t

Datashee

DC Brushless Fan Motor Drivers

Multifunction Single-phase Full-wave

Fan Motor Driver

BD6721FS

●General description

BD6721FS is a 1chip driver that composes H-bridge of

power DMOS FET.

Moreover, because the level amplifier is installed, the

temperature control by the thermistor is also easy.

●Features

Driver including power DMOS FET

Speed controllable by DC / direct PWM input

PWM soft switching

Quick start

Current limit

Lock protection and automatic restart

Rotation speed pulse signal (FG) output

Lock alarm signal (AL) output

●Application

Fan motors for general consumer equipment of desktop PC, and Projector, etc.

●Absolute maximum ratings

Parameter Symbol Limit Unit

Supply voltage Vcc 20 V

Power dissipation Pd 812.5

Operating temperature range Topr –40 to +100 °C

Storage temperature range Tstg –55 to +150 °C

Output voltage Vo 20 V

Output current Io 1.0

Rotation speed pulse signal (FG) output voltage Vfg 20 V

Rotation speed pulse signal (FG) output current Ifg 10 mA

Lock alarm signal (AL) output voltage Val 20 V

Lock alarm signal (AL) output current Ial 10 mA

Reference voltage (REF) output current Iref 8 mA

Junction temperature Tj 150 °C

*1 Reduce by 6.5mW/°C over Ta=25°C. (On 70.0mm×70.0mm×1.6mm glass epoxy board)

*2 This value is not to exceed Pd.

●Recommended operating conditions

Parameter Symbol Limit Unit

Operating supply voltage range Vcc 4.5 to 17.0 V

Operating input voltage range

(H+, H–, TH, MIN, LAIN) (more than Vcc=9V)

Operating input voltage range

(H+, H–, TH, MIN, LAIN) (less than Vcc=9V)

●Package W (Typ.) x D (Typ.) x H (Max.)

SSOP-A16 6.60mm x 6.20mm x 1.71mm

*1

mW

*2

A

0 to 7 V

Vin

0 to Vcc–2 V

SSOP-A16

○Product structure:Silicon monolithic integrated circuit ○This product is not designed protection against radioactive rays

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・14・001

1/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

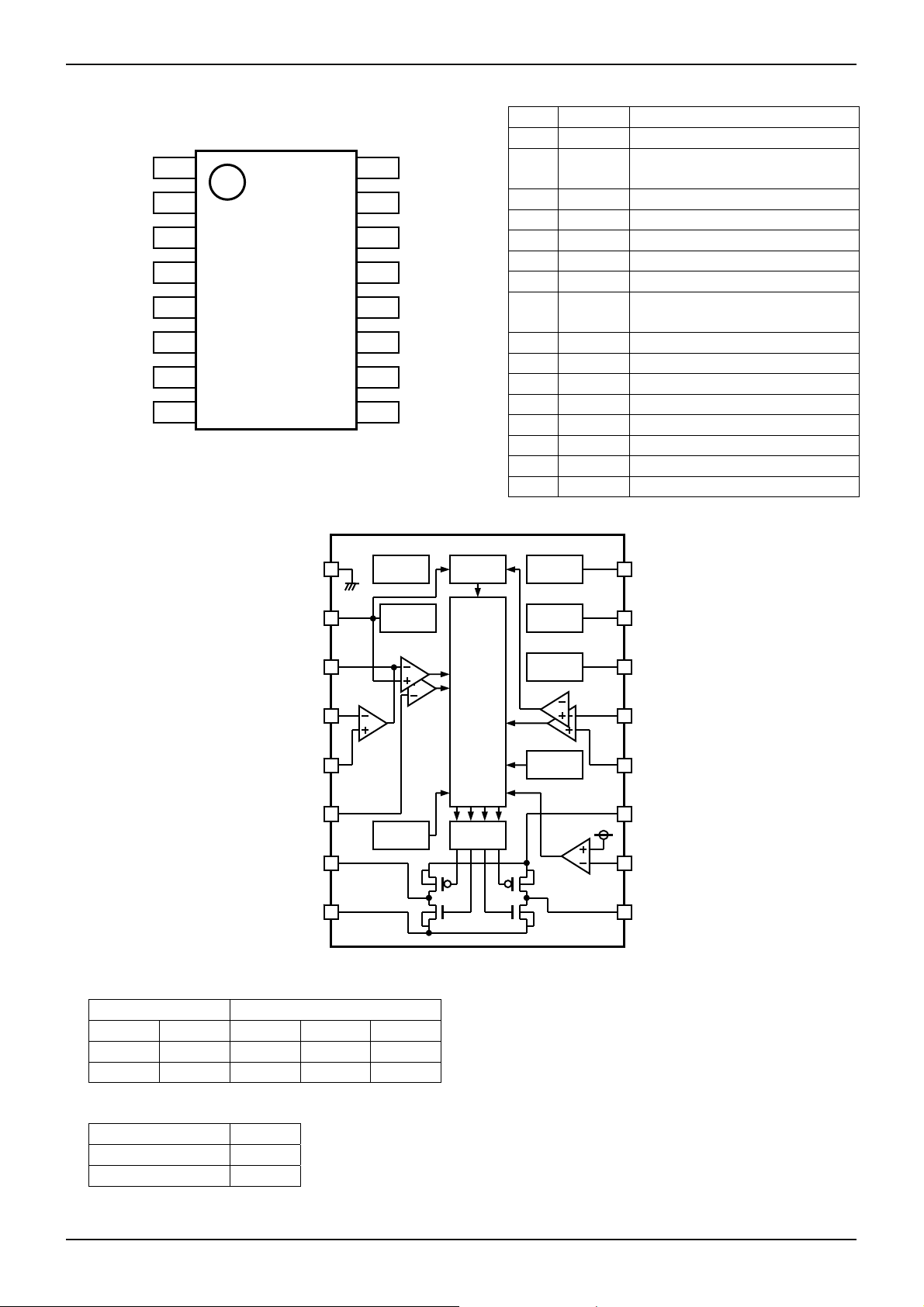

●Pin configuration

GND

OSC

1

2

LAOUT

LAIN

MIN

OUT1

RNF

TH

3

4

5

6

7

8

Fig.1 Pin configuration

●Block diagram

●I/O truth table

Hall input Driver output

H+ H– OUT1 OUT2 FG

H L L H Hi-Z

L H H L L

H; High, L; Low, Hi-Z; High impedance

FG output is open-drain type.

Motor state AL

Rotating L

Locking Hi-Z

L; Low, Hi-Z; High impedance

AL output is open-drain type.

(TOP VIEW)

Datasheet

●Pin description

P/No. T/Name Function

1 GND Ground terminal (signal ground)

16

15

AL

FG

2 OSC

3 LAOUT Level amplifier output terminal

Oscillating capacitor connecting

terminal

4 LAIN Level amplifier input terminal

REF

14

5 TH Output duty controllable input terminal

6 MIN Minimum output duty setting terminal

13

12

11

H–

H+

Vcc

7 OUT1 Motor output terminal 1

8 RNF

Output current detecting resistor

connecting terminal (motor ground)

9 OUT2 Motor output terminal 2

10 CS Output current detection terminal

CS

10

9

OUT2

11 Vcc Power supply terminal

12 H+ Hall + input terminal

13 H– Hall – input terminal

14 REF Reference voltage output terminal

15 FG Speed pulse signal output terminal

16 AL Lock alarm signal output terminal

Vcl

OUT2

AL

FG

REF

H–

H+

Vcc

CS

16

15

14

13

12

11

10

9

GND

1

OSC

2

LA

OUT

3

TSD

OSC

LA

IN

4

LEVEL

AMP

5

TH

MIN

6

QUICK

START

OUT1

7

RNF

8

PWM

COMP

PWM

COMP

PWM SOFT

SWITCHING

CONTROL

LOGIC

PRE-

DRIVER

SIGNAL

OUTPUT

SIGNAL

OUTPUT

REF

HALL

AMP

HALL

COMP

LOCK

PROTECT

CURRENT

LIMIT COMP

Fig.2 Block diagram

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

2/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

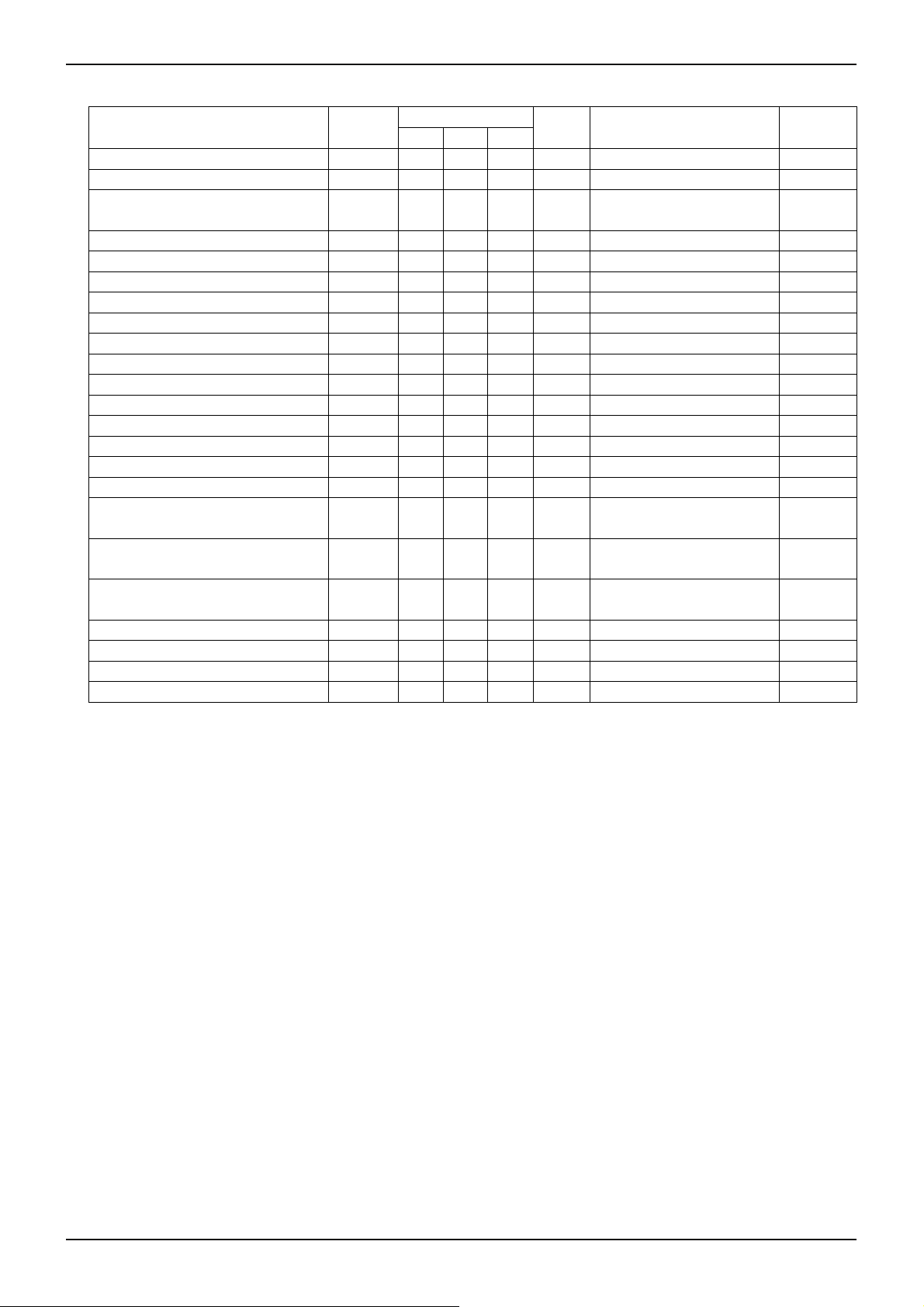

●Electrical characteristics(Unless otherwise specified Ta=25°C, Vcc=12V)

Parameter Symbol

Circuit current Icc 4 7 10 mA Fig.3

Hall input hysteresis voltage Vhys ±5 ±10 ±15 mV Fig.4

Output voltage Vo - 0.6 0.9 V

Lock detection ON time Ton 0.3 0.5 0.7 s Fig.9

Lock detection OFF time Toff 3.0 5.0 7.0 s Fig.10

FG output low voltage Vfgl - 0.15 0.30 V Ifg=5mA Fig.11, 12

FG output leak current Ifgl - - 10 µA Vfg=17V Fig.13

AL output low voltage Vall - 0.15 0.30 V Ial=5mA Fig.11, 12

AL output leak current Iall - - 10 µA Val=17V Fig.13

OSC high voltage Vosch 2.3 2.5 2.7 V Fig.14

OSC low voltage Voscl 0.8 1.0 1.2 V Fig.14

OSC charge current Icosc –50 –32 –26 µA Fig.15

OSC discharge current Idosc 26 32 50 µA Fig.15

Level amplifier gain Gla 50 - - dB Fig.16, 17

Level amplifier output high voltage Vlaoh - 1.6 2.0 V For Vcc voltage Fig.18

Level amplifier output low voltage Vlaol - 0.2 0.3 V Fig.19

Output ON duty 1 Poh1 85 90 95 %

Output ON duty 2 Poh2 45 50 55 %

Output ON duty 3 Poh3 5 10 15 %

Reference voltage Vref 2.8 3.0 3.2 V Iref=–2mA Fig.20, 21

Current limit setting voltage Vcl 290 310 330 mV Fig.22

TH input bias current Ith - - –0.2 µA Vth=0V Fig.23

MIN input bias current Imin - - –0.2 µA Vmin=0V Fig.24

About a current item, define the inflow current to IC as a positive notation, and the outflow current from IC as a negative notation.

Limit

Min. Typ. Max.

Unit Conditions

Io=±300mA,

High and low side total

Vth=Vref x 0.383

Output 1kΩ, OSC=470pF

Vth=Vref x 0.583

Output 1kΩ, OSC=470pF

Vth=Vref x 0.783

Output 1kΩ, OSC=470pF

Datasheet

Ref.

data

Fig.5 to 8

-

-

-

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

3/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

–

–

–

–

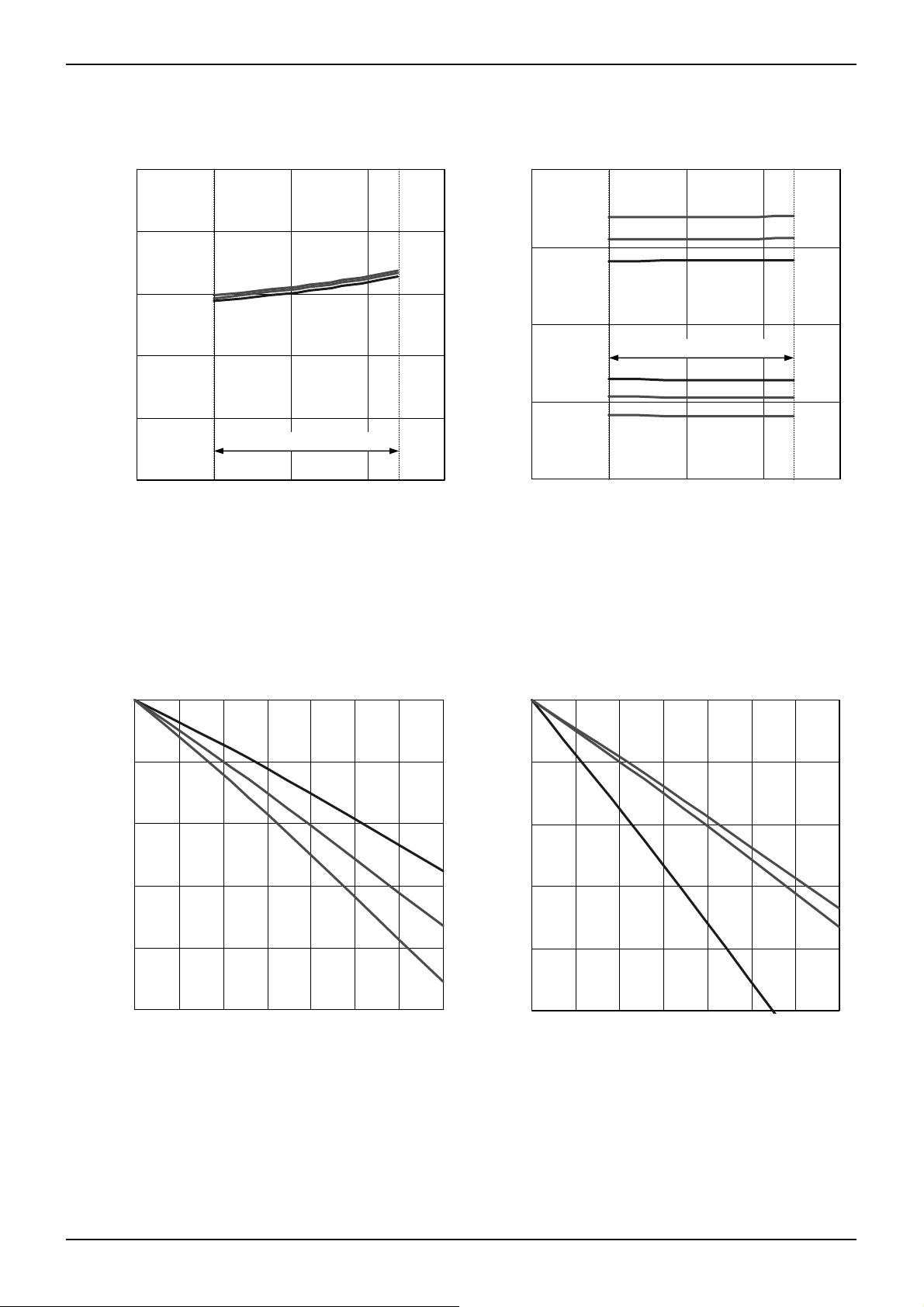

●Typical performance curves(Reference data)

10

8

6

4

Circuit current: Icc[mA]

2

Operating range

0

0 5 10 15 20

Supply voltage: Vcc[V]

Fig.3 Circuit current

0.0

-0.2

-0.4

-0.6

Output high voltage: Voh[V]

-0.8

-1.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Output source current: Io[A]

Fig.5 Output high voltage (Vcc=12V)

25°C

100°C

40°C

40°C

25°C

100°C

20

10

0

Operating range

-10

Hall input hysteresis voltage: Vhys[mV]

-20

0 5 10 15 20

Supply voltage: Vcc[V]

Fig.4 Hall input hysteresis voltage

0.0

-0.2

-0.4

-0.6

Output high voltage: Voh[V]

-0.8

-1.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Output source current: Io[A]

Fig.6 Output high voltage (Ta=25°C)

Datasheet

100°C

25°C

40°C

40°C

25°C

100°C

17V

12V

5V

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

4/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

–

–

–

●Typical performance curves(Reference data)

1.0

0.8

0.6

0.4

Output low voltage: Vol[V]

0.2

0.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Output sink current: Io[A]

Fig.7 Output low voltage (Vcc=12V)

0.7

0.6

0.5

0.4

Lock detection ON time: Ton[s]

Operating range

0.3

0 5 10 15 20

Supply voltage: Vcc[V]

Fig.9 Lock detection ON time

100°C

25°C

40°C

100°C

40°C

25°C

1.0

0.8

0.6

0.4

Output low voltage: Vol[V]

0.2

0.0

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Output sink current: Io[A]

Fig.8 Output low voltage (Ta=25°C)

7.0

6.0

5.0

4.0

Lock detection OFF time: Toff[s]

Operating range

3.0

0 5 10 15 20

Supply voltage: Vcc[V]

Fig.10 Lock detection OFF time

Datasheet

5V

12V

17V

100°C

40°C

25°C

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

5/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

–

–

–

–

●Typical performance curves(Reference data)

0.8

0.6

0.4

0.2

FG/AL output low voltage: Vfgl /Vall[V]

0.0

0246810

Output sink current: Ifg/Ial[mA]

Fig.11 FG/AL output low voltage (Vcc=12V)

8

6

4

2

0

FG/AL output leak current: Ifgl/Iall[uA]

-2

0 5 10 15 20

Fig.13 FG/AL output leak current

Operating range

Supply voltage: Vcc[V]

100°C

25°C

40°C

100°C

25°C

40°C

Datasheet

0.8

0.6

0.4

0.2

FG/AL output low voltage: Vfgl /Vall[V]

0.0

0246810

Output sink current: Ifg/Ial[mA]

Fig.12 FG/AL output low voltage (Ta=25°C)

3.0

100°C

2.5

2.0

Operating range

1.5

100°C

1.0

OSC high/low voltage: Vosch/Voscl [V]

0.5

0 5 10 15 20

Supply voltage: Vcc[V]

Fig.14 OSC high/low voltage

5V

12V

17V

25°C

40°C

25°C

40°C

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

6/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

–

–

–

–

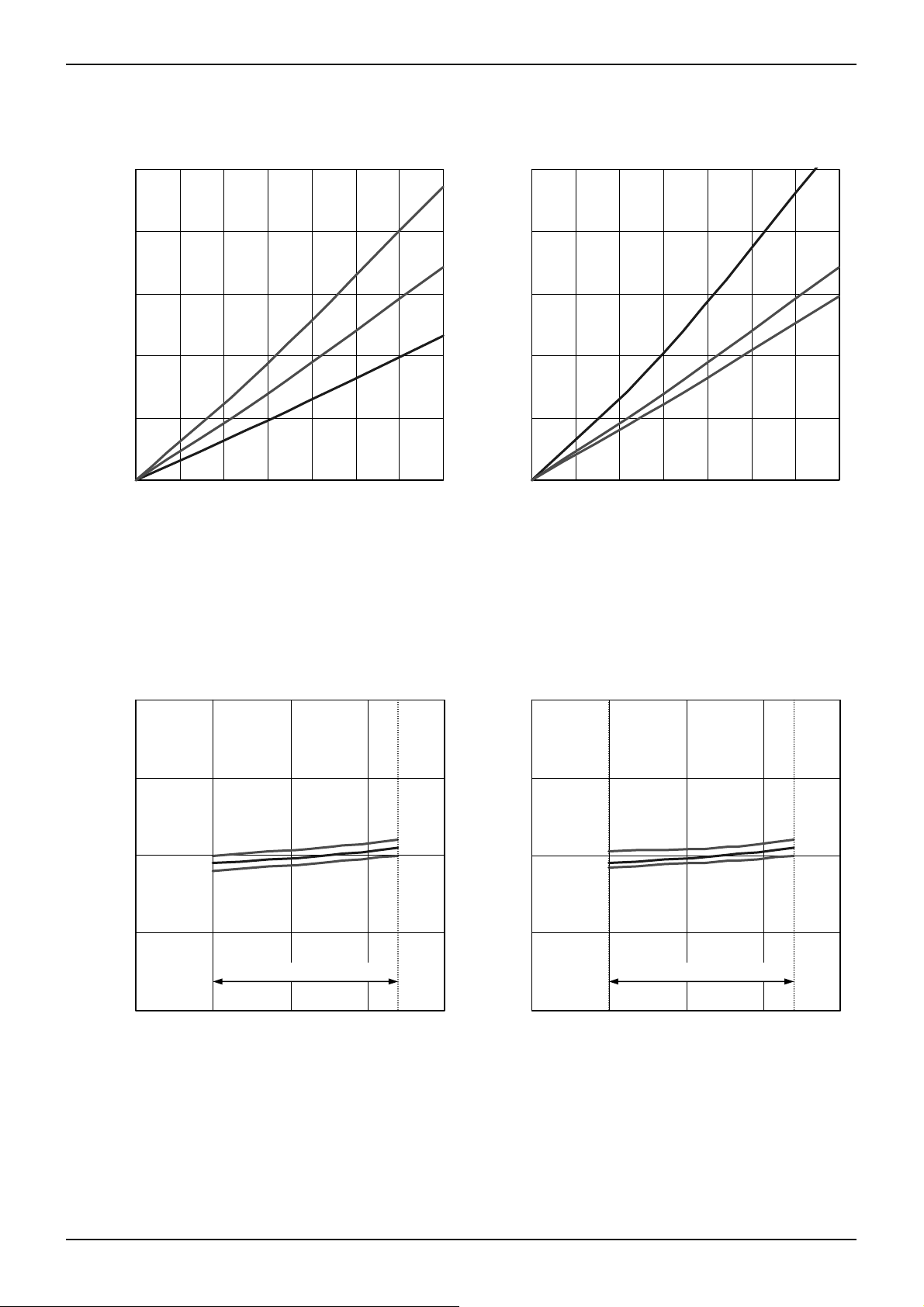

●Typical performance curves(Reference data)

60

40

20

0

-20

-40

OSC charge/discharge current: Icosc/Idosc [uA]

-60

0 5 10 15 20

Fig.15 OSC charge/discharge current

70

17V

12V

5V

60

50

40

Level amplifier gain: Gla[dB]

30

1.E+01 1.E+02 1.E+03 1.E+04

Fig.17 Level amplifier gain (Ta=25°C)

Operating range

Supply voltage: Vcc[V]

Input frequency: Flain[Hz]

40°C

25°C

100°C

100°C

25°C

40°C

Datasheet

70

60

50

40

Level amplifier gain: Gla[dB]

30

1.E+01 1.E+02 1.E+03 1.E+04

Input frequency: Flain[Hz]

Fig.16 Level amplifier gain (Vcc=12V)

2.0

1.8

1.6

1.4

1.2

Level amplifier output high voltage: Vlaoh[V]

1.0

0 5 10 15 20

Fig.18 Level amplifier output high voltage

Operating range

Supply voltage: Vcc[V]

40°C

25°C

100°C

40°C

25°C

100°C

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

7/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

–

–

–

–

●Typical performance curves(Reference data)

0.20

0.15

0.10

0.05

Level amplifi er output low voltage: Vlaol[V]

0.00

0 5 10 15 20

Fig.19 Level amplifier output low voltage

3.2

3.1

3.0

Reference voltage: Vref[V]

2.9

2.8

02468

Output source current: Iref[mA]

Fig.21 Reference voltage current ability (Vcc=12V)

Operating range

Supply voltage: Vcc[V]

100°C

25°C

40°C

100°C

25°C

40°C

3.2

3.1

3.0

Reference voltage: Vref[V]

2.9

Operating range

2.8

0 5 10 15 20

Supply voltage: Vcc[V]

Fig.20 Reference voltage

340

325

310

295

Current limit setting voltage: Vcl[mV]

280

0 5 10 15 20

Fig.22 Current limit setting voltage

Operating range

Supply voltage: Vcc[V]

Datasheet

100°C

25°C

40°C

100°C

25°C

40°C

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

8/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

–

–

●Typical performance curves(Reference data)

0.05

0.00

-0.05

-0.10

TH bias current: Ith[uA]

-0.15

-0.20

0 5 10 15 20

Operating range

Supply voltage: Vcc[V]

Fig.23 TH bias current

100°C

25°C

40°C

0.05

0.00

-0.05

-0.10

MIN bias current: Imin[uA]

-0.15

Operating range

-0.20

0 5 10 15 20

Supply voltage: Vcc[V]

Fig.24 MIN bias current

Datasheet

100°C

25°C

40°C

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

9/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

●Application circuit example(Constant values are for reference)

Output PWM frequency setting Hall bias is set according to the

Circuit that converts PWM duty

into DC voltage

to 1000pF

PWM

Minimum output duty setting

Maximum output voltage and

current are 20V and 1.0A.

To limit motor current, the

current is detected.

Note the power consumption of

detection resistance.

0.33Ω to

-

Gain setting according to

thermistor characteristic

Fig.25 PWM controllable 4 wires type (FG) motor application circuit

to 1000pF

Temperature control setting by

thermistor and linearized

resistance

330pF

330pF

1

2

3

4

5

6

7

8

1

2

3

4

5

GND

OSC

LA

OUT

LA

IN

TH

MIN

OUT1

RNF

GND

OSC

LA

OUT

LA

IN

TH

LEVEL

AMP

LEVEL

AMP

TSD

OSC

QUICK

START

PWM

COMP

PWM

COMP

PWM SOFT

SWITCHING

CONTROL

LOGIC

PRE-

DRIVER

SIGNAL

OUTPUT

SIGNAL

OUTPUT

HALL

AMP

HALL

COMP

PROTECT

M

So bypass capacitor, arrangement near

to Vcc terminal as much as possible

TSD

OSC

PWM

COMP

PWM

COMP

PWM SOFT

SWITCHING

CONTROL

LOGIC

SIGNAL

OUTPUT

SIGNAL

OUTPUT

HALL

AMP

HALL

COMP

PROTECT

REF

LOCK

REF

LOCK

Vcl

CURRENT

LIMIT COMP

OUT2

AL

FG

REF

H–

H+

Vcc

CS

AL

FG

REF

H–

H+

16

15

14

13

12

11

10

9

16

15

14

13

12

0.1µF to

1µF to

0.1µF to

Protection of FG open-drain

0Ω to

H

SIG

Stabilization of REF voltage

amplitude of hall element

output and hall input voltage

range.

Noise measures of su bstrate

Reverse-connected prevention

of the FAN connector

+

100pF

to 0.1µF

200Ω

to 20kΩ

Low-pass filter for RNF voltage

smoothing

Measure against back EMF

0Ω to

Protection of AL open-drain

SIG

H

6

7

8

MIN

OUT1

RNF

QUICK

START

PRE-

DRIVER

Vcl

CURRENT

LIMIT COMP

OUT2

Vcc

CS

11

10

9

1µF to

100pF

to 0.1µF

+

200Ω

to 20kΩ

0.33Ω to

M

-

Fig.26 Thermistor controllable 3 wires type (AL) motor application circuit

Substrate design note

a) IC power, motor outputs, and motor ground lines are made as fat as possible.

b) IC ground (signal ground) line is common with the application ground except motor ground (i.e. hall ground etc.),

and arranged near to (–) land.

c) The bypass capacitor and/or Zenner diode are arrangement near to Vcc terminal.

d) H+ and H– lines are arranged side by side and made from the hall element to IC as shorter as possible,

because it is easy for the noise to influence the hall lines.

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

10/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

0750

0

0

5

k

Datasheet

●Power dissipation

Power dissipation (total loss) indicates the power that can be consumed by IC at Ta=25°C (normal temperature). IC is

heated when it consumes power, and the temperature of IC chip becomes higher than ambient temperature. The

temperature that can be accepted by IC chip depends on circuit configuration, manufacturing process, etc, and consumable

power is limited. Power dissipation is determined by the temperature allowed in IC chip (maximum junction temperature)

and thermal resistance of package (heat dissipation capability). The maximum junction temperature is in general equal to

the maximum value in the storage temperature range.

Heat generated by consumed power of IC is radiated from the mold resin or lead frame of package. The parameter which

indicates this heat dissipation capability (hardness of heat release) is called heat resistance, represented b y the symbol

θja[°C/W]. This heat resistance can estimate the temperature of IC inside the package. Fig.27 shows the model of heat

resistance of the package. Heat resistance θja, ambient temperature Ta, junction temperature Tj, and power consumption P

can be calculated by the equation below:

θja = (Tj – Ta) / P [°C/W]

Thermal de-rating curve indicates power that can be consumed by IC with reference to ambient temperature. Power that

can be consumed by IC begins to attenuate at certain ambient temperature. This gradient is determined by thermal

resistance θja. Thermal resistance θja depends on chip size, power consumption, package ambient temperature, packaging

condition, wind velocity, etc., even when the same package is used. Thermal de-rating curve indicates a reference value

measured at a specified condition. Fig.28 shows a thermal de-rating curve (Value when mounting FR4 glass epoxy board

70[mm] x 70[mm] x 1.6[mm] (copper foil area below 3[%])). Thermal resistance θjc from IC chip joint part to the package

surface part of mounting the above-mentioned same substrate is shown in the following as a reference value.

θjc = 43 [°C/W] (reference value)

Pd[mW]

*Reduce by 6.5mW/°C over 25°C

Packa ge surface temperature Tc[°C]

Chip surface temperature Tj[°C]

(On 70.0mm x 70.0mm x 1.6mm glass epoxy board)

θja = (Tj – Ta) / P [°C/W]

812.

θjc = (Tj – Tc) / P [°C/W]

Ambien t t em perature Ta[°C]

50

θja=153.8 [°C/W]

25

25 50 75 100 125 150

Power consumption P[W]

Fig.27 Thermal resistance Fig.28 Thermal de-rating curve

Ta[°C]

●I/O equivalence circuit(Resistance values are typical)

1) Power supply terminal, 2) Hall input terminals, 3) Minimum output duty setting 4) Motor output terminals,

and Ground terminal Output duty controllable input terminal and Output current

terminal, detecting resistor

Output current detection connecting terminal

terminal, and

Level amplifier input terminal

Vcc

Vcc

GND

LAIN

H+

H–

TH

CS

Vcc

1kΩ

MIN

1

30Ω

Ω

5) Reference voltage output 6) Speed pulse signal output 7) Oscillating capacitor 8) Level amplifier output

terminal terminal connecting terminal terminal

Lock alarm signal output

terminal

31kΩ

Vcc Vcc

REF

20Ω

FG

AL

Vcc

Vcc

1kΩ

1kΩ

45Ω

45Ω

Vcc

Vcc

OUT1

OUT2

RNF

Vcc

1kΩ

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

11/13

OSC

TSZ02201-0H1H0B100170-1-2

LAOUT

28.JUL.2012 Rev.002

Datasheet

BD6721FS

●Operational Notes

1) Absolute maximum ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc.,

can break down the devices, thus making impossible to identify breaking mode, such as a short circuit or an open

circuit. If any over rated values will expect to exceed the absolute maximu m ratings, consider adding circuit protecti on

devices, such as fuses.

2) Connecting the power supply connector backward

Connecting of the power supply in reverse polarity can damage IC. Take precautions when connecting the power

supply lines. An external direction diode can be added.

3) Power supply line

Back electromotive force causes regenerated current to power supply lin e , therefore take a measure s u ch as plac ing a

capacitor between power supply and GND for routing regenerated current. And fully ensure that the capacitor

characteristics have no problem before determine a capacitor value. (When applying electrolytic capacitors,

capacitance characteristic values are reduced at low temperatures)

4) GND potential

It is possible that the motor output terminal may deflect below GND terminal because of influence by back

electromotive force of motor. The potential of GND terminal must be minimum potential in all operating conditions,

except that the levels of the motor outputs terminals are under GND level by the back electromotive force of the motor

coil. Also ensure that all terminals except GND and motor output terminals do not fal l below GND voltage including

transient characteristics. Malfunction may possibly occur depending on use con dition, environment, and property of

individual motor. Please make fully confirmation that no problem is found on operation of IC.

5) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating

conditions.

6) Inter-pin shorts and mounting errors

Use caution when positioning the IC for mounting on printed circuit boards. The IC may be damaged if there is any

connection error or if pins are shorted together.

7) Actions in strong electromagnetic field

Use caution when using the IC in the presence of a strong electromagnetic field as doing so may cause the IC to

malfunction.

8) ASO

When using the IC, set the output transistor so that it does not exceed absolute maximum rations or ASO.

9) Thermal shut down circuit

The IC incorporates a built-in thermal shutdown circuit (TSD circuit). Operation temperat ure is 175°C (typ.) and has a

hysteresis width of 25°C (typ.). When IC chip temperature rises and TSD circuit works, the output terminal becomes an

open state. TSD circuit is designed only to shut the IC off to prevent thermal runaway. It is not designed to protect the

IC or guarantee its operation. Do not continue to use the IC after operation this circuit or use the IC in an environment

where the operation of this circuit is assumed.

10) Testing on application boards

When testing the IC on an application board, connecting a ca pacitor to a pin with low impedance subjects the IC to

stress. Always discharge capacitors after each process or step. Always turn the IC’s power supply off before

connecting it to or removing it from a jig or fixture during the inspection process. Ground the IC during assembly steps

as an antistatic measure. Use similar precaution when transporting or storing the IC.

11) GND wiring pattern

When using both small signal and large current GND patterns, it is recommended to isolate the two ground patterns,

placing a single ground point at the ground potential of application so that the pattern wiring resistance and voltage

variations caused by large currents do not cause variations in the small signal ground voltage. Be careful not to

change the GND wiring pattern of any external components, either.

12) Capacitor between output and GND

When a large capacitor is connected between output and GND, if Vcc is shorted with 0V or GND for some cause, it is

possible that the current charged in the capacitor may flow into the output resulting in destruction. Keep the capacitor

between output and GND below 100µF.

13) IC terminal input

When Vcc voltage is not applied to IC, do not apply voltage to each input terminal. When voltage above Vcc or belo w

GND is applied to the input terminal, parasitic element is actuated due to the structure of IC. Operation of parasitic

element causes mutual interference between circuits, resulting in malfunct ion as well as destruction in the last. Do not

use in a manner where parasitic element is actuated.

14) In use

e are sure that the example of application circuit is preferable, but please check the character further more in

W

application to a part that requires high precision. In using the unit with external circuit constant changed, consider the

variation of externally equipped parts and our IC including not only static character but also transient character and

allow sufficient margin in determining.

●Status of this document

The Japanese version of this document is formal specification. A customer may use this translation version only for a

reference to help reading the formal version.

If there are any differences in translation version of this document, formal version takes priority.

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

12/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

BD6721FS

●Physical dimension tape and reel information

SSOP-A16

6.6± 0.2

(MAX 6.95 include BURR)

1216 14

13

15

11

10

9

6.2± 0.3

4.4± 0.2

2

1.5± 0.1

0.11

0.8

61

453

87

0.36± 0.1

0.1

0.3MIN

0.15± 0.1

(Unit : mm)

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

●Marking diagram

SSOP-A16

(TOP VIEW)

BD6721F

Part Number

LOT Number

1PIN Mark

●Revision history

Date Revision Comments

07.JUL.2012 001 New Release

28.JUL.2012 002 Color appearance change (There is no change i n the content.)

Datasheet

Direction of feed

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

13/13

TSZ02201-0H1H0B100170-1-2

28.JUL.2012 Rev.002

Datasheet

Datasheet

Notice

●General Precaution

1) Before you use our Products, you are requested to carefully read this document and fully understand its contents.

ROHM shall not be in any way responsible or liable for failure, malfunction or accident arising from the use of a ny

ROHM’s Products against warning, caution or note contained in this document.

2) All information contained in this document is current as of the issuing date and subject to change without any prior

notice. Before purchasing or using ROHM’s Products, please confirm the latest information with a ROHM sales

representative.

●Precaution on using ROHM Products

1) Our Products are designed and manufactured for application in ordinary electronic equip ments (such as AV equipment,

OA equipment, telecommunication equipment, home electronic appliances, amusement equipment, etc.). If you

intend to use our Products in devices requiring extremely high reliability (such as medical equipment, transport

equipment, traffic equipment, aircraft/spacecraft, nuclear power controllers, fuel controllers, car equipment including car

accessories, safety devices, etc.) and whose malfunction or failure may cause loss of human life, bodily injury or

serious damage to property (“Specific Applications”), please consult with the ROHM sales representative in advance.

Unless otherwise agreed in writing by ROHM in advance, ROHM shall not be in any way respons ible or liable for any

damages, expenses or losses incurred by you or third parties arising from the use of any ROHM’s Products for Specific

Applications.

2) ROHM designs and manufactures its Products subject to strict quality control system. However, semiconductor

products can fail or malfunction at a certain rate. Please be sure to implement, at your own responsibilities, adequate

safety measures including but not limited to fail-safe design against the physical injury, damage to any propert y, which

a failure or malfunction of our Products may cause. The following are examples of safety measures:

[a] Installation of protection circuits or other protective devices to improve system safety

[b] Installation of redundant circuits to reduce the impact of single or multiple circuit failure

3) Our Products are designed and manufactured for use under standard conditions and not under any special or

extraordinary environments or conditions, as exemplified below. Accordingly, ROHM shall not be in any way

responsible or liable for any damages, expenses or losses arising from the use of any ROHM’s Products under any

special or extraordinary environments or conditions. If you intend to use our Products under any special or

extraordinary environments or conditions (as exemplified below), your independent verification and confirmation of

product performance, reliability, etc, prior to use, must be necessary:

[a] Use of our Products in any types of liquid, including water, oils, chemicals, and organic solvents

[b] Use of our Products outdoors or in places where the Products are exposed to direct sunlight or dust

[c] Use of our Products in places where the Products are exposed to sea wind or corrosive gases, including Cl

2S, NH3, SO2, and NO2

H

[d] Use of our Products in places where the Products are exposed to static electricity or electromagnetic waves

[e] Use of our Products in proximity to heat-producing components, plastic cords, or other flammable items

[f] Sealing or coating our Products with resin or other coating materials

[g] Use of our Products without cleaning residue of flux (even if you use no-clean type fluxes, cleaning residue of

flux is recommended); or Washing our Products by using water or water-solub le cleaning agents for cleaning

residue after soldering

[h] Use of the Products in places subject to dew condensation

4) The Products are not subject to radiation-proof design.

5) Please verify and confirm characteristics of the final or mounted products in using the Products.

6) In particular, if a transient load (a large amount of load applied in a short per iod of time, such as pulse) is applied,

confirmation of performance characteristics after on-board mounting is strongly recomm ended. Avoid applying power

exceeding normal rated power; exceeding the power ratin g under steady-state loading condition may negatively affect

product performance and reliability.

7) De-rate Power Dissipation (Pd) depending on Ambient temperature (T a). When us ed in sealed area, confirm the actual

ambient temperature.

8) Confirm that operation temperature is within the specified range d escribed in the product specification.

9) ROHM shall not be in any way responsible or liable for fail ure induced under deviant condition from what is defined in

this document.

2,

Notice - Rev.003

© 2012 ROHM Co., Ltd. All rights reserved.

Datasheet

●Precaution for Mounting / Circuit board design

1) When a highly active halog enous (chlor ine, bromin e, etc.) flux is used, the residue of flux ma y negatively affect product

performance and reliability.

2) In principle, the reflow soldering meth od must be used; if flow soldering method is preferred, please consult with the

ROHM representative in advance.

For details, please refer to ROHM Mounting specification

●Precautions Regarding Application Examples and External Circuits

1) If change is made to the constant of an external circuit, please allow a sufficient margin considering variations of the

characteristics of the Products and external components, including transient characteristics, as well as static

characteristics.

2) You agree that application notes, reference designs, and associated data and inform ation contained in this document

are presented only as guidance for Products use. Therefore, in case you use such information, you are solely

responsible for it and you must exercise your own independent verification and judgmen t in the use of such information

contained in this document. ROHM shall not be in any way responsible or liable for any damages, expenses or losses

incurred by you or third parties arising from the use of such information.

●Precaution for Electrostatic

This Product is electrostatic sensitive product, which may be damaged due to electrostatic discharge. Please take proper

caution in your manufacturing process and storage so that voltage exceeding the Products maximum rating will not be

applied to Products. Please take special care under dr y condition (e.g. Gro unding of human bod y / equipment / solder iron,

isolation from charged objects, setting of Ionizer, friction prevention and temperature / humidity control).

●Precaution for Storage / Transportation

1) Product performance a nd soldered connections may deteriorate if the Products are stored in the places where:

[a] the Products are expos ed to sea winds or corrosive gases, including Cl2, H2S, NH3, SO2, and NO2

[b] the temperature or humidity exceeds those recommended by ROHM

[c] the Products are exposed to direct sunshine or condensation

[d] the Products are expos ed to high Electrostatic

2) Even under ROHM recommended storage condition, solderabil ity of products out of recommended storage time perio d

may be degraded. It is strongly recommended to confirm solderabilit y before using Products of which storage time is

exceeding the recommended storage time period.

3) Store / transport cartons in the correct direction, which is indicated on a c arton with a symbol. Otherwise bent leads

may occur due to excessive stress applied when dropping of a carton.

4) Use Products within the specified time after opening a humidity barrier bag. Baking is require d before using Products of

which storage time is exceeding the recommended storage time period.

●Precaution for Product Label

QR code printed on ROHM Products label is for ROHM’s internal use only.

●Precaution for Disposition

When disposing Products please dispose them properly using an authorized industry waste company.

●Precaution for Foreign Exchange and F oreign Trade act

Since our Products might fall under controlled goods prescribed by the applicable foreign exchange and foreign trade act,

please consult with ROHM representative in case of export.

●Precaution Regarding Intellectual Prop erty Rights

1) All information and data including but not limited to appl ication example contained in this document is for reference

only. ROHM does not warrant that foregoing information or data will not infringe an y intellectual property rights or any

other rights of any third party regarding such information or data. ROHM shall not be in any way responsible or liable

for infringement of any intellectual property rights or other damages arising from use of such information or data.:

No license, expressly or implied, is granted hereby under any intellectual property rights or other rights of ROHM or any

2)

third parties with respect to the information contained in this document.

Datasheet

Notice - Rev.003

© 2012 ROHM Co., Ltd. All rights reserved.

Datasheet

●Other Precaution

1) The information contained in this document is provided on an “as is” basis and ROHM does not warrant that all

information contained in this document is accurate and/or error-free. ROHM shall not be in any way responsible or

liable for any damages, expenses or losses incurred by you or third parties resulting from inaccuracy or errors of or

concerning such information.

2) This document may not be reprinted or reproduced, in whole or in part, without prior written consent of ROHM.

3) The Products may not be disassembled, converted, modified, reprod uced or otherwise changed without prior written

consent of ROHM.

4) In no event shall you use in any way whatsoever the Products and the related technical information contained in the

Products or this document for any military purposes, including but not limited to, the development of mass-destruction

weapons.

5) T he proper names of companies or products described in this document are trademarks or registered trademarks of

ROHM, its affiliated companies or third parties.

Datasheet

Notice - Rev.003

© 2012 ROHM Co., Ltd. All rights reserved.

Loading...

Loading...