A

Power Supply ICs for TFT-LCD Panels

5V Input Multi-channel

System Power Supply ICs

BD8163EFV

●Description

The BD8163EFV is a system power supply IC for TFT panels. A 1-chip IC providing a total of four voltages required for TFT

panels, i.e., logic voltage, sauce voltage, gate high-level, and gate low-level voltage, thus constructing a TFT panel power

supply with minimal components required.

●Features

1) Operates in an operating voltage range as low as 2.1 V to 6. 0 V.

2) Incorporates a step-up DC/DC converter.

3) Incorporates a 2.5 V regulator.

4) Incorporates positive and negative-side charge pumps.

5) Switching frequency of 1100 kHz

6) DC/DC converter feedback voltage of 1.24 V ± 1%

7) Incorporates a gate shading function

8) Under-voltage lockout protection circuit

9) Thermal shutdown circuit

10) Overcurrent protection circuit

11) HTSSOP-B24 package

●Applications

Liquid crystal TV, PC monitor, and TFT-LCD panel

●Absolute maximum ratings (Ta = 25℃)

Parameter Symbol Ratings Unit

No.10035EAT13

Power supply voltage VCC 7 V

Vo1 voltage Vo1 19 V

Vo2 voltage Vo2 32 V

SW voltage Vsw 19 V

Maximum junction temperature Tjmax 150 ℃

Power dissipation Pd 1100* mW

Operating temperature range Topr -40 to 125 ℃

Storage temperature range Tstg -55 to 150 ℃

* Reduced by 4.7 mW/℃ over 25℃, when mounted on a glass epoxy board. (70 mm 70 mm 1.6 mm).

●Recommended Operating Ranges

Ratings

Parameter Symbol

Min. Max.

Power supply voltage VCC 2.1 6 V

Vo1 voltage Vo1 8 18 V

Vo2 voltage Vsw — 18 V

SW Current Isw — 1.8 A

Vo2 Current Vo2 — 30 V

Unit

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

1/21

2010.12 - Rev.

A

BD8163EFV

●Electrical Characteristics (Unless otherwise specified, VCC = 5 V; Vo1 = 15 V; Vo2 = 25 V; Ta = 25℃)

1 DC/DC Converter Block

Limits

Parameter Symbol

Unit Conditions

Min. Typ. Max.

[Soft start]

Source current Iso 6 10 14 μA Vss = 0.5 V

Sinking current Isi 0.1 0.2 1.0 mA Vss = 0.5 V, VDD = 1.65 V

[Error amp]

Technical Note

Input bias current 1 I

Feedback voltage 1 V

— 0.1 0.5 μA

FB1

1.227 1.240 1.253 V Buffer

FB1

Voltage gain AV — 200 — V/V *

Sinking current IoI 25 50 100 μA VFB = 1.5 V VCOMP = 0.5 V

Source current Ioo -100 -50 -25 μA VFB = 1.0 V VCOMP = 0.5 V

[SW]

ON resistance N-channel R

Leak current N-channel I

Maximum duty cycle D

50 200 600 mΩ *

ON_N

— — 10 μA Vsw = 18 V

LEAKN

75 85 95 %

MAX

[Overcurrent protection]

Saw current limit Insw 2 3 — A *

2. Regulator controller

Limits

Parameter Symbol

Unit Conditions

Min. Typ. Max.

[Error amp]

VDD voltage VDD 2.4 2.5 2.6 V

Maximum base current I

Line regulation RegI — 10 30 mV Vcc = 4.5 V to 5.5 V

Load regulation RegL — 10 50 mV Io = 10 mA to 100 mA

[Under-voltage lockout protection]

Off threshold voltage V

On threshold voltage V

This product is not designed for protection against radioactive rays.

* Design guarantee (No total shipment inspection is made.)

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

2 7 15 mA

BMAX

1.7 1.8 1.9 V

ROFF

1.6 1.7 1.8 V

RON

2/21

2010.12 - Rev.

A

BD8163EFV

3. Charge pump

Parameter Symbol

[Error amp]

Technical Note

Limits

Unit Conditions

Min. Typ. Max.

Input bias current 2 I

Input bias current 3 I

Feedback voltage 2 V

Feedback voltage 3 V

— 0.1 0.5 μA

FB2

— 0.1 0.5 μA

FB3

1.183 1.240 1.307 V

FB2

0.15 0.2 0.25 V

FB3

[Delay start block]

Source current I

Sinking current I

3 5 7 μA VDLS = 0.5V

DSO

0.1 0.5 1.0 mA VDLS = 0.5V

DSI

Startup voltage VST 0.45 0.60 0.75 V

[Switch]

ON resistance N-channel R

ON resistance P-channel R

0.5 2 4 Ω Io = 10 mA *

ON_NC

0.5 4 8 Ω Io = -10 mA *

ON_PC

[Diode]

Voltage of diode Vf

600 710 800

mV Io = 10 mA

[Gate shading block]

ON resistance N-channel R

ON resistance P-channel R

Leak current N-channel I

Leak current P-channel I

LEAK_NG

LEAK_PG

2 10 20 Ω Io = 10 mA *

ON_NGS

2 10 20 Ω Io = -10 mA *

ON_PGS

S — — 10 μA

S — — 10 μA

High voltage IGH VDD × 0.7 VDD — V

Low voltage IGL — 0 VDD × 0.3 V

Input current IIG 8 16.5 30 μA IG = 3.3 V

This product is not designed for protection against radioactive rays.

* Design guarantee (No total shipment inspection is made.)

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

3/21

2010.12 - Rev.

A

BD8163EFV

4. Overall

Parameter Symbol

[Reference block]

Technical Note

Limits

Unit Conditions

Min. Typ. Max.

Reference voltage V

Drive current I

1.215 1.240 1.265 V

REF

— 23 — mA VREF = 0 V

REF

Load regulation ∆V — 1 10 mV IREF = -1 mA

[Oscillator]

Oscillating frequency Fosc 0.94 1.1 1.265 MHz

[Oscillator]

DET 1 On threshold voltage V

DET 1 Off threshold voltage V

DET 2 On threshold voltage V

DET 2 Off threshold voltage V

DET 3 On threshold voltage V

1.7 1.8 1.9 V

DON1

1.6 1.7 1.8 V

DOFF1

1.02 1.12 1.22 V

DON2

0.90 1.00 1.10 V

DOFF2

0.25 0.30 0.35 V

DON3

DET 3 Off threshold voltage V

DET 4 On threshold voltage V

DET 4 Off threshold voltage V

0.35 0.41 0.47 V

DOFF3

1.02 1.12 1.22 V

DON4

0.90 1.00 1.10 V

DOFF4

[Device]

Average circuit current Icc 0.5 2 5 mA No switching

This product is not designed for protection against radioactive rays.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

4/21

2010.12 - Rev.

A

BD8163EFV

●Reference Data (Unless otherwise specified, Ta = 25℃)

1

0.8

0.6

0.4

0.2

SUPPLY CURRENT : ICC[mA] .

0

01.5 34.56

Fig. 1 Total Supply Current 1

125℃

25℃

-40℃

SUPPLY VOLTAGE : VCC [V]

10

8

6

4

2

SUPPLY CURRENT : IDD[mA] .

0

01.534.56

SUPPLY VOLTAGE : VD D[V]

Fig. 2 Total Supply Current 2

1.6

1.6

1.2

1.2

0.8

0.8

0.4

REF VO LTAGE : VREF [V]

0.4

REF VO LTAGE : VREF [V]

0

01.534.56

SUPPLY VOLT AGE : VCC[ V]

Fig. 4 Internal

Reference Line Regulation

12

10

8

6

0

0 5 10 15 20 25 30

REF CURRENT : IREF[mA]

Reference Load Regulation

2

1.5

1

4

2

DLS SOURCE CURRENT : IDLS[µA] .

0

01.534.56

SUPPLY VOLT AGE : VD D[V]

Fig. 7 DLS Source Current

0.5

0

SWITCHHING FREQUENCY : f [MHz] .

-50 - 25 0 25 50 75 100 125

-40

AMBIEN T T EMPER ATU RE : T a[

Fig. 8 Switching Frequency

200

160

120

80

40

SW VOLTAGE : VSW [V] .

0

0 0.2 0.4 0.6 0.8 1

SW CURRENT : ISW [A]

Fig. 10 SW On Resistance

200

160

120

80

40

OUTPUT VOLTAGE : Vcp[mV].

0

0 20 40 60

INPUT CURRENT : Icp[mA]

Fig. 11 Charge Pump

125℃

Fig. 5 Internal

Temperature

N channel

P channel

On Voltage

25℃

-40℃

80

Technical Note

1.26

1.25

1.24

1.23

REF VO LTAGE : VREF [V]

1.22

-50 - 25 0 25 50 75 100 125

AMBIENT TEM PERATU RE : Ta[℃]

Fig. 3 Internal Reference

Temperature

12

10

8

6

4

2

SS SOURCE CURRENT : ISS[µA] .

0

01.5 34.56

SUPPLY VOLT AGE : VDD[V]

Fig. 6 SS Source Current

5

4

3

2

VDD VOLTAGE : VDD[V]

1

0

0246810

]

℃

GS VOLTAGE : Vgs[V]

100

BASE CURRENT : IBASE[mA]

Fig. 9 REG Current Capacity

1

0.8

0.6

N channel

0.4

0.2

0

0

20

GS CURRENT : Igs[mA]

P channel

40 60 80 100

Fig. 12 Gate Shading

On Voltage

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

5/21

2010.12 - Rev.

A

BD8163EFV

●Reference Data (Unless otherwise specified, Ta = 25℃)

15

10

5

OUT PUT VOLT AGE : VD D [V ]

0

01.534.56

SUPPLY VOLT AGE : VCC [ V]

Fig. 13 Vo1 Line Regulation

5

4

3

2

1

OUTPU T VOLTAGE : VDD[V]

0

0 0.4 0.8 1.2 1.6 2

OUTPUT CURRENT : IDD[mA]

Fig. 14 VDD Load Regulation

14

13

12

13V

12V

100

95

90

11

OUT PUT VOLT AGE : VO1[V]

10

0 100 200 300 400 500 600 700

Fig. 16 Vo1 Load Regulation

10.8V

OUTPUT CURRENT : IO[mA]

EFFICIENCY [ % ]

85

80

0 150 300 450 600

OUTPUT CURRENT : IO1[mA]

Fig. 17 Efficiency vs Output Current

1600

1200

23.8

23.7

800

23.6

400

MAXIMUM CURRENT : IoMAX[mA] .

0

1.5 3 4.5 6

SUPPLY VOLT AGE : VCC[ V]

23.5

OUT PUT VOLT AGE : VO2[V]

23.4

10 11.5 13 14.5 16

INPU T VOLTAGE : Vo1[v]

Fig. 19 Power Supply Voltage vs

Max. Output Current Capacity

Fig. 20 Vo2 Line Regulation Fig. 21 Vo2 Load Regulation

-6

-6

-6.1

-6.1

-6.2

-6.2

-6.3

OUT PUT VOLT AGE : VO3[V]

-6.4

10 11 12 13 14 15

INPU T VOLTAGE : VO 1[V]

Fig. 22 Negative-side Charge

Pump Line Regulation

-6.3

OUT PUT VOLT AGE : VO1[V]

-6.4

0 50 100 150 200

OUTPUT C UR RENT : IO[mA]

Fig. 23 Negative-side Charge

Pump Load Regulation

10.8V 12V 13V

Technical Note

12.5

12.4

12.3

12.2

12.1

12.0

11.9

11.8

Vo1 VOLT AGE : VO 1[V]

11.7

11.6

11.5

23 456

SUPPLY VOLT AGE : VCC[ V]

Fig. 15 Vo1 Line Regulation

100

90

80

EFFICIENCY [ % ]

70

60

2.5 3 3. 5 4 4. 5 5 5.5 6

SUPPLY VOLT AGE : VCC[ V]

Fig. 18 Efficiency vs Power

Supply Voltage

24

23.8

23.6

23.4

23.2

OUT PUT VOLTAGE : VO2[V]

23

0 50 100 150

OUTPUT CURRENT : IO2[mA]

IG

VO2GS

Fig. 24 Gate Shading

Output Waveform

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

6/21

2010.12 - Rev.

A

BD8163EFV

●Block Diagram

0.1µF

5.1k

1000pF

0.1µF

0.1µF

Ω

REF

COMP

DLS

Vcc

1µF

Technical Note

VREF

DET2

VCC

Regulator

Control

10µF

Step-up

Controller

Charge

Pump

Control 1

DET4

VDD

4.7µF

VCC

Vo1

Gate

Shading

Controller

Charge

Pump

Control 2

DET1

1.8V

VDD=2.5V

VCC

5V

SS

TSD

UVLO

Step-up

Controller

IG

BASE

Fig. 25 Block Diagram

PGND

DET4

PGND

Vo1

10µF

SW

Vo1

DET3

GND

DET2

1.1V

0.3V

GND

Vo1

1.1V

FB1

Vo2

C2H

C2L

C1H

C1L

FB2

Vo2GS

GSOUT

C3

0.1µF

FB3

10µF

0.1µF

0.1µF

160k

15kΩ

1µF

R

1µF

Ω

270k

Ω

16kΩ

0.01µF

91k

18kΩ

Vo1=14.5V (18V MAX)

Vo2 23.5V (30V MAX)

Vo2GS

Vo3=-5V

Ω

REF

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

7/21

2010.12 - Rev.

A

BD8163EFV

●Pin Assignments Diagram

GND

VDD

BASE

VCC

DLS

COMP

FB1

SS

PGND

SW

IG

FB2

REF

FB3

GND

C3

Vo1

C1H

C1L

C2L

C2H

GSOUT

Vo2GS

Vo2

Pin Arrangements

●Pin Assignments and Function

PIN

NO.

Pin

name

Function

PIN

NO.

Pin

name

Function

1 GND Ground pin 13 Vo2 Positive-side charge pump output

Technical Note

2 VDD LDO feedback input pin 14 Vo2GS Gate shading source output pin

3 BASE LDO base drive output pin 15 GSOUT Gate shading sink output pin

4 VCC Power supply input pin 16 C2H Flying capacitor connection pin

5 DLS Capacity connection pin for delay start 17 C2L Flying capacitor connection pin

6 COMP DC/DC difference amplifier output 18 C1L Flying capacitor connection pin

7 FB1 DC/DC feedback input 19 C1H Flying capacitor connection pin

8 SS Soft start capacitor connection pin 20 Vo1

Negative-side charge pump power

supply input pin

9 PGND Ground pin 21 C3 Negative-side charge pump driver output

10 SW Switch output 22 GND Ground pin

11 IG Gate shading input 23 FB3

12 FB2

Positive-side charge pump feedback

input

24 REF Internal standard output pin

Negative-side charge pump feedback

input

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

8/21

2010.12 - Rev.

A

BD8163EFV

Technical Note

●Block Function

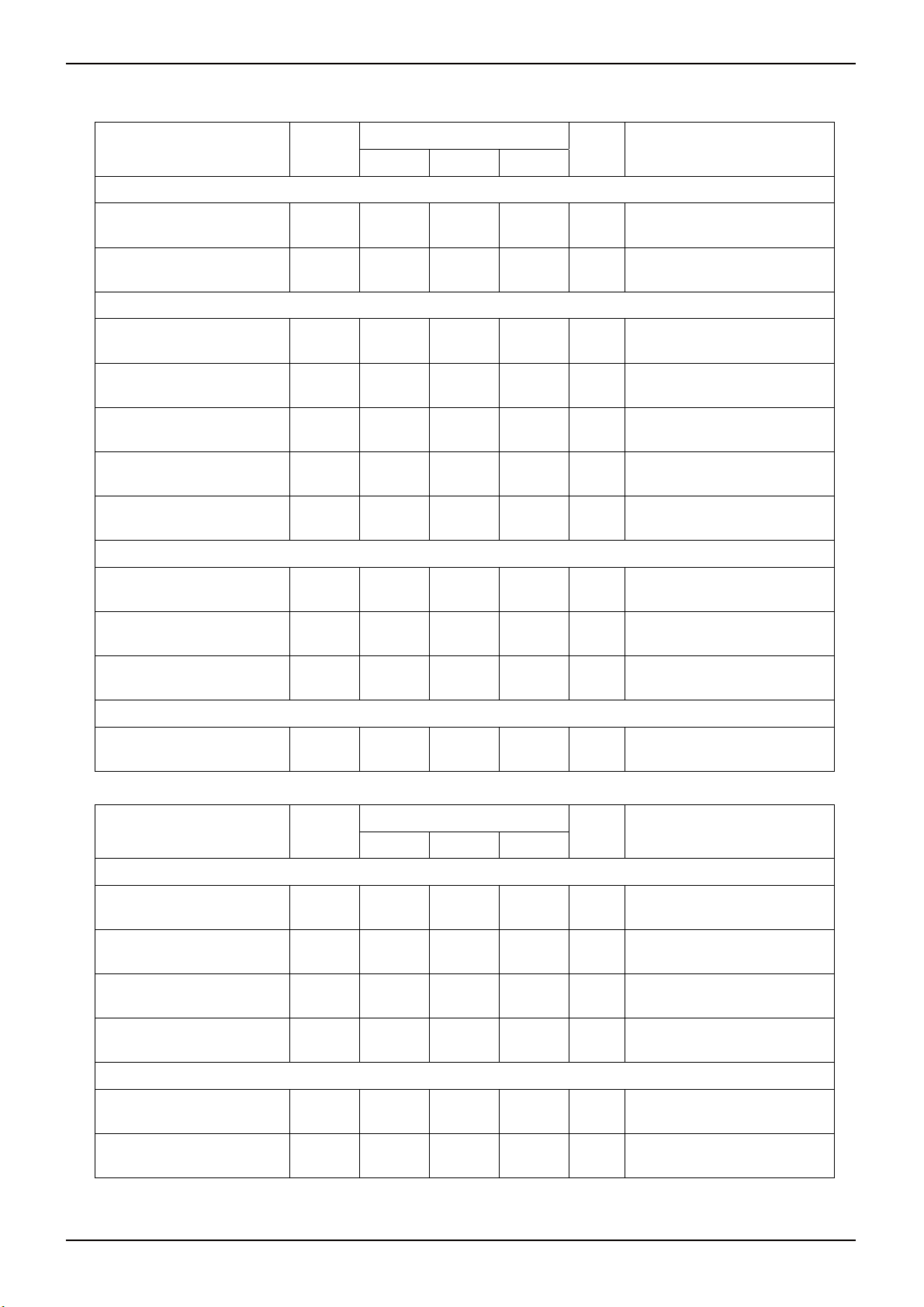

・Step-up Controller

A controller circuit for DC/DC boosting.

The switching duty is controlled so that the feedback voltage FB1 is set to 1.24 V (typ.). A soft start operates at the time of

starting. Therefore, the switching duty is controlled by the SS pin voltage.

・Charge Pump Control 1

A controller circuit for the positive-side charge pump.

The switching amplitude is controlled so that the feedback voltage FB2 will be set to 1.24 V (typ.). The start delay time can

be set in the DLS terminal at the time of starting. When the DLS voltage reaches 0.6 V (Typ.), switching waves will be

output from the C1L and C2L pins.

・Charge Pump Control 2

A controller circuit for the negative-side charge pump.

The switching amplitude is controlled so that the feedback voltage FB2 will be set to 0.6 V (Typ.).

・Gate Shading Controller

A controller circuit of gate shading.

The Vo2GS and GSOUT are in on/off control according to IG pin input.

・Regulator Control

A regulator controller circuit for VDD voltage generation.

The base pin current is controlled so that V

voltage will be set to 2.5 V (typ.).

DD

・DET 1 to DET 4

A detection circuit of each output voltage. This detected signal is used for the starting sequential circuit.

・Start-up Controller

A control circuit for the starting sequence.

Controls to start in order of V

VDD Vo1 Vo3 Vo2.

CC

・VREF

A block that generates internal reference voltage. 1.24V (Typ.) is output.

・TSD/UVLO

Thermal shutdown/Under-voltage lockout protection/circuit blocks.

The thermal shutdown circuit is shut down at an IC internal temperature of 175℃ and reset at 160℃. The under-voltage

lockout protection circuit shuts down the IC when the VCC is 1.8 V (typ.) or below.

・Starting sequence

For malfunction prevention, starting logic control operates so that each output will rise in order of

VDD Vo1 Vo3 Vo2.

V

CC

As shown below, detectors DET1 to DET3 detect that the output on the detection side has reached 90% (typ.) of the set

voltage, and starts the next block.

VCC

Reg

VDD

DET1

CTL1

Step up

DET2

Vo1

CTL2

Negative

Charge

Pump

DET3

Vo3

CTL3

Positive

Charge

Pump

Vo2

DET4 CLT4

Starting sequence model

0

0

0

5V

2.5V

Vcc

VDD

Vo2

Vo1

Vo3

Fig. 26 Starting Timing Chart

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

9/21

2010.12 - Rev.

A

BD8163EFV

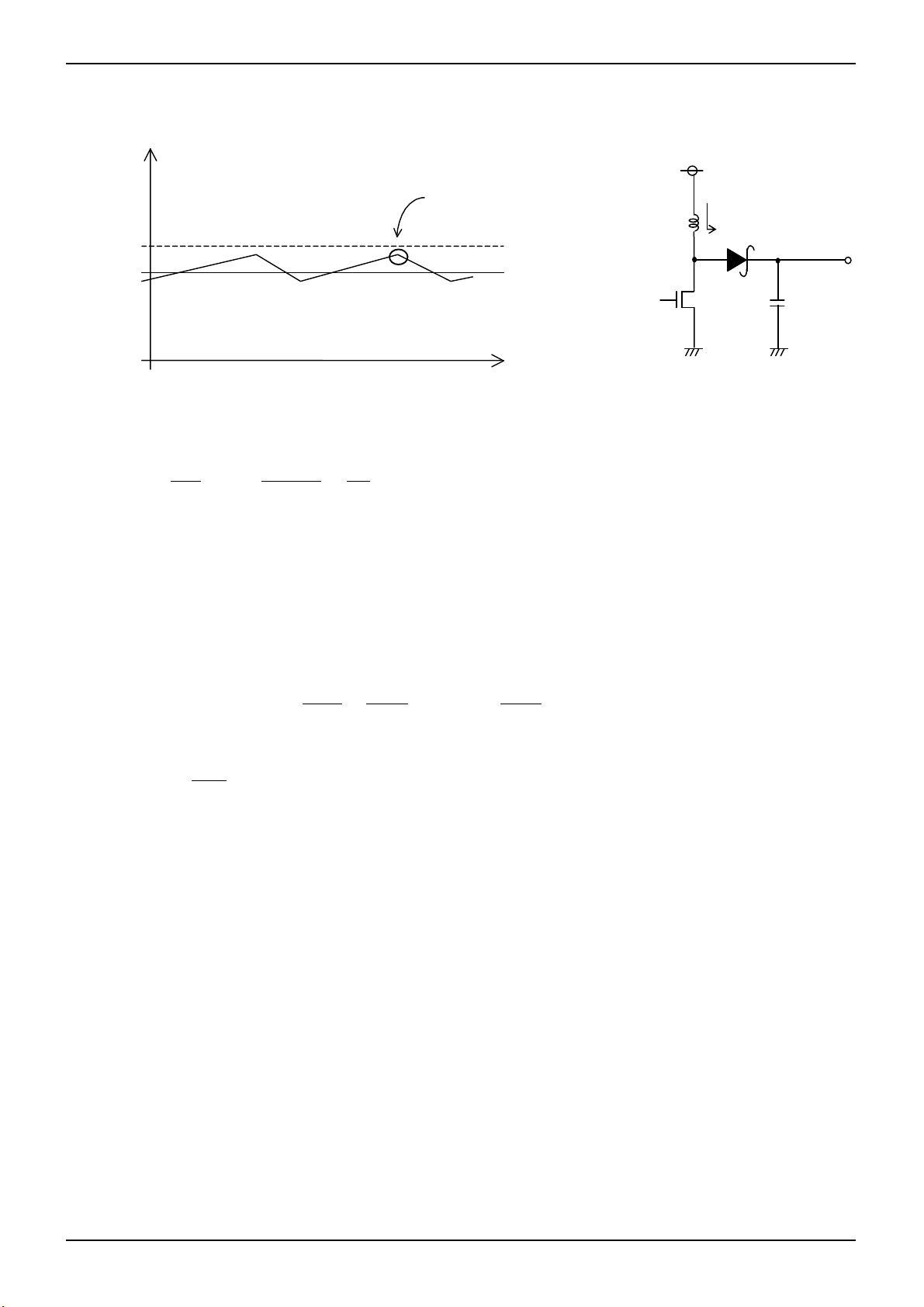

●Selecting Application Components

(1) Setting the Output L Constant

The coil to use for output is decided by the rating current I

IL

Fig. 27 Coil Current Waveform

Adjust so that I

+∆IL do not reach the rating current value ILR. At this time, ∆IL can be obtained by the following

INMAX

equation.

ΔI

1

=

L

Vcc

L Vcc f

Vo-Vcc

Set with sufficient margin because the coil value may have the dispersion of 30%. If the coil current exceeds the rating

current I

of the coil, it may damage the IC internal element.

LR

BD8163EFV uses the current mode DC/DC converter control and has the optimized design at the coil value. A coil

inductance (L) of 4.7 µH to 15 µH is recommended from viewpoints of electric power efficiency, response, and stability.

(2) Output Capacity Settings

For the capacitor to use for the output, select the capacitor which has the larger value in the ripple voltage V

value and the drop voltage allowance value at the time of sudden load change. Output ripple voltage is decided by the

following equation.

ΔVPP

= I

LMAX

R

ESR +

Perform setting so that the voltage is within the allowable ripple voltage range.

For the drop voltage during sudden load change; V

V

DR

ΔI

=

Co

10 µs [V]

However, 10 µs is the rough calculation value of the DC/DC response speed. Please set the capacitance considering

the sufficient margin so that these two values are within the standard value range.

(3) Selecting the Input Capacitor

Since the peak current flows between the input and output at the DC/DC converter, a capacitor is required to install at

the input side. For the reason, the low ESR capacitor is recommended as an input capacitor which has the value more

than 10 µF and less than 100 mΩ. If a capacitor out of this range is selected, the excessive ripple voltage is superposed

on the input voltage; accordingly it may cause the malfunction of IC.

However these conditions may vary according to the load current, input voltage, output voltage, inductance and

switching frequency. Be sure to perform the margin check using the actual product.

and input current maximum value I

LR

I

INMAX + ∆IL should not reach

the rating value level

ILR

I

INMAX

average current

1

1

fCo Vo 2

[A] Here, f is the switching frequency.

Vcc

(I

LMAX

, please perform the rough calculation by the following equation.

DR

-

ΔI

Technical Note

of the coil.

INMAX

VCC

L

L

Fig. 28 Output Application Circuit Diagram

L

[V] Here, f is the switching frequency.

)

I

Vo

Co

allowance

PP

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

10/21

2010.12 - Rev.

A

BD8163EFV

A

A

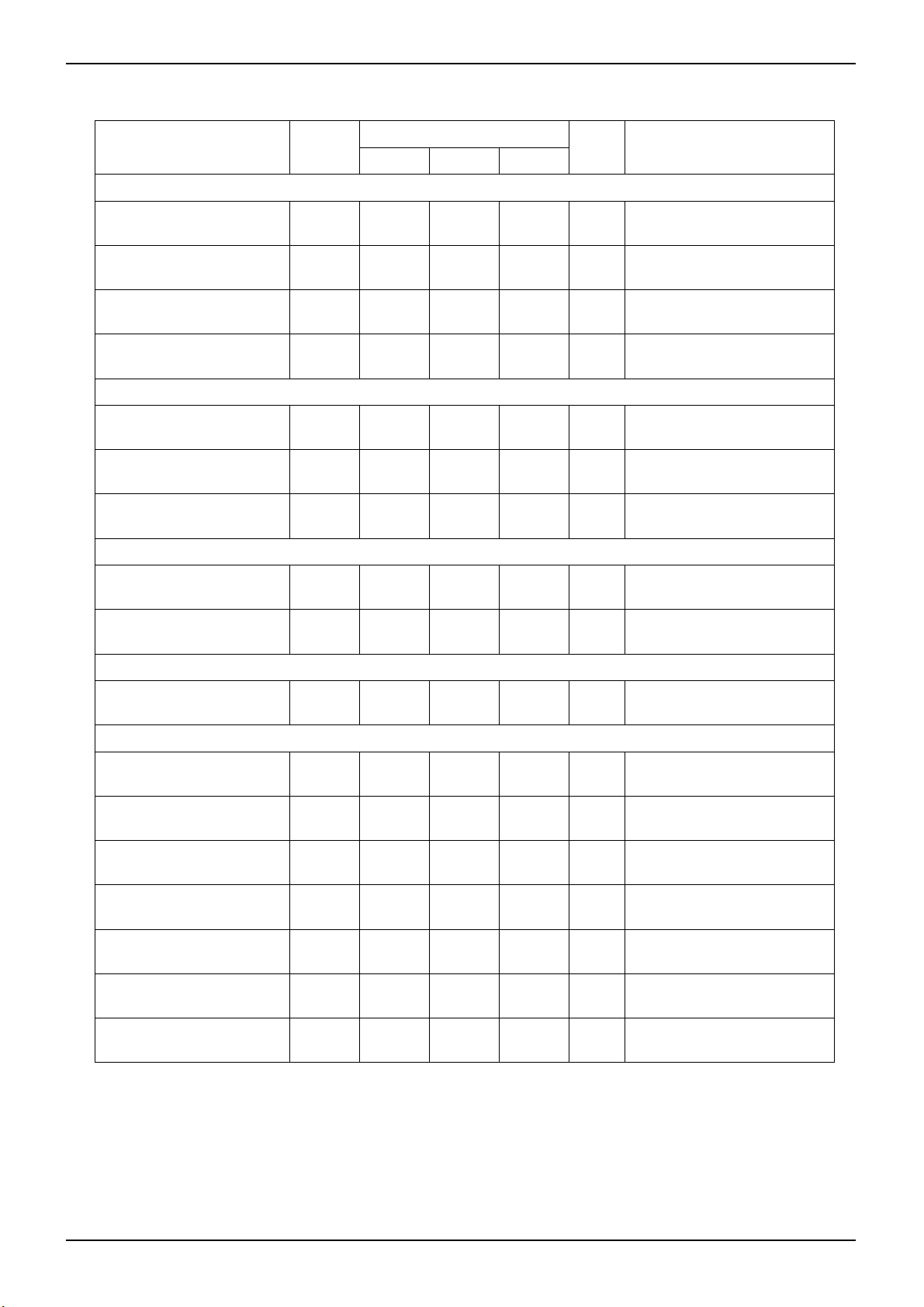

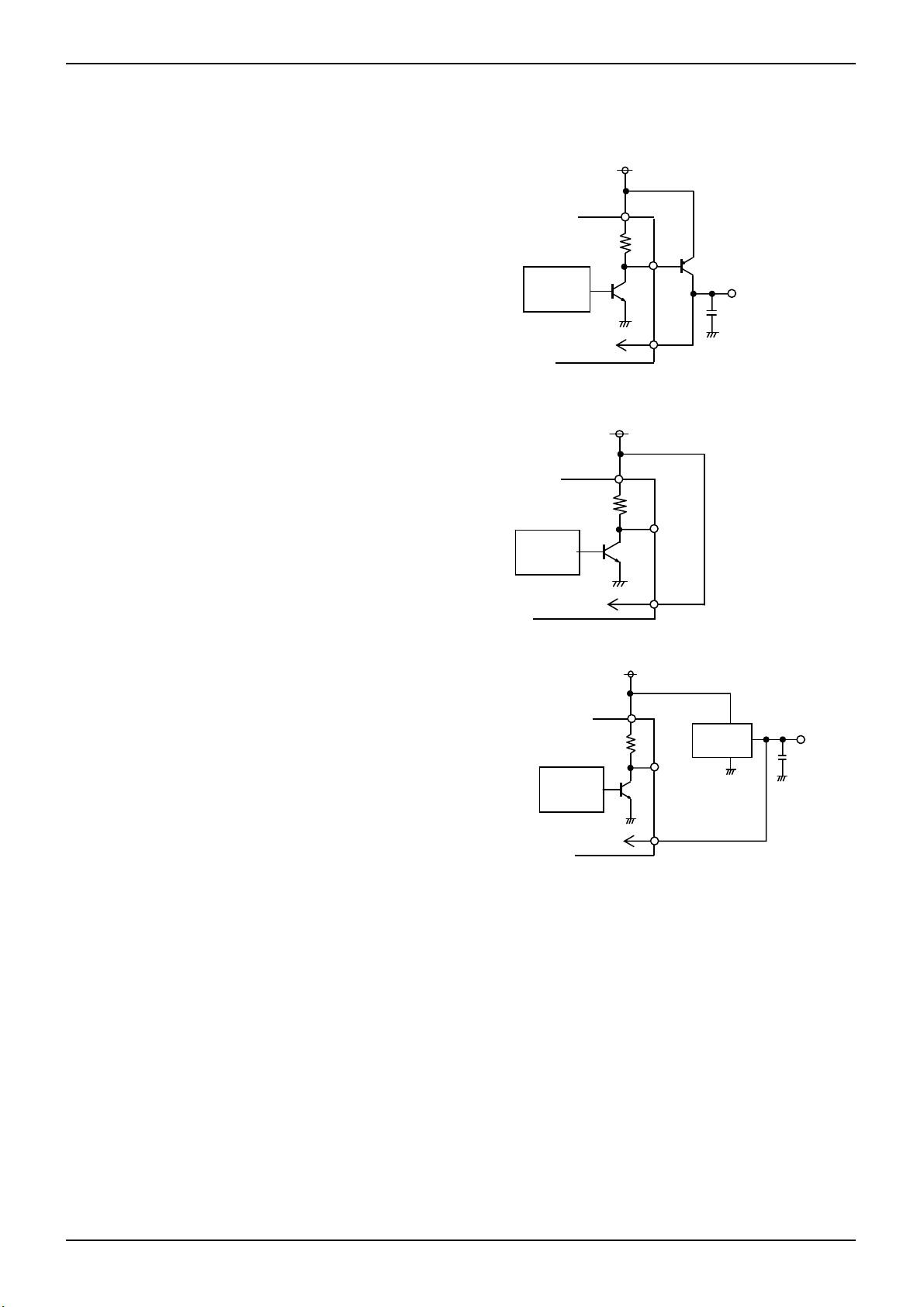

(4) Setting RC, CC of the Phase Compensation Circuit

In the current mode control, since the coil current is controlled, a pole (phase lag) made by the CR filter composed of the

output capacitor and load resistor will be created in the low frequency range, and a zero (phase lead) by the output

capacitor and ESR of capacitor will be created in the high frequency range. In this case, to cancel the pole of the power

amplifier, it is easy to compensate by adding the zero point with C

the illustration.

Open loop gain characteristics

Gain

[dB]

0

0

Phase

[deg]

-90

fp(Min)

OUT

l

Min

fp(Max)

OUT

l

Max

Error amp phase

compensation characteristics

Gain

[dB]

Phase

[deg]

0

0

-90

Fig. 29 Gain vs Phase

L

COMP

Vcc,PVcc

SW

GND,PGND

V

CC

Cin

Rc

Cc

Fig. 30 Application Circuit Diagram

It is possible to realize the stable feedback loop by canceling the pole fp(Min.), which is created by the output capacitor

and load resistor, with CR zero compensation of the error amp as shown below.

fz(Amp.) = fp(Min.)

1

2 Rc Cc 2 Romax Co

=

fz(ESR)

ESR

Co

Technical Note

and RC to the output from the error amp as shown in

C

1

Fp =

2 RO C

1

fz(ESR) =

2 E

SR

CO

Pole at the power amplification stage

When the output current reduces, the load resistance

increases and the pole frequency lowers.

R

o

fp(Min) =

2 R

1

OMax

CO

1

fz(Max) =

Zero at the power amplification stage

2 R

OMin

CO

When the output capacitor is set larger, the pole

frequency lowers but the zero frequency will not

change. (This is because the capacitor ESR becomes

1/2 when the capacitor becomes 2 times.)

1

fp(Amp.) =

2 Rc Cc

Vo

Ro

1

[Hz]

[Hz]

O

[Hz]

[Hz] at light load

[Hz] at heavy load

[Hz]

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

11/21

2010.12 - Rev.

A

BD8163EFV

(Open)

(5) Regulator Controller Settings

The IC incorporates a 2.5 V regulator controller, and a regulator can be formed by using an external PNP transistor.

Design the current capability of the regulator with a margin according to the following formula.

I

= 7mA hfe [A]

OMAX

The hfe is the current gain of the external PNP transistor.

7 mA is the sinking current of the internal transistor.

It is not necessary to use the regulator if the input voltage

is 2.5 V. In that case, input 2.5 V to both VCC and VDD.

When incorporating a regulator into the external

transistor, input the output voltage into the regulator.

Regulator

controller

IC

Regulator

controller

To inside

IC

Regulator

controller

To inside

To inside

IC

VCC=5 V

VCC

Fig.31

2.5 V

VCC

Fig.32

5 V

VCC

Fig.33

VDD

Base

VDD

Base

VDD

Technical Note

2.5 V

VDD=

Ceramic capacitor

with a capacity of

4.7 F or over

3 pin

regulator

Voltage other

than 2.5 V

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

12/21

2010.12 - Rev.

A

BD8163EFV

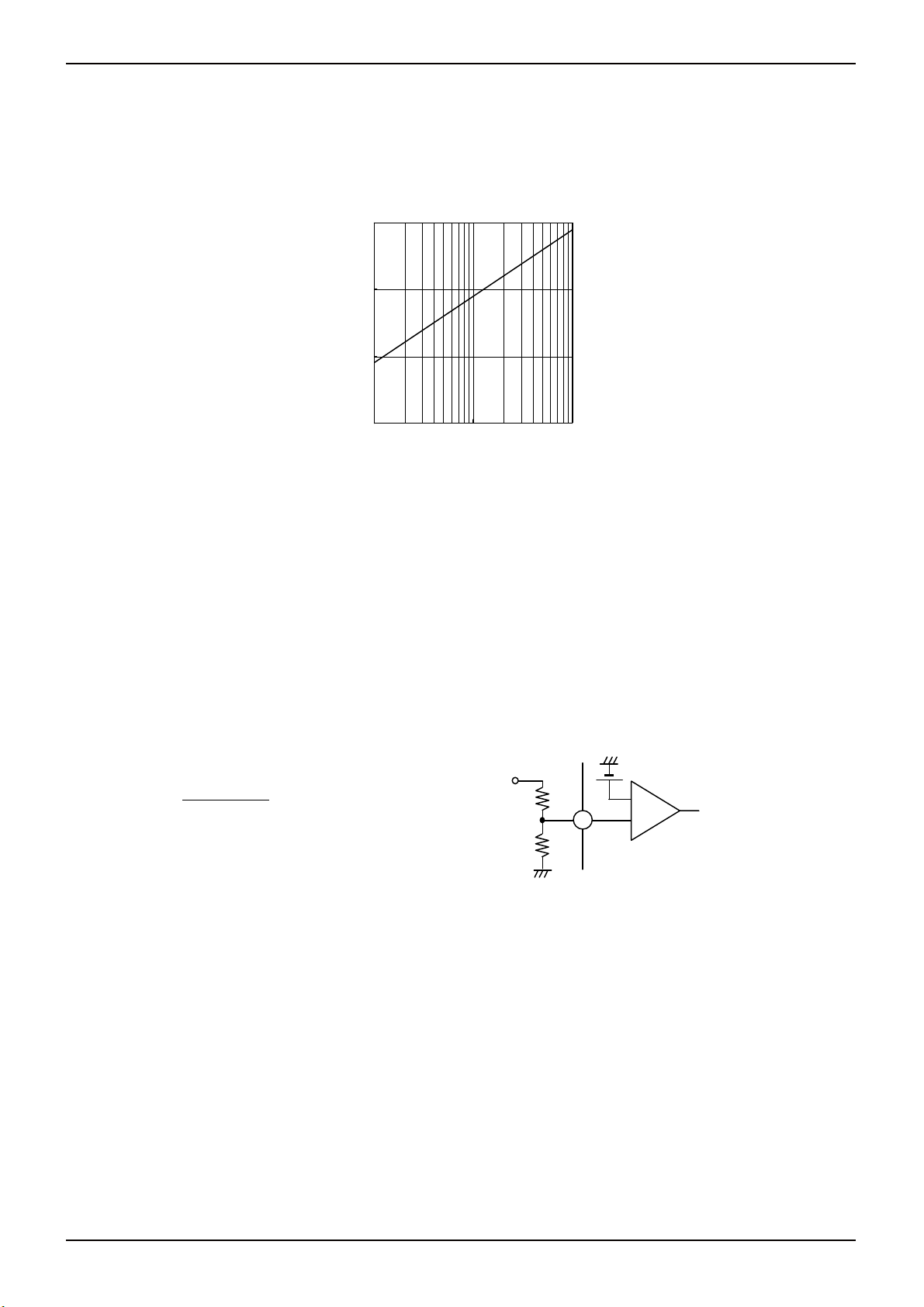

(6) Setting the Soft Start Time

Soft start is required to prevent the coil current at the time of start from increasing and the overshoot of the output

voltage at the starting time. The relation between the capacity and soft start time is shown in the following figure. Refer

to the figure and set capacity C1. Soft start is required to prevent the coil current at the time of start from increasing and

the overshoot of the output voltage at the starting time. Fig. 34 shows the relation between the capacitance and soft start

time. Please refer to it to set the capacitance.

As the capacitance, 0.001 µF to 0.1 µF is recommended. If the capacitance is set lower than 0.001 µF, the overshooting

may occur on the output voltage. If the capacitance is set larger than 0.1µF, the excessive back current flow may occur

in the internal parasitic elements when the power is turned OFF and it may damage IC. When there is the activation

relation (sequences) with other power supplies, be sure to use the high accuracy product (such as X5R). Soft start time

may vary according to the input voltage, loads, coils and output capacity. Be sure to verify the operation using the actual

product.

(7) Design of the Feedback Resistor Constant

Refer to the following equation to set the feedback resistor. As the setting range, 10 kΩto 330 kΩis recommended. If

the resistor is set lower than a 10 kΩ, it causes the reduction of power efficiency. If it is set more than 330 kΩ, the offset

voltage becomes larger by the input bias current 0.4 µA(Typ.) in the internal error amplifier.

Vo =

R8 + R9

R9

1.24 [V]

10

1

0.1

DELAY TIME[ms]

0.01

0.001 0.01 0.1

SS CAPACITANC E[uF ]

Fig. 34 SS Pin Capacitance vs Delay Time

Sep-up

Vo

R8

7

R9

FB1

Fig. 35

Technical Note

Reference voltage 1.24 V

+

ERR

-

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

13/21

2010.12 - Rev.

A

BD8163EFV

(8) Positive-side Charge Pump Settings

The IC incorporates a charge pump controller, thus making it possible to generate stable gate voltage.

The output voltage is determined by the following formula. As the setting range, 10 kΩto 330 kΩis recommended. If the

resistor is set lower than a 10kΩ, it causes the reduction of power efficiency. If it is set more than 330 kΩ, the offset

voltage becomes larger by the input bias current 0.4 µA (Typ.) in the internal error amp.

Vo =

R8 + R9

R9

In order to prevent output voltage overshooting, add capacitor C8 in parallel with R8. The recommended capacitance is

1000 pF to 4700 pF. If a capacitor outside this range is inserted, the output voltage may oscillate.

By connecting capacitance to the DLS, a rising delay time can be set for the positive-side charge pump.

The delay time is determined by the following formula.

Delay time of charge pump block t

= ( C

t

DELAY

where, C

is the external capacitance.

DLS

(9) Negative-side Charge Pump Settings

This IC incorporates a charge pump controller for negative voltage, thus making it possible to generate stable gate

voltage. The output voltage is determined by the following formula. As the setting range, 10 k Ω to 330 k Ω is

recommended. If the resistor is set lower than a 10 kΩ, it causes the reduction of power efficiency. If it is set more than

330 kΩ, the offset voltage becomes larger by the input bias current 0.4 µA (Typ.) in the internal error amp.

Vo3 = -

R6

R7

The delay time is internally fixed at 200 µs.

In order to prevent output voltage overshooting, insert capacitor C6 in parallel with R6. The recommended capacitance

is 1000 pF to 4700 pF. If a capacitor outside this range is inserted, the output voltage may oscillate.

1.24 [V]

0.6 )/5 µA [s6]

DLS

1.04 + 0.2 V [V]

C8

1000 pF to 4700 pF

DELAY

1000 pF to 4700 pF

Vo2

C6

R8

R9

Vo3

12

Fig. 36

R6

R7

Technical Note

Reference voltage 1.24 V

+

ERR

-

FB2

0.2 V

-

23

FB3

24

REF

Fig.37

ERR

+

1.24 V

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

14/21

2010.12 - Rev.

A

BD8163EFV

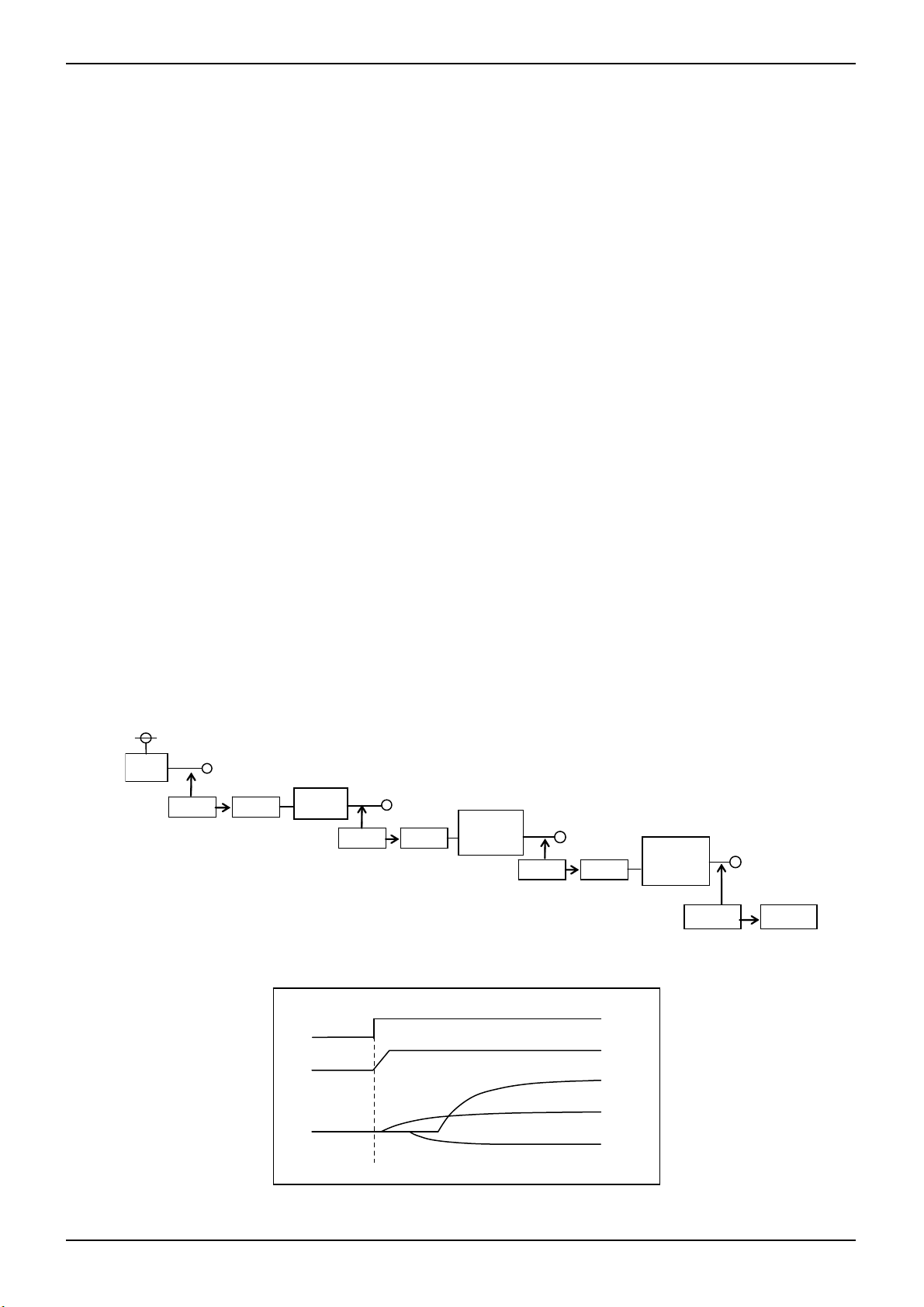

●Gate Shading Setting Method

The IG input signal allows the high-level and low-level control of the positive-side gate voltage. The slope of output can be

set by the external RC. The recommended resistance set value is 200 Ωto 5.1 kΩand the recommended capacitor set

value is 0.001 µF to 0.1 µF. The aggravation of efficiency may be caused if settings outside this range are made.

Determine ∆V by referring to the following value. The following calculation formula is used for ∆V.

tWH

Fig. 38

tWL

CR

Limits

) ) [V]

Unit Condition

TIMING STANDARD VALUE

Parameter Symbol

ΔV = Vo2GS ( 1 - exp ( -

IG

tWL

tLH

Vo2GS

ΔV

Min. Typ. Max.

Technical Note

H

L

H

L

IG “L” Time tWL 1 2 - µs -

IG “H” Time tWH 1 18 - µs -

Vo2GS “H” to “L Voltage difference ΔV - 10 - V TWL = 2 µs, R = 500Ω*

Vo2GS “L” to “H” Time tLH - 0.1 - µs ∆V = 10 V *

IG

IC

Gate

Shading

Control

Fig. 39

From positive-side pump

Vo2

Vo2GS

C

R

GSOUT

Gate driver

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

15/21

2010.12 - Rev.

A

BD8163EFV

●Application Examples

Although we are confident that the application circuit diagram reflects the best possible recommendations, be sure to verify

circuit characteristics for your particular application. When a circuit is used modifying the externally connected circuit

constant, be sure to decide allowing sufficient margins considering the dispersion of values by external parts as well as our

IC including not only the static but also the transient characteristic. For the patent, we have not acquired the sufficient

confirmation. Please acknowledge the status.

(a) Input voltage

5 V

(b) Input voltage

2.5 V

Vo3

REF

VDD

Vo3

REF

Vo2GS

Vo2

Fig. 40

VDD

Fig. 41

Technical Note

Vo1

Vo2GS

Vo2

Vo1

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

16/21

2010.12 - Rev.

A

BD8163EFV

(c) When Inserting PMOS Switch

Vo3

REF

VDD

Technical Note

Vo2GS

Vo2

Vo1

Fig. 42

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

17/21

2010.12 - Rev.

A

BD8163EFV

Technical Note

●I/O Equivalent Circuits

2.VDD 3.BASE 5.DLS,8.SS

VCC

120kΩ

30kΩ

VCC

VDD

6.COMP 7.FB1,12.FB2 10.SW

VDD

VDD

VDD

11.IG 13.Vo2 14.Vo2GS

VDD

200KΩ

VDD

Vo2

Vo2

15.GSOUT 16.C2H,19.C1H 17.C2L,18.C1L,21.C3

23.FB3 24.REF

Vo2

VDD

VDD

Vo1

VDD

Vo1

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

Fig. 43

18/21

2010.12 - Rev.

A

BD8163EFV

Technical Note

●Power Dissipation Reduction

1200

1000

1100mW

On 70 mm × 70 mm × 1.6 mm

Glass-epoxy PCB

800

600

400

200

Power Dissipation : Pd (mW)

0

0 25 50 75 100 125 150

Ambient Temperature: Ta

(℃)

Fig.44

●Notes for use

1) Absolute maximum ratings

Use of the IC in excess of absolute maximum ratings such as the applied voltage or operating temperature range may

result in IC damage. Assumptions should not be made regarding the state of the IC (short mode or open mode) when such

damage is suffered. A physical safety measure such as a fuse should be implemented when use of the IC in a special

mode where the absolute maximum ratings may be exceeded is anticipated.

2) GND potential

Ensure a minimum GND pin potential in all operating conditions.

3) Setting of heat

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating conditions.

4) Pin short and mistake fitting

Use caution when orienting and positioning the IC for mounting on printed circuit boards. Improper mounting may result in

damage to the IC. Shorts between output pins or between output pins and the power supply and GND pins caused by the

presence of a foreign object may result in damage to the IC.

5) Actions in strong magnetic field

Use caution when using the IC in the presence of a strong magnetic field as doing so may cause the IC to malfunction.

6) Testing on application boards

When testing the IC on an application board, connecting a capacitor to a pin with low impedance subjects the IC to stress.

Always discharge capacitors after each process or step. Ground the IC during assembly steps as an antistatic measure,

and use similar caution when transporting or storing the IC. Always turn the IC's power supply off before connecting it to or

removing it from a jig or fixture during the inspection process.

7) Ground wiring patterns

When using both small signal and large current GND patterns, it is recommended to isolate the two ground patterns,

placing a single ground point at the application's reference point so that the pattern wiring resistance and voltage

variations caused by large currents do not cause variations in the small signal ground voltage. Be careful not to change the

GND wiring patterns of any external components.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

19/21

2010.12 - Rev.

A

BD8163EFV

(

)

(

)

(

)

(

)

Technical Note

8) This monolithic IC contains P+ isolation and P substrate layers between adjacent elements in order to keep them isolated.

P/N junctions are formed at the intersection of these P layers with the N layers of other elements to create a variety of

parasitic elements. For example, when the resistors and transistors are connected to the pins as shown in Fig.45, a

parasitic diode or a transistor operates by inversing the pin voltage and GND voltage. The formation of parasitic elements

as a result of the relationships of the potentials of different pins is an inevitable result of the IC's architecture. The

operation of parasitic elements can cause interference with circuit operation as well as IC malfunction and damage. For

these reasons, it is necessary to use caution so that the IC is not used in a way that will trigger the operation of parasitic

elements, such as the application of voltages lower than the GND (P board) voltage to input and output pins.

Pin A

P+

N

P

Resistor

N

P

GND

~

~

P+

Parasitic element

Transistor (NPN)

Pin B

N

C

P+

N

Parasitic elements

B

N

N

P substrate

~

~

E

P

GND

GND

P+

N

Fig.45 Example of a Simple Monolithic IC Architecture

Pin B

Pin A

C

B

~

~

E

GND

Parasitic elements

~

~

Parasitic element

GND

9) Overcurrent protection circuits

An overcurrent protection circuit designed according to the output current is incorporated for the prevention of IC

destruction that may result in the event of load shorting. This protection circuit is effective in preventing damage due to

sudden and unexpected accidents. However, the IC should not be used in applications characterized by the continuous

operation or transitioning of the protection circuits. At the time of thermal designing, keep in mind that the current capability

has negative characteristics to temperatures.

10) Thermal shutdown circuit

This IC incorporates a built-in thermal shutdown circuit for the protection from thermal destruction. The IC should be used

within the specified power dissipation range. However, in the event that the IC continues to be operated in excess of its

power dissipation limits, the attendant rise in the chip's temperature Tj will trigger the thermal shutdown circuit to turn off all

output power elements. The circuit automatically resets once the chip's temperature Tj drops.

Operation of the thermal shutdown circuit presumes that the IC's absolute maximum ratings have been exceeded.

Application designs should never make use of the thermal shutdown circuit.

11) Testing on application boards

At the time of inspection of the installation boards, when the capacitor is connected to the pin with low impedance, be sure

to discharge electricity per process because it may load stresses to the IC. Always turn the IC's power supply off before

connecting it to or removing it from a jig or fixture during the inspection process. Ground the IC during assembly steps as

an antistatic measure, and use similar caution when transporting or storing the IC.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

20/21

2010.12 - Rev.

A

BD8163EFV

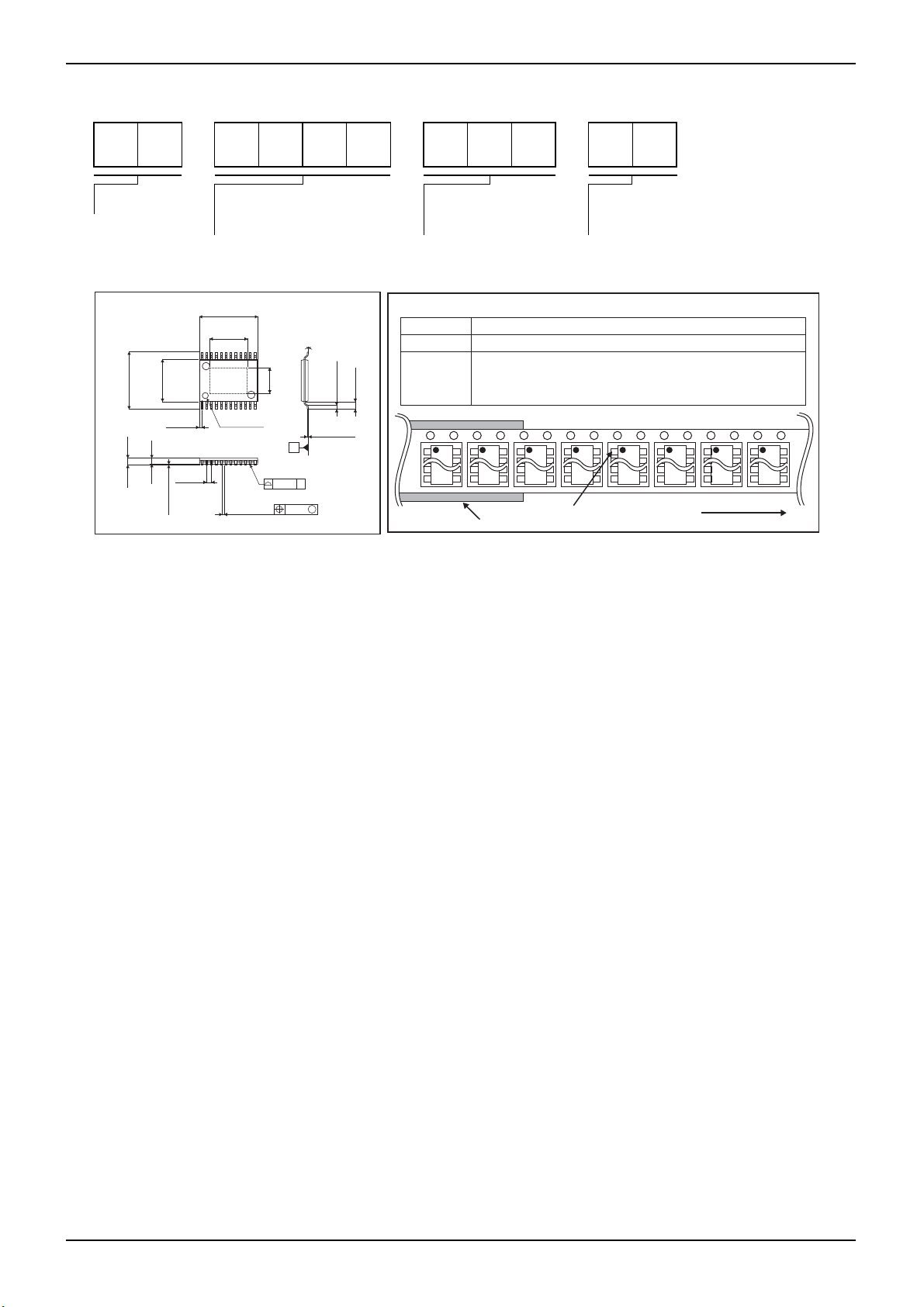

●Ordering part number

Technical Note

B

D 8 1 6 3 E F V - E 2

Part No. Part No. Package

HTSSOP-B24

7.6±0.2

5.6±0.1

0.325

1.0MAX

0.85±0.05

0.08±0.05

7.8±0.1

(MAX 8.15 include BURR)

(5.0)

24 13

112

1PIN MARK

0.65

+0.05

0.24

-

0.04

0.08

(3.4)

S

0.08

4°

S

M

+

6°

−

4°

0.53±0.15

+0.05

0.17

-

0.03

(Unit : mm)

1.0±0.2

<Tape and Reel information>

EFV: HTSSOP-B24

Embossed carrier tape (with dry pack)Tape

Quantity

Direction

of feed

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Packaging and forming specification

E2: Embossed tape and reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

21/21

2010.12 - Rev.

Notes

No copying or reproduction of this document, in par t or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injur y (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

http://www.rohm.com/contact/

R1010

A

Loading...

Loading...