Power Management Switch ICs for PCs and Digital Consumer Products

1ch High Side Switch ICs

for USB Devices and Memory Cards

BD82061FVJ,BD82065FVJ

●Description

Single channel high side switch IC for USB port is a high side switch having over-current protection used in power supply

line of universal serial bus (USB).

N-channel power MOSFET of low on-resistance and low supply current are realized in this IC.

And, over-current detection circuit, thermal shutdown circuit, under-voltage lockout and soft-start circuit are built in.

●Features

1) Low On-Resistance 70mΩ MOSFET Switch

2) Current Limit Threshold 2.4A

3) Control Input Logic

Active “Low” Control Logic : BD82061FVJ

Active “High” Control Logic : BD82065FVJ

4) Soft-Start Circuit

5) Over-Current Protection

6) Thermal Shutdown

7) Under-Voltage Lockout

8) Open-Drain Error Flag Output

9) Reverse Current Protection When Power Switch Off

10) Power Supply Voltage Range 2.7V~5.5V

11) TTL Enable Input

12) 0.8ms Typical Rise Time

13) 1μA Max Standby Current

●Applications

PC, PC peripheral equipment, USB hub in consumer appliances, Car accessory, and so forth

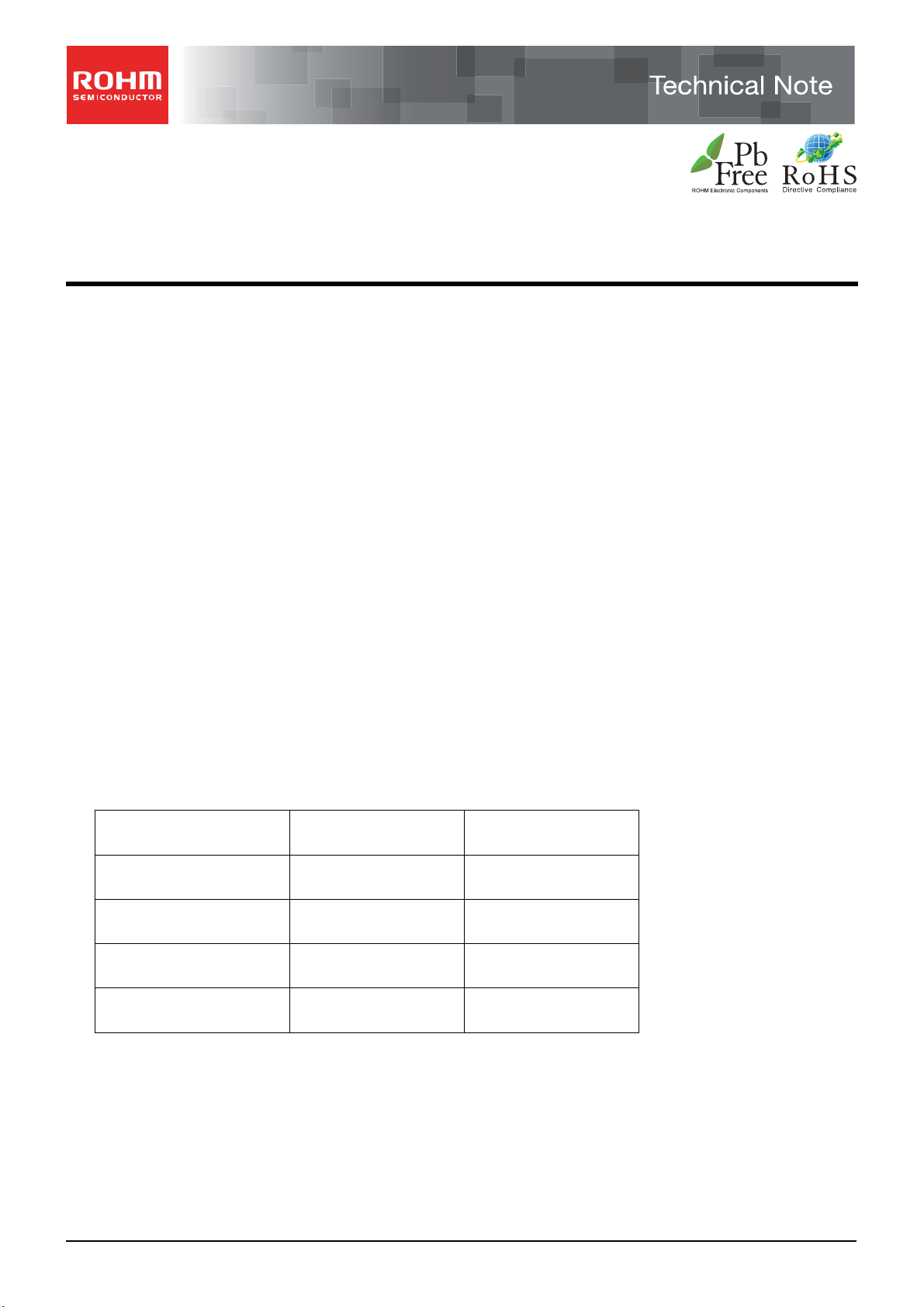

●Line Up Matrix

No.11029EBT21

Parameter BD82061FVJ BD82065FVJ

Current limit threshold (A) 2.4 2.4

Control input logic Low High

Number of channnels 1ch 1ch

Package TSSOP-B8J TSSOP-B8J

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

1/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

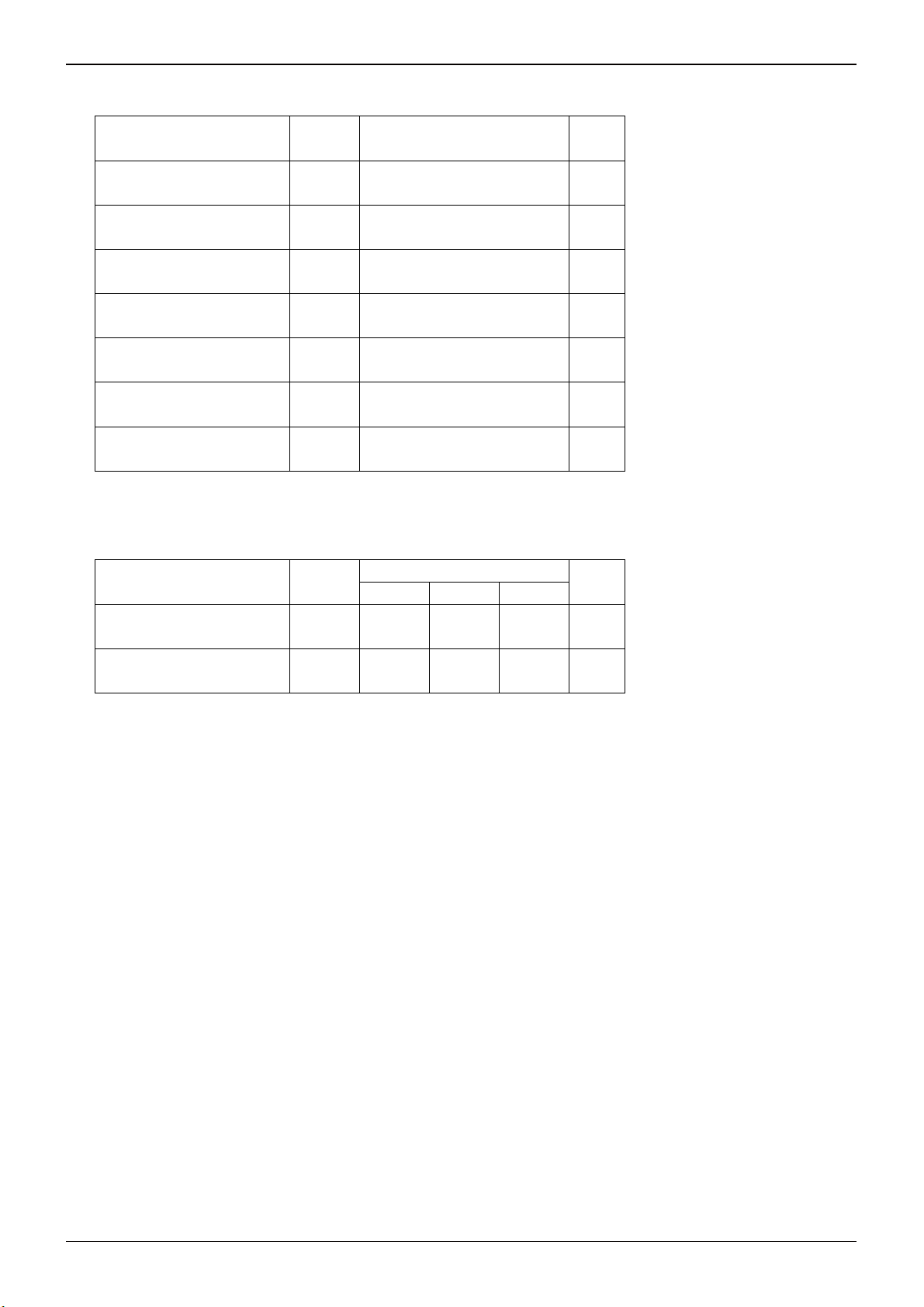

●Absolute maximum ratings(Ta=25℃)

Parameter Symbol Ratings Unit

Supply voltage VIN -0.3 ~ 6.0 V

Enable input voltage VEN -0.3 ~ 6.0 V

/OC voltage V/OC -0.3 ~ 6.0 V

/OC sink current IS/OC ~ 5 mA

OUT voltage VOUT -0.3 ~ 6.0 V

Storage temperature TSTG -55 ~ 150 ℃

Power dissipation Pd 587.5*1 mW

*1 Mounted on 70mm*70mm*1.6mm glass-epoxy PCB. Derating : 4.7mW/℃ above Ta=25℃

* This product is not designed for protection against radioactive rays.

●Operating conditions

Technical Note

Parameter Symbol

Operating voltage VIN 2.7 - 5.5 V

Operating temperature TOPR -40 - 85 ℃

Min. Typ. Max.

Ratings

Unit

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

2/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

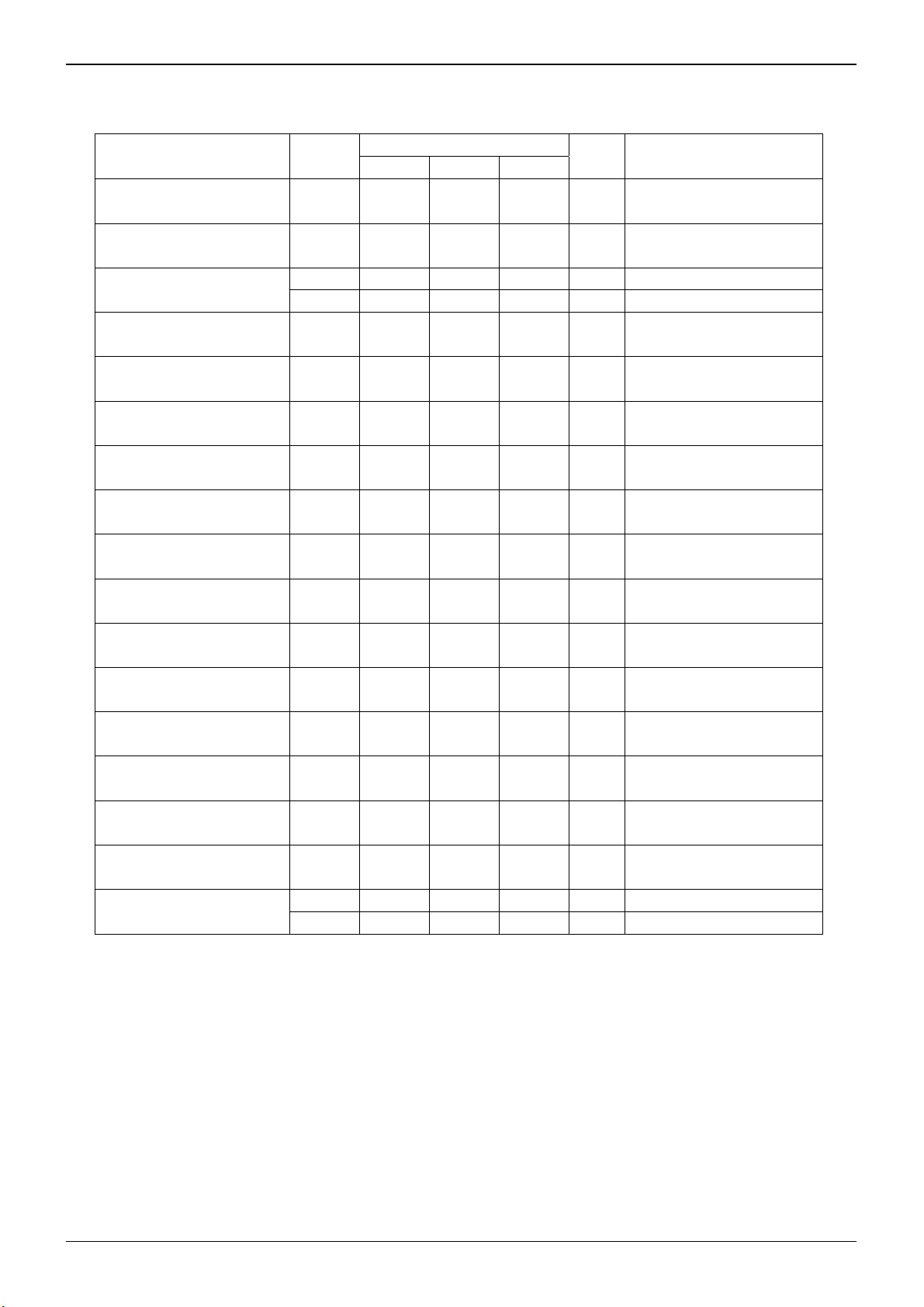

●Electrical Characteristics

Technical Note

○BD82061FVJ (Unless otherwise specified V

Parameter Symbol

IN = 5.0V, Ta = 25℃ )

Limits

Min. Typ. Max.

Unit Condition

Operating current IDD - 110 160 μA V/EN = 0V , OUT=OPEN

Standby current ISTB - 0.01 1 μA V/EN = 5V , OUT=OPEN

/EN 2.0 - - V High input

/EN input voltage

V

V/EN - - 0.8 V Low input

/EN input current I/EN -1.0 0.01 1.0 μA V/EN = 0V or V/EN = 5V

/OC output low voltage V/OCL - - 0.5 V I/OC = 0.5mA

/OC output leak current IL/OC - 0.01 1 μA V/OC = 5V

/OC delay time T/OC 10 15 20 ms

On-resistance RON - 70 110 mΩ IOUT = 500mA

Switch leak current ILSW - - 1.0 μA V/EN = 5V, VOUT = 0V

Reverse leak current ILREV - - 1.0 μA VOUT = 5.5V, VIN = 0V

Current limit threshold ITH 1.5 2.4 3.0 A

OUT = 0V

Short circuit current ISC 1.1 1.5 2.1 A

V

L = 47μF (RMS)

C

Output rise time TON1 - 0.8 10 ms RL = 10Ω

Output turn-on time TON2 - 1.1 20 ms RL = 10Ω

Output fall time TOFF1 - 5 20 μs RL = 10Ω

Output turn-off time T OFF2 - 10 40 μs RL = 10Ω

TUVH 2.1 2.3 2.5 V Increasing VIN

UVLO threshold

V

VTUVL 2.0 2.2 2.4 V Decreasing VIN

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

3/16

2011.05 - Rev.B

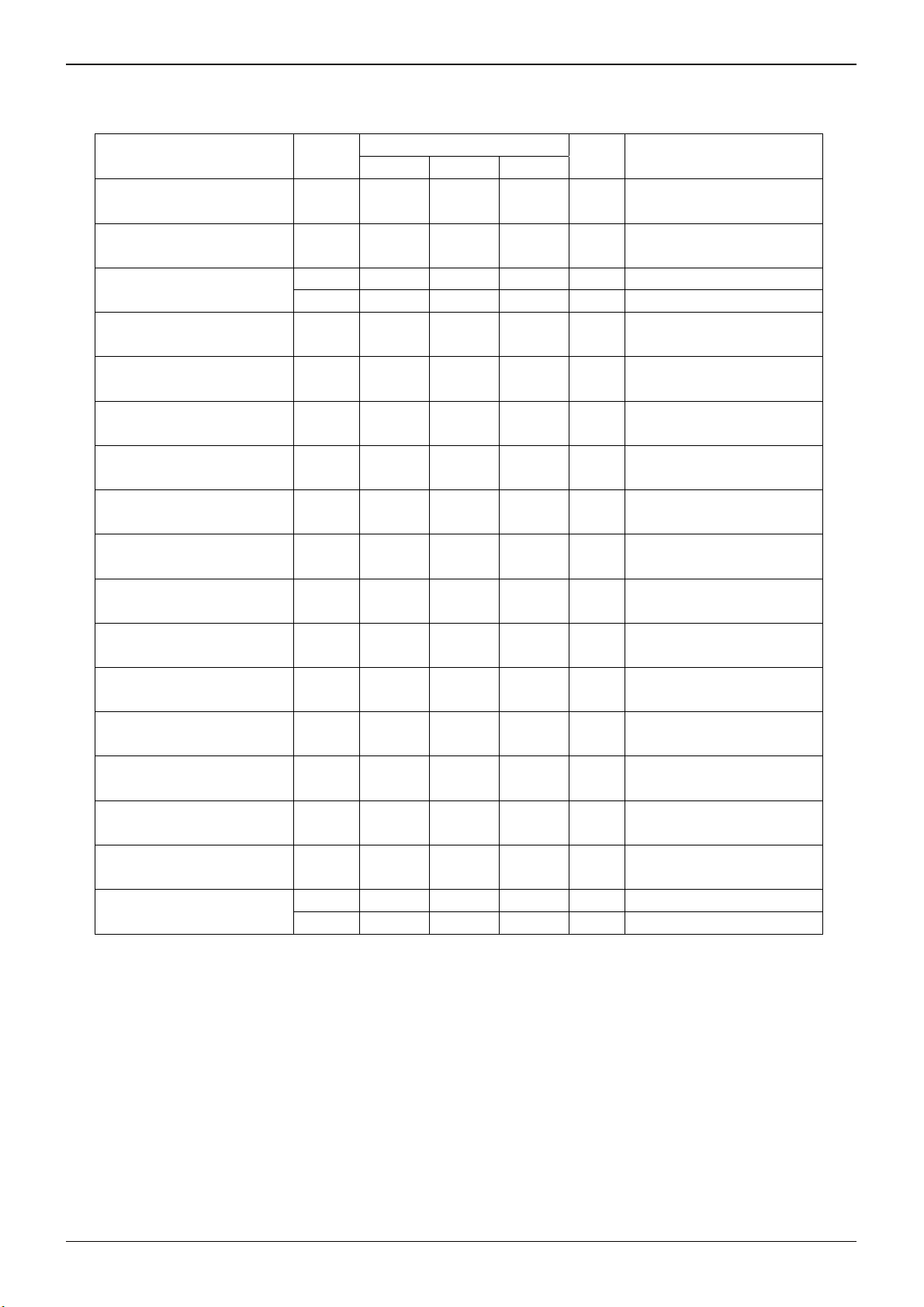

BD82061FVJ,BD82065FVJ

●

Technical Note

○BD82065FVJ (Unless otherwise specified V

Parameter Symbol

IN = 5.0V, Ta = 25℃)

Limits

Min. Typ. Max.

Unit Condition

Operating current IDD - 110 160 μA VEN = 5V , OUT=OPEN

Standby current ISTB - 0.01 1 μA VEN = 0V , OUT=OPEN

EN 2.0 - - V High input

EN input voltage

V

VEN - - 0.8 V Low input

EN input current IEN -1.0 0.01 1.0 μA VEN = 0V or VEN = 5V

/OC output low voltage V/OCL - - 0.5 V I/OC = 0.5mA

/OC output leak current IL/OC - 0.01 1 μA V/OC = 5V

/OC delay time T/OC 10 15 20 ms

On-resistance RON - 70 110 mΩ IOUT = 500mA

Switch leak current ILSW - - 1.0 μA VEN = 0V, VOUT = 0V

Reverse leak current ILREV - - 1.0 μA VOUT = 5.5V, VIN = 0V

Current limit threshold ITH 1.5 2.4 3.0 A

OUT = 0V

Short circuit current ISC 1.1 1.5 2.1 A

V

L = 47μF (RMS)

C

Output rise time TON1 - 0.8 10 ms RL = 10Ω

Output turn-on time TON2 - 1.1 20 ms RL = 10Ω

Output fall time TOFF1 - 5 20 μs RL = 10Ω

Output turn-off time T OFF2 - 10 40 μs RL = 10Ω

TUVH 2.1 2.3 2.5 V Increasing VIN

UVLO threshold

V

VTUVL 2.0 2.2 2.4 V Decreasing VIN

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

4/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

A

/

A

/

T

A

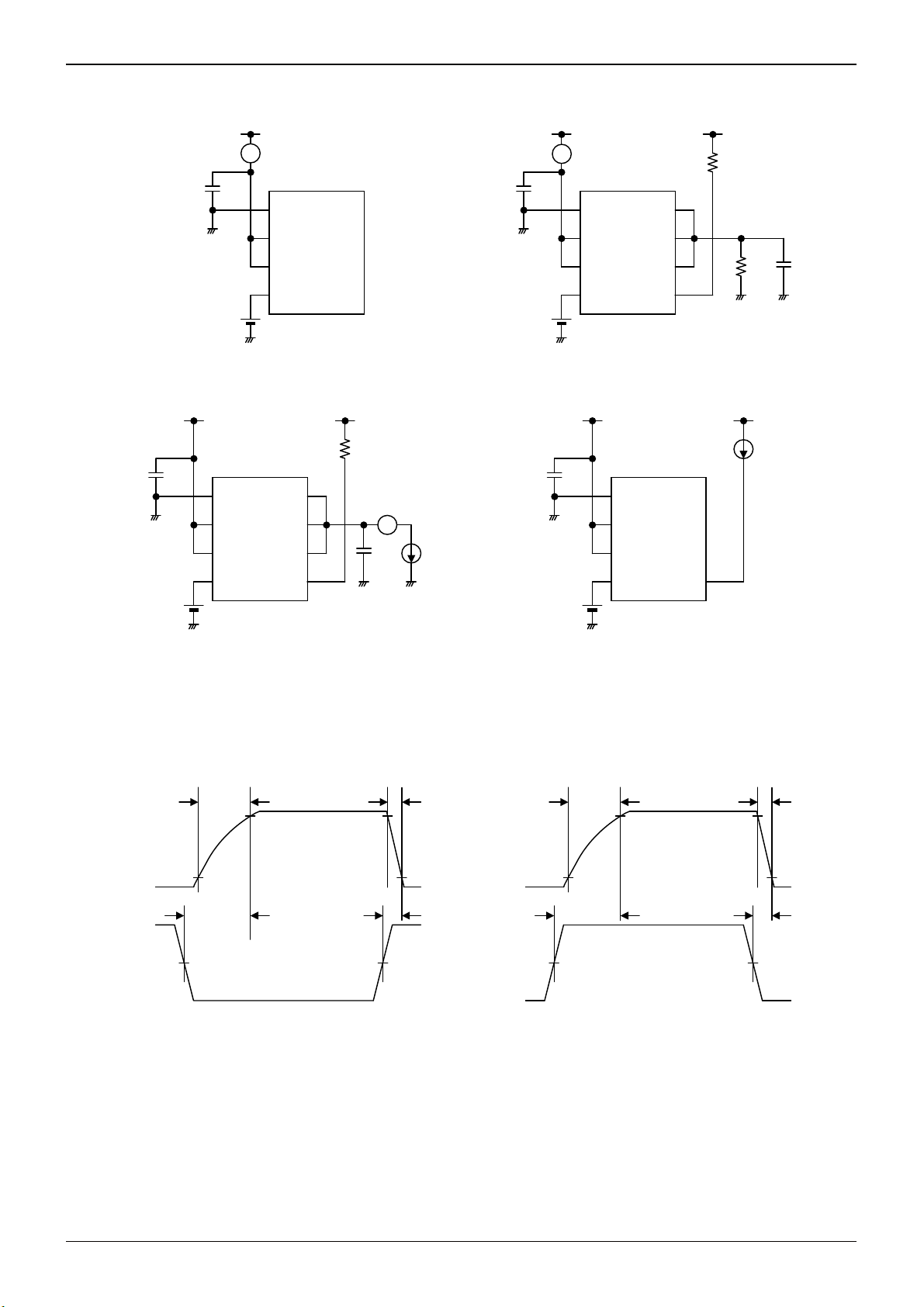

●Measurement Circuit

Technical Note

V

IN

1µF

GND

IN

IN

EN(/EN)

VEN(V

)

/EN

Operating current

OUT

OUT

OUT

/OC

V

IN

1µF

VEN(V

/EN

GND

IN

IN

EN(/EN)

)

OUT

OUT

OUT

OC

EN, /EN input voltage, Output rise, fall time

Inrush current

VIN

10kΩ

RL C

L

VIN VIN

10kΩ

1µF

GND

IN

IN

EN(/EN)

VEN(V

)

/EN

OUT

OUT

OUT

OC

C

I

L

OU

1µF

VEN(V

/EN

V

IN

GND

IN

IN

EN(/EN)

OUT

OUT

OUT

/OC

V

IN

I

/OC

)

On-resistance

Over-current detection

Fig.1 Measurement circuit

●Timing Diagram

○BD82061FVJ ○BD82065FVJ

T

ON1

90% 90%

V

OUT

10%

V

/EN

50%

T

ON2

50%

T

OFF1

T

OFF2

V

Fig.2 Timing diagram

/OC output low voltage

T

OFF1

T

ON1

90%

OUT

10%

T

ON2

V

EN

50%

90%

50%

T

OFF2

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

5/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

w

Technical Note

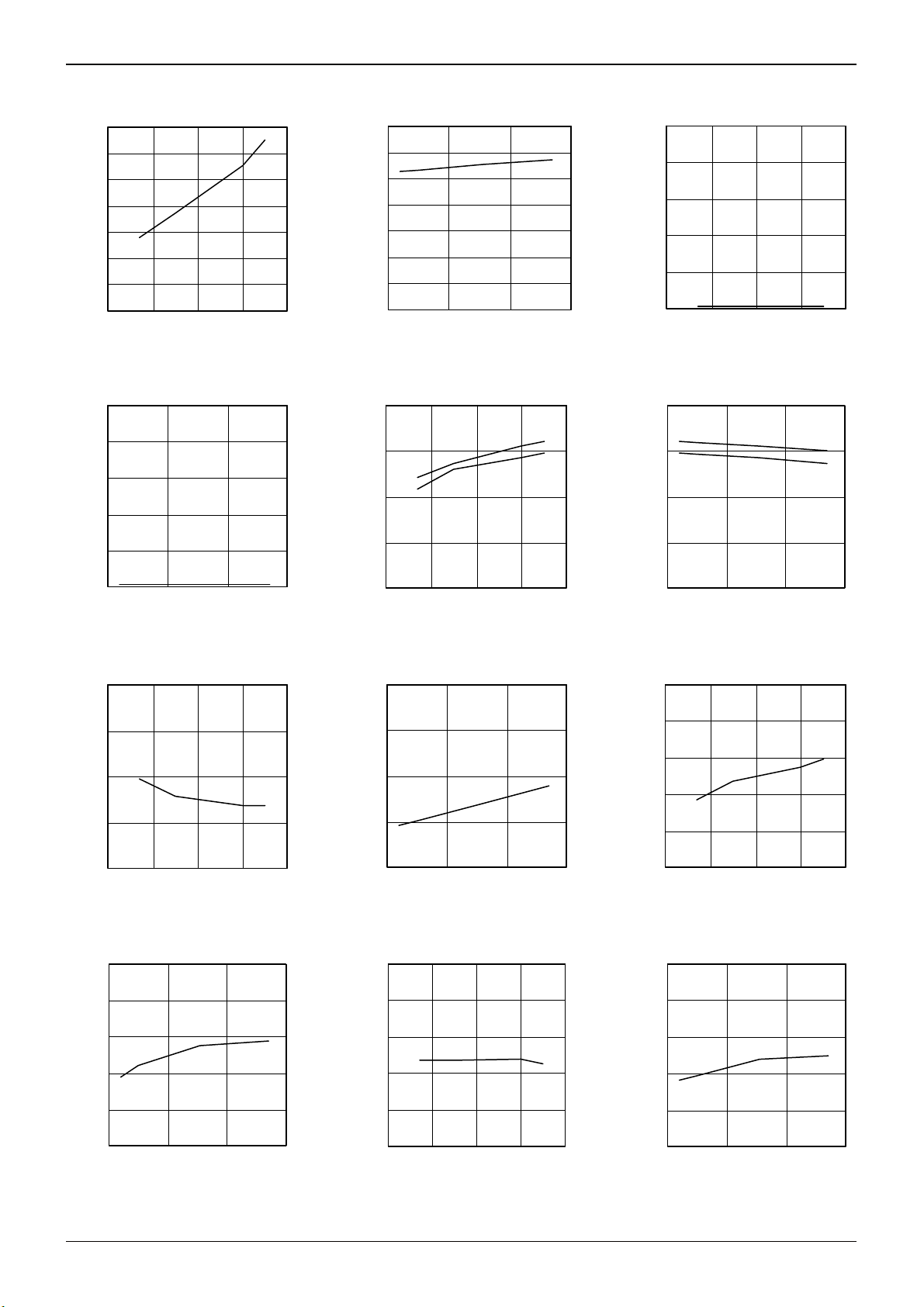

●Electrical Characteristic Curves (Reference Data)

140

Ta= 2 5° C

120

100

80

60

40

Oper ating Cur rent : I D D [µ A]

20

0

23456

Supply Vol tag e : VIN[V]

Fig.3 Operating current

EN,/EN enable

140

IN=5.0V

V

120

100

80

60

40

Oper ating Cur rent : I D D [µ A]

20

0

-50 0 50 100

Ambient Temperature : Ta[℃]

Fig.4 Operating current

EN,/EN enable

1.0

Ta= 2 5°

0.8

0.6

0.4

0.2

Standby C urr ent : I ST B [µA]

0.0

23456

Supply Vol tag e : VIN[V]

Fig.5 Standby current

EN,/EN disable

1.0

V

IN=5.0V

0.8

0.6

0.4

0.2

Standby C urr ent : I ST B [µA]

0.0

-50 0 50 100

200

150

Ambient Temperature : Ta[℃]

Fig.6 Standby current

EN,/EN disable

Ta= 2 5° C

100

2.0

Ta= 2 5° C

Low to High

1.5

High to Low

1.0

0.5

Enable I nput Vol tage : V EN [V]

0.0

23456

Supply Vol tag e : VIN[V]

2.0

IN=5.0V

V

1.5

1.0

0.5

Enable I nput Vol tage : V EN [V]

0.0

-50 0 50 100

Low to High

High to Lo

Ambient Temperature : Ta[℃]

Fig.7 EN,/EN input voltage Fig.8 EN,/EN input voltage

200

150

100

V

IN=5.0V

2.4

2.2

2.0

1.8

Ta= 2 5° C

50

ON Resistsnce : R ON [m O]

0

23456

Supply Vol tag e : VIN[V]

Fig.9 On-resistance

50

ON Resistsnce : R ON [mO]

0

-50 0 50 100

Ambient Temperature : Ta[℃]

Fig.10 On-resistance Fig.11 Current limit threshold

1.6

Curr ent Limi t Threshold : I TH [A]

1.4

23456

Supply Vol tag e : VIN[V]

2.4

V

IN=5.0V

2.2

2.0

Ta= 2 5° C

1.8

2.0

IN=5.0V

V

1.8

2.0

1.8

1.6

1.4

1.6

1.4

1.6

Curr ent Limi t Threshold : I TH[A]

1.4

-50 0 50 100

Ambient Temperature : Ta[℃]

Fig.12 Current limit threshold Fig.13 Short circuit current Fig.14 Short circuit current

1.2

Short-C ir cuit Current : I SC [A]

1.0

23456

Supply Vol tag e : VIN[V]

1.2

Short-C ir cuit C urrent : I SC [A]

1.0

-50 0 50 100

Ambient Temperature : Ta[℃]

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6/16

2011.05 - Rev.B

UVLO

Th

h

ld

V

V

L

BD82061FVJ,BD82065FVJ

100

Ta= 2 5° C

[mV]

/OC

80

100

VIN=5.0V

[mV]

80

/OC

60

40

20

/OC Output Low Volt age : V

0

23456

Fig.15 /OC output low voltage Fig.16 /OC output low voltage

Supply Vol tag e : VIN[V]

60

40

20

0

/OC Out put Low Voltage : V

-50 0 50 100

Ambient Temperature : Ta[℃]

1.0

[V]

HYS

0.8

0.6

5.0

Ta= 2 5° C

4.0

3.0

0.4

0.2

UVLO H ys teres is Voltage : V

0.0

-50 0 50 100

Fig.18 UVLO hysteresis voltage

Ambient T emperatur e : Ta[

]

℃

2.0

Rise Tim e : TON1[m s]

1.0

0.0

23456

Supply Voltag e : VIN[V]

Fig.19 Output rise time

5.0

Ta= 2 5° C

4.0

5.0

V

IN=5.0V

4.0

3.0

3.0

2.0

Turn ON T im e : TON2[m s]

1.0

2.0

Turn ON T ime : TON2[m s]

1.0

0.0

23456

Fig.21 Output turn-on time

Supply Vol tag e : VIN[V]

0.0

-50 0 50 100

Ambient Temperature : Ta[℃]

Fig.22 Output turn-on time

5.0

IN=5.0V

V

4.0

10.0

Ta= 2 5° C

8.0

3.0

2.0

Fall Time : TOFF1[µs]

1.0

6.0

4.0

Turn OFF Time : TOFF2[µs]

2.0

0.0

-50 0 50 100

Ambient Temperature : Ta[℃]

Fig.24 Output fall time

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

0.0

23456

Supply Vol tag e : VIN[V]

Fig.25 Output turn-off time

7/16

Technical Note

2.5

TUV

,

2.4

TUVH

2.3

:

o

2.2

res

2.1

2.0

5.0

4.0

3.0

2.0

Rise Tim e : TON1[m s]

1.0

0.0

5.0

4.0

3.0

2.0

Fall Time : TOFF1[µs]

1.0

0.0

10.0

8.0

6.0

4.0

2.0

Turn OFF Time : TOFF2[µs]

0.0

TUVH

V

V

TUVL

-50 0 50 100

Ambient Temperature : Ta[℃]

Fig.17 UVLO threshold voltage

V

IN=5.0V

-50 0 50 100

Ambient Temperatur e: Ta[℃ ]

Fig.20 Output rise time

Ta= 2 5° C

23456

Supply Vol tag e : VIN[V]

Fig.23 Output fall time

VIN=5.0V

-50 0 50 100

Ambient T emperatur e : Ta[℃]

Fig.26 Output turn-off time

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

]

]

20

18

Ta= 2 5° C

16

14

/OC Del ay Tim e : T /OC[ms

12

10

23456

Supply Vol tag e : VIN[V]

Fig.27 /OC delay time

20

VIN=5.0V

18

16

14

12

/OC Delay Time : T /OC [ms

10

-50 0 50 100

Ambient Temperature : Ta[℃]

Fig.28 /OC delay time

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

8/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

●Waveform Data(BD82065FVJ)

VEN

(5V/div.)

V

/OC

(5V/div.)

V

OUT

(5V/div.)

I

IN

(1.0A/div.)

Fig.29 Output rise characteristic

TIME(1ms/div.)

V

IN=5V

L=5Ω

R

CL=100μF

OUT

V

(5V/div.)

V

/OC

(5V/div.)

OUT

I

(1.0A/div.)

VEN

(5V/div.)

Fig.32 Over-current response

TIME(10ms/div.)

ramped load

VIN=5V

L=100μF

C

V

/OC

(5V/div.)

OUT

V

(5V/div.)

I

OUT

(1.0A/div.)

VIN

(5V/div.)

Fig.34 Over-current response

TIME(5ms/div.)

enable to shortcircuit

V

CL=100μF

OUT

V

(5V/div.)

/OC

V

(5V/div.)

I

OUT

(1.0A/div.)

TIME(10ms/div.)

Fig.37 UVLO response

increasing VIN

R

CL=100μF

IN=5V

L=5Ω

VEN

(5V/div.)

V

/OC

(5V/div.)

V

OUT

(5V/div.)

IN

I

(1.0A/div.)

OUT

V

(5V/div.)

V

/OC

(5V/div.)

OUT

I

(1.0A/div.)

V/OC

(5V/div.)

OUT

V

(5V/div.)

OUT

I

(1.0A/div.)

VIN

(5V/div.)

OUT

V

(5V/div.)

V

/OC

(5V/div.)

OUT

I

(1.0A/div.)

Fig.30 Output fall characteristic

TIME(1ms/div.)

Fig.33 Over-current response

TIME(2ms/div.)

ramped load

Fig.35 Over-current response

1Ωload connected at enable

TIME(5ms/div.)

TIME(10ms/div.)

Fig.38 UVLO response

decreasing V

IN

IN=5V

V

L=5Ω

R

CL=100μF

VIN=5V

L=100μF

C

IN=5V

V

CL=100μF

R

L=5Ω

CL=100μF

VEN

(5V/div.)

V

/OC

(5V/div.)

I

IN

(1.0A/div.)

/OC

V

(5V/div.)

OUT

V

(5V/div.)

OUT

I

(1.0A/div.)

Technical Note

C

L=220µF

L=100µF

C

L=47µF

C

IN=5V

V

L=5Ω

R

Fig.31. Inrush current response

Fig.36 Thermal shutdown

1Ωload connected at enable

TIME(1ms/div.)

Thermal Shutdown

TIME(200ms/div.)

VIN=5V

CL=100μF

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

9/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

●Block Diagram

GND

UVLO IN

Charge

Pump

OCD

OUT

OUT

Technical Note

GND

1

OUT

8

IN

IN

2

3

4

EN

/EN

IN

Gate

Logic

TSD

OUT

/OC

EN(/EN)

Top View

Fig.39 Block diagram Fig.40 Pin configuration

●Pin Configuration

Pin No. Symbol I / O Pin function

1 GND - Ground.

Power supply input.

2, 3 IN -

Input terminal to the power switch and power supply input terminal of the internal circuit.

At use, connect each pin outside.

Enable input.

4 EN , /EN I

Power switch on at Low level.(BD82061FVJ)

Power switch on at High level.(BD82065FVJ)

High level input > 2.0V, Low level input < 0.8V.

Error flag output.

5 /OC O

Low at over-current, thermal shutdown.

Open drain output.

OUT

7

OUT

6

/OC

5

6, 7, 8 OUT O

●I/O Circuit

Symbol Pin No Equivalent circuit

EN(/EN) 4

/OC 5

OUT 6,7,8

Power switch output.

At use, connect each pin outside.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

10/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

●Functional Descriptions

1. Switch operation

IN terminal and OUT terminal are connected to the drain and the source of switch MOSFET respectively. And the IN

terminalis used also as power source input to internal control circuit.

When the switch is turned on from EN, /EN control input, IN terminal and OUT terminal are connected by a 70mΩ switch.

In on status, the switch is bidirectional. Therefore, when the potential of OUT terminal is higher than that of IN terminal,

current flows from OUT terminal to IN terminal.

Since a parasitic diode between the drain and the source of switch MOSFET is canceled, in the off status, it is possible to

prevent current from flowing reversely from OUT to IN.

2. Thermal shutdown circuit (TSD)

If over-current would continue, the temperature of the IC would increase drastically. If the junction temperature were

beyond 170℃ (typ.) in the condition of over-current detection, thermal shutdown circuit operates and makes power

switch turn off and outputs error flag (/OC). Then, when the junction temperature decreases lower than 150℃ (typ.),

power switch is turned on and error flag (/OC) is cancelled. Unless the fact of the increasing chips temperature is

removed or the output of power switch is turned off, this operation repeats.

The thermal shutdown circuit operates when the switch is on (EN,/EN signal is active).

3. Over-current detection (OCD)

The over-current detection circuit limits current (I

MOSFET exceeds a specified value. There are three types of response against over-current. The over-current detection

circuit works when the switch is on (EN,/EN signal is active).

3-1. When the switch is turned on while the output is in shortcircuit status

When the switch is turned on while the output is in shortcircuit status or so, the switch gets in current limit status

soon.

3-2. When the output shortcircuits while the switch is on

When the output shortcircuits or large capacity is connected while the switch is on, very large current flows until the

over-current limit circuit reacts. When the current detection, limit circuit works, current limitation is carried out.

3-3. When the output current increases gradually

When the output current increases gradually, current limitation does not work until the output current exceeds the

over-current detection value. When it exceeds the detection value, current limitation is carried out.

4. Under-voltage lockout (UVLO)

UVLO circuit prevents the switch from turning on until the V

the switch turns on, then UVLO shuts off the power switch. UVLO has hysteresis of a 100mV(Typ.).

Under-voltage lockout circuit works when the switch is on (EN,/EN signal is active).

5. Error flag (/OC) output

Error flag output is N-MOS open drain output. At detection of over-current, thermal shutdown, low level is output.

Over-current detection has delay filter. This delay filter prevents instantaneous current detection such as inrush current at

switch on, hot plug from being informed to outside.

SC) and outputs error flag (/OC) when current flowing in each switch

IN exceeds 2.3V(Typ.). If the VIN drops below 2.2V(Typ.) while

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

11/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

V/EN

Technical Note

V

OUT

OUT

I

/OC

V

VEN

V

OUT

OUT

I

V/OC

Output shortcircuit

Thermal shut down

delay

Fig.41 Over-current detection, thermal shutdown timing

(BD82061FVJ)

Output shortcircuit

Thermal shut down

delay

Fig.42 Over-current detection, thermal shutdown timing

(BD82065FVJ)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

12/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

r

(

/EN)

●Typical application Circuit

5V(typ.)

IN

Regulator

OUT

10k~

USB

Controlle

●Application Information

When excessive current flows owing to output shortcircuit or so, ringing occurs by inductance of power source line to IC,

and may cause bad influences upon IC actions. In order to avoid this case, connect a bypath capacitor by IN terminal and

GND terminal of IC. 1μF or higher is recommended.

Pull up /OC output by resistance 10kΩ ~ 100kΩ.

Set up value which satisfies the application as CL and Ferrite Beads.

This system connection diagram doesn’t guarantee operating as the application.

The external circuit constant and so on is changed and it uses, in which there are adequate margins by taking into account

external parts or dispersion of IC including not only static characteristics but also transient characteristics.

100kΩ

IN

C

Fig.43 Typical application circuit

GND

IN

EN

OUT

OUTIN

OUT

/OC

+

C

L

-

Technical Note

Ferrite

Beads

VBUS

D+

D-

GND

Ferrite

Beads

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

13/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

●Power Dissipation Character

(TSSOP-B8J)

600

500

400

300

200

POWER DISSIPATION: Pd[mW]

100

Technical Note

0

0 25 50 75 100 125 150

AMBIENT TEMPERATURE: Ta [℃]

Fig.44 Power dissipation curve (Pd-Ta Curve)

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

14/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

●Cautions On Use

(1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can

break down devices, thus making impossible to identify breaking mode such as a short circuit or an open circuit. If any

special mode exceeding the absolute maximum ratings is assumed, consideration should be given to take physical safety

measures including the use of fuses, etc.

(2) Operating conditions

These conditions represent a range within which characteristics can be provided approximately as expected. The

electrical characteristics are guaranteed under the conditions of each parameter.

(3) Reverse connection of power supply connector

The reverse connection of power supply connector can break down ICs. Take protective measures against the

breakdown due to the reverse connection, such as mounting an external diode between the power supply and the IC’s

power supply terminal.

(4) Power supply line

Design PCB pattern to provide low impedance for the wiring between the power supply and the GND lines. In this regard,

for the digital block power supply and the analog block power supply, even though these power supplies has the same

level of potential, separate the power supply pattern for the digital block from that for the analog block, thus suppressing

the diffraction of digital noises to the analog block power supply resulting from impedance common to the wiring patterns.

For the GND line, give consideration to design the patterns in a similar manner.

Furthermore, for all power supply terminals to ICs, mount a capacitor between the power supply and the GND terminal. At

the same time, in order to use an electrolytic capacitor, thoroughly check to be sure the characteristics of the capacitor to be

used present no problem including the occurrence of capacity dropout at a low temperature, thus determining the constant.

(5) GND voltage

Make setting of the potential of the GND terminal so that it will be maintained at the minimum in any operating state.

Furthermore, check to be sure no terminals are at a potential lower than the GND voltage including an actual electric transient.

(6) Short circuit between terminals and erroneous mounting

In order to mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs. Erroneous mounting can

break down the ICs. Furthermore, if a short circuit occurs due to foreign matters entering between terminals or between

the terminal and the power supply or the GND terminal, the ICs can break down.

(7) Operation in strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

(8) Inspection with set PCB

On the inspection with the set PCB, if a capacitor is connected to a low-impedance IC terminal, the IC can suffer stress.

Therefore, be sure to discharge from the set PCB by each process. Furthermore, in order to mount or dismount the set

PCB to/from the jig for the inspection process, be sure to turn OFF the power supply and then mount the set PCB to the

jig. After the completion of the inspection, be sure to turn OFF the power supply and then dismount it from the jig. In

addition, for protection against static electricity, establish a ground for the assembly process and pay thorough attention

to the transportation and the storage of the set PCB.

(9) Input terminals

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the

parasitic element can cause interference with circuit operation, thus resulting in a malfunction and then breakdown of the

input terminal. Therefore, pay thorough attention not to handle the input terminals, such as to apply to the input terminals

a voltage lower than the GND respectively, so that any parasitic element will operate. Furthermore, do not apply a voltage

to the input terminals when no power supply voltage is applied to the IC. In addition, even if the power supply voltage is

applied, apply to the input terminals a voltage lower than the power supply voltage or within the guaranteed value of

electrical characteristics.

(10) Ground wiring pattern

If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND

pattern from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that

resistance to the wiring pattern and voltage fluctuations due to a large current will cause no fluctuations in voltages of the

small-signal GND. Pay attention not to cause fluctuations in the GND wiring pattern of external parts as well.

(11) External capacitor

In order to us

degradation in the nominal capacitance due to DC bias and changes in the capacitance due to temperature, etc.

(12) Thermal shutdown circuit (TSD)

When junction temperatures become detected temperatures or higher, the thermal shutdown circuit operates and turns a

switch OFF. The thermal shutdown circuit is aimed at isolating the LSI from thermal runaway as much as possible. Do not

continuously use the LSI with this circuit operating or use the LSI assuming its operation.

(13) Thermal design

Perform thermal design in which there are adequate margins by taking into account the power dissipation (Pd) in actual

states of use.

e a ceramic capacitor as the external capacitor, determine the constant with consideration given to a

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

15/16

2011.05 - Rev.B

BD82061FVJ,BD82065FVJ

●Ordering part number

B D 8 2 0 6 1 F V J - E 2

Part No.

TSSOP-B8J

Part No.

82061

82065

3.0± 0.1

(MAX 3.35 include BURR)

3.0± 0.1

4.9± 0.2

1234

0.525

1.1MAX

0.85±0.05

0.1±0.05

0.65

578

6

1PIN MARK

+0.05

0.32

−0.04

S

0.08 S

0.08

4 ± 4

0.45± 0.15

0.145

M

0.95± 0.2

+0.05

−0.03

(Unit : mm)

Package

FVJ : TSSOP-B8J

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

1pin

Reel

Packaging and forming specification

E2: Embossed tape and reel

Order quantity needs to be multiple of the minimum quantity.

∗

Technical Note

Direction of feed

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

16/16

2011.05 - Rev.B

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, of ce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes effor ts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...