to this product but If the absolute maximum ratings are exceeded, such as with

applied voltage or operational temperature range, a degradation or a destruction may occur. The short or open modes cannot be

specified. so if special modes which exceed the absolute maximum ratings are assumed, physical safety precautions such as fuses

should be in place.

2.) Reverse connection of power supply connector

The reverse connection of power connector may cause damage to IC. Please take countermeasures such as inserting a

diode between the power supply and IC’s external power supply pin for protection against the damage caused by the

reverse connection.

3.) Power supply line

The return of the regenerated current is caused by the back electromotive force of the external co il, so please take the

measures such as inserting a capacitor between power supply and GND as a route of r egenerated current, and determine

the capacitance value after thoroughly ensuring that there is no proble ms in the Characteristics of electrolyte capacitor,

such as no loss of capacitance at low temperature. Heat design should take into account of power dissipation (Pd) under actual

usage conditions, with wide enough margins

4.) GND Potential

The potential of the GND terminal should be the minimum potential under all operating conditions.

5.) Heat Design

Heat design should take into account of power dissipation under actual usage conditions, with wide enough margins.

6.) Short-circuiting between Terminals and Incorrect Mounting

When mounting to the PWB, pay special attention to the direction and proper placement of the IC. If the IC is attached incorrectly,

it may be destroyed. Furthermore, there is also a possibility of breakdown, when the foreign body enters during outputting and

between power supply and GND.

7.) The operation in the strong magnetic fields

Please be careful that there is a possibility of malfunction which is happening when you use it in a strong electrom agnetic

field.

8.) ASO

Please do the setting in such a way that the output Tr does not exceed the absolute maximum rating and ASO in case of

using this IC. For CMOS IC and the IC with more than one power supply, a rush current may flow instantaneously at the

time of power on, so please be careful about power supply coupling capacitance, power supply, GND pattern wiring width

and length.

9.) Thermal shutdown circuit (TSD circuit)

This IC incorporates a built-in thermal shutdown circuit (TSD circuit). The TSD circuit is that has des igned only to shut the

IC off to prevent the thermal runaway operation,not for IC protection or guarantee as purpose. Therefore, please do not

continue to use the IC after operating this circuit and also do not use the IC designating operation as prerequisite.

10.) Inspection of the Set Substrate

If a condenser is connected to a pin with low impedance when inspecting the set substrate , stress ma y be placed on the IC,

so please be sure to discharge after each process. Moreover, please be sure to turn off the power supply before connecting

& inspecting or before detaching when it is connected to jig at inspection process.

11.) About IC terminal input

This IC is a monolithic IC, and there are a P+ isolation and the P substrate for separation of element between each element. There is

a P-N junction formed between this P-layer and each element’s N-layer, forming every parasitic element, as shown in Fig.15, when

resistance and transistor are connected with terminal

〇 In the case of GND>(terminal A

ith resistance or GND>(terminal B) with transistor(NPN), the P-N junction operates as a

)w

parasitic diode.

〇 In addition, when GND> (terminal B) with the transistor (NPN), the parasitic NPN transistor operates due to the aforementioned

parasitic diode and the N layer of the other element approached

With the IC’s configuration, the production of parasitic elements is inevitable. The operation of parasitic elements causes

interferences between circuits, leading to malfunction and even destruction. Therefore, uses which cause the parasitic elements

to operate, such as applying voltage to the input terminal which is lower than the GND (P-substrate), should be avoided.

Resistance

+

抵抗

N

P Substrate

基板

P

P

Parasitic Element

寄生素子

GND

~ ~

(terminalB)

(端子B)

+

P

N

N

Parasitic Element

(terminalA)

(端子A)

P

N

P

C

(NPN)

+

寄生素子

Transistor

トランジスタ

B

N

N

P Substrate

基板

P

~ ~

P

GND

E

(terminalA)

GND

+

P

N

(端子A)

GND

~

~

Parasitic Element

寄生素子

other element approached

近接する他の素子

(terminalB)

(端子B)

C

B

~ ~

E

GND

Parasitic Element

寄生素

Fig..11 バイポーラ IC の簡易構造例

Fig.11 Simple Structure of bipolar IC (Sample)

www.rohm.com

11/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

BD9206EFV

●Ordering part number

B D 9 2 0 6 E F V - E 2

Part No. Part No.

HTSSOP-B20

6.4±0.2

0.325

1.0MAX

0.85±0.05

6.5±0.1

(MAX 6.85 include BURR)

(4.0)

4.4±0.1

110

0.65

0.08±0.05

0.24

1120

1.0±0.2

+0.05

0.17

-

0.03

(Unit : mm)

0.5±0.15

+0.05

-

0.04

(2.4)

S

0.08 S

Package

EFV: HTSSOP-B20

<Tape and Reel information>

Embossed carrier tape (with dry pack)Tape

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Packaging and forming specification

E2: Embossed tape and reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Technical Note

Direction of feed

www.rohm.com

12/12

© 2009 ROHM Co., Ltd. All rights reserved.

2009.07 - Rev.A

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes ef forts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...