Page 1

© 2017 ROHM Co., Ltd.

No. 60AP001E Rev.001

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

2017.4

Application Note

2.7V to 5.5V

BD71837MWV

BUCK1 0.9V / 3.6A

i.MX 8M Quad

i.MX 8M QuadLite

i.MX 8M Dual

LDO1 3.3V / 10mA

Power Mux Switch

1.8V/3.3V / 150mA

LPDDR4 Memory

SD Card

USB /

Li-Ion Battery

BUCK2 1.0V / 4.0A

BUCK3 1.0V / 2.1A

BUCK4 1.0V / 1.0A

LDO2 0.9V / 10mA

LDO7 3.3V / 150mA

BUCK6 3.3V / 3.0A

LDO3 1.8V / 150mA

LDO5 1.8V / 300mA

BUCK7 1.8V / 1.5A

LDO4 0.9V / 250mA

LDO6 0.9V / 300mA

BUCK5 1.0V / 2.5A

BUCK8 1.1V / 3.0A

I2C (slave)

Power Mode

Control Signals

Power

Sequencing

Controller

Die temp

UVLO

32.768kHz Crystal Oscillator Driver

Interrupt

VR Fault

Power On Key

Detection

Power On Key

Figure 1.1 The system power map

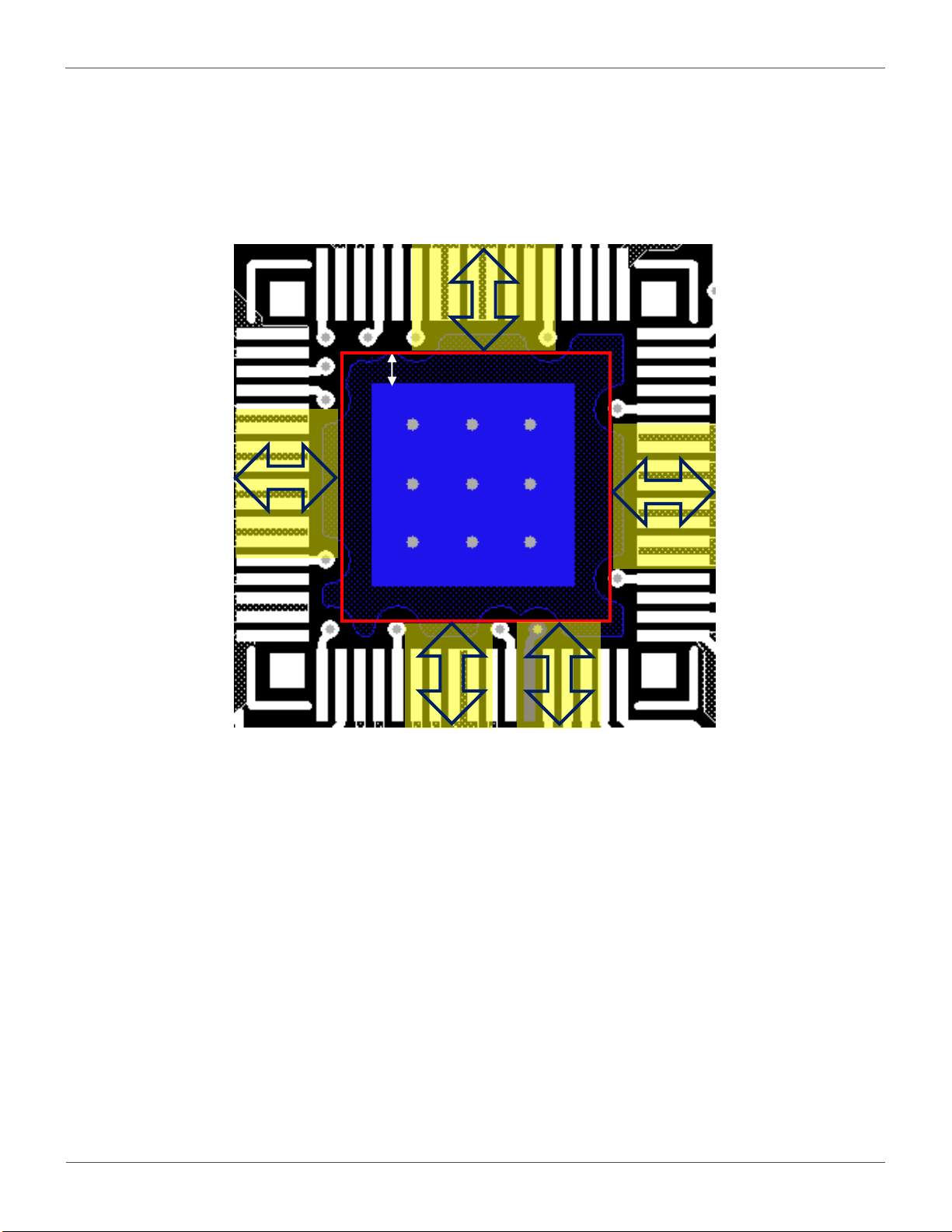

Figure 1.2 The package image

Power Management IC designed for “NXP

®

i.MX 8M Quad”

BD71837MWV Platform Design Guide

1. Introduction

BD71837MWV is a Power Management Integrated Circuit (PMIC) available in 68-QFN package and dedicated to the application

powered by 5V input. PMIC includes eight Buck convertors, seven LDOs, one internal load switch and crystal oscillator driver for RTC

clock. These functions are designed to support the specific power requirements from NXP i.MX 8M platform to achieve the required

performance for cost-sensitive applications.

The below figure is the outline of the power map between PMIC and i.MX 8M SoC, showing that all voltage rails required by SoC are

satisfied.

“BD71837MWV Platform Design Guide” provides the guideline for designing PCB including recommendatio n for the PCB layer stack

up, the components placement and the PCB routings.

To reduce the risk that comes from PCB layout or parts placement, the guideline is strongly recommended to be applied to the PCB

design.

1/46

Page 2

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

1. Introduction ................................................................................................................................................................................ 1

2. Revision History ......................................................................................................................................................................... 4

3. Features ..................................................................................................................................................................................... 5

3.1. Terminologies ...................................................................................................................................................................... 5

3.2. Reference Documents ........................................................................................................................................................ 5

3.3. PMIC futures ....................................................................................................................................................................... 6

4. General Design Considerations ................................................................................................................................................. 7

4.1. Package Dimension of BD71837MWV ............................................................................................................................... 7

4.2. Pin Configuration ................................................................................................................................................................ 8

4.3. General Stack-up Recommendations ................................................................................................................................. 9

4.4. 6-layer Board Stack-up ....................................................................................................................................................... 9

4.5. Via Guidelines ................................................................................................................................................................... 10

4.6. Placement of PTHs underneath the exposed pad.............................................................................................................. 11

4.7. Outline for PCB layout ...................................................................................................................................................... 12

5. Platform Power Delivery Guidelines ......................................................................................................................................... 18

5.1. Platform Power Delivery ................................................................................................................................................... 18

5.2. General Layout Guideline ................................................................................................................................................. 20

5.2.1. Overall Component Placement .................................................................................................................................. 20

5.2.2. Large Current Loop .................................................................................................................................................... 21

5.2.3. Power GND ................................................................................................................................................................ 22

5.2.4. VSYS (Power supply for BD71837MWV analog circuit) ............................................................................................ 22

5.2.5. Other Signal Pattern Precautions .............................................................................................................................. 22

5.2.6. Feedback Sense Lines .............................................................................................................................................. 22

5.2.7. AGND layout .............................................................................................................................................................. 23

5.3. BUCK Convertors ............................................................................................................................................................. 24

5.3.1. BUCK1 (VDD_SoC) ................................................................................................................................................... 24

5.3.1.1. Schematic Example ............................................................................................................................................... 24

5.3.1.2. Schematic checklist ................................................................................................................................................ 24

5.3.1.3. Parts placement for each decoupling capacitor ...................................................................................................... 25

5.3.2. BUCK2 (VDD_ARM) .................................................................................................................................................. 25

5.3.2.1. Schematic Example ............................................................................................................................................... 25

5.3.2.2. Schematic checklist ................................................................................................................................................ 26

5.3.2.3. Layout Example ..................................................................................................................................................... 26

5.3.3. BUCK3 (VDD_GPU) .................................................................................................................................................. 27

5.3.3.1. Schematic Example ............................................................................................................................................... 27

5.3.3.2. Schematic Checklist ............................................................................................................................................... 27

5.3.3.3. Layout Example ..................................................................................................................................................... 28

5.3.4. BUCK4 (VDD_VPU) .................................................................................................................................................. 29

5.3.4.1. Schematic Example ............................................................................................................................................... 29

5.3.4.2. Schematic Checklist ............................................................................................................................................... 29

5.3.4.3. Layout Example ..................................................................................................................................................... 30

5.3.5. BUCK5 (VDD_DRAM) ............................................................................................................................................... 30

2/46

Page 3

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

5.3.5.1. Schematic Example ............................................................................................................................................... 30

5.3.5.2. Schematic Checklist ............................................................................................................................................... 31

5.3.5.3. Layout Example ..................................................................................................................................................... 32

5.3.6. BUCK6 (NVCC_3P3) ................................................................................................................................................. 32

5.3.6.1. Schematic Example ............................................................................................................................................... 32

5.3.6.2. Schematic Checklist ............................................................................................................................................... 33

5.3.6.3. Layout Example ..................................................................................................................................................... 33

5.3.7. BUCK7 (NVCC_1V8) ................................................................................................................................................. 34

5.3.7.1. Schematic Example ............................................................................................................................................... 34

5.3.7.2. Schematic Checklist ............................................................................................................................................... 34

5.3.7.3. Layout Example ..................................................................................................................................................... 35

5.3.8. BUCK8 (NVCC_DRAM) ............................................................................................................................................. 36

5.3.8.1. Schematic Example ............................................................................................................................................... 36

5.3.8.2. Schematic Checklist ............................................................................................................................................... 36

5.3.8.3. Layout Example ..................................................................................................................................................... 37

5.4. LDOs ................................................................................................................................................................................. 38

5.4.1. LDO1 (NVCC_SNVS) ................................................................................................................................................ 38

5.4.2. LDO2 (VDD_SNVS) ................................................................................................................................................... 38

5.4.3. LDO3 (VDDA_1P8/VDDA_DRAM) ............................................................................................................................ 38

5.4.4. LDO4 (VDDA_0P9) .................................................................................................................................................... 38

5.4.5. LDO5 (1P8_PHY) ...................................................................................................................................................... 38

5.4.6. LDO6 (0P9_PHY) ...................................................................................................................................................... 38

5.4.7. LDO7 (3P3_PHY) ...................................................................................................................................................... 38

5.4.8. Schematic Examples ................................................................................................................................................. 39

5.4.8.1. Schematic Checklist ............................................................................................................................................... 39

5.5. Load SW ........................................................................................................................................................................... 41

5.5.1. MUXSW (NVCC_SD2)............................................................................................................................................... 41

5.5.1.1. Schematic Examples .............................................................................................................................................. 41

5.5.1.2. Schematic Checklist ............................................................................................................................................... 41

5.6. Crystal Oscillator Driver .................................................................................................................................................... 42

5.6.1. XIN / XOUT / C32K_OUT .......................................................................................................................................... 42

5.6.1.1. Schematic Examples .............................................................................................................................................. 42

5.6.1.2. Schematic Checklist ............................................................................................................................................... 42

5.6.1.3. Layout Example ..................................................................................................................................................... 43

5.7. Interfaces .......................................................................................................................................................................... 44

5.7.1. I2C ................................................................................................ ............................................................................. 44

5.7.2. System Control – Reset, Power, and Control Signals ................................................................................................ 45

5.7.3. MISC .......................................................................................................................................................................... 46

3/46

Page 4

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Revision Number

Description

Revision Date

001

Initial release

May. 1st, 2018

2. Revision History

Table 2.1 Revision History

4/46

Page 5

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Term

Definition

BOM

Bill Of Materials

PMIC

Power Management Integrated Circuit

FET

Field Effect Transistor

I2C

Inter-Integrated Circuit

IRQ

Interrupt ReQuest

LDO

Low Drop-Out Regulator

OCP

Over Current Protection

OVP

Over Voltage Protection

SoC

System-On-a-Chip

Document

BD71837MWV Datasheet Rev.001.pdf

BD71837MWV Reference Schematic Rev.001.pdf

BD71837MWV Reference BOM Rev001.xlsx

BD71837MWV Reference Layout Rev.001.brd

BD71837MWV Schematic Checklist Rev001.xlsx

3. Features

3.1. Terminologies

3.2. Reference Documents

Table 3.1 Acronyms, Conventions and Terminologies

Table 3.2 Reference Documents

5/46

Page 6

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

3.3. PMIC futures

BD71837MWV supply the power required by SoC and peripheral devices for NXP i.MX 8M platform.

Once PMIC powered up, it can be controlled by I2C interface to determine the internal register settings.

The followings explain the features incorporated in the IC.

Voltage Rails

■ 8ch low power consumption Buck Convertors with Integrated BUCK FETs

Buck1: 0.7V – 1.3V / 10mV step (DVS), I

Buck2: 0.7V – 1.3V / 10mV step (DVS), I

Buck3: 0.7V – 1.3V / 10mV step (DVS), I

Buck4: 0.7V – 1.3V / 10mV step (DVS), I

Buck5: 0.7V – 1.35V / 8 steps, I

Buck6: 3.0V – 3.3V / 100mV step, I

Buck7: 1.6V – 2.0V / 8 steps, I

Buck8: 0.8V – 1.4V / 10mV step, I

OMAX

OMAX

= 2.5A

OMAX

= 1.5A

OMAX

OMAX

OMAX

OMAX

OMAX

= 3.0A

= 3.0A

= 3.6A

= 4.0A

= 2.1A

= 1.0A

■ 7ch LDO Regulator

LDO1: 3.0V – 3.3V / 1.6V – 1.9V, I

LDO2: 0.9V / 0.8V, I

LDO3: 1.8V – 3.3V, I

LDO4: 0.9V – 1.8V, I

LDO5: 1.8V – 3.3V, I

LDO6: 0.9V – 1.8V, I

LDO7: 1.8V – 3.3V, I

OMAX

OMAX

OMAX

OMAX

OMAX

OMAX

= 10mA

= 300mA

= 250mA

= 300mA

= 300mA

= 150mA

OMAX

= 10mA

■ 1ch Internal General Switch

Mux Switch: 1.8V/3.3V, I

OMAX

= 150mA

Serial Interface

I2C interface provides access to configuration registers.

Crystal Oscillator Driver

32.768kHz Crystal Oscillator Driver is included.

6/46

Page 7

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

BD7 1837

ROHM

LOT Number

Part Number Marking

4. General Design Considerations

This chapter provides general PCB design guidelines such as BD71837MWV general parts placement.

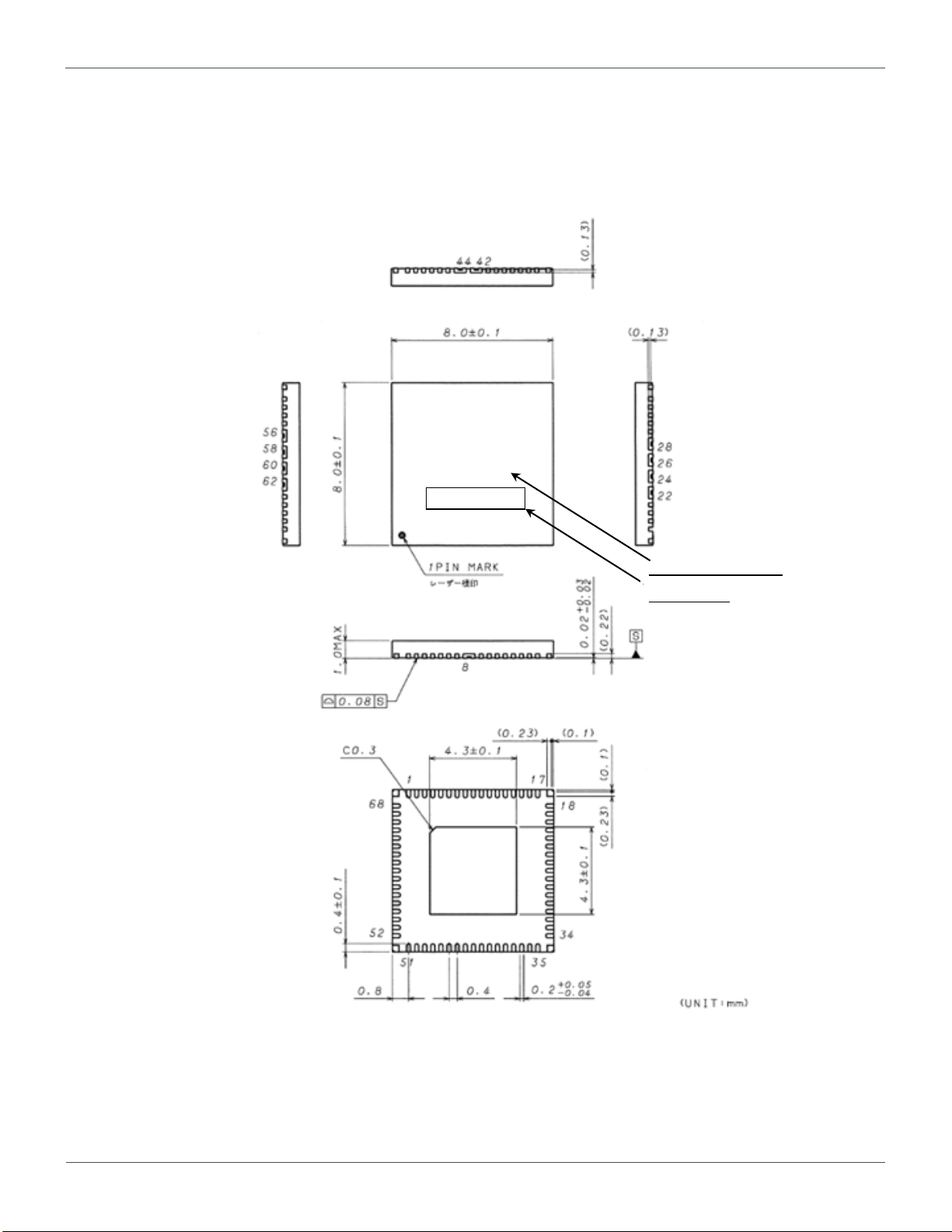

4.1. Package Dimension of BD71837MWV

Figure 4.1 The package dimension of BD71837MWV

7/46

Page 8

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

LDO4_FB

LDO4_VOUT

VSYS2

WDOG_B

RTC_RESET_B

BUCK8_FB

BUCK8_VIN

BUCK8_VIN

BUCK8_LX

BUCK8_LX

BUCK7_LX

BUCK7_VIN

BUCK7_FB

IRQ_B

POR_B

C32K_OUT

DVDD

(**)EXP-PAD

(**)EXP-PAD

LDO3_FB

VIN_3P3

LDO3_VOUT

VSYS3

BUCK4_FB

BUCK4_VIN

BUCK4_LX

BUCK3_LX

BUCK3_LX

BUCK3_VIN

BUCK3_FB

AGND

INTLDO1P5

LDO7_VOUT

VSYS1

XIN

XOUT

454443424140515049484746SDA33SCL32PMIC_ON_REQ

31

PMIC_STBY_REQ

3938373635

34

27

BUCK1_LX

26

BUCK1_LX

25

BUCK2_LX

30

BUCK1_FB

29

BUCK1_VIN

28

BUCK1_VIN

21

BUCK2_FB

20

PWRON_B

19

LDO1_VOUT

24

BUCK2_LX

23

BUCK2_VIN

22

BUCK2_VIN

18

LDO2_VOUT

12345678151617111213145591056

BUCK6_VIN

57

BUCK6_VIN

58

BUCK6_LX

68

LDO5_VOUT

(*)EXP-PAD

(PGND)

1Pin Mark

65

VIN_1P8_2

66

MUXSW_VOUT

BUCK6_FB

(**)EXP-PAD

(**)EXP-PAD

67

MUXSW_VOUT

62

BUCK5_VIN

63

BUCK5_VIN

64

BUCK5_FB

59

BUCK6_LX

60

BUCK5_LX

61

BUCK5_LX

52

VIN_1P8_1

53

LDO6_VOUT

54

SD_VSELECT

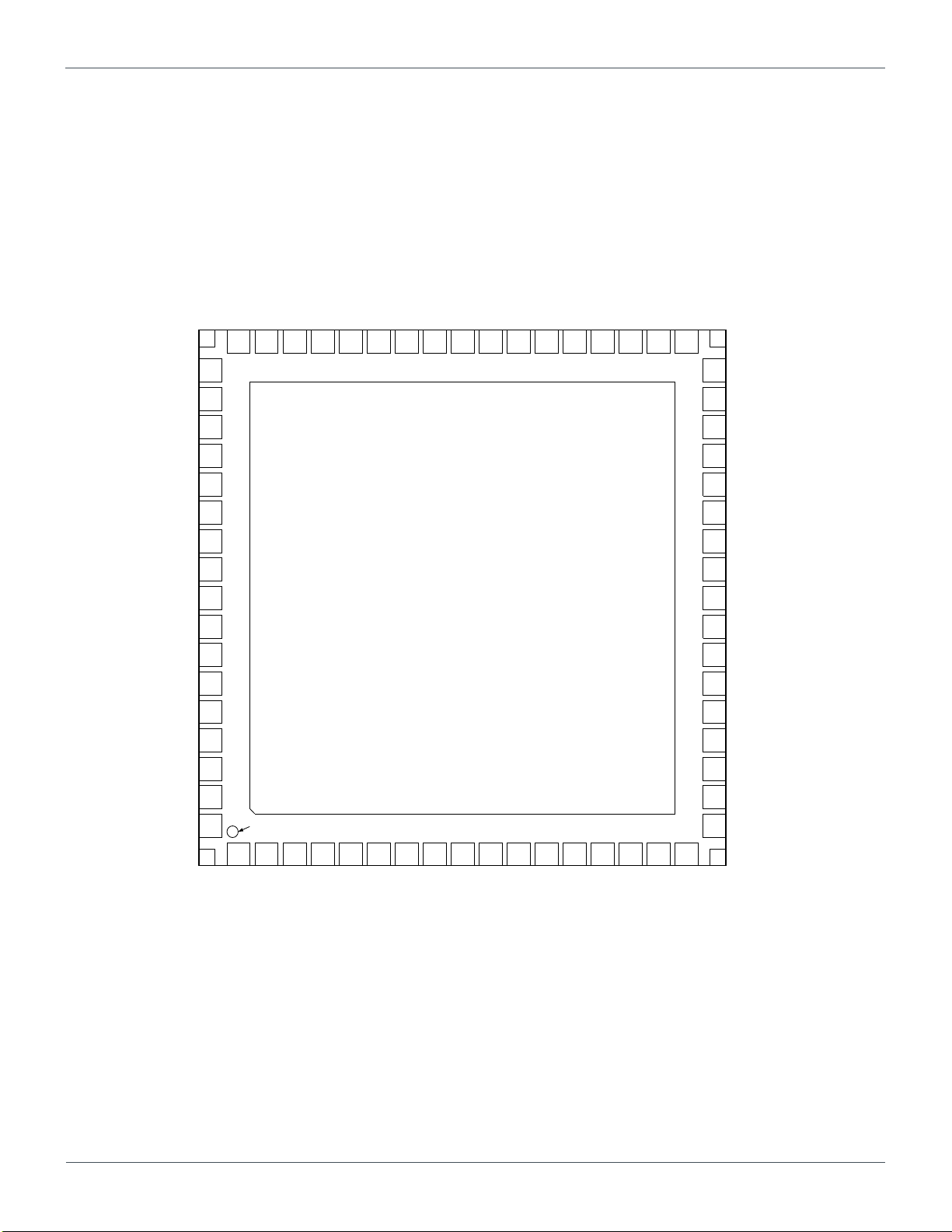

4.2. Pin Configuration

The pin configuration of BD71837MWV is designed and it will result in the effective routings between PMIC and SoC, memory device

and other components.

Note: (*) EXP-PAD is the power GND for PMIC so it should be soldered to GND plane.

(**) EXP-PAD assigned to 4 corners are also the same potentials with (*) EXP-PAD.

Figure 4.2 BD71837MWV pin configuration

8/46

Page 9

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

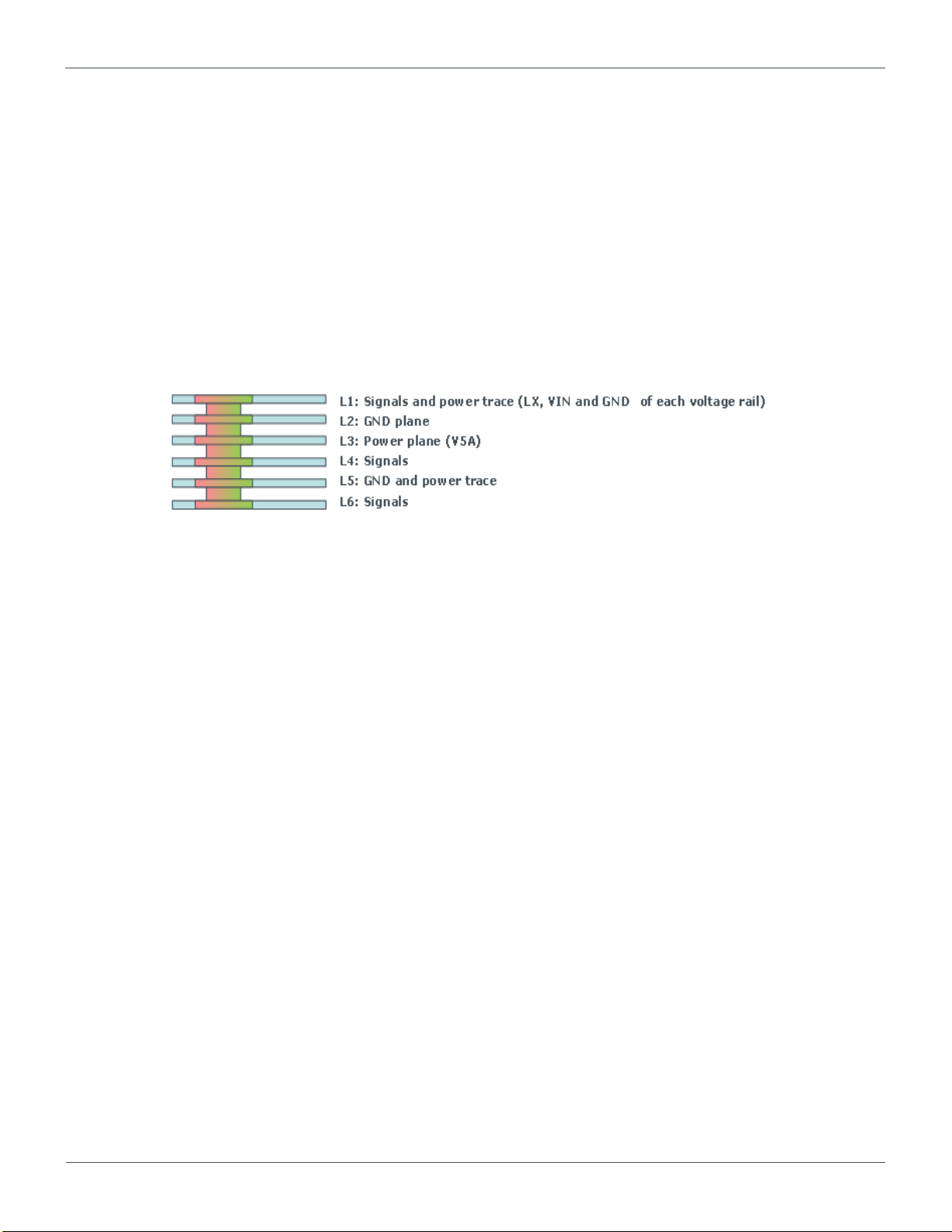

Figure 4.3 6-layers PCB stack-up

4.3. General Stack-up Recommendations

Type-3 and 6 layers PCB technology are used for BD71837MWV ROHM’s EVM.

The following general stack-up is strongly recommended to be applied to all the routings on the PCB.

Surface plane layers are recommended to apply 1.9 Mils thick copper.

Internal plane layers are recommended to apply 1.2 Mils thick copper.

It is recommended I2C signals to have the reference versus solid planes over the length of their routing and not to

cross plane splits. Ground should be the ideal reference.

The extra area in each layers should be filled with as much ground or other power rails as possible.

There should not be any large free areas with no metal for each layer because of the improvement for heat

dissipation. Large metal area also reduces stray resistance and inductance.

4.4. 6-layer Board Stack-up

BD71837MWV ROHM’s EVM uses Type 3 PCB technology and Figure 4.3 shows the 6-layer PCB stack-up.

9/46

Page 10

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Via type

Hole size

Pad size

Anti-Pad size

Plated through-hole (PTH)

12 mils

24 mils

32 mils

Hole size

Pad size

Anti-Pad size

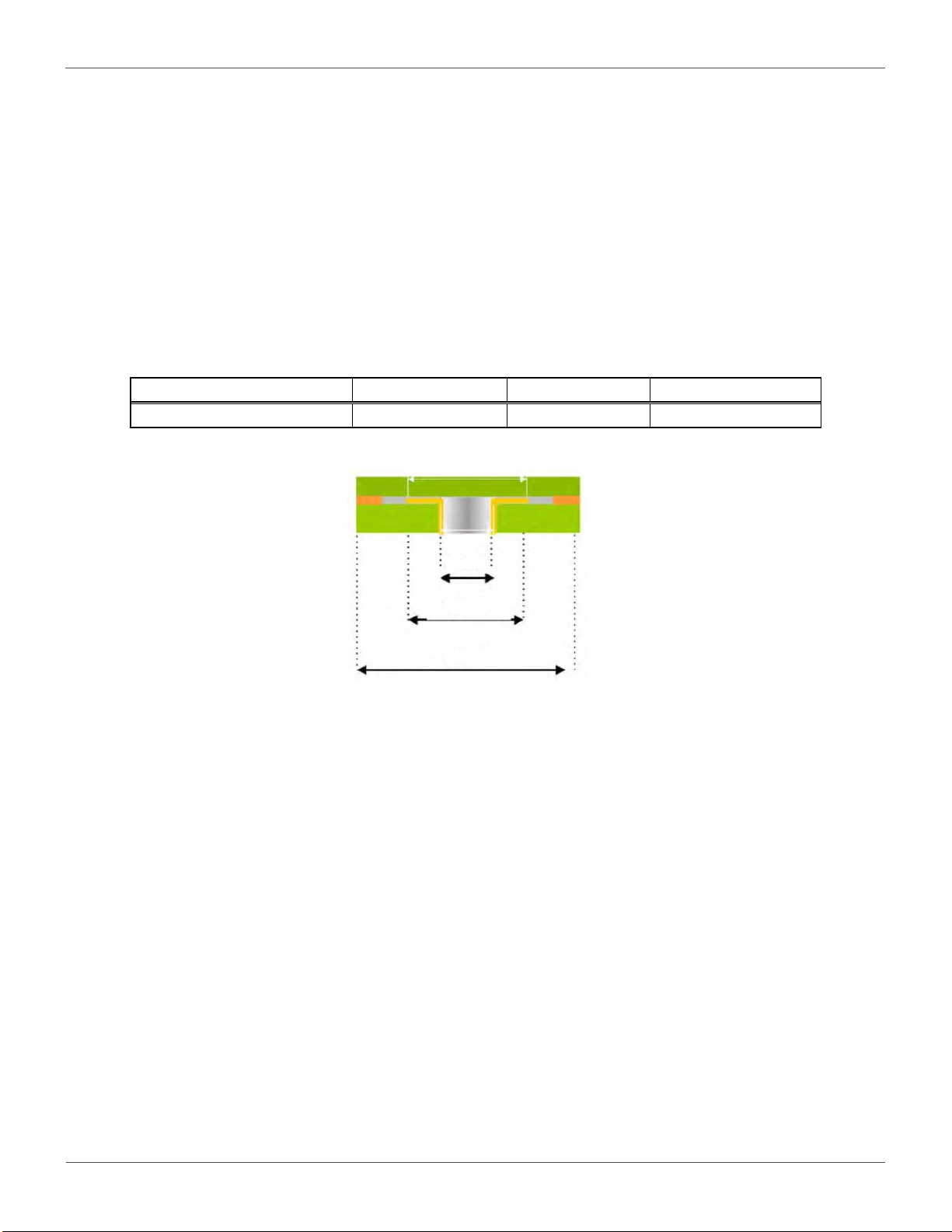

Figure 4.4 The image of PTH vias

4.5. Via Guidelines

This section explains proper via-drill, pad, and anti-pad size.

Note:

Improper drill, pad, and anti-pad size may cause some troubles on the PCB cost, reliability, manufacturability, and electrical

characteristics.

Type-3 PCB technology employs plated through-hole (PTH) vias for breakout routing. The dimension of PTH vias may vary as

necessary. Table 2.1 shows the recommended via dimension used for the breakout areas of BD71837MWV. Figure 4.4 shows the

image of PTH vias.

Table 4.1 Dimension example for PTH

10/46

Page 11

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

500μm or more

Current

flow

Exposed pad

Figure 4.5 The clearance between PTH and the exposed pad

4.6. Placement of PTHs underneath the exposed pad

When the distance between the edge of metal mask of the exposed pad and PTH is close, the solder may get on the resist then the

PTH and exposed pad of BD71837MWV will be shorted. To avoid the soldering issue, it is highly recommended to keep the positons

of PTHs away from the edge of the exposed pad by 500μm or more, and PTHs should be placed not to disrupt the current flows

between each GND of the output capacitors and the exposed pad.

Note

The spaces for the current flows between GNDs of each output capacitor and exposed pad for PMIC PGND should be ensured. So it

is recommended that the numbers of PTHs disturbing the current flows should be secured.

11/46

Page 12

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

BUCK8

BUCK5

BUCK1

MUXSW

BUCK7

BUCK2

BUCK3

BUCK4

BUCK6

i.MX 8M

Top layer is used as power trace for each VR.

It’s better to secure the power traces with enough width to

relief the effect of the parasitic impedance.

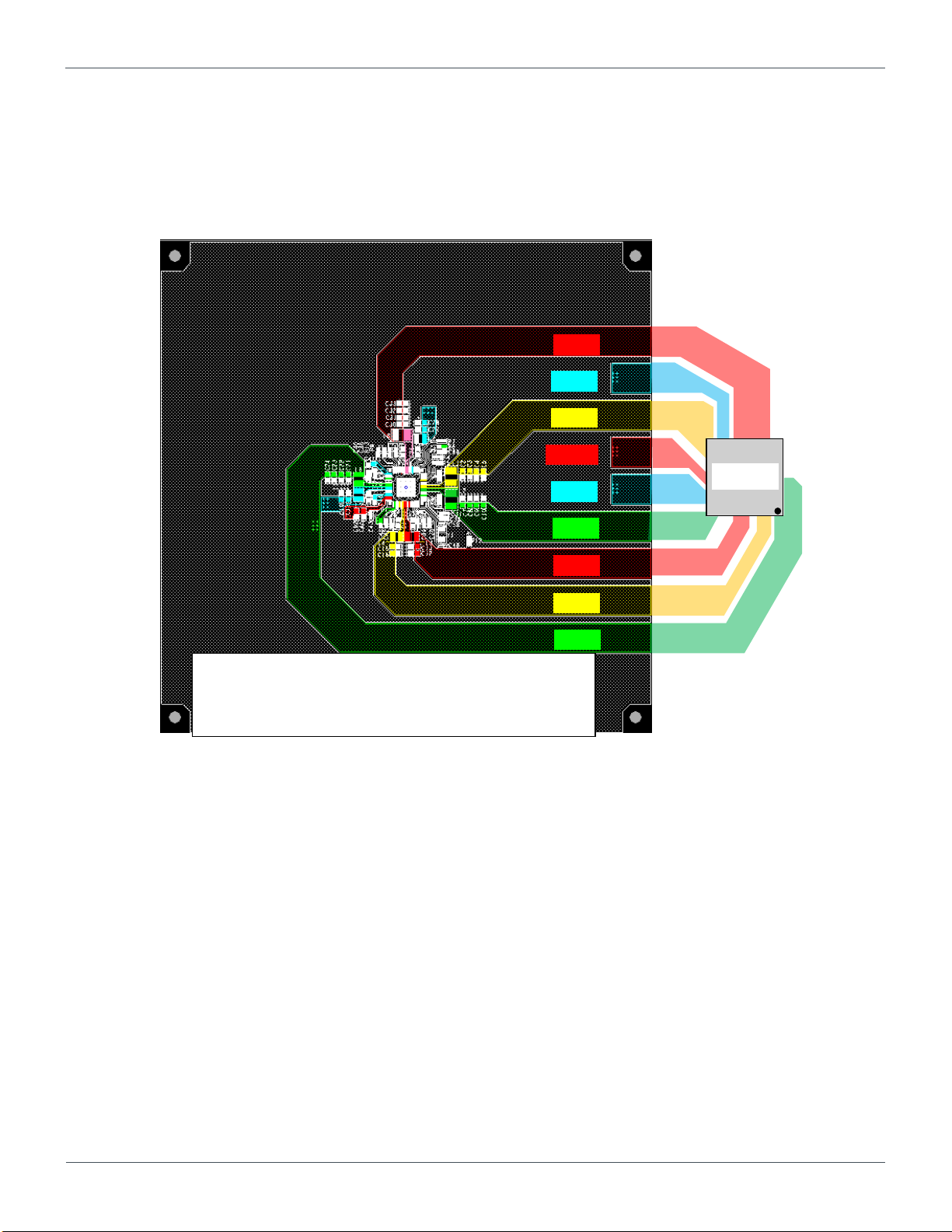

Figure 4.6 BD71837MWV Reference Board Outline (Top Layer)

4.7. Outline for PCB layout

For understanding the outline of ROHM’s reference layout, the layout data for Layer 1(Top Layer) to 6 (Bottom layer) are shown in

Figure 4.6 to Figure 4.11.

The layout is designed, supposing the position of the SoC as Figure 4.6.

(1st pin of SoC is positioned at lower right.)

12/46

Page 13

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

GND

Layer 2 is used as power GND.

It’s better to secure the wide plane for large switching currents.

The parasitic impedance between PGND and each capacitor should be as low as possible.

Figure 4.7 BD71837MWV Reference Board Outline (Layer 2)

13/46

Page 14

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

VSYS

Layer 3 is used as VSYS power (Input for each VR).

It’s better to secure the wide plane for large input currents

which happens between input source and input capacitors.

Figure 4.8 BD71837MWV Reference Board Outline (Layer 3)

14/46

Page 15

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Layer 4 is used as power traces for each VR.

It’s better to secure the enough width to relief the effect of

the parasitic impedance.

Figure 4.9 BD71837MWV Reference Board Outline (Layer 4)

15/46

Page 16

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

LDO4

LDO1

LDO2

LDO7

LDO3

LDO5

LDO6

Layer 5 is used as the power traces for each LDO.

It’s better to secure the enough width to relief the effect of

the parasitic impedance.

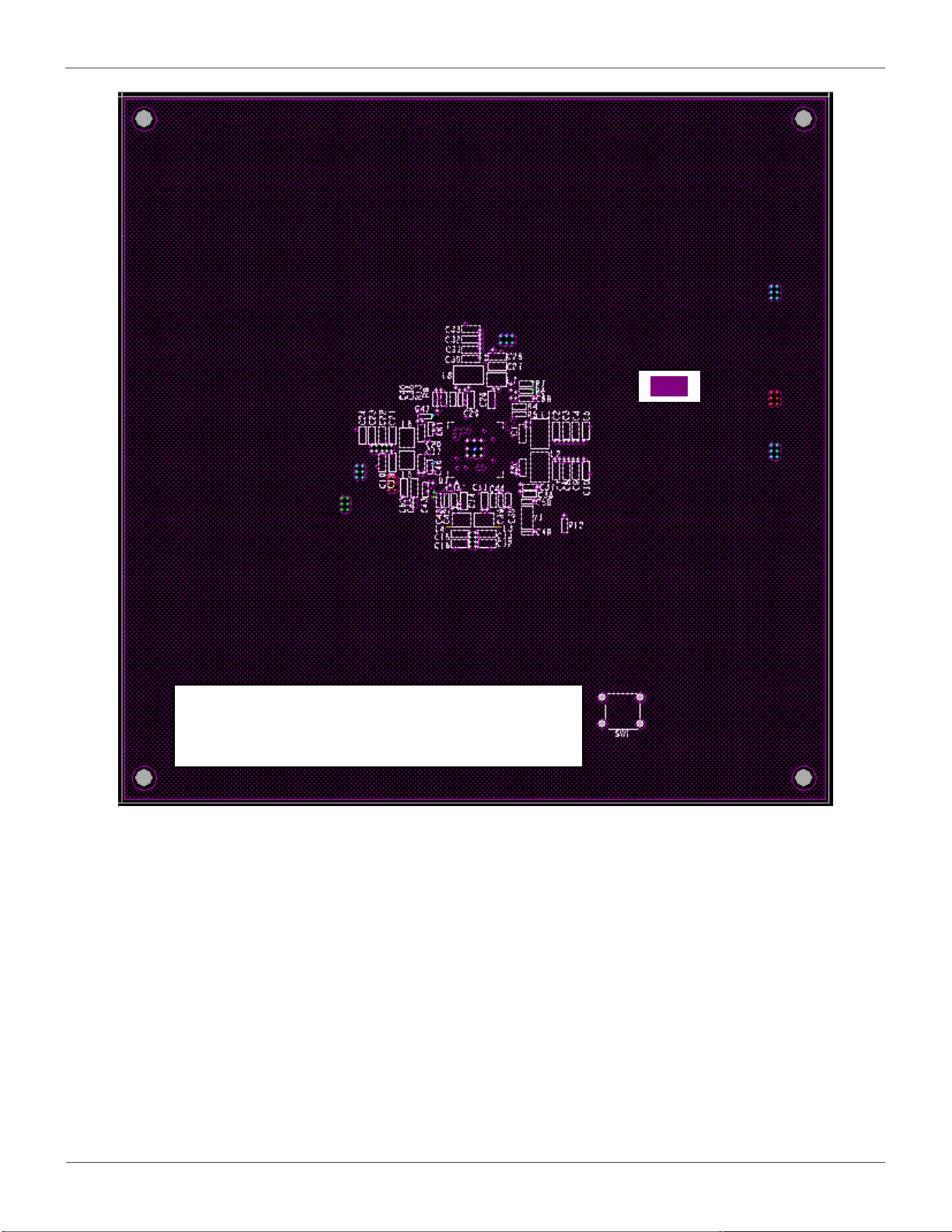

Figure 4.10 BD71837MWV Reference Board Outline (Layer 5)

16/46

Page 17

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

WDOG_B

SD_VSELECT

RTC_RESET_B

Layer 6 is used for routings of each feedback line and I/Os.

IRQ_B

POR_B

C32K_OUT

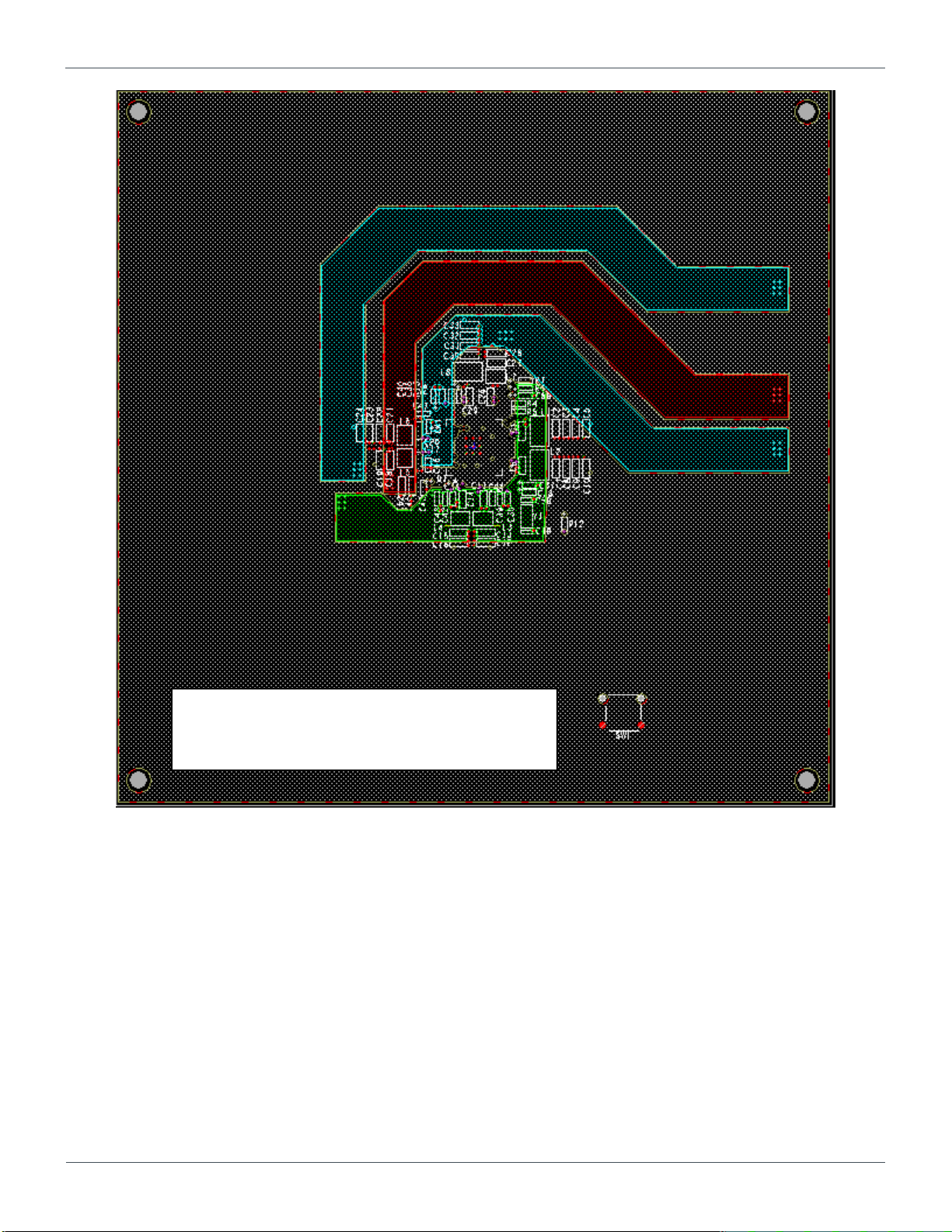

Figure 4.11 BD71837MWV Reference Board Outline (Layer 6)

17/46

Page 18

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Voltage Rail

Type

Input Voltage

Default

Output Voltage

[V]

Max

Current

[mA]

Over Current

Protection

Min [mA]

BUCK1

Buck

VSYS

0.7 – 1.3

3600

5000

BUCK2

Buck

VSYS

0.7 – 1.3

4000

5500

BUCK3

Buck

VSYS

0.7 – 1.3

2100

3000

BUCK4

Buck

VSYS

0.7 – 1.3

1000

2500

BUCK5

Buck

VSYS

0.7 – 1.35

2500

3500

BUCK6

Buck

VSYS

3.0 – 3.3

3000

4500

BUCK7

Buck

VSYS

1.6 – 2.0

1500

3000

BUCK8

Buck

VSYS

0.8 – 1.4

3000

4500

LDO1

LDO

VSYS

1.6 – 1.9

10

20

LDO2

LDO

VSYS

0.9 / 0.8

10

20

LDO3

LDO

BUCK6 / VSYS

1.8 – 3.3

300

390

LDO4

LDO

BUCK7 / VSYS

0.9 – 1.8

250

325

LDO5

LDO

BUCK6

1.8 – 3.3

300

390

LDO6

LDO

BUCK7

0.9 – 1.8

300

340

LDO7

LDO

VSYS

1.8 – 3.3

150

195

MUXSW

Load Switch

1.8V / 3.3V

1.8 / 3.3

150

-

5. Platform Power Delivery Guidelines

BD71837MWV is the PMIC that incorporates single BUCK regulators, LDOs, and the internal load switch.

It is essential to follow the guidelines to ensure the stable power delivery to the SoC and the system.

5.1. Platform Power Delivery

Figure 5.1 shows the voltages BD71837MWV provides to the SoC and other devices in the system and the information of the

maximum currents for each VR are summarized in Table 5.1.

Table 5.1 The Maximum Design Powers for BUCK convertors, LDOs, and the Load Switch

18/46

Page 19

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

0.9V

0.9V/1.0V

0.9V/1.0V

0.9V/1.0V

1.0V

3.3V

0.9V

3.3V

3.3V

1.8V

1.8V

1.8V

0.9V

0.9V

VSYS(5V)

1.1/1.2/1.35V

PMIC_STBY_REQ

HOST

I/F

32kHz

Xtal

Driver

150mA MUXSW

BD71837MWV

1.8V/3.3V(SD CARD)1.8V

3.3V

I2C I/F

WDOG_B

PMIC_ON_REQ

POR_B

RTC_RESET_B

SD_VSELECT

IRQ_B

XOUT

XIN

C32K_OUT

BUCK6

3.0A, 3.0 to 3.3V

/0.1V step

BUCK7

1.5A, 1.6V to 2.0V

/ 8steps

NVCC_DRAM

VDD_SOC

VDD_ARM

VDD_GPU

VDD_VPU

VDD_DRAM

NVCC_SNVS

3P3_PHY

GPIO_3V3

VDD_SNVS

VDDA_1P8

1P8_PHY

GPIO_1V8

VDDA_0P9

0P9_PHY

iMX8M

VDDA_DRAM

BUCK1 – DVS

3.6A, 0.7V to 1.3V

/10mV step

BUCK2 – DVS

4.0A, 0.7V to 1.3V

/10mV step

BUCK3 – DVS

2.1A, 0.7V to 1.3V

/10mV step

BUCK4 – DVS

1.0A,0.7V to 1.3V

/10mV step

BUCK5

2.5A,0.7V to 1.35V

/ 8steps

BUCK8

3.0A,0.8V to 1.4V

/10mV step

LDO1

10mA,3.0V to 3.3V

/1.6V to 1.9V

LDO2

10mA,

0.9V/0.8V

LDO7

150mA,

1.8V to 3.3V

LDO3

300mA,

1.8V to 3.3V

LDO5

300mA,

1.8V to 3.3V

LDO4

250mA,

0.9V to 1.8V

LDO6

300mA,

0.9V to 1.8V

PWRON_B

Figure 5.1 BD71837MWV Power Delivery Map

19/46

Page 20

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

BUCK1

BUCK6

BCUK7

BUCK8

BUCK4

BUCK3

BUCK5

LDO4

LDO1

LDO5

MUXSW

LDO7

LDO3

LDO6

5.2. General Layout Guideline

This section explains the guideline about the layout for voltage regulators. The voltage rails with higher Iomax current especially for

BUCK convertors should be carefully designed not to transmit the unwanted interference caused by switching noises to other signals

with high impedance.

And IR drop caused by large switching currents often influence the violation of the stability for the input level for each buck convertor

so the design for each input should be also taken care. It is highly recommended to follow the all guidelines in this section.

5.2.1. Overall Component Placement

Figure 5.2 shows the overall parts placement. The figure shows the positions of the components needed to be put closely to PMIC. It

is strongly recommended that the components controlling the higher currents like input / output capacitors and inductors are placed in

priority to any other components to guarantee the stabilities of each VR.

Figure 5.2 Overall component placement example

20/46

Page 21

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Cin

L

VIN

Vout

①

②

Cout

①

Tr2

Tr1

LX

GND

Cin

Cout

BUCK2

point

capacitor

Via for GND

Figure 5.4 Example of parts placement and routings for BUCK2 at the top layer

Figure 5.3 BUCK Convertor Large Current Loops

5.2.2. Large Current Loop

There are 2 high-pulsing current flow loops in the BUCK convertor system.

Loop1

When Tr2 turns ON, the loop starts from the input capacitor, to VIN terminal, to LX terminal, to L (inductor), to output capacitors, and

then returns to the input capacitor through GND.

Loop2

When Tr1 turns ON, the loop starts from Tr1, to L (inductor), to output capacitors, and then returns to Tr1 through GND.

To reduce the noise and improve efficiency, please minimize the impedance of the each loop.

Figure 5.3 shows the current loops to be designed carefully.

As Figure 5.4 shows, the patterns which handle the heavy currents should be routed as much shortly and widely as possible to

suppress the effect of the parasitic impedance coming from PCB layout, especially the node with drastic shift in current or voltage

level such as VIN (input voltage) and power ground (GND). Two vias with the diameter of 300μm are used for input and GND for each

input capacitor to make the impedance lower.

Via for input

Feedback

21/46

Page 22

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

VSYS

BD71837MWV

PTH

VSYS

(Top layer)

(Inner layer)

Input Cap

Figure 5.5 Layout for BUCK X_VIN and VSYS

5.2.3. Power GND

Power ground for BUCK Converters (exposed pad) is the noisy ground because of the current loops indicated in the previous section.

Thus, the power ground should take an area as large as possible to keep the impedance low and reduce the swing of ground voltage

level.

5.2.4. VSYS (Power supply for BD71837MWV analog circuit)

BUCK X_VIN (X is 1, 2, 3… and 8) of each VR’s input should be connected to VSYS plane directly to minimize the parasitic and

common impedance effects.

The enough numbers of vias for input capacitors should be used and the decoupling capacitors should be placed as close to PMIC as

possible. The reference layout (BD71837MWV reference layout) can be referred to for your reference.

5.2.5. Other Signal Pattern Precautions

Make sure to leave adequate space between noisy lines of voltage rail and serial interface (I2C).

5.2.6. Feedback Sense Lines

Feedback sense lines (e.g., BUCK1_FB, BUCK2_FB etc.) should be routed to monitor the accurate output voltages for each voltage

rail. In order to avoid the effects of IR drop and switching noise, please make sure that the feedback sense lines are independently

routed from the point near output capacitors.

As the method for voltage sensing, “Local sensing” is recommended in all VRs.

In addition, these lines are interfered by noisy lines since these sense lines are high impedance nodes. Please don’t route these

sense lines by overlapping with or in parallel with noisy lines such as LX, SCL and SDA.

Drastic voltage shift in feedback lines result in unexpected voltage violations.

22/46

Page 23

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Figure 5.6 Connection between Power GND and Analog GND

5.2.7. AGND layout

AGND is recommended not to be connected to PGND for PMIC (exposed pad) directly to avoid noise effect. It’s better to short AGND

to a GND at inner GND plane (stable GND) through PTH.

The reference layout as above can be referred to.

23/46

Page 24

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

Buck1 (VDD_SoC)

BUCK1_VIN[1:0]

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 10μF.

Select the input capacitor with the capacitance≧3.5μF including the DC bias effect

at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BBJ106MALT, size:1608, capacitance: 10μF, tolerance:10V

BUCK1_LX[1:0]

O

Connect to BUCK1 via the inductor.

Connect one 0.47μH ±20% inductors to BUCK1_LX0 and 1.

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.HMLE32251E-R47MSR, size: 3225 , Rated DC Current : 7.2A

As output capacitors, use two 22μF capacitors.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

BUCK1_FB

I

Connect to the sense pin of BUCK1_FB to near output capacitors.

5.3. BUCK Convertors

In this section, application circuits for each voltage rail are explained.

For more detail information, the document of “BD71837MWV schematic check list” can be referred to.

5.3.1. BUCK1 (VDD_SoC)

BUCK1 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage.

This VR can dynamically change its output voltage setting using the I2C interface. BUCK1 output voltage range is from 0.7V to 1.3V

by 10mV step.

5.3.1.1. Schematic Example

5.3.1.2. Schematic checklist

Figure 5.7 BUCK1 Schematic Example

Table 5.2 BUCK1 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

24/46

Page 25

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Output Cap

BUCK1_VIN

BUCK1_LX

Input Cap

Feedback

point

Inductor

5.3.1.3. Parts placement for each decoupling capacitor

About the parts placement for each capacitor around BUCK1, the below reference layout can be referred to.

BUCK1_FB should be connected to near output capacitors.

Figure 5.8 BUCK1 Layout Example (Top Layer)

5.3.2. BUCK2 (VDD_ARM)

BUCK2 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage. This VR can

dynamically change its output voltage setting using the I2C interface. BUCK2 output voltage range is from 0.7V to 1.3V by 10mV

step.

5.3.2.1. Schematic Example

Figure 5.9 BUCK2 Schematic Example

25/46

Page 26

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

BUCK2 (VDD_ARM)

BUCK2_VIN[1:0]

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 10μF.

Select the input capacitor with the capacitance≧3.5μF including the DC bias effect

at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BBJ106MALT, size:1608, capacitance: 10μF, tolerance:10V

BUCK2_LX[1:0]

O

Connect to BUCK2 via the inductor.

Connect one 0.47μH ±20% inductors to BUCK2_LX0 and 1.

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.HMLE32251E-R47MSR, size: 3225 , Rated DC Current : 7.2A

As output capacitors, use two 22μF capacitors.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

BUCK2_FB

I

Connect to the sense pin of BUCK2_FB to near output capacitors.

Output Cap

BUCK2_VIN

BUCK2_LX

Input Cap

Feedback

point

Inductor

5.3.2.2. Schematic checklist

Table 5.3 BUCK2 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

5.3.2.3. Layout Example

About the parts placement for each capacitor around BUCK2, the below reference layout can be referred to.

BUCK2_FB should be connected to near output capacitors.

Figure 5.10 BUCK2 Layout Example (Top Layer)

26/46

Page 27

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

BUCK3 (VDD_GPU)

BUCK3_VIN

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 4.7μF.

Select the input capacitor with the capacitance≧1.88μF including the DC bias effect

at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BJ475MA, size:1608, capacitance: 4.7μF, tolerance:10V

BUCK3_LX[1:0]

O

Connect to BUCK3 via the inductor.

Connect one 0.47μH ±20% inductors to BUCK3_LX0 and 1.

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.MAMK2520HR47M, size: 2520 , Rated DC Current : 5.8A

As output capacitors, use one 22μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet of

BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

BUCK3_FB

I

Connect to the sense pin of BUCK3_FB to near output capacitors.

5.3.3. BUCK3 (VDD_GPU)

BUCK3 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage. This VR can

dynamically change its output voltage setting using the I2C interface. BUCK3 output voltage range is from 0.7V to 1.3V by 10mV

step.

5.3.3.1. Schematic Example

5.3.3.2. Schematic Checklist

Figure 5.11 BUCK3 Schematic Example

Table 5.4 BUCK3 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

27/46

Page 28

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Output Cap

BUCK3_VIN

BUCK3_LX

Input Cap

Feedback

point

Inductor

5.3.3.3. Layout Example

About the parts placement for each capacitor around BUCK3, the below reference layout can be referred to.

BUCK3_FB should be connected to near output capacitors.

Figure 5.12 BUCK3 Layout Example (Top Layer)

28/46

Page 29

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

BUCK4 (VDD_VPU)

BUCK4_VIN

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 4.7μF.

Select the input capacitor with the capacitance≧1.88μF including the DC bias

effect at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BJ475MA, size:1608, capacitance: 4.7μF, tolerance:10V

BUCK4_LX

O

Connect to BUCK3 via the inductor.

Connect one 0.47μH ±20% inductors to BUCK3_LX.

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.MAMK2520HR47M, size: 2520 , Rated DC Current : 5.8A

As output capacitors, use one 22μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

BUCK4_FB

I

Connect to the sense pin of BUCK4_FB to near output capacitors.

5.3.4. BUCK4 (VDD_VPU)

BUCK4 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage. This VR can

dynamically change its output voltage setting using the I2C interface. BUCK4 output voltage range is from 0.7V to 1.3V by 10mV

step.

5.3.4.1. Schematic Example

5.3.4.2. Schematic Checklist

Figure 5.13 BUCK4 Schematic Example

Table 5.5 BUCK4 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

29/46

Page 30

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Output Cap

BUCK4_VIN

BUCK4_LX

Input Cap

Feedback

point

Inductor

5.3.4.3. Layout Example

About the parts placement for each capacitor around BUCK4, the below reference layout can be referred to.

BUCK4_FB should be connected to near output capacitors.

Figure 5.14 BUCK4 Layout Example (Top Layer)

5.3.5. BUCK5 (VDD_DRAM)

BUCK5 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage. BUCK5 output voltage

is programmable by the register and its range is from 0.7V to 1.35V.

5.3.5.1. Schematic Example

Figure 5.15 BUCK5 Schematic Example

30/46

Page 31

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : inch)

Check

BUCK5 (VDD_DRAM)

BUCK5_VIN[1:0]

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 10μF.

Select the input capacitor with the capacitance≧3.5μF including the DC bias effect

at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BBJ106MALT, size:1608, capacitance: 10μF, tolerance:10V

BUCK5_LX[1:0]

O

Connect to BUCK5 via the inductor.

Connect one 0.47μH ±20% inductors to BUCK5_LX[1:0].

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.MAMK2520HR47M, size: 2520 , Rated DC Current : 5.8A

BUCK5_FB

I

As output capacitors, use one 22μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

5.3.5.2. Schematic Checklist

Table 5.6 BUCK5 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

31/46

Page 32

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Output Cap

BUCK5_VIN

BUCK5_LX

Input Cap

Feedback

point

Inductor

5.3.5.3. Layout Example

About the parts placement for each capacitor around BUCK5, the below reference layout can be referred to.

BUCK5_FB should be connected to near output capacitors.

Figure 5.16 BUCK5 Layout Example (Top Layer)

5.3.6. BUCK6 (NVCC_3P3)

BUCK6 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage. BUCK6 output voltage

is programmable by the register and its range is from 3.0V to 3.3V by 100mV step.

5.3.6.1. Schematic Example

Figure 5.17 BUCK6 Schematic Example

32/46

Page 33

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : inch)

Check

BUCK6 (NVCC_3P3)

BUCK6_VIN[1:0]

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 22μF.

Select the input capacitor with the capacitance≧7.7μF including the DC bias effect

at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BBJ226MA-T, size:1608, capacitance: 22μF, tolerance:10V

BUCK6_LX[1:0]

O

Connect to BUCK6 via the inductor.

Connect one 1.0μH ±20% inductors to BUCK6_LX[1:0].

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.MAMK2520H1R0M, size: 2520 , Rated DC Current : 3.1A

BUCK6_FB

I

As output capacitors, use two 22μF capacitors.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

Output Cap

BUCK6_VIN

BUCK6_LX

Input Cap

Feedback

point

Inductor

5.3.6.2. Schematic Checklist

Table 5.7 BUCK6 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

5.3.6.3. Layout Example

Figure 5.18 BUCK6 Layout Example (Top Layer)

33/46

Page 34

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : inch)

Check

BUCK7 (NVCC_1V8)

BUCK7_VIN

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 4.7μF.

Select the input capacitor with the capacitance≧1.88μF including the DC bias

effect at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BJ475MA, size:1608, capacitance: 4.7μF, tolerance:10V

BUCK7_LX

O

Connect to BUCK7 via the inductor.

Connect one 0.47μH ±20% inductors to BUCK7_LX.

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.MAMK2520HR47M, size: 2520 , Rated DC Current : 5.8A

BUCK7_FB

I

As output capacitors, use one 22μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

5.3.7. BUCK7 (NVCC_1V8)

VBUCK7 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage. BUCK7 output

voltage is programmable by the register and its range is from 1.6V to 2.0V by eight steps.

5.3.7.1. Schematic Example

Figure 5.19 BUCK7 Schematic Example

5.3.7.2. Schematic Checklist

Table 5.8 BUCK7 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

34/46

Page 35

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Output Cap

BUCK7_VIN

BUCK7_LX

Input Cap

Feedback

point

Inductor

5.3.7.3. Layout Example

About the parts placement for each capacitor around BUCK7, the below reference layout can be referred to.

BUCK7_FB should be connected to near output capacitors.

Figure 5.20 BUCK7 Layout Example (Top Layer)

35/46

Page 36

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : inch)

Check

BUCK8 (NVCC_DRAM)

BUCK8_VIN[1:0]

I

Connect to the 5V power supply in the system.

As a decoupling capacitor, use one 10μF.

Select the input capacitor with the capacitance≧3.5μF including the DC bias effect

at VSYS=5.0V.

<The recommended part of capacitor is shown below.>

A.LMK107BBJ106MALT, size:1608, capacitance: 10μF, tolerance:10V

BUCK8_LX[1:0]

O

Connect to BUCK8 via the inductor.

Connect one 0.47μH ±20% inductors to BUCK8_LX0 and 1.

Select the inductor to be used according to board area and cost restrictions.

<The recommended part of inductor is shown below.>

A.HMLE32251E-R47MSR, size: 3225 , Rated DC Current : 7.2A

BUCK8_FB

I

As output capacitors, use two 22μF capacitors.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

5.3.8. BUCK8 (NVCC_DRAM)

BUCK8 is a high-efficiency buck converter which converts VSYS (2.7V to 5.5V) voltage to a regulated voltage. BUCK8 output voltage

is programmable by the register and its range is from 0.8V to 1.4V by 10mV step.

5.3.8.1. Schematic Example

Figure 5.21 BUCK8 Schematic Example

5.3.8.2. Schematic Checklist

Table 5.9 BUCK8 schematic checklist

Note: Some dummy pads for output capacitors should be prepared like the reference schematic for the fine tuning in the actual board.

36/46

Page 37

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Output Cap

BUCK8_VIN

BUCK8_LX

Cap

Feedback

point

Inductor

5.3.8.3. Layout Example

About the parts placement for each capacitor around BUCK8, the below reference layout can be referred to.

BUCK8_FB should be connected to near output capacitors.

Input

Figure 5.22 BUCK8 Layout Example (Top Layer)

37/46

Page 38

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

5.4. LDOs

5.4.1. LDO1 (NVCC_SNVS)

VLDO1 converts VSYS (2.7V to 5.5V) voltage to a regulated voltage.

LDO1 output voltage is programmable by the register and its range is from 3.0V to 3.3V or 1.6V to 1.9V by 100mV step.

LDO1 should be used as the input for DVDD and pull up voltages for IRQ_B, RTC_RESET_B, WDOG_B and I2C interface.

5.4.2. LDO2 (VDD_SNVS)

VLDO2 converts VSYS (2.7V to 5.5V) voltage to a regulated voltage.

LDO2 output voltage is programmable and can be selected between 0.8V and 0.9V by the register.

5.4.3. LDO3 (VDDA_1P8/VDDA_DRAM)

VLDO3 converts VSYS (2.7V to 5.5V) voltage to a regulated voltage when BUCK6 is OFF.

After BUCK6 is ON, the input source will be changed from VSYS to BUCK6 automatically.

LDO3 output voltage is programmable and its voltage range is from 1.8V to 3.3V by 100mV step.

5.4.4. LDO4 (VDDA_0P9)

VLDO4 converts VSYS (2.7V to 5.5V) voltage to a regulated voltage when BUCK7 is OFF.

After BUCK7 is ON, the input source will be changed from VSYS to BUCK7 automatically.

LDO4 output voltage is programmable and its voltage range is from 0.9V to 1.8V by 100mV step.

5.4.5. LDO5 (1P8_PHY)

VLDO5 converts BUCK6 voltage to the regulated voltage.

LDO5 output voltage is programmable and its voltage range is from 1.8V to 3.3V by 100mV step.

5.4.6. LDO6 (0P9_PHY)

VLDO6 converts BUCK7 voltage to the regulated voltage.

LDO6 output voltage is programmable and its voltage range is from 0.9V to 1.8V by 100mV step.

5.4.7. LDO7 (3P3_PHY)

VLDO7 converts VSYS (2.7V to 5.5V) voltage to the regulated voltage.

LDO7 output voltage is programmable and its voltage range is from 0.9V to 1.8V by 100mV step.

38/46

Page 39

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

LDO1 (NVCC_SNVS) : Vout = 3.0V-3.3V / 1.6V-1.9V , Iomax=10mA

LDO1

O

As the output capacitor, use one 1μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of capacitor is shown below.>

A.JMK105BJ105MV-F, size:1005, capacitance: 1.0μF, tolerance:6.3V

LDO2 (VDD_SNVS) : Vout = 0.9V / 0.8V , Iomax=10mA

LDO2

O

As the output capacitor, use one 1μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of capacitor is shown below.>

A.JMK105BJ105MV-F, size:1005, capacitance: 1.0μF, tolerance:6.3V

LDO3 (VDDA_DRAM) : Vout = 1.8V - 3.3V, Iomax=300mA

LDO3

O

As the output capacitor, use one 2.2μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of capacitor is shown below.>

A.JMK105BJ225MV-F, size:1005, capacitance: 2.2μF, tolerance:6.3V

5.4.8. Schematic Examples

5.4.8.1. Schematic Checklist

Figure 5.23 LDO1 to 7 Schematic Example

Table 5.10 LDO1-7 schematic checklist

39/46

Page 40

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

LDO4 (VDDA_0P9) : Vout = 0.9V - 1.8V, Iomax=250mA

LDO4

O

As the output capacitor, use one 2.2μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of capacitor is shown below.>

A.JMK105BJ225MV-F, size:1005, capacitance: 2.2μF, tolerance:6.3V

LDO5 (1.8V PHY) : Vout = 1.8 - 3.3V, Iomax=300mA

LDO5

O

As the output capacitor, use one 2.2μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of capacitor is shown below.>

A.JMK105BJ225MV-F, size:1005, capacitance: 2.2μF, tolerance:6.3V

LDO6 (0.9V PHY) : Vout = 0.9V - 1.8V, Iomax=300mA

LDO6

O

As the output capacitor, use one 2.2μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of capacitor is shown below.>

A.JMK105BJ225MV-F, size:1005, capacitance: 2.2μF, tolerance:6.3V

LDO7 (3.3V PHY) : Vout = 1.8V - 3.3V, Iomax=150mA

LDO7

O

As the output capacitor, use one 2.2μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of capacitor is shown below.>

A.JMK105BJ225MV-F, size:1005, capacitance: 2.2μF, tolerance:6.3V

Inputs for LDOs

VSYS1

I

As the input capacitor, use one 2.2μF capacitor.

<The recommended part of capacitor is shown below.>

A.GRM155R61A225KE95, size:1005, capacitance: 2.2μF, tolerance:10V

VSYS2

I

As the input capacitor, use one 2.2μF capacitor.

<The recommended part of capacitor is shown below.>

A.GRM155R61A225KE95, size:1005, capacitance: 2.2μF, tolerance:10V

VSYS3

I

As the input capacitor, use one 2.2μF capacitor.

<The recommended part of capacitor is shown below.>

A.GRM155R61A225KE95, size:1005, capacitance: 2.2μF, tolerance:10V

VIN_1P8_1

I

The input for LDO4, 6 and connect to BUCK7.

As the input capacitor, use one 4.7μF capacitor.

<The recommended part of capacitor is shown below.>

A.JMK105BBJ475MV-F, size:1005, capacitance: 4.7μF, tolerance:6.3V

VIN_3P3

I

The input for LDO3, 5, MUXSW and connect to BUCK6.

As the input capacitor, use one 4.7μF capacitor.

<The recommended part of capacitor is shown below.>

A.JMK105BBJ475MV-F, size:1005, capacitance: 4.7μF, tolerance:6.3V

40/46

Page 41

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

MUXSW : Vout = 1.8V / 3.3V, Iomax=150mA

VIN_1P8_2

I

The input for MUXSW and connect to BUCK7.

As the input capacitor, use one 4.7μF capacitor.

<The recommended part of capacitor is shown below.>

A.JMK105BBJ475MV-F, size:1005, capacitance: 4.7μF, tolerance:6.3V

MUXSW_VOUT[1:0]

O

As the output capacitor, use one 22μF capacitor.

Select the output capacitors within the capacitance range defined in the datasheet

of BD71837MWV.

<The recommended part of 22μF capacitor is shown below.>

A.GRM188R60J226MEA0D, size:1608, capacitance: 22μF, tolerance:6.3V

5.5. Load SW

5.5.1. MUXSW (NVCC_SD2)

VMUXSW is the internal load switch for SD card power.

MUXSW output voltage supports 1.8V and 3.3V which are determined by the setting of SD_VSELECT.

5.5.1.1. Schematic Examples

Figure 5.24 MUXSW Schematic Example

5.5.1.2. Schematic Checklist

Table 5.11 MUXSW schematic checklist

Note: According to the setting of SD_VSELECT by SoC, the output of MUXSW is determined.

When SD_VSELECT = 0V, "3.3V mode" is selected and VIN_3P3 is used as the input.

When SD_VSELECT = DVDD, "1.8V mode" is selected and VIN_1P8_2 is used as the input.

41/46

Page 42

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Notes (Unit of parts size : mm)

Check

Crystal Oscillator Driver

XIN

I

As the load capacitor, use one 18pF capacitor.

<The recommended part of capacitor is shown below.>

A.UMK063CH180JT-F, size:0603, capacitance: 18pF, tolerance:50V

XOUT

O

As the load capacitor, use one 18pF capacitor.

<The recommended part of capacitor is shown below.>

A.UMK063CH180JT-F, size:0603, capacitance: 18pF, tolerance:50V

C32K_OUT

Connect to SoC

5.6. Crystal Oscillator Driver

5.6.1. XIN / XOUT / C32K_OUT

BD71837MWV has the crystal oscillator driver for 32.768 kHz for RTC in SoC internally.

The external load capacitors of C49 and C50 shown in the Figure 5.25 are set to 18pF and this value was determined after fine tuning

the specific parameters for the crystal of ST3215SB32768H5HPWAA (Load capacitance is 12.5pF) together with ROHM’s evaluation

board.

So it is ideal to confirm the valid capacitance value supported by the crystal supplier finely since the peripheral environment around

the crystal including the crystal part number itself should be different from the condition in ROHM’s evaluation.

5.6.1.1. Schematic Examples

Figure 5.25 Crystal Oscillator Driver Schematic Example

5.6.1.2. Schematic Checklist

Table 5.12 Schematic checklist of crystal oscillator driver

Note: As the crystal oscillator for RTC clock circuit, 32.768 kHz and 12.5pF (KYOCERA) is used together with BD71837MWV

evaluation board.

It is recommended to tune the load capacitance finely in the actual set to guarantee the stable oscillation.

<The recommended part of capacitor is shown below.>

A. ST3215SB32768H5HPWAA, size:3215, Load capacitance: 12.5pF

42/46

Page 43

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Crystal

XOUT

XIN

Load Cap

Load Cap

5.6.1.3. Layout Example

Crystal oscillator driver circuit is extremely sensitive to external environment like parasitic capacitance due to the long wirings for XIN

and XOUT. So it is recommended to position the Crystal oscillator part near PMIC to shorten the length of the wirings.

Figure 5.26 XIN / XOUT Layout Example (Top Layer)

43/46

Page 44

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Signal

Voltage

Level

System

Pull-up/Pull-down

(RTT)

Termination

if it is not

used

Notes

Check

I2C

DVDD

I

- - -

The input power source for

C32K_OUT and I2C interface.

Capacitor for decoupling, use one

1.0μF ± 20%

(size : 1005, capacitance : 1.0μF,

tolerance : 6.3V)

SCL

I

DVDD

Pulled up to DVDD

with 1kohm

-

Connect to SoC (Note)

If pull up resistor is prepared within

SoC,

the additional pull up resistor is not

needed.

SDA

I/O

DVDD

Pulled up to DVDD

with 1kohm

-

Connect to SoC (Note)

If pull up resistor is prepared within

SoC,

the additional pull up resistor is not

needed.

5.7. Interfaces

I2C interface is selected for the communication between PMIC and SoC.

5.7.1. I2C

Table 5.13 Schematic checklist of I2C

Note: Recommended to use LDO1 (NVCC_SNVS) as power source for DVDD.

If DVDD is not used as the pull up voltage for SCL and SDA, it's recommended to use NVCC_I2C in SoC as the pull up voltage.

44/46

Page 45

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Expected

Signal

Voltage

Level

Expected System

Pull-up/Pull-down

(RTT)

Termination

if it is not

used

Notes

Check

System Control - Reset, Power, and Control Signals

PWRON_B

I

VSYS

Pulled up to VSYS

with 100kohm

Pulled up to

VSYS

with 100kohm

Connect to Power Button

POR_B

O

BUCK6

Refer to

Notes

Pulled up to

BUCK6

with 10kohm

NC

Connect to SoC (Note1)

If pull up resistor is prepared within SoC,

the additional pull up resistor is not

needed.

IRQ_B

O

DVDD

Refer to

Notes

Pulled up to DVDD

with 10kohm

NC

Connect to SoC (Note2)

If pull up resistor is prepared within SoC,

the additional pull up resistor is not

needed.

RTC_RESET_B

O

DVDD

Refer to

Notes

Pulled up to DVDD

with 10kohm

NC

Connect to SoC (Note3)

If pull up resistor is prepared within SoC,

the additional pull up resistor is not

needed.

PMIC_STBY_REQ

I

DVDD

Refer to

Notes

-

-

Connect to SoC (Note4)

PMIC_ON_REQ

I

DVDD

Refer to

Notes

-

-

Connect to SoC (Note4)

WDOG_B

I

DVDD

Refer to

Notes

Pulled up to DVDD

with 10kohm

Pulled up to

DVDD

with 10kohm

Connect to SoC (Note2)

If pull up resistor is prepared within SoC,

the additional pull up resistor is not

needed.

SD_VSELECT

I

DVDD

Refer to

Notes

-

GND

Connect to SoC (Note5)

5.7.2. System Control – Reset, Power, and Control Signals

Table 5.14 Schematic checklist of System Control – Reset, Power, and Control Signals

Note1: The source for pull up should be BUCK6 to avoid a leakage current. POR_B keeps L level until PMIC_ON_REQ is issued by

SoC and POR_B is de- asserted during the power sequence.

Note2: If the power source for NVCC_GPIO1 in SoC is different from the voltage of DVDD in PMIC, the pull up voltage is set to

NVCC_GPIO1.

Note3: If DVDD is different from the voltage of NVCC_SNVS in SoC, the pull up voltage is set to NVCC_SNVS.

Note4: This signal comes from SoC so the signal voltage level depends on the power source for NVCC_SNVS.

Note5: The voltage level depends on the power source for NVCC_GPIO1 which is the power source for GPIO in SoC.

45/46

Page 46

Application Note

BD71837MWV Platform Design Guide

© 2018 ROHM Co., Ltd.

No. 61AN002E Rev.001

May.2018

Pin Names

Dir.

Signal

Voltage Level

Notes

Check

MISC

AGND

-

GND

Connect to PGND at inner GND plane

EXP-PADs

(PGND0~4)

-

GND

Connect to the inner GND plane with lower impedance

5.7.3. MISC

Table 5.15 Schematic checklist of MISC

Note: The package has one pad at bottom and four corner pads to fix the position of the part.

These pads are shorted internally and it is recommended to solder these pads to the board.

46/46

Page 47

Notes

The information contained herein is subject to change without notice.

1)

Before you use our Products, please contact our sales representative

2)

tions :

Although ROHM is continuously working to improve product reliability and quality, semicon-

3)

ductors can break down and malfunction due to various factors.

Therefore, in order to prevent personal injury or fire arising from failure, please take safety

measures such as complying with the derating characteristics, implementing redundant and

fire prevention designs, and utilizing backups and fail-safe procedures. ROHM shall have no

responsibility for any damages arising out of the use of our Poducts beyond the rating specified by

ROHM.

Examples of application circuits, circuit constants and any other information contained herein are

4)

provided only to illustrate the standard usage and operations of the Products. The peripheral

conditions must be taken into account when designing circuits for mass production.

The technical information specified herein is intended only to show the typical functions of and

5)

examples of application circuits for the Products. ROHM does not grant you, explicitly or implicitly,

any license to use or exercise intellectual property or other rights held by ROHM or any other

parties. ROHM shall have no responsibility whatsoever for any dispute arising out of the use of

such technical information.

The Products specified in this document are not designed to be radiation tolerant.

6)

For use of our Products in applications requiring a high degree of reliability (as exemplified

7)

below), please contact and consult with a ROHM representative : transportation equipment (i.e.

cars, ships, trains), primary communication equipment, traffic lights, fire/crime prevention, safety

equipment, medical systems, servers, solar cells, and power transmission systems.

Do not use our Products in applications requiring extremely high reliability, such as aerospace

8)

equipment, nuclear power control systems, and submarine repeaters.

ROHM shall have no responsibility for any damages or injury arising from non-compliance with

9)

the recommended usage conditions and specifications contained herein.

ROHM has used reasonable care to ensurH the accuracy of the information contained in this

10)

document. However, ROHM does not warrants that such information is error-free, and ROHM

shall have no responsibility for any damages arising from any inaccuracy or misprint of such

information.

Please use the Products in accordance with any applicable environmental laws and regulations,

11)

such as the RoHS Directive. For more details, including RoHS compatibility, please contact a

ROHM sales office. ROHM shall have no responsibility for any damages or losses resulting

non-compliance with any applicable laws or regulations.

When providing our Products and technologies contained in this document to other countries,

12)

you must abide by the procedures and provisions stipulated in all applicable export laws and

regulations, including without limitation the US Export Administration Regulations and the Foreign

Exchange and Foreign Trade Act.

This document, in part or in whole, may not be reprinted or reproduced without prior consent of

13)

ROHM.

and verify the latest specifica-

Notice

ZZZURKPFRP

652+0&R/WG$OOULJKWVUHVHUYHG

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

5

%

Loading...

Loading...