Page 1

© 2017 ROHM Co., Ltd.

No. 60AP001E Rev.001

2017.4

User Guide

© 2018 ROHM Co., Ltd.

No. 60UG064E Rev.001

19 Feb 2018

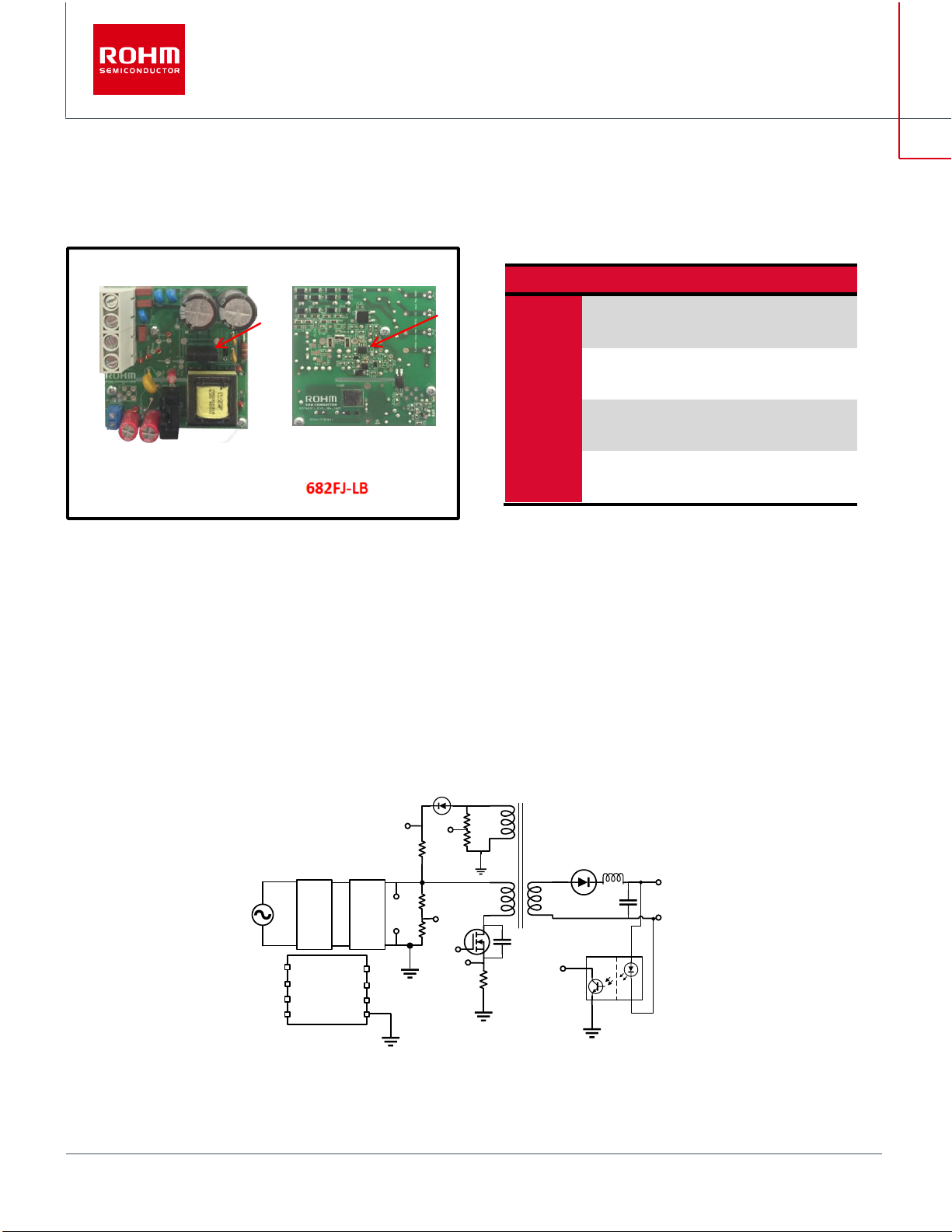

High voltage input aux power supply ev. Board

1 – 1700V SiC MOSFET SCT2H12NZ

2 – Quasi-resonant controller BD7F682FJ-LB

Board dimensions 80mm x 80mm

1

2

D

sec

V

OUT

AC Filter

Diode

Bridge

L

prim

L

sec

L

aux

Brown

Out

Gate

V

CC

V

CC

Gate

I

sense

ZT

Feedback

I

sense

Feedback

BD7682FJ

Q1

D

aux

C

OSS

+

-

Optocoupler

V

DC

+

-

ZT

Mask

Param.

Description

Value

VIN

Input

voltage

210…480 VAC

300…to 900 VDC

V

OUT

Output

voltage

12 VDC ± 3%

P

OUT

Output

power

30 W @ V

IN.MIN

40 W @ V

IN.MAX

fsw

Switching

frequency

90..120 kHz

Table 1- main electrical parameters.

BD7682FJ-EVK-301 EV BOARD USER GUIDE

Figure 1 – Top and Bottom views

The AUX board is able to operate with both AC and DC input voltages. It is therefore possible to derive the power directly

from the grid or from the system DC link, e.g. after the PFC stage. In case of AC input, the accepted input voltage range

goes from 210 VAC to 480 VAC. In case of DC input, the input range goes from 300 VDC to 900 VDC. This board version “301”

mounts screw connections to facilitate the cabling to 3phase input or Vdc input. It is possible to remove the connectors

and use vertical mounting connectors as an example of module board for Aux power supply in a power system.

The simplified schematic of the AUX board is shown in Figure 2.

Figure 2 – Simplified schematic of the AUX board.

1/16

Page 2

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Contents

1 Board information ....................................................................................................................................... 3

1.1 Schematics........................................................................................................................................ 3

1.2 Flyback Transformer ........................................................................................................................... 3

2 Board usage............................................................................................................................................... 4

2.1 General information before cabling and powering the board: ................................................................... 4

2.2 Cabling ............................................................................................................................................. 5

2.2.1 3 Phase AC connections: ............................................................................................................... 5

2.2.2 DC connections: ........................................................................................................................... 5

2.3 Test points ........................................................................................................................................ 6

3 Implementation and practical tests with AUX Board ........................................................................................ 7

3.1 Operation at no load ........................................................................................................................... 7

3.2 Normal operation ............................................................................................................................... 8

3.3 Efficiency and temperature measurements ............................................................................................ 8

4 Summary ................................................................................................................................................ 10

5 References ............................................................................................................................................... 10

Appendix A. Transformer datasheet and pictures ................................................................................... 11

Appendix B. Bill of Materials ............................................................................................................... 12

Appendix C. AUX Board layout ............................................................................................................ 14

Appendix D. Alternative Start-up Circuitry ............................................................................................ 15

This evaluation board is intended for research and development and for expert use in the research and

development facility only. This board is not intended for use for volume production.

2/16

Page 3

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Parameter

Calculated

Transformer (E25)

Primary inductance

1.07 mH

0.95 mH ±10%

Leakage inductance

--

1% (9 µH)

Maximum primary current

0.86 A

1.5 A *

Turn-ratio primary to secondary

10

10 ± 1%

Turn-ratio secondary to auxiliary

1.92

2 ± 1%

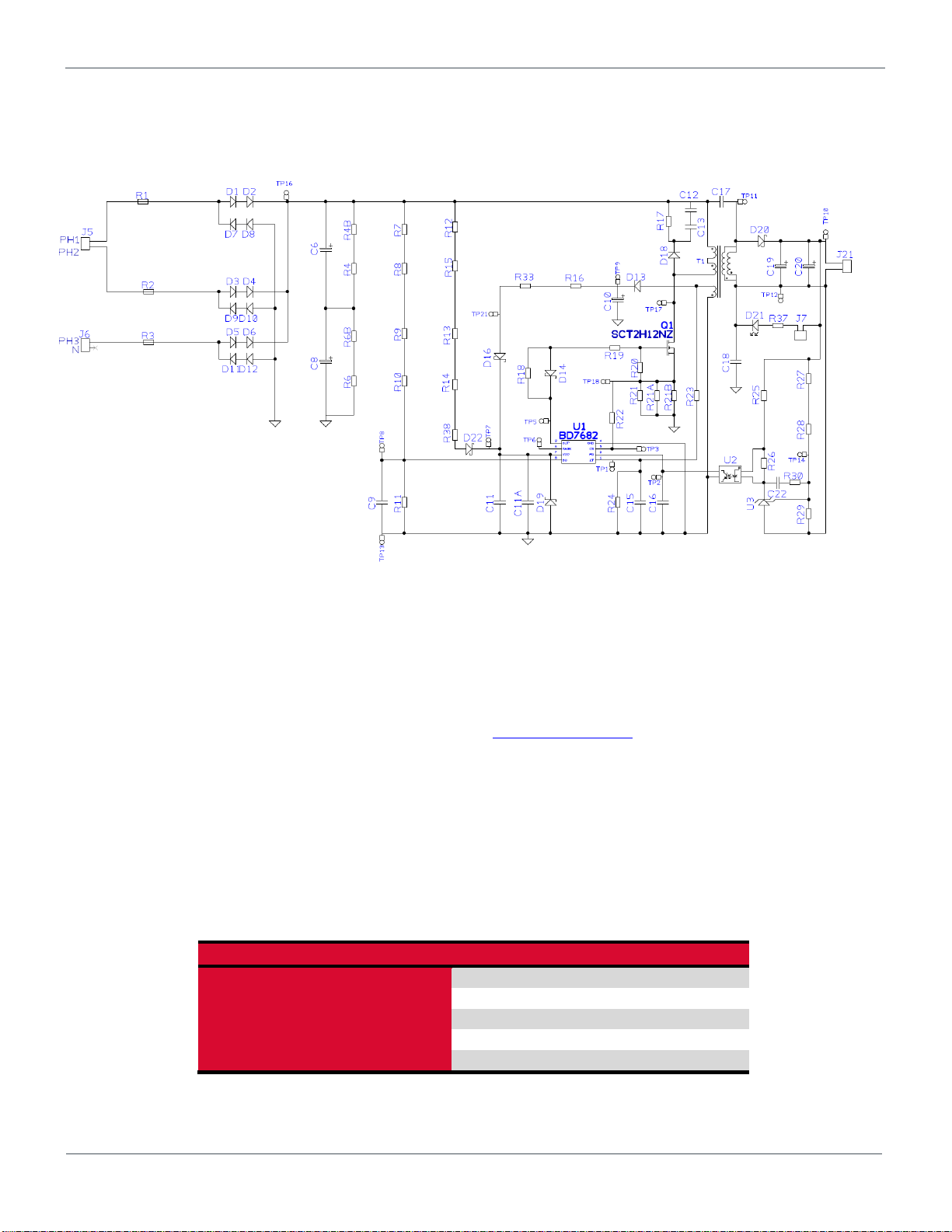

Figure 3 - Full schematic of the AUX board

* Core saturation current

1 Board information

1.1 Schematics

Please refer to Appendix B for BOM, Appendix C for Layout and Appendix D for alternative startup circuit to improve

efficiency.

1.2 Flyback Transformer

A customized transformer manufactured by Würth Elektronik (www.we-online.com), has been designed.

It is possible to order and get all the information by contacting the producer referring code n. 750316318.

The datasheet of the transformer can be found in Appendix A.

The primary side is composed by two windings in series, while the secondary side has been implemented with two

windings in parallel. The half-windings are interposed, in order to reduce the leakage inductance around 1% of L

will impact the switching behavior of the MOSFET. In addition, the windings have been implemented with Litz wire to

reduce the losses due to skin effect.

. This

pri

Table 2 - Calculated parameters and characteristics of the used transformer.

3/16

Page 4

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

2 Board usage

2.1 General information before cabling and powering the board:

- Check carefully that the input voltages are within the maximum input range in table 1.

- Double check the cabling before powering the board.

- This board is protected against overload and short circuit.

- Avoid any imperfect connection that can create sparks

- Check the isolation class and section of the cables.

- Apply all appropriate checks and precautions for use of a high voltage board.

- Refer to the notice at the end of this document for proper usage of this board.

- Only use in a technical environment by professionals trained to safely manage high voltage boards.

- This board is only for evaluation purposes and it’s not guaranteed for prolonged usage or usage

in any final product

4/16

Page 5

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Phase 1

Phase 2

Phase 3

Neutral

12Vdc To Load +

Volt Ref To Load -

400Vac to

480Vac 3 Phase

Input DC Voltage+

Input DC Voltage -

12Vdc To Load +

Volt Ref To Load -

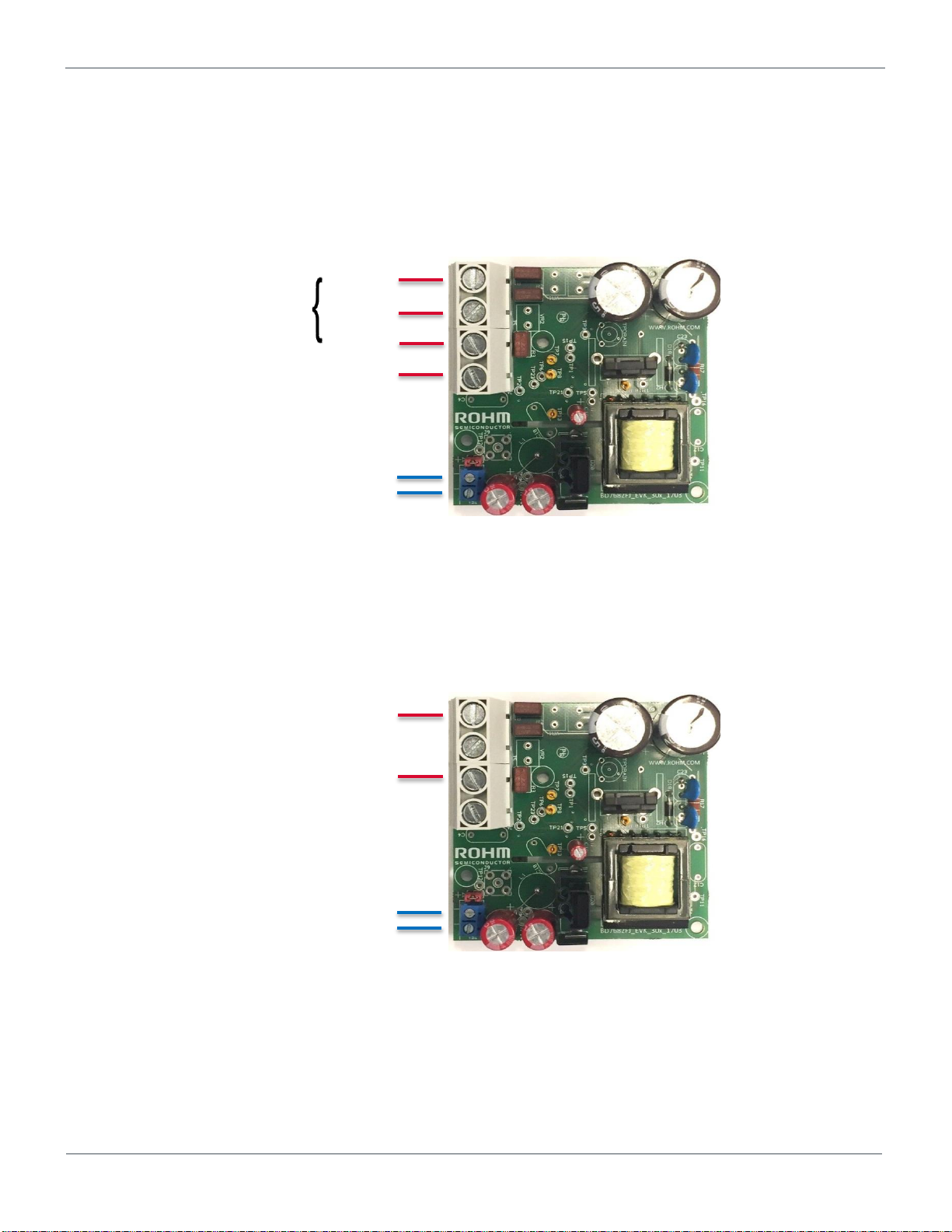

2.2 Cabling

2.2.1 3 Phase AC connections:

The board can be connected directly to 3 Phase mains as for the below connection guide.

Figure 4 - 3Phase AC connection

2.2.2 DC connections:

If the board is connected to an DC source please follow the below connection guide

Figure 5 – DC Voltage input connection

Please note that the board mounts diodes for the possibility to be supplied by AC. Due to high voltage input compatibility

are used 2 diodes in series. To avoid the drop of diodes effect on functionalities (i.e. efficiency measurements) connect

directly to the positive of Capacitor C6 and negative of capacitor C8

5/16

Page 6

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Test Point

Signal***

TP1

Controller ZT pin

TP2

Controller FB pin

TP5

Controller OUT pin

TP7

Controller V

CC pin

TP8

Controller Brown-out pin

TP10

Board V

OUT

TP11

Trafo sec. terminal

TP13

Controller GND pin

TP16

Input voltage V

IN

TP18

Controller CS pin

Table 3 – Testing points in AUX board.

2.3 Test points

The AUX board contains several testing points, from which it is possible to observe the board operation. The test points

and the related signals are given in the following table.

6/16

Page 7

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

DC voltage

Stand-by losses

300 V

0.372 W

900 V

1.7 W

T1

Q1

D20

U1

V

GS

V

DS

VDC=800V

3 Implementation and practical tests with AUX Board

The AUX board has been implemented in a printed circuit board (PCB), whose dimensions are 8 cm x 8 cm – see Figure

6. All surface mount devices (SMD) components have been assembled on the bottom side. On the top side were soldered

the thru hole devices (THD) and connectors. The layout of both sides is given in Appendix C. In the following sections,

experimental results at different input voltages and output power are presented and discussed.

Figure 6 – Top side (left) and bottom side (right) of the AUX board.

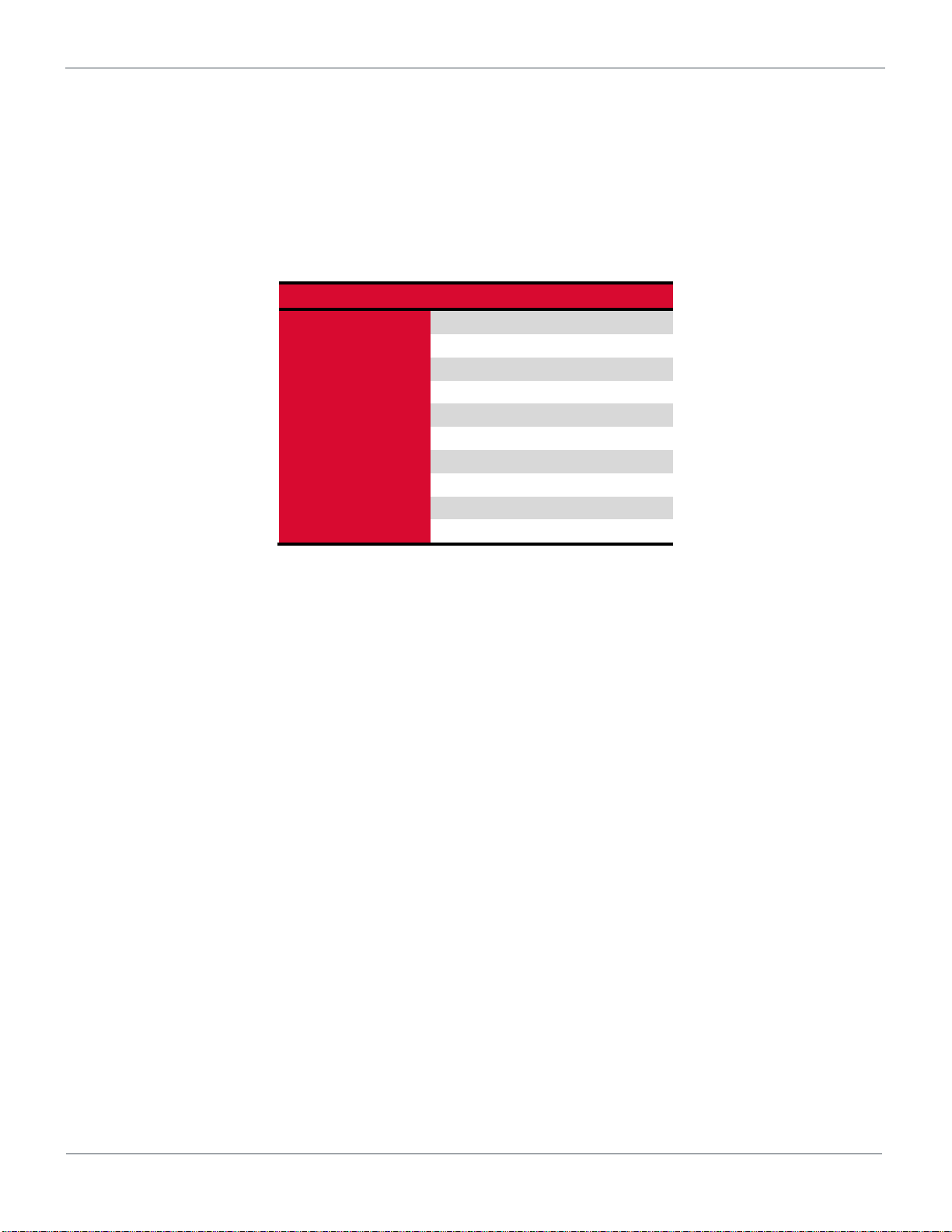

3.1 Operation at no load

At no load operation, the controller goes in burst mode – see Figure 16 – and the switching frequency is reduced to some

kHz. The dynamic losses of the Flyback components are consequently reduced. Measured stand-by losses are given in the

table on the right side of Figure 7. They are expected to come mainly from the resistive dividers present on the circuit:

input capacitor balance, start-up and input voltage sense.

Figure 7 – Waveforms from Flyback switch during burst mode, for VDC = 800 V.

7/16

Page 8

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

P

out

= 5W

P

out

= 20W

P

out

= 40W

V

GS

V

DS

t

delay

t

decay

t

on

fsw=45.7 kHz

VDC=800 V

V

GS

V

DS

fsw=105.0 kHz

VDC=800 V

V

GS

V

DS

VDC=800 V

fsw=109.0 kHz

3.2 Normal operation

Figure 8 presents the waveforms from SCT2H12NZ during normal operation of the Flyback circuit, for VDC = 800 V and

different values of output power. Time periods ton, t

eference source not found..

For light power – left side – the controller waits several valleys to switch the MOSFET on. Therefore, the switching

frequency is quite low, eventually below the defined frequency range.

As the output power increases, the number of oscillations is reduced. As consequence, t

frequency increases. At nominal power, the turn-on occurs already in the first valley.

decay

and t

are indicated, according to the description in Error!

delay

is reduced, and the switching

delay

Figure 8 – Waveforms from Flyback switch during different output power conditions, VDC = 800 V.

3.3 Efficiency and temperature measurements

The efficiency of the AUX board has been measured for three different input voltage values. The efficiency curves are

shown in Figure 9. As a DC power source was used, it was connected directly to the input capacitors. This way, the

rectifying bridge is by-passed, saving the losses that would otherwise come from the bridge diodes.

Efficiency is increasing with the output power, and it is higher for lower levels of input voltage. For VDC = 300 V, the

measured peak efficiency η=88% at P

The temperature of the main components of AUX board has been measured, namely the SiC MOSFET (Q1), the Flyback

transformer and the secondary diode (D20). The measurements were performed using an infrared camera. The thermal

images are presented in Figure 10. They were taken at room temperature, VDC=800 V and P

temperature of the SiC MOSFET (Sp1) is around 84°C, even without the use of an external heatsink and without forced

ventilation. The temperature of the Flyback transformer (Sp2), registered on the winding corner, is slightly above 70°C.

The measured temperature of the output diode (Sp3) was around 95°C.

=33W – above that the overload protection was activated.

OUT

=40W. The case

OUT

8/16

Page 9

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Sp1

Sp2

Sp3

Figure 9 – Efficiency curve of the AUX board for several DC input voltage values.

Figure 10 – Temperature measurements from main components of the AUX board.

9/16

Page 10

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

4 Summary

This document presented the design procedure of an auxiliary power supply, based on Flyback topology, focused on

industrial applications as auxiliary power supply. Main devices of this design are the SiC MOSFET SCT2H12NZ, with very

low on resistance, and the quasi resonant controller BDF768xFJ-LB. They enable a simple electrical and thermal design,

reducing the amount of devices, and avoiding the use of heat-sink for the Flyback switch.

Experimental tests in the AUX board proved the operation principle of the quasi resonant controller. Thermal and efficient

measurements showed also the reduced amount of losses in the SiC MOSFET, proving it is the right choice for auxiliary

supplies in 3-phase industrial systems.

5 References

[1] Datasheet of SCT2H12NZ http://www.rohm.com/web/global/datasheet/SCT2H12NZ/sct2h12nz-e

[2] Datasheet of BDF768xFJ-LB controller family, available at:

http://www.rohm.de/web/de/products/-/product/BD7682FJ-LB

[3] Application Note “BD768xFJ-LB series Quasi-Resonant converter Technical Design”, available at:

http://rohmfs.rohm.com/en/products/databook/applinote/ic/power/acdc_converter/bd768xfj-lb_appli-e.pdf

10/16

Page 11

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Appendix A. Transformer datasheet and pictures

Fig. A.1 – Datasheet of the constructed Flyback transformer.

Fig. A.2 – Side view (left) and top view (right) of the Flyback transformer.

11/16

Page 12

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Position Name

Value

Description

Manufacturer

Manufacturer’s

Code

Mounted

C4, C17, C18, C23

---

----

----

---

No

C6, C8

100 uF

Electrolytic capacitor 450V 7.5mm

pitch 18mm diameter

NICHICON

UCY2W101MHD

Yes

C9, C15

47 pF

Ceramic capacitor 0805 10% 50V

COG

WURTH

885012007055

Yes

C10

22 uF

Electrolytic capacitor 50V 2mm

pitch 5mm diameter

WURTH

860040672001

Yes

C11

2.2 uF

Ceramic capacitor 0805 35V X7R

TDK

C2012X7R1V225K085AC

Yes

C11A, C22

100nF

Ceramic capacitor 0805 50V X7R

WURTH

885012207098

Yes

C12, C13

2.2 nF

Ceramic capacitor 1kV 5mm pitch

8.5mm diameter

TDK

CK45-B3AD222KYNNA

Yes

C16

2.2 nF

Ceramic capacitor 0805 50V X7R

WURTH

885012207088

Yes

C19, C20

470 uF

Electrolytic Aluminium capacitor

35V 5mm pitch 10mm diameter

WURTH

860080575017

Yes

C21

---

----

----

---

No

D1, D2, D3, D4, D5,

D6, D7, D8, D9,

D10, D11, D12

1A 1000V

Rectifier Diode S1M Vishay

VISHAY

S1M-E3/61T

Yes

D13

---

Fast Diode 400V 1A

ROHM

RF101L4S

Yes

D14, D16

---

Schottky Diode 60V 1A

ROHM

RB160M-60

Yes

D15, D15B

---

----

----

---

No

D17

---

Zener Diode 20V 1W

ROHM

KDZVTR20B

No

D18

---

Ultrafast Diode 1200V 1A

STM

STTH112RL

Yes

D19

---

Zener Diode 24V 1W

ROHM

KDZVTR24B

Yes

D20

---

Schottky Barrier Diode 200V 30A

SANGDEST

MBRF30200CT

Yes

D20B

---

----

----

---

No

D21

---

SML-A12P8T Side LED Green 20mA

ROHM

SML-A12P8T

Yes

D22

0 Ohm

Resistor 0805 footprint

ROHM

MCR10EZPJ000

Yes

D22 (ASC)

---

Schottky Diode 60V 1A

ROHM

RB160M-60

No

H1

---

Heatsink for TO220 Transistor

AAVID

574602B03700G

Yes

H2

---

Heatsink for TO247 Transistor

OHMITE

WA-T247-101E

No

J5, J6

---

Connector pitch 10.16mm 2 pins

Wurth

691 219 610 002

Yes

J7

---

Header connector male pitch

2.54mm

3M

961102-6404-AR

Yes

J21

---

Connector pitch 5mm 2 pins

Wurth

691102710002

Yes

Q1

---

1700V 3.7A SIC MOSFET

ROHM

SCT2H12NZ

Yes

Q2

---

NPN transistor 50V 0.5A

ROHM

2SD1484KT146R

No

Q3

---

500V 800mA Normally on MOSFET

IXYS

IXTY08N50D2

No

R1, R2, R3

3.15 A

Fuse 250V

Littelfuse

4001315

Yes

Appendix B. Bill of Materials

12/16

Page 13

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Position Name

Value

Description

Manufacturer

Manufacturer’s

Code

Mounted

R4, R4B, R6, R6B,

R7, R8, R9, R10

470kOhm

Resistor 1206 footprint

ROHM

MCR18ERTF4703

Yes

R11

10kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF1002

Yes

R12A, R13A, R14A,

R35, R39

0 Ohm

Resistor 0805 footprint

ROHM

MCR10EZPJ000

No

R16

4.7kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF4701

Yes

R17

330kOhm

Resistor 2W V

VISHAY

PR02000203303JR500

Yes

R18

100 Ohm

Resistor 0805 footprint

ROHM

MCR10ERTF1000

Yes

R19

10 Ohm

Resistor 0805 footprint

ROHM

MCR10ERTF10R0

Yes

R20

47kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF4702

Yes

R21, R21A

3 Ohm

Resistor footprint 1020 Wide

ROHM

LTR50UZPF3R00

Yes

R21B

6.8 Ohm

Resistor footprint 1020 Wide

ROHM

LTR50UZPF6R80

Yes

R22, R38

0 Ohm

Resistor 0805 footprint

ROHM

MCR10EZPJ000

Yes

R23

120kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF1203

Yes

R24, R30

12kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF1202

Yes

R25

300 Ohm

Resistor 0805 footprint

ROHM

MCR10ERTF3000

Yes

R26, R37

1kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF1001

Yes

R27

15kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF1502

Yes

R28

180kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF1803

Yes

R29

51kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF5102

Yes

R31

---

----

----

---

No

R34

4.7kOhm

Resistor 0805 footprint

ROHM

MCR10ERTF4701

No

R36

10kOhm

Res 0805 footprint

ROHM

MCR10ERTF1002

No

T1

---

FLyback Transformer

WURTH

750316318

Yes

U1

---

ACDC flyback driver for SIC

MOSFET

ROHM

BD7682

Yes

U2

---

5kV Optocoupler

SHARP

PC817XNNIP0F

Yes

U3

---

Voltage reference 2.49V

TI

TL431AIDBZR

Yes

13/16

Page 14

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Appendix C. AUX Board layout

Fig. C.1 – Layout of top side (left) and bottom side (right) of the AUX board.

14/16

Page 15

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

V

DC

GND

To VCC pin

C6

C8

C11

R36

D22

Q3

D17

R34

Appendix D. Alternative Start-up Circuitry

This section presents an alternative start-up circuitry (ASC) for the AUX board. It aims to reduce the start-up time,

avoiding at the same time extra losses coming from the start-up resistor divider. The working principle of the ASC is

depicted in Fig. D.1.

Fig. D.1 – Work principle of the alternative start-up circuitry (ASC).

During start-up a current flows from input capacitor C8 through the depletion mode MOSFET Q3 (normally-on). This

current will charge the VCC capacitor C11. The gate pin of Q3 is connected in the middle of the resistor divider formed by

R36 and R34. As the voltage over C11 increases, the gate voltage of Q3 becomes negative with respect to its source

voltage. When threshold voltage of Q3 is achieved, it turns off. Resistors R36 and R34, and Zener diode D17 are

dimensioned so that VCC achieves the minimum value (UVLO) for the controller to start. From this point, controller will be

fed by the auxiliary winding, and Q3 will stay off until the next start-up. Diode D22 is placed to avoid losses through R36

and R34 after start-up.

The dimensioning of ASC starts from the choice of the MOSFET Q3. Since silicon FETs rated for 900 V are not available, Q3

is connected to the middle point between the input capacitors C6 and C8. This enables the MOSFET to be rated to 500 V.

The recommended part is IXTY08N50D2, from IXYS. According to datasheet, the threshold voltage has minimum and

maximum levels of -4 V and -2 V, respectively. The minimum VCC voltage for the controller to start is UVLO = 20 V (max),

and the overvoltage protection of VCC is OVP = 27.5 V (min).

During start-up, the voltage over resistor R36 is the voltage between gate and source of Q3. By setting R36 = 10 kΩ:

By using a 20 V Zener diode as D17, the first condition is automatically satisfied.

For the second condition, the current through R36 can be calculated as:

(1)

(2)

(3)

15/16

Page 16

User Guide

BD7682FJ-EVK-301 EV BOARD

© 2018 ROHM Co., Ltd.

No. 60TRxxxJ Rev.001

No. 60UG064E Rev.001

19 Feb 2018

Q1 V

DS

V

CC

UVLO

~100 ms

Standard start-up

V

CC

<1 ms

Q3 V

DS

Q3 V

GS

UVLO

Standard through ASC

Which leads to:

Chosen value for R34 = 4.7 kΩ.

Fig. D.2 presents the waveforms of the start-up of the AUX board, done by standard configuration and with ASC. It is

possible to observe that the start-up time is reduced by a factor of 100. Moreover, since the start-up resistive divider is not

used in ASC, the losses caused by those resistors are not present in the ASC configuration

(4)

Fig. D.2 – Schematics of the AUX board with alternative start-up circuitry (ASC).

The full schematic of AUX board with implemented ASC is depicted in Fig. D.3. Devices different from original schematics

are drawn in a different color. Please note they are not assembled in the original board. However, their respective

footprints are present on the board, assuming the devices given in the bill of materials list – see Appendix B.

In addition to extra components, the resistors R38 and R12 must be removed. Finally, before D22 is placed, the originally

soldered 0 Ω resistor must be removed.

Fig. D.3 – Schematics of the AUX board with alternative start-up circuitry (ASC).

16/16

Page 17

Notes

The information contained herein is subject to change without notice.

1)

Before you use our Products, please contact our sales representative

2)

tions :

Although ROHM is continuously working to improve product reliability and quality, semicon-

3)

ductors can break down and malfunction due to various factors.

Therefore, in order to prevent personal injury or fire arising from failure, please take safety

measures such as complying with the derating characteristics, implementing redundant and

fire prevention designs, and utilizing backups and fail-safe procedures. ROHM shall have no

responsibility for any damages arising out of the use of our Poducts beyond the rating specified by

ROHM.

Examples of application circuits, circuit constants and any other information contained herein are

4)

provided only to illustrate the standard usage and operations of the Products. The peripheral

conditions must be taken into account when designing circuits for mass production.

The technical information specified herein is intended only to show the typical functions of and

5)

examples of application circuits for the Products. ROHM does not grant you, explicitly or implicitly,

any license to use or exercise intellectual property or other rights held by ROHM or any other

parties. ROHM shall have no responsibility whatsoever for any dispute arising out of the use of

such technical information.

The Products specified in this document are not designed to be radiation tolerant.

6)

For use of our Products in applications requiring a high degree of reliability (as exemplified

7)

below), please contact and consult with a ROHM representative : transportation equipment (i.e.

cars, ships, trains), primary communication equipment, traffic lights, fire/crime prevention, safety

equipment, medical systems, servers, solar cells, and power transmission systems.

Do not use our Products in applications requiring extremely high reliability, such as aerospace

8)

equipment, nuclear power control systems, and submarine repeaters.

ROHM shall have no responsibility for any damages or injury arising from non-compliance with

9)

the recommended usage conditions and specifications contained herein.

ROHM has used reasonable care to ensurH the accuracy of the information contained in this

10)

document. However, ROHM does not warrants that such information is error-free, and ROHM

shall have no responsibility for any damages arising from any inaccuracy or misprint of such

information.

Please use the Products in accordance with any applicable environmental laws and regulations,

11)

such as the RoHS Directive. For more details, including RoHS compatibility, please contact a

ROHM sales office. ROHM shall have no responsibility for any damages or losses resulting

non-compliance with any applicable laws or regulations.

When providing our Products and technologies contained in this document to other countries,

12)

you must abide by the procedures and provisions stipulated in all applicable export laws and

regulations, including without limitation the US Export Administration Regulations and the Foreign

Exchange and Foreign Trade Act.

This document, in part or in whole, may not be reprinted or reproduced without prior consent of

13)

ROHM.

and verify the latest specifica-

Notice

ZZZURKPFRP

652+0&R/WG$OOULJKWVUHVHUYHG

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

5

%

Page 18

Ŷ<High Voltage Safety Precautions>

ۍ Read all safety precautions before use

Please note that this document covers only the BD7682FJ & SCT2H12NZ evalua

(BD7682FJ-EVK-301) and its functions. For additional information, please refer to the

asheet.

dat

tion board

To ensure safe operation, please carefully read all precautions

before handling the evaluation board

Depending on the configuration of the board and voltages used,

Potentially lethal voltages may be generated.

Therefore, please make sure to read and observe all safety precautions

described in the red box below.

Before Use

[1] Verify that the parts/components are not damaged or missing (i.e. due to the drops).ᴾ

[2] Check that there are no conductive foreign objects on the board.

Be c

[3]

[4] Check that there is no condensation or water droplets on the circuit board.

During Use

[5] Be careful to not allow conductive objects to come into contact with the board.

[6] Brief accidental contact or even bringing your hand close to the board may result in

[7] If used under conditions beyond its rated voltage, it may cause defects such as short-circuit

[8] Be sure to wear insulated gloves when handling is required during operation.

After Use

[9] The ROHM Evaluation Board contains the circuits which store the high voltage. Since it

[10] Protect against electric shocks by wearing insulated gloves when handling.

areful when performing soldering on the module and/or evaluation board to ensure that

solder splash does not occur.

discharge and lead to severe injury or death.

Therefore, DO NOT touch the board with your bare hands or bring them too close to

the board.

In addition, as mentioned above please exercise extreme caution when using conductive

tools such as tweezers and screwdrivers.

or, depending on the circumstances, explosion or other permanent damages.

stores the charges even after the connected power circuits are cut, please discharge the

electricity after using it, and please deal with it after confirming such electric discharge.ᴾ

This evaluation board is intended for use only in research and development facilities and should by

handled

only by qualified personnel familiar with all safety and operating

procedures.

We recommend carrying out operation in a safe environment that includes the use of high voltage

signage at all entrances, safety interlocks, and protective glasses.

Loading...

Loading...