Page 1

System Lens Driver Series for Digital Still Cameras / Single-lens Reflex Cameras

7ch System Lens Drivers for

Digital Still Cameras / Single-lens Reflex Cameras

BD6757KN, BD6889GU

No.09014EAT04

●Description

BD6757KN and BD6889GU motor drivers provide 6 Full-ON Drive H-bridge channels and 1 Linear Constant-Current Drive

H-bridge channel. Stepping motors can be used for the auto focus, zoom, and iris, making it possible to configure a

sophisticated, high precision lens drive system. ROHM’s motor drivers are both compact, multifunctional, and enable

advanced features such as lens barrier and anti shock.

●Features

1) Subminiature grid array package: 5.0 5.0 1.2mm

3

(BD6889GU)

2) DMOS output allowing a range power supply: 2.0V to 8.0V (BD6757KN)

3) Low ON-Resistance Power MOS output:

Full-ON Drive block with 1.3Ω Typ. and Linear Constant-Current Drive block with 0.9Ω Typ. (BD6757KN, BD6889GU)

4) Built-in two digital NPN transistor circuits for photo-interrupter waveform shaping:

Input-dividing type with output pull-up resistance (BD6757KN)

5) Built-in four digital NPN transistor circuits for photo-interrupter waveform shaping:

Input-dividing type with output pull-up resistance (BD6889GU)

6) Built-in four digital PNP transistor circuits for photo-interrupter waveform shaping:

Input-dividing type with output pull-down resistance (BD6889GU)

7) Built-in voltage-regulator circuit for photo-interrupter (BD6889GU)

8) Built-in two-step output current setting switch for the Linear Constant-Current Drive block (BD6757KN)

9) 0.9V±2% high-precision reference voltage output

10) Constant-Current Drive block features phase compensation capacitor-free design

11) Built-in ±3% high-precision Linear Constant-Current Driver

12) Built-in charge pump circuit for the DMOS gate voltage drive(BD6757KN)

13) UVLO (Under Voltage Lockout Protection) function

14) Built-in TSD (Thermal Shut Down) circuit

15) Standby current consumption: 0μA (Typ.)

●Absolute Maximum Ratings

Parameter Symbol

BD6757KN BD6889GU

Limit

Unit

Power supply voltage VCC -0.5 to +7.0 -0.5 to +7.0 V

Motor power supply voltage VM -0.5 to +10.0 -0.5 to +7.0 V

Charge pump voltage VG 15.0 None V

Control input voltage VIN -0.5 to VCC+0.5 -0.5 to VCC+0.5 V

Power dissipation Pd 950

Operating temperature range Topr -25 to +75 -25 to +85 °C

1

※

980

2

※

mW

Junction temperature Tjmax +150 +150 °C

Storage temperature range Tstg -55 to +150 -55 to +150 °C

H-bridge output current Iout -800 to +800

※1 Reduced by 7.6mW/°C over 25°C, when mounted on a glass epoxy board (70mm 70mm 1.6mm).

※2 Reduced by 7.84mW/°C over 25°C, when mounted on a glass epoxy board (70mm 70mm 1.6mm).

※3 Must not exceed Pd, ASO, or Tjmax of 150°C.

3

※

-800 to +800

3

※

mA/ch

●Operating Conditions (Ta=-25 to +75°C(BD6757KN), -25 to +85°C(BD6889GU))

Parameter Symbol

BD6757KN

Limit

BD6889GU

Unit

Power supply voltage VCC 2.5 to 5.5 2.5 to 5.7 V

Motor power supply voltage VM 2.5 to 8.0 2.5 to 5.7 V

Control input voltage VIN 0 to VCC 0 to VCC V

H-bridge output current Iout -500 to +500

※4 Must not exceed Pd or ASO.

4

※

-500 to +500

4

※

mA/ch

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

1/15

2009.06 - Rev.A

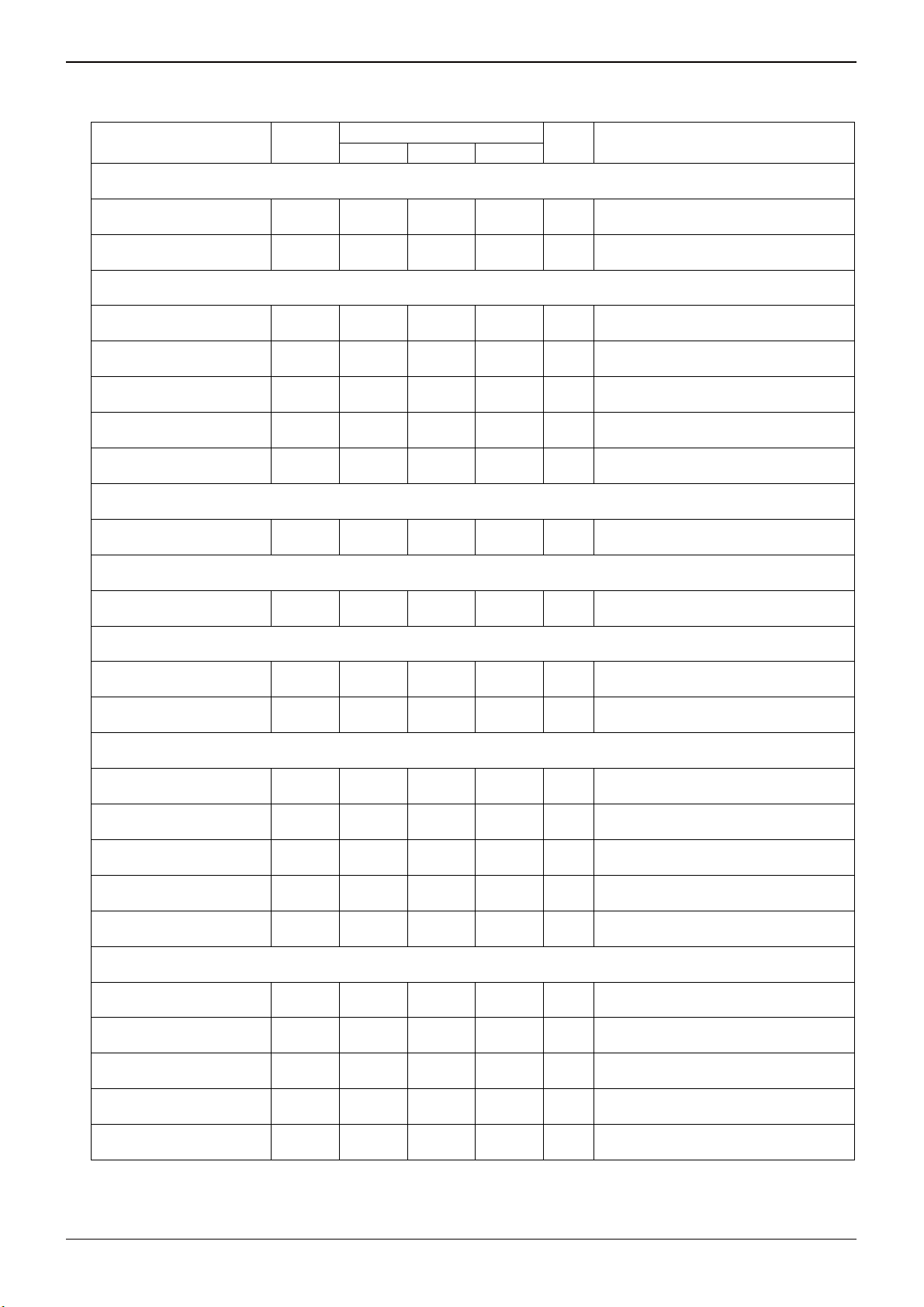

Page 2

BD6757KN, BD6889GU

●Electrical Characteristics

1) BD6757KN Electrical Characteristics (Unless otherwise specified, Ta=25°C, VCC=3.0V, VM=5.0V)

Parameter Symbol

Min. Typ. Max.

Limit

Unit Conditions

Overall

Technical Note

Circuit current

during standby operation

ICCST - 0 10 μA PS=0V

Circuit current ICC - 1.0 3.0 mA PS=VCC with no signal

Control input (IN=PS, IN1A to IN7B, and LIMSW)

High level input voltage VINH 2.0 - - V

Low level input voltage VINL - - 0.7 V

High level input current IINH 15 30 60 μA VINH=3V

Low level input current IINL -1 0 - μA VINL=0V

Pull-down resistor RIN 50 100 200 kΩ

Charge pump

Charge pump voltage VCP 10 11 - V

UVLO

UVLO voltage VUVLO 1.6 - 2.4 V

Full-ON Drive block (ch1 to ch6)

Output ON-Resistance RON - 1.3 1.6 Ω

Io=±400mA on high and low sides

in total

Pulse input response tp 100 - - ns With an input pulse with of 200ns

Linear Constant-Current Drive block (ch7)

Output ON-Resistance RON - 0.9 1.1 Ω

Io=±400mA on high and low sides

in total

VREF output voltage VREF 0.88 0.90 0.92 V Iout=0~1mA

Output limit current 1 IOL1 388 400 412 mA

Output limit current 2 IOL2 285 300 315 mA

Output limit current 3 IOL3 190 200 210 mA

RNF=0.5Ω with a load of 10Ω

VLIMH(L)=0.2V, LIMSW=0V(3V)

RNF=0.5Ω with a load of 10Ω

VLIMH(L)=0.15V, LIMSW=0V(3V)

RNF=0.5Ω with a load of 10Ω

VLIMH(L)=0.1V, LIMSW=0V(3V)

Digital NPN transistor block for photo-interrupter waveform shaping

Input current ISIH - - 0.1 mA SIx=3V

Low level output voltage VSOL - 0.1 0.25 V SIx=3V, ISO=0.5mA

Input dividing resistance RSIL 70 100 130 kΩ

Output pull-up resistance RSOH 5 10 20 kΩ

5

※

5

※

Input dividing resistance

comparison

※5 Design target value (Not all shipped devices are fully tested.)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

- 0.8 1.0 1.2 -

2/15

Division resistance comparison

between SIx and GND

5

※

2009.06 - Rev.A

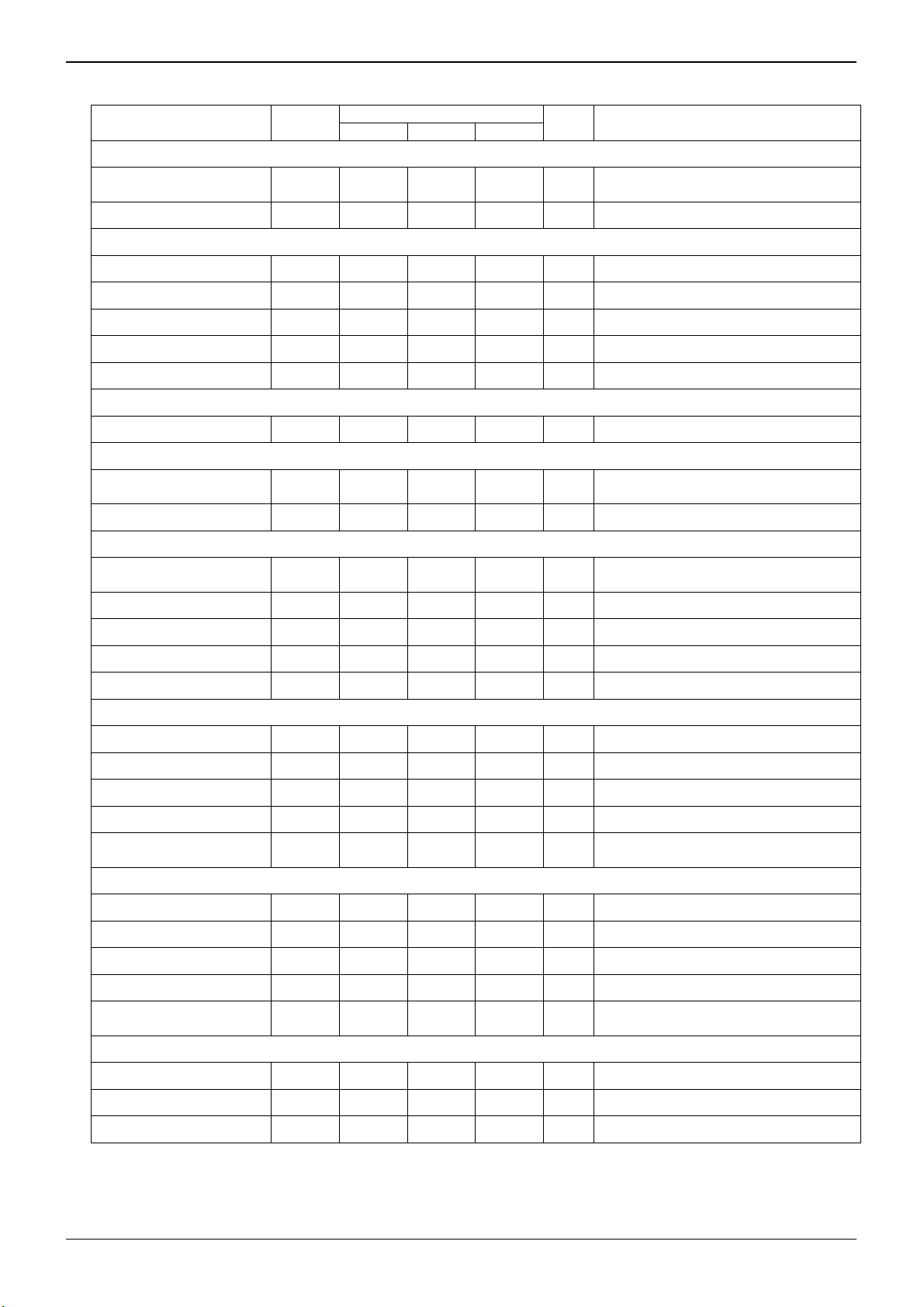

Page 3

BD6757KN, BD6889GU

Technical Note

2) BD6889GU Electrical Characteristics (Unless otherwise specified, Ta=25°C, VCC=3.0V, VM=5.0V)

Parameter Symbol

Min. Typ. Max.

Limit

Unit Conditions

Overall

Circuit current

during standby operation

ICCST - 0 10 μA PS=0V

Circuit current ICC - 1.5 3.0 mA PS=VCC with no signal

Control input (IN=PS, IN1A to IN7B, SW, DSW, DSEL1, and DSEL2)

High level input voltage VINH 2.0 - - V

Low level input voltage VINL - - 0.7 V

High level input current IINH 15 30 60 μA VINH=3V

Low level input current IINL -1 0 - μA VINL=0V

Pull-down resistor RIN 50 100 200 kΩ

UVLO

UVLO voltage VUVLO 1.6 - 2.4 V

Full-ON Drive block (ch1 to ch6)

Output ON-Resistance RON - 1.3 1.6 Ω

Io=±400mA on high and low sides

in total

Pulse input response tp 100 - - ns With an input pulse with of 200ns

Linear Constant-Current Drive block (ch7)

Output ON-Resistance RON - 0.9 1.1 Ω

Io=±400mA on high and low sides

in total

VREF output voltage VREF 0.88 0.90 0.92 V Iout=0~1mA

Output limit current 1 IOL1 388 400 412 mA RNF=0.5Ω with a load of 10Ω, VLIM=0.2V

Output limit current 2 IOL2 285 300 315 mA RNF=0.5Ω with a load of 10Ω, VLIM=0.15V

Output limit current 3 IOL3 190 200 210 mA RNF=0.5Ω with a load of 10Ω, VLIM=0.1V

Digital NPN transistor block for photo-interrupter waveform shaping

Input current ISIH - - 0.1 mA SIx=3V

Low level output voltage VSOL - 0.1 0.25 V SIx=3V, ISO=0.5mA

Input dividing resistance RSIN 70 100 130 kΩ

Output pull-up resistance RSOH 23 33 43 kΩ

Input dividing resistance

comparison

- 0.8 1.0 1.2 -

Division resistance comparison

between SIx and GND

6

※

Digital PNP transistor block for photo-interrupter waveform shaping

Input current ISIL -0.1 - - mA SIx=0V

High level output voltage VSOH VCC-0.25 VCC-0.1 - V SIx=0V, ISO=-0.5mA

Input dividing resistance RSIP 70 100 130 kΩ

Output pull-down resistance RSOL 23 33 43 kΩ

Input dividing resistance

comparison

- 0.8 1.0 1.2 -

Division resistance comparison

between SIx and VCC

6

※

Voltage-regulator for photo-interrupter

High level output voltage VREGH VCC-0.25 VCC-0.2 - V IREG=100mA

Output ON-Resistance RONREG - 2 2.5 Ω IREG=100mA

Output leak current ILPI - 0 1 μA SW=VCC

※6 Design target value (Not all shipped devices are fully tested.)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

3/15

2009.06 - Rev.A

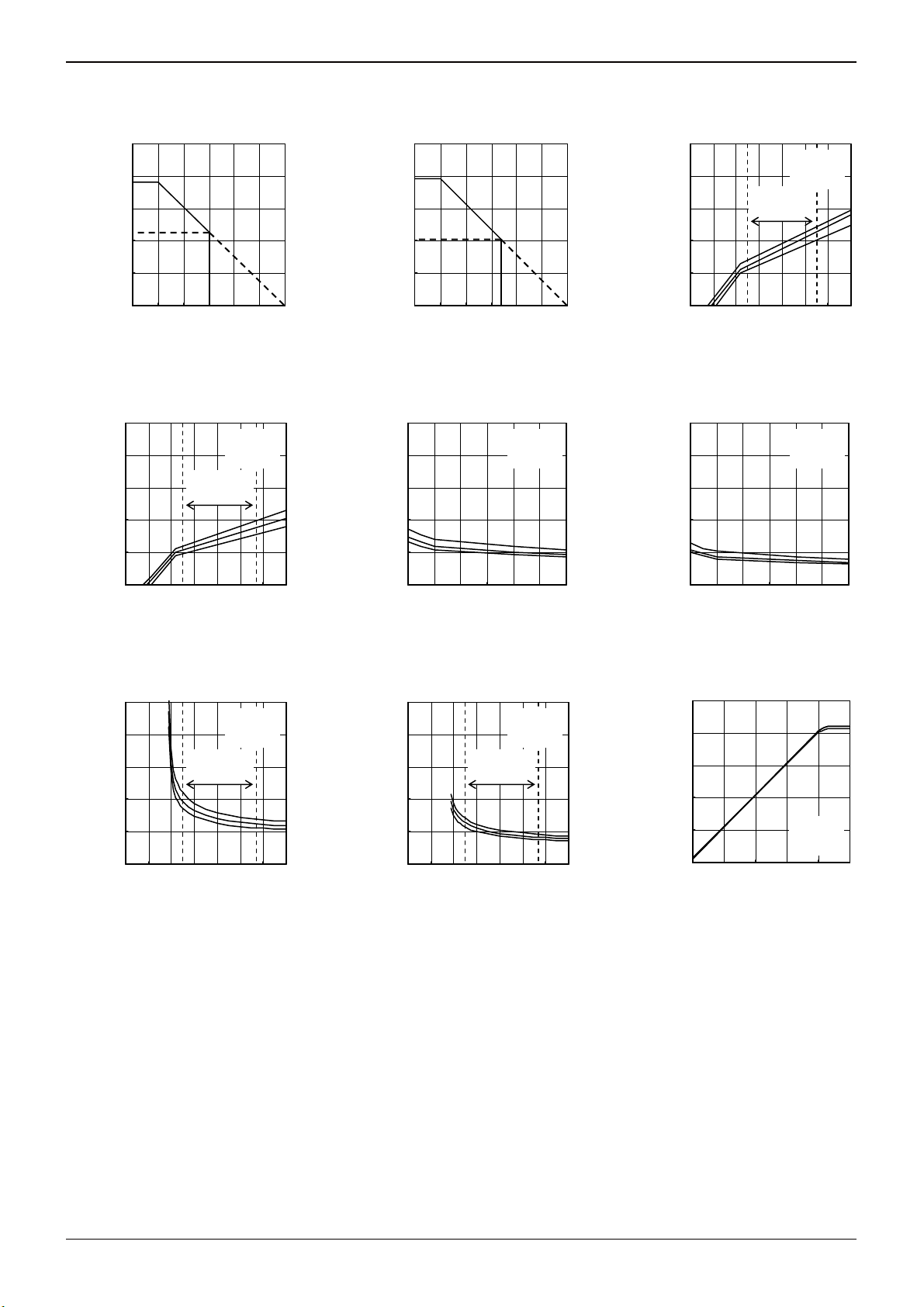

Page 4

BD6757KN, BD6889GU

●Electrical Characteristic Diagrams

1250

1000

940mW

750

570mW

500

250

Power dissipation : Pd [mW]

0

0 25 50 75 100 125 150

Ambient t emperature : Ta [° C]

Fig.1 Power Dissipation Reduction

5.0

4.0

3.0

2.0

1.0

Circuit current : ICC [mA]

0.0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

Fig.4 Circuit current

(2.5V to 5.7V)

Supply voltag e : VCC [V]

5.0

4.0

3.0

2.0

1.0

Output ON resistance : RON [Ω]

0.0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

Fig.7 Output ON-Resistance

(Full-ON Drive block)

(2.5V to 5.7V)

Supply voltag e : VM [V]

75°C

Op. range

Op. range

BD6757KN

BD6889GU

Top 8 5 ° C

Mid 25°C

Low -25°C

BD6889GU

Top 8 5 ° C

Mid 25°C

Low -25°C

1250

980mW

1000

750

510mW

500

250

Power dissipation : Pd [mW]

0

0 25 50 75 100 125 150

Ambient t emperature : Ta [° C]

BD6889GU

85°C

Fig.2 Power Dissipation Reduction

5.0

4.0

3.0

2.0

1.0

Output ON resistance : RON [Ω]

0.0

9.0 10.0 11.0 12.0 13.0 14. 0 15. 0

Supply voltag e : VG [V]

BD6757KN

Top 7 5 ° C

Mid 25°C

Low -25°C

Fig.5 Output ON-Resistance

(Full-ON Drive block)

Op. range

BD6889GU

Top 8 5 ° C

Mid 25°C

Low -25°C

5.0

4.0

3.0

2.0

1.0

Output ON resistance : RON [Ω]

0.0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

(2.5V to 5.7V)

Supply voltag e : VM [V]

Fig.8 Output ON-Resistance

(Linear Constant-Current Drive block)

5.0

4.0

3.0

2.0

1.0

Circuit current : ICC [mA]

0.0

5.0

4.0

3.0

2.0

1.0

Output ON resistance : RON [Ω]

0.0

(Linear Constant-Current Drive block)

250

200

150

100

RNF voltage : VRNF [mV]

Technical Note

BD6757KN

Top 7 5 ° C

Mid 25°C

Low -25°C

Op. range

(2.5V to 5.5V)

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

Supply voltag e : VCC [V]

Fig.3 Circuit current

BD6757KN

Top 7 5 ° C

Mid 25°C

Low -25°C

9.0 10.0 11.0 12. 0 13. 0 14.0 15.0

Supply voltag e : VG [V]

Fig.6 Output ON-Resistance

BD6757KN, BD6889GU

50

0

0 50 100 150 200 250

VLIM voltage : VLIM [mV]

Fig.9 Output limit voltage

(RNF=0.5Ω)

Top 8 5 ° C

Mid 25°C

Low -25°C

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

4/15

2009.06 - Rev.A

Page 5

BD6757KN, BD6889GU

Technical Note

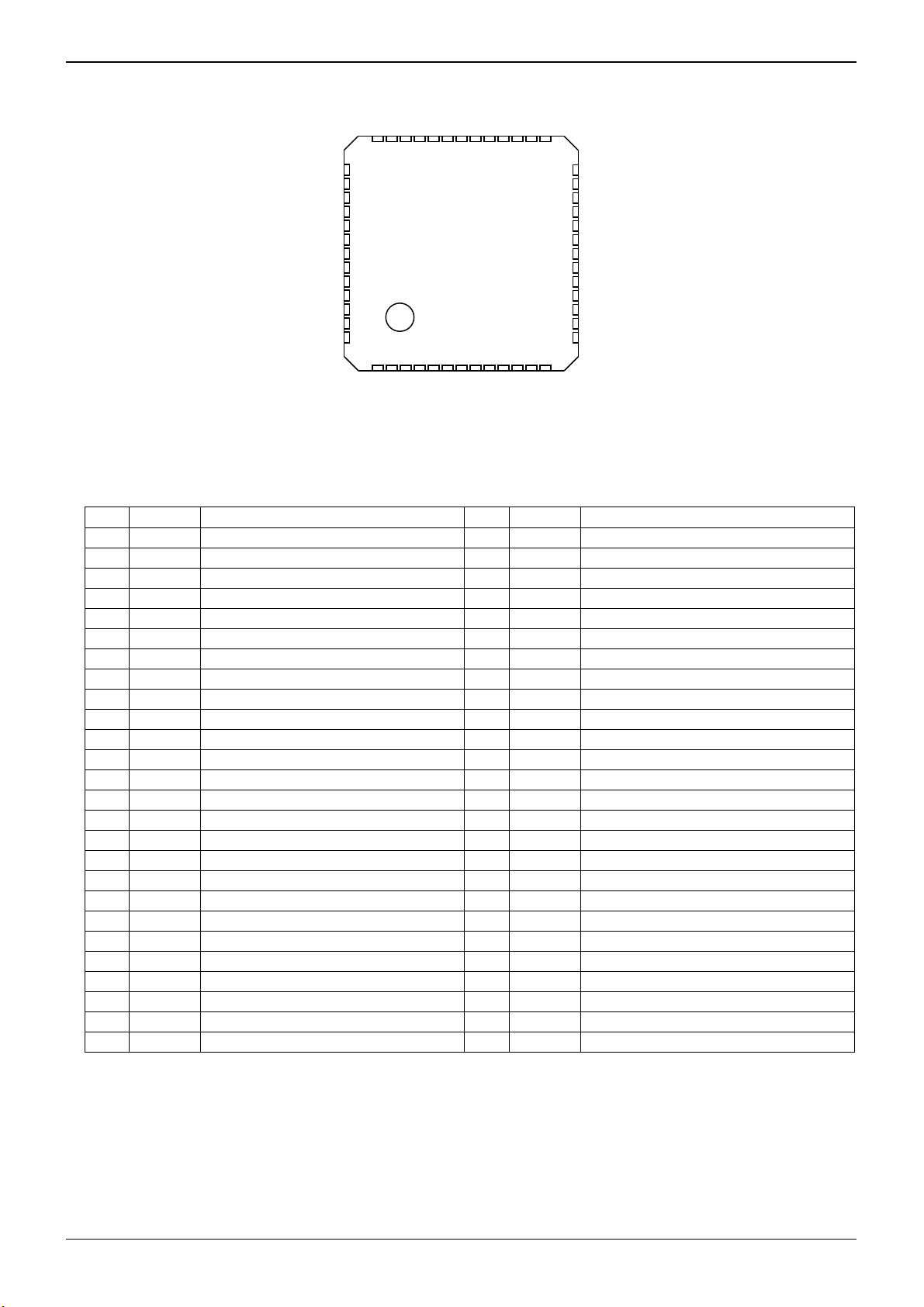

●Pin arrangement and Pin Function

39

VG

CP4

CP3

CP2

CP1

VM3

IN4B

IN4A

SI1

SI2

OUT5A

OUT5B

PGND2

OUT6A

OUT6B

OUT7A

RNF

OUT7B

SENSE

SO2

SO1

52

IN3B

BD6757KN

IN7B

VM4

IN7A

GND

VREF

VLIMH

VM2

IN3A

IN2B

IN2A

IN1B

26

IN1A

OUT4A

OUT4B

OUT3A

OUT3B

PGND1

OUT2B

OUT2A

OUT1B

OUT1A

IN5A

IN5B

VLIML

LIMSW

VCC

VM1

PS

IN6B

IN6A

13

Fig.10 BD6757KN Pin Arrangement (Top View)

UQFN52 Package

BD6757KN Pin Function Table

No. Pin Name Function No. Pin Name Function

1 IN7B Control input pin ch7 B 27 IN2A Control input pin ch2 A

2 VM4 Motor power supply pin ch7 28 IN2B Control input pin ch2 B

3 IN7A Control input pin ch7 A 29 IN3A Control input pin ch3 A

4 GND Ground Pin 30 VM2 Motor power supply pin ch3 and ch4

5 VREF Reference voltage output pin 31 CP1 Charge pump capacitor connection pin 1

6 VLIMH Output current setting pin 1 ch7 32 CP2 Charge pump capacitor connection pin 2

7 VLIML Output current setting pin 2 ch7 33 CP3 Charge pump capacitor connection pin 3

8 LIMSW Output current setting selection pin ch7 34 CP4 Charge pump capacitor connection pin 4

9 VCC Power supply pin 35 VG Charge pump output pin

10 VM1 Motor power supply pin ch1 and ch2 36 VM3 Motor power supply pin ch5 and ch6

11 PS Power-saving pin 37 IN3B Control input pin ch3 B

12 IN6B Control input pin ch6 B 38 IN4A Control input pin ch4 A

13 IN6A Control input pin ch6 A 39 IN4B Control input pin ch4 B

14 IN5B Control input pin ch5 B 40 SI1 Digital transistor input pin 1

15 IN5A Control input pin ch5 A 41 SI2 Digital transistor input pin 2

16 OUT1A H-bridge output pin ch1 A 42 OUT5A H-bridge output pin ch5 A

17 OUT1B H-bridge output pin ch1 B 43 OUT5B H-bridge output pin ch5 B

18 OUT2A H-bridge output pin ch2 A 44 PGND2 Motor ground pin ch5 and ch6

19 OUT2B H-bridge output pin ch2 B 45 OUT6A H-bridge output pin ch6 A

20 PGND1 Motor ground pin ch1 to ch4 46 OUT6B H-bridge output pin ch6 B

21 OUT3B H-bridge output pin ch3 B 47 OUT7A H-bridge output pin ch7 A

22 OUT3A H-bridge output pin ch3 A 48 RNF Resistance connection pin for output current detection ch7

23 OUT4B H-bridge output pin ch4 B 49 OUT7B H-bridge output pin ch7 B

24 OUT4A H-bridge output pin ch4 A 50 SENSE Output current detection pin ch7

25 IN1A Control input pin ch1 A 51 SO2 Digital transistor output pin 2

26 IN1B Control input pin ch1 B 52 SO1 Digital transistor output pin 1

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

5/15

2009.06 - Rev.A

Page 6

BD6757KN, BD6889GU

Technical Note

1 2 3 4 5 6 7 8

A N.C. OUT6A OUT6B VM3 PGND3 OUT5B OUT5A N.C.

B DSW IN6A IN6B SO4P SO4N REG OUT4A

C OUT7A SW DSEL2 IN7A SI4 IN5A PS OUT4B

D VM4 VCC VREF IN7B IN5B SI3 SO3P VM2

E RNF DSEL1 IN1A IN1B IN4B IN4A SO3N PGND2

F SENSE VLIM IN2A SI1 SI2 IN3A IN3B OUT3B

G OUT7B GND IN2B SO1P SO1N SO2P SO2N OUT3A

H N.C. OUT1A OUT1B PGND1 VM1 OUT2B OUT2A N.C.

Fig.11 BD6889GU Pin Arrangement (Top View)

VBGA063T050 Package

BD6889GU Pin Function Table

No. Pin Name Function No. Pin Name Function

A1 N.C. - E1 RNF Resistance connection pin for output current detection ch7

A2 OUT6A H-bridge output pin ch6 A E2 DSEL1 Selection pin for transistor output 1

A3 OUT6B H-bridge output pin ch6 B E3 IN1A Control input pin ch1 A

A4 VM3 Motor power supply pin ch5 and ch6 E4 IN1B Control input pin ch1 B

A5 PGND3 Motor ground pin ch5 and ch6 E5 IN4B Control input pin ch4 B

A6 OUT5B H-bridge output pin ch5 B E6 IN4A Control input pin ch4 A

A7 OUT5A H-bridge output pin ch5 A E7 SO3N NPN transistor output pin 3

A8 N.C. - E8 PGND2 Motor ground pin ch3 and ch4

B1 F1 SENSE Output current detection pin ch7

B2 DSW Enable input pin for transistor F2 VLIM

Output current setting ch7

B3 IN6A Control input pin ch6 A F3 IN2A Control input pin ch2 A

B4 IN6B Control input pin ch6 B F4 SI1 Digital transistor input pin 1

B5 SO4P PNP transistor output pin 4 F5 SI2 Digital transistor input pin 2

B6 SO4N NPN transistor output pin 4 F6 IN3A Control input pin ch3 A

B7 REG Regulator output pin for PI F7 IN3B Control input pin ch3 B

B8 OUT4A H-bridge output pin ch4 A F8 OUT3B H-bridge output pin ch3 B

C1 OUT7A H-bridge output pin ch7 A G1 OUT7B H-bridge output pin ch7 B

C2 SW Regulator input pin for PI G2 GND Ground pin

C3 DSEL2 Selection pin for transistor output 2 G3 IN2B Control input pin ch2 B

C4 IN7A Control input pin ch7 A G4 SO1P PNP transistor output pin 1

C5 SI4 Digital transistor input pin 4 G5 SO1N NPN transistor output pin 1

C6 IN5A Control input pin ch5 A G6 SO2P PNP transistor output pin 2

C7 PS Power-saving pin G7 SO2N NPN transistor output pin 2

C8 OUT4B H-bridge output pin ch4 B G8 OUT3A H-bridge output pin ch3 A

D1 VM4 Motor power supply pin ch7 H1 N.C. D2 VCC Power supply pin H2 OUT1A H-bridge output pin ch1 A

D3 VREF Reference voltage output pin H3 OUT1B H-bridge output pin ch1 B

D4 IN7B Control input pin ch7 B H4 PGND1 Motor ground pin ch1 and ch2

D5 IN5B Control input pin ch5 B H5 VM1 Motor power supply pin ch1 and ch2

D6 SI3 Digital transistor input pin 3 H6 OUT2B H-bridge output pin ch2 B

D7 SO3P PNP transistor output pin 3 H7 OUT2A H-bridge output pin ch2 A

D8 VM2 Motor power supply pin ch3 and ch4 H8 N.C. -

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

6/15

2009.06 - Rev.A

Page 7

BD6757KN, BD6889GU

●Application Circuit Diagram

Motor control input

(p.9/16)

Motor control input

(p.9/16)

Motor control input

(p.9/16)

Motor control input

(p.9/16)

When using the VREF voltage (0.9V) resistance divi sion

value as VLIMH and VLIML input value, select R

values such that,

1kΩ≦R

1+R2+R3

Bypass filter Capacitor for

power supply input. (p.14/16)

Power-saving (p.9/16)

H : Active

L : Standby

≦20kΩ (p.9/16)

IN1A

IN1B

IN2A

IN2B

IN3A

IN3B

IN4A

IN4B

IN5A

IN5B

IN6A

IN6B

IN7A

IN7B

1

1~100uF

PS

11

25

26

27

28

29

37

38

39

15

14

13

12

3

1

, R2, and R3

VCC

9

OSC

Power Save

Logic12

Logic12

Logic34

Logic56

Logic7

0.1μF 0.1μF

CP1 31CP2

32

Charge Pump Charge Pump

TSD & UVLO

VG

Level Shift

&

Pre Driver

VG

Level Shift

&

Pre Driver

VG

VG

Level Shift

&

Pre Driver

VG

Level Shift

&

Pre Driver

0.1μF

CP3 33CP4 34VG

Const. Current

SelectorVREF

4

5 6 78

VREF LIMSW VLIMH VLIML

R1

Output current selection

(p.9/16)

H : VLIML

L : VLIMH

R2 R3

40

SI1 52SO1

Fig.12 BD6757KN Application Circuit Diagram

35

BandGap

10

VM1

16

H bridge

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

VCC

41

SI2 51SO2 GND

The sensor signal SI1, for le ns position

detection, is reshaped and output to SO1.

p.10/16

OUT1A

OUT1B

17

18

OUT2A

OUT2B

19

30

VM2

22

OUT3A

OUT3B

21

24

OUT4A

OUT4B

23

PGND1

20

36

VM3

42

OUT5A

OUT5B

43

45

OUT6A

OUT6B

46

PGND2

44

2

VM4

47

OUT7A

OUT7B

49

RNF

48

0.1Ω~5.0Ω

50

SENSE

VCC

The output current is converted to a voltage with

the RNF external resistor and transmitted to the

SENSE pin. (p.9/16)

Iout[A] = (VLIMH or VLIML[V])÷RNF[Ω]

The sensor signal SI2, for le ns position

detection, is reshaped and output to SO2.

p.10/16

1~100uF

M

1~100uF

M

1~100uF

M

1~100uF

Technical Note

Bypass filter Capacitor for

power supply input. (p.14/16)

Bypass filter Capacitor for

power supply input. (p.14/16)

Bypass filter Capacitor for

power supply input. (p.14/16)

Bypass filter Capacitor for

power supply input. (p.14/16)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

7/15

2009.06 - Rev.A

Page 8

BD6757KN, BD6889GU

A7A6A2A

A

A

Power-saving (p.9/16)

H : Active

L : Standby

Motor control input

(p.9/16)

IN1A

IN1B

IN2A

IN2B

Motor control input

(p.9/16)

IN3A

IN3B

IN4A

IN4B

Motor control input

(p.9/16)

Motor control input

(p.9/16)

IN5A

IN5B

IN6A

IN6B

IN7A

IN7B

Selector for Digital

transistor (p.10/16)

DSEL1

DSEL2

DSW

REG Switch (p.10/16)

H : REG output ON

L : REG output OFF

SW

Power supply for photo

interrupter (p.10/16)

REG

The sensor signal SI1, for le ns position

detection, is reshaped and output t o SO1x.

(p.10/16)

PS

C7

E3

E4

F3

G3

F6

F7

E6

E5

C6

D5

B3

B4

C4

D4

E2

C3

B2

C2

B7

VCC VCC

G2

GND

Bypass filter Capacitor for

power supply input. (p.14/16)

1~100uF

Power Save

Logic12

Logic12

Logic34

TSD & UVLO

Level Shift

Pre Driver

Level Shift

Pre Driver

Level Shift

Logic56

Pre Driver

Level Shift

Logic7

DTR Selector

SW SW

F4

SO1N

SI1

REG REG REG

Pre Driver

Digital

transistor SW

VCC

VCC VCC

VCC

G4

G5

SO1P

The sensor signal SI2, for le ns position

detection, is reshaped and output t o SO2x.

(p.10/16)

VCC

D2

BandGap

H bridge

&

&

&

&

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

Full ON

H bridge

Const. Current

VREF

VCC VCC

SWSW

VCC VCC

VCC

SWSW

SO2N

G7

F5

SI2

G6

SO2P

SWSW

D6

SI3

Fig.13 BD6889GU Application Circuit Diagram

1~100uF

H5

VM1

H2

OUT1A

OUT1B

H3

H7

OUT2A

OUT2B

H6

PGND1

H4

1~100uF

D8

VM2

G8

OUT3A

OUT3B

F8

B8

OUT4A

OUT4B

C8

PGND2

E8

1~100uF

4

VM3

OUT5A

OUT5B

OUT6A

OUT6B

3

PGND3

5

1~100uF

D1

VM4

C1

OUT7A

OUT7B

G1

RNF

E1

0.1Ω~5.0Ω

F1

SENSE

VLIM

F2

R2

R

1

D3

VREF

SO4P

B5

VCC

SO4N

B6

REG

C5

SI4

The sensor signal SI4, for le ns position

VCC

D7

E7

SO3N

SO3P

The sensor signal SI3, for le ns position

detection, is reshaped and output t o SO3x.

(p.10/16)

detection, is reshaped and output t o SO4x.

(p.10/16)

Technical Note

Bypass filter Capacitor for

power supply input. (p.14/16)

M

Bypass filter Capacitor for

power supply input. (p.14/16)

M

Bypass filter Capacitor for

power supply input. (p.14/16)

M

Bypass filter Capacitor for

power supply input. (p.14/16)

The output current is converted

to a voltage with the RNF

external resistor and transmitted

to the SENSE pin. (p.9/16)

Iout[A] = VLIM[V]÷RNF[Ω]

When using the VREF voltage (0.9V)

resistance division value as VLIM input

value, select R

and R2 values such that,

1

1kΩ≦R

1+R2

≦20kΩ (p.9/16)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

8/15

2009.06 - Rev.A

Page 9

BD6757KN, BD6889GU

●Function Explanation

1) Power-saving function

When Low-level voltage is applied to PS pin, the IC will be turned off internally and the circuit current will be 0μA (Typ.).

During operating mode, PS pin should be High-level. (See the Electrical Characteristics; p.2/16 and p.3/16)

2) Motor Control input

(1) INxA and INxB pins

These pins are used to program and control the motor drive modes. The Full-ON drivers and the Linear Constant-Current

driver use IN/IN and EN/IN input modes, respectively. (See the Electrical Characteristics; p.2/16 and p.3/16, and I/O Truth

Table; p.10/16)

3) H-bridge

The 7-channel H-bridges can be controlled independently. For this reason, it is possible to drive the H-bridges

simultaneously, as long as the package thermal tolerances are not exceeded.

The H-bridge output transistors of the BD6757KN and BD6889GU consist of Power DMOS, with the charge pump step-up

power supply VG, and Power CMOS, with the motor power supply VM, respectively. The total H-bridge ON-Resistance on

the high and low sides varies with the VG and VM voltages, respectively. The system must be designed so that the

maximum H-bridge current for each channel is 800mA or below. (See the Operating Conditions; p.1/16)

4) Drive system of Linear Constant-Current H-bridge (BD6757KN: ch7 and BD6889GU: ch7)

BD6757KN (ch7) and BD6889GU (ch7) enable Linear Constant-Current Driving.

(1) Reference voltage output (with a tolerance of ±2%)

The VREF pin outputs 0.9V, based on the internal reference voltage. The output current of the Constant-Current Drive

block is controllable by connecting external resistance to the VREF pin of the IC and applying a voltage divided by the

resistor to the output current setting pins. (BD6757KN: VLIMH and VLIML pins, BD6889GU: VLIM pin) It is

recommended to set the external resistance to 1kΩ or above in consideration of the current capacity of the VREF pin,

and 20kΩ or below in order to minimize the fluctuation of the set value caused by the base current of the internal

transistor of the IC.

(2) Output current settings and setting changes (BD6757KN)

When the Low-level control voltage is applied to the LIMSW pin, the value on the VLIMH pin will be used as an output

current set value to control the output current. When the High-level control voltage is applied to the LIMSW pin, the

value on the VLIML pin will be used as an output current set value to control the output current. (See the Electrical

Characteristics; P.2/16)

(3) Output current detection and current settings

By connecting external resistor (0.1Ω to 5.0Ω) to the RNF pin of the IC, the motor drive current will be converted into

voltage in order to be detected. The output current is kept constant by shorting the RNF and SENSE pins and

comparing the voltage with the VLIMH or VLIML voltage (VLIM voltage in the case of the BD6889GU). To perform

output current settings more precisely, trim the external RNF resistance if needed, and supply a precise voltage externally to

the VLIMH or VLIML pin of the IC (VLIM pin in the case of the BD6889GU). In that case, open the VREF pin.

Output current value Iout[A] =

VLIMH[V] or VLIML[V]

RNF[Ω]

VLIM[V]

RNF[Ω]

(BD6889GU)

Select VLIMH when LIMSW is Low-level

Select VLIML when LIMSW is High-level

The output current is 400mA3% if 0.2V is applied to the VLIMH or VLIML pin (VLIM pin in the case of the

BD6889GU) and a 0.5Ω resistor is connected externally to the RNF pin.

If the VLIMH and VLIML pins (VLIM pin in the case of the BD6889GU) are shorted to the VCC pin (or the same voltage

level as the VCC is applied) and the SENSE and RNF pins are shorted to the ground, this channel can be used as a

Full-ON Drive H-bridge like the other six channels.

5) Charge pump (BD6757KN)

Each output H-bridge of the BD6757KN on the high and low sides consists of Nch DMOS. Therefore, the gate voltage VG

should be higher than the VM voltage to drive the Nch DMOS on the high side.

The BD6757KN has a built-in charge pump circuit that generates VG voltage by connecting an external capacitor (0.01μF

to 0.1μF).

If a 0.1μF capacitor is connected between: CP1 and CP2, CP3 and CP4, VG and GND

Then, VG pin output voltage will be: VM1 + (VCC 2)

If a 0.1μF capacitor is connected between: CP1 and CP2, VG and GND

CP4 and VG pins are shorted, and CP3 pin is open

Then, VG pin output voltage will be: VM1 + VCC

The VM1 to VM4 respectively can be set to voltages different to one another. In order to ensure better performance, the

voltage differential between VG and VM must be 4.5V or higher, and the VG voltage must not exceed the absolute

maximum rating of 15V.

Technical Note

(BD6757KN)

・・・・・・(1)

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

9/15

2009.06 - Rev.A

Page 10

BD6757KN, BD6889GU

6) Digital transistor for photo-interrupter waveform shaping (BD6757KN and BD6889GU)

The BD6757KN, and BD6889GU build in two digital NPN transistor circuits, and eight digital NPN and PNP transistor

circuits for photo-interrupter waveform shaping, respectively. The sensor signal, for lens position detection, is reshaped

and output to the DSP. The input (SIx pin) is a dividing resistance type, and provided with NPN output (SOxN pin) pull-up

resistor and PNP output (SOxP pin) pull-down resistor. This is so that VCC, and GND voltage will be NPN output, and

PNP output, respectively, when the input is open. In the case of the BD6889GU, DSW, DSEL1, and DSEL2 pins can

control the switching of NPN and PNP transistor. The inputs are provided with input pull-down resistor. This is so that

GND voltage will be input, when these three pins are open. (See I/O Truth Table; P.12/16)

7) Voltage-regulator for photo-interrupter (BD6889GU)

The BD6889GU builds in voltage-regulator circuits for photo-interrupter. When High-level voltage is applied to SW pin,

the REG pin will be turned on. The input is provided with input pull-down resistor. This is so that REG pin will be turn off,

when the input is open.

●I/O Truth Table

BD6757KN and BD6889GU Full-ON Driver ch1 to ch6 I/O Truth Table

Drive mode

INPUT OUTPUT

INxA INxB OUTxA OUTxB

L L Z Z Standby

IN/IN

H L H L CW

L H L H CCW

H H L L Brake

L: Low, H: High, X: Don't care, Z: High impedance

At CW, current flows from OUTA to OUTB. At CCW, current flows from OUTB to OUTA.

BD6757KN and BD6889GU Linear Constant-Current Driver ch7 I/O Truth Table

Drive mode

INPUT OUTPUT

IN7A IN7B OUT7A OUT7B

L X Z Z Standby

EN/IN

H L H L CW

H H L H CCW

L: Low, H: High, X: Don't care, Z: High impedance

At CW, current flows from OUTA to OUTB. At CCW, current flows from OUTB to OUTA.

BD6889GU Digital Transistor I/O Truth Table

DSW DSEL1 DSEL2 PNP1 NPN1 PNP2 NPN2 PNP3 NPN3 PNP4 NPN4

INPUT OUTPUT

L X X OFF OFF OFF OFF OFF OFF OFF OFF

H L L OFF ON OFF ON OFF ON OFF ON

Logic

H L H OFF ON OFF ON ON OFF ON OFF

H H L ON OFF ON OFF OFF ON OFF ON

H H H ON OFF ON OFF ON OFF ON OFF

L: Low, H: High, X: Don’t care, OFF: GND (in the case of PNP), VCC (in the case of NPN)

PNPx output to SOxP terminal, NPNx output to SOxN terminal

Technical Note

Output mode

Output mode

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

10/15

2009.06 - Rev.A

Page 11

BD6757KN, BD6889GU

In the case of drive the Stepping Motor using ch1 and ch2 IN/IN input mode of the BD6757KN and BD6889GU

2 Phases

INPUT OUTPUT

IN1A IN1B IN2A IN2B OUT1A OUT1B OUT2A OUT2B

Output mode

ch1 / ch2

L L L L Z Z Z Z Stand by

H L H L H L H L 1. CW / CW

L H H L L H H L 3. CCW / CW

L H L H L H L H 5. CCW / CCW

H L L H H L L H 7. CW / CCW

L: Low, H: High, X: Don't care, Z: High impedance

At CW, current flows from OUTA to OUTB. At CCW, current flows from OUTB to OUTA.

1-2 Phases

INPUT OUTPUT

IN1A IN1B IN2A IN2B OUT1A OUT1B OUT2A OUT2B

Output mode

ch1 / ch2

L L L L Z Z Z Z Stand by

H L H L H L H L 1. CW / CW

L L H L Z Z H L 2. Z / CW

L H H L L H H L 3. CCW / CW

L H L L L H Z Z 4. CCW / Z

L H L H L H L H 5. CCW / CCW

L L L H Z Z L H 6. Z / CCW

H L L H H L L H 7. CW / CCW

H L L L H L Z Z 8. CW / Z

L: Low, H: High, X: Don't care, Z: High impedance

At CW, current flows from OUTA to OUTB. At CCW, current flows from OUTB to OUTA.

IN1A

IN1B

IN2A

IN2B

OUT1A

OUT1B

OUT2A

OUT2B

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

1 3 5 7 1 3 5 7 1 2 3 4 5 6 7 8

OUT1A

OUT1B

OUT2A

OUT2B

IN1A

IN1B

IN2A

IN2B

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

Fig.14 2 Phases Timing Sequence with IN/IN Input Fig.15 1-2 Phases Timing Sequence with IN/IN Input

CW

OUT2A

Forward

OUT1B

CCW

3

5 7

1

OUT1A

CW

OUT1B

CCW

Reverse

Fig.16 Torque Vector of 2 Phases Mode

OUT2B

CCW

Reverse

Fig.17 Torque Vector of 1-2 Phases Mode

CW

OUT2A

3

2

4 8

6

5 7

OUT2B

CCW

1

Technical Note

:High impedance

Forward

OUT1A

CW

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

11/15

2009.06 - Rev.A

Page 12

BD6757KN, BD6889GU

Technical Note

●I/O Circuit Diagram

PS, INxA, INxB, LIMSW VMx, OUTxA, OUTxB, PGNDx, RNF VLIMH, VLIML, SENSE

VREF

VCC

VCC

VMx

VCC VCC

VCC

10kΩ

100kΩ

OUTxA

OUTxB

PGNDx

RNF

50kΩ

CP3, CP1 SOx

SIx VG, CP4, CP2

VCC VCC VCC

VCC

VG

CP4

VCC

100kΩ

10kΩ

CP2

100kΩ

Fig.18 BD6757KN I/O Circuit Diagram (Resistance values are typical ones)

VM1

PS, INxA, INxB, SW, DSW, DSEL1,

DSEL2

VCC

VCC

VMx, OUTxA, OUTxB, PGNDx, RNF VLIM, SENSE

VMx

VREF

VCC VCC

VCC

10kΩ

OUTxA

100kΩ

OUTxB

PGNDx

RNF

100kΩ

SIx SOxP SOxN REG

VCC VCC

100kΩ

VCC

VCC VCC

33kΩ

VCC

VCC

100kΩ

100kΩ

33kΩ

100kΩ

Fig.19 BD6889GU I/O Circuit Diagram (Resistance values are typical ones)

10kΩ

1kΩ

VCC

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

12/15

2009.06 - Rev.A

Page 13

BD6757KN, BD6889GU

●Heat Dissipation

1) Power Consumption

The power consumption of the IC (Pw) is expressed by the following formula.

Pw[W] = VCC[V] ICC[A] + Iout2[A2] RON[Ω] (Full-ON Drive block and PWM Constant-Current Drive block) ・・・・・・(2)

= VCC[V] ICC[A] + Iout[A] (VM[V] - VRNF[V] - Iout[A] Rm[Ω]) (Linear Constant-Current Drive block) ・・・・・・(3)

Pw: Power consumption of the IC

VCC: Power supply voltage on the VCC pin

ICC: Current consumption of the VCC pin

Iout: Current consumption of the VM pin on the drive channel

RON: Total ON-Resistance on the high and low drive channel

VM: Power supply voltage on the VM pin on the drive channel

VRNF: Voltage on the RNF pin on the drive channel

Rm: Resistance on the motor on the drive channel

While in operation, check that the junction temperature (Tjmax) of the IC will not be in excess of 150℃, in consideration

of formula (2), formula (3), the package power (Pd), and ambient temperature (Ta). If the junction temperature exceeds

150℃, the IC will not work as a properly. This can cause problems, such as parasitic oscillation and temperature leakage.

If the IC is used under such conditions, it will result in characteristic degradation and eventually fail. Be sure to keep the

junction temperature lower than 150℃.

2) Measurement Method of Junction Temperature

The junction temperature can be measured by the following method.

VIN

VIN

V

V

GND

GND

50μA

Fig.20 Tjmax Measurement Circuit Diagram

If the exact junction temperature is desired, it is necessary to measure the specific temperature characteristic of the

internal diode, of each IC.

●Notes for use

1) Absolute maximum ratings

Use of the IC in excess of absolute maximum ratings such as the applied voltage or operating temperature range may

result in IC damage. Assumptions should not be made regarding the state of the IC (short mode or open mode) when

such damage is suffered. The implementation of a physical safety measure such as a fuse should be considered when

use of the IC in a special mode where the absolute maximum ratings may be exceeded is anticipated.

2) Storage temperature range

As long as the IC is kept within this range, there should be no problems in the IC’s performance. Conversely, extreme

temperature changes may result in poor IC performance, even if the changes are within the above range.

3) Power supply pins and lines

None of the VM line for the H-bridges is internally connected to the VCC power supply line, which is only for the control

logic or analog circuit. Therefore, the VM and VCC lines can be driven at different voltages. Although these lines can be

connected to a common power supply, do not open the power supply pin but connect it to the power supply externally.

Regenerated current may flow as a result of the motor's back electromotive force. Insert capacitors between the power

supply and ground pins to serve as a route for regenerated current. Determine the capacitance in full consideration of all

the characteristics of the electrolytic capacitor, because the electrolytic capacitor may loose some capacitance at low

temperatures. If the connected power supply does not have sufficient current absorption capacity, regenerative current

will cause the voltage on the power supply line to rise, which combined with the product and its peripheral circuitry may

exceed the absolute maximum ratings. It is recommended to implement a physical safety measure such as the insertion

of a voltage clamp diode between the power supply and ground pins.

For this IC with several power supplies and a part consists of the CMOS block, it is possible that rush current may flow

instantaneously due to the internal powering sequence and delays, and to the unstable internal logic, respectively. Therefore,

give special consideration to power coupling capacitance, width of power and ground wirings, and routing of wiring.

Technical Note

By using the diode temperature characteristics of the control input pin, on a

channel that is not driven, the junction temperature X can be measured in a

pseudo manner.

The junction temperature X[℃] under certain conditions is expressed by formula

(4), provided that the temperature characteristic of the diode is -2 mV/℃

X[°C] = + 25[°C] ・・・・・・(4)

X: Junction temperature

a: The voltmeter V value at a junction temperature of 25℃

b: The voltmeter V value at a junction temperature of X℃

-2: Temperature characteristic of diode

a - b[mV]

-2 [mV/°C]

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

13/15

2009.06 - Rev.A

Page 14

BD6757KN, BD6889GU

4) Ground pins and lines

Ensure a minimum GND pin potential in all operating conditions. Make sure that no pins are at a voltage below the GND

at any time, regardless of whether it is a transient signal or not.

When using both small signal GND and large current MGND patterns, it is recommended to isolate the two ground

patterns, placing a single ground point at the application's reference point so that the pattern wiring resistance and

voltage variations caused by large currents do not cause variations in the small signal ground voltage. Be careful not to

change the GND wiring pattern of any external components, either.

The power supply and ground lines must be as short and thick as possible to reduce line impedance.

5) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating conditions.

6) Pin short and wrong direction assembly of the device

Use caution when positioning the IC for mounting on printed circuit boards. The IC may be damaged if there is any

connection error or if positive and ground power supply terminals are reversed. The IC may also be damaged if pins are

shorted together or are shorted to other circuit’s power lines.

7) Actions in strong magnetic field

Use caution when using the IC in the presence of a strong magnetic field as doing so may cause the IC to malfunction.

8) ASO

When using the IC, set the output transistor for the motor so that it does not exceed absolute maximum ratings or ASO.

9) Thermal shutdown circuit

If the junction temperature (Tjmax) reaches 175°C, the TSD circuit will operate, and the coil output circuit of the motor will

open. There is a temperature hysteresis of approximately 20°C (BD6757KN Typ.) and 25°C (BD6889GU Typ.). The TSD

circuit is designed only to shut off the IC in order to prevent runaway thermal operation. It is not designed to protect the IC

or guarantee its operation. The performance of the IC’s characteristics is not guaranteed and it is recommended that the

device is replaced after the TSD is activated.

10) Testing on application board

When testing the IC on an application board, connecting a capacitor to a pin with low impedance subjects the IC to stress.

Always discharge capacitors after each process or step. Always turn the IC's power supply off before connecting it to, or

removing it from a jig or fixture, during the inspection process. Ground the IC during assembly steps as an antistatic

measure. Use similar precaution when transporting and storing the IC.

11) Application example

The application circuit is recommended for use. Make sure to confirm the adequacy of the characteristics. When using

the circuit with changes to the external circuit constants, make sure to leave an adequate margin for external components

including static and transitional characteristics as well as dispersion of the IC.

12) Regarding input pin of the IC

This monolithic IC contains P

+

isolation and P substrate layers between adjacent elements to keep them isolated. P-N

junctions are formed at the intersection of these P layers with the N layers of other elements, creating a parasitic diode or

transistor. For example, the relation between each potential is as follows:

When GND > Pin A, the P-N junction operates as a parasitic diode.

When GND > Pin B, the P-N junction operates as a parasitic diode and transistor.

Parasitic elements can occur inevitably in the structure of the IC. The operation of parasitic elements can result in mutual

interference among circuits, operational faults, or physical damage. Accordingly, methods by which parasitic elements

operate, such as applying a voltage that is lower than the GND (P substrate) voltage to an input pin, should not be used.

Pin A

N

+

P

P

P

Parasitic element

GND

Resistor Transistor (NPN)

Pin A

+

N N

P substrate

Fig.21 Example of Simple IC Architecture

Parasitic

element

Pin B

N

Parasitic element

C

+

P

Technical Note

B

E

N

P

P substrate

GND

+

P

N

GND

Pin B

B C

Other adjacent

elements

E

GND

Parasitic

element

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

14/15

2009.06 - Rev.A

Page 15

BD6757KN, BD6889GU

●Ordering part number

B D 6 7 5 7 K N - E 2

Technical Note

Part No. Part No.

6757 : Wide power supply

voltage range

6889 : Subminiature package

UQFN52

7.2± 0.1

0.6

(1.2)

(0.55)

7.0± 0.1

+0.1

-

0.22± 0.05

0.3

7.2± 0.1

7.0± 0.1

27

39

1

0.2± 0.05

26

14

13

0.05

0.02

-

+0.03

0.02

0.05

3-(0.45)

40

52

0.4

(0.2)

VBGA063T050

1PIN MARK

63-φ0.3±0.05

M

φ

0.05

0.08 S

ABS

H

G

F

E

D

C

B

A

5.0±0.1

P=0.5×7

0.5

51

3

4

A

762

5.0± 0.1

0.75±0.1

B

8

M

0.95MAX

Notice :

Do not use the dotted line area

for soldering

(Unit : mm)

0.23

S

1.2MAX

0.5

P=0.5×7

0.75±0.1

(Unit : mm)

Package

KN : UQFN52

GU : VBGA063T050

<Tape and Reel information>

Embossed carrier tape (with dry pack)Tape

Quantity

Direction

of feed

<Tape and Reel information>

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Embossed carrier tape (with dry pack)Tape

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Packaging and forming specification

E2: Embossed tape and reel

Direction of feed

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

Order quantity needs to be multiple of the minimum quantity.

∗

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

15/15

2009.06 - Rev.A

Page 16

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machiner y, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...