A

Stepping Motor Driver series

High Voltage Series

Stepping Motor Drivers

BD6422EFV (PARALLEL-IN type)

BD6425, BD6423EFV (CLK-IN type)

●Description

These products are a low power consumption PWM constant current-drive driver of bipolar stepping motor with power

supply’s rated voltage of 45V and rated output current of 1.0A, 1.5A.

●Feature

1) Power supply: one system drive (rated voltage of 45V)

2) Rated output current: 1.0A, 1.5A

3) Low ON resistance DMOS output

4) CLK-IN drive mode (BD6425/6423EFV)

5) Parallel IN drive mode (BD6422EFV)

6) PWM constant current control (other oscillation)

7) Built-in spike noise blanking function (external noise filter is unnecessary)

8) FULL STEP & HALF STEP (two kinds), applicable to QUARTER STEP

9) Current decay mode switching function (4 kinds of FAST/SLOW DECAY ratio)

10) Normal rotation & reverse rotation switching function (BD6425/6423EFV)

11) Power save function

12) Built-in logic input pull-down resistor

13) Power-on reset function(BD6425/6423EFV)

14) Thermal shutdown circuit (TSD)

15) Over current protection circuit (OCP)

16) Under voltage lock out circuit (UVLO)

17) Malfunction prevention at the time of no applied power supply (Ghost Supply Prevention)

18) Electrostatic discharge: 8kV (HBM specification)

19) Microminiature, ultra-thin and high heat-radiation (exposed metal type) HTSSOP package

●Application

serial dot impact printer、sewing machine etc.

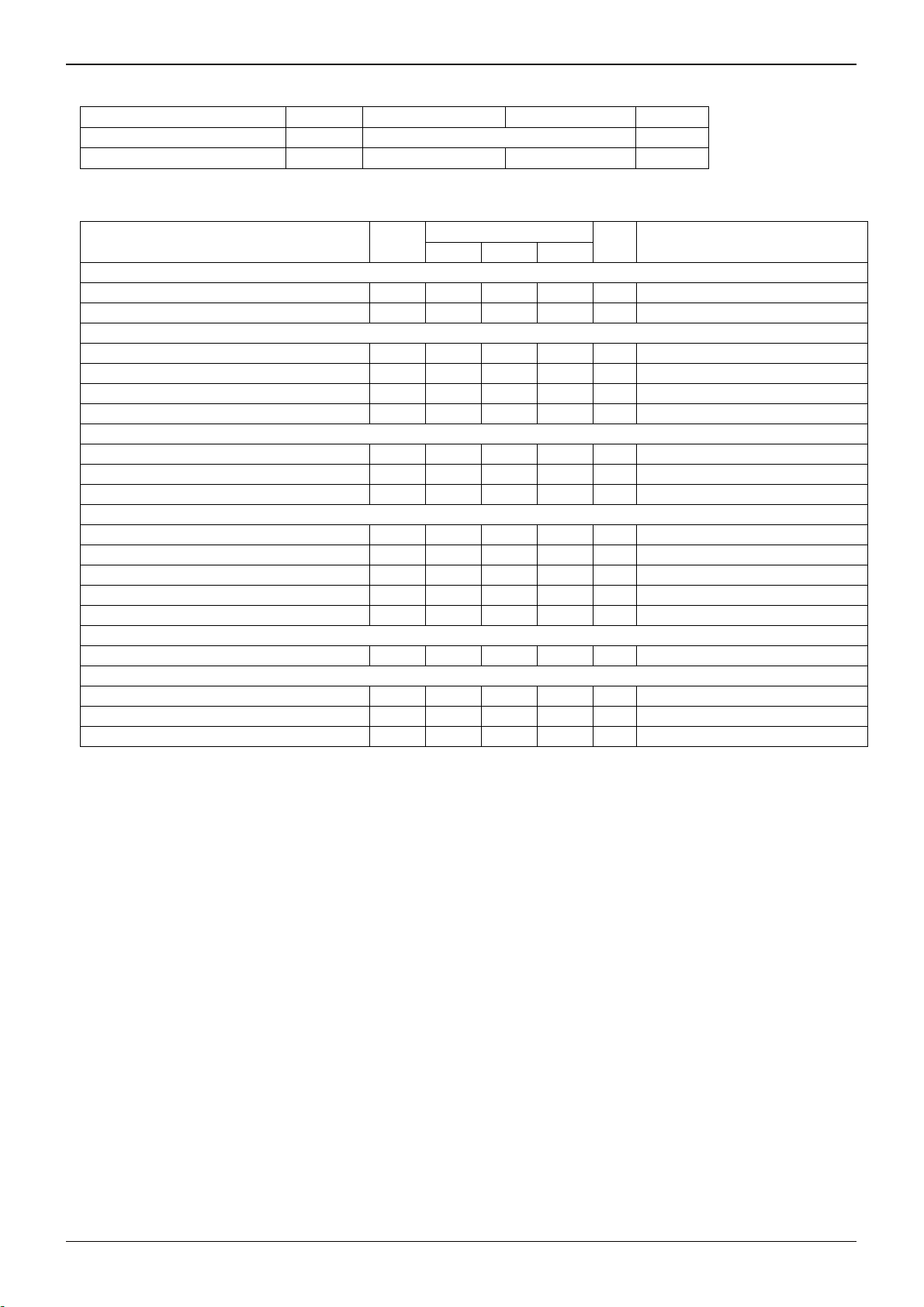

●Absolute maximum ratings(Ta=25℃)

Item Symbol BD6425EFV BD6423/6422EFV Unit

Supply voltage V

Power dissipation Pd

Input voltage for control pin VIN -0.2~+5.5 -0.2~+5.5 V

RNF maximum voltage V

Maximum output current I

Operating temperature range T

Storage temperature range T

Junction temperature T

※1 70mm×70mm×1.6mm glass epoxy board. Derating in done at 11.6mW/℃ for operating above Ta=25℃.

※2 4-layer recommended board. Derating in done at 37.6mW/℃ for operating above Ta=25℃.

※3 70mm×70mm×1.6mm glass epoxy board. Derating in done at 8.8mW/℃ for operating above Ta=25℃.

※4 4-layer recommended board. Derating in done at 32.0mW/℃ for operating above Ta=25℃.

※5 Do not, however exceed Pd, ASO and Tjmax=150℃.

-0.2~+45.0 -0.2~+45.0 V

CC1,2

0.7 0.7 V

RNF

1.5

OUT

-25~+85 -25~+85 ℃

opr

-55~+150 -55~+150 ℃

stg

+150 +150 ℃

jmax

1

※

1.45

1.1

2

※

4.70

4.0

5

※

1.0

3

※

4

※

5

※

A/phase

No.12009EAT06

W

W

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

1/8

2012.02 - Rev.

BD6422EFV, BD6423EFV, BD6425EFV

A

●Operating conditions( (Ta= -25~+85℃)

Item Symbol BD6425EFV BD6423/6422EFV Unit

Supply voltage V

Maximum Output current (DC) I

※6 Do not however exceed Pd, ASO.

19~42 V

CC1,2

1.2

OUT

6

※

0.7

●Electrical characteristics (Unless otherwise specified Ta=25℃、V

Item Symbol

Min. Typ. Max.

Whole

Circuit current at standby

Circuit current

I

CCST

ICC - 2.0 5.0 mA PS=H, VREF=3V

- 1.0 2.5 mA PS=L

Control input

V

H level input voltage

L level input voltage

H level input current

L level input current

2.0 - - V

INH

V

- - 0.8 V

INL

I

35 50 100 μAVIN=5V

INH

I

-10 0 - μAVIN=0V

INL

Output (OUT1A, OUT1B, OUT2A, OUT2B)

Output ON resistance(BD6425EFV)

Output ON resistance(BD6423/6422EFV)

Output leak current

RON - 1.10 1.43 Ω I

R

- 2.00 2.60 Ω I

ON

I

- - 10 μA

LEAK

Current control

RNFXS input current (BD6425EFV)

RNFX input current

VREF input current

VREF input voltage range

Minimum on time (Blank time)

I

RNFS

I

RNF

I

VREF

V

REF

t

ONMIN

-2.0 -0.1 - μA RNFXS=0V

-40 -20 - μA RNFX=0V

-2.0 -0.1 - μAVREF=0V

0 - 3.0 V

0.5 1.5 3.0 μs C=470pF, R=82kΩ

BD6425/6423EFV

Comparator threshold

V

CTH

0.57 0.60 0.63 V VREF=3V

BD6422EFV

Comparator threshold 100% V

Comparator threshold 67% V

Comparator threshold 33% V

CTH100

CTH67

CTH33

0.57 0.60 0.63 V VREF=3V, (I0X,I1X)=(L,L)

0.38 0.40 0.42 V VREF=3V, (I0X,I1X)=(H,L)

0.18 0.20 0.22 V VREF=3V, (I0X,I1X)=(L,H)

CC1,2

=37V)

Limit

6

※

A/phase

Unit Condition

=1.0A,Sum of upper and lower

OUT

=0.5A,Sum of upper and lower

OUT

Technical Note

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

2/8

2012.02 - Rev.

BD6422EFV, BD6423EFV, BD6425EFV

A

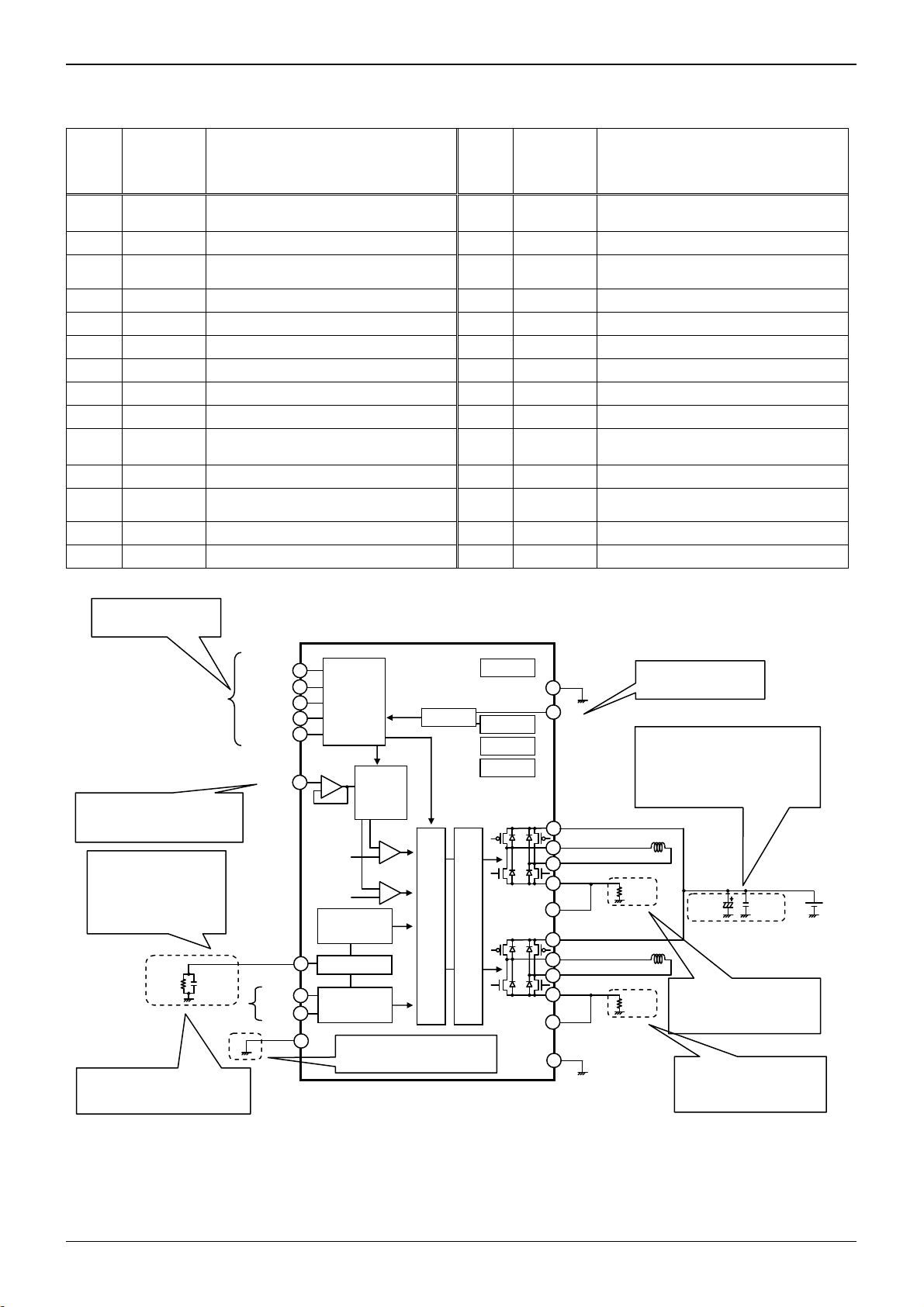

●Terminal function and Application circuit diagram

1) BD6425EFV

Pin

Pin name Function

No.

Technical Note

Pin

Pin name Function

No.

1 GND Ground terminal 15 CLK

Clock input terminal for advancing the

electrical angle.

2 OUT1B H bridge output terminal 16 CW_CCW Motor rotating direction setting terminal

3 RNF1

Connection terminal of resistor for output

current detection

17 TEST

Terminal for testing

(used by connecting with GND)

4 RNF1S Input terminal of current limit comparator 18 MODE0 Motor excitation mode setting terminal

5 OUT1A H bridge output terminal 19 MODE1 Motor excitation mode setting terminal

6 NC Non connection 20 ENABLE Power supply terminal

7 VCC1 Power supply terminal 21 NC Non connection

8 NC Non connection 22 VCC2 Power supply terminal

9 GND Ground terminal 23 NC Non connection

10 CR

Connection terminal of CR for setting

chopping frequency

24 OUT2A H bridge output terminal

11 DEC1 Current decay mode setting terminal 25 RNF2S Input terminal of current limit comparator

12 DEC2 Current decay mode setting terminal 26 RNF2

Connection terminal of resistor for output

current detection

13 VREF Output current value setting terminal 27 OUT2B H bridge output terminal

14 PS Power save terminal 28 NC Non connection

Logic input terminal.

Set the output currenet.

Input by resistor divison.

Set the chopping

frequency.

Setting range is

C:330pF~1500pF

R:15kΩ~200kΩ

82kΩ

Logic input terminal.

for setting current decay mode

470pF

CW_CCW

MODE1

ENABLE

VREF 13

CR

TEST

15 CLK

16

18 MODE0

19

20

10

11 DEC1

12 DEC2

17

Translator

+

-

RNF1

RNF2

Blank time

PWM control

Mix decay

2bit DAC

+

-

+

-

OSC

control

Terminal for testing.

Please connect to GND.

RESET

Control logic

Regulator

Predriver

UVLO

TSD

OCP

9

14

7

5

2

3

4

22

24

27

26

25

1

GND

PS

VCC1

OUT1A

OUT1B

RNF1

RNF1S

VCC2

OUT2A

OUT2B

RNF2

RNF1S

GND

Power save terminal.

Bypass capacitor.

Setting range is

100uF~470uF(electrolytic)

0.01uF~0.1uF(multilayer ceramic etc.)

Be sure to short VCC1 & VCC2.

0.3Ω

0.3Ω

100uF

Resistor for current. detecting.

Setting range is

0.2Ω~0.4Ω.

Resistor for current. detecting.

Setting range is

0.2Ω~0.4Ω.

0.1uF

Fig.1 Block diagram & Application circuit diagram of BD6425EFV

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

3/8

2012.02 - Rev.

BD6422EFV, BD6423EFV, BD6425EFV

A

R

K

Technical Note

2) BD6423EFV

Pin

No.

Pin name Function

1 GND Ground terminal 13 CLK

Pin

No.

Pin name Function

Clock input terminal

for advancing the electrical angle.

2 OUT1B H bridge output terminal 14 CW_CCW Motor rotating direction setting terminal

3 RNF1

Connection terminal of resistor for output

current detection

15 TEST

Terminal for testing

(used by connecting with GND)

4 OUT1A H bridge output terminal 16 MODE0 Motor excitation mode setting terminal

5 VCC1 Power supply terminal 17 MODE1 Motor excitation mode setting terminal

6 NC Non connection 18 ENABLE Output enable terminal

7 GND Ground terminal 19 NC Non connection

8 CR

9 DEC1

10 DEC2

Connection terminal of CR for setting

PWM frequency

Current decay mode setting terminal

Current decay mode setting terminal

20 VCC2 Power supply terminal

21 OUT2A H bridge output terminal

22 RNF2

Connection terminal of resistor for output

current detection

11 VREF Output current value setting terminal 23 OUT2B H bridge output terminal

12 PS Power save terminal 24 NC Non connection

Logic input terminal

Setting output current

Input by resistance division.

Set the PWM frequency.

Setting range is

C:330pF~1500pF

R:15kΩ~200kΩ

Logic input terminal

for setting current decay mode

82kΩ

470pF

CW_CCW

MODE1

ENABLE

VREF 11

C

TEST

13 CL

14

16 MODE0

17

18

8

9 DEC1

10 DEC2

15

Translator

+

-

2bit DAC

RNF1

RNF2

Blank time

PWM control

OSC

Mix decay

control

Regulator

RESET

+

-

+

-

Control logic

UVLO

TSD

OCP

Predriver

7

12

5

4

2

3

20

21

23

22

1

GND

PS

VCC1

OUT1A

OUT1B

RNF1

VCC2

OUT2A

OUT2B

RNF2

GND

Power save terminal.

Bypass capacitor.

Setting range is

100uF~470uF(electrolytic)

0.01uF~0.1uF(multilayer ceramic etc.)

Be sure to short VCC1 & VCC2.

0.5Ω

100uF

Resistor for current. detecting.

0.5Ω

Setting range is

0.4Ω~0.8Ω.

Terminal for testing.

Please connect to GND.

Resistor for current. detecting.

Setting range is

0.4Ω~0.8Ω.

Fig.2 Block diagram & Application circuit diagram of BD6423EFV

0.1uF

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

4/8

2012.02 - Rev.

BD6422EFV, BD6423EFV, BD6425EFV

A

equency

R

3) BD6422EFV

Pin

Pin name Function

No.

Technical Note

Pin

Pin name Function

No.

1 GND Ground terminal 13 PHASE1

Phase selection terminal

2 OUT1B H bridge output terminal 14 I01 VREF division ratio setting terminal

3 RNF1

Connection terminal of resistor for output

current detection

15 I11

VREF division ratio setting terminal

4 OUT1A H bridge output terminal 16 PHASE2 Phase selection terminal

5 VCC1 Power supply terminal 17 I02

6 NC Non connection 18 I12

VREF division ratio setting terminal

VREF division ratio setting terminal

7 GND Ground terminal 19 NC Non connection

8 CR

9 DEC1

10 DEC2

Connection terminal of CR for setting

PWM fr

Current decay mode setting terminal

Current decay mode setting terminal

20 VCC2

Power supply terminal

21 OUT2A H bridge output terminal

22 RNF2

Connection terminal of resistor for output

current detection

11 VREF Output current value setting terminal 23 OUT2B H bridge output terminal

12 PS Power save terminal 24 NC Non connection

Logic input terminal.

Setting output current.

Input by resistance division.

Set the PWM frequency.

Setting range is

C:330pF~1500pF

R:15kΩ~200kΩ

82kΩ

Logic input terminal.

for setting current decay mode

470pF

16 PHASE2

I01

I11

I02

I12

18

VREF 11

C

13 PHASE1

14

15

17

RNF1

RNF2

8

9 DEC1

10 DEC2

+

-

2bit DAC

Blank time

PWM control

OSC

Mix decay

control

Regulator

UVLO

TSD

+

-

+

-

Control Logic

OCP

Predriver

7

12

5

4

2

3

20

21

23

22

1

GND

PS

VCC1

OUT1A

OUT1B

RNF1

VCC2

OUT2A

OUT2B

RNF2

GND

Power save terminal.

Bypass capacitor.

Setting range is

100uF~470uF(electrolytic)

0.01uF~0.1uF(multilayer ceramic etc.)

Be sure to short VCC1 & VCC2.

0.5Ω

100uF

Resistor for current. detecting.

0.5Ω

Resistor for current. detecting.

Setting range is

0.4Ω~0.8Ω.

Setting range is

0.4Ω~1.0Ω.

Fig.3 Block diagram & Application circuit diagram of BD6422EFV

0.1uF

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

5/8

2012.02 - Rev.

BD6422EFV, BD6423EFV, BD6425EFV

A

●Usage Notes

(1) Absolute maximum ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can

break down the devices, thus making impossible to identify breaking mode, such as a short circuit or an open circuit. If

any over rated values will expect to exceed the absolute maximum ratings, consider adding circuit protection devices,

such as fuses.

(2) Connecting the power supply connector backward

Connecting of the power supply in reverse polarity can damage IC. Take precautions when connecting the power supply

lines. An external direction diode can be added.

(3) Power supply Lines

Design PCB layout pattern to provide low impedance GND and supply lines. To obtain a low noise ground and supply line,

separate the ground section and supply lines of the digital and analog blocks. Furthermore, for all power supply terminals

to ICs, connect a capacitor between the power supply and the GND terminal. When applying electrolytic capacitors in the

circuit, not that capacitance characteristic values are reduced at low temperatures.

(4) GND Potential

The potential of GND pin must be minimum potential in all operating conditions.

(5) Metal on the backside (Define the side where product markings are printed as front)

The metal on the backside is shorted with the backside of IC chip therefore it should be connected to GND. Be aware that

there is a possibility of malfunction or destruction if it is shorted with any potential other than GND.

(6) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating conditions.

Users should be aware that these products have been designed to expose their frames at the back of the package, and

should be used with suitable heat dissipation treatment in this area to improve dissipation. As large a dissipation pattern

should be taken as possible, not only on the front of the baseboard but also on the back surface. It is important to

consider actual usage conditions and to take as large a dissipation pattern as possible.

(7) Inter-pin shorts and mounting errors

When attaching to a printed circuit board, pay close attention to the direction of the IC and displacement. Improper

attachment may lead to destruction of the IC. There is also possibility of destruction from short circuits which can be

caused by foreign matter entering between outputs or an output and the power supply or GND.

(8) Operation in a strong electric field

Use caution when using the IC in the presence of a strong electromagnetic field as doing so may cause the IC to

malfunction.

(9) ASO

When using the IC, set the output transistor so that it does not exceed absolute maximum ratings or ASO.

(10) Thermal shutdown circuit

The IC has a built-in thermal shutdown circuit (TSD circuit). If the chip temperature becomes Tjmax=150℃, and higher,

coil output to the motor will be open. The TSD circuit is designed only to shut the IC off to prevent runaway thermal

operation. It is not designed to protect or indemnify peripheral equipment. Do not use the TSD function to protect

peripheral equipment.

TSD on temperature [℃] (Typ.) Hysteresis Temperature [℃] (Typ.)

175 25

(11) Inspection of the application board

During inspection of the application board, if a capacitor is connected to a pin with low impedance there is a possibility

that it could cause stress to the IC, therefore an electrical discharge should be performed after each process. Also, as a

measure again electrostatic discharge, it should be earthed during the assembly process and special care should be

taken during transport or storage. Furthermore, when connecting to the jig during the inspection process, the power

supply should first be turned off and then removed before the inspection.

Technical Note

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

6/8

2012.02 - Rev.

BD6422EFV, BD6423EFV, BD6425EFV

A

P

iti

P

iti

Technical Note

(12) Input terminal of IC

This IC is a monolithic IC, and between each element there is a P+ isolation for element partition and a P substrate.

This P layer and each element’s N layer make up the P-N junction, and various parasitic elements are made up.

For example, when the resistance and transistor are connected to the terminal as shown in figure 4,

○When GND>(Terminal A) at the resistance and GND>(Terminal B) at the transistor (NPN),

the P-N junction operates as a parasitic diode.

○Also, when GND>(Terminal B) at the transistor (NPN)

The parasitic NPN transistor operates with the N layers of other elements close to the aforementioned

parasitic diode.

Because of the IC’s structure, the creation of parasitic elements is inevitable from the electrical potential relationship. The

operation of parasitic elements causes interference in circuit operation, and can lead to malfunction and destruction.

Therefore, be careful not to use it in a way which causes the parasitic elements to operate, such as by applying voltage

that is lower than the GND (P substrate) to the input terminal.

Pin A

Resistor Transistor (NPN)

Pin B

C

Pin A

B

E

Pin B

C

Parasitic element

+

N

P

P

P

P substrate

GND

+

N N

aras

element

N

c

P+ P

Parasitic element

N

GND

+

P

P substrate

N

GND

B

E

Other adjacent elements

Fig. 4 Pattern Diagram of Parasitic Element

(13) Ground Wiring Patterns

When using both small signal and large current GND patterns, it is recommended to isolate the two ground patterns,

placing a single ground point at the application's reference point so that the pattern wiring resistance and voltage

variations caused by large currents do not cause variations in the small signal ground voltage. Be careful not to change

the GND wiring pattern potential of any external components, either.

(14) TEST Terminal (BD6425/6423EFV)

Be sure to connect TEST pin to GND.

GND

aras

element

c

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

7/8

2012.02 - Rev.

BD6422EFV, BD6423EFV, BD6425EFV

A

●Ordering part number

Technical Note

B D 6 4 2 2 E F V - E 2

形名

HTSSOP-B24

HTSSOP-B28

7.6±0.2

1.0MAX

6.4±0.2

0.625

1.0MAX

(MAX 8.15 include BURR)

5.6±0.1

0.325

0.85±0.05

0.65

0.08±0.05

(MAX 10.05 include BURR)

4.4±0.1

0.65

0.08±0.05

0.85±0.05

7.8±0.1

(5.0)

24 13

(3.4)

112

1PIN MARK

S

0.08

+0.05

9.7±0.1

(5.5)

0.24

1PIN MARK

+0.05

0.24

-

0.04

0.08

-

0.04

1528

(2.9)

141

S

0.08 S

M

0.08

パッケージ

EFV=HTSSOP-B24(BD6423EFV

/BD6422EFV)

EFV=HTSSOP-B28(BD6425EFV)

<Tape and Reel information>

4°

S

M

4

°

+

6°

−

4°

0.53±0.15

+0.05

0.17

-

0.03

(Unit : mm)

+

6

°

−4°

0.5±0.15

+0.05

0.17

-

0.03

(Unit : mm)

Quantity

Direction

1.0±0.2

of feed

<Tape and Reel information>

Quantity

1.0±0.2

Direction

of feed

Embossed carrier tape (with dry pack)Tape

2000pcs

E2

()

Embossed carrier tape (with dry pack)Tape

2500pcs

E2

()

The direction is the 1pin of product is at the upper left when you hold

reel on the left hand and you pull out the tape on the right hand

Reel

The direction is the 1pin of product is at the upper left when you hold

reel on the left hand and you pull out the tape on the right hand

Reel

包装、フォーミング仕様

E2: リール状エンボステーピング

1pin

∗

1pin

∗

Direction of feed

Order quantity needs to be multiple of the minimum quantity.

Direction of feed

Order quantity needs to be multiple of the minimum quantity.

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

8/8

2012.02 - Rev.

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes effor ts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injur y, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2012 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...