Page 1

For brush motors

H-bridge drivers

(18V max.)

BD6220, BD6221, BD6222, BD6225, BD6226, BD6227

zOverview

These H-bridge drivers are full bridge drivers for brush motor applications. Each IC can operate at a wide range of

power-supply voltages (from 3V to 36V), supporting output currents of up to 2A. MOS transistors in the output stage allow

for PWM signal control, while the integrated VREF voltage control function of previous models offers direct replacement of

deprecated motor driver ICs. These highly efficient H-bridge driver ICs facilitate low-power consumption design.

zFeatures

1) Built-in, selectable one channel or two channels configuration

2) Low standby current

3) Supports PWM control signal input (20kHz to 100kHz)

4) VREF voltage setting pin enables PWM duty control

5) Cross-conduction prevention circuit

6) Four protection circuits provided: OCP, OVP, TSD and UVLO

zApplications

VCR; CD/DVD players; audio-visual equipment; optical disc drives; PC peripherals;

car audios; car navigation systems; OA equipments

zLine up matrix

TECHNICAL NOTE

Rating voltage Channels

7V

18V

36V

* Packages; F:SOP8, FV: SSOPB24, HFP:HRP7, FP:HSOP25, FM:HSOPM28

1ch

2ch

1ch

2ch

1ch

2ch

Maximum output current

0.5A 1.0A 2.0A

BD6210

HFP / F

BD6215

FV / FP

BD6220

HFP / F

BD6225

FV / FP

BD6230

HFP / F

BD6235

FV / FP

BD6211

HFP / F

BD6216

FP / FM

BD6221

HFP / F

BD6226

FP / FM

BD6231

HFP / F

BD6236

FP / FM

BD6212

HFP / FP

BD6217

FM

BD6222

HFP / FP

BD6227

FM

BD6232

HFP / FP

BD6237

FM

Aug.2007

Page 2

zAbsolute maximum ratings (Ta=25°C)

Parameter Symbol Ratings Unit

Supply voltage VCC 18 V

Output current IOMAX 0.5 *1 / 1.0 *2 / 2.0 *3 A

All other input pins VIN -0.3 ~ VCC V

Operating temperature TOPR -40 ~ +85 °C

Storage temperature TSTG -55 ~ +150 °C

Power dissipation Pd 0.687 *4 / 0.98 *5 / 1.4 *6 / 1.45 *7 / 2.2 *8 W

Junction temperature Tjmax 150 °C

*** Notes: All voltages are with respect to ground.

*1 BD6220 / BD6225. Do not, exceed Pd or ASO.

*2 BD6221 / BD6226. Do not, exceed Pd or ASO.

*3 BD6222 / BD6227. Do not, exceed Pd or ASO.

*4 SOP8 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 5.5mW/°C above 25°C.

*5 SSOPB24 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 7.8mW/°C above 25°C.

*6 HRP7 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 11.2mW/°C above 25°C.

*7 HSOP25 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 11.6mW/°C above 25°C.

*8 HSOPM28 package. Mounted on a 70mm x 70mm x 1.6mm FR4 glass-epoxy board with less than 3% copper foil. Derated at 17.6mW/°C above 25°C.

zOperating conditions (Ta=25°C)

Parameter Symbol Conditions Unit

Supply voltage VCC 6 ~ 15 V

VREF voltage VREF 3 ~ 15 V

z Electrical characteristics (Unless otherwise specified, Ta=25°C and VCC=VREF=12V)

Limits

Parameter Symbol

Unit Conditions

Min. Typ. Max.

Supply current (1ch) ICC 0.8 1.3 2.5 mA Forward / Reverse / Brake

Supply current (2ch) ICC 1.3 2.0 3.5 mA Forward / Reverse / Brake

Stand-by current ISTBY - 0 10 µA Stand-by

Input high voltage VIH 2.0 - - V

Input low voltage VIL - - 0.8 V

Input bias current IIH 30 50 100 µA VIN=5.0V

Output ON resistance *1 RON 1.0 1.5 2.5 Ω IO=0.25A, vertically total

Output ON resistance *2 RON 1.0 1.5 2.5 Ω IO=0.5A, vertically total

Output ON resistance *3 RON 0.5 1.0 1.5 Ω IO=1.0A, vertically total

VREF bias current IVREF -10 0 10 µA VREF=VCC

Carrier frequency FPWM 20 25 35 kHz VREF=9V

Input frequency range FMAX 20 - 100 kHz FIN / RIN

*1 BD6220 / BD6225

*2 BD6221 / BD6226

*3 BD6222 / BD6227

2/16

Page 3

z Electrical characteristic curves (Reference data)

2.0

1.5

1.0

Circuit Current: Icc [mA]

0.5

6 9 12 15 18

85°C

25°C

-40°C

Supply Voltage: Vcc [V]

8

A]

µ

[

6

STBY

4

2

Stand-by Current: I

0

6 9 12 15 18

Supply Voltage: Vcc [V]

-40°C

25°C

85°C

1.5

-40°C

25°C

85°C

1.0

0.5

0.0

Internal Logic: H/L [-]

-0.5

1 1.2 1.4 1.6 1.8 2

Input Voltage: VIN [V]

85°C

25°C

-40°C

Fig.1 Supply current (1ch) Fig.2 Stand-by current Fig.3 Input threshold voltage

400

A]

µ

[

300

IH

200

100

Input Bias Current: I

0

85°C

25°C

-40°C

0 6 12 18

Input Voltage: VIN [V]

10

A]

µ

[

5

VREF

0

-5

Input Bias Current: I

-10

012345

Input Voltage: V

REF

[V]

85°C

25°C

-40°C

1.0

0.8

0.6

0.4

0.2

Switching Duty: D [Ton/T]

0.0

0 0.2 0.4 0.6 0.8 1

Input Voltage: V

REF

-40°C

25°C

85°C

/ VCC [V]

Fig.4 Input bias current Fig.5 VREF input bias current Fig.6 VREF - DUTY

(VCC=12V)

40

[kHz]

PWM

30

20

10

Oscillation Frequency: F

6 9 12 15 18

Supply Voltage: VCC [V]

85°C

25°C

-40°C

9

6

3

85°C

25°C

-40°C

Internal signal: Release [V]

0

44.555.56

Supply Voltage: VCC [V]

35

85°C

25°C

28

-40°C

21

14

7

Internal signal: Release [V]

0

20 24 28 32

Supply Voltage: VCC [V]

Fig.7 VCC - Carrier frequency Fig.8 Under voltage lock out Fig.9 Over voltage protection

1.5

1.0

1.5

1.0

85°C

25°C

-40°C

1.5

1.0

85°C

25°C

-40°C

0.5

0.5

0.5

0.0

Internal Logic: H/L [-]

-0.5

125 150 175 200

Junction T em perature: Tj [°C]

0.0

Internal Logic: H/L [-]

-0.5

22.533.54

Load Current / Iomax: Normalized

0.0

Internal Logic: H/L [-]

-0.5

1 1.25 1.5 1.75 2

Load Current / Iomax: Normalized

Fig.10 Thermal shutdown Fig.11 Over current protection (H side) Fig.12 Over current protection (L side)

3/16

Page 4

z Electrical characteristic curves (Reference data) – Continued

0.4

[V]

OUT

0.3

-V

CC

0.2

85°C

25°C

-40°C

[V]

OUT

-V

CC

0.8

0.6

0.4

85°C

25°C

-40°C

[V]

OUT

-V

CC

1.2

0.9

0.6

85°C

25°C

-40°C

0.1

0.2

0.3

Output Voltage: V

0

0 0.1 0.2 0.3 0.4 0.5

Output Current: I

OUT

[A]

Output Voltage: V

0

0 0.2 0.4 0.6 0.8 1

Output Current: I

OUT

[A]

Output Voltage: V

0

0 0.4 0.8 1.2 1.6 2

Output Current: I

OUT

[A]

Fig.13 Output high voltage (0.5A class) Fig.14 Output high voltage (1A class) Fig.15 Output high voltage (2A class)

[V]

OUT

V

CC-

2

1.5

1

-40°C

25°C

85°C

[V]

OUT

V

CC-

2

1.5

1

-40°C

25°C

85°C

[V]

OUT

V

CC-

2

1.5

1

-40°C

25°C

85°C

0.5

Output Voltage:V

0

0 0.1 0.2 0.3 0.4 0.5

Output Current: I

OUT

[A]

0.5

Output Voltage:V

0

0 0.2 0.4 0.6 0.8 1

Output Current: I

OUT

[A]

0.5

Output Voltage:V

0

0 0.4 0.8 1.2 1.6 2

Output Current: I

OUT

[A]

Fig.16 High side body diode (0.5A class) Fig.17High side body diode (1A class) Fig.18 High side body diode (2A class)

0.4

[V]

0.3

OUT

85°C

25°C

-40°C

[V]

OUT

1.2

0.9

85°C

25°C

-40°C

[V]

OUT

1.2

0.9

85°C

25°C

-40°C

0.2

0.6

0.6

0.1

Output Voltage: V

0

0 0.1 0.2 0.3 0.4 0.5

Output Current: I

OUT

[A]

0.3

Output Voltage: V

0

0 0.2 0.4 0.6 0.8 1

Output Current: I

OUT

[A]

0.3

Output Voltage: V

0

0 0.4 0.8 1.2 1.6 2

Output Current: I

OUT

[A]

Fig.19 Output low voltage (0.5A class) Fig.20 Output low voltage (1A class) Fig.21 Output low voltage (2A class)

[V]

OUT

2

1.5

-40°C

25°C

85°C

[V]

OUT

2

1.5

-40°C

25°C

85°C

[V]

OUT

2

1.5

-40°C

25°C

85°C

1

1

1

0.5

Output Voltage: V

0

0 0.1 0.2 0.3 0.4 0.5

Output Current: I

OUT

[A]

0.5

Output Voltage: V

0

0 0.2 0.4 0.6 0.8 1

Output Current: I

OUT

[A]

0.5

Output Voltage: V

0

0 0.4 0.8 1.2 1.6 2

Output Current: I

OUT

[A]

Fig.22 Low side body diode (0.5A class) Fig.23 Low side body diode (1A class) Fig.24 Low side body diode (2A class)

4/16

Page 5

z Block diagram and pin configuration

BD6220F / BD6221F

6 VREF DUTY

PROTECT

RIN

5

CTRL

4

FIN

OUT1 OUT2

Fig.25 BD6220F / BD6221F

OUT1

VCC

VCC

FIN

GND

OUT2

VREF

RIN

Fig.26 SOP8

BD6220HFP / BD6221HFP / BD6222HFP

VREF DUTY

1

PROTECT

FIN

RIN

3

5

CTRL

FIN

GND

OUT1 OUT2

Fig.27 BD6220/21/22HFP

VREF

OUT1

FIN

GND

RIN

OUT2

VCC

Fig.28 HRP7

VCC

3

VCC

2

Pin Name Function

Table 1 BD6220/21F

1 OUT1 Driver output

2 VCC Power supply

8 GND

7 1

3 VCC Power supply

4 FIN Control input (forward)

5 RIN Control input (reverse)

6 VREF Duty setting pin

7 OUT2 Driver output

8 GND Ground

Table 2 BD6220/21/22HFP

VCC

7

Pin Name Function

1 VREF Duty setting pin

2 OUT1 Driver output

GND

4

6 2

3 FIN Control input (forward)

4 GND Ground

5 RIN Control input (reverse)

6 OUT2 Driver output

7 VCC Power supply

FIN GND Ground

5/16

Page 6

A

A

A

A

A

A

z Block diagram and pin configuration – Continued

BD6222FP

VREF DUTY

17

FIN

20

RIN

19

CTRL

6

GND

PROTECT

FIN

GND

12 1

2 13

OUT1 OUT2

VCC

21

22

VCC

23

7

RNF

8

Fig.29 BD6222FP

OUT1

OUT1

NC

NC

NC

GND

GND

RNF

RNF

NC

NC

NC

OUT2

OUT2

NC

NC

VCC

VCC

VCC

FIN

GND

RIN

NC

VREF

NC

NC

NC

Fig.30 HSOP25

BD6225FV

VREFA DUTY

8

FINA

10

RINA

9

GND

19

VREFB DUTY

20

FINB

RINB

22

21

CTRL

CTRL

PROTECT

PROTECT

VCC

23

VCC

24

OUT1A

1

OUT2A

5

RNFA

3

VCC

11

VCC

12

OUT1B

13

OUT2B

17

GND

7

RNFB

15

Fig. 31 BD6225FV

OUT1

RNF

OUT2

GND

VREF

RIN

FIN

VCC

VCC

NC

NC

NC

VCC

VCC

FINB

RINB

VREFB

GND

NC

OUT2B

NC

RNFB

NC

OUT1B

Fig. 32 SSOPB24

Table 3 BD6222FP

Pin Name Function

1,2 OUT1 Driver output

6 GND Small signal ground

7,8 RNF Power stage ground

12,13 OUT2 Driver output

17 VREF Duty setting pin

19 RIN Control input (reverse)

20 FIN Control input (forward)

21 VCC Power supply

22,23 VCC Power supply

FIN GND Ground

Note: All pins not described above are NC pins.

Table 4 BD6225FV

Pin Name Function

1 OUT1A Driver output

3 RNFA Power stage ground

5 OUT2A Driver output

7 GND Small signal ground

8 VREFA Duty setting pin

9 RINA Control input (reverse)

10 FINA Control input (forward)

11 VCC Power supply

12 VCC Power supply

13 OUT1B Driver output

15 RNFB Power stage ground

17 OUT2B Driver output

19 GND Small signal ground

20 VREFB Duty setting pin

21 RINB Control input (reverse)

22 FINB Control input (forward)

23 VCC Power supply

24 VCC Power supply

Note: All pins not described above are NC pins.

6/16

Page 7

A

A

A

A

A

A

A

A

A

A

A

A

z Block diagram and pin configuration – Continued

BD6225FP, BD6226FP/FM

CTRL

PROTECT

VCC

24

VCC

25

OUT1A

1

OUT2A

6

VREFA DUTY

9

FINA

RINA

11

10

GND

20

VREFB DUTY

21

FINB

23

RINB

22

GND

8

PROTECT

CTRL

FIN

GND

RNFA

3

VCC

12

VCC

13

OUT1B

14

OUT2B

19

RNFB

16

Fig. 33 BD6225FP, BD6226FP

OUT1

RNF

OUT2

GND

GND

VREF

RIN

FIN

VCC

VCC

NC

NC

NC

NC

VCC

VCC

FINB

RINB

VREFB

GND

GND

OUT2B

NC

NC

RNFB

NC

OUT1B

Fig. 34 HSOP25

OUT1

RNF

OUT2

GND

NC

NC

NC

NC

VCC

NC

VCC

FINB

RINB

VREFB

GND

GND

GND

VREF

RIN

FIN

VCC

VCC

NC

NC

OUT2B

NC

NC

RNFB

NC

OUT1B

Fig. 35 HSOPM28

Table 5 BD6225F P / BD6226FP

Pin Name Function

1 OUT1A Driver output

3 RNFA Power stage ground

6 OUT2A Driver output

8 GND Small signal ground

9 VREFA Duty setting pin

10 RINA Control input (reverse)

11 FINA Control input (forward)

12 VCC Power supply

13 VCC Power supply

14 OUT1B Driver output

16 RNFB Power stage ground

19 OUT2B Driver output

20 GND Small signal ground

21 VREFB Duty setting pin

22 RINB Control input (reverse)

23 FINB Control input (forward)

24 VCC Power supply

25 VCC Power supply

FIN GND Ground

Note: All pins not described above are NC pins.

Table 6 BD6226FM

Pin Name Function

1 OUT1A Driver output

3 RNFA Power stage ground

6 OUT2A Driver output

8 GND Small signal ground

9 VREFA Duty setting pin

10 RINA Control input (reverse)

11 FINA Control input (forward)

12 VCC Power supply

14 VCC Power supply

15 OUT1B Driver output

17 RNFB Power stage ground

20 OUT2B Driver output

22 GND Small signal ground

23 VREFB Duty setting pin

24 RINB Control input (reverse)

25 FINB Control input (forward)

26 VCC Power supply

28 VCC Power supply

FIN GND Ground

Note: All pins not described above are NC pins.

7/16

Page 8

A

A

A

A

A

A

F

A

A

A

z Block diagram and pin configuration – Continued

BD6227FM

VREFA DUTY

9

FINA

RINA

11

10

GND

22

VREFB DUTY

23

FINB

RINB

25

24

GND

8

PROTECT

CTRL

PROTECT

CTRL

FIN

GND

VCC

26

27

VCC

28

1

OUT1A

2

6

OUT2A

7

3

RNFA

4

VCC

12

13

VCC

14

15

OUT1B

16

20

OUT2B

21

17

RNFB

18

Fig. 36 BD6227FM

OUT1

OUT1

RNF

RNF

OUT2

OUT2

NC

VCC

VCC

VCC

FINB

RINB

VREFB

GND

GND

GND

VRE

GND

RIN

FIN

VCC

VCC

VCC

OUT2B

OUT2B

NC

RNFB

RNFB

OUT1B

OUT1B

Fig. 37 HSOPM28

Table 7 BD6227FM

Pin Name Function

1,2 OUT1A Driver output

3,4 RNF A Power stage ground

6,7 OUT2A Driver output

8 GND Small signal ground

9 VREFA Duty setting pin

10 RINA Control input (reverse)

11 FINA Control input (forward)

12 VCC Power supply

13,14 VCC Power supply

15,16 OUT1B Driver output

17,18 RNFB Power stage ground

20,21 OUT2B Driver output

22 GND Small signal ground

23 VREFB Duty setting pin

24 RINB Control input (reverse)

25 FINB Control input (forward)

26 VCC Power supply

27,28 VCC Power supply

FIN GND Ground

Note: All pins not described above are NC pins.

8/16

Page 9

zFunctional descriptions

1) Operation modes

FIN RIN VREF OUT1 OUT2 Operation

a L L X Hi-Z* Hi-Z* Stand-by (idling)

b H L VCC H L Forward (OUT1 > OUT2)

c L H VCC L H Reverse (OUT1 < OUT2)

d H H X L L Brake (stop)

e PWM L VCC H PWM

f L PWM VCC PWM

g H L Option H PWM

h L H Option PWM

* Hi-Z is the off state of all output transistors. Please note that this is the state of the connected diodes, which differs from that of the mechanical relay.

X : Don’t care

a) Stand-by mode

Stand-by operates independently of the VREF pin voltage. In stand-by mode, all internal circuits are turned off,

including the output power transistors. Motor output goes to high impedance. If the motor is running at the switch to

stand-by mode, the system enters an idling state because of the body diodes. However, when the system switches

to stand-by from any other mode (except the brake mode), the control logic remains in the high state for at least

50µs before shutting down all circuits.

b) Forward mode

This operating mode is defined as the forward rotation of the motor when the OUT1 pin is high and OUT2 pin is low.

When the motor is connected between the OUT1 and OUT2 pins, the current flo ws from OUT1 to OUT2. For

operation in this mode, connect the VREF pin with VCC pin.

c) Reverse mode

This operating mode is defined as the reverse rotation of the motor when the OUT1 pin is low and OUT2 pin is high.

When the motor is connected between the OUT1 and OUT2 pins, the current flo ws from OUT2 to OUT1. For

operation in this mode, connect the VREF pin with VCC pin.

d) Brake mode

This operating mode is used to quickly stop the motor (short circuit brake). It differs from the stand-by mode

because the internal control circuit is operating in the brake mode. Please switch to the stand-by mode (rather than

the brake mode) to save power and reduce consumption.

OFF

OFF

a) Stand-by mode b) Forward mode c) Reverse mode d) Brake mode

M

OFF

OFF

Table 8 Logic table

Forward (PWM control)

Forward (VREF control)

OFF

OFF

ON

ON

ON

OFF

H Reverse (PWM control)

H Reverse (VREF control)

M

Fig.38 Four basic operations (output stage)

M

ON

OFF

OFF

ON

OFF

M

ON

9/16

Page 10

e) f) PWM control mode

The rotational speed of the motor can be controlled by the switching duty when the PWM signal is input to the FIN

pin or the RIN pin. In this mode, the high side output is fixed and the low side output does the switching,

corresponding to the input signal. The switching operates by the output state toggling between "L" and "Hi-Z".

The PWM frequency can be input in the range between 20kHz and 100kHz. Note that control ma y not be attained

by switching on duty at frequencies lower than 20kHz, since the operation functions via the stand-by mode. Also,

circuit operation may not respond correctly when the input signal is higher than 100kHz. To operate in this mode,

connect the VREF pin with VCC pin. In addition, establish a current path for the recovery current from the motor , by

connecting a bypass capacitor (10µF or more is recommended) between VCC and ground.

ON

OFF

M

OFF

ON

ON

OFF

Control input : H Control input : L

Fig.39 PWM control operation (output stage)

FIN

RIN

OUT1

OUT2

Fig.40 PWM control operation (timing chart)

g) h) VREF control mode

The built-in VREF-switching on duty conversion circuit provides switching duty correspon ding to the voltage of the

VREF pin and the VCC voltage. The function offers the same level of control as the high voltage output setting

function in previous models. The on duty is shown by the following equation.

DUTY ≈ VREF [V] / VCC [V]

For example, if VCC voltage is 12V and VREF pin voltage is 9V, the switching on duty is about 75 percent.

However, please note that the switching on duty might be limited by the range of VREF pin voltage (Refer to the

operating conditions, shown on page 2). The PWM carrier frequency in this mode is 25kHz (nominal), and the

switching operation is the same as it is the PWM control modes. When operating in this mode, do not input the

PWM signal to the FIN and RIN pins. In addition, establish a current path for the recovery current from the motor,

by connecting a bypass capacitor (10µF or more is recommended) between VCC and ground.

VCC

VREF

0

FIN

RIN

OUT1

OUT2

Fig.41 VREF control operation (timing chart)

OFF

M

OFF

10/16

Page 11

2) Cross-conduction protection circuit

In the full bridge output stage, when the upper and lower transistors are turned on at the same time, and this condition

exists during the period of transition from high to low, or low to high, a rush current flows from the power supply to

ground, resulting in a loss. This circuit protects against the rush current by providing a dead time (about 400ns,

nominal) at the transition.

3) Output protection circuits

a) Under voltage lock out (UVLO) circuit

To secure the lowest power supply voltage necessary to operate the controller, and to prevent under voltage

malfunctions, a UVLO circuit has been built into this driver. When the power supply voltage falls to 5.0V (nominal)

or below, the controller forces all driver outputs to high impedance. When the voltage rises to 5.5V (nominal) or

above, the UVLO circuit ends the lockout operation and returns the chip to normal operation.

b) Over voltage protection (OVP) circuit

When the power supply voltage exceeds 30V (nominal), the controller forces all driver outputs to high i mpedance.

The OVP circuit is released and its operation ends when the voltage drops back to 25V (nominal) or below. This

protection circuit does not work in the stand-by mode. Also, note that this circuit is supplementary, and thus if it is

asserted, the absolute maximum ra ting will have been ex ceeded. Therefore, do not continue to use the IC after this

circuit is activated, and do not operate the IC in an environment where activation of the circuit is assumed.

c) Thermal shutdown (TSD) circuit

The TSD circuit operates when the junction temperature of the driver exceeds th e preset temperature (175°C

nominal). At this time, the controller forces all driver outputs to high impedance. Since thermal hysteresis is

provided in the TSD circuit, the chip returns to normal operation when the junction temperature falls below the

preset temperature (150°C nominal). Thus, it is a self-returning type circuit.

The TSD circuit is designed only to shut the IC off to prevent thermal runaway. It is not designed to protect the IC or

guarantee its operation in the presence of extreme heat. Do not continue to use the IC after the TSD circuit is

activated, and do not operate the IC in an environment where activation of the circuit is assumed.

d) Over current protection (OCP) circuit

To protect this driver IC from ground faults, power supply line faults and load short circuits, the OCP circuit

monitors the output current for the circuit’s monitoring time (10µs, nominal). When the protection circuit detects an

over current, the controller forces all driver outputs to high impedance during the off time (290µs, nominal). The IC

returns to normal operation after the off time period has elapsed (self-returning type). At the tw o channels type, this

circuit works independently for each channel.

Threshold

Iout

CTRL Input

Internal status

Monitor / Timer

0

mon.

OFF ON

off timer

ON

Fig.42 Over current protection (timing chart)

1 1 /16

Page 12

z Thermal design

Pd [W]

10.0

8.0

6.0

4.0

2.0

0.0

i) Package onl y (copper foi l: 10.5mm x 10. 5m m )

ii ) 2 l ayers P CB (coppe r f o i l : 15 m m x 15m m )

iii) 2 lay er s PCB (c oppe r foil: :70mm x 70 mm)

iv) 4 layers PCB (copper f oi l : 70m m x 70m m )

iv) 7.3W

iii) 5.5W

ii) 2.3W

i) 1.4W

0 25 50 75 100 125 150

AMBIENT TEM PERATURE [°C]

1.5

Pd [W]

i) Package only

ii) Mounted on ROHM standard PCB

(70mm x 70m m x 1. 6mm FR4 glass-epoxy board)

1.0

ii) 0.687W

0.5

i) 0.562W

Pd [W]

1.5

i) Package only

ii) Mounted on ROHM standard PCB

(70mm x 70mm x 1.6m m FR4 glass-epoxy board)

1.0

0.5

ii) 0.976W

i) 0.787W

0.0

0 25 50 75 100 125 150

AMBIENT TEM PERATURE [°C]

0.0

0 25 50 75 100 125 150

AMBIENT TEM PERATURE [°C]

Fig.43 Thermal derating curve Fig.44 Thermal derating curve Fig.45 Thermal derating curve

(SOP8) (SSOPB24) (HRP7)

3

Pd [W]

i) Package only

ii) Mounted on ROHM standard PCB

(70mm x 70mm x 1. 6m m F R4 glass-epoxy board)

2

ii) 1.45W

1

i) 0.85W

0

0 25 50 75 100 125 150

AMBIENT TEMPERATURE [°C]

3

i) Package only

ii) Mounted on ROHM standard PCB

(70mm x 70mm x 1. 6m m F R4 glass-epoxy board)

2

ii) 2.20W

i) 1.80W

Pd [W]

1

0

0 25 50 75 100 125 150

AMBIENT TEMPERATURE [°C]

Table 9 Thermal resistance

Package

θ

[°C/W]

j-a

SOP8 182

SSOPB24 122

HRP7 89.3

HSOP25 86.2

HSOP28 56.8

Mounted on a 70mmx70mmx1.6mm FR4 glass- epoxy

board with less than 3% copper foil.

Fig.46 Thermal derating curve Fig.47 Thermal derating curve

(HSOP25) (HSOPM28)

Thermal design needs to meet the following operating conditions.

In creating the thermal design, sufficient margin must be provided to guarantee the temperature conditions below.

1. The ambient temperature Ta must be 85°C or below

2. The junction temperature Tj must be 150°C or below

The junction temperature Tj can be determined using the following equation.

θ

Tj ≈ Ta +

x Pc [°C]

j-a

The power consumption Pc can be determined using the following equation. Refer to page 4 about V

ON(H)

and V

F(H)

.

Pc ≈ (I

x RON) x (V

OUT

/ VCC) + I

REF

OUT

x (V

ON(H)

+ V

) x (1 - V

F(H)

/ VCC) + VCC x ICC [W]

REF

2

Example using the BD6221F

Conditions: Ta=50°C, VCC=VREF=12V, Iout=0.1A.

The power consumption of the IC and the junction temperature are as follows:

2

Pc ≈ 0.1

x 1.5 + 12 x 1.3m = 30.6mW

Tj ≈ 50 + 182 x 30.6m = 55.6 [°C]

Where the Tjmax parameter is 150°C and the derating is set to 80 percents, the maximum ambient temperature

Tamax is determined as follows.

θ

Ta ≤ Tjmax x 0.8 -

x Pc ≈ 115 [°C]

j-a

In this example, thermal design can be considered satisfactory (meaning that there are no problems in thermal design),

since the system meets the operating temperature conditions.

12/16

Page 13

zInterfaces

FIN

RIN

VCC

100k

100k

VREF

VCC

10k

VCC

OUT1

OUT2

GND

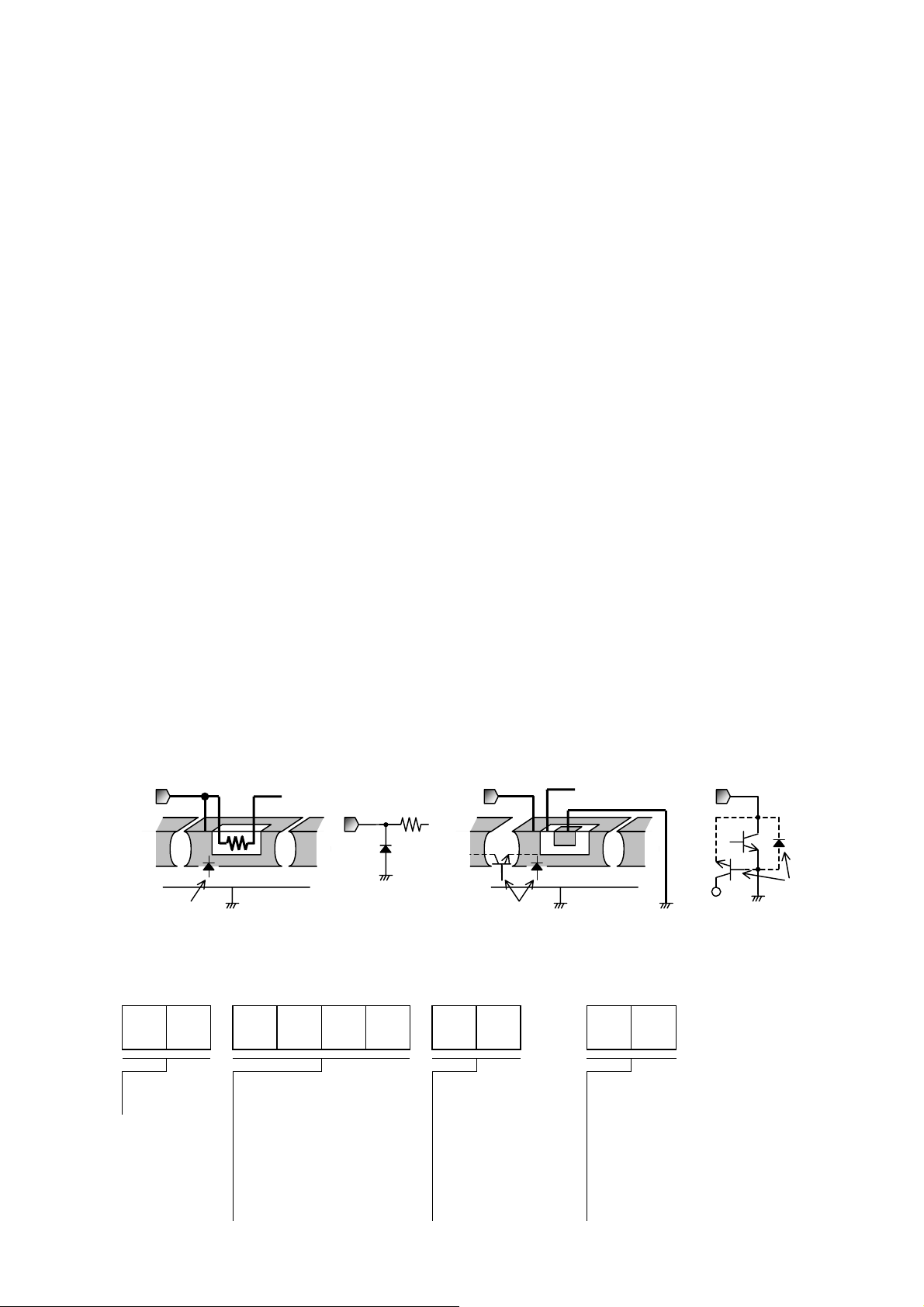

Fig.48 FIN / RIN Fig.49 VREF Fig.50 OUT1 / OUT2 Fig.51 OUT1 / OUT2

(SOP8/HRP7) (SSOPB24/HSOP25/HSOPM28)

zNOTES FOR USE

1) Absolute maximum ratings

Devices may be destroyed when supply voltage or operating tem perature exceeds the absolute maximum rating.

Because the cause of this damage cannot be identified as, for example, a short circuit or an open circuit, it is important

to consider circuit protection measures – such as adding fuses – if any value in excess of absolute maximum ratings is

to be implemented.

2) Connecting the power supply connector backward

Connecting the power supply in reverse polarity can damage the IC. Take precautions against reverse polarity when

connecting the power supply lines, such as adding an external direction diode.

3) Power supply lines

Return current generated by the motor’s Back-EMF requires countermeasures, such as providing a return current path

by inserting capacitors across the power supply and GND. In this case, it is important to conclusively confirm that none

of the negative effects sometimes seen with electrolytic capacitors – including a capacitance drop at low temperatures

- occurs. Also, the connected power supply must have sufficient current absorbing capability. Otherwise, the

regenerated current will increase voltage on the power supply line, which may in turn cause problems with the product,

including peripheral circuits exceeding the absolute maximum rating. To help protect against damage or degradation,

physical safety measures should be taken, such as providing a voltage clamping diode across the power supply and

GND.

4) Electrical potential at GND

Keep the GND terminal potential to the minimum potential under any operating condition. In addition, check to

determine whether there is any terminal that provides voltage below GND, including the voltage during transient

phenomena. When both a small signal GND and high c urrent GND are present, single-point grounding (at the set’s

reference point) is recommended, in order to separate the small signal and high curr ent GND, and to ensure that

voltage changes due to the wiring resistance and high current do not affect the voltage at the small signal GND. In the

same way, care must be taken to avoid changes in the GND wire pattern in any external connected component.

5) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) under actual operating

conditions.

6) Inter-pin shorts and mounting errors

Use caution when positioning the IC for mounting on printed circuit boards. The IC may be damaged if there is any

connection error, or if pins are shorted together.

7) Operation in strong electromagnetic fields

Using this product in strong electromagnetic fields may cause IC malfunctions. Use extreme caution with

electromagnetic fields.

VCC

OUT1

OUT2

RNF

GND

13/16

Page 14

8) ASO - Area of Safety Operation

P

iti

P

iti

When using the IC, set the output transistor so that it does not exceed absolute maximum ratings or ASO.

9) Built-in thermal shutdown (TSD) circuit

The TSD circuit is designed only to shut the IC off to prevent thermal runaway. It is not designed to protect the IC or

guarantee its operation in the presence of extreme heat. Do not continue to use the IC after the TSD circuit is activated,

and do not operate the IC in an environment where activation of the circuit is assumed.

10) Capacitor between output and GND

In the event a large capacitor is connected between the output and GND, if VCC and VIN are short-circuited with 0V or

GND for any reason, the current charged in the capacitor flows into the output and may destroy the IC. Use a capacitor

smaller than 1µF between output and GND.

11) Testing on application boards

When testing the IC on an application board, connecting a capacitor to a low impedance pin subjects the IC to stress.

Therefore, always discharge capacitors after each process or step. Always turn the IC's power supply off before

connecting it to or removing it from the test setup during the inspection process. Ground the IC during assembly steps

as an antistatic measure. Use similar precaution when transporting or storing the IC.

12) Switching noise

When the operation mode is in PWM control or VREF control, PWM switching noise may effects to the control input

pins and cause IC malfunctions. In this case, insert a pulled down resistor (10kΩ is r ecommended) between each

control input pin and ground.

13) Regarding the input pin of the IC

This monolithic IC contains P+ isolation and P substrate layers between adjacent elements, in order to keep them

isolated.

P-N junctions are formed at the intersection of these P layers with the N layers of other elements, creating a parasitic

diode or transistor. For example, the relation between each potential is as follows:

When GND > Pin A and GND > Pin B, the P-N junction operates as a parasitic diode.

When GND > Pin B, the P-N junction operates as a parasitic transistor.

Parasitic diodes inevitably occur in the structure of the IC. The operation of parasitic diodes can result in mutual

interference among circuits, as well as operating malfunctions and physical damage. Therefore, do not use meth ods

by which parasitic diodes operate, such as applying a voltage lower than the GND (P substrate) voltage to an input pin.

Pin A

Parasitic element

N

+

P

P

P

P substrate

GND

+

zOrdering part number

Resistor Transistor (NPN)

Pin B

Pin A

N N

Appendix: Example of monolithic IC structure

aras

element

N

c

Parasitic element

+

P

B

C

E

N

GND

+

P

P

P substrate

N

GND

Pin B

B C

E

aras

element

GND

Other adjacent elements

c

B D 6 2 X X -

ROHM part

number

Type

1X: 7V max.

2X: 18V max.

3X: 36V max.

X0: 1ch/0.5A X5: 2ch/0.5A

X1: 1ch/1A X6: 2ch/1A

Package

F: SOP8

FV: SSOPB24

FP: HSOP25

FM: HSOPM28

HFP: HRP7

Packaging spec.

E2: Embossed taping

(SOP8/SSOPB24

TR: Embossed taping

(HRP7)

X2: 1ch/2A X7: 2ch/2A

14/16

/HSOP25/HSOPM28)

Page 15

y

Di

1234

Di

Di

(

y

p

p

y

Di

<Dimension>

<Dimension>

SSOP-B24

<Dimension>

<Dimension>

4.4±0.2

4.4±0.2

6.2±0.3

6.2±0.3

1.27

1.27

0.11

0.11

1.5±0.1

1.5±0.1

<Dimension>

24

5.6 ± 0.2

7.6 ± 0.3

1

0.1

0.65

1.15 ± 0.1

HSOP25

25 14

7.8 ± 0.3

5.4 ± 0.2

1

0.11

1.9 ± 0.1

HSOP-M28

28 15

9.9 ± 0.3

7.5 ± 0.2

114

0.8

0.11

2.2 ± 0.1

5.0±0.2

5.0±0.2

85

85

0.4±0.1

0.4±0.1

7.8 ± 0.2

13.6 ± 0.2

2.75 ± 0.1

1.95 ± 0.1

0.8

0.36 ± 0.1

18.5 ± 0.2

5.15 ± 0.1

0.35 ± 0.1

0.08

16.0 ± 0.2

41

41

13

12

0.22 ± 0.1

M

0.15±0.1

0.15±0.1

0.1

0.1

0.1

13

0.3Min.

0.3Min.

0.3Min.

0.15 ± 0.1

0.1

0.1 S

0.3Min.

0.25 ± 0.1

0.5 ± 0.2

0.25 ± 0.1

(Unit:mm)

(Unit:mm)

Unit:mm)

(Unit:mm)

(Unit:mm)

<Tape and reel information>

<Tape and reel information>

Tape

Tape

Quantit

Quantit

Direction

Direction

of feed

of feed

Embossed carrier tape

Embossed carrier tape

2500pcs

2500pcs

E2

E2

(Holding the reel with the left hand and pulling the tape out with the right,

(Holding the reel with the left hand and pulling the tape out with the right,

pin 1 will be on the upper left-hand side.)

pin 1 will be on the upper left-hand side.)

1234

1234

1234

Reel

Reel

1234

1234

1234

※When you order , please order in times the amount of package quantity.

※Orders should be placed in multiples of package quantity.

<Tape and Reel information>

Tape

Quantit

Direction

of feed

Embossed carrier ta

2000

cs

E2

(Holding the reel with the left hand and pulling the tape out with the right,

pin 1 will be on the upper left-hand side.)

1234

1234

1234

Reel

※Orders should be placed in multiples of package quantity.

<Tape and reel information>

Tape

Quantity

Direction

of feed

Embossed carrier tape

2000pcs

E2

(Holding the reel with the left hand and pulling the tape out with the right,

pin 1 will be on the upper left-hand side.)

1234

Reel

※Orders should be placed in multiples of package quantity.

<Tape and reel information>

Tape

Quantity

Direction

of feed

Embossed carrier tape

1500pcs

E2

(Holding the reel with the left hand and pulling the tape out with the right,

pin 1 will be on the upper left-hand side.)

1234

Reel

※Orders should be placed in multiples of package quantity.

1Pin

1Pin

1pin

1234

1234

1234

1Pin

1Pin

e

1234

1234

1234

1234

1234

1234

1234

1234

1234

rection of feed

rection of feed

1234

1234

Direction of feed

1234

1234

rection of feed

1234

1234

rection of feed

1234

1234

1234

1234

1234

15/16

Page 16

x x

x x

p

HRP7

<Dimension>

0.8875

9.395 ± 0.125

(MAX 9.745 include BURR)

0.28.0

±

1.017

0.13

±

0.05

±

0.08

8.82 – 0.1

(5.59)

<Tape and reel information>

1.905 ± 0.1

Tape

Quantity

Direction

(7.49)

765432S1

0.73 ± 0.11.27

0.08

0.13

±

0.15

0.2

±

±

10.54

1.523

0.835

+

5.5

-

4.5

4.5

+

0.1

0.27

-

0.05

S

of feed

(Unit:mm)

Embossed carrier tape

cs

2000

TR

(Holding the reel with the left hand and pulling the tape out with the right,

pin 1 will be on the upper right-hand side.)

x x x x x x x x x x x x x x x x

Reel

※Orders should be placed in multiples of package quantity.

1pin

Direction of feed

x x

x x

Catalog NO.05N000A '05.4 ROHM C 3000 TSU

Page 17

Appendix

Notes

No technical content pages of this document may be reproduced in any form or transmitted by any

means without prior permission of ROHM CO.,LTD.

The contents described herein are subject to change without notice. The specifications for the

product described in this document are for reference only. Upon actual use, therefore, please request

that specifications to be separately delivered.

Application circuit diagrams and circuit constants contained herein are shown as examples of standard

use and operation. Please pay careful attention to the peripheral conditions when designing circuits

and deciding upon circuit constants in the set.

Any data, including, but not limited to application circuit diagrams information, described herein

are intended only as illustrations of such devices and not as the specifications for such devices. ROHM

CO.,LTD. disclaims any warranty that any use of such devices shall be free from infringement of any

third party's intellectual property rights or other proprietary rights, and further, assumes no liability of

whatsoever nature in the event of any such infringement, or arising from or connected with or related

to the use of such devices.

Upon the sale of any such devices, other than for buyer's right to use such devices itself, resell or

otherwise dispose of the same, no express or implied right or license to practice or commercially

exploit any intellectual property rights or other proprietary rights owned or controlled by

ROHM CO., LTD. is granted to any such buyer.

Products listed in this document are no antiradiation design.

The products listed in this document are designed to be used with ordinary electronic equipment or devices

(such as audio visual equipment, office-automation equipment, communications devices, electrical

appliances and electronic toys).

Should you intend to use these products with equipment or devices which require an extremely high level

of reliability and the malfunction of which would directly endanger human life (such as medical

instruments, transportation equipment, aerospace machinery, nuclear-reactor controllers, fuel controllers

and other safety devices), please be sure to consult with our sales representative in advance.

It is our top priority to supply products with the utmost quality and reliability. However, there is always a chance

of failure due to unexpected factors. Therefore, please take into account the derating characteristics and allow

for sufficient safety features, such as extra margin, anti-flammability, and fail-safe measures when designing in

order to prevent possible accidents that may result in bodily harm or fire caused by component failure. ROHM

cannot be held responsible for any damages arising from the use of the products under conditions out of the

range of the specifications or due to non-compliance with the NOTES specified in this catalog.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact your nearest sales office.

ROHM Customer Support System

www.rohm.com

THE AMERICAS / EUPOPE / ASIA / JAPAN

Contact us : webmaster@ rohm.co. jp

Copyright © 2007 ROHM CO.,LTD.

21, Saiin Mizosaki-cho, Ukyo-ku, Kyoto 615-8585, Japan

TEL : +81-75-311-2121

FAX : +81-75-315-0172

Appendix1-Rev2.0

Loading...

Loading...