LED Drivers for LCD Backlights

White Backlight LED Driver

for Medium to Large LCD Panels

(Switching Regulator Type)

BD6150MUV

●Description

BD6150MUV is white LED driver IC with PWM step-up DC/DC converter that can boost max 40V and current driver that can

drive max 30mA. The wide and precision brightness can be controlled by external PWM pulse. BD6150MUV has very

accurate current drivers, and it has few current errors between each strings. So, it will be helpful to reduce brightness spots

on the LCD. Small package type is suited for saving space.

●Features

1) High efficiency PWM step-up DC/DC converter (fsw=1.25MHz / 0.75MHz)

2) High accuracy & good matching current drivers (MAX30mA/ch)

3) Integrated 50V power Nch MOSFET

4) Soft start

5) Drive up to 10 in series 6strings in parallel

6) Wide input voltage range (4.2V ~ 26V)

7) Rich safety functions

・Over-voltage protection ・Over current limit

・LED terminal open/short protect ・External SBD open detect / Output short protection

・UVLO ・Thermal shutdown

8) Small & thin package (VQFN024V4040) 4.0 × 4.0 × 1.0mm

●Applications

All middle size LCD equipments backlight of Notebook PC, portable DVD player, car navigation systems, etc.

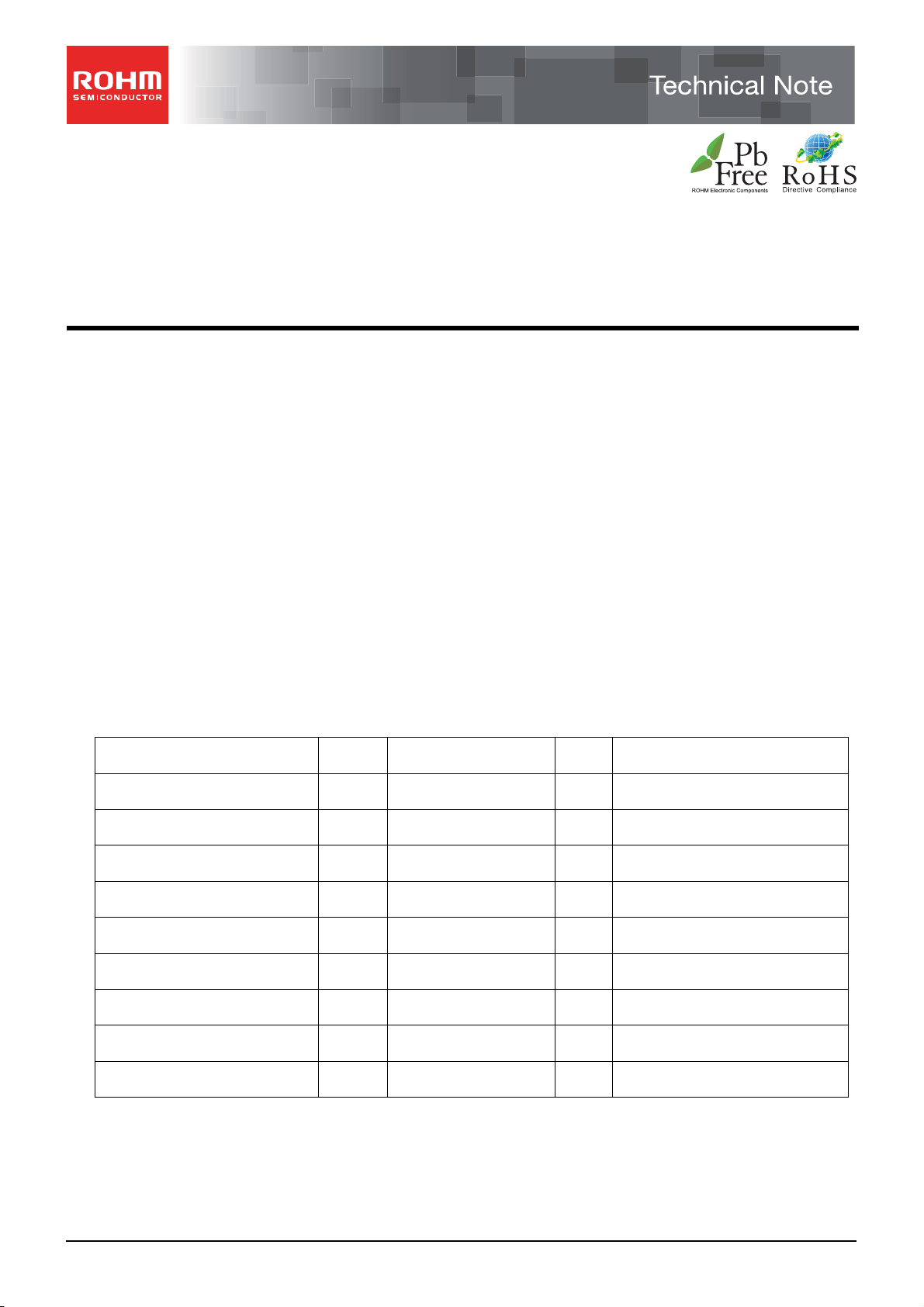

●Absolute maximum ratings (Ta=25℃)

Parameter Symbol Ratings Unit Condition

No.11040EBT06

Maximum applied voltage 1 VMAX1 7 V

Maximum applied voltage 2 VMAX2 25 V

Maximum applied voltage 3 VMAX3 30.5 V VBAT, FAILFLAG, PWMPOW

Maximum applied voltage 4 VMAX4 41 V SW

Power dissipation 1 Pd1 500 *1 mW

Power dissipation 2 Pd2 780 *2 mW

Power dissipation 3 Pd3 1510 *3 mW

Operating temperature range Topr -40 ~ +85 ℃

Storage temperature range Tstg -55 ~ +150 ℃

*1 Reduced 4.0mW/℃ With Ta>25℃ when not mounted on a heat radiation Board.

*2 1 layer (ROHM Standard board) has been mounted. Copper foil area 0mm

*3 4 layer (JEDEC Compliant board) has been mounted. Copper foil area 1layer 6.28mm

When it’s used by more than Ta=25℃, it’s reduced by 12.1mW/℃.

2

, When it’s used by more than Ta=25℃, it’s reduced by 6.2mW/℃.

2

, Copper foil area 2~4layers 5655.04mm2,

VREG, ISET, PWMDRV, FSEL,

OCPSET, VDET, TEST

LED1, LED2, LED3,

LED4, LED5, LED6

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

1/28

2011.06 - Rev.B

BD6150MUV

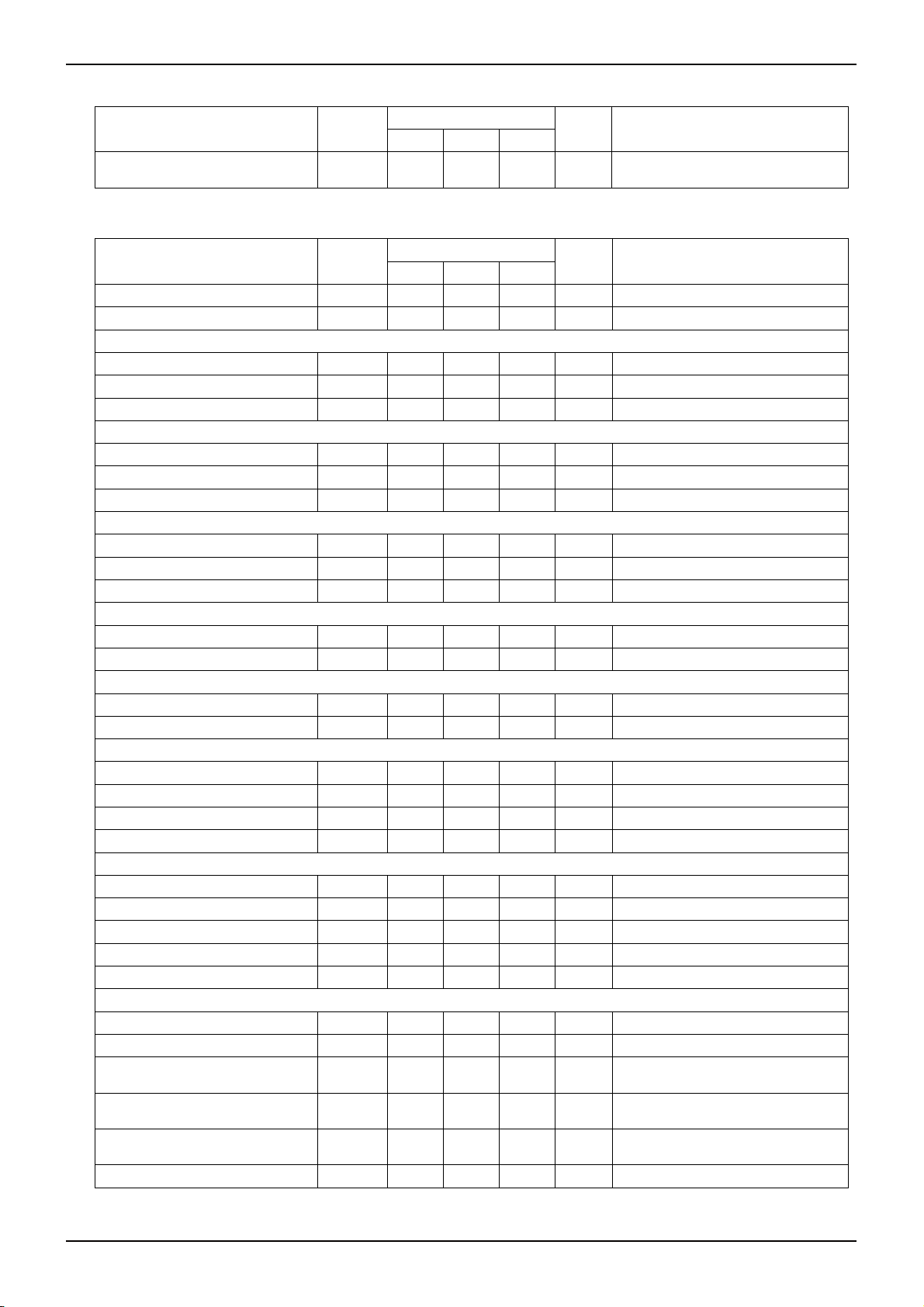

●Recommended operating range (Ta=-40℃ ~ +85℃)

Parameter Symbol

Power supply voltage VBAT 4.2 12.0 26.0 V

●Electrical characteristic (Unless otherwise specified, VBAT=12V, Ta = +25℃)

Parameter Symbol

Quiescent current Iq - 1.6 4.4 µA PWMPOW=0V

Current consumption Idd - 3.2 4.8 mA VDET=0V,ISET=22k

[PWMPOW Terminal]

Low input voltage range1 POWL 0 - 0.9 V

High input voltage range1 POWH 2.1 - VBAT V

Pull down resistor1 POWR 100 300 500 k PWMPOW=3V

[PWMDRV Terminal]

Low input voltage range2 PDRVL 0 - 0.9 V

High input voltage range2 PDRVH 2.1 - 5.5 V

Pull down resistor2 DRVR 100 300 500 k

[FSEL Terminal]

Low input voltage range3 FSL 0 - 0.9 V

High input voltage range3 FSH 2.1 - 6.0 V

Pull down resistor3 FSR 100 300 500 k FSEL=1V

[FAILFLAG]

Input resistor FFIR 1.0 2.0 3.0 k FAILFLAG=2.5V

Off current FFIST - 0.1 2.0 µA PWMPOW=0V

[Regulator]

VREG voltage VREG 4.2 5.0 6.0 V No load

Under voltage lock out UVLO 3.3 3.7 4.1 V VBAT falling edge

[Switching Regulator]

LED control voltage VLED 0.56 0.70 0.84 V

Switching frequency fsw 1.00 1.25 1.50 MHz FSEL=L (GND short)

Duty cycle limit Duty 91 95.0 99.0 % LED1-6=0.3V

SW Nch FET RON RON - 0.48 0.58 ISW=80mA

[Protection]

Over current limit Ocp 1.4 2.0 2.6 A

OCPSET open protect OOP - 0.0 0.1 A OCPSET=2M

Over voltage limit Input Ovl 0.96 1.00 1.04 V Detect voltage of VDET pin

SBD open protect Sop 0.02 0.05 0.08 V Detect voltage of VDET pin

VDET leak current OVIL - 0.1 1.0 µA

[Current driver]

LED maximum current ILMAX - - 30 mA

LED current accuracy ILACCU - - ±3.0 % ILED=16~20mA

LED current matching ILMAT - - ±1.5 %

LED current limiter ILOCP - 0 0.1 mA

Min. Typ. Max.

Min. Typ. Max.

Limits

Limits

Unit Condition

Unit Condition

*1

OCPSET=68k

Each LED current/Average (LED1-6)

ILED=16~20mA

Current limit value at ISET

resistor 1k setting

Technical Note

LED terminal Over voltage protect LEDOVP 10.0 11.5 13.0 V PWMDRV=2.5V

ISET voltage Iset 0.5 0.6 0.7 V

*1 This parameter is tested with DC measurement.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

2/28

2011.06 - Rev.B

BD6150MUV

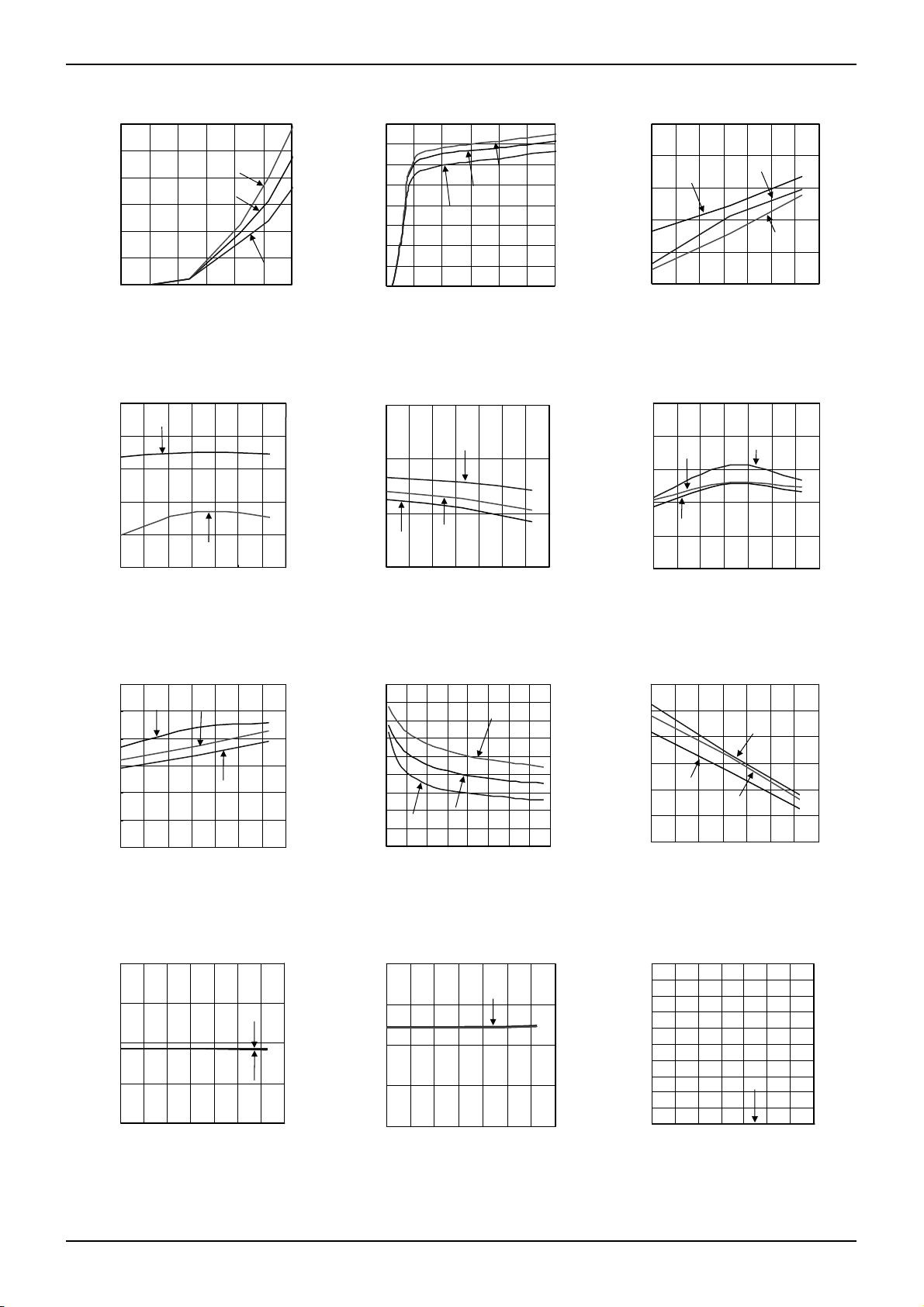

●Reference Data

30

25

20

15

ICC [uA]

10

5

0

0 5 10 15 20 25 30

Fig 1. Quiescent Current Fig 2. Current Consumption Fig 3. VREG Voltage

3.9

3.8

3.7

RISING

3.6

UVLO (V)

3.5

3.4

-40 -20 0 20 40 60 80 100

Fig 4. Under Voltage Lock Out

98

4.2V

97

96

95

Max D uty [%]

94

93

92

-40 - 20 0 20 40 60 80 100

Fig 7. Max Duty

1.2

1.1

1

VDET [V]

0.9

0.8

-40 - 20 0 20 40 60 80 100

Fig 10. Over Voltage Protect

25℃

VBAT [V]

FALLING

TEMP (°C)

5V

TEMP [℃]

TEMP [°C ]

85℃

6V

5V, 6V

4.2V

-40℃

4

3.5

3

2.5

2

ICC [mA]

1.5

1

0.5

0

0 5 10 15 20 25 30

620

610

ISET [mV]

600

4.2V

590

-40-200 20406080100

-40℃

5V

TEMP [°C ]

85℃

25℃

VBAT [V]

6V

Fig 5. ISET Voltage

900

800

700

600

500

400

RON [m]

300

200

-40℃

100

0

2.4 3 3.6 4.2 4.8 5.4 6 6. 6 7.2

85℃

25℃

VREG [V]

Fig 8. LX NcH RON

70

60

50

VDET [mV]

40

30

-40 - 20 0 20 40 60 80 100

4.2V, 5V, 6V

TEMP [℃]

Fig 11. SBD Open Protect

Technical Note

5.3

5.2

6V

5.1

5

VREG [V]

4.9

4.8

-40 -20 0 20 40 60 80 100

1500

1400

5V

1300

1200

FREQ [kHz]

1100

1000

4.2V

-40 - 20 0 20 40 60 80 100

Fig 6. Switching Frequency

2.6

2.4

2.2

2

1.8

SW_ICOIL [A]

1.6

1.4

4.2V

-40 -20 0 20 40 60 80 100

Fig 9. Over Current Limit

1

0.9

0.8

0.7

A]

0.6

µ

0.5

0.4

VDET [

0.3

0.2

0.1

0

VBAT=VREG=5V

-40 - 20 0 20 40 60 80 100

Fig 12. VDET Leak Current

22V

TEMP [℃]

6V

TEMP [℃]

6V

5V

TEMP [°C ]

TEMP [°C ]

12V

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

3/28

2011.06 - Rev.B

BD6150MUV

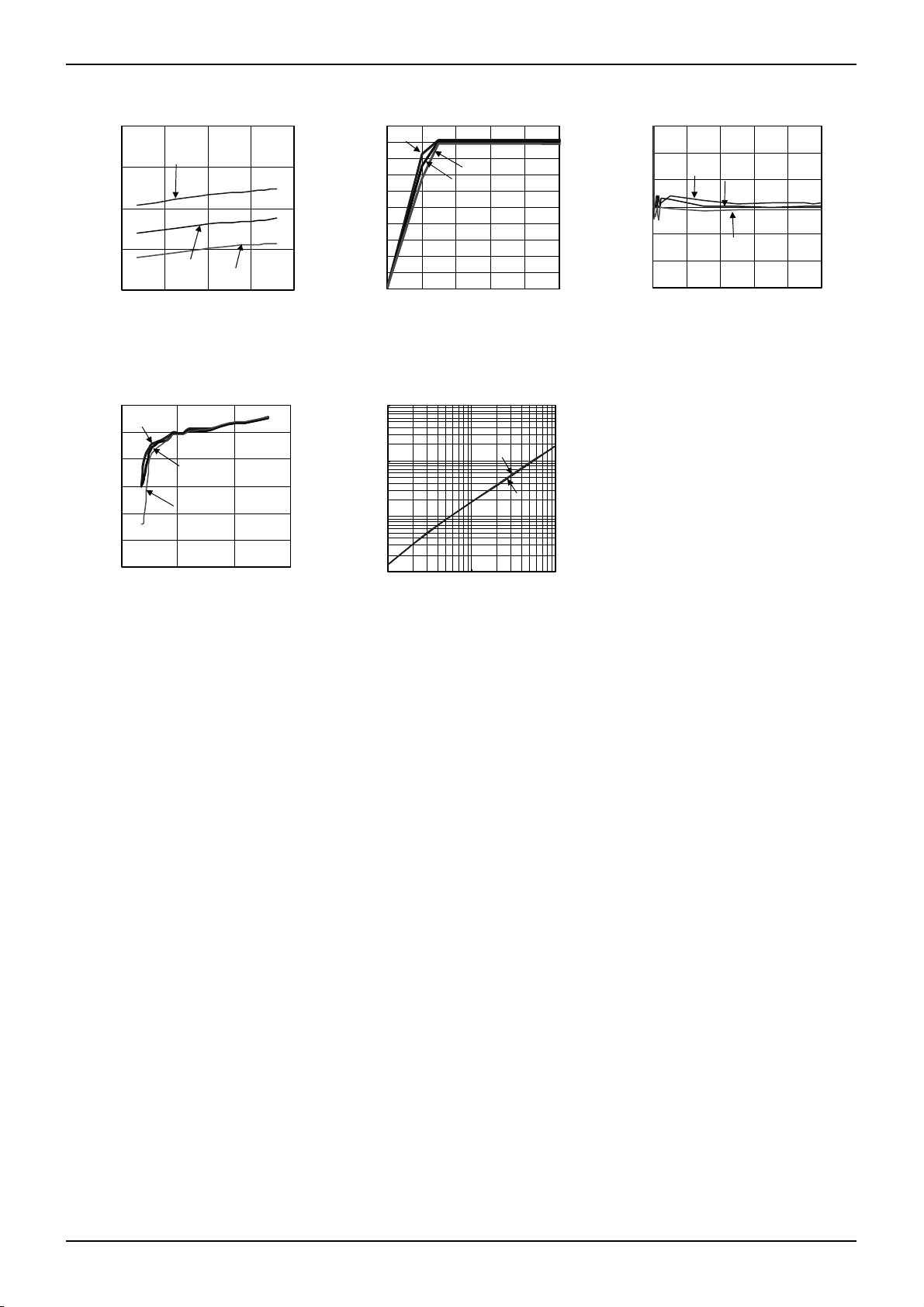

50

45

40

ILED Max [m A]

35

30

34567

100

-40℃

90

80

70

Efficiency [%]

60

50

40

0102030

Fig 16. Efficiency

10LEDx6CH

-40℃

25℃

VBAT [V]

25℃

85℃

VBAT [V]

85℃

20

-40℃

18

16

14

12

10

ILED [mA]

8

6

4

2

0

0 0.2 0.4 0.6 0.8 1

85℃

25℃

VLED [V]

Fig 14. LED Current vs LED VoltageFig 13. LED Max Current

100

10

ILED [mA]

1

0.1

1 10 100

6V

12V, 26V

Duty [%]

Fig 17. LED Current vs PWM Duty

PWM Freq=200Hz LED 10x6CH

Technical Note

3

2

-40℃

1

0

-1

Mat chi ng [%]

-2

-3

0 20406080100

Fig 15. LED Current Matching

25℃

85℃

Duty [%]

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

4/28

2011.06 - Rev.B

BD6150MUV

p

R

T

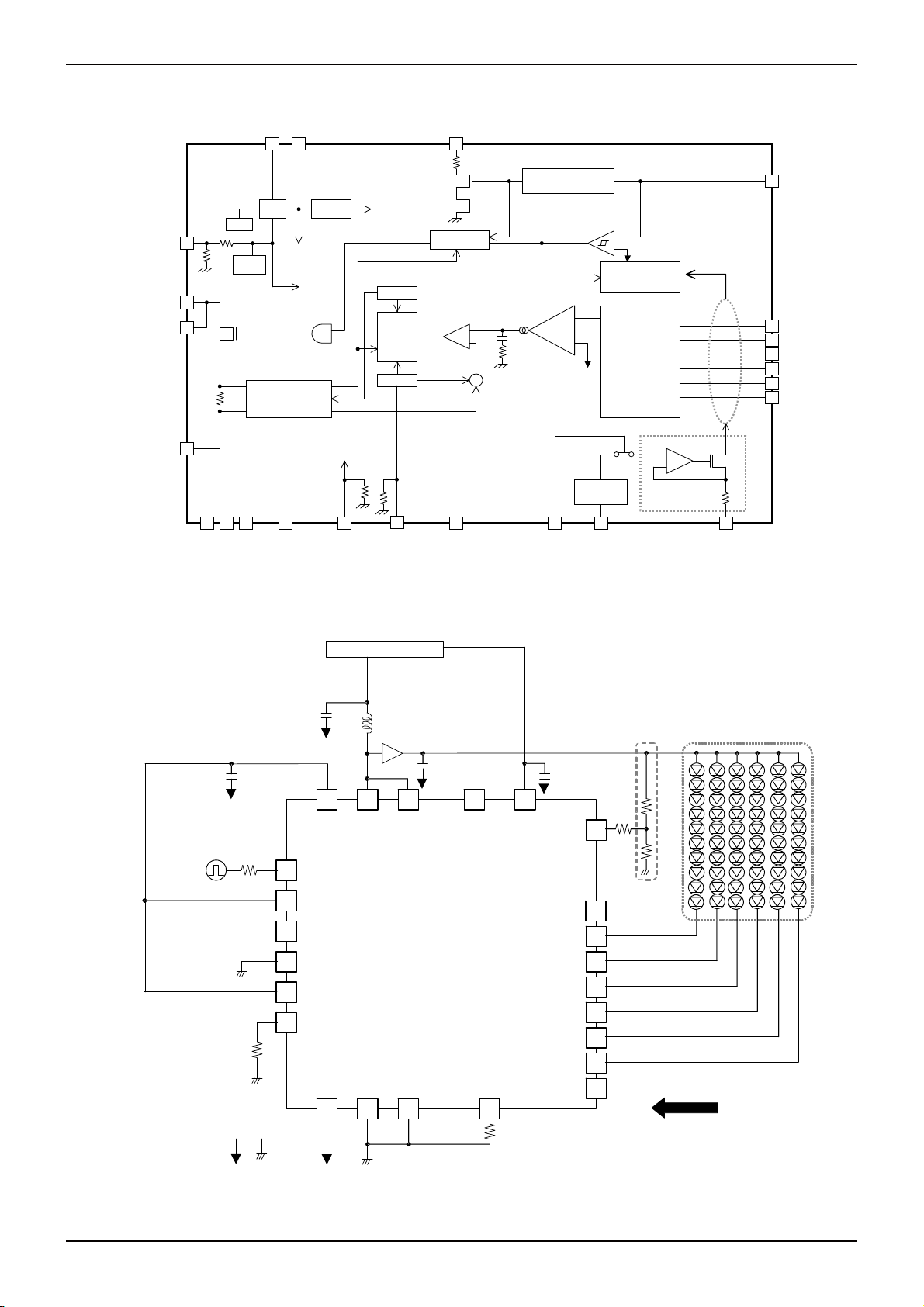

●Block diagram

PWMPOW

SW

SW

PGND

●Application example

2.2µF

Vin=2.1V to 5.5V

f

=100Hz~ 1kHz

PWM

PWM

VBAT VREG

REG

TSD

5.5V

Clam

Internal Power

Current SENCE

Over Current Protect

Internal Power

Supply

Control

UVLO

Internal Reset

Soft start

Control

SENCE

OSC

FSEL

FAIL FLAG

FAULT

DETECTO

PWM COMP

GND TEST OCPSET N.C. N.C. N.C.

Output Over Voltage PROTECT

+

SBD OPEN/

Output short PROTECT

ERRAMP

-

+

ISET

Resistor driver

PWMDRV ISET

LED TERMINAL

OPEN/SHORT

DETECTOR

LED

RETURN

SELECT

Fig.18 BD6150MUV block diagram

Battery or adapter

4.2V to 26V

1MΩ 26.7kΩ

10kΩ

PGND

10kΩ

68kΩ

4.7µH

SW SW

VREG

PWMPOW

PWMDRV

N.C.

TEST

FSEL

2.2µF

/ 50V

FAILFLAG

BD6150MUV

1µF

VDET

VBAT

N.C.

LED1

LED2

LED3

LED4

OCPSET

PGND

GND GND

ISET

LED5

LED6

N.C.

22kΩ

Fig.19 Application example (10LED × 6parallel, Switching frequency 750kHz)

Technical Note

6ch

+

-

Current Driver

GND

10LED × 6 parallel

19.6mA

VDE

LED1

LED2

LED3

LED4

LED5

LED6

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

5/28

2011.06 - Rev.B

BD6150MUV

A

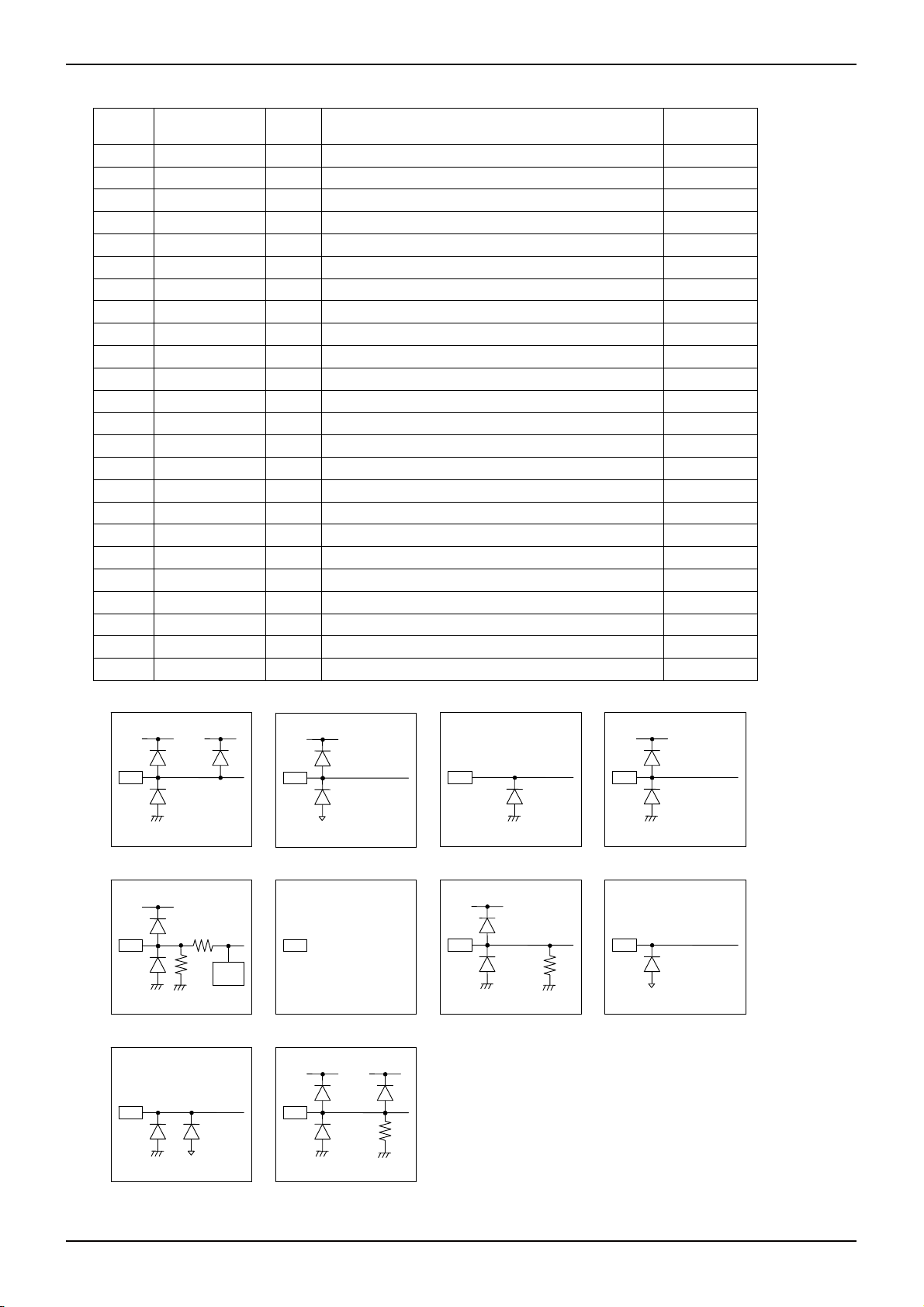

●Pin assignment table

PIN

No.

PIN Name

1 SW Out Switching Tr drive terminal H

2 SW Out Switching Tr drive terminal H

3 N.C. - No connect pin F

4 PGND - PGND for switching Tr D

5 FAILFLAG Out Fail Flag C

6 OCPSET In Current Limiter setting A

7 VDET In Detect input for SBD open and OVP A

8 TEST In TEST signal J

9 FSEL In Selection of Frequency, ‘L’: 1.25MHz, ‘H’: 0.75MHz J

10 ISET In Resister connection for LED current setting A

11 GND - GND for Switching Regulator B

12 N.C. In No connect pin F

13 LED1 In Current sink for LED C

14 LED2 In Current sink for LED C

15 LED3 In Current sink for LED C

16 LED4 In Current sink for LED C

17 LED5 In Current sink for LED C

18 LED6 In Current sink for LED C

19 N.C. In No connect pin F

20 GND - GND for Current driver B

21 PWMDRV In PWM input pin for power ON/OFF only driver G

22 VREG Out Regulator output / Internal power-supply D

23 PWMPOW In PWM input pin for power ON/OFF E

24 VBAT In Battery input I

VBAT

PIN

GND

VBAT

PIN

GND

E

PIN

GND

PGND

I

VREG

5.5V

Clump

In/

Out

PIN

PIN

PIN

VBAT

PGND

VBAT

GND

Technical Note

VBAT

GND

PGND

Terminal

D

H

diagram

Function

PIN

GND

VBAT

GND

C

G

B

PIN

F

VREG

J

PIN

PIN

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6/28

2011.06 - Rev.B

BD6150MUV

●Description of Functions

1) PWM current mode DC/DC converter

While this IC is power ON, the lowest voltage of LED terms is detected, PWM duty is decided to be 0.7V and output

voltage is kept invariably. As for the inputs of the PWM comparator as the feature of the PWM current mode, one is

overlapped with error components from the error amplifier, and the other is overlapped with a current sense signal that

controls the inductor current into Slope waveform to prevent sub harmonic oscillation. This output controls internal Nch

Tr via the RS latch. In the period where internal Nch Tr gate is ON, energy is accumulated in the external inductor, and in

the period where internal Nch Tr gate is OFF, energy is transferred to the output capacitor via external SBD.

This IC has many safety functions, and their detection signals stop switching operation at once.

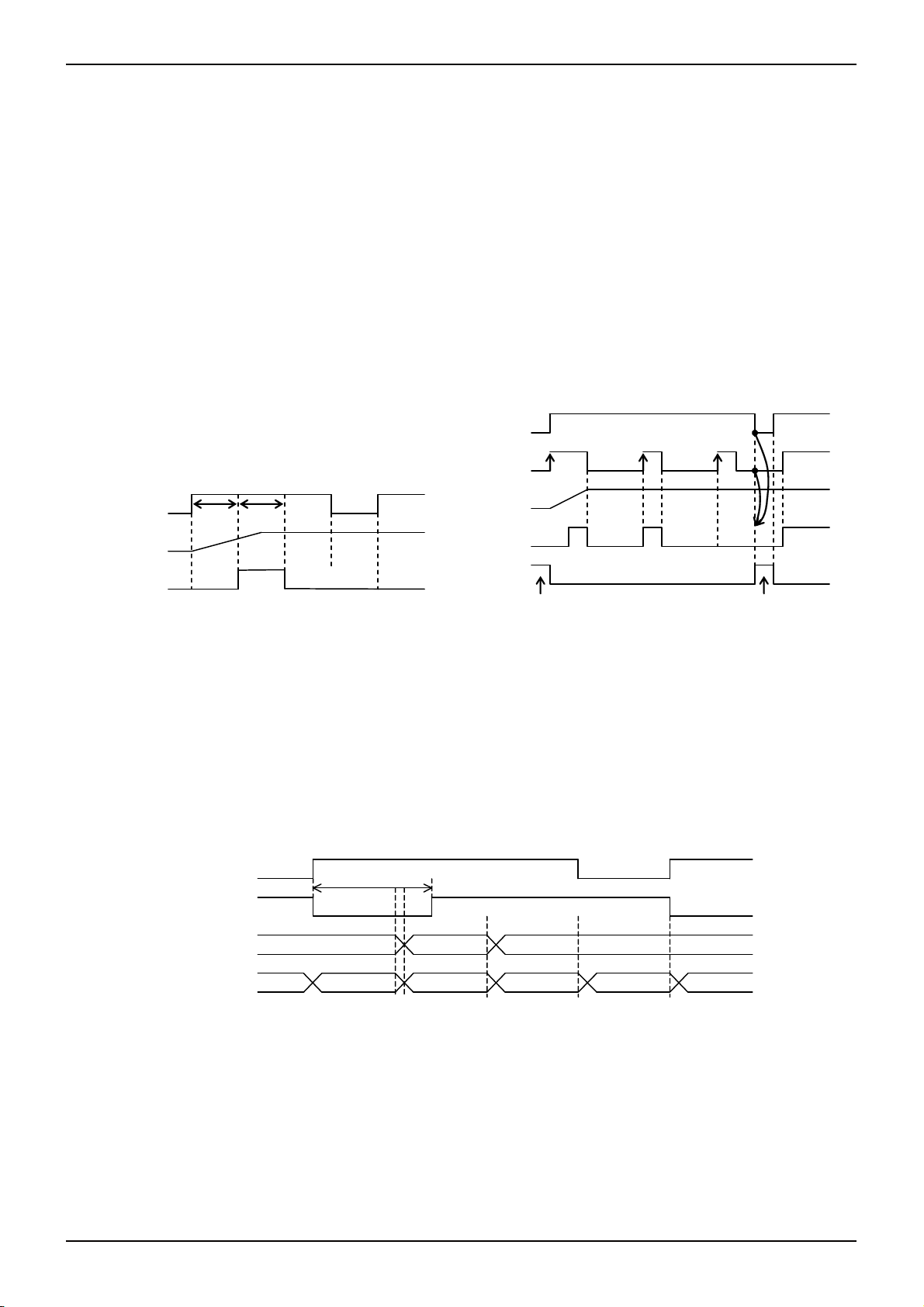

2) Soft start

This IC has soft start function.

The soft start function prevents large coil current.

Rush current at turning on is prevented by the soft start function.

After PWMPOW, PWMDRV is changed L H, soft start becomes effective for within 4ms and soft start doesn't become

effective even if PWMPOW is changed L H after that.

And, when the H section of PWMPOW is within 4ms, soft start becomes invalid when PWMPOW is input to H more than

three times. The invalid of the soft start can be canceled by making PWMPOW, PWMDRV L.

Technical Note

PWMDRV

PWMPOW

PWMPOW

VREG

Soft start

3) FAILFLAG

When the error condition occurs, boost operating is stopped by the protection function, and the error condition is

outputted from FAILFLAG. After power ON, when the protection function is operating under about 1ms have passed.

Object of protect function is as shown below.

Max 1ms

Max 3ms

OFF ON

OFF

OFF

Soft start

Soft start

reset

OFF ON ON OFF OFF OFF ON

Reset Reset

Fig.20 Soft start Fig.21 Soft start reset and set

・Over-voltage protection

・External SBD open detect/ Output Short protection

・LED terminal open/short protection

・Over current limit

VREG

PWMPOW

FAI LFL AG

about 1ms

Protection

function

un-detection detect un-detection

Boost

operating

off

normal boost stop normal off normal

Fig.22 FAILFLAG operating description

OFF OFF

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

7/28

2011.06 - Rev.B

BD6150MUV

t

k

V

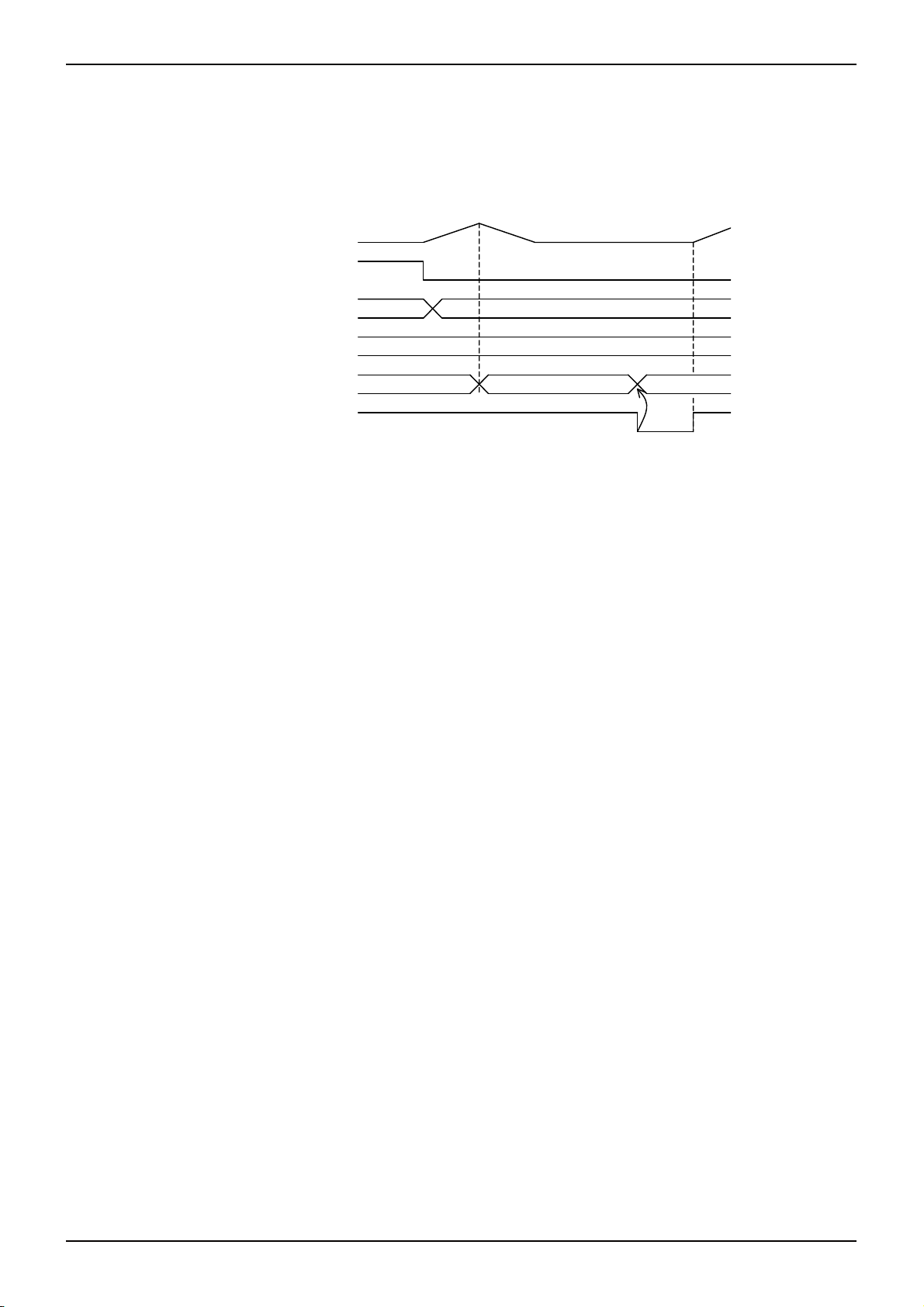

●Protection

・Over voltage protection

At such an error of output open as the output DC/DC and the LED is not connected to IC, the DC/DC will boost too much

and the VDET terminal exceed the absolute maximum ratings, and may destruct the IC. Therefore, when VDET becomes

sensing voltage or higher, the over voltage limit works, and turns off the output Tr, and the pressure up made stop.

At this moment, the IC changes from activation into non-activation, and the output voltage goes down slowly. And, when

the Feedback of LED1 isn’t returned, so that Vout will return normal voltage.

Technical Note

Vou

LED1 voltage

LED1 connection

normal

LED2 connection

LED1 FeedBac

return return off

PWMPOW, PWMDR

Fig.23 VDET operating description

・External SBD open detect / Output short protection

In the case of external SBD is not connected to IC, or VOUT is shorted to GND, the coil or internal Tr may be destructed.

Therefore, at such an error as VDET becoming 0.05V or below, and turns off the output Tr, and prevents the coil and the IC

from being destructed.

And the IC changes from activation into non-activation, and current does not flow to the coil (0mA).

・Thermal shut down

This IC has thermal shut down function.

The thermal shut down works at 175℃ or higher, and the IC changes from activation into non-activation.

open

normal

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

8/28

2011.06 - Rev.B

BD6150MUV

Technical Note

●How to set over voltage limit

This section is especially mentioned here because the spec shown electrical characteristic is necessary to explain this

section.

Over voltage limit min 0.96V typ 1.00V max 1.04V

LED control voltage min 0.56V typ 0.70V max 0.84V

LED terminal over voltage protect min 10.0V typ 11.5 V max 13.0V

1. Calculate the conditions that the total value of LED VF is MAX.

Example) In the case of serial 8 LEDs with VF=2.9V(min), 3.2V(typ), 3.5V(max) => 3.5V x 8=28V

2. Then calculate the biggest value of output with the following formula.

The biggest value of output = the biggest value calculated for 1 + the biggest value of LED terminal voltage. (0.84V)

Example) The biggest value of output = 28V + 0.84V =28.84V

3. Set the smallest value of over voltage larger than the biggest value of output.

If over voltage is closer to the total value of VF, it could be occurred to detect over voltage by ripple, noise, and so on.

It is recommended that some margins should be left on the difference between over voltage and the total value of VF.

This time around 6% margin is placed.

Example) Against the biggest value of output = 28.84V, the smallest value of over voltage = 28.84V x 1.06 = 30.57V

Ic over voltage limit min=0.96V,typ=1.00V, max=1.04V

typ = 30.57V×(1.00V/0.96V) = 31.8V

max = 31.8V×(1.04V/1.00V) = 33.1V

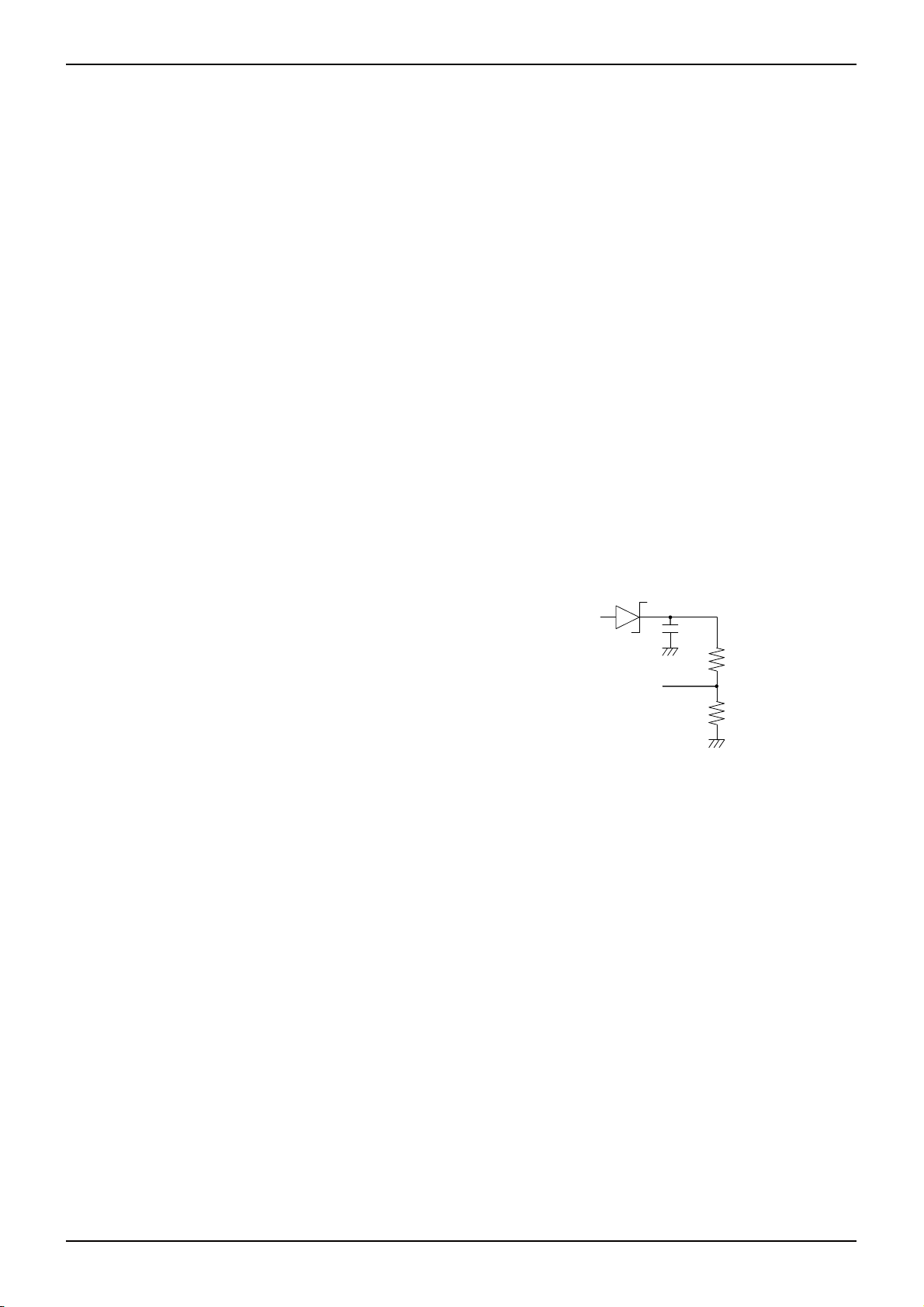

4. The below shows how to control resistor setting over voltage

Please fix resistor 2.2MΩ between VDET and output and then set over voltage after changing resistor between VDET

and GND. While PWM is off, output voltage decreases by minimizing this resistor. Due to the decrease of output voltage,

ripple of output voltage increases, and singing of output condenser also becomes bigger.

Example) Selecting OVP resistor.

(Example 1) VF=3.6V max, serial = 7 LED

OVP = 1.0V, R1 = 2.2M, R2 = 78.7k

VOUT = 1.0 × (2.2M + 78.7k)/ 78.7k = 28.95V

VOUT

(Example 2) VF=3.6V max, serial = 8 LED

OVP = 1.0V, R1 = 2.2M, R2 = 69.8k

VOUT = 1.0 × (2.2M + 69.8k)/ 69.8k = 32.52

(Example 3) VF=3.6V max, serial = 9 LED

VDET

R1

OVP = 1.0V, R1 = 2.2M, R2 = 62k

VOUT = 1.0 × (2.2M + 62k)/ 62k = 36.48V

R2

(Example 4) VF=3.6V max, serial = 10 LED

OVP = 1.0V, R1 = 1.0M, R2 = 26.7k

VOUT = 1.0 × (1.0M + 26.7k)/ 26.7k =

38.45V

5. The following shows how to confirm if LEDs are not turned on while selecting terminals. If the difference between the

VF’s total value of LED and over voltage is less than min.10V of LED terminal over voltage protect, LEDs should be

turned on.

LEDs are turned on, as the following formula shows; 33.1V-2.9V x 8 serial = 9.9V<10.0V.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

9/28

2011.06 - Rev.B

Loading...

Loading...