・14・

t

100

B

GND

6-Channel White LED Driver

for up to 72 LEDs

BD6581GU

●General Description

BD6581GU is white LED driver IC with PWM step-up

DC/DC converter that can boost max 42.5V and

current driver that can drive max 25mA. The wide and

precision brightness can be controlled by external

PWM pulse.

BD6581GU has very accurate current drivers, and it

has few current errors between each strings.

So, it will be helpful to reduce brightness spots on the

LCD.

Small package type is suited for saving space.

●Features

High efficiency PWM step-up DC/DC converter

(fsw=1MHz), max efficiency 93%

High accuracy & good matching (±1.5%) current

drivers 6ch

Drive up to 12

*

in series, 6 strings in parallel =72

white LEDs (*white LED Vf=3.5Vmax)

Rich safety functions

・Over-voltage protection (OVP)

・Over current limit

・External SBD open detect

・Thermal shutdown

●Ty pical A pplication Circuit

Battery

10F

RTR020N05

m

Powe r

ON/OFF

200Hz

PWM

1F

4.7H

2 .2F *

SW

SENSP

SENSN

RST

PWMPOW

PWMDRV

VBAT

VREG

GN

Figure 1. Typical Application Circuit

BD6581GU

TEST

GNDGND

●Key Specification

Operating power supply voltage range: 2.7V ~ 22.0V

Quiescent Current 1: 0.6A (Typ.)

Quiescent Current 2: 4.6A (Typ.)

Operating temperature range: -30℃ ~+85℃

●Package W(Typ.) x D(Typ.) x H(Max.)

VCSP85H2: 2.60mm x 2.60mm x 1.00mm

[bottom view]

ELED6 LED5 LED4 LED3 LED2

D RSTB GND FAILSEL GND LED1

CVBAT PWMPOW VREG ISETL PWMDRV

B N.C - TEST ISETH GND

A VDET N.C SW SENSP SENSN

●Application

All middle size LCD equipments backlight of Notebook

PC, portable DVD player, car navigation systems, etc.

FAILSEL

VDET

Each 20mA

ISET H

24k

ISETL

LED1

LED2

LED3

LED4

LED5

LED6

Datashee

1 2 3 4 5

10LED x 6parallel

○Product structure:Silicon monolithic integrated circuit○This product is not designed protection against radioactive rays

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111

001

1/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

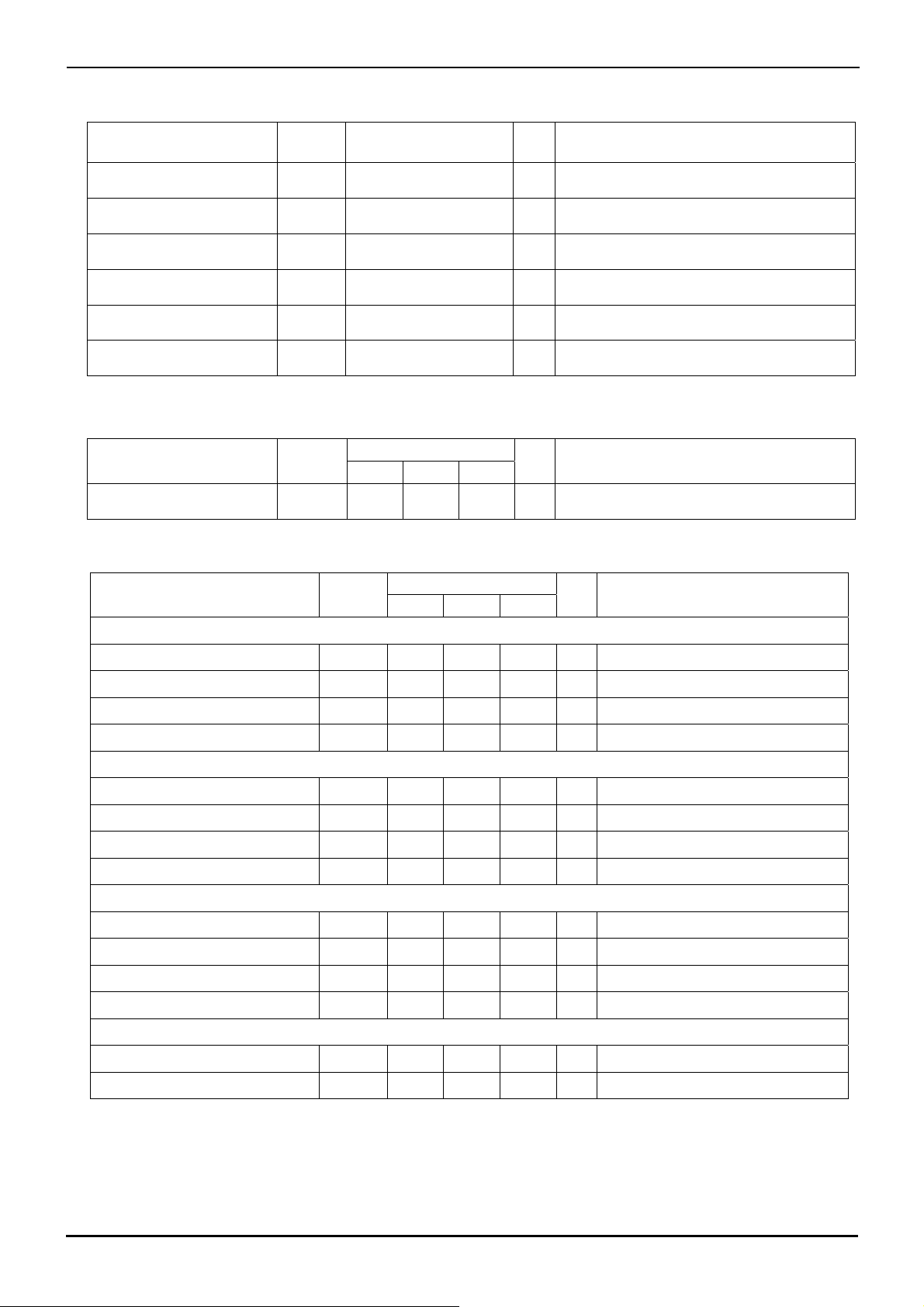

●Absolute Maximum Ratings

All middle size LCD equipments backlight of Notebook PC, portable DVD player, car navigation systems, etc.

Parameter Symbol Ratings Unit Condition

Datasheet

Terminal voltage 1 VMAX1 7 V

TEST, VREG, SENSP, SENSN, SW, RSTB,

PWMPOW, PWMDRV, FAILSEL, ISETH, ISETL

Terminal voltage 2 VMAX2 25 V LED1, LED2, LED3, LED4, LED5, LED6, VBAT

Terminal voltage 3 VMAX3 50.5 V VDET

Power dissipation 1 Pd1 1100 mW *1

Operating temperature range Topr -30 to +85

℃

Storage temperature range Tstg -55 to +150 ℃

*1 This value is the measurement value that was mounted on the PCB by ROHM.

Temperature deleting: 8.8mW/ ℃ from Ta>25℃

-

-

●Recommended Operating Rating (Ta=-30℃ to +85℃)

Parameter Symbol

Min. Typ. Max.

Limits

Unit Condition

Power supply voltage VBAT 2.7 12.0 22.0 V

●Electrical Characteristic

(Unless otherwise specified, VBAT=12V, RSTB=2.5V, Ta = +25

Parameter Symbol

Min. Typ. Max.

Limits

℃)

Unit Condition

[FAILSEL,PWMDRV Terminal]

EN threshold voltage (Low) VthL 0 - 0.2 V

EN threshold voltage (High) 1 VthH1 1.4 - 5.0 V VBAT>5.0V

EN threshold voltage (High) 2 VthH2 1.4 - VBAT V VBAT<5.0V

EN terminal input current Iin - 8.3 14.0 µA Input=2.5V

[PWMPOW Terminal]

Low Input Voltage range PWML 0 - 0.2 V

High Input Voltage range1 PWMH1 1.4 - 5.0 V VBAT>5.0V

High Input Voltage range2 PWMH2 1.4 - VBAT V VBAT<5.0V

PWM pull down resistor PWMR 300 500 700 k

[RSTB Terminal]

Low Input Voltage range RSTBL 0 - 0.2 V

High Input Voltage range1 RSTBH1 2.25 2.5 5.0 V VBAT>5.0V

High Input Voltage range2 RSTBH2 2.25 2.5 VBAT V VBAT<5.0V

Current Consumption IRSTB - 89 134 µA RSTB=2.5V, LED1-6=3V

[Regulator]

VREG Voltage VREG 4.0 5.0 6.0 V No load

Under Voltage Lock Out UVLO 2.05 2.25 2.65 V

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

2/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

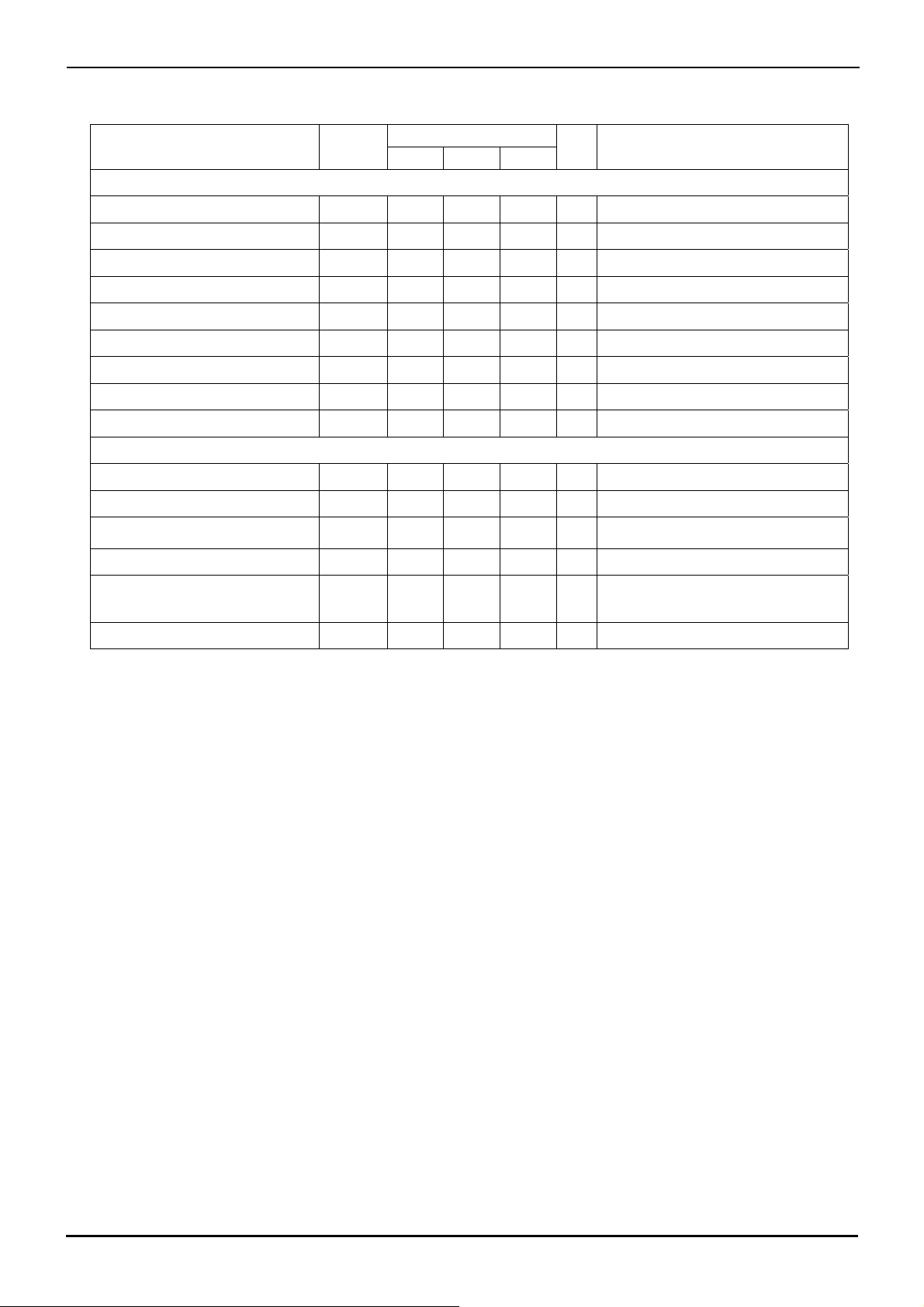

BD6581GU

●Electrical Characteristic – continued

(Unless otherwise specified, VBAT=12V, RSTB=2.5V, Ta = +25 ℃)

Parameter Symbol

[Switching Regulator]

Quiescent Current 1 Iq1 - 0.6 3.4 µA RSTB=0V, VBAT=12V

Quiescent Current 2 Iq2 - 4.6 10 µA RSTB=0V, VBAT=22V

Current Consumption Idd - 3.4 5.1 mA VDET=0V,ISETH=24k

LED Control voltage VLED 0.4 0.5 0.6 V

Over Current Limit voltage Ocp 70 100 130 mV *1

SBD Open Protect Sop - - 0.1 V Detect voltage of VDET pin

Switching frequency fSW 0.8 1.0 1.2 MHz

Duty cycle limit Duty 92.5 95.0 99.0 % LED1-6=0.3V

Over voltage limit Ovl 43.0 44.7 46.4 V LED1-6=0.3V

[Current driver]

LED maximum current ILMAX - - 25 mA

Min. Typ. Max.

Limits

Unit Condition

Datasheet

LED current accuracy ILACCU - - ±3 % ILED=16mA

LED current matching ILMAT - - ±1.5 %

ISET voltage Iset 0.5 0.6 0.7 V

LED current limiter ILOCP 35 60 90 mA

LED Terminal Over Voltage Protect LEDOVP 10.0 11.5 13.0 V RSTB=PWMDRV=2.5V

*1 This parameter is tested with dc measurement.

Each LED current/Average (LED1- 6)

ILED=16mA

Current limit value at ISET

resistance 4.7k setting

LED1, 2, 3, 4, 5, 6=0.5V

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

3/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●Pin Descriptions

PIN

Name

In/Out

PIN

Number

Function

T erminal equivalent

A1 VDET In Detect input for SBD open and OVP C

A2 N.C. - No connect pin F

A3 SW Out Switching Tr drive terminal G

A4 SENSP In + Side Current sense terminal G

A5 SENSN In - Side Current sense terminal A

B1 N.C. - No connect pin F

B3 TEST In TEST input (Pull down 100k to GND) G

B4 ISETH In Resistor connection for ,LED current setting at PWMDRV=H A

B5 GND - GND B

C1 VBAT In Battery input C

C2 PWMPOW In PWM input pin for power ON/OFF E

C3 VREG Out Regulator output / Internal power-supply D

C4 ISETL In Resistor connection for ,LED current setting at PWMDRV=L A

C5 PWMDRV In PWM input pin for power ON/OFF only driver E

D1 RSTB In Reset pin L :Reset H :Reset cancel E

D2 GND - GND B

D3 FAILSEL In Latch selectable pin of protect function E

D4 GND - GND B

D5 LED1 In Current sink for LED1 C

E1 LED6 In Current sink for LED6 C

E2 LED5 In Current sink for LED5 C

E3 LED4 In Current sink for LED4 C

E4 LED3 In Current sink for LED3 C

E5 LED2 In Current sink for LED2 C

●Pin ESD Type

VBAT VREG

VBAT

PIN

PIN

PIN

GND

GND

A

VBAT

VBAT

B

C

PIN

GND

VBAT

D

VREG

PIN

GND

PIN

5.5V

Clamp

E

F

PIN

GND

G

Figure 2. Pin ESD Type

Datasheet

circuit diagram

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

4/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

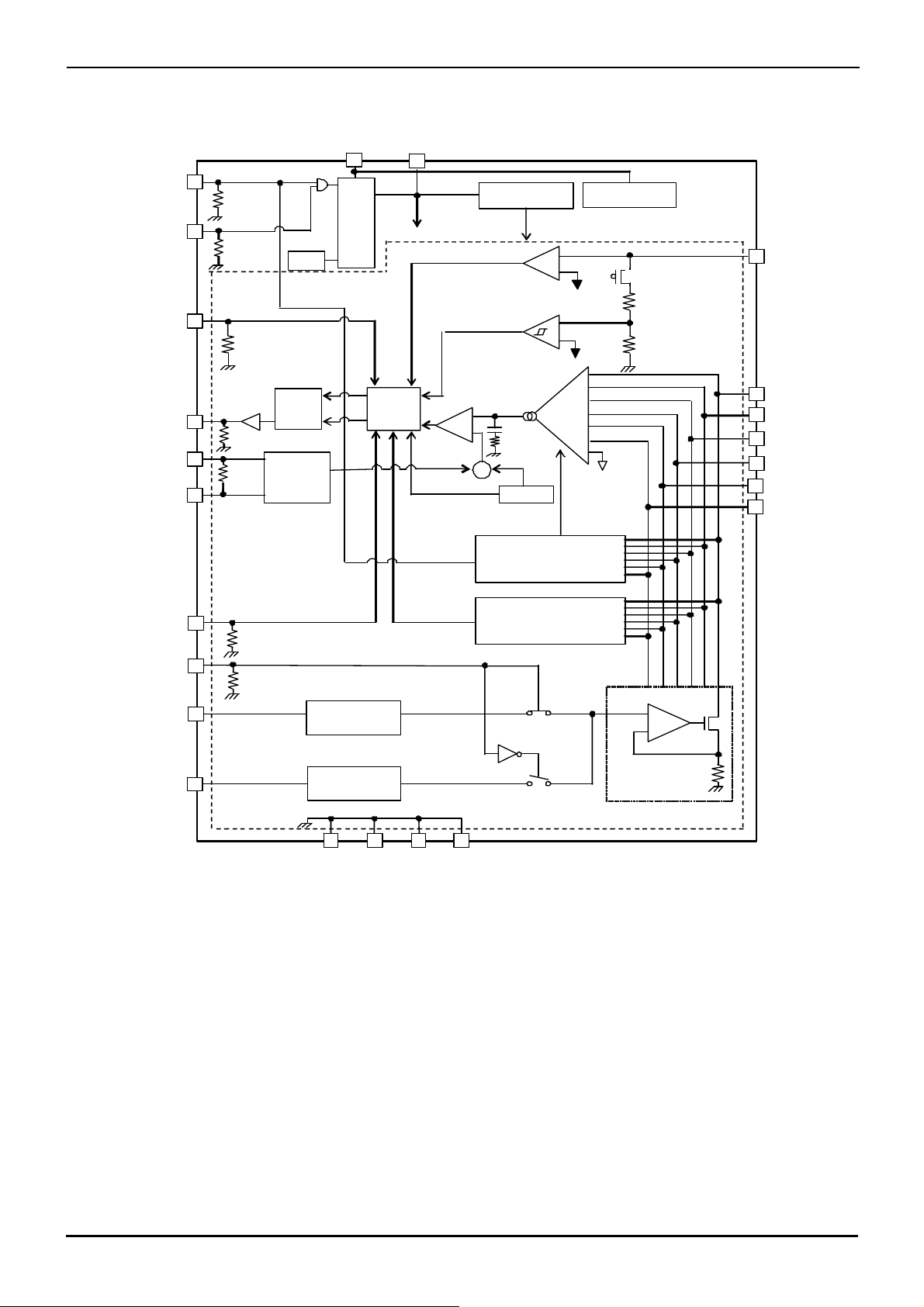

●Block Diagram

RSTB

PWMPOW

FAILSEL

SW

SE NSP

SENSN

TEST

PWM DRV

ISETH

IS E TL

Datasheet

VBAT VREG

300k

500 k

300 k

1M

10 0K

100k

300k

TSD

Q R

Current

Sense

REG

S

ISET H

Resi stor driver

ISET L

Resi stor driver

GND

GND

Intern al Power suplly

SBD Open protect

over voltage protect

C ontrol

sense

GND GN D

VIN detector

ERRAMP

PW M comp

+

+

OSC

LED TERMINA L

LED TERM IN AL

Over Voltage Protect

PWMDRV=H

PWMDRV=L

Detect

On

On

Pin number 23pin

Figure 3. Block Diagram

UVLO

+

-

VDET

+

-

-

-

-

-

-

-

+

LED 1

LED 2

LED 3

LED 4

LE D 5

LE D 6

+

-

Current Driver

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

5/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

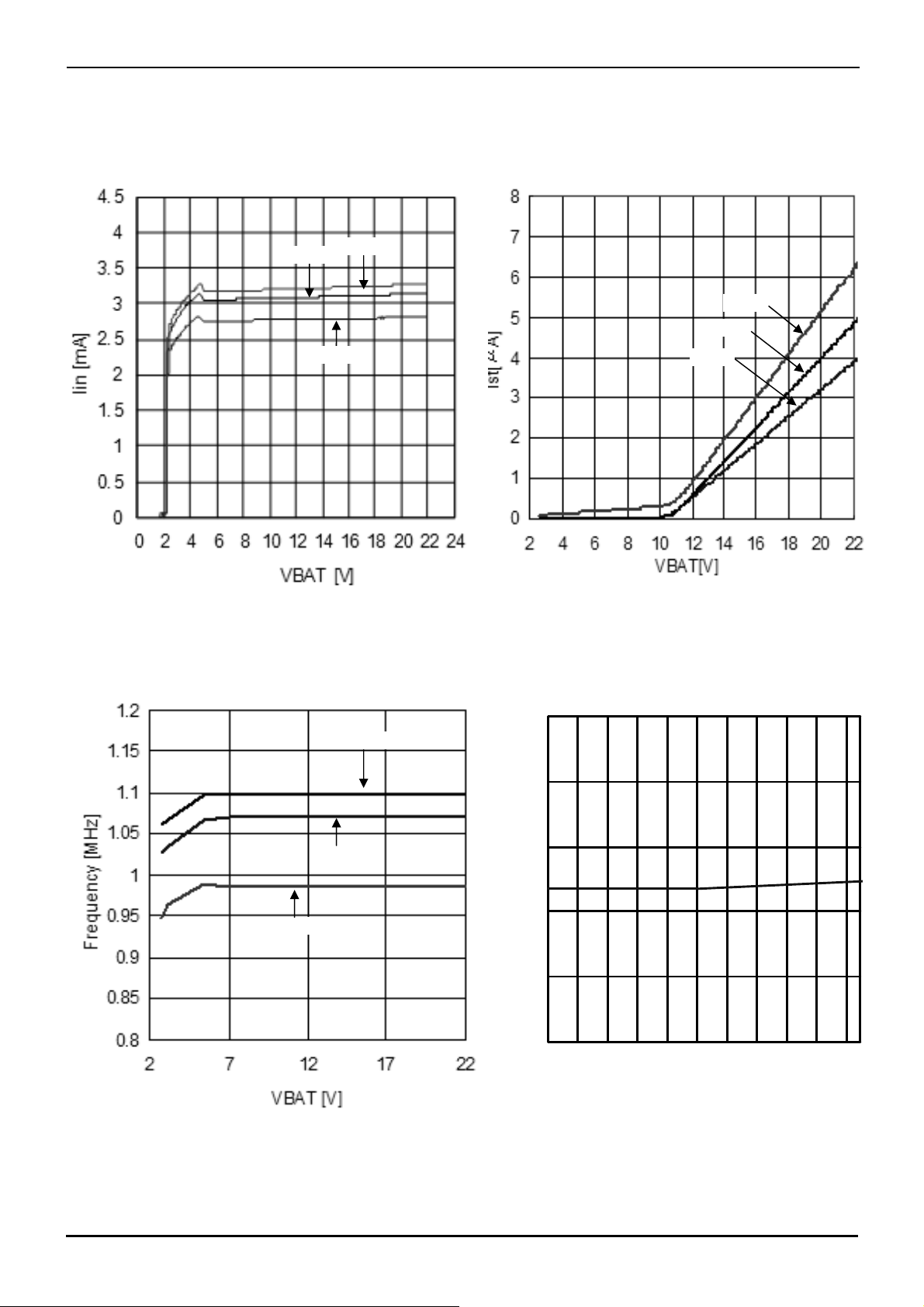

●Typical Performance Curves

Figure 4. Current Consumption vs VBAT

Figure 6. Oscillation frequency vs VBAT

25℃

85℃

-30℃

-30℃

85℃

25℃

25℃

-30℃

Figure 5. Quiescent current vs VBAT

2.3

2.28

2.26

VBAT [V]

2.24

2.22

2.2

-30 25 80

Ta [oC]

Figure 7. UVLO vs Temperature

Datasheet

85℃

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

6/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

S

BD6581GU

●Typical Performance Curves - continued

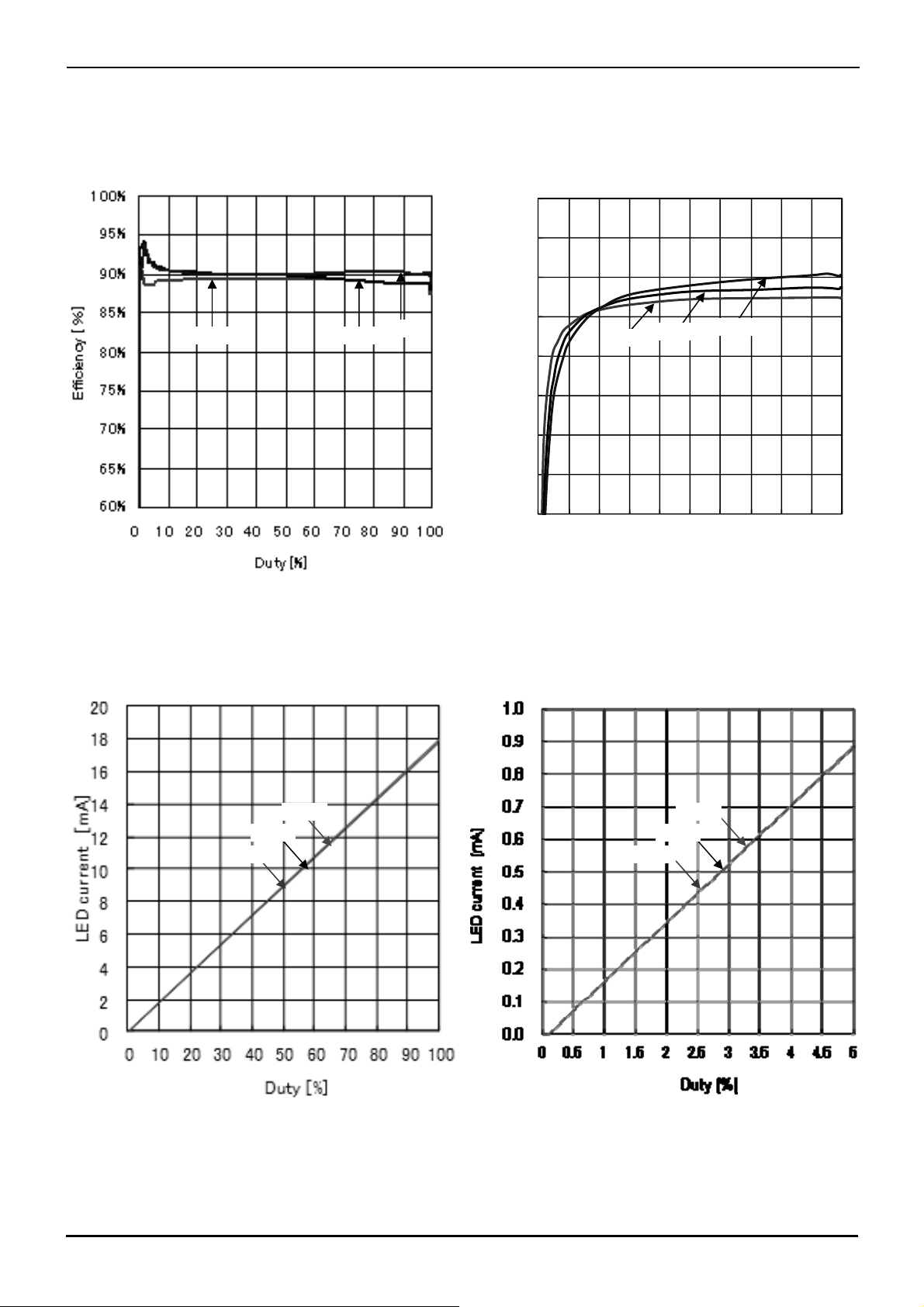

Figure 8. Efficiency vs PWMPOW-HI Duty

6V 12V

ISETH=24k, PWM=200Hz

16V 16V

12V

6V

16V

100%

95%

90%

85%

80%

75%

Effici e n cy [ %]

70%

65%

60%

0 102030405060708090100

Figure 9. Efficiency vs PWMDRV-HI Duty

I

Datasheet

6V

12V

Duty [%]

ETH=24k, PWM=200Hz

12V

6V

16V

Figure 10. LED current vs PWMDRV-HI Duty

PWM = 200Hz

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

7/32

Figure 11. LED current vs PWMDRV-HI Duty

( Expansion) PWM = 200Hz

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

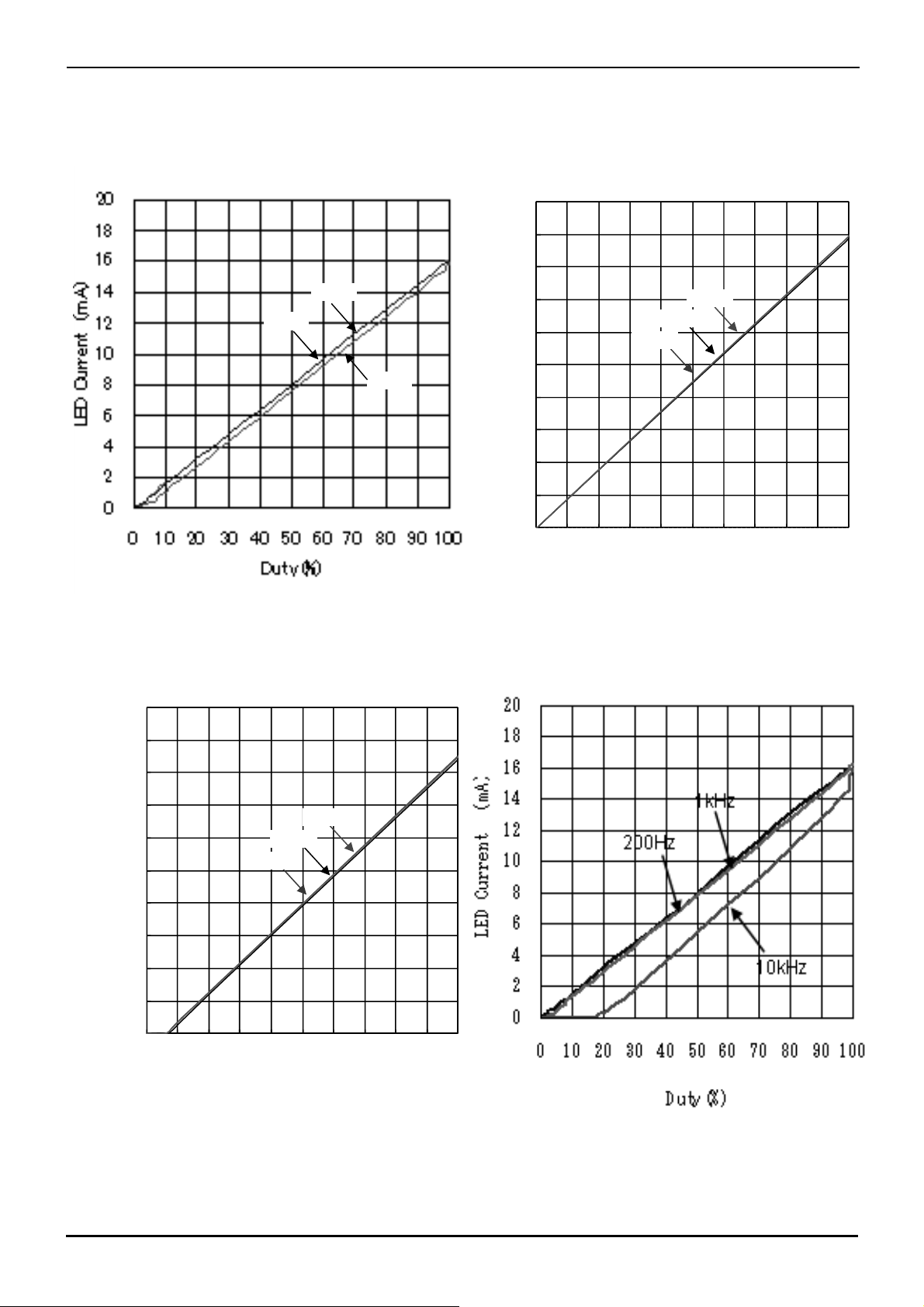

●Typical Performance Curves - continued

LED Current [mA]

Figure 12. LED current vs PWMDRV-HI Duty

PWM = 200Hz, 1kHz,10kHz

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Figure 14. LED current vs PWMPOW-HI Duty

( Expansion) PWM = 200Hz

200Hz

6V

1kHz

10kHz

16V

12V

Duty (%)

20

18

16

14

12

10

8

LED cur r ent [mA]

6

4

2

0

0 102030405060708090100

Figure 13. LED current vs PWMPOW-HI Duty

Figure 15. LED current vs PWMPOW-HI Duty

PWM = 200Hz, 1kHz,10kHz

6V

16V

12V

Duty [%]

TPWM = 200Hz

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

8/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

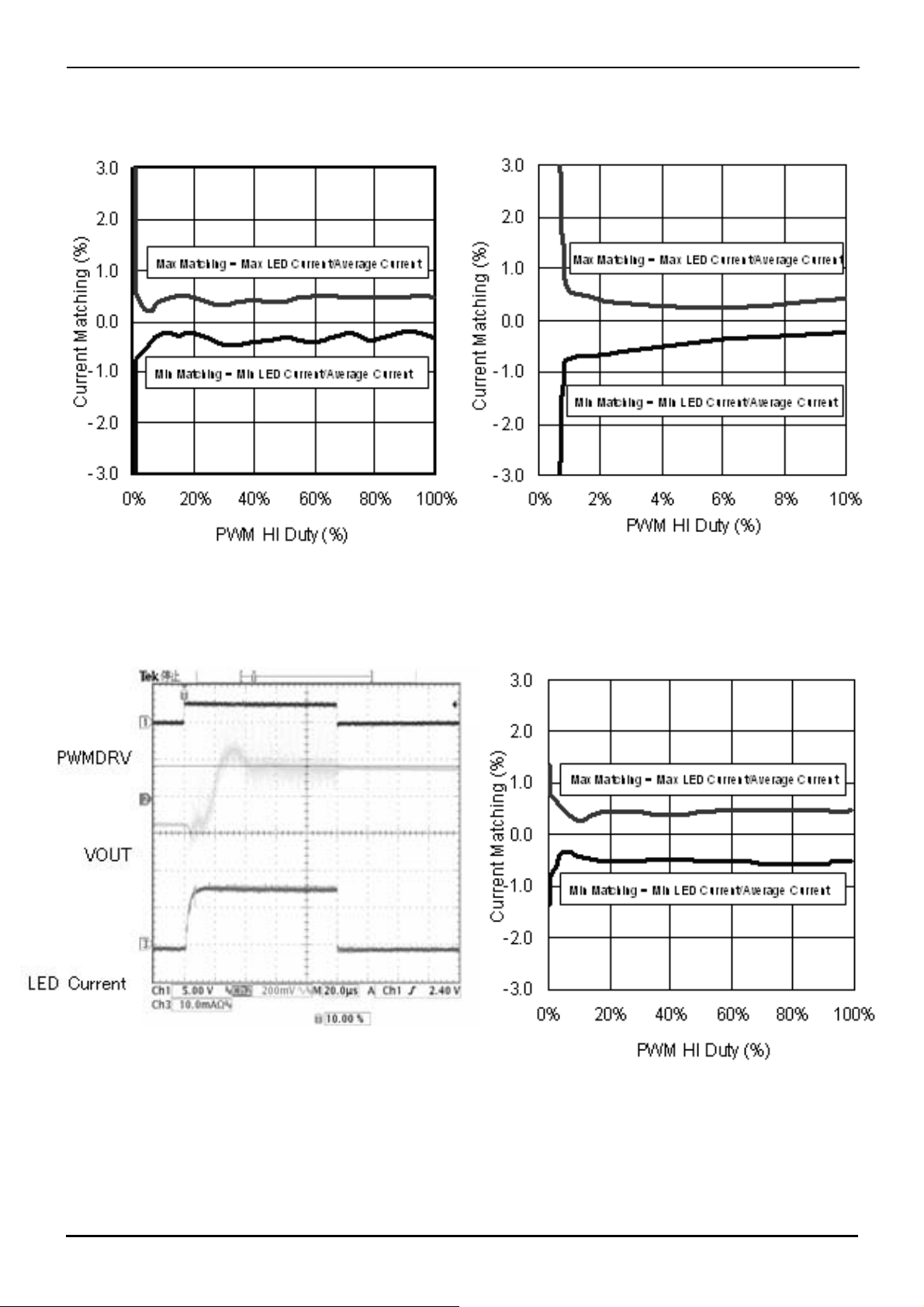

●Typical Performance Curves - continued

Figure 16. LED current matching vsPWMDRV-HI Duty

PWM = 200Hz

Figure 18. VOUT response

Driver Control PWM (PWMDRV)

Figure 17. LED current matching vs PWMDRV-HI Duty

(Expansion) PWM = 200Hz

Figure 19. LED current matching vs

Datasheet

PWMPOW-HI Duty

PWM = 200Hz

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

9/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

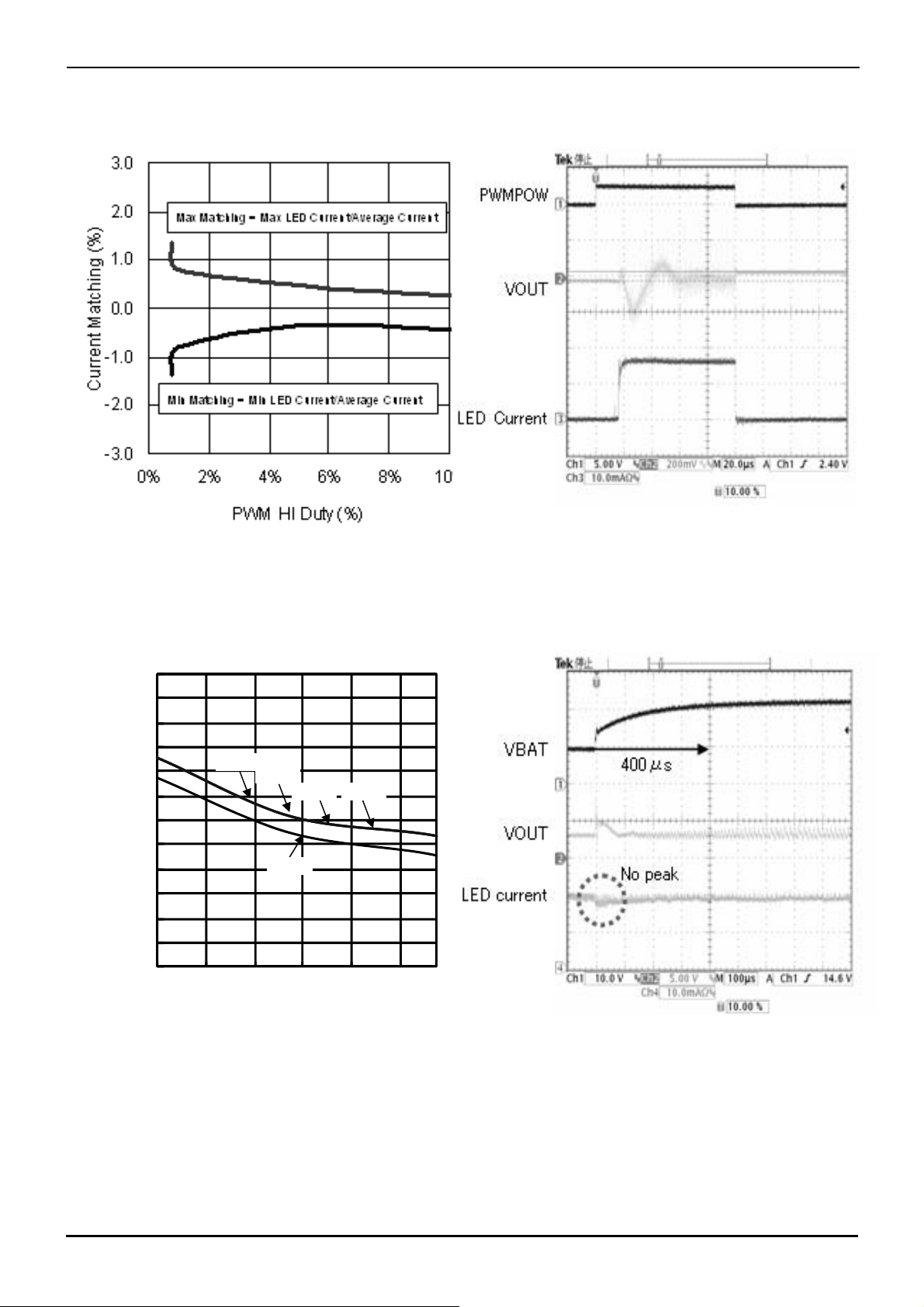

●Typical Performance Curves - continued

16.30

16.25

16.20

16.15

16.10

16.05

16.00

15.95

15.90

LEDCurrent [mA]

15.85

15.80

15.75

15.70

Figure 20. LED current matching vs

PWMPOW-HI Duty

(Expansion) PWM = 200Hz

5V

7V

12V

2.7V

22V

-3 0 -1 0 10 30 50 70

temp [℃]

Figure 22. LED current vs Temperature

PWMDRV=H, ISETH=30k (16mA setting)

Figure 21. VOUT response

Power Control PWM (PWMPOW)

Figure 23. Line Transient (10V to 22V)

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

10/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

(

BD6581GU

●Typical Performance Curves - continued

Datasheet

Figure 24. Line Transient (22V to 10V)

Figure 25. VOUT@OVP

LED OPEN)

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

11/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

p

BD6581GU

Datasheet

●Description of Functions

1) PWM current mode DC/DC converter

While BD6581GU is power ON, the lowest voltage of LED1, 2, 3, 4, 5, 6 is detected, PWM duty is decided to be 0.5V a nd

output voltage is kept invariably. As for the inputs of the PWM comparator as the feature of the PWM current mode, one is

overlapped with error components from the error amplifier, and the other is overlapped with a current sense signal that

controls the inductor current into Slope waveform to prevent sub harmonic oscillatio n. This output controls external Nch

Tr via the RS latch. In the period where external Nch Tr gate is ON, energy is accumulated in the external inductor, and in

the period where external Nch Tr gate is OFF, energy is transferred to the output capacitor via external SBD.

BD6581GU has many safety functions, and their detection signals stop switching operation at once.

2) Soft start

BD6581GU has soft start function.

The soft start function prevents large coil current.

Rush current at turning on is prevented by the soft start function.

After RSTB is changed L H, when PWMPOW is changed L H, soft start becomes effective for within 1ms and soft

start doesn't become effective even if PWMPOW is changed L H after that.

And, when the H section of PWMPOW is within 1ms, soft start becomes invalid when PWMPOW is input to H more than

three times. The invalid of the soft start can be canceled by making RSTB L.

3) FAILSEL pin

When the error condition occurs, boost operating is stopped by t he protecti on functi on, an d the error con dition is av oid ed.

On that occasion, the way to stop of boost operating by the protection function can be s elected with FAILSEL pin. Details

are as shown in Figure 26, 27.

After power ON, when the protection function is operating under about 1ms have passed, the stop state of the boost

operating can be held through FAILSEL is H, the stop state can reset through RSTB is L.

And, boost operating is stopped when the protection function is operating t hrough FAILSEL is L, but when the protection

function becomes un-detect, boost operating is started again. It never keeps holding the stop state of boost operating.

In PWM control by PWMDRV can’t use this function.

When it is off over 10ms on PWM control by PWMPOW using this function, it may be stopped the boost operating

as over current protection work at off on PWMPOW=L.

Object of protect function is as shown below.

・Over-voltage protection

・External SBD open detect

・Thermal shutdown

・LED terminal over-voltage protection

・Over current limit

<FAILSEL=H>

RSTB

“H”

FAILSEL

Protection

function

Boost

operating

<FAILSEL=L>

RSTB

Protection

func tion

operating

“L”

Boost

about 1ms

un-operating ran ge

un-detection un-detection

normal operating off boost stop

about 1ms

un-operating range FAILSEL

un-detectio

normal operating off

detection

detection

boost stop

un-detection

normal

erating

o

off normal operating

off normal

< When it is off on PWMPOW>

RSTB

PWMDRV

PWMPOW

Output

voltage

Coil current

FAILSEL

function

< When it is off on RSTB>

RSTB

PWMDRV

PWMPOW

Output

voltage

Coil current

FAILSEL

function

invalid valid

invalid

Figure 26. FAILSEL operating description Figure 27. FAILSEL=H light off control

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

12/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

4) Extern al SBD open detect and over voltage protection

BD6581GU has over boost protection by external SBD open an d over voltage protection. It detects VDET voltage and is

stopped output Tr in abnormal condition. Details are as shown below.

・External SBD open detect

In the case of external SBD is not connected to IC, the coil or external Tr may be destructed. Therefore, at such an

error as VOUT becoming 0.1V or below, the Under Detector shown in the figure works, and turns off the output Tr, and

prevents the coil and the IC from being destructed.

And the IC changes from activation into non-activation, and current does not flow to the coil (0mA).

・Over voltage protection

At such an error of output open as the output DC/DC and the LED is not connected to IC, the DC/DC will boost too

much and the VDET terminal exceed the absolute maximum ratings, and may destruct the IC. Therefore, when VDET

becomes sensing voltage or higher, the over voltage limit works, and turns off the output Tr, and the pressure up made

stop.

At this moment, the IC changes from activation into non-activation, and the output voltage goes down slowly. And,

when the output voltage becomes the hysteresis of the over voltage limit or below, the output voltage pressure up to

sensing voltage once again and unless the application error is recovered, this operation is repeated.

5) Thermal shut down

BD6581GU has thermal shut down function.

The thermal shut down works at 175°C or higher, and the IC changes from activation into non-activation. Because

non-activation is different from RSTB=L, it doesn’t’ be reset inside IC. Moreover, even if thermal shut down function works,

soft start, FAILSEL, selection the number of LED lines of the current driver and starting current setting at PWMDRV=L

related RSTB are hold.

6) Over Current L imit

Over current flows the current detection resistor that is connected to switching transistor source and between GND,

SENSP pin voltage turns more than detection voltage, over current protection is operating and it is prevented from

flowing more than detection current by reducing ON duty of switching Tr without stopping boost.

As over current detector of BD6581GU is detected peak current, current more tha n over current setting value does not

flow.

And, over current value can decide freely by changing over current detection voltage.

<Derivation sequence of detection resistor>

Detection resistor =Over current detection voltage / Over current setting value

TYP value of over current detection voltage is 100mV, MIN = 70mV and MAX = 130 mV and after the current value

which was necessary for the normal operation was decided, detection resistor is derived by using MIN value of ov er

current detection value.

For example, detection resistor when necessary current value was set at 1A is given as shown below.

Detection resistor =70mV / 1A = 70m

MAX current dispersion of this detection resistor value is

MAX current = 130mV / 70m = 1.86A

<The estimate of the current value which need for the normal operation >

As over current detector of BD6581GU is detected the peak current, it have to estimate peak current to flow to the coil

by operating condition.

In case of, Supply voltage of coil = VIN Inductance value of coil = L

Switching frequency = fswMIN=0.8MHz, T yp=1MHz, MAX=1.2MHz

Output voltage = VOUT Total LED current = IOUT

Average current of coil = Iave Peak current of coil = Ipeak

Efficiency = eff (Please set up having margin, it refers to data on page 7.)

O

Ipeak = (VIN / L) x (1 / fsw) x (1-(VIN / VOUT))

Iave=(VOUT x IOUT / VIN) / eff

Ton=(Iave x (1-VIN/VOUT) x (1/fsw) x (L/VIN) x 2)

Each current is calculated.

As peak current varies according to whether there is the direct current superposed, the next is decided.

(1-VIN/VOUT) x (1/fsw) < Ton peak current = Ipeak /2 + Iave

(1-VIN/VOUT) x (1/fsw) > Ton peak current = Ipeak

(Example 1)

In case of, VIN=6.0V, L=4.7µH, fsw=1MHz, VOUT=39V, IOUT=80mA, Efficiency=85%

Ipeak = (6.0V / 4.7µH) x (1 / 1MHz) x (1-(6.0V / 39V)) =1.08A

Iave = (39V x 80mA / 6.0V) / 85% = 0.61A

Ton = (0.61A x (1-6.0V / 39V) x (1 / 1MHz) x ( 4.7µH /6.0V) x 2)

(1-VIN/VOUT) x (1/fsw)=0.85µs < Ton

Peak current = 1.08A/2+0.61A = 1.15A

N time of switching transistor = Ton

1/2

1/2

= 0.90µs

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

13/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

Datasheet

(Example 2)

In case of, VIN=12.0V, L=4.7µH, fsw=1MHz, VOUT=39V, IOUT=80mA, Efficiency=85%

Ipeak = (12.0V / 4.7µH) x (1 / 1MHz) x (1-(12V / 39V)) =1.77A

Iave = (39V x 80mA / 12.0V) / 85% = 0.31A

Ton = (0.31A x (1-12 V / 39V) x (1 / 1MHz) x ( 4.7µH /12 V) x 2)

1/2

= 0.41µs

(1-VIN/VOUT) x (1/fsw)=0.69µs > Ton

Peak current = 12V/4.7µH x 0.41µs = 1.05A

*When too large current is set, output overshoot is caused, be careful enough because it is led to break down of the IC

in case of the worst.

●Operating of the Application Deficiency

1) When 1 LED or 1parallel OPEN during the operating

In case of FAILSEL=L, the LED parallel which became OPEN isn't lighting, but other LED parallel is lighting.

At that time, output boosts up to the over voltage protection voltage 44.7V so that LED terminal may be 0V or it boost to

the output voltage that LED terminal voltage becomes LED terminal over voltage protection 11.5V or it becomes the

output voltage restricted by the over current limit.

In case of FAILSEL=H, boost stops when LED becomes OPEN and all LED turns off the lights.

2) When LED short-circuited in the plural

In case of FAILSEL=L, all LED is turned on unless LED terminal voltage is LED terminal over voltage protection of more

than 11.5V. When it was more than 11.5V only the line which short-circuited is turned on normally and LED current of

other lines fall or turn off the lights. In case of FAILSEL=H, boost stops at more than 11.5V and all LED turns off the lights.

3) When Schottky diode came off

Regardless of FAILSEL, all LED isn't turned on. Also, IC and a switching transistor aren't destroyed because boost

operating stops by the Schottky diode coming off protected function.

4)When over current detection resistor came off

Regardless of FAILSEL, all LED isn't turned on. Because the resistance of 100k is between SENSP and SENSN

terminal, over current protection works instantly and LED current can't be flow.

●Control Signal Input Timing

2.7V

①

5V

②

③

Min. 100μs

5V

5V

0V

VBAT

220

PIN

Rin

VBAT

RSTB

PWMPOW

PWMDRV

VREG

DC/DC VOUT

Figure 28. control Signal timing

Figure 29. Voltage with a control sign higher than VBAT

Example corresponding to application of conditions

GND

In case you input control signs, such as RSTB, PWMPOW, and PWMDRV, in the condition that the standup of supply

voltage (VBAT) is not completed, be careful of the following point.

①Input each control signal after VBAT exceeds 2.7V.

②Please do not input each control sign until VBAT exceeds HI voltage of RSTB, PWMPOW, and PWMDRV.

③When you input RSTB during the standup of VBAT and HI voltage is inputted into PWMPOW,

please give the standup time to stable voltage as Min.100µs 2.7V of VBAT.

There is no timing limitation at each input signal of RSTB, PWMPOW and PWMDRV.

If each control sign changes into a condition lower than VBAT in (1) and (2), it goes via the ESD custody diode by the side

of VBAT of each terminal. A power supply is supplied to VBAT and there is a possibility of malfunctioning. Moreover, when

the entrance current to the terminal exceeds 50mA, it has possibility to damage the LSI. In order to av oid this condition, as

shown in the above figure, please insert about 220ohm in a signal line, and appl y current qualification. Please confirm an

internal pull down resistor in the block diagram and electrical property of P.5.

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

14/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●How to Select the Number of LED Lines of the Current Driver

When the number of LED lines of the current driver is reduced, the un-s elect can be set the matter that the unnecessary

LED1 to 6 terminal is connected to GND. When it uses with 4 lines a nd so on, it can correspond to it by connecting 2

unnecessary lines to GND.

RSTB is used as a power supply of this decision circuit. The select of the terminal is j udged, It has n o relation t o the l ogic of

PWMPOW and PWMDRV and it isn't judged an unnecessary LED line even if it is connected to GND when it is judged a

necessary terminal once. This information can be reset by setting RSTB at 0V.

●Start Control and Select LED Current Driver

BD6581GU can control the IC system by RSTB, and IC can power off compulsory by setting 0.2V or below. Also, It powers

on PWMPOW is at more than 1.4V and RSTB is at more than 2.25V.

When RSTB=PWMPOW=H, ISETH current is selected at PWMDRV=H and ISETL current is selected at PWMDRV=L.

The starting current in PWMDRV=L sets OFF second time rise of PWMDRV and it becomes 0mA setting after that.

After RSTB sets L once, the starting current can be flowed again by changing it to H.

RSTB PWMPOW PWMDRV IC LED current

1 0 0 Off OFF

1 1 0 On Starting current decided with ISETL

1 0 1 Off OFF

1 1 1 On Current decided with ISETH

0 0, 1 0, 1 Off OFF

●Attendance Point of the Restriction Resistance Input to RSTB

When the restriction resistance is input to RSTB, it is necessary to consider the input current of RST B. The input current of

RSTB changes that depending on the power-supply voltage and the tempe r ature reference to Figure 30.

Because the temperature characteristic of the input current is shown in Figure 30, please choos e resistance for which the

voltage of the terminal can be guaranteed to 2.1V or more.

And, it has the margin in the decision of resistance, and please confirm and make sure it is no problem in a real application.

The decision example of restriction resistance

1. When use the current driver of 6 parallel

2.9V(to RSTB power-supply) - restriction resistance value×124µA(100℃ input current) > 2.1V

restriction resistance value<(2.9-2.1)/124μA=6.45k

2. When use the current driver of 3 parallel

2.9V(to RSTB power-supply) - restriction resistance value×430A(100℃ input current) > 2.1V

restriction resistance value<(2.9-2.1)/430A=1.86k

Figure 31. RSTB terminal voltage-RSTB inflow current

(At the time of the current driver six lines use)

Power supply

for RSTB

RSTB inflow current

In addition, the selection number of parallel number of the current driver is changed, the power-supply current of RSTB will

be increased. Because the maximum value of the consumption current at the RST B=2.1V is indicated i n the following Table

1, be careful enough when you calculate the restriction resistance.

Table. the use parallel number of current driver at RSTB=2.1V , 100℃ vs. RSTB input current

Parallel numbers used for current driver RSTB input current

Limit resistor

Figure 30.

6 0.12mA

5 0.23mA

4 0.33mA

3 0.43mA

2 0.53mA

1 0.63mA

0 0.74mA

BD6581GU

RSTB

terminal

250

200

150

input current[uA]

100

RSTB

50

2.1 2.4 2.7 3 3.3 3.6

RSTB[V ]

Datasheet

+100℃

+80℃

+25℃

-30℃

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

15/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

V

W

BD6581GU

●Start to Use PWMPOW Terminal for the PWM Control, PWM Operating

After RSTB and PWMDRV is changing L → H, input PWM to PWMPOW terminal.

There is no constraint in turn of RSTB and PWMDRV.

And, because it corresponds to PWM drive of shorter ON time than soft start time (1ms), when PWMPOW is input H more

than three times, the soft start is invalidated and it enable to correspond the high-speed drive. Until RSTB is set L,

invalidation of the soft start isn't canceled.

In case of lighting → light off → lighting, when it turns off the lights with PWM=L and It starts without soft start when it sets

PWM modulated light again.

But the peak current of the coil changes owing to discharge of output capacitor, It may flow to the over current limit value,

as follows Figure 32. Because soft start can be used when it turns off the lights with RSTB=L, The peak current of the coil

can be suppressed, as follows Figure 33 and this process of light off is recommended.

RSTB

PWMDR

PWMPO

Output Voltage

Datasheet

Current

Figure 32. Light off control of PWMPOW pin at PWM control on PWM=L

Output Voltage

Current

Figure 33. Light off control of PWMPOW pin at PWM control on RSTB=L

coil

RSTB

PWMDRV

PWMPOW

coil

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

16/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

W

V

t

BD6581GU

●Start to Use PWMDRV Terminal for the PWM Control, PWM Operating

After RSTB and PWMPOW is changing L → H, input PWM to PWMDRV terminal.

There is no constraint in turn of RSTB and PWMPOW.

After RSTB and PWMPOW is changing L → H as follows Figure 34, when it is not input PWM to PWMDRV pin but input L,

boost of DC/DC is unstable state because current driver doesn’t pass current.

The starting current is pulled from each LED terminal and pressure up operating is stabilized to escape from this state.

Also, the starting current can be set up by the resistance value connected to the ISETL terminal.

After starting, as the starting current in PWM brightness control become useless, the starting current is set up 0mA at the

second rise time of PWMDRV automatically as follows Figure 34.

In case of lighting → light off → lighting, when it turns off the lights with PWM=L and It starts without soft start because of

soft start period was end when it sets PWM modulated light again.

But the peak current of the coil changes owing to discharge of output capacitor, It may flow to the over current limit value,

as follows Figure 35. Because soft start can be used when it turns off the lights with RSTB=L, The peak current of the coil

can be suppressed, as follows Figure 36 and this process of light off is recommended.

PWMPOW

PWMDRV

Output voltage

Current driver of

starting current

RSTB

L H L H L H L

LED pin

ON OFF ON OFF

Figure 34. Off timing of starting current at PWMDRV=L

Output Voltage

Figure 35. Light off control of PWMDRV pin at PWM control on PWM=L

RSTB

PWMPOW

PWMDRV

Current

RSTB

coil

PWMPO

PWMDR

Output voltage

Coil curren

Figure 36. Light off control of PWMDRV pin at PWM control on RSTB=L

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

17/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●Brightness Control

There are two dimming method is available, first method is analog dimming that apply analog voltage to ISET terminal, and

second method is PWM control via digital dimming of PWMPOW or PWMDRV. Because each method has the different

merit, please choose a suitable method for the application of use.

Two techniques can be used as digital dimming by the PWM control One is PWM control of current driver, the other is PWM

control of power control.

As these two characteristics are shown in the below, selects to PWM control process comply with application.

・Efficiency emphasis in the low brightness which has an influence with the battery life → 2) Power control PWM control

・LED current dispersion emphasis in the PWM brightness control → 1) Current driver PWM control

(Reference)

PWM regulation process

Current driver 70% 0.2%

Power control 93% 0.5%

1) Current driver PWM control is controlled by providing PWM signal to PWMDRV, as it is shown Figure 41.

The current set up with ISETH is chosen as the Hi section of PWMDRV and the current is off as the Lo section. Therefore,

the average LED current is increasing in proportion to duty cycl e of PWMDRV signal. This method that it lets internal

circuit and DC/DC to work, because it becomes to switch the driver, the current tolerance is a few when the PWM

brightness is adjusted, it makes it possible to brightness control until 50µs (MIN1% at 200Hz). And, don't use for the

brightness control, because effect of ISETH, ISETL changeover is big under 50µs ON time and under 50µs OFF time.

Typical PWM frequency is 100Hz to 10kHz. When RSTB sets H → L, so the starting current may be effective, after

RSTB sets L→ H, it becomes PWM of the starting current and PWM of ISETH setting current to PW M two times.

Efficiency of LED current 0.5mA

(PWM Duty=2.5%)

PWM frequency 200Hz

Limit dispersion capability of low duty

Datasheet

PWMDRV

LED current

Coil current

IC’s active current

Figure 37. PWM modulated light by PWM DRV Pin

2) Power control PWM control is controlled by providing PWM signal to PWMPOW, as it is shown Figure 43. The current

setting set up with PWMDRV logic is chosen as the Hi section and the current is off as the Lo section. Therefore, the

average LED current is increasing in proportion to duty cycle of PWMPOW signal. This method is, because IC can be

power-off at off-time, the consumption current can be suppress, and the high efficiency can be availa ble, so it makes it

possible to brightness control until 50µs (MIN1% at 200Hz). And, don't use for the brightness control, because effect of

power ON/OFF time changeover is big under 50µs ON time and under 50µs OFF time.

Typical PWM frequency is 100Hz to 1kHz. Also, PWM can't control RSTB and PWMPOW at the same time.

After RSTB sets H, control PWM only PWMPOW.

PWMPOW

LED current

Coil current

ON OFF

ON OFF

ON OFF

ON

ON OFF

ON

ON

OFF

OFF

IC’s active current

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

ON OFF

Figure 38. PWM modulated by PWM Pow Pin

18/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

Datasheet

●LED Current Setting Range

LED current can set up Normal and Starting setting current.

LED current can set up Normal current by resistance value (RISETH) connecting to ISETH voltage and LED current can set

Starting current by resistance value (RISETL) connecting to ISETL voltage.

Setting of each LED current is given as shown below.

Normal current = 20mA (24k/RISETH) Starting constant current = 0.6/RISET L

Also, Normal current setting range is 10mA to 25mA, Starting current setting range is OFF setting or 1µA to 100µA.

LED current can set OFF setting by open setting ISETL pin.

LED current becomes a leak current MAX 1µA at OFF setting.

ISETH Normal current setting example ISETL Starting current setting example

RISETH LED current RISETL LED current

24k (E24) 20mA 6.2k (E24) 97µA

25.5 k (E96) 18.8mA 10k (E6) 60µA

27 k (E12) 17.8mA 47k (E6) 13µA

28k (E96) 17.1mA 100 k (E6) 6µA

30k (E24) 16.0mA 560 k (E12) 1.1µA

33k (E6) 14.5mA Connect to VREG pin 0mA

●The Separations of the IC Power Supply and Coil Power Supply

This IC can work in separating the power source in both IC power supply and coil po wer supply. With this application, it

can obtain that decrease of IC power consumption, and the applied voltage exceeds IC rating 22V.

That applicatio n is shown in below figure 39. The higher voltage source is applied to the power source of coil that is

connected from an ada pter etc. Next, the IC power supply is connected with a different coil power supply. Under the

conditi ons for inputting from 2.7V to 5.5V into IC VBAT, please follow the recommend desig n in figure 35. It connects

VBAT terminal and VREG terminal together at IC outside.

When the coil power supply is appl ied, it is no any problem even though IC power supply is the state of 0V. Although

IC power supply is set to 0V, pull-down resistance is arranged for the power off which cuts off the leak route from coil

power supply in IC inside, the leak route is cut off. And, there is no power on-off sequence of coil power supply and IC

power supply.

IC Power supply

Coil Power supply

7V to 28V

Battery

4.7H

10F

2.2F

RTR020N05

100m

Power

ON/OFF

200Hz

PWM

2.7V to 5.5V

1F

SW

SENSP

SENSN

RSTB

PWMDRV

PWMPOW

VBAT

VREG

GND

10LED x 6

FAILSEL

ISETL

ISETH

TEST

GND

GNDGND

24k

VDET

LED1

LED2

LED3

LED4

LED5

LED6

20mA each

Figure 39. Application at the time of power supply isolation

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

19/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

A

t

T

r

BD6581GU

Datasheet

●The Coil Selection

The DC/DC is designed by more than 4.7µH. When L value sets to a lower value, it is possibility that the specific

sub-harmonic oscillation of current mode DC / DC will be happened. Please do not let L value to 3.3µH or below.

And, L value increases, the phase margin of DC / DC becomes to zero. Please enlarge the output capacitor value when you

increase L value.

Example)

4.7µH = output capacitor 2.2µF/50V 1pcs

6.8µH = output capacitor 2.2µF/50V 2pcs

10µH = output capacitor 2.2µF/50V 3pcs

This value is just examples, please made sure the final judgment is under an enough evaluation.

●Layout

In order to make the most of the performance of this IC, its layout pattern is very important. Characteristics such as

efficiency and ripple and the likes change greatly with layout patterns, which please note carefully.

to Anode of each LED

E

Rese

PWM

C

D

BA

C

B

LED5 LED4 LED3 LED2 LED6

RSTB

GND FAILSEL GND LED1

VBAT

PWMPOW VREG ISETL PWMDRV

TEST ISETH

GND

C

REG

RISET

VDET SW SENSP SENSN

12345

SBD

T

R

SENSE

C

OUT

to GND

L

C

IN

to Cathode of LED

Figure 40. Layout

Connect the input bypath capacitor CIN(10µF) nearest to coil L, as shown in the upper diagram.

Wire the power supply line by the low resistance from CIN to VBAT pin. Thereby, the input voltage ripple of the IC can be

reduced. Connect smoothing capacitor CREG of the regulator nearest to between VREG and GND pin, as shown in the

upper diagram. Connect schottky barrier diode SBD of the regulator nearest to between coil L and switching transistor Tr.

And connect output capacitor COUT nearest to between CIN and GND pin. Thereby, the output voltage ripple of the IC can

be reduced.

Connect switching transistor Tr nearest to SW pin. Wire coil L and switching transistor Tr, current sensing resistor R

the low resistance. Wiring to the SENSP pin isn't Tr side, but connect it from R

low when wiring from Tr side. Connect R

pin wiring from R

pin to GND pin. And R

SENSE

of GND side isolated to SENS pin. Don’t wire between R

SENSE

GND line must be wired directly to GND pin of output capacitor. It

SENSE

side. Over current value may become

SENSE

and SNESN

SENSE

SENSE

by

has the possibility that restricts the current drive performance by the influence of the noise when other GND is connected to this

GND.Connect LED current setting resistor RISET nearest to ISET pin. There is possibility to oscill ate when capacity is

added to ISET terminal, so pay attention that capacity isn't added. And, RISET of GND side must be wired directly to

GND pin. When those pins are not connected directly near the chip, influe nce is given to the performance of BD6581GU,

and may limit the current drive performance. As for the wire to the inductor, make its resistance component small so as to

reduce electric power consumption and increase the entire efficiency.

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

20/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●Selection of External Parts

Recommended external parts are as shown below.

When to use other parts than these, select the following equivalent parts.

・Coil

Size

Value Manufacturer Product number

4.7H TOKO A915AY-4R7M 5.2 5.2 3.0 1870 0.045

4.7H TOKO B1015AS-4R7M 8.4 8.3 4.0 3300 0.038

4.7H TOKO A1101AS-4R7M 4.1 4.1 1.2 1400 0.115

4.7H TDK LTF5022T-4R7N2R0 5.0 5.2 2.2 2000 0.073

4.7H TDK VLP6810T-4R7M1R6 6.3 6.8 1.0 1600 0.167

10H TDK VLP6810T-100M1R1 6.3 6.8 1.0 1100 0.350

・Capacitor

Value Pressure Manufacturer Product number

[ Supply voltage capacitor ]

10F 25V MURATA GRM31CB31E106K 3.2 1.6 1.6±0.2 B +/-10%

10F 10V MURATA GRM219R61A106K 2.0 1.25 0.85±0.15 X5R +/-10%

4.7F 25V MURATA GRM319R61E475K 3.2 1.6 0.85±0.1 X5R +/-10%

4.7F 25V MURATA GRM21BR61E475K 2.0 1.25 1.25±0.1 X5R +/-10%

[ Smoothing capacitor for built-in regulator ]

1F 10V MURATA GRM188B10J105K 1.6 0.8 0.8±0.1 B +/-10%

[ Output capacitor ]

1F 50V MURATA GRM31MB31H105K 3.2 1.6 1.15±0.1 B +/-10%

1F 50V MURATA GRM21BB31H105K 2.0 1.25 1.25±0.1 B +/-10%

2.2F 50V MURATA GRM31CB31H225K 3.2 1.6 1.6±0.2 B +/-10%

0.33F 50V MURATA GRM219B31H334K 2.0 1.25 0.85±0.1 B +/-10%

・Resistor

Value Tolerance Manufacturer Product number

[ Resistor for LED current decision <ISETH pin> ]

30k ±0.5% ROHM MCR006YZPD303 0.6 0.3 0.23

[ Resistor for over current decision <SENSP pin> ]

100m ±1% ROHM MCR10EZHFSR100 2.0 1.25 0.55

・SBD

Pressure Manufacturer Product number

60V ROHM RB160M-60 3.5 1.6 0.8

・MOS FET Nch

Pressure Manufacturer Product number

45V ROHM RTR020N05 2.8 2.9 1.0 2A 2.5V

Vertical Horizontal

Vertical Horizontal Height

Vertical Horizontal Height

Vertical Horizontal Height

Vertical Horizontal Height

Height

(MAX)

Size

Size

Size

Size

DC

current

(mA)

Current

Datasheet

DCR

()

TC

Ability

Cap

Tol

Driving

Voltage

60V ROHM RSS065N06 6.0 5.0 1.75 6.5A 4.0V

The coil is the part that is most influential to efficiency. Select the coil whose direct current resist or (DCR) and current inductance characteristic is excellent. BD6581GU is designed for the inductance value of 4.7µH. Doesn’t use the

inductance value less than 2.2 µH. Select a capacitor of ceramic type with excellent frequency and temperature

characteristics. Further, select Capacitor to be used with small direct current resistance, and pay sufficient attention to the

layout pattern shown in P.20.

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

21/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●Attention Point of Board Layout

In board pattern design, the wiring of power supply line should be low Impedance, and put the bypass capacitor if necessary.

Especially the wiring impedance must be lower around the DC/DC converter.

●About Heat Loss

In heat design, operate the DC/DC converter in the following condition.

(The following temperature is a guarantee temperature, so consider the margin.)

1. Periphery temperature Ta must be less than 85

2. The loss of IC must be less than dissipation Pd.

o

C.

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

22/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

y

y

BD6581GU

●Application Example

10F

RTR020N 05

100m

Power

ON/OFF

200Hz

PWM

Figure 41. 10

Battery

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

GND

series x 6parallel Hi current 20mA setting Figure 42. 10 series x 4parallel Hi current 20mA setting

FAILSEL

ISETH

ISETL

TEST

24k

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Each 20mA

10LED x 6parallel

10F

RTR020N05

150m

ON/OFF

200Hz

PWM

Power

Batter

1F

4.7H

2.2F *

SENSP

SENSN

GND

RSTB

PWMPOW

PWMDR V

SW

VBAT

VREG

GND

GND GND

TEST

FAILSEL

ISETH

24k

ISETL

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Current driver PWM application Current driver PWM application

*

Please select the capacitor which the little bias fluctuation.

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Each 20mA

10LED x 6parallel

10F

RTR020N05

100m

Power

ON/OFF

200Hz

PWM

2.7V to 5.5V

Batter

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

VREG

GND

VBAT

GND

VDET

FAILSEL

LED1

LED2

LED3

LED4

LED5

ISETH

ISETL

TEST

GNDGND

24k

LED6

Each 20mA

RTR020N05

100m

10F

Power

ON/OFF

200Hz

PWM

Batte ry

1F

4.7H

2.2F *

SENSP

SENSN

RSTB

GND

SW

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETH

ISETL

TEST

24k

Figure 43. 10 series x 6parallel LED current

20mA setting

Figure 44. Non-used Inside REG or operating

under 5V application

Power control PWM application

* Please select the capacitor which the little bias fluctuation.

Terminal Processing

TEST pin = Connect to GND

N.C. = Nothing specified in particular. Open is recommended.

VREG = When IC is driving from the outside of 2.7 to 5.5V, short VBAT and VREG, and put the voltage to VREG

FAILSEL, PWMDRV = Connect to GND in case of fixing at L level.

Connect to VREG of IC or the power supply of more than 1.4V in case of fixing at H level.

LED1-6 = When each LED driver are not used, conne ct to GND of IC

GND = Each GND is connecting inside IC, but, connect to GND of all board

RSTB = RSTB is used as a power supply of internal circuit.

So, you mustn’t input RSTB voltage with pull up resistor of several k.

And, please care about the relation between VBAT and RSTB enough.

Datasheet

10LED x 4aprallel

Each 20mA

10LED x 6parallel

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

23/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

y

BD6581GU

Datasheet

• LED current setting controlled ISETH resistor.

19.6k: 24.5mA

24k: 20mA

30k: 16mA

33k: 14.5mA

• Brightness control

Please input PWM pulse from PWMPOW or PWMDRV terminal.

Please refer electrical characteristic page.6 and function (page.17).

15inch panel

Battery

4.7H

10F

2.2F *

RTR020N 05

47m

ON/OFF

100Hz~10kHz

PWM

Power

1F

GND

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETL

ISETH

TEST

24k

Figure 45. 10 series×6 parallel, LED current 20mA setting

Current driver PWM application

13 to 14inch panel

Battery

4.7H

10F

2.2F *

RTR020N 05

51m

ON/OFF

100Hz~1kHz

PWM

Power

1F

GND

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETL

ISETH

TEST

24k

Figure 46. 8 series×6 parallel, LED current 20mA setting Figure 47. 8 series×6 parallel, LED current 20mA setting

Power control PWM application Current driver PWM application

10LED x 6 parallel

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Can be set up to each 10 ~25mA

Each 20mA

Batter

51m

PWM

10F

Power

ON/OFF

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

GND

VBAT

VREG

GND

8LED x 6 para lle l

VDET

RTR020N05

LED1

LED2

LED3

LED4

LED5

LED6

Each 20mA

Can be set up to each 10~25mA

Please select the capacitor which the little bias fluctuation.

*

100Hz~10kHz

8LED x 6 para lle l

VDET

FAILSEL

LED1

LED2

LED3

LED4

LED5

ISETH

ISETL

TEST

GNDGND

24k

LED6

Each 20mA

Ca n b e se t u p to e a c h 1 0 ~ 2 5 m A

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

24/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

y

A

y

BD6581GU

Datasheet

• LED current setting controlled ISETH resistor.

19.6k: 24.5mA

24k: 20mA

30k: 16mA

33k: 14.5mA

• Brightness control

• Brightness control

Please input PWM pulse from PWMPOW or PWMDRV terminal.

Please refer electrical characteristic page.6 and function (page.17).

10 to 12inch panel

Battery

Batter

10F

RTR020N 05

56m

ON/OFF

100Hz~10kHz

PWM

Power

1F

4.7H

2.2F *

SENSP

SENSN

GND

SW

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

7LED x 6 para lle l

VDET

RTR020N05

FAILSEL

LED1

LED2

LED3

LED4

LED5

ISETL

ISETH

TEST

30k

LED6

Can be set up to each 10~25mA

Each 16mA

100Hz~10kHz

56m

PWM

10F

Power

ON/OFF

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

GND

VBAT

VREG

GND

FAILSEL

ISETH

ISETL

TEST

GNDGND

24k

Figure 48. 7 series×6 parallel, LED current 16mA setting Figure 49. 10 series×4 parallel, LED current 20mA setting

Current driver PWM application Current driver PWM application

7inch panel

8LED x 3 para lle l

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Can be set up to each 10~25mA

Each 20m

10F

RTR020N05

68m

ON/OFF

100Hz~10kHz

PWM

Power

Batter

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

GND

VBAT

VREG

GND

FAILSEL

ISETH

ISETL

TEST

GNDGND

24k

10F

RTR020N 05

68m

ON/OFF

100Hz~10kHz

PWM

Battery

Power

1F

4.7H

2.2F *

SENSP

SENSN

GND

SW

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETL

ISETH

TEST

24k

Figure 50. 8 series×3 parallel, LED current 20mA setting Figure 51. 6 series×4 parallel, LED current 20mA setting

Current driver PWM application Current driver PWM application

Please select the capacitor which the little bias fluctuation.

*

10LED x4 parallel

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Can be set up to each 10~25mA

Each 20mA

6LED x 4 para lle l

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Each 20mA

Can be set up to each 10~25mA

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

25/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

A

y

y

BD6581GU

Datasheet

• LED current setting controlled ISETH resistor.

19.6k: 24.5mA

24k: 20mA

30k: 16mA

33k: 14.5mA

• Brightness control

• Brightness control

Please input PWM pulse from PWMPOW or PWMDRV terminal.

Please refer electrical characteristic page.6 and function (page.17).

7inch panel

Battery

Batter

10F

RTR020N 05

68m

ON/OFF

100Hz~1kHz

PWM

Power

1F

4.7H

2.2F *

SENSP

SENSN

GND

SW

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

4LED x 6 para lle l

VDET

RTR020N05

FAILSEL

LED1

LED2

LED3

LED4

LED5

ISETL

ISETH

TEST

24k

LED6

Each 20m

Ca n b e se t u p to e a c h 1 0 ~ 2 5 m A

100Hz~1kHz

68m

PWM

10F

Power

ON/OFF

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

GND

VBAT

VREG

GND

FAILSEL

ISETH

ISETL

TEST

GNDGND

24k

Figure 52. 4 series×6 parallel, LED current 20mA setting Figure 53. 8 series×3 parallel, LED current 40mA setting

Power control PWM application Power control PWM application

5inch panel

8LED x 2 para lle l

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Each 20mA

Ca n b e se t u p to e a c h 1 0 ~ 2 5 m A

10F

RTR020N05

82m

ON/OFF

100Hz~1kHz

PWM

Power

Batter

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

GND

VBAT

VREG

GND

FAILSEL

ISETH

ISETL

TEST

GNDGND

24k

10F

RTR020N 05

82m

ON/OFF

100Hz~10kHz

PWM

Battery

Power

1F

4.7H

2.2F *

SENSP

SENSN

GND

SW

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETL

ISETH

TEST

24k

Figure 54. 8 series×2 parallel, LED current 20mA setting Figure 55. 8 series×2 parallel, LED current 40mA setting

Current driver PWM application Power control PWM application

Please select the capacitor which the little bias fluctuation.

*

8LED x 3 para lle l

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Can be set up to each 20~50mA

Each 40mA

8LED x 2 para lle l

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Ca n b e se t u p to e a c h 2 0 ~ 5 0 m A

Each 40mA

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

26/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

y

BD6581GU

Datasheet

• LED current setting controlled ISETH resistor.

19.6k: 24.5mA

24k: 20mA

30k: 16mA

33k: 14.5mA

• Brightness control

• Brightness control

Please input PWM pulse from PWMPOW or PWMDRV terminal.

Please refer electrical characteristic page.6 and function (page.17).

5inch panel

Battery

Batter

10F

RTR020N 05

82m

ON/OFF

100Hz~10kHz

PWM

Power

1F

4.7H

2.2F *

SENSP

SENSN

GND

SW

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

4LED x 4 para lle l

VDET

RTR020N05

FAILSEL

LED1

LED2

LED3

LED4

LED5

ISETL

ISETH

TEST

24k

LED6

Can be set up to each 10~25mA

Each 20mA

100Hz~10kHz

82m

PWM

10F

Power

ON/OFF

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

GND

VBAT

VREG

GND

FAILSEL

ISETH

ISETL

TEST

GNDGND

24k

Figure 56. 4 series×4 parallel, LED current 20mA setting Figure 57. 8 series×2 parallel, LED current 60mA setting

Current driver PWM application Current driver PWM application

3LED x 5 para lle l

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Ca n b e se t u p to e a c h 1 0 ~ 2 5 m A

Each 20mA

10F

RTR020N 05

82m

ON/OFF

100Hz~1kHz

PWM

Battery

Power

1F

4.7H

2.2F *

SENSP

SENSN

GND

SW

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETL

ISETH

TEST

24k

Figure 58. 3 series×5 parallel, LED current 20mA setting

Power control PWM application

* Please select the capacitor which the little bias fluctuation.

8LED x 2 para lle l

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Ca n b e se t u p to e a c h 3 0 ~ 7 5 m A

Each 60mA

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

27/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

zPWM

y

zPWM

BD6581GU

• LED current setting controlled ISETH resistor.

19.6k: 24.5mA

24k: 20mA

30k: 16mA

33k: 14.5mA

Please select the capacitor which the little bias fluctuation.

*

• Brightness control

Please input PWM pulse from PWMPOW or PWMDRV terminal.

Please refer electrical characteristic page.6 and function (page.17).

For the application of 22V and more For big current LED

Coil power supply

6~30V

Battery

4.7H

10F

2.2F *

RTR020N 05

51m

2.7~22V

IC

power

supply

Power

ON/OFF

200H

SW

1F

1F

GND

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETL

ISETH

TEST

24k

Figure 59. Figure 60.

The separation of less than an IC power supply 5V and the coil power supply

Coil power supply

6~30V

Battery

4.7H

10F

2.2F *

RTR020N 05

51m

2.7~5.5V

IC

power

supply

ON/OFF

200H

Power

SW

1F

1F

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

VREG

GND

VBAT

GND

GND

GND

TEST

FAILSEL

ISETH

Figure 61.

Batter

82m

PWM

10F

Power

ON/OFF

1F

4.7H

2.2F *

SW

SENSP

SENSN

RSTB

PWMPOW

PWMDRV

GND

VBAT

VREG

GND

8LED x 6 parallel

VDET

LED1

LED2

LED3

LED4

LED5

LED6

Can be set up to each 10~25mA

Each 20mA

RTR020N 05

100Hz~10kHz

10LED x 6 parallel

VDET

LED1

LED2

LED3

LED4

LED5

24k

ISETL

LED6

Can be set up to each 10~25mA

Each 20mA

Please select the capacitor which the little bias fluctuation.

*

FAILSEL

ISETH

ISETL

TEST

GNDGND

24k

8LED x 1 parallel

VDET

LED1

LED2

LED3

LED4

LED5

LED6

120mA

Can be set up to 60~150mA

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

28/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

A

BD6581GU

Control LED current to charged D/A voltage.

Show application example and typ control.

Please decide final value after you evaluated application, characteristic.

VDET

LED1

LED2

LED3

LED4

LED5

LED6

D/A

24k

Each 20mA

8LED x 6 parallel

LED current =

typ LED current =

10F

RTR020N 05

51m

ON/OFF

Battery

Power

1F

4.7H

2.2F *

SENSP

SENSN

GND

SW

RSTB

PWMPOW

PWMDRV

VBAT

VREG

GND

GND

GND

FAILSEL

ISETH

ISETL

TEST

470k

Figure 62. Analog style optical application

Please select the capacitor which the little bias fluctuation.

*

D/A LED current

0.05V 19.4mA

0.2V 14.4mA

0.4V 7.7mA

0.5V 4.4mA

0.6V 1.0mA

0.7V 0mA

ISET voltage

470k

0.6V

470k

ISET voltage -D/

+

24k

0.6V-D/A

+

24k

Datasheet

×800

×800

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

29/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●Operational Notes

(1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can

break down devices, thus making impossible to identify breaking mode such as a short circuit or an open circuit. If any

special mode exceeding the absolute maximum ratings is assumed, considerati on sh ould be g iven to take physical s afet y

measures including the use of fuses, etc.

(2) Operating conditions

These conditions represent a range within which characteristics can be provided approximately as expected. The

electrical characteristics are guaranteed under the conditions of each parameter.

(3) Reverse connection of power supply connector

The reverse connection of power supply connector can break down ICs. Take protective measures against the breakdown due

to the reverse connection, such as mounting an external diode between the power supply and the IC’ s pow er supply terminal.

(4) Power supply line

Design PCB pattern to provide low impedance for the wiring between the power supply and the GND lines. In this regard,

for the digital block power supply and the analog block power supply, even though these power supplies has the same

level of potential, separate the power supply pattern for the digital block from that for the analog block, thus suppressing

the diffraction of digital noises to the analog block power supply resulting from impedanc e common to the wiring patterns.

For the GND line, give consideration to design the patterns in a similar manner.

Furthermore, for all power supply terminals to ICs, mount a capacitor between the power supply and the GND terminal.

At the same time, in order to use an electrolytic capacitor, thoroughly check to be sure the characteristics of the capacitor to be

used present no problem including the occurrence of capacity dropout at a low temperatu re, th us determining the const ant.

(5) GND voltage

Make setting of the potential of the GND terminal so that it will be maintained at the mi nimum in any operating state.

Furthermore, check to be sure no terminals are at a potential low er than the GND voltage in cluding an actual electric tran sient.

(6) Short circuit between terminals and erroneous mounting

In order to mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs. Erroneous mounting can

break down the ICs. Furthermore, if a short circuit occurs due to foreign matters entering bet ween terminals or between

the terminal and the power supply or the GND terminal, the ICs can break down.

(7) Operation in strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

(8) Inspection with set PCB

On the inspection with the set PCB, if a capacitor is connected to a low-impedance IC terminal, the IC can suffer stress.

Therefore, be sure to discharge from the set PCB by each process. Furthermore, in order to mount or dismount the set

PCB to/from the jig for the inspection process, be sure to turn OFF the power supply and then mount the set PCB to the

jig. After the completion of the inspection, be sure to turn OFF the power supply and then dismo unt it from the jig. In

addition, for protection against static electricity, establish a ground for the assembly process and pay thorough attention

to the transportation and the storage of the set PCB.

(9) Input terminals

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the

parasitic element can cause interference with circuit operation, thus resulting in a malfunct ion and then breakdo wn of the

input terminal. Therefore, pay thorough attention not to handle the input terminals, such as to apply to the input terminals

a voltage lower than the GND respectively, so that any parasitic element will operate. Furthermore, do not apply a voltage

to the input terminals when no power supply voltage is applied to the IC. In addition, even if the power supply voltage is

applied, apply to the input terminals a voltage lower than the power supply voltage or within the guaranteed value of

electrical characteristics.

(10) Ground wiring pattern

If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND

pattern from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that

resistance to the wiring pattern and voltage fluctuations due to a large current will cause no fluctuations in voltages of the

small-signal GND. Pay attention not to cause fluctuations in the GND wiring pattern of external parts as well.

(11) External capacitor

In order to use a ceramic capacitor as the external capacitor, determine the constant with consideration given to a

degradation in the nominal capacitance due to DC bias and chan

(12) Thermal shutdown circuit (TSD)

When junction temperatures become 175°C (typ) or higher, the thermal shutdown circuit operates and turns a switch OFF.

The thermal shutdown circuit, which is aimed at isolating the LSI from thermal runaway as much as possible, is not aimed

at the protection or guarantee of the LSI. Therefore, do not continuously use the LSI with this circuit operating or use the

LSI assuming its operation.

(13) Thermal design

Perform thermal design in which there are adequate margins by taking into account the permissible dissipation (Pd) in

actual states of use.

(14) Selection of coil

Select the low DCR inductors to decrease power loss for DC/DC converter.

ges in the capacitance due to temperature, etc.

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

30/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●Ordering Information

B D 6 5 8 1 G U - E 2

Datasheet

Part Number

Package

GU: VCSP85H2

●Marking Diagram

VCSP85H2

(TOP VIEW)

BD6581

Figure 63 Marking Diagram

●Physical Dimension Tape and Reel Information

VCSP85H2

(BD6581GU)

1PIN MARK

2.60±0.1

24-φ0.3±0.05

0.05

BA

(φ0.15)INDEX POST

0.3±0.1

E

D

C

B

A

1 2345

P=0.5× 4

0.08 S

2.60±0.1

1.0MAX

0.25±0.1

S

A

0.3±0.1

B

P=0.5× 4

(Unit : mm)

Figure 64 VCSP85H2 (BD6581GU)

Packaging and forming specification

E2: Embossed tape and reel

1PIN MARK

Part Number Marking

LOT Number

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

3000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

31/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

BD6581GU

●Revision History

Date Revision Changes

03.Dec.2012 001 New Release

Datasheet

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

TSZ22111・15・001

32/32

TSZ02201-0G3G0C400170-1-2

03.Dec.2012 Rev.001

Datasheet

Datasheet

Notice

●General Precaution

1) Before you use our Products, you are requested to carefully read this document and fully understand its contents.

ROHM shall not be in any way responsible or liable for failure, malfunction or accident arising from the use of a ny

ROHM’s Products against warning, caution or note contained in this document.

2) All information contained in this document is current as of the issuing date and subject to change without any prior

notice. Before purchasing or using ROHM’s Products, please confirm the latest information with a ROHM sales

representative.

●Precaution on using ROHM Products

1) Our Products are designed and manufactured for application in ordinary electronic equipments (such as AV equipment,

OA equipment, telecommunication equipment, home electronic appliances, amusement equipment, etc.). If you

intend to use our Products in devices requiring extremely high reliability (such as medical equipment, transport

equipment, traffic equipment, aircraft/spacecraft, nuclear power controllers, fuel controllers, car equipment including car

accessories, safety devices, etc.) and whose malfunction or failure may cause loss of human life, bodily injury or

serious damage to property (“Specific Applications”), please consult with the ROHM sales representative in advance.

Unless otherwise agreed in writing by ROHM in advance, ROHM shall not be in any way respons ible or liable for any

damages, expenses or losses incurred by you or third parties arising from the use of any ROHM’s Products for Specific

Applications.

2) ROHM designs and manufactures its Products subject to strict quality control system. However, semiconductor

products can fail or malfunction at a certain rate. Please be sure to implement, at your own responsibilities, adequate

safety measures including but not limited to fail-safe design against the physical injury, damage to any propert y, which

a failure or malfunction of our Products may cause. The following are examples of safety measures:

[a] Installation of protection circuits or other protective devices to improve system safety

[b] Installation of redundant circuits to reduce the impact of single or multiple circuit failure

3) Our Products are designed and manufactured for use under standard conditions and not under any special or

extraordinary environments or conditions, as exemplified below. Accordingly, ROHM shall not be in any way

responsible or liable for any damages, expenses or losses arising from the use of any ROHM’s Products under any

special or extraordinary environments or conditions. If you intend to use our Products under any special or

extraordinary environments or conditions (as exemplified below), your independent verification and confirmation of

product performance, reliability, etc, prior to use, must be necessary:

[a] Use of our Products in any types of liquid, including water, oils, chemicals, and organic solvents

[b] Use of our Products outdoors or in places where the Products are exposed to direct sunlight or dust

[c] Use of our Products in places where the Products are exposed to sea wind or corrosive gases, including Cl

H

2S, NH3, SO2, and NO2

[d] Use of our Products in places where the Products are exposed to static electricity or electromagnetic waves

[e] Use of our Products in proximity to heat-producing components, plastic cords, or other flammable items

[f] Sealing or coating our Products with resin or other coating materials

[g] Use of our Products without cleaning residue of flux (even if you use no-clean type fluxes, cleaning residue of

flux is recommended); or Washing our Products by using water or water-solub le cleaning agents for cleaning

residue after soldering

[h] Use of the Products in places subject to dew condensation

4) The Products are not subject to radiation-proof design.

5) Please verify and confirm cha racteristics of the final or mounted products in using the Products.

6) In particular, if a transient load (a large amount of load applied in a short per iod of time, such as pulse) is applied,

confirmation of performance characteristics after on-board mounting is strongly recomm ended. Avoid applying power

exceeding normal rated power; exceeding the power ratin g under steady-state loading condition may negatively affect

product performance and reliability.

7) De-rate Po wer Dissipation (P d) dependi ng on Ambient temperature (T a). When used i n sealed area, confirm the actual

ambient temperature.

8) Confirm that operation temperature is within the specified range described in the product specification.

9) ROHM shall not be in any way responsible or liable for failure induced under dev iant condition from what is defined in

this document.

2,

Notice - Rev.004

© 2013 ROHM Co., Ltd. All rights reserved.

Datasheet

●Precaution for Mounting / Circuit board design

1) When a highly active halogenous (chlor ine, bromine, etc.) flux is used, the residue of flux ma y negatively affect product

performance and reliability.

2) In principle, the reflow soldering method mu st be used; if flow soldering method is preferred, please consult with the

ROHM representative in advance.

For details, please refer to ROHM Mounting specification

●Precautions Regarding Application Examples and External Circuits

1) If change is made to the constant of an external circuit, please allow a sufficient margin considering variations of th e

characteristics of the Products and external components, including transient characteristics, as well as static

characteristics.

2) You agree that application notes, reference designs, and associated data and information contai ned in this document

are presented only as guidance for Products use. Therefore, in case you use such information, you are solely

responsible for it and you must exercise your own independent verification and judgmen t in the use of such information