Power Management ICs for Automotive Body Control

White Backlight LED Drivers

for Medium to Large LCD Panels

(Switching Regulator Type)

BD8112EFV-M

●Description

BD8112EFV-M is a white LED driver with the capability of withstanding high input voltage (36V MAX). This driver has

2ch constant-current drivers integrated in 1-chip, which each channel can draw up to 150mA max, so that high brightness

LED driving can be realized. Furthermore, a current-mode buck-boost DC/DC controller is also integrated to achieve stable

operation against voltage input and also to remove the constraint of the number of LEDs in series connection.

The brightness can be controlled by either PWM or VDAC techniques.

●Features

1) Input voltage range 5.0 -30 V

2) Integrated buck-boost current-mode DC/DC controller

3) Two integrated LED current driver channels (150 mA max. each channel)

4) PWM Light Modulation (Minimum Pulse Width 25µs)

5) Oscillation frequency accuracy ±5%

6) Built-in protection functions (UVLO, OVP, TSD, OCP, SCP)

7) LED abnormal status detection function (OPEN/ SHORT)

8) HTSSOP-B24 package

●Applications

Backlight for display audio, small type panels, etc.

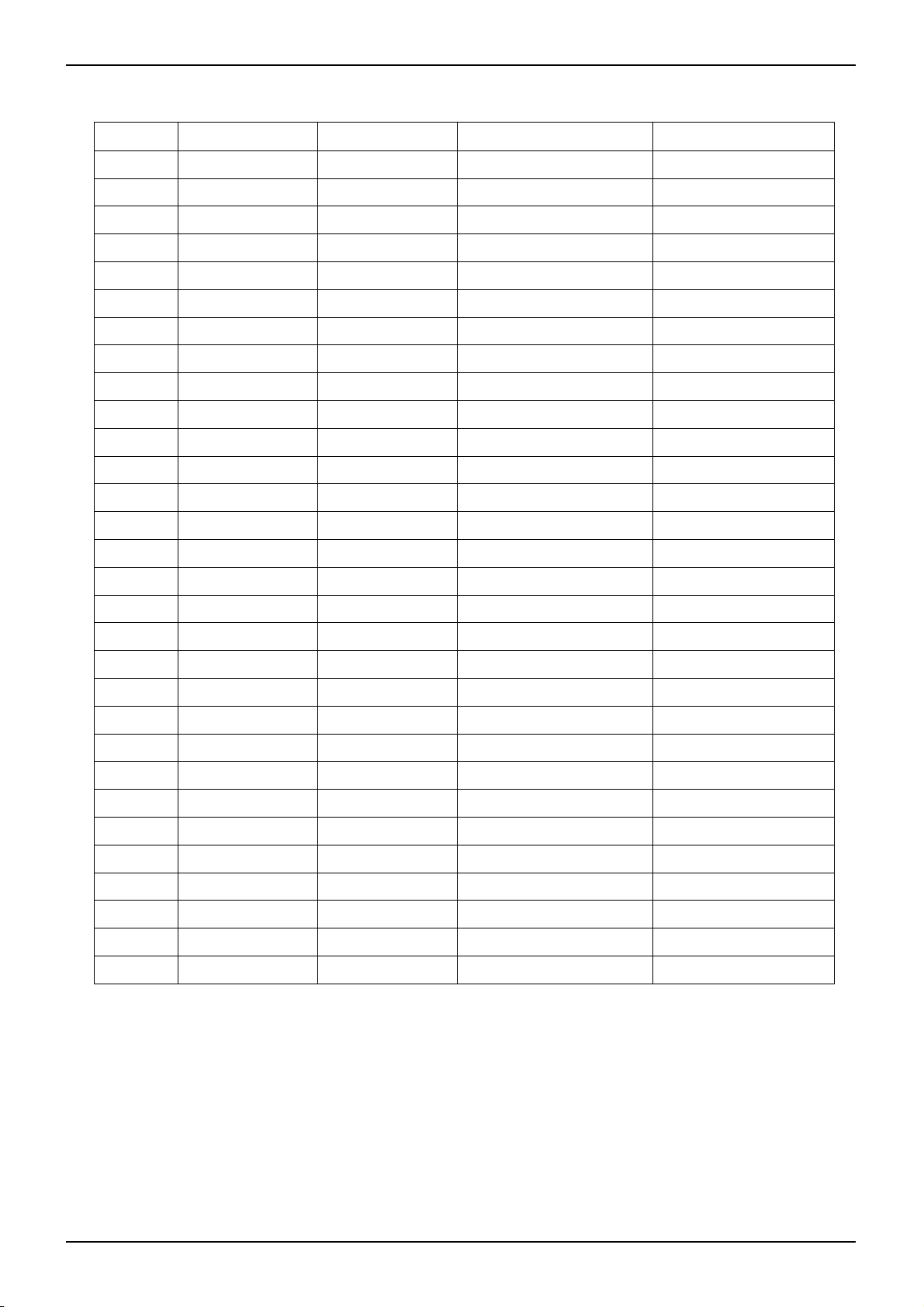

●Absolute maximum ratings (Ta=25℃)

Parameter Symbol Ratings Unit

Power supply voltage VCC 36 V

No.11039ECT11

BOOT , OUTH Voltage V

SW, CS Voltage V

BOOT-SW Voltage V

LED output voltage V

VREG, OVP, OUTL, FAIL1, FAIL2,

LEDEN, ISET, VDAC, PWM, SS, COMP,

RT, SYNC, EN voltage

Power Consumption Pd 1.10 *1 W

Operating temperature range Topr -40~+105 ℃

Storage temperature range Tstg -55~+150 ℃

LED maximum output current I

Junction temperature Tjmax 150 ℃

*1 IC mounted on glass epoxy board measuring 70mm × 70mm × 1.6mm, power dissipated at a rate of 8.8mw/℃ at temperatures above 25℃.

*2 Dispersion figures for LED maximum output current and VF are correlated. Please refer to data on separate sheet.

*3 Amount of current per channel.

V

VREG, VOVP, VOUTL, VFAIL1, VFAI L2 ,

V

LEDEN, VISET, VVDAC, VPWM, VSS, VCOMP,

BOOT, VOUTH

SW, VCS

BOOT-SW

LED1,2

V

RT, VSYNC, VEN

41 V

36 V

7 V

36 V

-0.3~7 < V

150

LED

V

CC

*2 *3

mA

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

1/22

2011.08 - Rev.C

BD8112EFV-M

●Operating conditions (Ta=25℃)

Parameter Symbol Limits Unit

Power supply voltage VCC 5.0~30 V

Technical Note

Oscillating frequency range F

External synchronization

frequency range

*4 *5

External synchronization

pulse duty range

*4 Connect SYNC to GND or OPEN when not using external frequency synchronization.

*5 Do not switch between internal and external synchronization when an external synchronization signal is input to the device.

250~600 kHz

OSC

F

fosc~600 kHz

SYNC

40~60 %

F

SDUTY

●Electrical characteristics (Unless otherwise specified, VCC=12V Ta=25℃)

Parameter Symbol

Min Typ Max.

Circuit current ICC - 7 14 mA

Limits

Unit Conditions

EN=Hi, SYNC=Hi, RT=OPEN

PWM=Low, ISET=OPEN, C

Standby current IST - 4 8 µA EN=Low

[VREG Block (VREG)]

Reference voltage V

4.5 5 5.5 V I

REG

REG

[OUTH Block]

OUTH high-side ON resistance R

1.5 3.5 7.0 Ω ION=-10mA

ONHH

=-5mA, C

REG

=2.2µF

=10µF

IN

OUTH low-side ON resistance R

Over-current protection

operating voltage

V

[OUTL Block]

OUTL high-side ON resistance R

OUTL low –side ON resistance R

[SW Block]

SW low -side ON resistance R

[Error Amplifie Block]

LED voltage V

COMP sink current I

COMP source current I

COMPSINK

COMPSOURCE

[Oscillator Block]

Oscillating frequency F

1.0 2.5 5.0 Ω ION=10mA

ONHL

V

V

OLIMIT

ONLH

ONLL

ON_SW

LED

-0.66

2.0 4.0 8.0 Ω ION=-10mA

1.0 2.5 5.0 Ω ION=10mA

2.0 4.5 9.0 Ω I

0.9 1.0 1.1 V

CC

CC

-0.6

VCC

-0.54

V

ON_SW

15 25 35 µA V

-35 -25 -15 µA V

285 300 315 KHz RT=100kΩ

OSC

=10mA

=2V, Vcomp=1V

LED

=0V, Vcomp=1V

LED

◎This product is not designed for use in radioactive environments.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

2/22

2011.08 - Rev.C

BD8112EFV-M

Parameter Symbol

[OVP Block]

Over-voltage detection

reference voltage

Limits

Min Typ Max.

V

1.9 2.0 2.1 V V

OVP

Technical Note

Unit Conditions

=Sweep up

OVP

OVP hysteresis width V

SCP Latch OFF Delay Time T

0.45 0.55 0.65 V V

OHYS

70 100 130 ms RT=100kΩ

SCP

[UVLO Block ]

UVLO voltage V

UVLO hysteresis width V

4.0 4.3 4.6 V VCC : Sweep down

UVLO

50 150 250 mV VCC : Sweep up

UHYS

[LED Output Block]

LED current

relative dispersion width

LED current

absolute dispersion width

ISET voltage V

-3 - +3 %

△I

LED1

△I

-5 - +5 %

LED2

1.96 2.0 2.04 V R

ISET

PWM minimum pulse width Tmin 25 - - µs F

PWM maximum duty Dmax - - 100 % F

PWM frequency F

- - 20 KHz Duty=50%, I

PWM

=Sweep down

OVP

=50mA,

I

LED

=(I

ΔI

LED1

I

=50mA,

LED

ΔI

=(I

LED2

=120kΩ

ISET

=150Hz, I

PWM

=150Hz, I

PWM

LED/ILED_AVG

/50mA-1)×100

LED

=50mA

LED

=50mA

LED

=50mA

LED

-1)×100

=0~2V, R

V

VDAC gain G

Open detection voltage V

LED Short detection Voltage V

LED Short Latch OFF Delay Time T

PWM Latch OFF Delay Time T

- 25 - mA/V

VDAC

0.2 0.3 0.4 V V

OPEN

4.2 4.5 4.8 V V

SHORT

70 100 130 ms RT=100kΩ

SHORT

70 100 130 ms RT=100kΩ

PWM

DAC

=VDAC÷R

I

LED

= Sweep down

LED

= Sweep up

OVP

[Logic Inputs (EN, SYNC, PWM, LEDEN)]

Input HIGH voltage V

Input LOW voltage V

Input current 1 IIN 20 35 50 µA

2.1 - 5.5 V

INH

GND - 0.8 V

INL

V

=5V

IN

(SYNC, PWM, LEDEN)

Input current 2 IEN 15 25 35 µA VEN=5V (EN)

[FAIL Output (open drain) ]

=120kΩ

ISET

×Gain

ISET

FAIL LOW voltage VOL - 0.1 0.2 V IOL=0.1mA

◎This product is not designed for use in radioactive environments.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

3/22

2011.08 - Rev.C

BD8112EFV-M

●Electrical characteristic curves (Reference data) (Unless otherwise specified, Ta=25℃)

5.5

5.3

5.1

Vcc= 12V

400

Vcc= 12V

360

320

4.9

280

4.7

OUT PUT VOLTAGE:VREG [V]

4.5

-40 - 15 10 35 60 85

TEM PERATU RE:Ta [℃]

Fig.1 VREG temperature

characteristic

240

Fig.3 OSC 温度特性

SWITCHING FREQUENCY:FOSC [kHz]

200

-40 - 15 10 35 60 85

TEMPERATURE:Ta [℃]

Fig.2 OSC temperature

characteristic

55

50

53

51

49

47

OUTPUTCURRENT :ILED [mA]

45

Vcc= 12V

-40 - 15 10 35 60 85

TEMPER ATUR E:Ta [℃]

Fig.4 ILED temperature

characteristic

40

30

20

10

OUTPUTCURRENT :ILED [mA]

0

0 0.5 1 1.5 2

VDAC VOLTAGE:VD AC[V]

Fig.5 VDAC Gain① Fig.6 VDAC Gain②

100

85

70

55

EFFIC IENCY [%]

40

VCC=30V

100

85

VCC=12V

70

55

EFFICIENCY [%]

40

25

50 100 150 200 250

Total_Io [mA]

Fig.7 Efficiency

(LED2 Parallel 5 step)

0.66

0.64

0.62

0.60

0.58

0.56

OUT PUT VOLTAGE:Vcc-Vcs [V]

0.54

-40 - 15 10 35 60 85

TEMPER ATUR E:Ta [℃]

Fig.10 Overcurrent detecting voltage

temperature characteristic

VCC=12V

25

50 100 150 200 250

OUTPUT CURRENT [mA]

Fig.8 Efficiency

(LED2 Parallel 7 step)

10

8

6

4

2

OUT PUT VOLTAGE:VREG [V]

0

012345

EN VOLTAGE:VEN [V]

Fig.11 EN threshold voltage

Technical Note

400

360

Vcc= 12V

320

280

240

SWITCHING FREQUENCY:FOSC [kHz]

200

-40 - 15 10 35 60 85

TEM PERATU RE:Ta [℃]

Fig.3 ILED depend on VLED

5

4

3

2

1

OUTPU TCURR ENT :ILED [mA]

0

0 0.02 0.04 0.06 0.08 0.1

VDAC VOLTAGE:VDAC [V]

6.0

4.0

2.0

OUTPUT CARRENT:Icc [mA]

0.0

0 6 12 18 24 30 36

10

8

6

4

2

OUTPUTCURRENT :ILED [mA]

0

01 23 45

Fig.12 PWM threshold voltage

Vcc=12V

SUPPLY VOLTAGE:Vcc [V]

Fig.9 Circuit Current

(Switching OFF)

PWM VOLT AGE:VEN [V]

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

4/22

2011.08 - Rev.C

BD8112EFV-M

●Block diagram and pin configuration

Vin

Ccomp

CRT

C

RISET

IN

RT

C

C

VREG

VCC

EN

SYNC

RT

COMP

R

PC

PC

SS

SS

PWM

VDAC

ISET

VREG

OCP OVP

PWM

OSC

SS

UVLO TSD

SLOPE

ISET

Timer

Latch

Control Logic

Open Short Detect

OVP

-

PWM

+

ERR AMP

Current driver

Timer

Latch

LEDEN

Fig.13

-

-

+

Open Det

Short Det

OCP

DRV

CTL

Technical Note

C

OUT

OVP

+

-

VREG

CS

FAIL1

BOOT

OUTH

SW

DGND

OUTL

GND

LED1

LED2

PGND

FAIL2

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

5/22

2011.08 - Rev.C

BD8112EFV-M

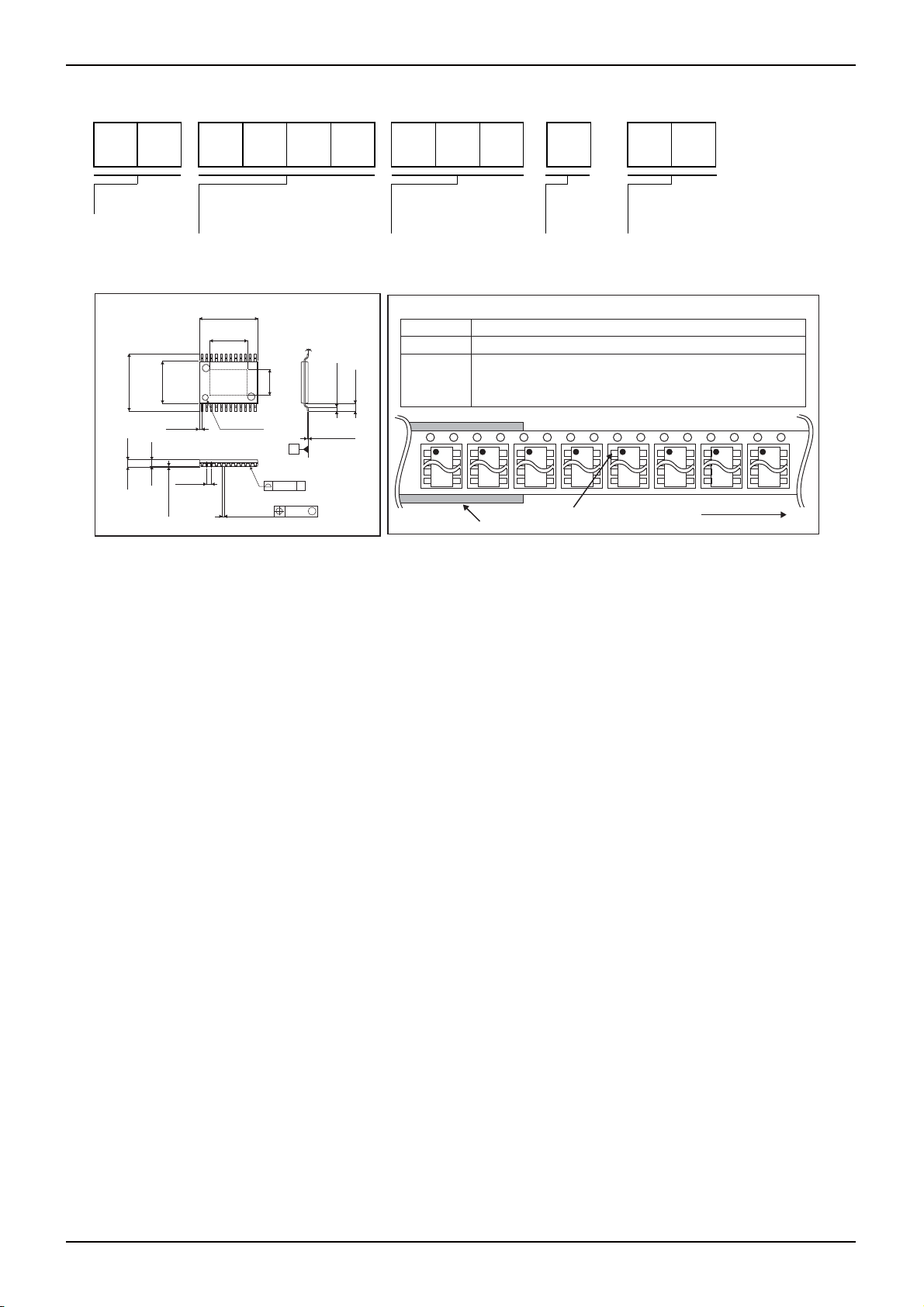

●Pin layout

BD8112EFV-M(HTSSOP-B24)

●Pin function table

Pin Symbol Function

COMP

SS

VCC

EN

RT

SYNC

GND

PWM

FAIL1

FAIL2

LEDEN

LED1

10

11

12

Technical Note

1

2

3

4

5

6

7

8

9

Fig.14

24

23

22

21

20

19

18

17

16

15

14

13

VREG

BOOT

CS

OUTH

SW

DGND

OUTL

PGND

ISET

VDAC

OVP

LED2

1 COMP Error amplifier output

2 SS Soft start time-setting capacitance input

3 VCC Input power supply

4 EN Enable input

5 RT Oscillation frequency-setting resistance input

6 SYNC External synchronization signal input

7 GND Small-signal GND

8 PWM PWM light modulation input

9 FAIL1 Failure signal output

10 FAIL2 LED open/short detection signal output

11 LEDEN LED output enable pin

12 LED1 LED output 1

13 LED2 LED output 2

14 OVP Over-voltage detection input

15 VDAC DC variable light modulation input

16 ISET LED output current-setting resistance input

17 PGND LED output GND

18 OUTL Low-side external MOSFET Gate Drive out put

19 DGND Low-side internal MOSFET Source out put

20 SW High-side external MOSFET Source pin

21 OUTH High-side external MOSFET Gate Drive out pin

22 CS DC/DC Current Sense Pin

23 BOOT High-side MOSFET Power Supply pin

24 VREG Internal reference voltage output

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

6/22

2011.08 - Rev.C

BD8112EFV-M

Technical Note

●5V voltage reference (VREG)

5V (Typ.) is generated from the VCC input voltage when the enable pin is set high. This voltage is used to power internal

circuitry, as well as the voltage source for device pins that need to be fixed to a logical HIGH. UVLO protection is integrated

into the VREG pin. The voltage regulation circuitry operates uninterrupted for output voltages higher than 4.45 V (Typ.),

but if output voltage drops to 4.3 V (Typ.) or lower, UVLO engages and turns the IC off. Connect a capacitor (Creg = 2.2µF

Typ.) to the VREG terminal for phase compensation. Operation may become unstable if Creg is not connected.

●Constant-current LED drivers

If less than four constant-current drivers are used, unused channels should be switched off via the LEDEN pin configuration.

The truth table for these pins is shown below. If a driver output is enabled but not used (i.e. left open), the IC’s open

circuit-detection circuitry will operate. Please keep the unused pins open. The LEDEN terminals are pulled down internally

in the IC, so if left open, the IC will recognize them as logic LO. However, they should be connected directly to VREG or

fixed to a logic HI when in use.

LED

LED EN

1 2

L ON ON

H ON OFF

・Output current setting

LED current is computed via the following equation:

= min[VDAC , VISET(=2.0V)] / RSET x GAIN [A]

I

LED

(min[VDAC , 2.0V] = the smaller value of either VDAC or VISET; GAIN = set by internal circuitry.)

In applications where an external signal is used for output current control, a control voltage in the range of 0.0 to 2.0 V

can be connected on the VDAC pin to control according to the above equation. If an external control signal is not used,

connect the VDAC pin to VREG (do not leave the pin open as this may cause the IC to malfunction). Also, do not switch

individual channels on or off via the LEDEN pin while operating in PWM mode.

The following diagram illustrates the relation between ILED and GAIN.

3150

ILED vs GAIN

GAIN

3100

3050

3000

2950

2900

2850

0 20 40 60 80 100 120 140 160

ILED[mA]

In PWM intensity control mode, the ON/OFF state of each current driver is controlled directly by the input signal on the

PWM pin; thus, the duty ratio of the input signal on the PWM pin equals the duty ratio of the LED current. When not

controlling intensity via PWM, fix the PWM terminal to a high voltage (100%). Output light intensity is greatest at 100%

input.

PWM

PWM

ILED(50mA/div)

ILED

PWM=150Hz Duty=0.

PWM=150Hz Duty=50%

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

7/22

2011.08 - Rev.C

BD8112EFV-M

Technical Note

●Buck-Boost DC/DC controller

・Number of LEDs in series connection

Output voltage of the DCDC converter is controlled such that the forward voltage over each of the LEDs on the output is

set to 1.0V (Typ.). DCDC operation is performed only when the LED output is operating. When two or more LED outputs

are operating simultaneously, the LED voltage output is held at 1.0V (Typ.) per LED over the column of LEDs with the

highest VF value. The voltages of other LED outputs are increased only in relation to the fluctuation of voltage over this

column. Consideration should be given to the change in power dissipation due to variations in VF of the LEDs. Please

determine the allowable maximum VF variance of the total LEDs in series by using the description as shown below:

VF variation allowable voltage 3.7V (Typ.) = short detecting voltage 4.5V (Typ.)-LED control voltage 1.0V (Typ.)

The number of LEDs that can be connected in series is limited due to the open-circuit protection circuit, which engages at

85% of the set OVP voltage. Therefore, the maximum output voltage of the under normal operation becomes

30.6 V (= 36 V x 0.85, where (30.6 V – 1.0 V) / VF > N [maximum number of LEDs in series]).

・Over-voltage protection circuit (OVP)

The output of the DCDC converter should be connected to the OVP pin via a voltage divider. In determining an

appropriate trigger voltage of for OVP function, consider the total number of LEDs in series and the maximum variation in

VF. Also, bear in mind that over-current protection (OCP) is triggered at 0.85 x OVP trigger voltage. If the OVP

function engages, it will not release unless the DCDC voltage drops to 72.5% of the OVP trigger voltage. For example, if

ROVP1 (output voltage side), ROVP2 (GND side), and DCDC voltages VOUT are conditions for OVP, then:

VOUT ≥ (ROVP1 + ROVP2) / ROVP2 x 2.0 V.

OVP will engage when VOUT ≧ 32 V if ROVP1 = 330 kΩ and ROVP2 = 22 kΩ.

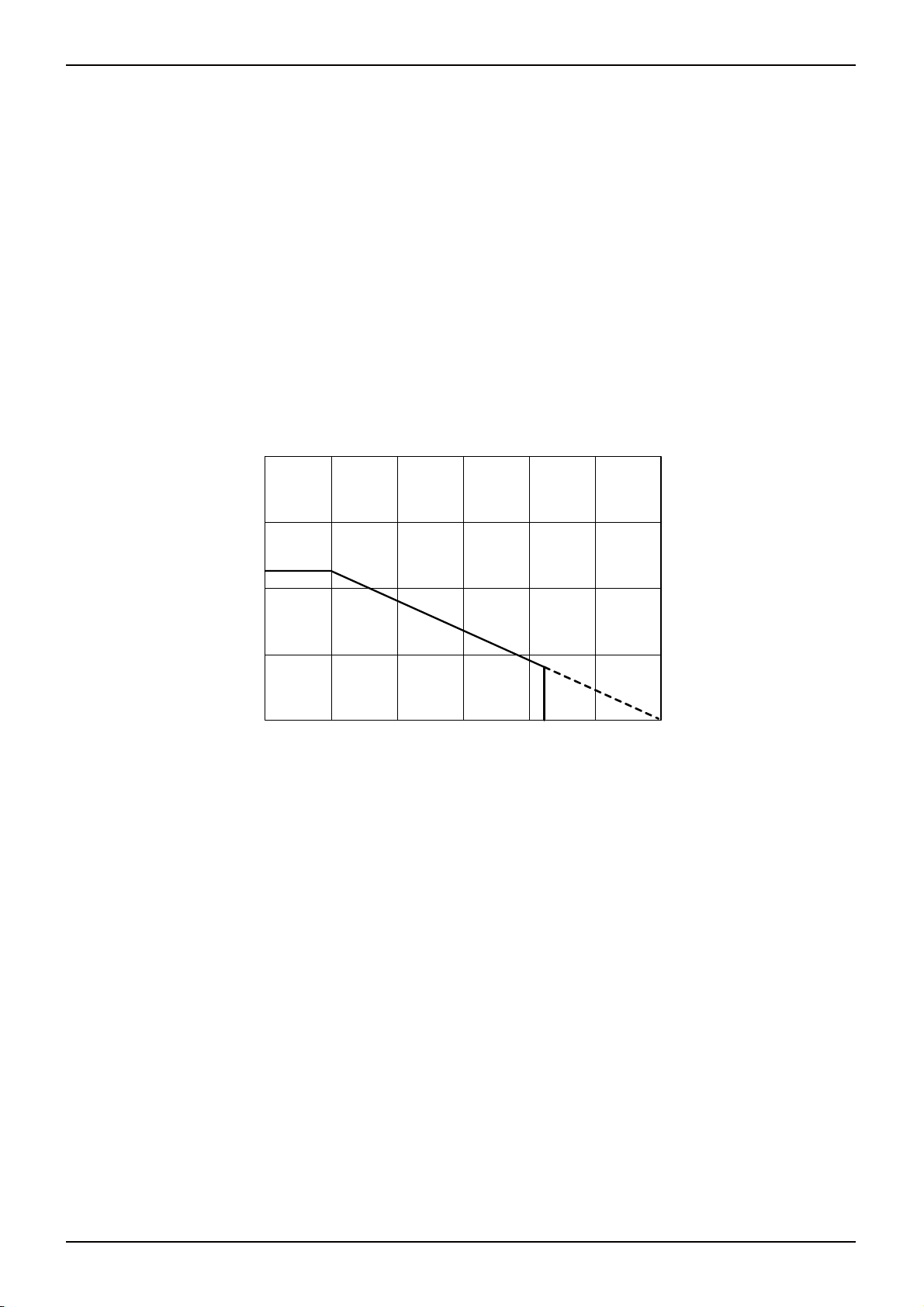

・Buck-boost DC/DC converter oscillation frequency (FOSC)

The regulator’s internal triangular wave oscillation frequency can be set via a resistor connected to the RT pin (pin 5).

This resistor determines the charge/discharge current to the internal capacitor, thereby changing the oscillating frequency.

Refer to the following theoretical formula when setting RT:

30 x 10

fosc = x α [kHz]

6

(V/A/S) is a constant (±5%) determined by the internal circuitry, and α is a correction factor that varies in relation

30 × 10

RT [Ω]

6

to RT:

{ RT: α = 50kΩ: 0.94, 60kΩ: 0.985, 70kΩ: 0.99, 80kΩ: 0.994, 90kΩ: 0.996, 100kΩ: 1.0,

150kΩ: 1.01, 200kΩ: 1.02, 300kΩ: 1.03, 400kΩ: 1.04, 500kΩ: 1.045}

A resistor in the range of 47kΩ~523kΩ is recommended. Settings that deviate from the frequency range shown below

may cause switching to stop, and proper operation cannot be guaranteed.

600k

500k

400k

300k

Fr equency [kHz ]

200k

100k

k

0 100 200 300 400 500 600 700 800

RT[kΩ]

Fig.15 RT versus switching frequency

・External DC/DC converter oscillating frequency synchronization (FSYNC)

Do not switch from external to internal oscillation of the DC/DC converter if an external synchronization signal is present

on the SYNC pin. When the signal on the SYNC terminal is switched from high to low, a delay of about 30 µs (typ.)

occurs before the internal oscillation circuitry starts to operate (only the rising edge of the input clock signal on the SYNC

terminal is recognized). Moreover, if external input frequency is less than the internal oscillation frequency, the internal

oscillator will engage after the above-mentioned 30 µs (typ.) delay; thus, does not input a synchronization signal with a

frequency less than the internal oscillation frequency.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

8/22

2011.08 - Rev.C

BD8112EFV-M

Technical Note

・Soft Start Function

The soft-start (SS) limits the current and slows the rise-time of the output voltage during the start-up, and hence leads to

prevention of the overshoot of the output voltage and the inrush current.

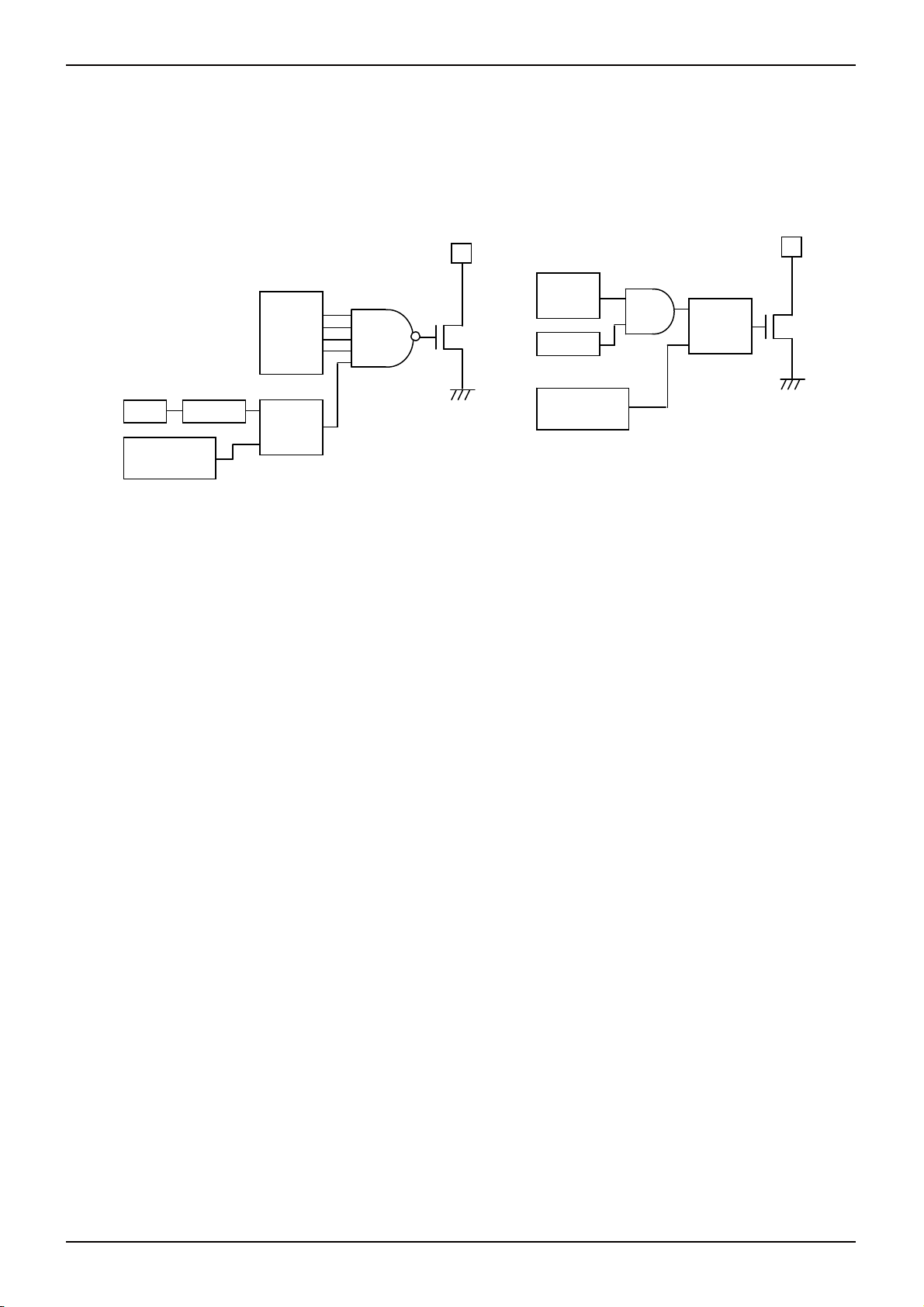

・Self-diagnostic functions

The operating status of the built-in protection circuitry is propagated to FAIL1 and FAIL2 pins (open-drain outputs). FAIL1

becomes low when UVLO, TSD, OVP, or SCP protection is engaged, whereas FAIL2 becomes low when open or short

LED is detected.

UVLO

TSD

OVP

OCP

FAIL1

OPEN

SHORT

MASK

S

Q

R

EN=Low

UVLO/TSD

Counter SCP

S

Q

R

EN=Low

UVLO/TSD

・Operation of the Protection Circuitry

・Under-Voltage Lock Out (UVLO)

The UVLO shuts down all the circuits other than REG when VREG ≦ 4.3V (TYP).

・Thermal Shut Down (TSD)

The TSD shuts down all the circuits other than REG when the Tj reaches 175℃ (TYP), and releases when the Tj

becomes below 150℃ (TYP).

・Over Current Protection (OCP)

The OCP detects the current through the power-FET by monitoring the voltage of the high-side resistor, and activates

when the CS voltage becomes less than VCC-0.6V (TYP).

When the OCP is activated, the external capacitor of the SS pin becomes discharged and the switching operation of

the DCDC turns off.

・Over Voltage Protection (OVP)

The output voltage of the DCDC is detected with the OVP-pin voltage, and the protection activates when the OVP-pin

voltage becomes greater than 2.0V (TYP).

When the OVP is activated, the external capacitor of the SS pin becomes discharged and the switching operation of

the DCDC turns off.

・Short Circuit Protection (SCP)

When the LED-pin voltage becomes less than 0.3V (TYP), the internal counter starts operating and latches off the circuit

approximately after 100ms (when FOSC = 300 kHz). If the LED-pin voltage becomes over 0.3V before 100ms, then the

counter resets. When the LED anode (i.e. DCDC output voltage) is shorted to ground, then the LED current becomes off

and the LED-pin voltage becomes low. Furthermore, the LED current also becomes off when the LED cathode is shorted

to ground. Hence in summary, the SCP works with both cases of the LED anode and the cathode being shorted.

・LED Open Detection

When the LED-pin voltage 0.3V (TYP) as well as OVP-pin voltage 1.7V (TYP) simultaneously, the device detects as

LED open and latches off that particular channel.

FAIL2

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

9/22

2011.08 - Rev.C

BD8112EFV-M

Technical Note

・LED Short Detection

When the LED-pin voltage 4.5V (TYP) as well as OVP-pin voltage 1.6V (TYP) simultaneously the internal counter

starts operating, and approximately after 100ms (when FOSC = 300 kHz) the only detected channel (as LED short)

latches off. With the PWM brightness control, the detecting operation is processed only when PWM-pin = High. If the

condition of the detection operation is released before 100ms (when FOSC = 300 kHz), then the internal counter resets.

* The counter frequency is the DCDC switching frequency determined by the RT. The latch proceeds at the count of 32770.

Detecting Condition

Protection

Operation after detect

[Detect] [Release]

UVLO VREG<4.3V VREG>4.45V

TSD Tj>175℃ Tj<150℃

All blocks (but except REG)

shut down

All blocks (but except REG)

shut down

OVP VOVP>2.0V VOVP<1.45V SS discharged

OCP VCS≦VCC-0.6V VCS>VCC-0.6V SS discharged

SCP

(100ms delay when FOSC=300kHz)

VLED<0.3V

EN or UVLO

Counter starts and then latches off all

blocks (but except REG)

LED open VLED<0.3V & VOVP>1.7V EN or UVLO The only detected channel latches off

LED short

VLED>4.5V & VOVP<1.6V

(100ms delay when FOSC=300kHz)

EN or UVLO

The only detected channel latches off

(after the counter sets)

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

10/22

2011.08 - Rev.C

BD8112EFV-M

●Protection Sequence

VCC

*

EN

VREG

UVLO

VDAC

SYNC

PWM

1

4.45V

*

1

*

2

*

2

SS

ILED1

ILED2

ILED1'

ILED2'

VLED1

VLED2

VLED1'

VLED2'

1.0V

VOVP

*

FAIL1

4

<0.3V

1.7V

①

②

>4.5V

100ms

*

3

FAIL2

*1 After VCC voltage reached to operating conditions, set VDAC voltage, and turn on the EN.

After VREG≧4.6V, turn on SYNC and PWM inputs.

*2 Don’t care input sequence PWM and SYNC.

*3 Aprox 100ms of delay when Fosc = 300kHz

*4 When FAIL1 pull-up to outside power supply.

① Case for LED2 in open-mode

When VLED2<0.3V and VOVP>1.7V simultaneously, then LED2 becomes off and FAIL2 becomes low

② Case for LED1’ in short-mode

When VLED1’>4.5V and VOVP<1.6V simultaneously, then LED1’ becomes off after 100ms approx

③ Case for LED2’ in short to GND

③-1 DCDC output voltage increases, and then SS discharges and FAIL1 becomes low

③-2 Detects VLED2’<0.3V and shuts down after 100ms approx

0.3V

2.0V

100ms

③

Technical Note

④

*

3

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

11/22

2011.08 - Rev.C

BD8112EFV-M

●Procedure for external components selection

Follow the steps as shown below for selecting the external components

1. Work out IL_MAX from the operating conditions.

2. Select the value of RSC such that IOCP > IL_MAX

3. Select the value of L such that 0.05[V/µs] <

4. Select coil, schottky diodes, MOSFET and RCS which meet with the ratings

5. Select the output capacitor which meets with the ripple voltage requirements

6. Select the input capacitor

7. Work on with the compensation circuit

8. Work on with the Over-Voltage Protection (OVP) setting

9. Work on with the soft-start setting

10. erify experimentally

Vout

*RCS < 0.3[V/ µs]

L

Technical Note

Feedback the value of L

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

12/22

2011.08 - Rev.C

BD8112EFV-M

Technical Note

1. Computation of the Input Peak Current and IL_MAX

①Calculation of the maximum output voltage (Vout_max)

To calculate the Vout_max, it is necessary to take into account of the VF variation and the number of LED connection in

series.

Vout_max = (VF + ΔVF) × N + 1.0V ΔVF: VF Variation N: Number of LED connection in series

②Calculation of the output current Iout

Iout = ILED × 1.05 × M M:Number of LED connection in parallel

③Calculation of the input peak current IL_MAX

IL_MAX = IL_AVG + 1/2ΔIL

IL_AVG = (VIN + Vout) × Iout / (n × VIN)

ΔIL= × × n: efficiency Fosc: switching frequency

VIN

L

1

Fosc

Vout

IN+Vout

V

・The worst case scenario for VIN is when it is at the minimum, and thus the minimum value should be applied in the

equation.

・ The L value of 10µF 47µF is recommended. The current-mode type of DC/DC conversion is adopted for

BD8112EFV-M, which is optimized with the use of the recommended L value in the design stage. This recommendation

is based upon the efficiency as well as the stability. The L values outside this recommended range may cause irregular

switching waveform and hence deteriorate stable operation.

・n (efficiency) is approximately 80%

VIN

Rcs

IL

CS

M1

L

D2

Vout

D1

M2

Co

External Application Circuit

2. The setting of over-current protection

Choose Rcs with the use of the equation Vocp_min (=0.54V) / Rcs > IL_MAX

When investigating the margin, it is worth noting that the L value may vary by approximately ±30%.

3. The selection of the L

In order to achieve stable operation of the current-mode DC/DC converter, we recommend selecting the L value in the

range indicated below:

0.05 [V/µs] < < 0.3 [V/µs]

The smaller allows stability improvement but slows down the response time.

Vout×Rcs

L

Vout×Rcs

L

4. Selection of coil L, diode D1 and D2, MOSFET M1 and M2, and Rcs

Current rating Voltage rating Heat loss

Coil L > IL_MAX ―

Diode D1 > Iocp > VIN_MAX

Diode D2 > Iocp > Vout

MOSFET M1 > Iocp > VIN_MAX

MOSFET M2 > Iocp > Vout

Rcs ― ― > Iocp2 × Rcs

* Allow some margin, such as the tolerance of the external components, when selecting.

* In order to achieve fast switching, choose the MOSFETs with the smaller gate-capacitance.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

13/22

2011.08 - Rev.C

BD8112EFV-M

A

Technical Note

5. Selection of the output capacitor

Select the output capacitor Cout based on the requirement of the ripple voltage Vpp.

Vpp = × × + IL_MIN × RESR

Iout

Cout

Vout

Vout+V

IN

1

Fosc

Choose Cout that allows the Vpp to settle within the requirement. Allow some margin also, such as the tolerance of the

external components.

6. Selection of the input capacitor

A capacitor at the input is also required as the peak current flows between the input and the output in DC/DC conversion.

We recommend an input capacitor greater than 10µF with the ESR smaller than 100m. The input capacitor outside of

our recommendation may cause large ripple voltage at the input and hence lead to malfunction.

7. Phase Compensation Guidelines

In general, the negative feedback loop is stable when the following condition is met:

・Overall gain of 1 (0dB) with a phase lag of less than 150º (i.e. a phase margin of 30º or more)

However, as the DC/DC converter constantly samples the switching frequency, the gain-bandwidth (GBW) product of the

entire series should be set to 1/10 the switching frequency of the system. Therefore, the overall stability characteristics

of the application are as follows:

・Overall gain of 1 (0dB) with a phase lag of less than 150º (i.e. a phase margin of 30º or more)

・GBW (frequency at gain 0dB) of 1/10 the switching frequency

Thus, to improve response within the GBW product limits, the switching frequency must be increased.

The key for achieving stability is to place fz near to the GBW.

Vout

Phase-lead fz = [Hz]

Phase-lag fp1 = [Hz]

1

2πCpcRpc

1

2πRLCout

LED

FB

COMP

Good stability would be obtained when the fz is set between 1kHz~10kHz.

In buck-boost applications, Right-Hand-Plane (RHP) Zero exists. This Zero has no gain but a pole characteristic in terms

of phase. As this Zero would cause instability when it is in the control loop, so it is necessary to bring this zero before the

GBW.

fRHP= [Hz] I

Vout+VIN/(Vout+VIN)

2πI

LOAD

L

LOAD: Maximum Load Current

It is important to keep in mind that these are very loose guidelines, and adjustments may have to be made to ensure

stability in the actual circuitry. It is also important to note that stability characteristics can change greatly depending on

factors such as substrate layout and load conditions. Therefore, when designing for mass-production, stability should be

thoroughly investigated and confirmed in the actual physical design.

Rpc

Cpc

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

14/22

2011.08 - Rev.C

BD8112EFV-M

Technical Note

8. Setting of the over-voltage protection

We recommend setting the over-voltage protection Vovp 1.2V to

1.5V greater than Vout which is adjusted by the number of LEDs

in series connection. Less than 1.2V may cause unexpected

detection of the LED open and short during the PWM brightness

control. For the Vovp greater than 1.5V, the LED short detection

may become invalid.

9. Setting of the soft-start

The soft-start allows minimization of the coil current as well as

Vo

ROVP2

ROVP1

OVP

-

+

2.0V/1.45V

-

+

1.7V/1.6V

the overshoot of the output voltage at the start-up.

For the capacitance we recommend in the range of 0.001 0.1µF. For the capacitance less than 0.001µF may cause

overshoot of the output voltage. For the capacitance greater than 0.1µF may cause massive reverse current through the

parasitic elements of the IC and damage the whole device. In case it is necessary to use the capacitance greater than

0.1µF, ensure to have a reverse current protection diode at the Vcc or a bypass diode placed between the SS-pin and the

Vcc.

Soft-start time TSS

TSS = CSSX0.7V / 5µA [s] CSS: The capacitance at the SS-pin

10.Verification of the operation by taking measurements

The overall characteristic may change by load current, input voltage, output voltage, inductance, load capacitance,

switching frequency, and the PCB layout. We strongly recommend verifying your design by taking the actual

measurements.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

15/22

2011.08 - Rev.C

BD8112EFV-M

●Power Dissipation Calculation

Power dissipation can be calculated as follows:

Pc(N) = ICC*VCC + 2*Ciss*VREG*Fsw*Vcc+[VLED*N+△Vf*(N-1)]*ILED

Maximum circuit current

I

CC

V

Supply power voltage

CC

C

External FET capacitance

iss

V

SW gate voltage

sw

F

SW frequency

sw

V

LED control voltage

LED

N LED parallel numeral

ΔV

LED Vf fluctuation

f

I

LED output current

LED

Sample Calculation:

Pc(2) = 10mA × 30V + 500pF × 5V × 300kHz × 30V + [1.0V × 2 + △Vf × 1] × 100mA

When △Vf = 3.0V, Pc (2) = 0.82W

Power Dissipation

2.0

1.5

1.0

1.1W

0.5

Power Dissipation Pd [W]

0

25

Ambient Temperature Ta[℃]

105

1501251007550

Note 1: Power dissipation calculated when mounted on 70mm X 70mm X 1.6mm glass epoxy substrate (1-layer platform/copper thickness 18µm)

Note 2: Power dissipation changes with the copper foil density of the board. This value represents only observed values, not guaranteed values.

Technical Note

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

16/22

2011.08 - Rev.C

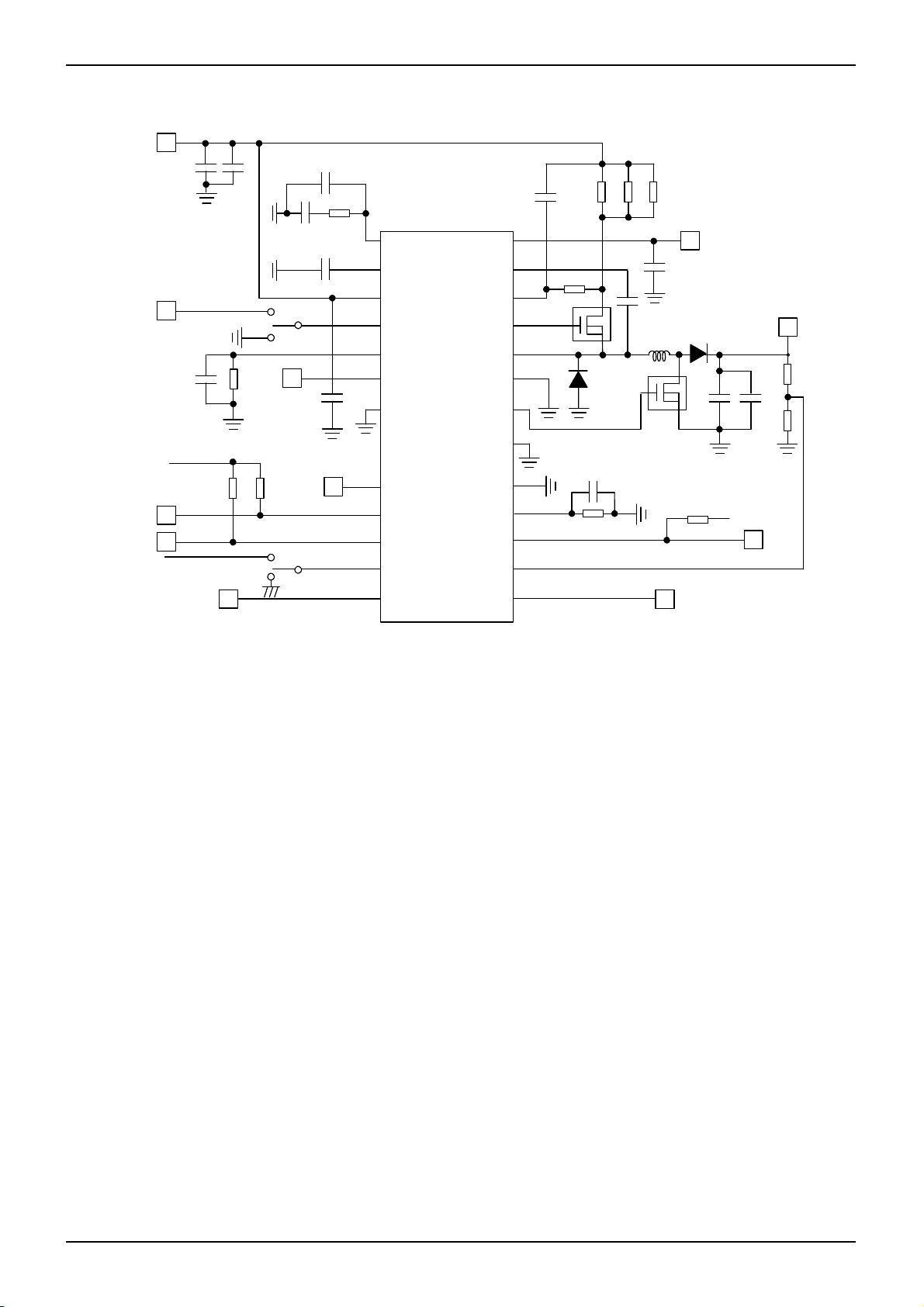

BD8112EFV-M

VCC

EN

VREG

FAIL1

FAIL2

VREG

VCC

CIN1 CIN2

CRT

RRT

LED1

SYNC

RFL1 RFL2

CPC1

SW1

SW2

PWM

CPC2

CSS

RPC1

CIN3

1. COMP

2. SS

3. VCC

4. EN

5. RT

6. SYNC

7. GND

FIN. FIN

8. PWM

9. FAIL1

10. FAIL2

11. LEDEN

12. LED1

24. VREG

23. BOOT

21. OUTH

19. DGND

18. OUTL

FIN. FIN

17. PGND

16. ISET

15. VDAC

14. OVP

13. LED2

22. CS

20. SW

FIN. FIN

Technical Note

CCS

RCS

G

5

M

1 S

CISET

RISET

D1

RCS1 RCS2 RCS3

D

CBT

G

M2 S

CREG

L1

D

RDAC

LED2

VREG

D2

COUT1 COUT2

VREG

VDAC

VOUT

ROVP2

ROVP1

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

17/22

2011.08 - Rev.C

BD8112EFV-M

●How to select parts of application

serial No.

component name component value product name Manufacturer

1 CIN1 10µF GRM31CB31E106KA75B murata

2 CIN2 -

3 CIN3 -

4 CPC1 0.1µF

5 CPC2 - murata

6 RPC1 510Ω

7 CSS 0.1µF GRM188B31H104KA92 murata

8 RRT 100kΩ MCR03 Series Rohm

9 CRT -

10 RFL1 100kΩ MCR03 Series Rohm

11 RFL2 100kΩ MCR03 Series Rohm

12 CCS -

13 RCS1 620mΩ MCR100JZHFLR620 Rohm

Technical Note

14 RCS2 620mΩ MCR100JZHFLR620 Rohm

15 RCS3 -

16 RCS5 0Ω

17 CREG 2.2µF GRM188B31A225KE33 murata

18 CBT 0.1µF GRM188B31H104KA92 murata

19 M1 - RSH070N05 Rohm

20 M2 - RSH070N05 Rohm

21 D1 - RB050L-40 Rohm

22 D2 - RF201L2S Rohm

23 L1 33µH CDRH105R330 Sumida

24 COUT1 10µF GRM31CB31E106KA75B murata

25 COUT2 10µF GRM31CB31E106KA75B murata

26 ROVP1 30kΩ MCR03 Series Rohm

27 ROVP2 360kΩ MCR03 Series Rohm

28 RISET 120kΩ MCR03 Series Rohm

29 CISET -

30 RDAC 0Ω

When performing open/short tests of the external components, the open condition of D1 or D2 may cause permanent

damage to the driver and/or the external components. In order to prevent this, we recommend having parallel connections

for D1 and D2.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

18/22

2011.08 - Rev.C

BD8112EFV-M

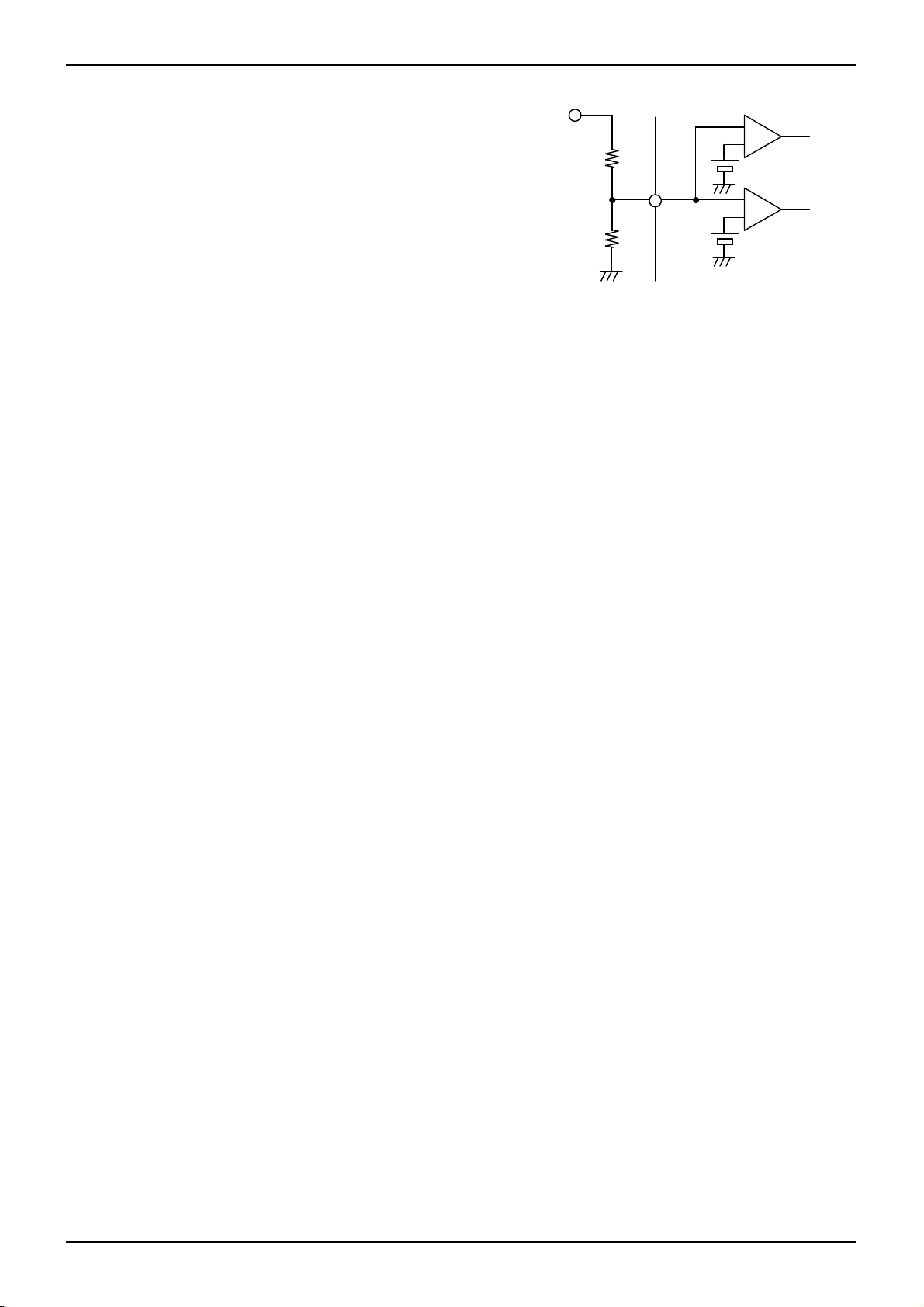

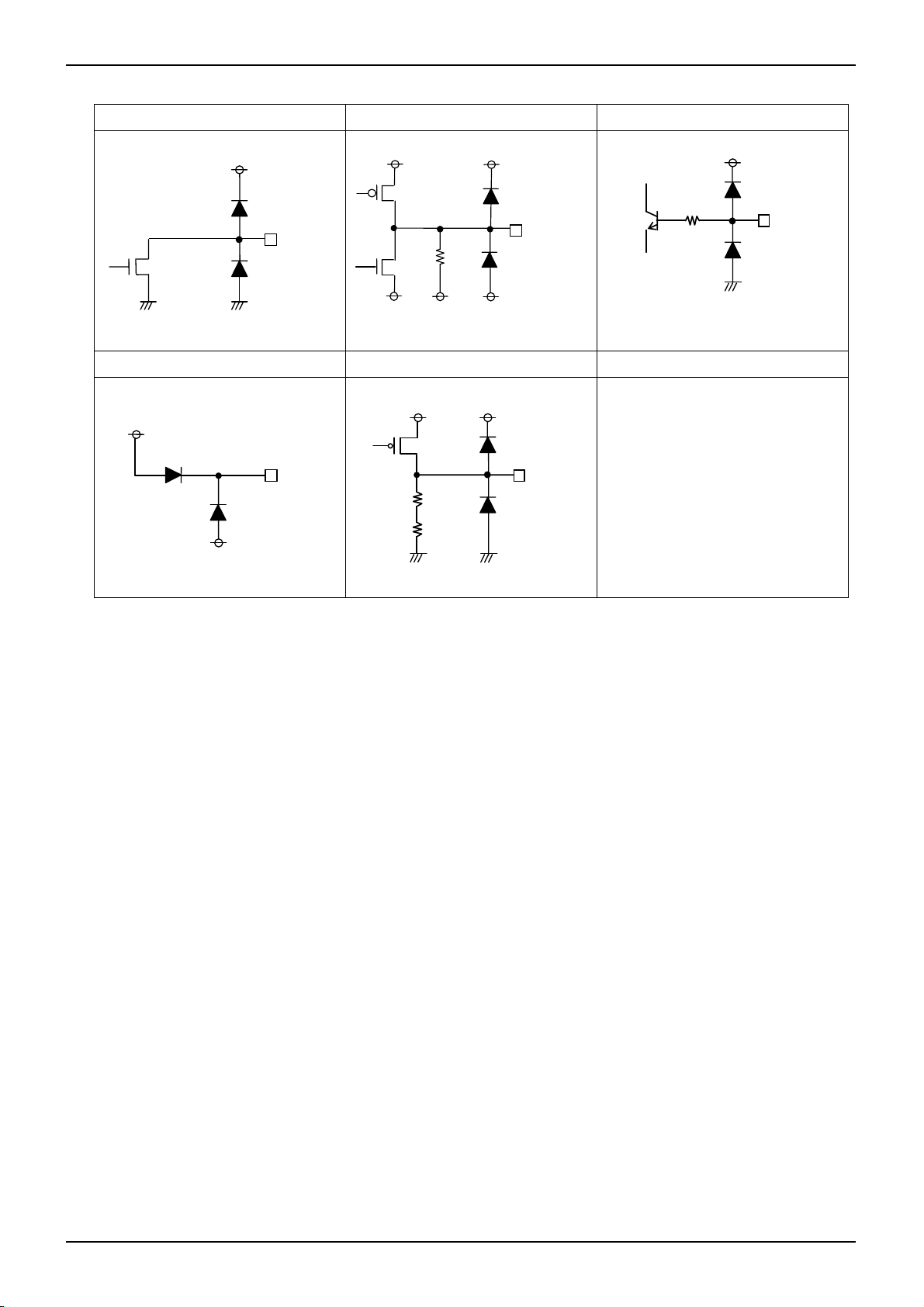

●Input/output Equivalent Circuits (terminal name follows pin number)

1. COMP 2. SS 4. EN

VREG VREG

VccVREG

2K

2K

1K

COMP

SS

5. RT 6. SYNC, 8. PWM 9. FAIL1, 10. FAIL2

VREG

167

RT

3.3V

10K

150K

SYNC

PWM

1K

10k

Technical Note

Vcc

175k

135k

FAIL1

FAIL2

EN

11. LEDEN 12. LED1, 13. LED2 14. OVP

3.3V

Vcc

10K

150K

10K

LEDEN

5K

LED1,2

2.5K

15. VDAC 16. ISET 18. OUTL

VREG

Vcc

500

VDAC

VREG

Vcc

500

12.5

ISET

VREG

10k

100K

Vcc

OVP

VREG

OUTL

*All values typical.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

19/22

2011.08 - Rev.C

BD8112EFV-M

20. SW 21. OUTH 22. CS

Vcc

SW

BOOT

BOOT

OUTH

100K

Technical Note

5K

Vcc

CS

SW

SW

SW

23. BOOT 24. VREG

VREG

VccVREG

*All values typical.

SW

BOOT

VREG

205K

100K

●Notes for use

1. Absolute maximum ratings

We are careful enough for quality control about this IC. So, there is no problem under normal operation, excluding that it

exceeds the absolute maximum ratings. However, this IC might be destroyed when the absolute maximum ratings, such

as impressed voltages or the operating temperature range (Topr) is exceeded, and whether the destruction is short circuit

mode or open circuit mode cannot be specified. Please take into consideration the physical countermeasures for safety,

such as fusing, if a particular mode that exceeds the absolute maximum rating is assumed.

2. Reverse polarity connection

Connecting the power line to the IC in reverse polarity (from that recommended) will damage the part. Please utilize the

direction protection device as a diode in the supply line.

3. Power supply line

Due to return of regenerative current by reverse electromotive force, using electrolytic and ceramic suppress filter

capacitors (0.1µF) close to the IC power input terminals (Vcc and GND) are recommended. Please note the electrolytic

capacitor value decreases at lower temperatures and examine to dispense physical measures for safety.

And, for ICs with more than one power supply, it is possible that rush current may flow instantaneously due to the internal

powering sequence and delays. Therefore, give special consideration to power coupling capacitance, width of power

wiring, GND wiring, and routing of wiring. Please make the power supply lines (where large current flow) wide enough to

reduce the resistance of the power supply patterns, because the resistance of power supply pattern might influence the

usual operation.

4. GND line

The ground line is where the lowest potential and transient voltages are connected to the IC.

5. Thermal design

Do not exceed the power dissipation (Pd) of the package specification rating under actual operation, and please design

enough temperature margins.

6. Short circuit mode between terminals and wrong mounting

Do not mount the IC in the wrong direction and be careful about the reverse-connection of the power connector.

Moreover, this IC might be destroyed when the dust short the terminals between them or power supply, GND.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

20/22

2011.08 - Rev.C

BD8112EFV-M

Technical Note

7. Radiation

Strong electromagnetic radiation can cause operation failures.

8. ASO(Area of Safety Operation.)

Do not exceed the maximum ASO and the absolute maximum ratings of the output driver.

9. TSD(Thermal shut-down)

The TSD is activated when the junction temperature (Tj) reaches 175℃(with 25℃ hysteresis), and the output terminal is

switched to Hi-z. The TSD circuit aims to intercept IC from high temperature. The guarantee and protection of IC are not

purpose. Therefore, please do not use this IC after TSD circuit operates, nor use it for assumption that operates the TSD

circuit.

10. Inspection by the set circuit board

The stress might hang to IC by connecting the capacitor to the terminal with low impedance. Then, please discharge

electricity in each and all process. Moreover, in the inspection process, please turn off the power before mounting the IC,

and turn on after mounting the IC. In addition, please take into consideration the countermeasures for electrostatic

damage, such as giving the earth in assembly process, transportation or preservation.

11. IC terminal input

This IC is a monolithic IC, and has P

+

isolation and P substrate for the element separation. Therefore, a parasitic PN

junction is firmed in this P-layer and N-layer of each element. For instance, the resistor or the transistor is connected to

the terminal as shown in the figure below. When the GND voltage potential is greater than the voltage potential at

Terminals A or B, the PN junction operates as a parasitic diode. In addition, the parasitic NPN transistor is formed in said

parasitic diode and the N layer of surrounding elements close to said parasitic diode. These parasitic elements are

formed in the IC because of the voltage relation. The parasitic element operating causes the wrong operation and

destruction. Therefore, please be careful so as not to operate the parasitic elements by impressing to input terminals

lower voltage than GND (P substrate). Please do not apply the voltage to the input terminal when the power-supply

voltage is not impressed. Moreover, please impress each input terminal lower than the power-supply voltage or equal to

the specified range in the guaranteed voltage when the power-supply voltage is impressing.

Terminal-A

+

P

Parasitic

element

Resistor

P

P-Substrate

GND

Transistor(NPN)

GND

Terminal-B

Surrounding

elements

C

B

E

Parasitic

element

GND

Terminal-B

Terminal-A

+

P

Parasitic

element

CB

+

P

Parasitic

element

E

P

P-Substrate

GND

+

P

Simplified structure of IC

12. Earth wiring pattern

Use separate ground lines for control signals and high current power driver outputs. Because these high current outputs

that flows to the wire impedance changes the GND voltage for control signal. Therefore, each ground terminal of IC must

be connected at the one point on the set circuit board. As for GND of external parts, it is similar to the above-mentioned.

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

21/22

2011.08 - Rev.C

BD8112EFV-M

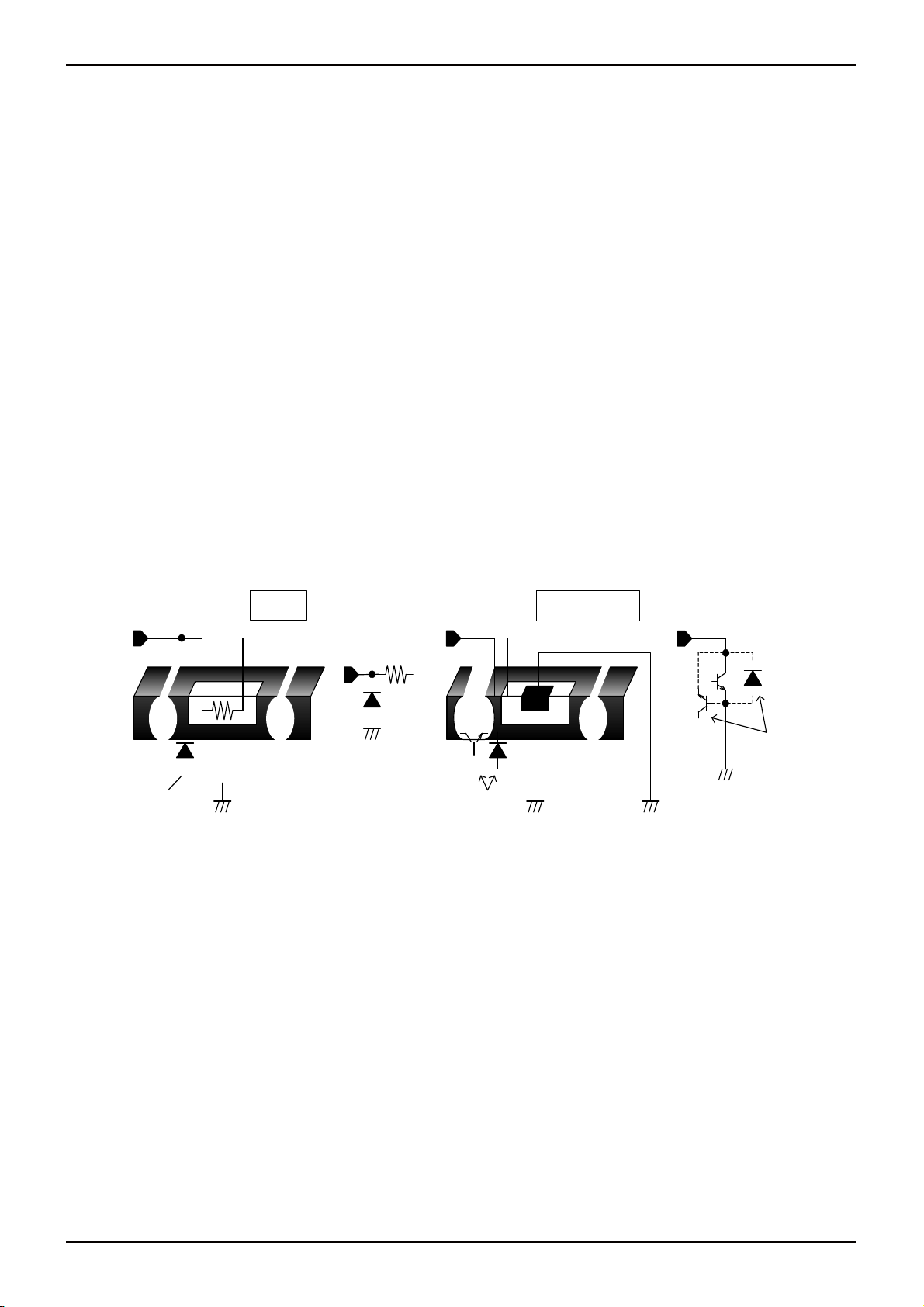

●Ordering part number

Technical Note

B D 8 1

1 2

Part No. Part No. Package

HTSSOP-B24

7.8±0.1

(MAX 8.15 include BURR)

(5.0)

24 13

+

6°

4°

−

4°

+0.05

-

0.04

0.08

(3.4)

S

S

0.08

0.53±0.15

+0.05

0.17

-

M

(Unit : mm)

1.0±0.2

0.03

7.6±0.2

5.6±0.1

112

0.325

1PIN MARK

1.0MAX

0.85±0.05

0.08±0.05

0.65

0.24

E F V - M E 2

Packaging and forming specification

EFV: HTSSOP-B24

<Tape and Reel information>

Embossed carrier tape (with dry pack)Tape

Quantity

Direction

of feed

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

E2: Embossed tape and reel

Direction of feed

www.rohm.com

© 2010 ROHM Co., Ltd. All rights reserved.

22/22

2011.08 - Rev.C

Notes

No copying or reproduction of this document, in par t or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes effor ts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...