Page 1

IC Card Interface ICs

IC Card Interface ICs

with Built-in Low Noise LDO Regulator

BD8918F,BD8918FV,BD8919F,BD8919FV

No.09056EDT01

●Overview

This is an interface IC for a 5V smart card.

It works as a bidirectional signal buffer between a smart card and a controller. Also, it supplies 5V power to a smart card.

With an electrostatic breakdown voltage of more than HBM; ±6000V, it protects the card contact pins.

●Features

1) 1 half duplex bidirectional buffers

2) Protection against short-circuit for all the card contact pins

3) 5V power source for the card (VCC)

4) Over-current protection for card power source

5) Built-in thermal shutdown circuit

6) Built-in supply voltage detector

7) Automatic activation/deactivation sequence function for card contact pin

Activation sequence: driven by a signal from controller (CMDVCCB)

Deactivation sequence: driven by a signal from controller (CMDVCCB) and fault detection (card removal, short

circuit of card power, IC overheat detection, VDD or VDDP drop)

8) Card contact pin ESD voltage ≧ ±6000V

9) Recommend frequency of crystal oscillator: 8MHz (BD8918F/FV), 16MHz (BD8919F/FV)

10) Programmable for card clock division of output signal: 1/1 and 1/2(BD8918F/FV), 1/2 and 1/4(BD8919F/FV).

11) RST output control by RSTIN input signal (positive output)

12) One multiplexed card status output by OFFB signal

●Applications

Interface for CLASS A smart cards

Interface for B-CAS cards

●Line up matrix

Part No

BD8918F

BD8918FV SSOP-B16

BD8919F

BD8919FV SSOP-B16

Ratio of dividing frequency

Card clock

1/1f, 1/2f

1/2f, 1/4f

Package

SOP16

SOP16

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

1/15

2010.4 - Rev.D

Page 2

BD8918F,BD8918FV,BD8919F,BD8919FV

●Absolute maximum ratings (Ta=25°C)

Parameter Symbol Ratings Unit Notes

VDD Input Voltage VDD -0.3 ~ 6.5 V

Technical Note

VDDP Input Voltage V

I/O Pin Voltage

-0.3 ~ 6.5 V

DDP

V

V

MIN

MOUT

-0.3 ~ +6.5 V

Pin: XTAL1, XTAL2, CLKSEL, RSTIN, IO_U

CMDVCCB, OFFB

Card Contact Pin Voltage VCD -0.3 ~ +6.5 V Pin: PRES, CLK, RST, IO_C

Junction Temperature T

Storage Temperature T

Power Dissipation P

*1 BD8918F/BD8919F, *2 BD8918FV/BD8919FV

• This product is not designed to be radiation tolerant.

• Absolute maximum ratings are not meant for guarantee of operation.

+150 °C

jmax

-55 ~ +150 °C

stg

*1

tot

0.375

0.500

*2

T = -20 ~ +85°C

W

(Refer to the following package power dissipation)

●Operating Conditions (Ta=25°C)

Parameter

Symb

ol

Ratings Unit Notes

MIN TYP MAX

VDD Input Voltage VDD 2.7 - 5.5 V

VDDP Input Voltage V

Operating Temperature T

4.75 - 5.5 V VCC ≥ 4.55V

DDP

-40 - +85 °C

opr

●Package Power Dissipation

The power dissipation of a simple package in case of a boadless will be as follows.

Use of this device beyond the following the power dissipation may cause permanent damage.

BD8918F/BD8919F Pd=375mW; however, reduce 3mW per 1°C when used at Ta ≥ 25°C.

BD8918FV/BD8919FV Pd=500mW; however, reduce 4mW per 1°C when used at Ta ≥ 25°C.

0.4

Package power

0.6

Package power

0.3

0.5

0.4

0.2

Pd (W)

0.3

Pd (W)

0.1

0.2

0.1

0.0

0 25 50 75 100 125 150

Temp (℃)

0.0

0 25 50 75 100 125 150

Temp (℃)

Fig. 1.1 BD8918F/BD8919F Power Dissipation Fig. 1.2 BD8918FV/BD8919FV Power Dissipation

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

2/15

2010.4 - Rev.D

Page 3

BD8918F,BD8918FV,BD8919F,BD8919FV

●Block Diagram

2.7V-5.5V

VDD

0.1uF

VIREF

VDET

TSD

VDD

LVS

20k

POWER_ ON

ALARM

OFFB

RSTIN

CMDVCCB

CLKSEL

VDD

50k

50k

50k

CLK

DIV

SEQUENCER

DIVEN

DIVCLK

22pF

22

F

pF

IO_U

XTAL1

220Ω

XTAL

XT

OSC

2

MAX 1MHz

VDD

11k 11k

GND

BD8918F/FV F=8MHz

BD8919F/FV F=16MHz

TSD

ALARM

IOEN

Fig. 2

VREF

VCCEN

VCC

ALARM

RSTEN

CLKEN

IO TRANS

LVS

VDD

4.75V-5.5V

VDDP

LDO

LVS

RST BUF

LV S

CLK BUF

LVS

VDD

10µF

50k

VCC

Technical Note

5V

VCC

1µF

CGND

RST

CLK

PRES

IO_C

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

3/15

2010.4 - Rev.D

Page 4

BD8918F,BD8918FV,BD8919F,BD8919FV

●Pin Description

Pin No. Pin Name I/O

Signal

Level

Technical Note

Pin Function

1 XTAL1 I VDD

2 XTAL2 O VDD

3 VDD S VDD

4 CLKSEL I VDD

5 RSTIN I VDD

6 IO_U I/O VDD

7 CGND S GND

8 IO_C I/O VCC

9 RST O VCC

10 CLK O VCC

11 VCC O VCC

12 VDDP S VDDP

13 PRES I VDD

14 OFFB O VDD

15 CMDVCCB I VDD

Crystal connection or input for external clock

Crystal connection (leave open pin when external clock source is used)

3.3 V power source pin for host interface.

Connect 0.1µF capacitor between the VDD and GND pins.

Input for clock frequency

division setting.

Pulled down to GND

with a 50k resistor.

Card reset signal input. Pulled down to GND with a 50k resistor.

Host data I/O line; Pulled up to VDD with an 11k resistor

GND

I/O data line on the card side. Pulled up to VCC with an 11kresistor.

Card reset output

Card clock output

Card supply voltage. Connect 1µF capacitor between VCC and the CGND pins.

5V power source pin for card power feed. Connect 10µF capacitor between the

VDDP and CGND pins.

Card presence contact input (“H” active). Pulled up to VDD with a 50k resistor.

Connected to a switch where GND level is inputted when no card is inserted and

OPEN is inputted when a card is inserted. When “H” level is detected, a card is

assumed to be inserted and waits for the CMDVCCB input for the confirmation,

after the debounce time of typ. 8ms.

Alarm output pin (“L” active).

NMOS open drain output. Pulled up to VDD with a 20k resistor.

Activation sequence command input; The activation sequence starts by signal

input (HL) from the host

BD8918F/FV H: 1/1 division; L: 1/2 division.

BD8919F/FV H: 1/2 division; L: 1/4 division.

16 GND S GND

*Capacitors to be connected to VDD, VDDP and VCC should be placed immediately next to the pins (ESR<100m).

GND

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

4/15

2010.4 - Rev.D

Page 5

BD8918F,BD8918FV,BD8919F,BD8919FV

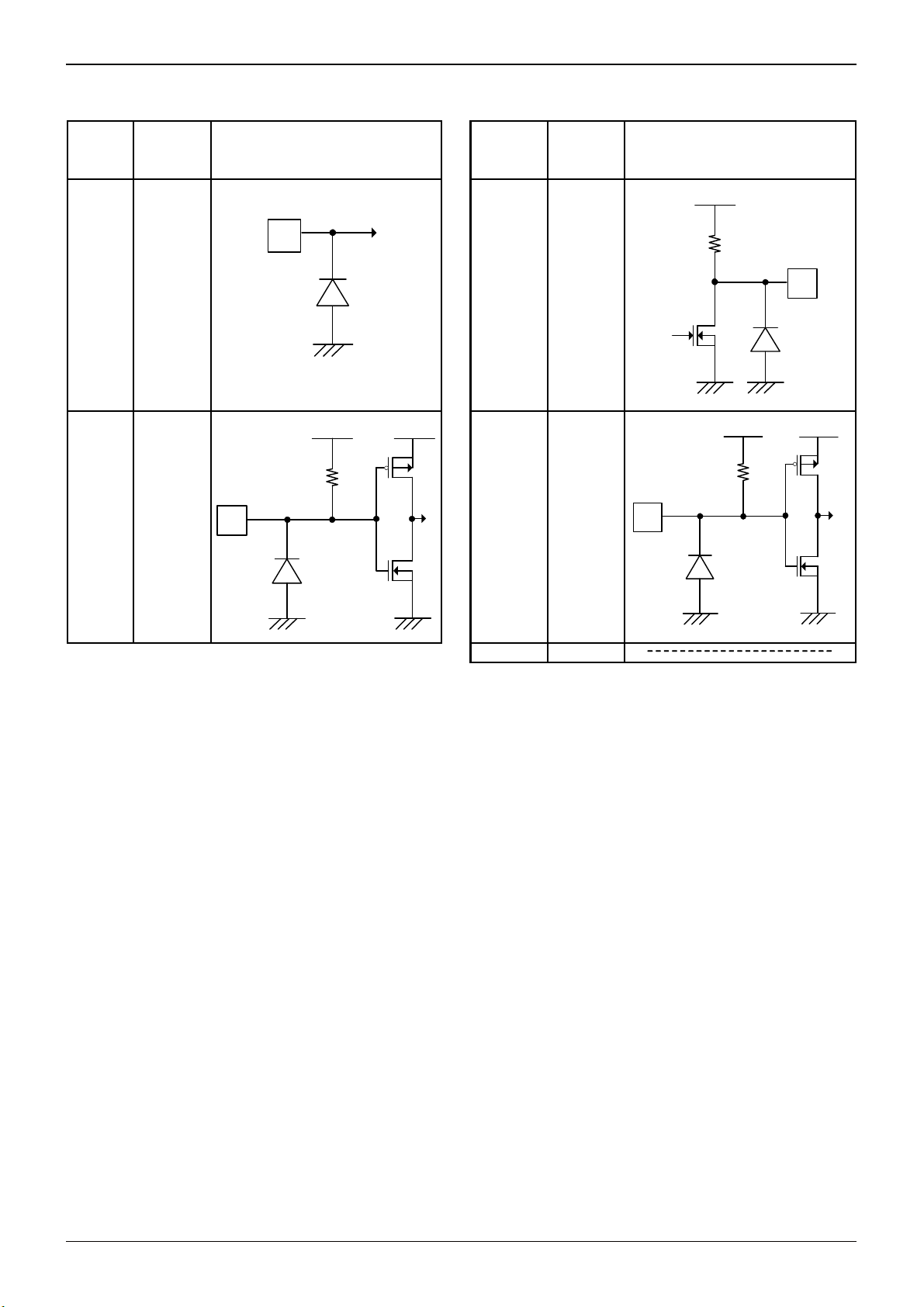

●Pin Function Diagram

Pin

No.

Pin

Name

Pin function Diagram

Pin

No.

Pin

Name

Technical Note

Pin function Diagram

VDD

VDD

1XTAL1

1

2

1. 2 M

Ω

100

Ω

8IO_C

2XTAL2

3

3VDD 9 RST

VDD

4CLKSEL

VDDP8VREG

11K

Ω

VREG

VREG

VREG

VDDP

9

VDDP

4,5

50K

5RSTIN

6IO_U 11 VCC

5

Ω

VDD VDD

11 K

Ω

10 CLK

7CGND

VDDP

1

Ω

10

VDDP

11

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

5/15

2010.4 - Rev.D

Page 6

BD8918F,BD8918FV,BD8919F,BD8919FV

Technical Note

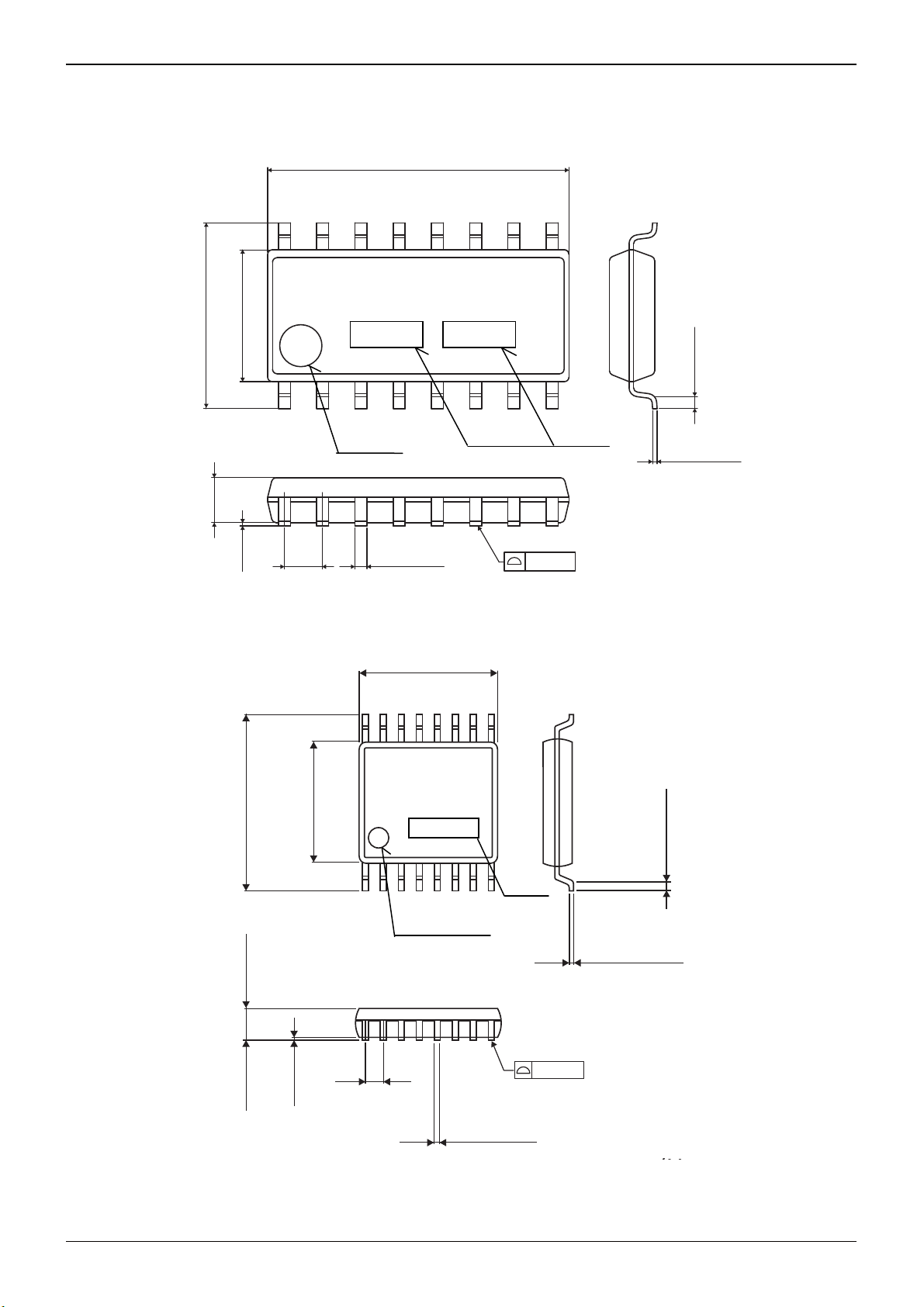

Pin No. Pin No.

Pin Name Pin function Diagram Pin Name Pin function Diagram

12

12 VDDP 14 OFFB

VDD

5KΩ

13 PRES 15

13

VDD

CMDVCCB

15

VDD

20KΩ

VDD

50KΩ

14

VDD

16 GND

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

6/15

2010.4 - Rev.D

Page 7

BD8918F,BD8918FV,BD8919F,BD8919FV

5.0±0.2

10±0.2

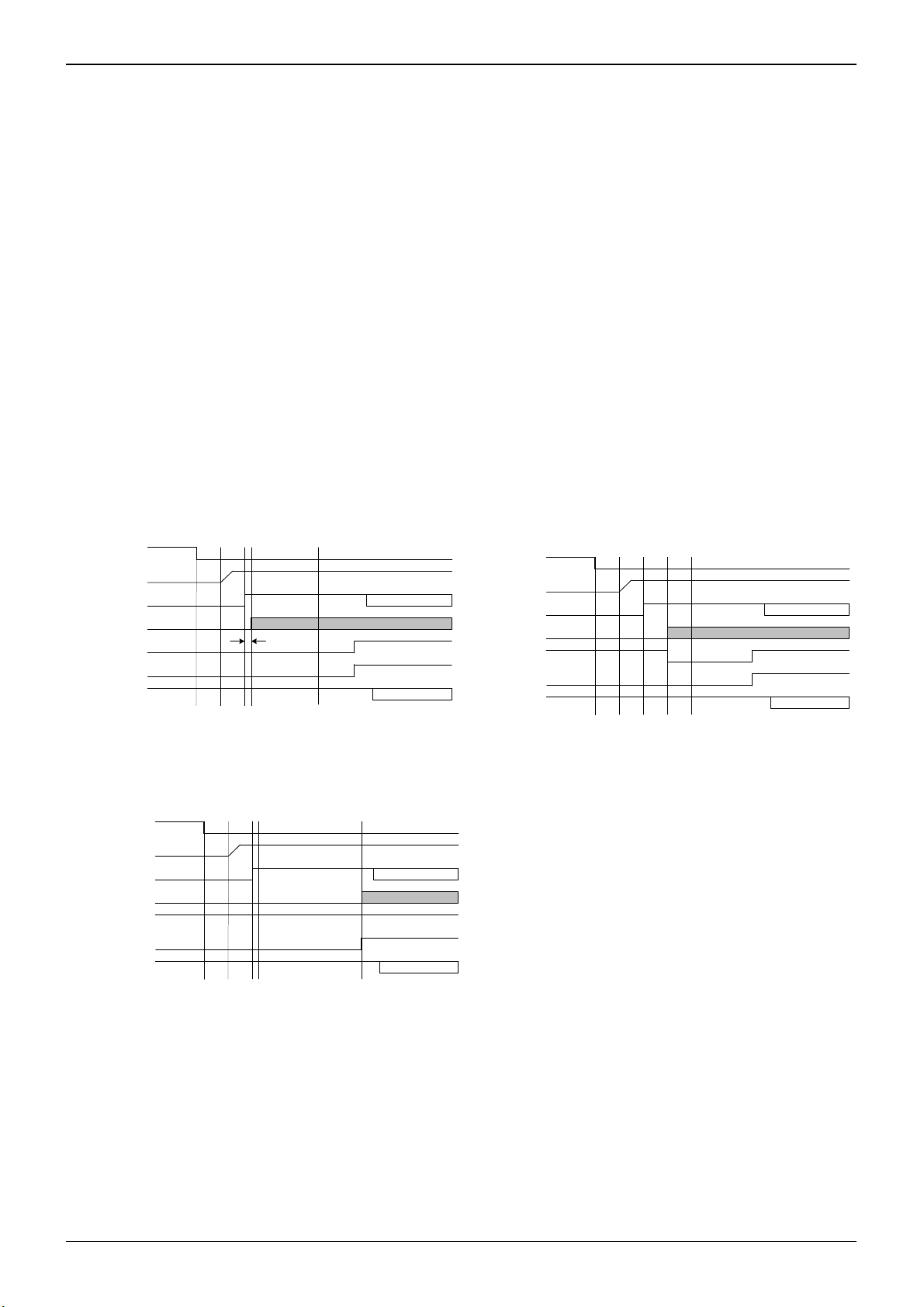

●Package

Package Name: SOP16 Note : X is 8 or 9.

Package Name: SSOP-B16

6.2± 0.3

1.5± 0.1

4.4± 0.2

0.11

6.4±0.3

1.15±0.1

(MAX 10.35 include BURR)

16

BD891XF

1

1PIN MARK

1.27

4.4±0.2

0.10

0.4± 0.1

Fig. 3.1 SOP16 Package Dimension

16

D891X

1

1PIN MARK

0.65

Fig. 3.2 SSOP-B16 Package Dimension

9

Lot No.

8

0.22±0.1

9

8

0.1

0.1

Lot No.

0.15± 0.1

(UNIT : mm)

0.3Min.

0.15±0.1

(UNIT : mm)

Technical Note

0.3MIN

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

7/15

2010.4 - Rev.D

Page 8

BD8918F,BD8918FV,BD8919F,BD8919FV

●Function

1) Power supply

Power supply pins are VDD and VDDP. Set VDD at the same voltage as the signal from the system controller side.

VDDP and CGND are for the 5V power source and GND, respectively, on the card side.

2) Input voltage detector

The IC remains in wait mode until the power on reset is released 16ms after the VDD supply voltage is increased over

Vthd and the VDDP supply voltage is increased over Vthp, making the CMDVCCB signal turn from H to L.

Vthd=1.7V(typ) Vthp=2.25V(typ)

3) Operation sequence

3-1) Wait mode

The IC remains in wait mode until the power on reset is released after the VDD supply voltage is increased over Vthd and

the VDDP supply voltage is increased over Vthp, making the CMDVCCB signal turn from H to L.

In this mode, the VDD and VDDP supply voltage detector (VDET), thermal shutdown circuit (TSD), reference circuit

(VREF) and crystal oscillation circuit (XT OSC) are activated.

IO_U is pulled up to VDD with an 11k resistor and all the card contact pins are at Lo level.

3-2) Card presence

Card presence is detected by PRES pin. When the PRES pin is active, a card is assumed to be present.

Technical Note

Table 1

PRES “High” active

When a card is present in wait mode, the card insertion identification pin, PRES (“H” active) becomes active and OFFB

becomes “H” after approx. 8ms (debounce time).

If a card is present before the VDD and VDDP power sources are applied and the internal reset is released, it is internally

reset and OFFB becomes “H” after the debounce time.

The PRES pin is pulled up to VDD with a 50k resistor.

Descriptions of transition times (example. Debounce time: 8msec) for the operation

sequences are adapted in the conditions of the following input frequency.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

8MHz (BD8918F/ FV), 16MHz (BD8919F/ FV)

8/15

2010.4 - Rev.D

Page 9

BD8918F,BD8918FV,BD8919F,BD8919FV

Technical Note

3-3) Activation sequence

When OFFB is in the “High” state and the CMDVCCB signal from the controller turns from H to L, the activation sequence

starts to activate each functional block in the following order:

The RST outputs signals based on the RSTIN input, being reset approximately 472sec after the CMDVCCB signal turns

from H to L. The RSTIN input becomes effective approximately 48s after I/O TRANS turns ON. If RSTIN becomes Lo

after RSTIN becomes effective and the RST output is released, the CLK signal is output. If RSTIN is High when the RST

output is released, the CLK signal is output as soon as the RST output is released. (Refer to Fig. 4-1, 4-2 and 4-3)

LDO ON (VCC output)

I/O TRANS ON (IO_C, IO_U Bus: Pull-up)

__________________________________________________

When RSTIN remains High until RST is released

(RSTINAlways High) (RSTIN=Always High)

CLK BUF ON (CLK output) CLK, RST BUF ON (CLK output, RST release)

RST BUF ON (RST release)

[Activation sequence under different RSTIN input timings]

CMDVCCB

VCC

IO_C

CLK

RSTIN

RST

IO_U

t0

t1 t2 t3

Min:200ns

t4= tact

ART

CMDVCCB

VCC

IO_C

CLK

RSTIN

RST

IO_U

t0

t1 t2 t3 t4= tact

Fig. 4-1 Activation sequence 1 Fig. 4-2 Activation sequence 2

CMDVCCB

VCC

IO_C

CLK

RSTIN

RST

IO_U

t0

t1 t2 t3 t4= tact

ART

t1: LDO startup time = typ. 24µs

Fig.6-3 立ち上げシーケンス 3

t2: I/O ON time = typ. 424µs

t3: CLK output release time (t3-t2) = Min. 200ns

t4: RST release time = typ,472µs, max.

481s

(Activation time)

Fig. 4-3 Activation sequence 3

(RSTIN input sequence not specified by ISO7816)

ART

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

9/15

2010.4 - Rev.D

Page 10

BD8918F,BD8918FV,BD8919F,BD8919FV

Technical Note

3-4) Deactivation sequence

When the CMDVCCB input turns from L to H or the alarm signal (described later) is detected, the following deactivation

sequence is initiated in the following order, transitioning to the wait mode.

RST BUF OFF (RST: Lo)

CLK BUF OFF (CLK: Lo)

I/O TRANS OFF (I/O Bus on the controller side: Pull-up)

(I/O Bus on the card side: Lo)

LDO OFF (VCC: Lo)

CMDVCCB

RST

CLK

I/O

t11: CLK OFF time = typ. 10µs

t12: I/O OFF time = typ. 20μs

t13: Starting time of VCC fall = typ. 30μs

tde: Operational sequence completion time =Max. 200μs

VCC

t10

t11 t12

tde

t13

Fig. 5 Deactivation sequence

4) LDO

LDO supplies power to the IC card through VCC pin.

This regulator has a built-in over-current limiter circuit. It generates an internal alarm with a load current of approximately

140mA or more and enters into the deactivation sequence. Also, the output voltage is regarded as abnormal if it drops to

less than 1.6V and the output current is shut off; an internal alarm signal is generated and the deactivation sequence is

initiated.

Connect a capacitor of 1µF or 2.2µF between VCC and CGND as close as possible to the VCC pin, in order to reduce

the output voltage variation as much as possible. Also, ensure that ESR is kept at less than 100m.

LDO output is also a power source for CLK, RST and IO_C output. Therefore, the CLK, RST and IO_C output level is the

same as the VCC output level.

5) I/O data transitions

The data line, IO_C - IO_U, transmits/receives two-way data.

The IO_U pin for the controller side is pulled up with an 11k resistor to High (VDD voltage) and card contact pins IO_C

is set to Lo until I/O TRANS becomes ON by the activation sequence.

When I/O TRANS becomes On, IC becomes idle mode and the I/O pin is pulled up with an 11k resistor to keep the

IO_U pin to VDD voltage (High) and the IO_C pin to VCC voltage (High).

The pin which turns to L from H first becomes the master and the other output side becomes the slave between the pins

on the controller side and card contact pins. Then the data are transferred from the master side to the slave side.

When the both signal levels become High, they become idle mode.

When the signal transits from L to H and it passes over a threshold, an active pull-up (100 ns or less) works to drive the

data High at high speed. After the active pull-up is completed, the pin is pulled up with an 11k resistor. After the active

pull-up is completed, the pin is pulled up with an 11k resistor. This function enables signal transmission up to 1MHz.

Also, an over-current limiter of 30mA in the card contact pin, IO_C.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

10/15

2010.4 - Rev.D

Page 11

BD8918F,BD8918FV,BD8919F,BD8919FV

Technical Note

6) Card clock supply

Card clock is supplied from the CLK pin dividing the input frequency of XTAL1 pin with the CLKSEL pin setting. The clock

division switching time is within the 8 clocks of the XTAL1 signal.

The input signal to the XTAL1 pin is made by a crystal oscillator (BD8918F/FV:8Hz, BD8919F/FV:16MHz) between the

XTAL1 pin and XTAL2 pin or external pulse signal.

When a crystal oscillator is used, the voltage between XTAL1 and XTAL2 may decrease to become close to “-1V”, which

is not a problem.

When an external pulse signal is applied to the XTAL1 pin (except for signal input by crystal oscillation), the duty of the

XTAL1 pin should be 48% - 52% and the transition time of the XTAL1 pin should be within 5% of the signal cycle to

ensure the duty factor of 45% - 55% at the CLK pin.

Table 2 Clock frequency selection (f

BD8918F/FV

CLKSEL f

1

0

: Frequency at XTAL1)

XTAL

clk

f

XTAL

f

XTAL

2

BD8919F/FV

CLKSEL f

1

0

f

f

XTAL

XTAL

7) RSTIN input, RST output

The RSTIN input becomes effective after the CMDVCCB signal input turns to L from H, activation sequence is initiated

and approximately 48s after I/O TRANS turns ON. The RST output is released in approximately 472sec (max.

481sec) after the CMDVCCB signal turns from H to L to output a signal based on the RSTIN input.

8) Fault detection

When the following fault state is detected, the circuit enters the wait mode after it generates an internal alarm signal and

is deactivated.

If a card is not present, it remains in the wait mode.

• When the VCC pin becomes less than 1.6V, or is loaded high current (TYP: 140mA)

• When VDDP voltage is less than the threshold voltage (detected by supply voltage detector)

• When a high temperature is detected by the thermal shutdown circuit

• When the card is removed during operation or the card is not present from the beginning (PRES=L)

9) OFFB output

The OFFB output pin indicates the IC is ready to operate. It is pulled up to VDD with a 20k resistor.

When the IC is in the ready state, OFFB is High.

After activation, the OFFB outputs OFF state (Lo) when a fault state is detected.

When a card is present and CMDVCCB becomes High, the internal alarm is released and the OFFB output becomes

High.

PRES

OFFB

CMDVCCB

t

VCC

debounce

t

debounce

t

debounce

Shutdown by card removal Shutdown by short-circuiting of pins

端子ショート等による停止動作カード取り外しによる停止動作

Fig. 6 OFFB, CMDVCCB, PRES, VCC operation

clk

2

4

= typ 8ms

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

11/15

2010.4 - Rev.D

Page 12

BD8918F,BD8918FV,BD8919F,BD8919FV

●An example of software control

Start

OFFB=H ?

No (No card)

Yes (Card detect)

CMDVCCB: H→L

Activation start

↓

Regulator on (VCC)

↓

IO enable (IO)

Card communication start

RSTIN: L→H

↓

Complete

CMDVCCB: L→H

No alarm

Error message 2

・Detects error at card

communication

Deactivation start

↓

IO disable (IO)

↓

Regulator off (VCC)

End

Fig. 7 An example of software control

Error message 1

・Card insert

OFFB=L ?

Deactivation start

IO disable (IO)

Regulator off (VCC)

CMDVCCB: L→H

End

Alarm detect

・Card off

・Over current

・Drop VDDP

・Thermal

shutdown

↓

↓

End

* Ensure to set CMDVCCB LH to confi rm that LSI

could detect alarm at the host side

Technical Note

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

12/15

2010.4 - Rev.D

Page 13

BD8918F,BD8918FV,BD8919F,BD8919FV

_

●Application examples

BD8918F/FV application examples

CONTROLLER

+3.3V

(22pF)

(22pF

)

8MHz

220Ω

XTAL1

XTAL2

VDD

CLKSEL

RSTIN

IO_U

CGND

IO_C

+3. 3V

XTAL 1 GND

VDD

CLKSEL

RSTIN

IO_U

CGND

IO

0.1µF

1

2

3

BD8918F/

4

BD8918FV

5

6

7

8

CARD CONNECTION

1µF

0.22µF

C5C6C1

C7

C8C3C4

16

15

14

13

12

11

10

9

C2

K1

K2

Fig.8

CONTROLLER

0.1uF

1

2

3

BD8918F/

4

BD8918FV

5

6

7

C

8

1uF

CARD CONNECTION

0.2 2 uF

C5C6C1

C2

C7C8C3

C4

K1

K2

Fig.9

GND

CMDVCCB

OFFB

PRES

VDDP

VCC

CLK

RST

16

CMDVCCB

15

OFFB

14

13

VDDP

12

11

10

9

PRES

VCC

CLK

RST

Technical Note

10µF

+5V

10uF

+5V

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

13/15

2010.4 - Rev.D

Page 14

BD8918F,BD8918FV,BD8919F,BD8919FV

Technical Note

BD8919F/FV application examples

CONTROLLER

+3.3V

(22pF)

(22pF)

16MHz

220Ω

XTAL1

XTAL2

VDD

CLKSEL

RSTIN

IO_U

CGND

IO_C

0.1µF

1

2

3

BD8919F/

4

BD8919FV

5

6

7

8

GND

16

CMDVCCB

15

OFFB

14

PRES

13

VDDP

12

VCC

11

CLK

10

RST

9

10µF

+5V

1µF

CARD CONNECTION

0.22µF

C5C6C1

C2

C7

C8C3C4

K1

K2

●Precautions for use

1) The capacitor for the VCC pin should be placed as close as possible to the IC between VCC and CGND so that the ESR

becomes less than 100Ω

2) Connect a capacitor of over 0.1µF for VDD and over 10µF for VDDP as close as possible to the IC so that the ESR

becomes less than 100m to reduce the power line noise. We recommend the use of capacitors with the largest possible

capacitance.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

14/15

2010.4 - Rev.D

Page 15

BD8918F,BD8918FV,BD8919F,BD8919FV

Ordering part number

B D 8 9 1 8 F V - E 2

Part No.

SOP16

SSOP-B16

Part No.

8918

8919

10± 0.2

(MAX 10.35 include BURR)

16

4.4± 0.2

6.2± 0.3

1

1.5± 0.1

1.27

0.10

0.4± 0.1

5.0±0.2

16

4.4±0.2

1

0.65

0.11

6.4±0.3

1.15±0.1

9

0.3MIN

8

0.15± 0.1

0.1

(Unit : mm)

9

0.3Min.

8

0.15±0.1

0.1

0.22±0.1

(Unit : mm)

Package

F: SOP16

FV: SSOP-B16

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

<Tape and Reel information>

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Embossed carrier tapeTape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Packaging and forming specification

E2: Embossed tape and reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Technical Note

Direction of feed

Direction of feed

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

15/15

2010.4 - Rev.D

Page 16

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1010

A

Loading...

Loading...