A

LED Drivers for LCD Backlights

Multifunction Backlight LED Drivers

for Small LCD Panels (Charge Pump Type)

BD6081GU, BD6081GVW

●Description

BD6081GU / BD6081GVW is compound LED Driver which is the most suitable for the cellular phone.

Main LCD Back Light LED Driver (Max 4 Light), Sub LCD Back Light LED Driver (Max 2 Light), 2 system RGB LED Drivers,

2Ch LDO (2.8V/1.8V) included. This is PMIC (Power Management IC) that is the most suitable for "the indication part" of the

cellular phone.A charge pump form is adopted, and a coil is never used for the part DC/DC. This IC achieves compact size

with the chip size package (VCSP85H3). [BD6081GU] This IC solves a mounting problem by BGA package

(SBGA063W060). [BD6081GVW]

●Features

1) Main LCD Back Light LED Driver (Max 4 Light)

4 Lighting / 3 Lighting can be chosen (register setting)

2) Sub LCD Back Light LED Driver (Max 2 Light)

2 Lighting / 1 Lighting can be chosen (register setting)

3) RGB LED Driver (2 System)

Slope control is built in.(2 system independence can be controlled.)

LED connection (for G1LED,G2LED,B1LED,B2LED) can be set up in the battery or the DC/DC output.(register setting)

LED connection (for R1LED,R2LED) can be set up in the battery only.

4) 2ch Series Regulator

2.8V output Iomax=150mA

1.8V output Iomax=150mA(normal mode)

1.8V output low current consumption mode / normal mode Switching is possible. (The outside pin control / regi ster setting)

5) Charge Pump DC/DC

Soft start Functions

Over voltage protection (Auto-return type)

Over current protection (Auto-return type)

6) Thermal shutdown (Auto-return type)

2

7) I

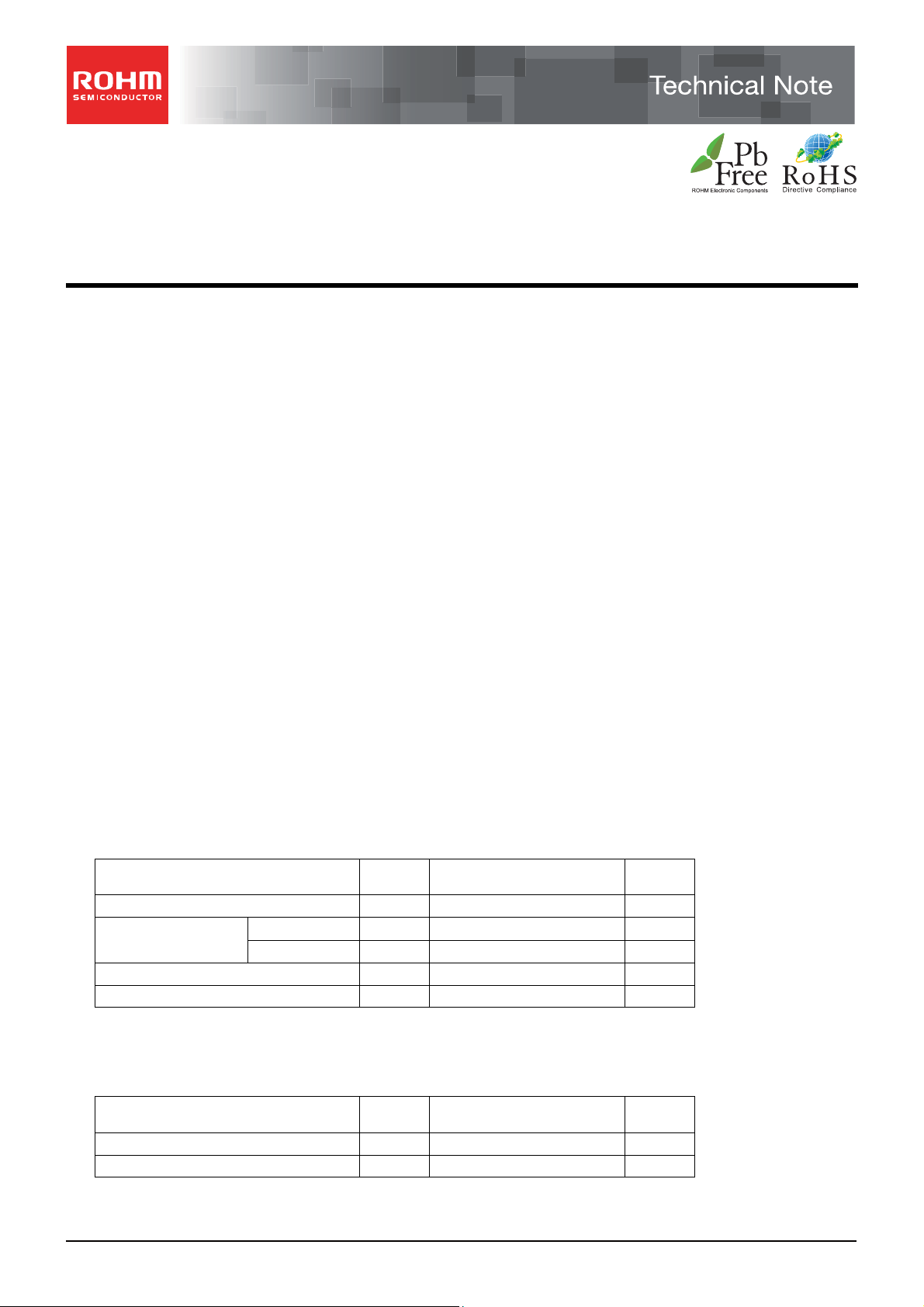

●Absolute Maximum Ratings (Ta=25

C BUS Fast-mode (max 400kHz)Writing

*This chip is not designed to protect itself against radioactive rays.

*This material may be changed on its way to designing.

*This material is not the specification.

℃)

Parameter

Symbol Ratings Unit

No.11040EAT27

Maximum Applied voltage VMAX 7 V

Power Dissipation

Operating Temperature Range Topr -25 ~ +85 ℃

Storage Temperature Range Tstg -55 ~ +150 ℃

cote1)Power dissipation deleting is 13.8mW/ ℃, when it’s used in over 25 ℃.

(It’s deleting is on the board that is ROHM’s standard))

Note2)Power dissipation deleting is 8.48mW/

(It’s deleting is on the board that is ROHM’s standard))

●Operating conditions (VBATVIO, Ta=-25~85

Parameter Symbol

VBAT input voltage VBAT 2.7 ~ 5.5 V

VIO pin voltage VIO 1.65 ~ 3.3 V

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

BD6081GU Pd 1725 note1) mW

BD6081GVW Pd 1060 note2) mW

℃, when it’s used in over 25 ℃.

℃)

1/35

Ratings

Unit

2011.04 - Rev.

A

BD6081GU,BD6081GVW

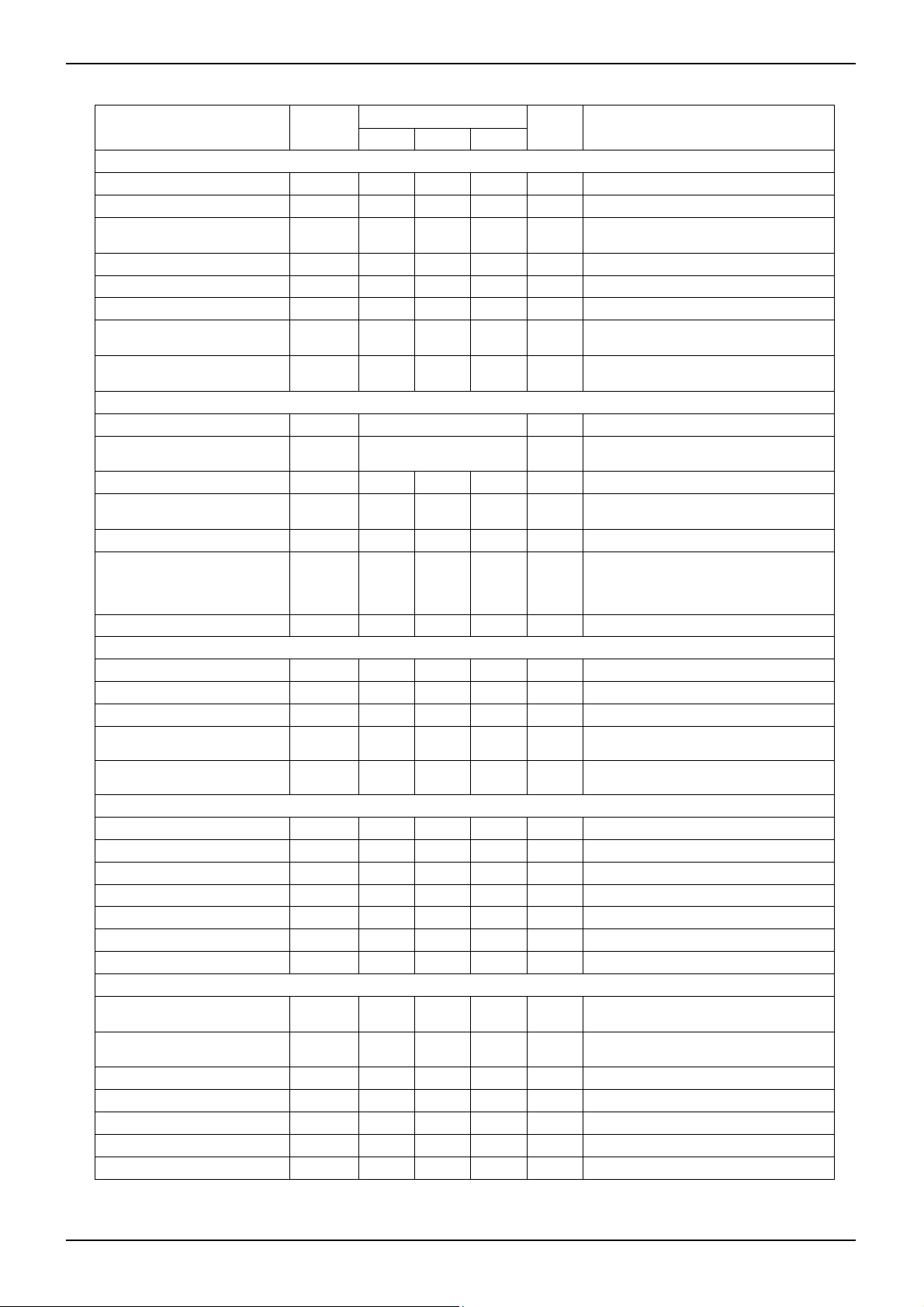

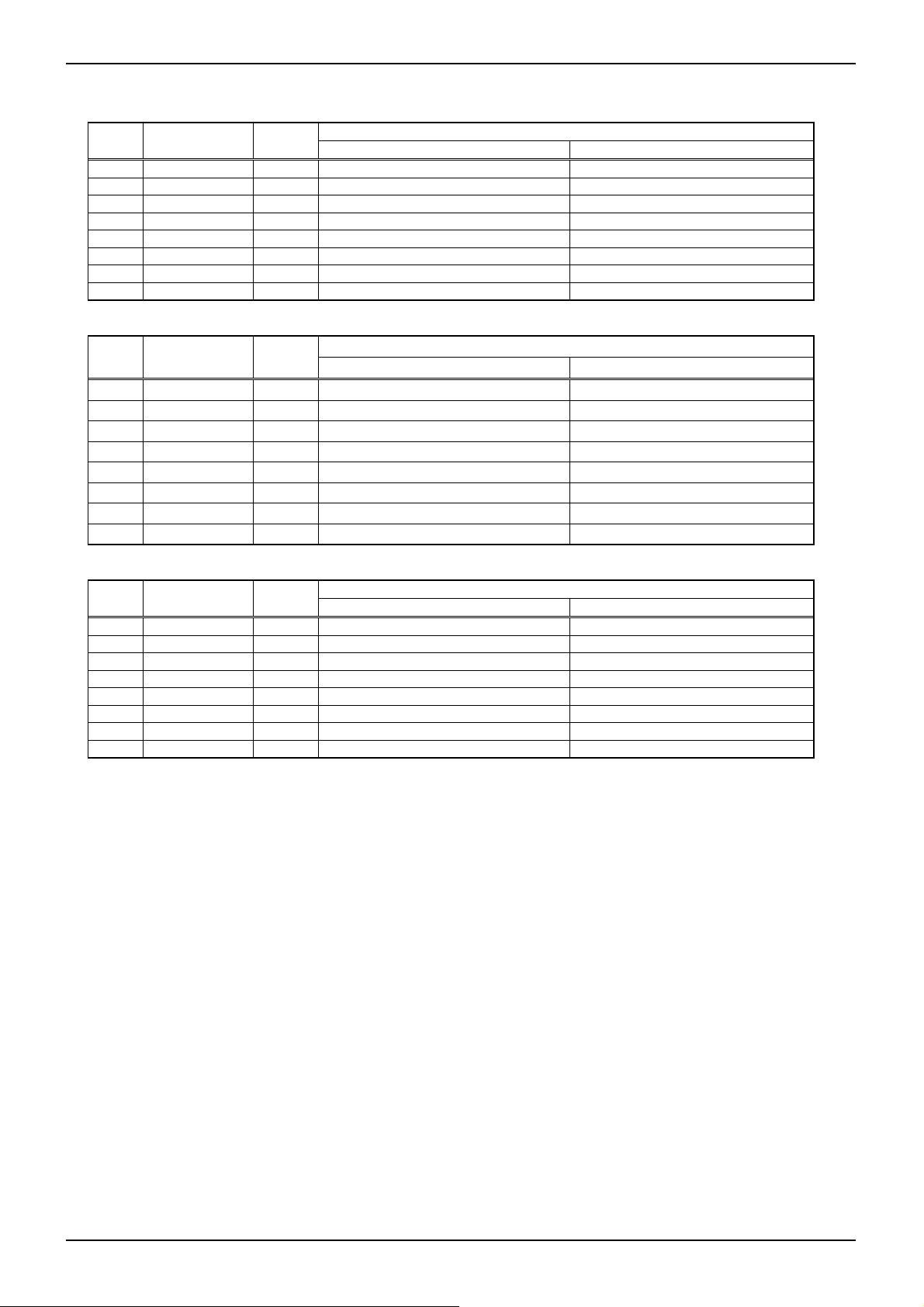

●Electrical Characteristics (Unless otherwise specified, Ta=25℃, VBAT=3.6V, VIO=1.8V)

Parameter Symbol

【Circuit Current】

VBAT Circuit current 1 IBAT1 - 0.1 3.0 A

VBAT Circuit current 2 IBAT2 - 0.5 3.0 A

VBAT Circuit current 3 IBAT3 - 6.2 9.5 A

VBAT Circuit current 4 IBAT4 - 100 150 A

VBAT Circuit current 5 IBAT5 - 140 210 A

VBAT Circuit current 6 IBAT6 - 63 95 mA

VBAT Circuit current 7 IBAT7 - 95 143 mA

VBAT Circuit current 8 IBAT8 - 125 188 mA

【LED Driver】

LED current Step1 ILEDSTP1 32 Step

LED current Step2 ILEDSTP2 64 Step

LED Maximum setup current 1

LED Maximum setup current 2

LED current accurate ILED 18 20 22 mA

LED current Matching ILEDMT - 5 10 %

LED OFF Leak current ILKLED - - 1.0 A

【DC/DC(Charge Pump)】

Output voltage V℃P Vf+0.15 Vf+0.2 - V

Current Load IOUT - - 255 mA

Oscillator frequency fosc 0.8 1.0 1.2 MHz

Over voltage protection

detect voltage

Over current protection

detect current

【REG1】

Output voltage Vo1 2.716 2.80 2.884 V

I/O voltage difference Vsat1 - 0.2 0.3 V

Load stability Vo11 - 10 60 mV

Input stability Vo12 - 10 60 mV

Ripple Rejection Ratio RR1 30 40 - dB

Short circuit current limit Ilim01 - 225 450 mA

Discharge resister at OFF ROFF1 - 1.0 1.5 k

【REG2】

Output voltage 1 Vo21 1.74 1.8 1.86 V

Output voltage 2 Vo22 1.71 1.8 1.89 V

Load stability Vo21 - 10 60 mV

Input stability Vo22 - 10 60 mV

Ripple Rejection Ratio RR2 30 40 - dB

Short circuit current limit Ilim02 - 225 450 mA

Discharge resister at OFF ROFF2 - 1.0 1.5 k

IMAX1 - - 32 mA

IMAX2 - - 31.5 mA

OVP - 6.0 6.5 V

OCP - 250 375 mA

Min. Typ. Max.

Limits

Unit Condition

RESET=0V, VIO=0V

RESET=0V, VIO=1.8V

REG2 low current consumption mode,

Io=0mA

REG2 normal mode, Io=0mA

REG1, REG2 normal mode, Io=0mA

DC/DC x1mode, Io=60mA,VBAT=4.0V

DC/DC x1.5mode,

Io=60mA,VBAT=3.6V

DC/DC x2 mode,

Io=60mA,VBAT=2.7V

MLED1~4, SLED1~2

R1LED, G1LED, B1LED,R2LED,

G2LED, B2LED (with 0mA setting)

MLED1~4, SLED1~2, ISET=120k

R1LED, G1LED, B1LED,R2LED,

G2LED, B2LED, ISET=120k

ILED=20mA, ISET=120k

Between MLED1~4

Between SLED1~2

Between R1LED, G1LED and B1LED

Between R2LED, G2LED and B2LED

Vf is LED forward voltage

VBAT3.2V, VOUT=4V

VOUT=0V

Io=150mA, VBAT3.1V

VBAT=2.5V, Io=150mA

Io=1~150mA

VBAT=3.2~5.5V, Io=150mA

f=100Hz, Vin=200mVp-p

Vo=0V

Io=150mA

(normal mode)

Io=100A

(low current consumption mode)

Io=1~150mA

VBAT=3.2~5.5V, Io=150mA

f=100Hz, Vin=200mVp-p

Vo=0V

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

2/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Technical Note

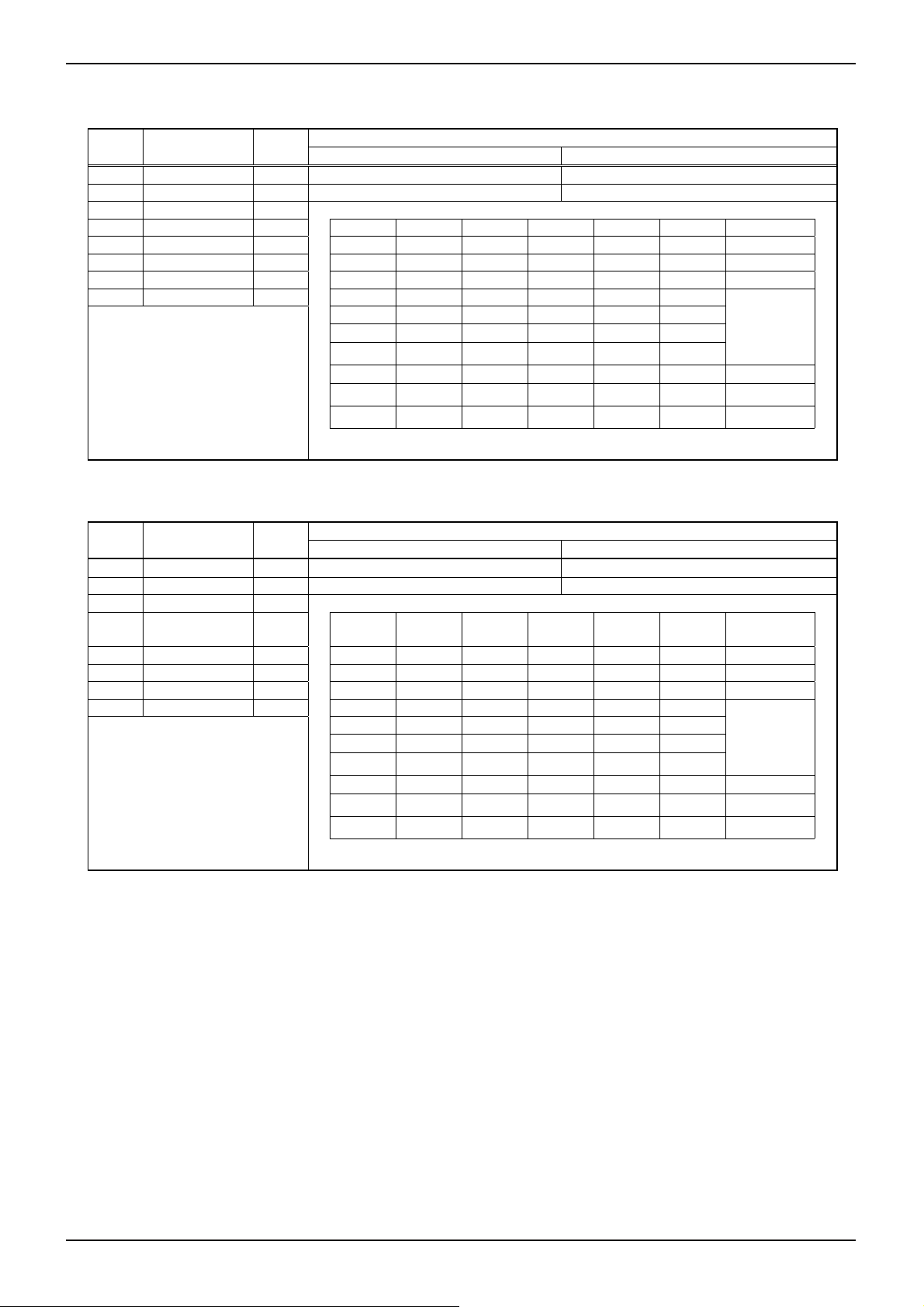

●Electrical Characteristics (Unless otherwise specified, Ta=25℃, VBAT=3.6V, VIO=1.8V)

Parameter Symbol

Min. Typ. Max.

Limits

Unit Condition

【I2C Input (SDA, SCL)】

LOW level input voltage

HIGH level input voltage

Hysteresis of Schmitt trigger input

LOW level output voltage

(SDA) at 3mA sink current

Input current each I/O pin

VIL -0.3 - 0.25 ×VIO V

VIH 0.75 ×VIO - VBAT+0.3 V

Vhys 0.05 ×VIO - - V

VOL 0 - 0.3 V

lin -10 - 10 A

Input voltage =

0.1×VIO~0.9×VIO

【RESET, RGB1CNT, RGB2CNT】

LOW level input voltage

HIGH level input voltage1

HIGH level input voltage2

Input current each I/O pin1

Input current each I/O pin2

VIL -0.3 - 0.25 ×VIO V

VIH1 0.75 ×VIO - VBAT+0.3 V

VIH2 0.75 ×VIO - VIO+0.3 V

Iin -10 - 10 A

Iin - 6 15 A

RESET Pin

RGB1CNT, RGB2CNT Pin

Input voltage =

0.1×VIO~0.9×VIO,RESET Pin

Input voltage = .9×VIO

,RGB1CNT, RGB2CNT Pin

【REG2EN, REG2MD】

LOW level input voltage

HIGH level input voltage

Input current each I/O pin

VIL -0.3 - 0.3 V

VIH 1.4 - VBAT,+0.3 V

Iin - 6 15 A Vin=1.8V

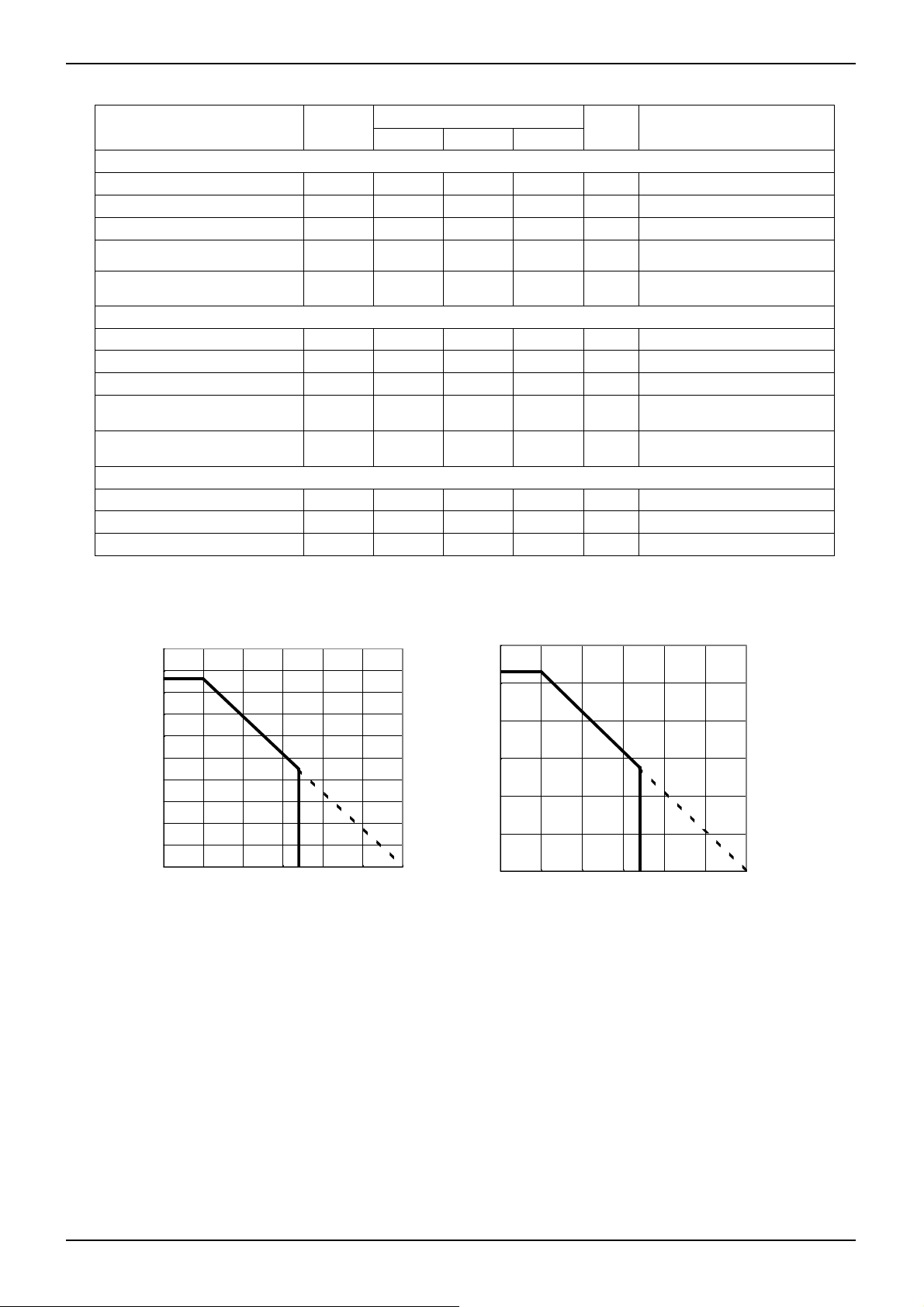

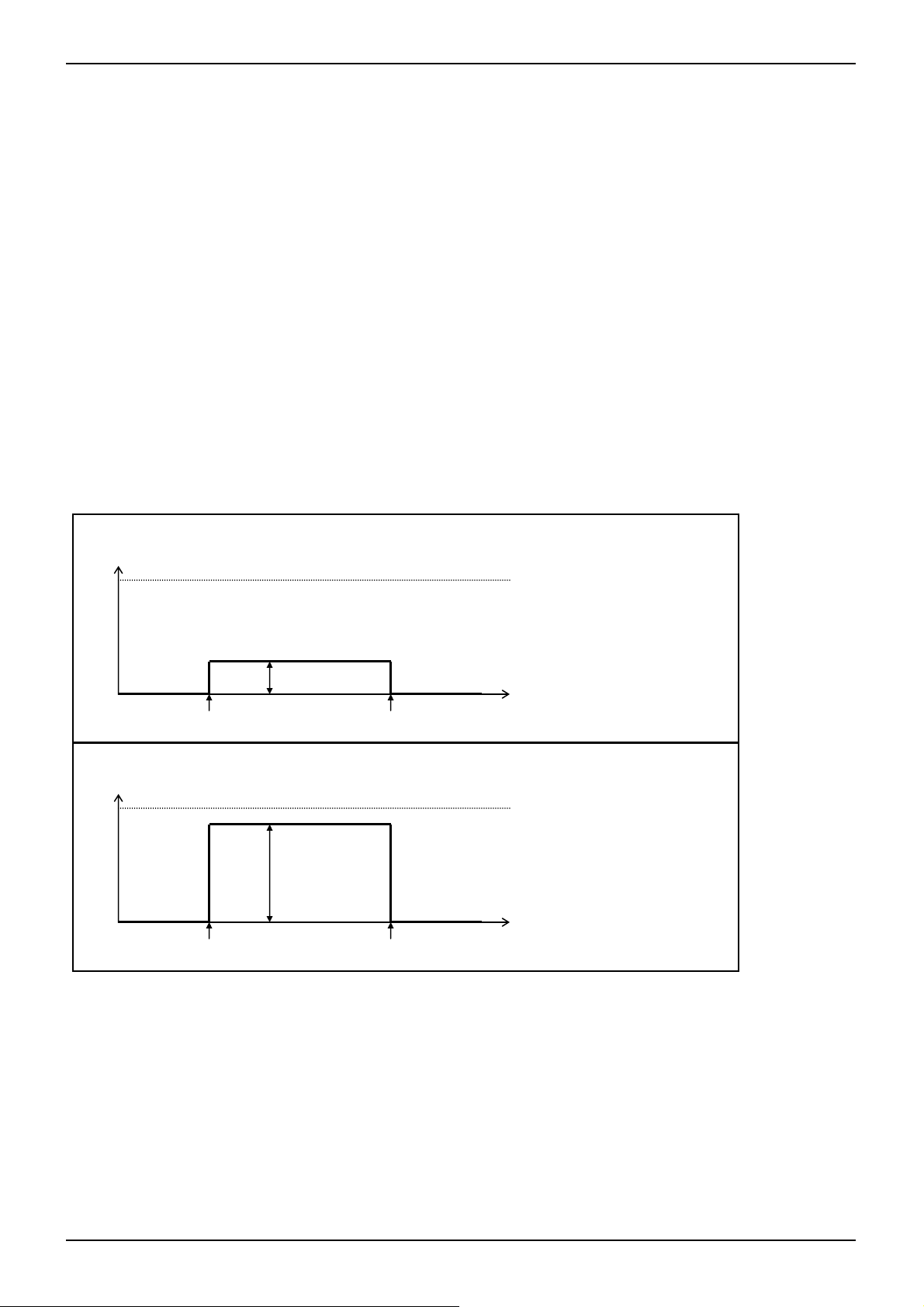

●Power dissipation (On the ROHM’s standard board)

BD6081GU BD6081GVW

2.0

1.8

1725mW

1.6

1.4

W)

1.2

(

1.0

0.8

Power Dissipation

0.6

0.4

0.2

0.0

0 25 50 75 100 125 150

Ta(

℃)

1.2

1.0

1060mW

0.8

W)

(

0.6

Power Dissipation

0.4

0.2

0.0

0 25 50 75 100 125 150

Ta( ℃)

Fig.1 Fig.2

Information of the ROHM’s standard board Information of the ROHM’s standard board

Material: glass-epoxy Material: glass-epoxy

Size: 50mm×58mm×1.75mm (8 Layer) Size: 114.3mm×76.2mm×1.6mm

Pattern of the board: Refer to it that goes later.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

3/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

A

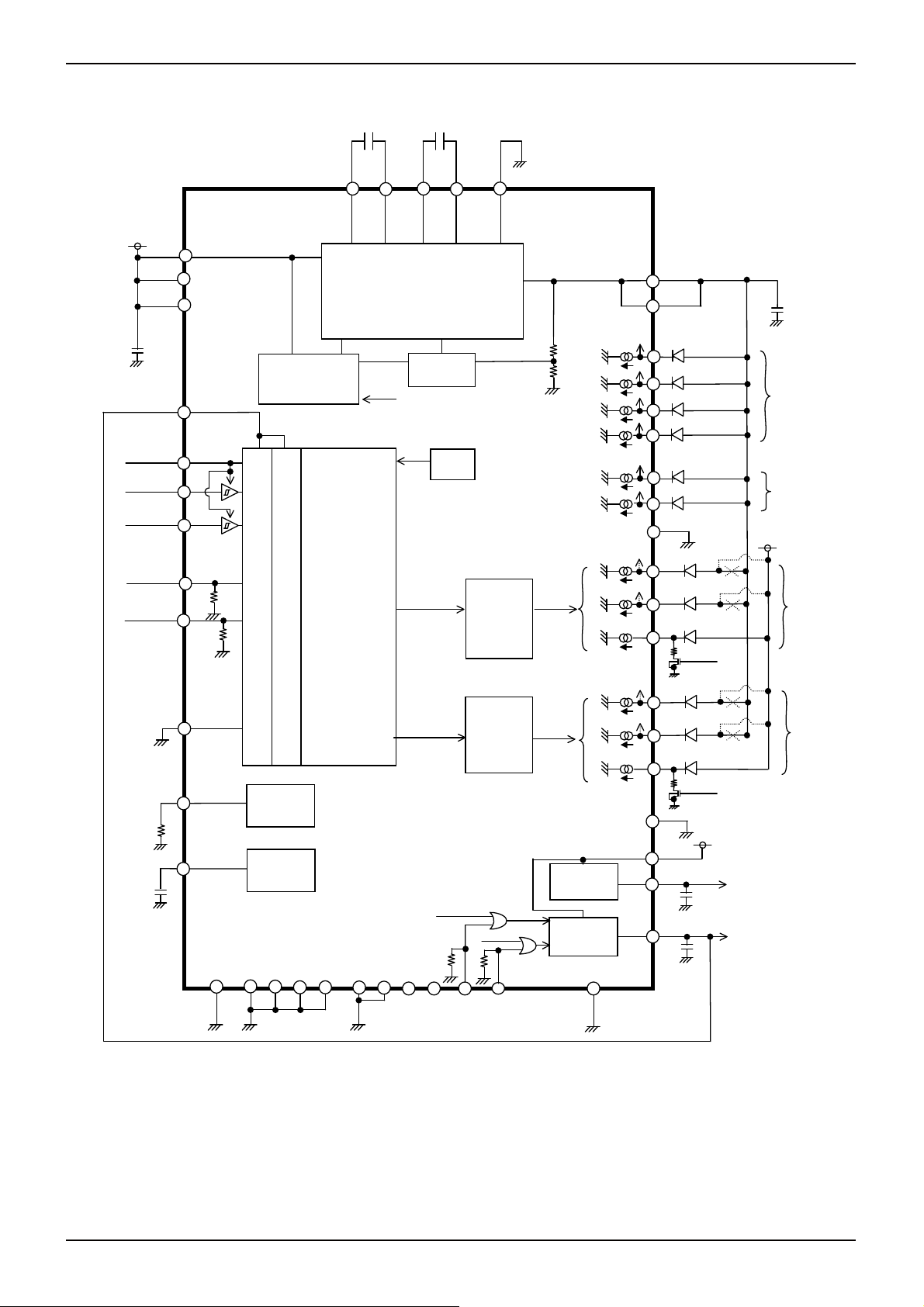

●Block Diagram / Application Circuit example

VBATCP

VBAT1

VBAT2

Charge Pump

Mode Control

VIO

RESET

SCL

SD

RGB1CNT

RGB2CNT

I/O

LEVEL

SHIFT

I2C

CONTROL

DGND

120k

0.1µF

ISET

CREF

IREF

VREF

T3

T1

REFGND

T2

T4

Fig.3 Block Diagram / Application Circuit example

1F (10V)

C1N

1F (10V)

C1P

C2N

Charge Pump

x1 / x1.5 / x2

OVP

LED terminal voltage feedback

Register control

TESTI2

TESTI1

TESTO1

TESTO2

C2P

TSD

Register control

REG2EN

CPGND

Slope

Control

(RGB1)

Slope

Control

(RGB2)

REG2MD

REG1

2.8V

Io=150mA

REG2

1.8V

Io=150mA

REGGND

VOUT

VOUTM

MLED1~4

SLED1~2

BLGND

G1LED

B1LED

R1LED

G2LED

B2LED

R2LED

RGBGND

VBATREG

REG1O

REG2O

Technical Note

VBAT

External Control

External Control

VBAT

1F

1F

1F

(10V)

Main LCD

Back Light

Sub LCD

Back Light

RGB1 LED

RGB2 LED

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

4/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

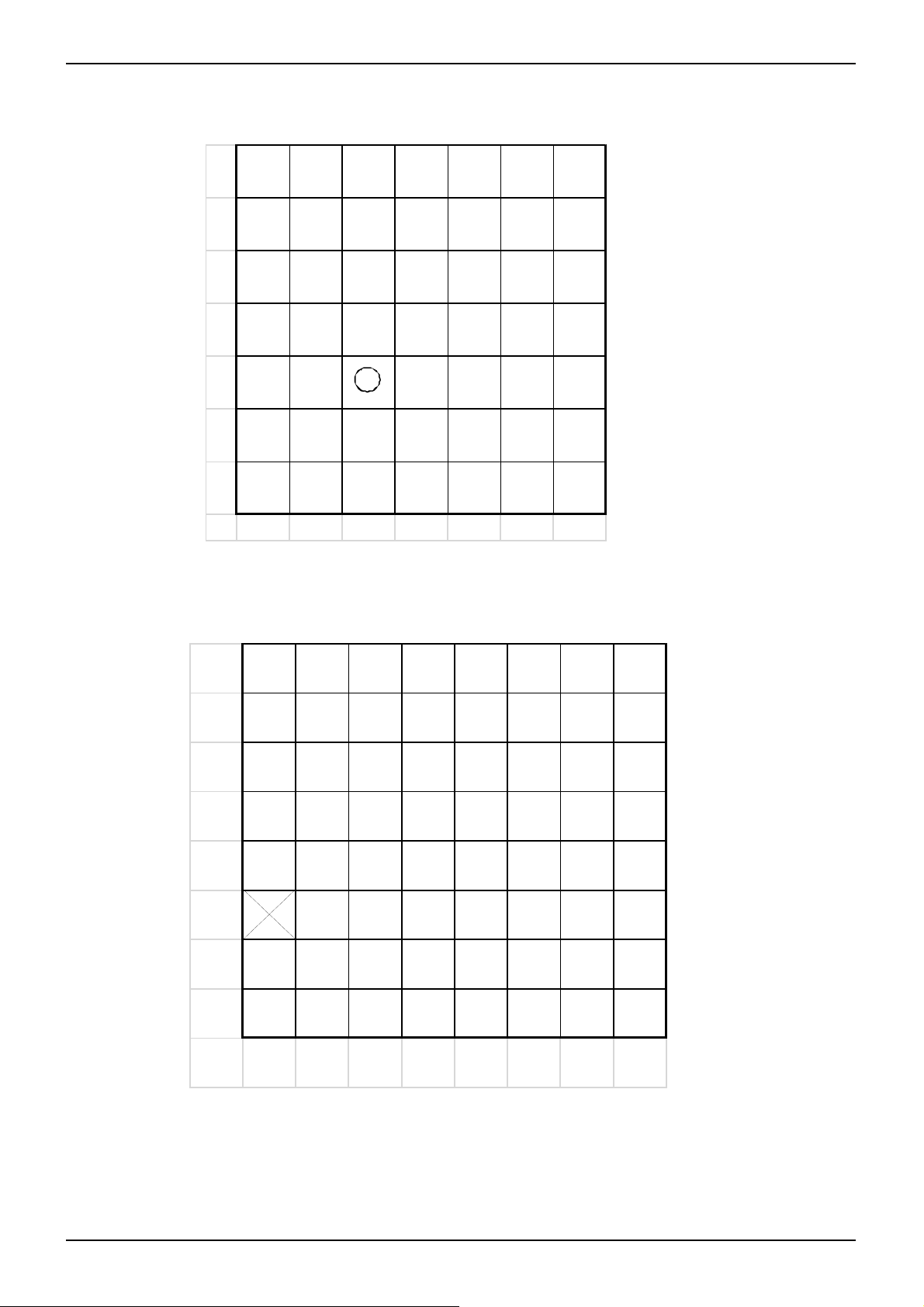

●Pin Arrangement [Bottom View]

BD6081GU

T4 VBAT1 REG2O

G

REFGND R1LED CREF REG1O REG2M D

F

G1LED B1LED ISET REG2EN

E

RGBGND R2LED TESTI1 TESTI2 SCL VOUTM VOUT

D

G2LED B2LED

C

SLED1 BLGND MLED2 MLED4 CPGND C1N VBATCP

B

T1 SLED2 MLED1 MLED3 V BA T2 C2N T2

A

1234567

Total: 48ball

There is no Ball only in C3 for index.

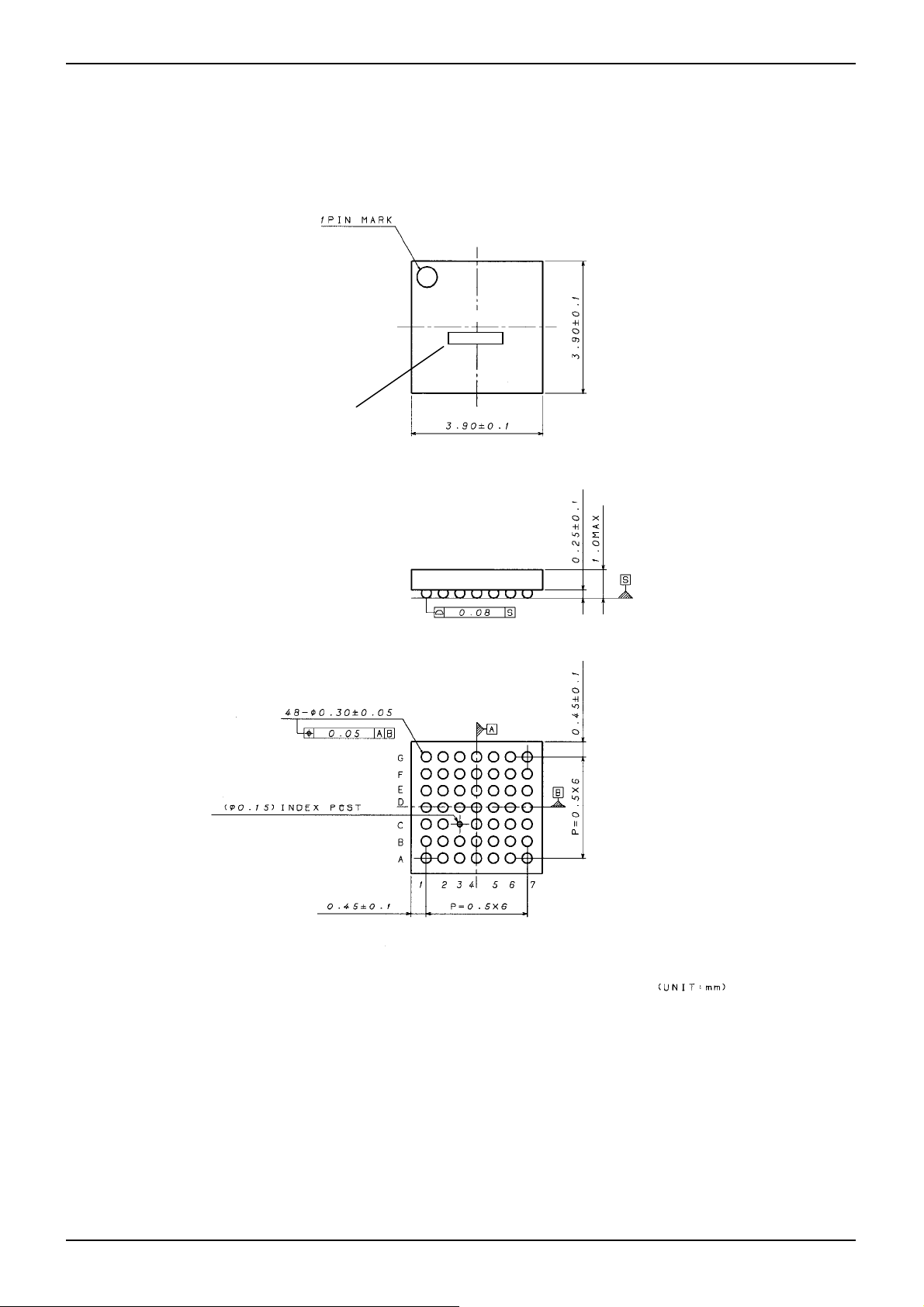

BD6081GVW

H

T2 C1P C2P - - SDA RESET T3

G

C1N - - VOUT M TESTO 1 SCL

CPGND C2N TESTI1 VOUT DGND

F

MLED3 MLED4 VBAT2

E

MLED2 - MLED1 - - REG1O

D

(index) BLGND B2LED - - TESTI2 CR EF REG2O

C

SLE D2 SLED1 R2LED - -

B

A

T1 G2LED

12345678

Total: 63ball

There is no Ball only in C1 for index.

“-“ means NC pin (Non connect to internal circuit)

VBATREG

TESTO2 TESTO1 C1P C2P

index

RGBGND

REGGND VIO T3

RGB2CNT

VBATCP

B1LED G1LED R1LED ISET T4

-

RGB1CNT

SDA DGN D

RGB1CNT

REG2EN

REFGND

RESET

RGB2CNT

TESTO2

REGGND

VBATREG

VIO

REG2MD

-VBAT1

Technical Note

-

-

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

5/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

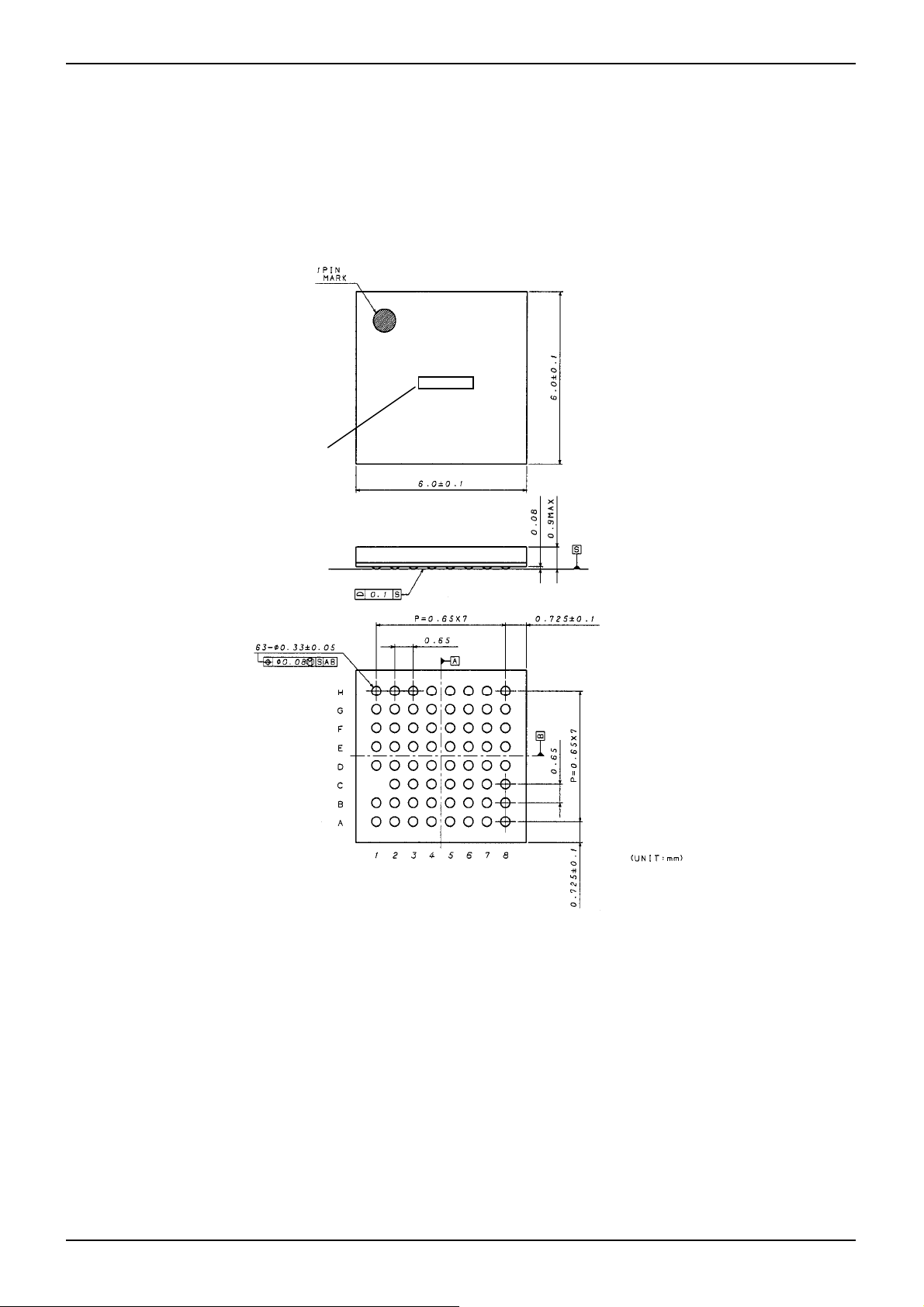

●Package

BD6081GU

VCSP85H3 CSP small Package

SIZE : 3.90mm×3.90mm(A difference in public: X and Y, together, ± 0.1mm) height 1.0mm max

A ball pitch : 0.5mm

BD6081

Lot No.

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

6/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

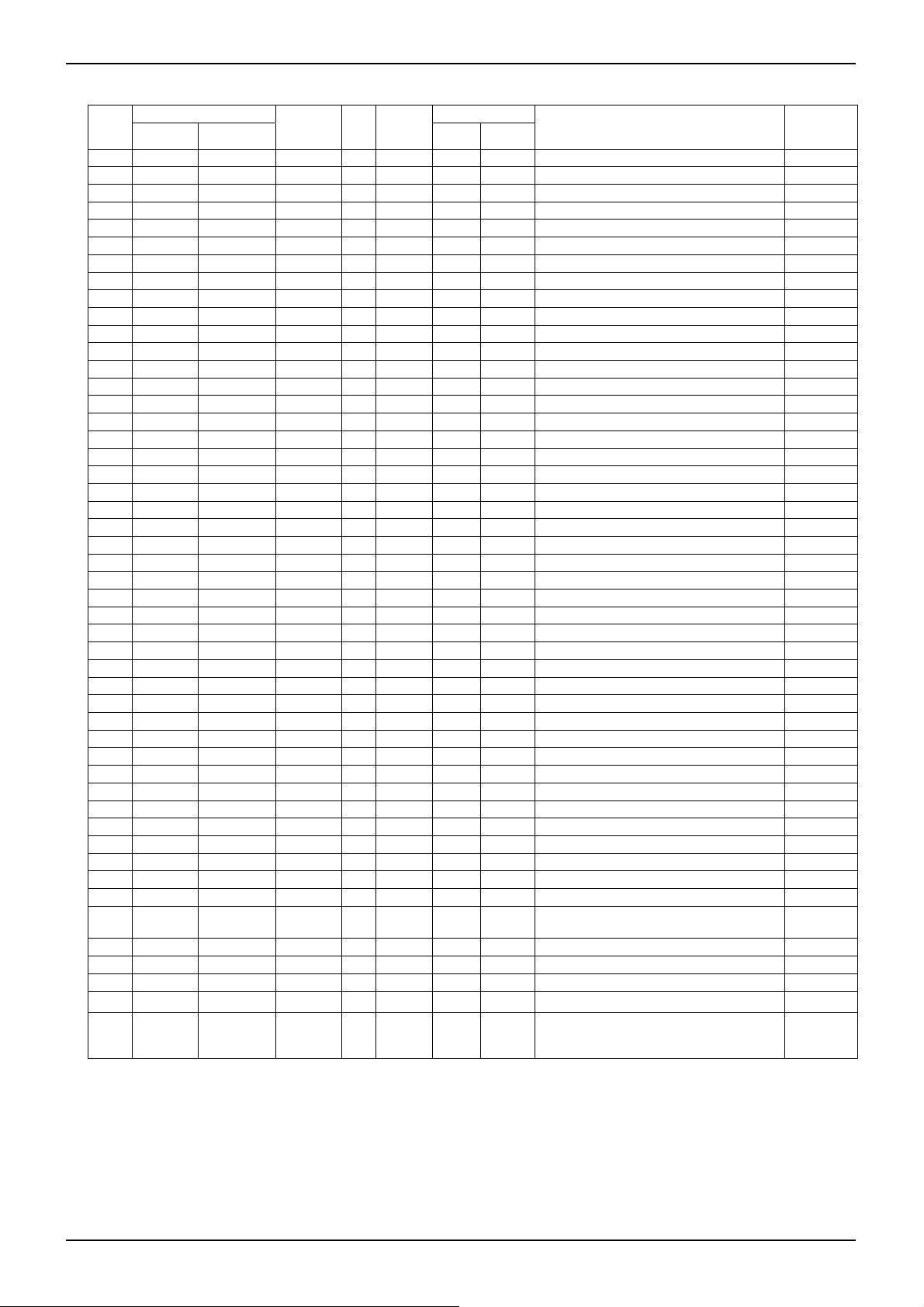

●Package

BD6081GVW

SBGA063W060

SIZE : 6.0mm×6.0mm(A difference in public: X and Y, together, ± 0.1mm) height 0.9mm max

A ball pitch : 0.65mm

BD6081

Lot No.

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

7/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

m

Technical Note

●Pin Functions

No

BD6081GU BD6081GVW

1 B7 E4 VBATCP - - - GND Battery is connected A

2 G2 B8 VBAT1 - - - GND Battery is connected A

3 A5 E3 VBAT2 - - - GND Battery is connected A

4 G4 D7 VBATREG - - - GND Battery is connected A

5 A1 A1 T1 - - - GND Test Pin (short to GND) A

6 A7 H1 T2 - - - GND Test Pin (short to GND) A

7 G7 H8 T3 - - VBAT GND Test Pin (short to GND) J

8 G1 A8 T4 - - VBAT GND Test Pin (short to GND) J

9 F3 C7 CREF O - VBAT GND Reference voltage output P

10 G6 G8 VIO - - VBAT GND I/O voltage source is connected C

11 F7 H7 RESET I VIO VBAT GND Reset input (L: RESET, H: RESET cancel) H

12 E6 H6 SDA I VIO VBAT GND I2C data input I

13 D5 G6 SCL I VIO VBAT GND I2C clock input H

14 B5 F1 CPGND - - VBAT - Ground B

15 F1 B6 REFGND - - VBAT - Ground B

16 G5 E7 REGGND - - VBAT - Ground B

17 B2 C2 BLGND - - VBAT - Ground B

18 D1 A3 RGBGND - - VBAT - Ground B

19 E7 F5 DGND - - VBAT - Ground B

20 B6 G1 C1N I/O - VBAT GND Charge Pump capacitor is connected F

21 C6 H2 C1P I/O - - GND Charge Pump capacitor is connected G

22 A6 F2 C2N I/O - VBAT GND Charge Pump capacitor is connected F

23

24 D7 F4 VOUT O 25 D6 G4 VOUTM O - - GND Charge Pump output pin output pin A

26 E3 A7 ISET I - VBAT GND LED standard current O

27 F4 D6 REG1O O - VBAT GND REG1 output pin Q

28 G3 C8 REG2O O - VBAT GND REG2 output pin Q

29 A3 D3 MLED1 I - VBAT GND Main LCD Back Light LED is connected 1 D

30 B3 D1 MLED2 I - VBAT GND Main LCD Back Light LED is connected 2 D

31 A4 E1 MLED3 I - VBAT GND Main LCD Back Light LED is connected 3 D

32 B4 E2 MLED4 I - VBAT GND Main LCD Back Light LED is connected 4 D

33 B1 B2 SLED1 I - VBAT GND Sub LCD Back Light LED is connected 1 D

34 A2 B1 SLED2 I - VBAT GND Sub LCD Back Light LED is connected 2 D

35 F2 A6 R1LED I

36 E1 A5 G1LED I - VBAT GND Green LED1 is connected D

37 E2 A4 B1LED I - VBAT GND Blue LED1 is connected D

38 D2 B3 R2LED I

39 C1 A2 G2LED I - VBAT GND Green LED2 is connected D

40 C2 C3 B2LED I - VBAT GND Blue LED2 is connected D

41 F6 F6 RGB1CNT I VIO VIO GND RGB1 LED external ON/OFF Synchronism Pin K

42 E5 G7 RGB2CNT I VIO VIO GND RGB2 LED external ON/OFF Synchronism Pin K

43 E4 E6 REG2EN I (VBAT) VBAT GND REG2 ON/OFF control Pin (L: OFF, H: ON) L

44 F5 F8 REG2MD I (VBAT) VBAT GND

45 D3 F3 TESTI1 I - VBAT GND Test input pin 1 (short to GND) H

46 D4 C6 TESTI2 I - VBAT GND Test input pin 2 (short to GND) H

47 C5 G5 TESTO1 O - VBAT GND Test output pin 1 (OPEN) M

48 C4 F7 TESTO2 O - VBAT GND Test output pin 2 (OPEN) N

49

-

63

※ The LED pin which isn't used is to short-circuit to the ground. But, the setup of a register concerned with LED that isn’t used is prohibited.

Total: Functional 48Pin

48 balls (BD6081GU)

63 balls (BD6081GVW)

Pin No.

C7

- (Other) NC - - - - Non connect pin -

H3 C2P I/O - - GND Charge Pump capacitor is connected G

Pin Name I/O

Input

Level

-

-

ESD Diode

For

Power

VBAT GND Red LED1 is connected D

VBAT GND Red LED2 is connected D

For

Ground

-

GND Charge Pump output pin A

REG2 Mode control Pin

(L: low current consumption, H: normal)

Functions

Equivalent

circuit diagra

L

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

8/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

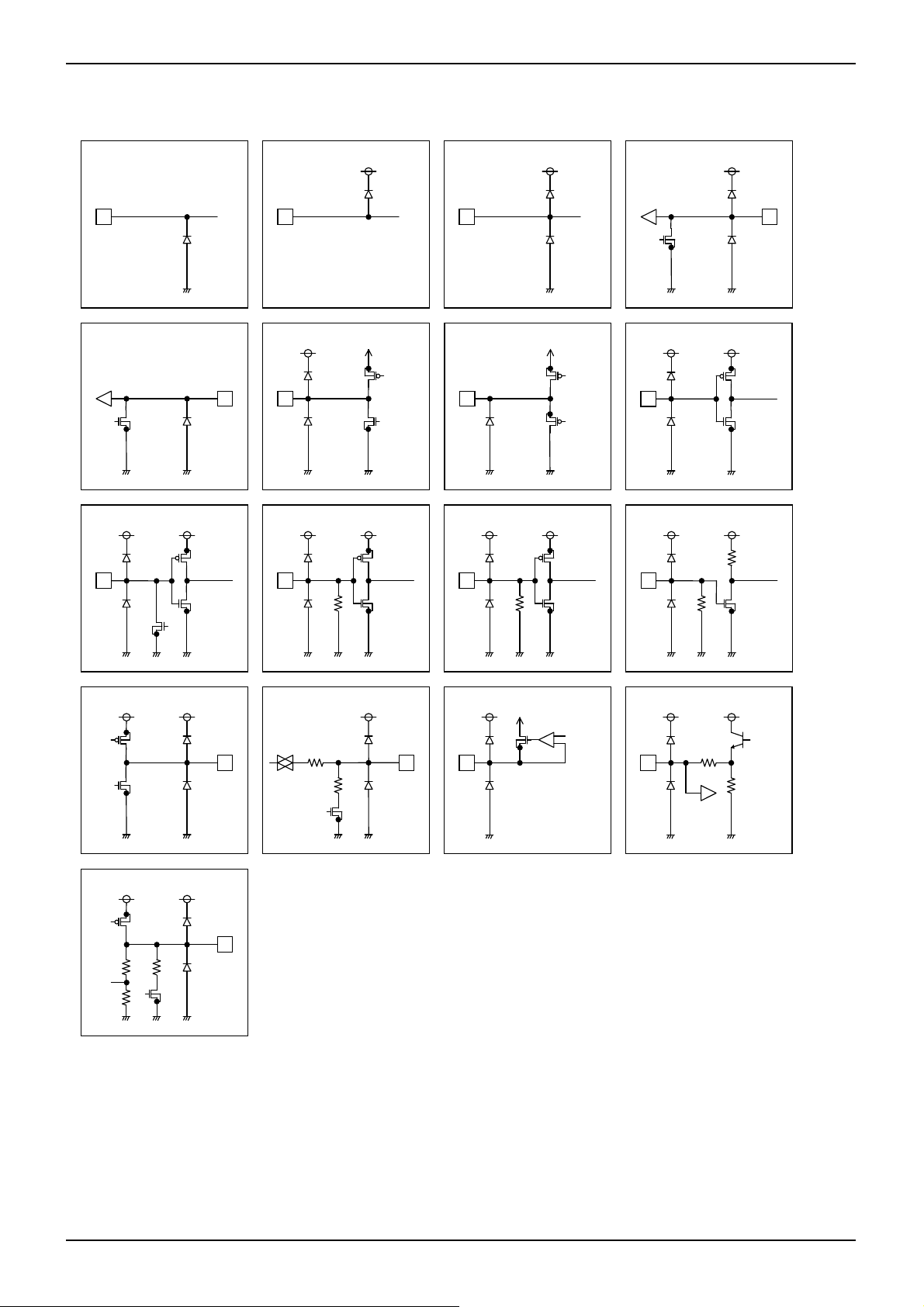

●Equivalent circuit diagram

A VBATB

C

VBAT

Technical Note

VBAT D

E

M

VBAT VBAT

F G

VBAT

VIO VBAT I VIO VBAT

J

N

VBAT

K

O

VBAT

H

VIOVIO

P

VBAT VBAT

VIO VBAT

VBAT VBAT L

Q

VBAT VBAT

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

9/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

r

Technical Note

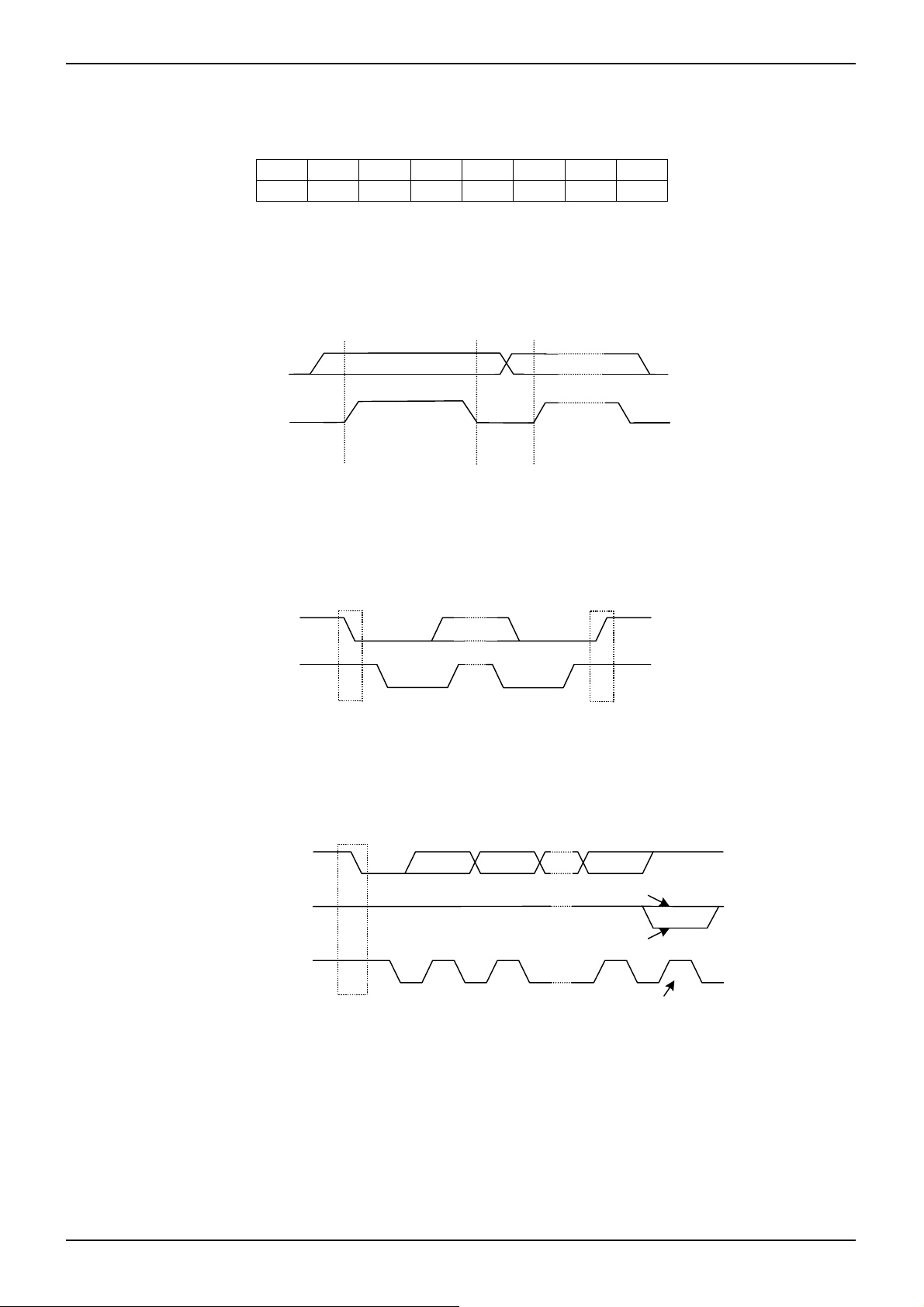

●I2C BUS format

The writing/reading operation is based on the I2C slave standard.

・Slave address

A7 A6 A5 A4 A3 A2 A1 W

1 1 1 0 1 1 0 0

・Bit Transfer

SCL transfers 1-bit data during H. SCL cannot change signal of SDA during H at the time of bit transfer. If SDA changes

while SCL is H, START conditions or STOP conditions will occur and it will be interpreted as a control signal.

SDA

SCL

Data lin e stable;

Data valid

Change of data

allowed

・START and STOP condition

When SDA and SCL are H, data is not transferred on the I

2

C- bus. This condition indicates, if SDA changes from H to L

while SCL has been H, it will become START (S) conditions, and an access start, if SDA changes from L to H while SCL

has been H, it will become STOP (P) conditions and an access end.

SDA

SCL

S P

START Condition

STOP Condition

・Acknowledge

It transfers data 8 bits each after the occurrence of START condition. A transmitter opens SDA after transfer 8bits data, and

a receiver returns the acknowledge signal by setting SDA to L.

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

SCL from maste

S

START condition

12 89

not acknowledge

acknowledge

clock pulse for

acknowledgement

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

10/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

A A

A

A

A7 A6 A5A4A3A2A1A

A

A

_

S

2

Technical Note

・ Writing protocol

A register address is transferred by the next 1 byte that transferred the slave address and the write-in command. The 3rd

byte writes data in the internal register written in by the 2nd byte, and after 4th byte or, the increment of register address is

carried out automatically. However, when a register address turns into the last address (1Ah), it is set to 00h by the next

transmission. After the transmission end, the increment of the address is carried out.

*1 *1

D7 D6D5 D4D3 D2D1D0 D7 D6 D5 D4 D3 D2D1D0

X X X X X X X

S

R/W=0(write)

from m aste r to slave

from slave to master

register addressslave address

00

DATA

register address

increment

=acknowledge(SDA LOW)

=not acknowledge(SDA HIGH)

S=START condition

P=STOP condition

*1: Write Timing

DATA

register address

●Timing diagram

SDA

BUF

t

SU;DAT

t

CL

LOW

t

HD;STA

t

HD;DAT

S Sr P

t

t HIGH

t

HD;STA

SU;STA

t

t SU;STO

S

●Electrical Characteristics(Unless otherwise specified, Ta=25 ℃, VBAT=3.6V, VIO=1.8V)

Standard-mode Fast-mode

Min. Typ. Max. Min. Typ. Max.

【I

C BUS format】

Parameter Symbol

SCL clock frequency fSCL 0 - 100 0 - 400 kHz

LOW period of the SCL clock tLOW 4.7 - - 1.3 - - s

HIGH period of the SCL clock tHIGH 4.0 - - 0.6 - - s

Hold time (repeated) START condition

After this period, the first clock is generated

tHD;STA 4.0 - - 0.6 - - s

Set-up time for a repeated START condition tSU;STA 4.7 - - 0.6 - - s

Data hold time tHD;DAT 0 - 3.45 0 - 0.9 s

Data set-up time tSU;DAT 250 - - 100 - - ns

Set-up time for STOP condition tSU;STO 4.0 - - 0.6 - - s

Bus free time between a STOP

and START condition

BUF 4.7 - - 1.3 - - s

t

P

Unit

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

11/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Technical Note

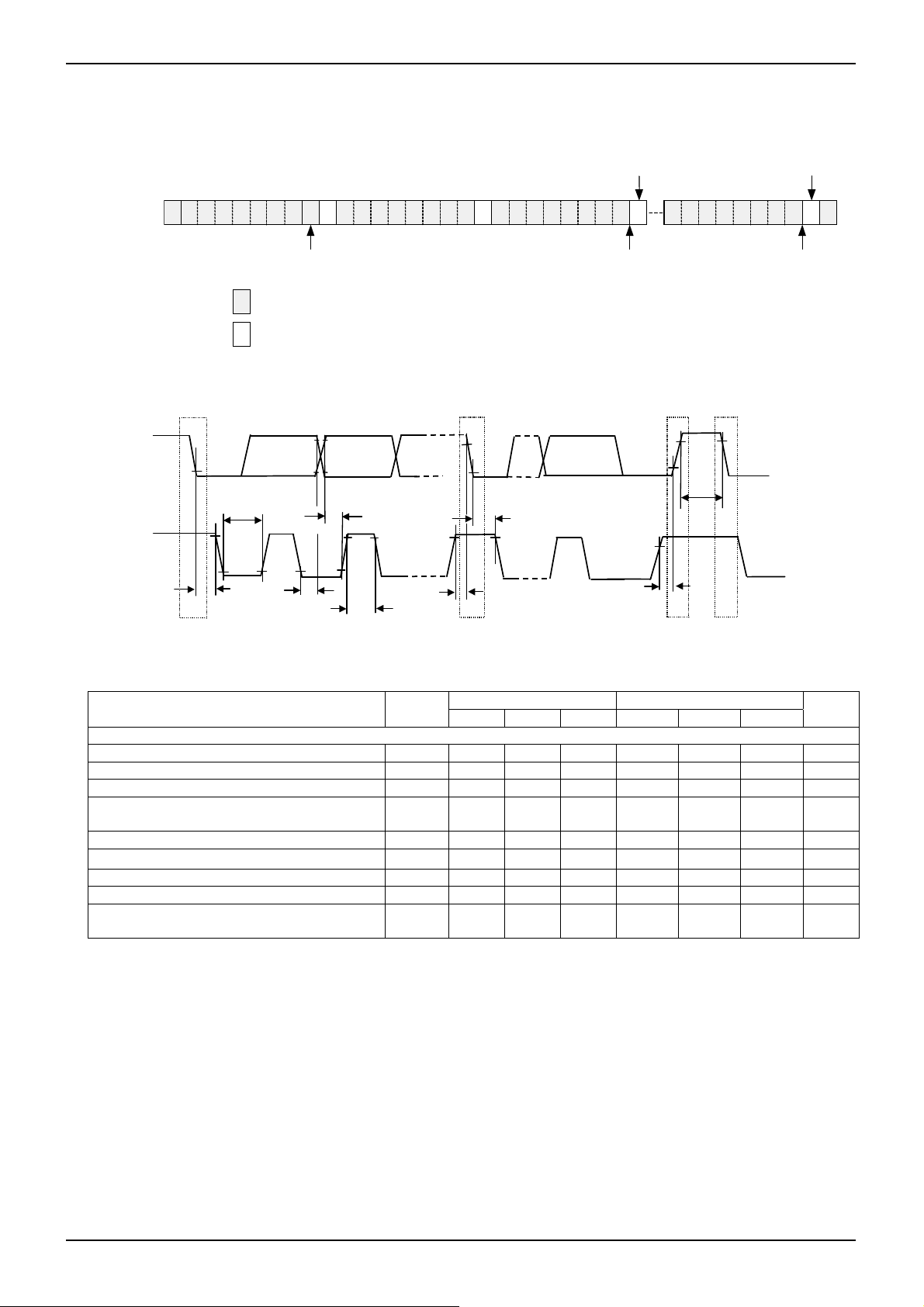

●Register List

Address

00h

01h

02h

03h

04h

05h

06h

07h

08h

09h

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

13h

14h

15h

16h - - I1G2LED5 I1G2LED4 I1G2LED3 I1G2LED2 I1G2LED1 I1G2LED0 G2 LED current value1

17h

18h

19h

1Ah

1Dh

1Eh

1Fh

D7 D6 D5 D4 D3 D2 D1 D0

- - - - - - - SFTRST Software reset

- - REG2NML REG2PD - - - REG1PD Control LDO

- - SLEDSEL SLEDEN - - MLEDSEL MLEDEN Control Back Light

- - - IMLED4 IMLED3 IMLED2 IMLED1 IMLED0 Main Back Light current value

- - - ISLED4 ISLED3 ISLED2 ISLED1 ISLED0 Sub Back Light current value

- B2LEDMD G2LEDMD RGB2STA - B1LEDMD G1LEDMD RGB1STA

RGB1MD1 RGB1MD0 B1LEDPL G1LEDPL R1LEDPL B1LEDEN G1LEDEN R1LEDEN Control RGB1 LED

RGB1WT1TM3 RGB1WT1TM2 RGB1WT1TM1 RGB1WT1TM0 RGB1WT2TM3 RGB1WT2TM2 RGB1WT2TM1 RGB1WT2TM0 RGB1 ON time setting

RGB1SL1

STEP3

- - - - - RGB1SLNUM2 RGB1SLNUM1 RGB1SLNUM0 RGB1 slope step number setting

- - I1R1LED5 I1R1LED4 I1R1LED3 I1R1LED2 I1R1LED1 I1R1LED0 R1 LED current value1

- - IDLTR1LED5 IDLTR1LED4 IDLTR1LED3 IDLTR1LED2 IDLTR1LED1 IDLTR1LED0

- - I1G1LED5 I1G1LED4 I1G1LED3 I1G1LED2 I1G1LED1 I1G1LED0 G1 LED current value1

- - IDLTG1LED5 IDLTG1LED4 IDLTG1LED3 IDLTG1LED2 IDLTG1LED1 IDLTG1LED0

- - I1B1LED5 I1B1LED4 I1B1LED3 I1B1LED2 I1B1LED1 I1B1LED0 B1 LED current value1

- - IDLTB1LED5 IDLTB1LED4 IDLTB1LED3 IDLTB1LED2 IDLTB1LED1 IDLTB1LED0

RGB2MD1 RGB2MD0 B2LEDPL G2LEDPL R2LEDPL B2LEDEN G2LEDEN R2LEDEN Control RGB2 LED

RGB2WT1TM3 RGB2WT1TM2 RGB2WT1TM1 RGB2WT1TM0 RGB2WT2TM3 RGB2WT2TM2 RGB2WT2TM1 RGB2WT2TM0 RGB2 ON time setting

RGB2SL1

STEP3

- - - - - RGB2SLNUM2 RGB2SLNUM1 RGB2SLNUM0 RGB2 slope step number setting

- - I1R2LED5 I1R2LED4 I1R2LED3 I1R2LED2 I1R2LED1 I1R2LED0 R2 LED current value1

- - IDLTR2LED5 IDLTR2LED4 IDLTR2LED3 IDLTR2LED2 IDLTR2LED1 IDLTR2LED0

- - IDLTG2LED5 IDLTG2LED4 IDLTG2LED3 IDLTG2LED2 IDLTG2LED1 IDLTG2LED0

- - I1B2LED5 I1B2LED4 I1B2LED3 I1B2LED2 I1B2LED1 I1B2LED0 B2 LED current value1

- - IDLTB2LED5 IDLTB2LED4 IDLTB2LED3 IDLTB2LED2 IDLTB2LED1 IDLTB2LED0

- - - - - - RGB2MEL RGB1MEL

RGB1SL1

STEP2

RGB2SL1

STEP2

RGB1SL1

STEP1

RGB2SL1

STEP1

Input "0” for "-".

Prohibit to accessing the address that isn’t mentioned and the register for test.

Register data

Control RGB1, RGB2 LED

Setting GB LED connection

RGB1SL1

STEP0

RGB2SL1

STEP0

RGB1SL2

STEP3

RGB2SL2

STEP3

Reserved For test

Reserved For test

Reserved For test

RGB1SL2

STEP2

RGB2SL2

STEP2

RGB1SL2

STEP1

RGB2SL2

STEP1

RGB1SL2

STEP0

RGB2SL2

STEP0

RGB1 slope

1step time setting

current value

for R1 LED current step

current value

for G1 LED current step

current value

for B1 LED current step

RGB2 slope

1step time setting

current value

for R2 LED current step

current value

for G2 LED current step

current value

for B2 LED current step

RGB1, RGB2 LED

external ON/OFF control

Function

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

12/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

●Register Map

Address 00h <Software reset>

BIT Name Initial

D7 - - - D6 - - - D5 - - - D4 - - - D3 - - - D2 - - - D1 - - - D0 SFTRST 0 Reset cancel Reset

Address 01h <Control LDO>

BIT Name Initial

D7 - - - D6 - - - D5 REG2NML 0 REG2 low current consumption mode REG2 normal mode

D4 REG2PD 0 REG2 power OFF REG2 power ON

D3 - - - D2 - - - D1 - - - D0 REG1PD 0 REG1 power OFF REG1 power ON

Address 02h <Control Back Light>

BIT Name Initial

D7 - - - D6 - - - D5 SLEDSEL 0 2 lights ON (SLED1~2) 1 lights ON (SLED1)

D4 SLEDEN 0 Sub Back Light OFF Sub Back Light ON

D3 - - - D2 - - - D1 MLEDSEL 0 4 lights ON (MLED1~4) 3 lights ON (MLED1~3)

D0 MLEDEN 0 Main Back Light OFF Main Back Light ON

0 1

0 1

0 1

Function

Function

Function

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

13/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 03h <Main Back Light current value>

BIT Name Initial

D7 - - - D6 - - - D5 - - - D4 IMLED4 0

D3 IMLED3 0 IMLED4 IMLED3 IMLED2 IMLED1 IMLED0 Current value

D2 IMLED2 0 0 0 0 0 0 1mA

D1 IMLED1 0 0 0 0 0 1 2mA

D0 IMLED0 0 0 0 0 1 0 3mA

・ ・ ・ ・ ・

・ ・ ・ ・ ・

・ ・ ・ ・ ・

1 1 1 0 1 30mA

1 1 1 1 0 31mA

1 1 1 1 1 32mA

When 120k is connected to ISET pin.

0 1

Function

Technical Note

1mA

Step

Address 04h <Sub Back Light current value>

BIT Name Initial

D7 - - - D6 - - - D5 - - - D4 ISLED4 0

D3 ISLED3 0

D2 ISLED2 0

D1 ISLED1 0

D0 ISLED0 0

ISLED4 ISLED3 ISLED2 ISLED1 ISLED0 Current value

0 0 0 0 0 1mA

0 0 0 0 1 2mA

0 0 0 1 0 3mA

・ ・ ・ ・ ・

・ ・ ・ ・ ・

・ ・ ・ ・ ・

1 1 1 0 1 30mA

1 1 1 1 0 31mA

1 1 1 1 1 32mA

When 120k is connected to ISET pin.

0 1

Function

1mA

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

14/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 05h <Control RGB1, RGB2 LED, Setting GB LED connection>

BIT Name Initial

D7 - - - D6 B2LEDMD 0 B2LED connection =VBAT B2LED connection =VOUT

D5 G2LEDMD 0 G2LED connection =VBAT G2LED connection =VOUT

D4 RGB2STA 0 RGB2 LED Lighting stop RGB2 LED Lighting start

D3 - - - D2 B1LEDMD 0 B1LED connection =VBAT B1LED connection =VOUT

D1 G1LEDMD 0 G1LED connection =VBAT G1LED connection =VOUT

D0 RGB1STA 0 RGB1 LED Lighting stop RGB1 LED Lighting start

Address 06h <Control RGB1 LED>

BIT Name Initial

D7 RGB1MD1 0 Refer to the following Refer to the following

D6 RGB1MD0 0 Refer to the following Refer to the following

D5 B1LEDPL 0 Refer to the following Refer to the following

D4 G1LEDPL 0 Refer to the following Refer to the following

D3 R1LEDPL 0 Refer to the following Refer to the following

D2 B1LEDEN 0 B1 LED OFF B1 LED ON

D1 G1LEDEN 0 G1 LED OFF G1 LED ON

D0 R1LE DEN 0 R1 LED OFF R1 LED ON

RGB1MD1 RGB1MD0 *1LEDPL Mode

0 0 0 / 1 Normal 1

0 1 0 / 1 Normal 2

Address 07h <RGB1 ON time setting>

1 0

1 1

*1LEDPL : R1LEDPL, G1LEDPL, B1LEDPL is shown.

0 1

0 1

Function

Function

0 Blink 1

1 Blink 2

0 Slope 1

1 Slope 2

Technical Note

BIT Name Initial Function

D7 RGB1WT1TM3 0

D6 RGB1WT1TM2 0 RGB1WT1TM3 RGB1WT1TM2 RGB1WT1TM1 RGB1WT1TM0 Current light time

D5 RGB1WT1TM1 0 0 0 0 0 0.256s

D4 RGB1WT1TM0 0 0 0 0 1 0.512s

・

・

・

1 1 0 1 3.584s

D3 RGB1WT2TM3 0

D2 RGB1WT2TM2 0 RGB1WT2TM3 RGB1WT2TM2 RGB1WT2TM1 RGB1WT2TM0 Current light t ime

D1 RGB1WT2TM1 0 0 0 0 0 0.256s

D0 RGB1WT2TM0 0 0 0 0 1 0.512s

1 1 1 0 3.84s

1 1 1 1 4.096s

Lighting time depends on internal OSC frequency.

・

・

・

1 1 0 1 3.584s

1 1 1 0 3.84s

1 1 1 1 4.096s

Lighting time depends on internal OSC frequency.

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

0.256s

Step

0.256s

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

15/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 08h <RGB1 slope 1step time setting>

BIT Name Initial Function

Technical Note

D7 RGB1SL1STEP3 0

D6 RGB1SL1STEP2 0

D5 RGB1SL1STEP1 0 0 0 0 0 4ms

D4 RGB1SL1STEP0 0 0 0 0 1 8ms

D3 RGB1SL2STEP3 0

D2 RGB1SL2STEP2 0

D1 RGB1SL2STEP1 0 0 0 0 0 4ms

D0 RGB1SL2STEP0 0 0 0 0 1 8ms

RGB1SL1

STEP3

・

・

・

1 1 0 1 56ms

1 1 1 0 60ms

1 1 1 1 64ms

Lighting time depends on internal OSC frequency.

RGB1SL2

STEP3

・

・

・

1 1 0 1 56ms

1 1 1 0 60ms

1 1 1 1 64ms

RGB1SL1

STEP2

・

・

・

RGB1SL2

STEP2

・

・

・

RGB1SL1

STEP1

RGB1SL2

STEP1

・

・

・

・

・

・

RGB1SL1

STEP0

RGB1SL2

STEP0

・

・

・

・

・

・

Current light time

4ms

Step

Current light time

4ms

Step

Lighting time depends on internal OSC frequency.

Address 09h <RGB1 slope step number setting>

BIT Name Initial

D7 - - - D6 - - - D5 - - - D4 - - - D3 - -

D2 RGB1SLNUM2 0

D1 RGB1SLNUM1 0 RGB1SLNUM2 RGB1SLNUM1 RGB1SLNUM0 Step

D0 RGB1SLNUM0 0 0 0 0 1 Step

0 0 1 2 Step

0 1

0 1 0 4 Step

0 1 1 8 Step

1 0 0 16 Step

1 0 1 32 Step

1 1 0 64 Step

1 1 1 (Prohibited)

Function

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

16/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 0Ah <R1 LED current value 1>

BIT Name Initial

D7 - - - D6 - - - D5 I1R1LED5 0

D4 I1R1LED4 0

D3 I1R1LED3 0

D2 I1R1LED2 0 0 0 0 0 0 1 0.5mA

D1 I1R1LED1 0 0 0 0 0 1 0 1mA

D0 I1R1LED0 0 ・ ・ ・ ・ ・ ・

Address 0Bh < current value for R1 LED current step>

BIT Name Initial

D7 - - - D6 - - - D5 IDLTR1LED5 0

D4 IDLTR1LED4 0

D3 IDLTR1LED3 0

D2 IDLTR1LED2 0 0 0 0 0 0 1 0.5mA

D1 IDLTR1LED1 0 0 0 0 0 1 0 1mA

D0 IDLTR1LED0 0 ・ ・ ・ ・ ・ ・

I1R1

LED5

0 0 0 0 0 0 0mA

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

When 120k is connected to ISET pin.

IDL TR1

LED5

0 0 0 0 0 0 0mA

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

0 1

I1R1

LED4

0 1

IDL TR1

LED4

I1R1

LED3

IDL TR1

LED3

Function

I1R1

LED2

Function

IDL TR1

LED2

I1R1

LED1

IDL TR1

LED1

I1R1

LED0

IDL TR1

LED0

Technical Note

Current value

0.5mA

Current value

0.5mA

Step

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

When 120k is connected to ISET pin.

17/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Technical Note

Address 0Ch <G1 LED current value1>

BIT Name Initial

D7 - - - D6 - - - D5 I1G1LED5 0

D4

D3 I1G1LED3 0 0 0 0 0 0 0 0mA

D2 I1G1LED2 0 0 0 0 0 0 1 0.5mA

D1 I1G1LED1 0 0 0 0 0 1 0 1mA

D0 I1G1LED0 0 ・ ・ ・ ・ ・ ・

I1G1LED4 0

・ ・ ・ ・ ・ ・

I1G1

LED5

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

When 120k is connected to ISET pin.

0 1

I1G1

LED4

I1G1

LED3

Function

I1G1

LED2

I1G1

LED1

I1G1

LED0

Current

value

0.5mA

Address 0Dh < current value for G1 LED current step >

BIT Name Initial

D7 - - - D6 - - - D5 IDLTG1LED5 0

D4

D3 IDLTG1LED3 0 0 0 0 0 0 0 0mA

D2 IDLTG1LED2 0 0 0 0 0 0 1 0.5mA

D1 IDLTG1LED1 0 0 0 0 0 1 0 1mA

D0 IDLTG1LED0 0 ・ ・ ・ ・ ・ ・

IDLTG1LED4 0

・ ・ ・ ・ ・ ・

IDLTG1

LED5

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

When 120k is connected to ISET pin.

0 1

IDLTG1

LED4

IDLTG1

LED3

Function

IDLTG1

LED2

IDLTG1

LED1

IDLTG1

LED0

Current value

0.5mAStep

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

18/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 0Eh <B1 LED Current value1>

BIT Name Initial

D7 - - - D6 - - - D5 I1B1LED5 0

D4

D3 I1B1LED3 0 0 0 0 0 0 0 0mA

D2 I1B1LED2 0 0 0 0 0 0 1 0.5mA

D1 I1B1LED1 0 0 0 0 0 1 0 1mA

D0 I1B1LED0 0 ・ ・ ・ ・ ・ ・

I1B1LED4 0

・ ・ ・ ・ ・ ・

I1B1

LED5

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

When 120k is connected to ISET pin.

0 1

I1B1

LED4

I1B1

LED3

Function

I1B1

LED2

I1B1

LED1

I1B1

LED0

Technical Note

Current value

0.5mA

Address 0Fh < current value for B1 LED current step >

BIT Name Initial

D7 - - - D6 - - - D5 IDLTB1LED5 0

D4

D3 IDLTB1LED3 0 0 0 0 0 0 0 0mA

D2 IDLTB1LED2 0 0 0 0 0 0 1 0.5mA

D1 IDLTB1LED1 0 0 0 0 0 1 0 1mA

D0 IDLTB1LED0 0 ・ ・ ・ ・ ・ ・

IDLTB1LED4 0

・ ・ ・ ・ ・ ・

IDLTB1

LED5

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

When 120k is connected to ISET pin.

0 1

IDLTB1

LED4

IDLTB1

LED3

Function

IDLTB1

LED2

IDLTB1

LED1

IDLTB1

LED0

Current value

0.5mA

Step

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

19/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 10h <Control RGB2 LED>

BIT Name Initial

D7 RGB2MD1 0 Refer to following Refer to following

D6 RGB2MD0 0 Refer to following Refer to following

D5 B2LEDPL 0 Refer to following Refer to following

D4 G2LEDPL 0 Refer to following Refer to following

D3 R2LEDPL 0 Refer to following Refer to following

D2 B2LEDEN 0 B2 LED OF F B2 LED ON

D1 G2LEDEN 0 G2 LED OFF G2 LED ON

D0 R2LEDEN 0

RGB2MD1 RGB2MD0 *2LEDPL Mode

0 0 0 / 1 Normal 1

0 1 0 / 1 Normal 2

1 0

1 1

*2LEDPL : R2LEDPL, G2LEDPL, B2LEDPL is shown.

Address 11h <RGB2 ON time setting>

0 1

R2 LED OFF R2 LED ON

Function

0 Blink 1

1 Blink 2

0 Slope 1

1 Slope 2

Technical Note

BIT Name

D7 RGB2WT1TM3 0

D6 RGB2WT1TM2 0

D5 RGB2WT1TM1 0 0 0 0 0 0.256s

D4 RGB2WT1TM0 0 0 0 0 1 0.512s

D3 RGB2WT2TM3 0

D2 RGB2WT2TM2 0

D1 RGB2WT2TM1 0 0 0 0 0 0.256s

D0 RGB2WT2TM0 0 0 0 0 1 0.512s

Initial Function

RGB2WT1

TM3

・

・

・

1 1 0 1 3.584s

1 1 1 0 3.845s

1 1 1 1 4.096s

RGB2WT2

TM3

・

・

・

1 1 0 1 3.584s

1 1 1 0 3.845s

1 1 1 1 4.096s

RGB2WT1

TM2

・

・

・

Lighting time depends on internal OSC frequency.

RGB2WT2

TM2

・

・

・

Lighting time depends on internal OSC frequency.

RGB2WT1

TM1

・

・

・

RGB2WT2

TM1

・

・

・

RGB2WT1

TM0

・

・

・

RGB2WT2

TM0

・

・

・

Current ON time

setting

0.256s

Step

Current ON time

setting

0.256s

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

20/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 12h <RGB2 slope 1step time setting>

Technical Note

BIT

D7 RGB2SL1STEP3 0

D6 RGB2SL1STEP2 0

D5 RGB2SL1STEP1 0 0 0 0 0 4ms

D4 RGB2SL1STEP0 0 0 0 0 1 8ms

D3 RGB2SL2STEP3 0

D2 RGB2SL2STEP2 0

D1 RGB2SL2STEP1 0 0 0 0 0 4ms

D0 RGB2SL2STEP0 0 0 0 0 1 8ms

Name Initial Function

RGB2SL1STEP3 RGB2SL1STEP2 RGB2SL1STEP1 RGB2SL1STEP0

・

・

・

1 1 0 1 56ms

1 1 1 0 60ms

1 1 1 1 64ms

Lighting time depends on internal OSC frequency.

RGB2SL2STEP3 RGB2SL2STEP2 RGB2SL2STEP1 RGB2SL2STEP0

・

・

・

1 1 0 1 56ms

1 1 1 0 60ms

1 1 1 1 64ms

Lighting time depends on internal OSC frequency.

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

・

Current ON time setting

4ms

Step

Current ON time setting

4ms

Step

Address 13h <RGB2 slope step number setting>

BIT Name Initial

D7 - - - D6 - - - D5 - - - D4 - - - D3 - -

D2 RGB2SLNUM2 0

D1 RGB2SLNUM1 0 RGB2SLNUM2 RGB2SLNUM1 RGB2SLNUM0 Step

D0 RGB2SLNUM0 0 0 0 0 1 Step

0 0 1 2 Step

0 1

0 1 0 4 Step

0 1 1 8 Step

1 0 0 16 Step

1 0 1 32 Step

1 1 0 64 Step

1 1 1 (Prohibited)

Function

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

21/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Technical Note

Address 14h <R2 LED current value1>

BIT Name Initial

D7 - - - D6 - - - D5 I1R2LED5 0

D4 I1R2LED4 0 I1R2LED5 I1R2LED4 I1R2LED3 I1R2LED2 I1R2LED1 I1R2LED0 Current value

D3 I1R2LED3 0 0 0 0 0 0 0 0mA

D2 I1R2LED2 0 0 0 0 0 0 1 0.5mA

D1 I1R2LED1 0 0 0 0 0 1 0 1mA

D0 I1R2LED0 0 ・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

When 120k is connected to ISET pin.

0 1

Function

0.5mA

Address 15h < current value for R2 LED current step >

BIT Name Initial

D7 - - - D6 - - - D5 IDLTR2LED5 0

D4 IDLTR2LED4 0

D3 IDLTR2LED3 0 0 0 0 0 0 0 0mA

D2 IDLTR2LED2 0 0 0 0 0 0 1 0.5mA

D1 IDLTR2LED1 0 0 0 0 0 1 0 1mA

D0 IDLTR2LED0 0 ・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

IDLTR2

LED5

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

When 120k is connected to ISET pin.

0 1

IDL TR2

LED4

IDL TR2

LED3

Function

IDL TR2

LED2

IDL TR2

LED1

IDL TR2

LED0

Current

value

0.5mA

Step

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

22/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Technical Note

Address 16h <G2 LED current value1>

BIT Name Initial

D7 - - - D6 - - - D5 I1G2LED5 0

D4 I1G2LED4 0

D3 I1G2LED3 0 0 0 0 0 0 0 0mA

D2 I1G2LED2 0 0 0 0 0 0 1 0.5mA

D1 I1G2LED1 0 0 0 0 0 1 0 1mA

D0 I1G2LED0 0 ・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

Address 17h < current value for G2 LED current step >

BIT Name Initial

D7 - - - D6 - - - D5 IDLTG2LED5 0

D4 IDLTG2LED4 0

D3 IDLTG2LED3 0

D2 IDLTG2LED2 0 0 0 0 0 0 1 0.5mA

D1 IDLTG2LED1 0 0 0 0 0 1 0 1mA

D0 IDLTG2LED0 0 ・ ・ ・ ・ ・ ・

I1G2LED5 I1G2LED4 I1G2LED3 I1G2LED2 I1G2LED1 I1G2LED

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

IDLTG2

LED5

0 0 0 0 0 0 0mA

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

0 1

When 120k is connected to ISET pin.

0 1

IDLTG2

LED4

IDLTG2

LED3

Function

Function

IDLTG2

LED2

IDLTG2

LED1

0

IDLTG2

LED0

Current value

0.5mA

Current

value

0.5mA

Step

Step

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

When 120k is connected to ISET pin.

23/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Address 18h <B2 LED current value1>

BIT Name Initial

D7 - - - D6 - - - D5 I1B2LED5 0

D4 I1B2LED4 0 I1B2LED5 I1B2LED4 I1B2LED3 I1B2LED2 I1B2LED1 I1B2LED0 Current value

D3 I1B2LED3 0 0 0 0 0 0 0 0mA

D2 I1B2LED2 0 0 0 0 0 0 1 0.5mA

D1 I1B2LED1 0 0 0 0 0 1 0 1mA

D0 I1B2LED0 0 ・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

0 1

When 120k is connected to ISET pin.

Function

Technical Note

0.5mA

Address 19h < current value for B2 LED current step >

BIT Name Initial

D7 - - - D6 - - - D5 IDLTB2LED5 0

D4 IDLTB2LED4 0

D3 IDLTB2LED3 0 0 0 0 0 0 0 0mA

D2 IDLTB2LED2 0 0 0 0 0 0 1 0.5mA

D1 IDLTB2LED1 0 0 0 0 0 1 0 1mA

D0 IDLTB2LED0 0 ・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

IDLTB2

LED5

・ ・ ・ ・ ・ ・

・ ・ ・ ・ ・ ・

1 1 1 1 0 1 30.5mA

1 1 1 1 1 0 31mA

1 1 1 1 1 1 31.5mA

0 1

IDLTB2

LED4

IDLTB2

LED3

When 120k is connected to ISET pin.

Function

IDLTB2

LED2

IDLTB2

LED1

IDLTB2

LED0

Current value

0.5mA

Step

Step

Address 1Ah <RGB1, RGB2 LED external ON/OFF control>

BIT Name Initial

D7 - - - D6 - - - D5 - - - D4 - - - D3 - - - D2 - - - D1 RGB2MEL 0

D0 RGB1MEL 0 RGB*MEL RGB*CNT (external pin) RGB* LED Lighting

0 L ON

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Function

0 1

0 H ON

1 L OFF

1 H ON

But, a state of lighting depends on the setup of other registers.

24/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

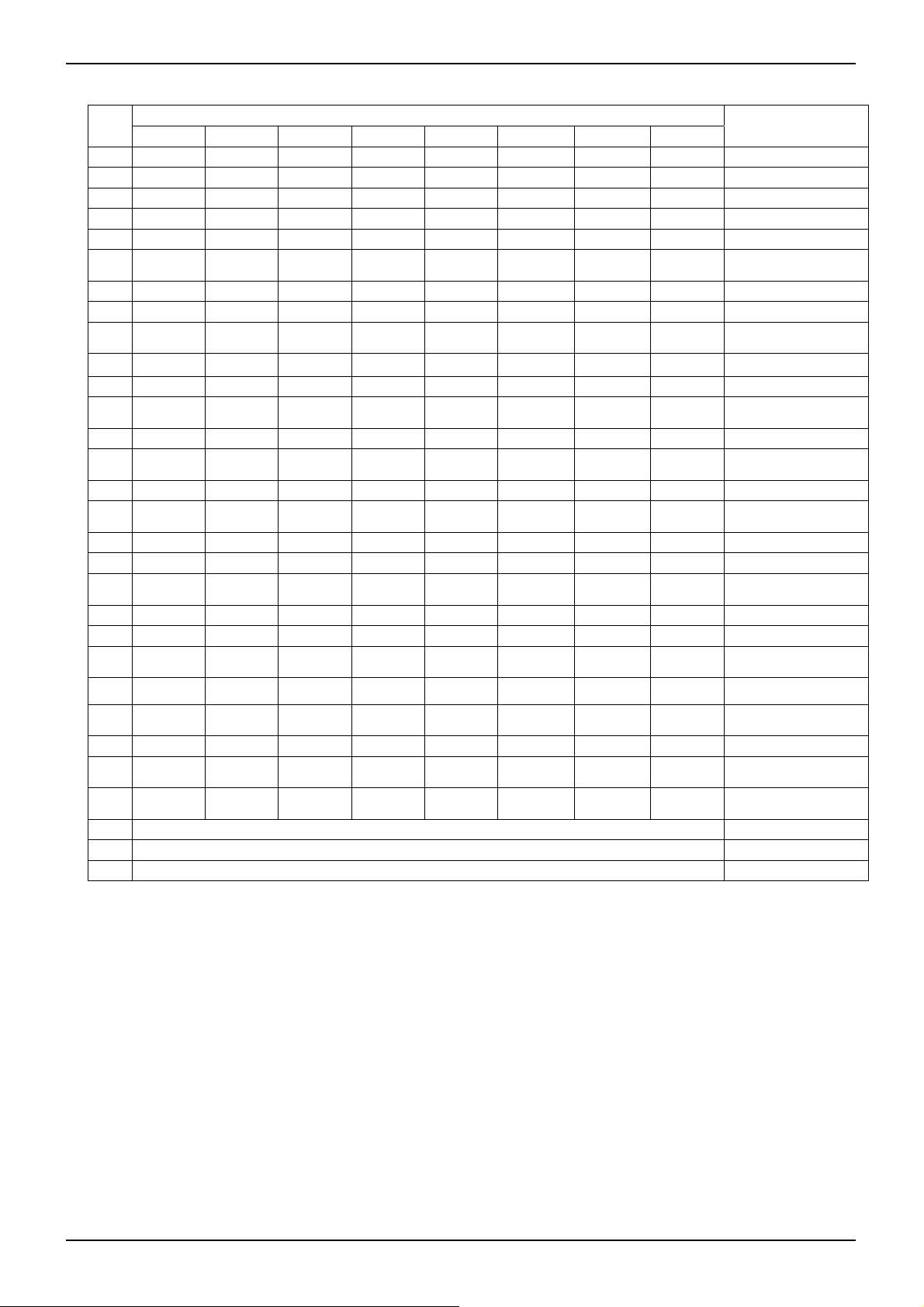

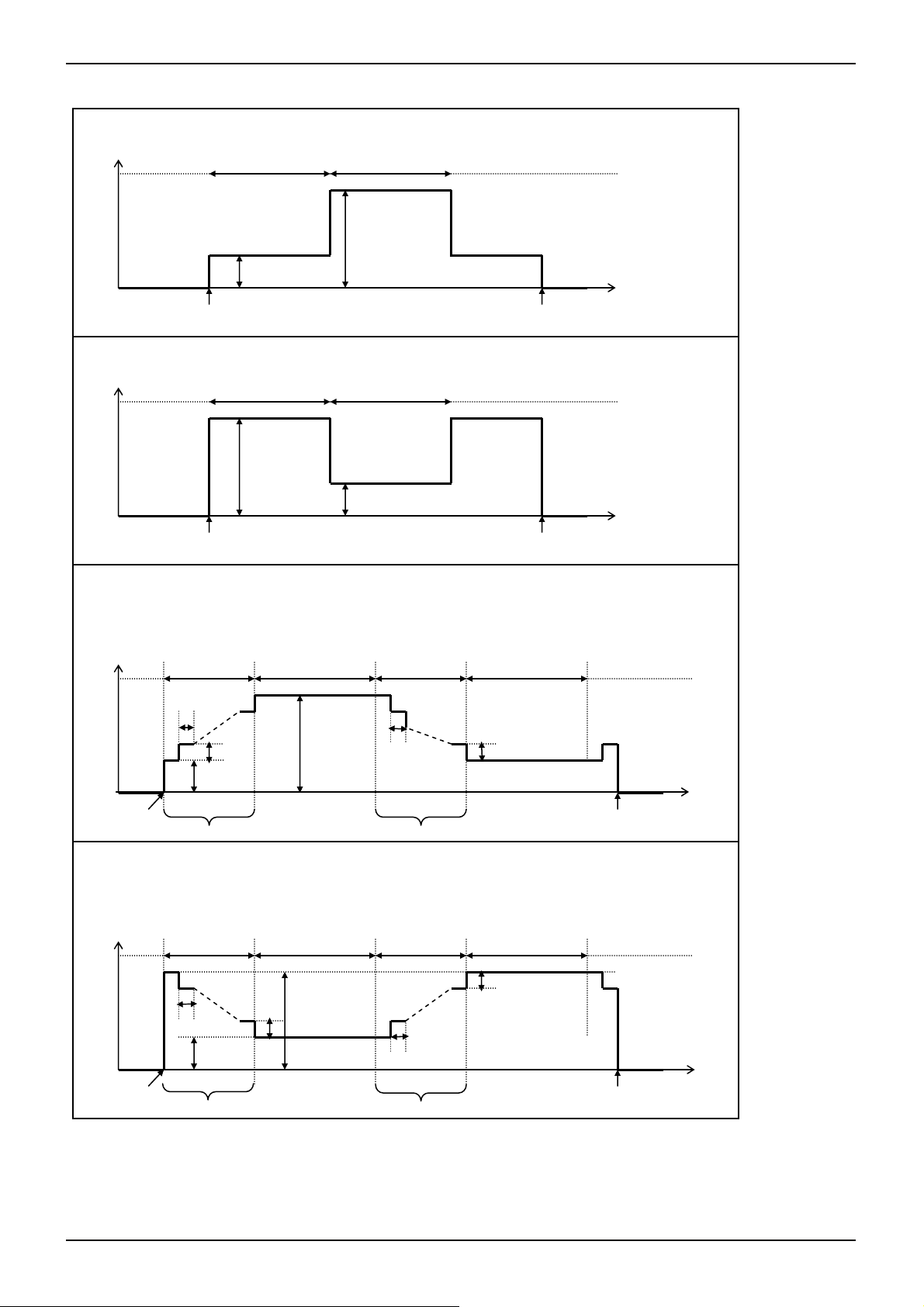

●RGB LED operating

1. Operating mode

RGB LED can set up the following operating mode by the setup of the register.

<Setup register>

I1**LED : (register) Initial electric current value [mA]

IDLT**LED : (register) The electric current value of around 1Step [mA]

RGB*SLNUM : (register) slope step number (1,2,4,8,16,32,64 Step)

RGB*SL1STEP : (register) The first half slope 1Step time [ms]

RGB*SL2STEP : (register) The latter half slope 1Step time [ms]

RGB*WT1TM : (register) The first half lighting time [ms]

RGB*WT2TM : (register) The latter half lighting time [ms]

As for the following setup, calculate it from the ab ove setup.

I2**LED : At the time of middle lighting current value [mA] = I1**LED + IDLT**LED x RGB*SLNUM

(In case of the value that a calculation exceeds maximum value, the current value is at the limit with maximum.)

RGB*SL1TM : The first half slope time [ms] = RGB*SL1STEP x RGB*SLNUM

RGB*SL2TM : The latter half slope time [ms] = RGB*SL2STEP x RGB*SLNUM

Each setup is necessary for DC current (at Normal mode or Blink mode).

(* : 1/ 2 channels is shown. ** : R1/G1/B1/R2 /G2/B2 is shown.)

Note) The current value in the table, it is value when 120k is connected to ISET pin.

Normal mode 1

31.5mA

0mA

RGB*STA=1 RGB*STA=0

I1**LED

Time

Normal mode 2

31.5mA

I2**LED

I2**LED is a calculation.

0mA

RGB*STA=1 RGB*STA=0

Time

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

25/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Blink mode 1

31.5mA

RGB*WT1TM RGB*WT2TM

0mA

I1**LED

RGB*STA=1

Blink mode 2

31.5mA

RGB*WT1TM RGB*WT2TM

I2**LED

0mA

RGB*STA=1

Slope mode 1

31.5mA

RGB*SL1STEP

0mA

IDL T**LED

I1**LED

RGB*STA=1

RGB*SLNUM Step

Slope mode 2

31.5mA

RGB*WT1TM RGB*SL2TM RGB*SL1TM RGB*WT2TM

0mA

RGB*STA=1

RGB*SL1STEP

I1**LED

RGB*SLNUM Step

RGB*WT1TM/RGB*WT2TM is repeated.

I2**LED

RGB*STA=0

I2**LED is a calculation.

RGB*WT1TM/RGB*WT2TM is repeated.

I1**LED

RGB*STA=0

I2**LED,RGB*SL1TM,RGB*SL2TM is a calculation.

Until it becomes RGB*STA=0, Slope control is repeated.

RGB*WT1TM RGB*SL2TM RGB*SL1TM RGB*WT2TM

I2**LED

RGB*SL2STEP

IDL T**LED

RGB*SLNUM Step

I2**LED,RGB*SL1TM,RGB*SL2TM is a calculation.

Until it becomes RGB*STA=0, Slope control is repeated.

IDL T**LED

I2**LED

IDL T**LED

RGB*SL2STEP

RGB*SLNUM Step

Technical Note

Time

Time

Time

RGB*STA=0

Time

RGB*STA=0

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

26/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

(A)

(B) (B) (C)

Technical Note

External pin control

31.5mA

RGB*WT1TM

RGB*WT2TM

0mA

I1**LED

I2**LED

RGB*STA=1 RGB*STA=0

Time

RGB*MEL

(register)

RGB*CNT

(External pin)

When RGB*MEL =0,

lighting

RGB*MEL=1 and RGB*CNT=H,

Lighting.

When RGB*MEL=0,

lighting

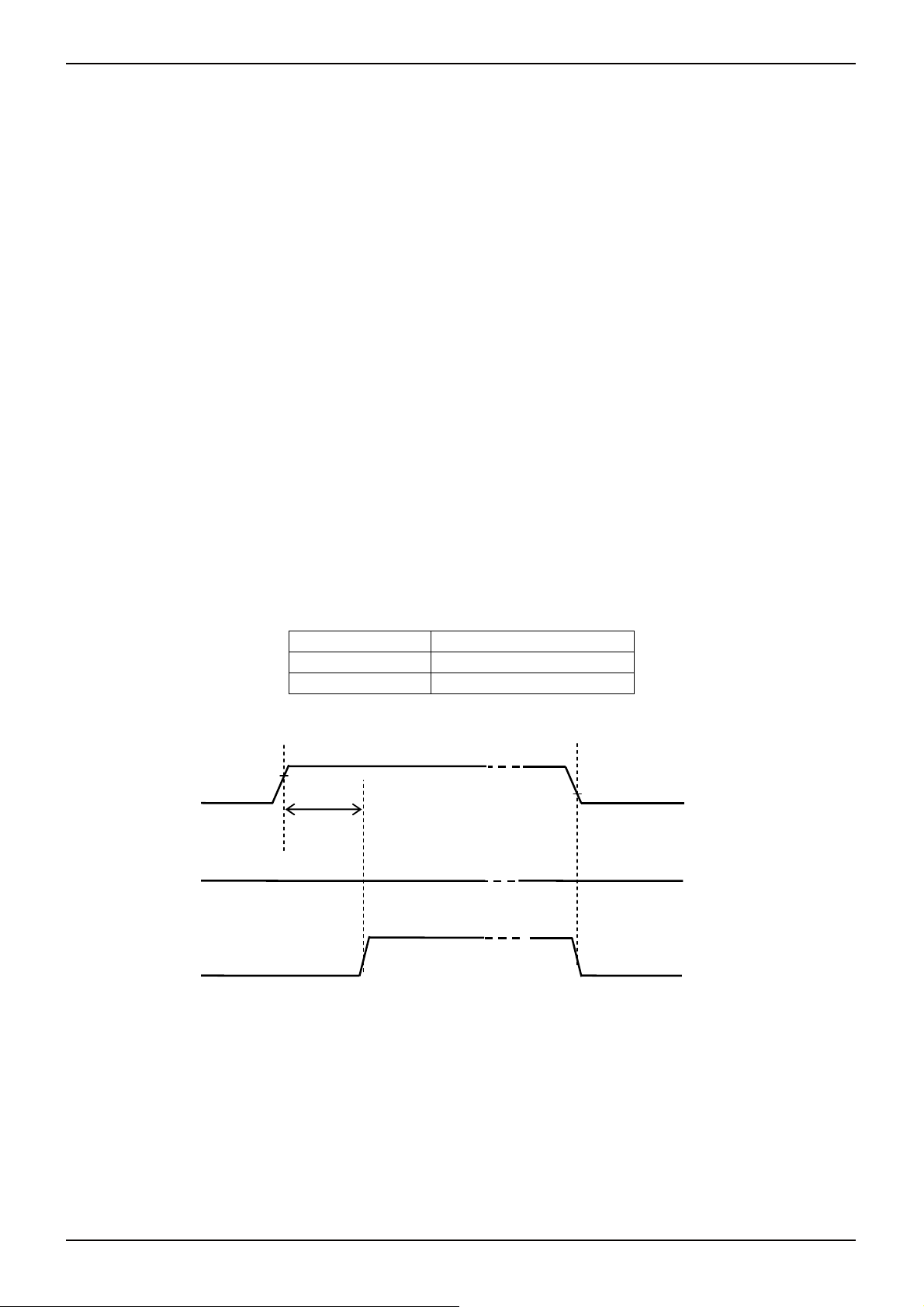

2. Slope control

The slope control that this LSI is equipped processes step ti me inside as follows.

It is made to have electric current by the log curve that is a simple target as to the slope.

RGB*STA

IDLT**LED

I1**LED

LED

current

T1

T2

T3

T4

T5

T7

T6

T8

(A)Section : It transits at the step time of two times when it was set up with RGB*SL1STEP

(B)Section : It transits at the step time when it was set up with RGB*SL1STEP.

(C)Section : It transits at the step time of a half times when it was set up with RGB*SL1STEP.

The time of the total (RGB*SL1TM) is calculated with RGB*SL1STEP x RGB*SLNUM.

A similar movement is done on the descent (RGB*SL2TM) side as well.

The acceptance of the setup of a register concerned with LED working during the slope movement stops.

But, a RGB*STA signal interrupts even during the slope movement, and it is possible that LED is turned off.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

27/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

●Explanation for operate

1. Reset

There are two kinds of reset, software reset and hardware reset.

(1) Software reset

・All the registers are initialized more than making a register (SFTRST) setup "1".

・The register of software resetting is an automatic return (Auto Return 0).

(2) Hardware reset

・It shifts to hardware reset by changing RESET pin “H” “L”.

・The condition of all the registers under hardware reset pi n is returned to the initial value,

and it stops accepting all address.

・It’s possible to release from a state of hardware reset by setting register “L” “H”.

・RESET pin has delay circuit. It doesn’t recognize as hardware reset in “L” period under 5s.

(3) Reset Sequence

・When hardware reset was done during software reset, software reset is canceled when

hardware reset is canceled. (Because the initial value of software reset is “0”)

2. Thermal shutdown

The blocks which thermal shutdown function is effective in the following.

Charge pump

LED Driver

REG1

REG2 is not shut down by thermal shutdown function, because REG2 can be used for I/O voltage.

A thermal shutdown function works in about 195

Detection temperature has a hysteresis, and detection rel ease temperature is about 175

(Design reference value)

℃.

Technical Note

℃.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

28/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

V

3. DC/DC

Start up

DC/DC circuit operates when either LED turns ON.

(But, when LED connection is set to DC/DC output (VOUT) only.)

DC/DC circuit has soft start function to prevent a rush current.

VBAT and VIO sequence is as follow.

BAT

VIO

RESET

EN (*)

VOUT

LED Current

(*) An EN signal means the following in the upper figure.

EN = “MLEDEN” or “SLEDEN” or “RGB1STA” or “RGB2STA”

(= LED The LED lighting control of a setup of connection VOUT)

But, as for VBAT < 2.2V (typ) or Ta > T

Mode transition

The transition of boosts multiple transits automatically by the VBAT voltage and the voltage of the LED electric current

inflow pin.

Condition:○

1

mode down=”H”

mode down=”H”

Over voltage protection / Over current protection

DC/DC circuit output (VOUT) is equipped with the over-voltage protection and the over current protection function.

A VOUT over-voltage detection voltage is about 6.0V.

A detection voltage has a hysteresis, and a detection release voltage is about 5.75V. (Design reference value)

And, when VOUT output short-circuits in GND, drain electric current is controlled by an over current protection function.

T

VBATON

T

VIOON=min 0.1ms

T

RSTB=min 0.1ms

T

(typ : 195° C), a protection function functions, and an EN signal doesn't become effective.

TSD

STANDBY

MLEDEN=”1” or SLEDEN =”1” or RGB *STA=”1”

(But, LED connection= It is limited to the LED lighting co ntrol of a setup of VOUT.)

1

○

VBAT>2.2V(typ) and Ta<T

SOFT

VOUT>1.5V(typ) After it is detected, 128us(typ) wait

X1.0

mode up=”H”

X1.5

mode up=”H”

X2.0 CP x2.0mode

T

VBATOFF

T

VIOOFF=min 1ms

T

RST=min 0ms

SOFT

ALL off

and

CP x1.0 mode

CP x1.0 mo de

CP x1.5mode

TSD

(VOUT at the time of rise in a voltage)

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

29/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

4. LED Driver

LED current value setting

LED maximum current value (White LED driver and RGB LED Driver common) can be established in the resistance

value RISET that it is connected to the ISET Pin.

A setting is shown in the following.

ILEDmax = 6.4 x 0.6 [V] / RISET [k] [A] (Typ) MLED1to4, SLED1to2

ILEDmax = 6.3 x 0.6 [V] / RISET [k] [A] (Typ) All RGB LED

The maximum setting of LED current is 32mA (MLED and SLED), 31.5mA (RGB) on the D range of the internal circuit.

LED current overload protection

ISET Pin is mount with the GND short detection function. LED current value prevents excessive LE D current from

flowing when ISET Pin becomes low impedance because it is shown with a formula of the former extension.

White LED Driver

The number of lighting of white LED can be set up by the register MLEDSEL and SLEDSEL (address02h).

The settlement of the number of lighting can be setup with follow.

Main LCD Back light

Sub LCD Back light

・・・3 Light (MLED1 ~ 3) or 4 Light (MLED1 ~ 4)

・・・1 Light (SLED1) or 2 Light (SLED1 ~ 2)

Connect the LED pin that isn't used to the ground.

RGB LED Driver

By register B*LEDMD and G*LEDMD (address05h), a place of connection of Green LED and Blue LED It can be set up

in VBAT or VOUT. When Vf is low, it is connected to VBAT, and it is possible that efficiency is raised.

When a VBAT connection is chosen, a feedback route to the DC/DC circuit is interrupted, and it works as a simple

constant current driver.

A write protect is given in the following address when "1" is written in the RGB*STA register.

Register A protected address

RGB1STA 06h ~ 0Fh

RGB2STA 10h ~ 19h

VBAT connection a start in the setup Sequence

RGB*STA

T

on

(Max:6ms)

VOUT

LED current

When the connection of LED is VBAT, only a LED driver turns it on, and a DC/DC circuit is turned off.

The LED pin which isn't used is to short to the ground.

But, the setup of a register concerned with LED that isn’t used is prohibited.

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

30/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

Technical Note

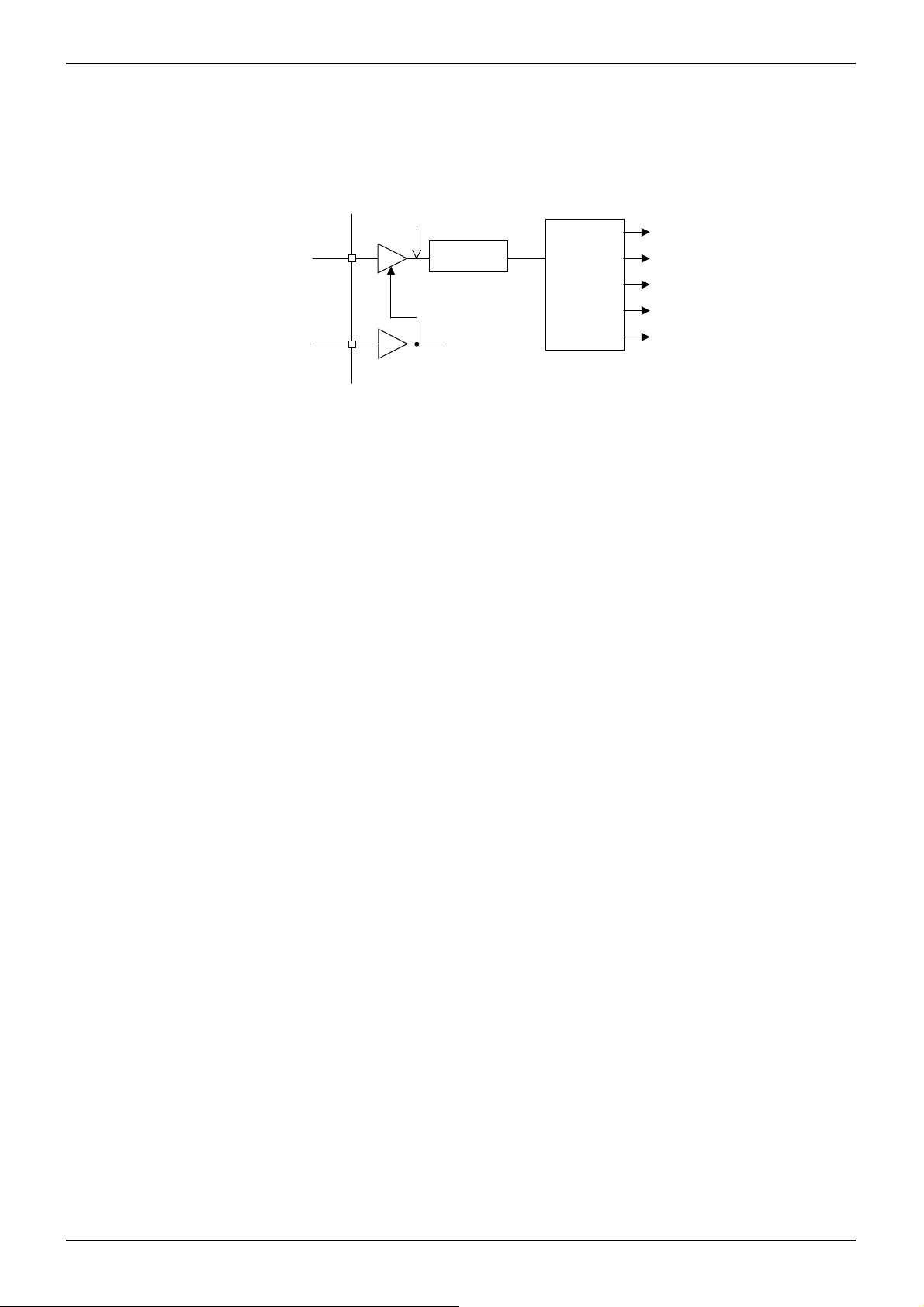

5. I/O

CPU interface control input is possible low voltage interface. Interface peripheral block diagram is as follows.

VIO voltage or interface voltage is possible the setting range of 1.65~3.3V. (But, VBAT voltage VIO voltage)

Also, I/O of with enable is being used for SCL, SDA input as a prevention of clock propagation to the inside when other LSI

shared the SCL, SDA line.

RESET=L, Output "H"

SCL

(SDA)

RESET

EN

Level shift

Logic

An equivalent circuit around the part I/O becomes p.8. By rising turn of the I/O power supply and the input level be careful

enough because an electric current route may occur through the protection Diode of the pin.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

31/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

A

6. About the start of REG2 (the voltage for I/O)

It must start as follows when REG2 output is used as VIO voltage.

VBAT (force)

RESET

(external pin control)

REG2EN

(external pin control)

REG2MD

(external pin control)

REG2O(output)

(=VIO voltage)

Min:7.5ms (*2)

Min:0ms (*4)

Technical Note

Low current

Stand By

(*1) This sequence is when REG2O is used as an I/O voltage.

(*2) When the low consumption mode is unnecessary, REG2EN=REG2MD (simultaneous control) is possible.

(*3) REG2 should go for a release of RESET at the time of the normal mode.

(*4) REG2EN= Though "L" and RESET= "L" don't care even about the simultaneous timing,

It is prohibition to take REG2EN= "L" in front of RESET= "L".

consumption mode

Min:2ms(*2)

Take the specifications of the outside power supply into consideration when the I/O voltage is applied from outside.

But, at that case as well, REG2 rising time in the normal mode Take a (Min : 2ms) into consideration.

Normal mode

Register access is possible (*3)

Stand By

It must start as follows when external power supply is used as VIO voltage.

VBAT(force)

VIO(force)

RESET(external pin control)

Register control

Impossible

VIO should go for a release of RESET after the time of the rising mode.

nd it is forbid to fall VIO before RESET=”L”.

Possible

Impossible

7. About the pin management of the function that isn't used and test pins

Please connect the pin that isn ’t used and test pin referred to equivalent circuit (P.8).

TESTI1, TESTI2 Short to GND (Must) because input pin for test

TESTO1, TESTO2 Be OPEN because out put for test

T1~T4 Short to GND (Must) because input pin for test

Non-used LED Pin Short to GND

But, the setup of a register concerned with LED that isn’t used is prohibited.

REG2EN, REG2MD, RGB1CNT, RGB2CNT Pull-Down resistance is built in.

Short to GND

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

32/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

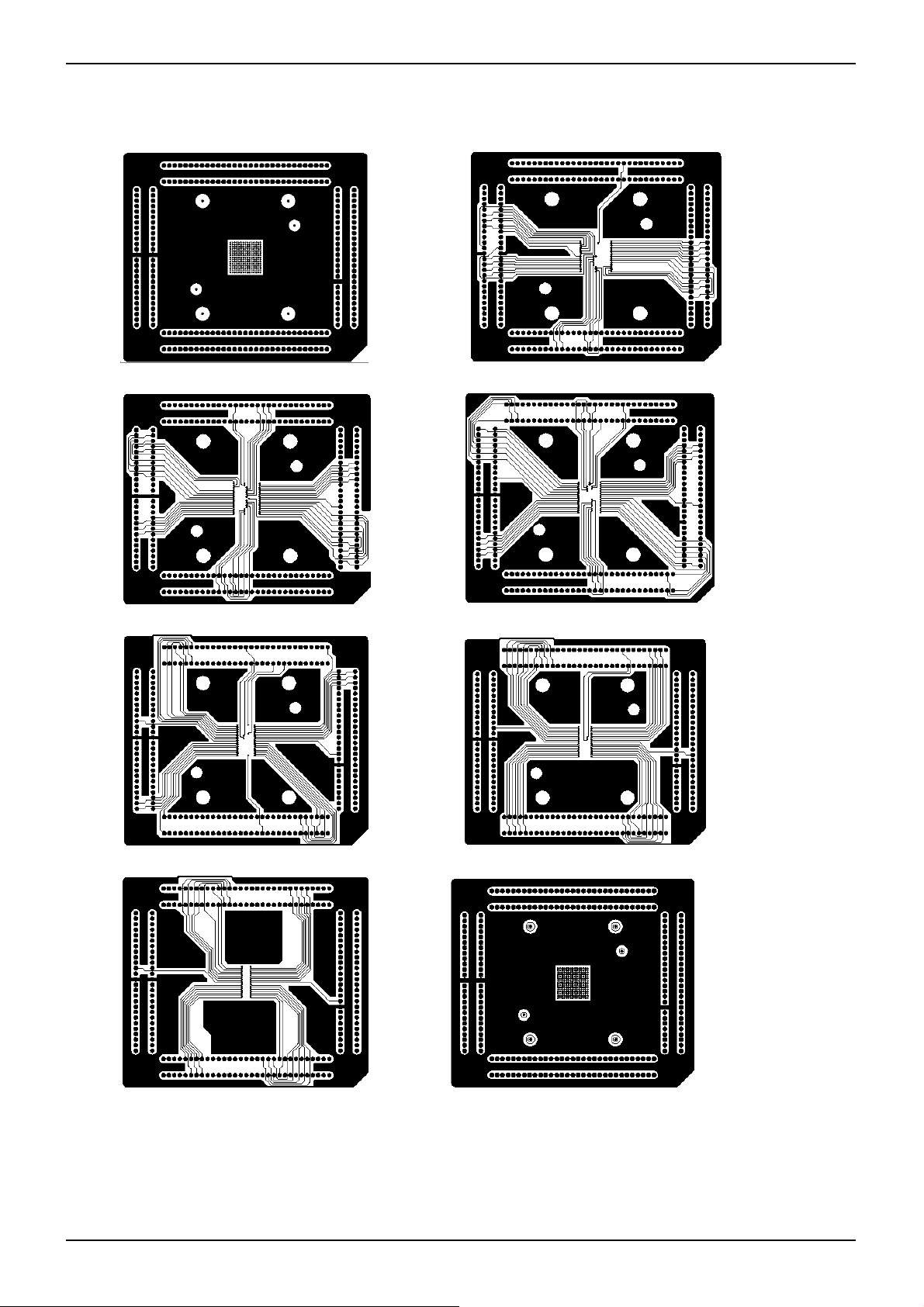

10. BD6081GU PCB pattern of the Power dissipation measuring board

Technical Note

1

st

layer(component) 2nd layer

3

rd

laye r 4th layer

5

th

layer 6th layer

th

layer 8th layer(solder)

7

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

33/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

●Notes for use

(1) Absolute Maximum Ratings

An excess in the absolute maximum ratings, such as supply voltage, temperature range of operating conditions, etc., can

break down devices, thus making impossible to identif y breaking mode such as a short circuit or an open circuit. If any

special mode exceeding the absolute maximum ratings is a ssumed, consideration should be given to take physical safety

measures including the use of fuses, etc.

(2) Power supply and ground line

Design PCB pattern to provide low impedance for the wiring between the power supply and the ground lines. Pay attention

to the interference by common impedance of layout pattern when there are plural power supplies and ground lines.

Especially, when there are ground pattern for small signal and ground pattern for large current included the external

circuits, please separate each ground pattern. Furthermore, for all power supply pins to ICs, mount a capacitor between

the power supply and the ground pin. At the same time, in order to use a capacitor, thoroughly check to be sure the

characteristics of the capacitor to be used present no problem includin g the occurrence of capacity dropout at a low

temperature, thus determining the constant.

(3) Ground voltage

Make setting of the potential of the ground pin so that it will be maintained at the minimum in any operating state.

Furthermore, check to be sure no pins are at a potential lo wer than the ground voltage including an actual electric

transient.

(4) Short circuit between pins and erroneous mounting

In order to mount ICs on a set PCB, pay thorough attention to the direction and offset of the ICs. Erroneous mounting can

break down the ICs. Furthermore, if a short circuit occurs due to foreign matters entering between pins or between the pin

and the power supply or the ground pin, the ICs can break down.

Technical Note

(5) Operation in strong electromagnetic field

Be noted that using ICs in the strong electromagnetic field can malfunction them.

(6) Input pins

In terms of the construction of IC, parasitic elements are inevitably formed in relation to potential. The operation of the

parasitic element can cause interference with circuit operation, thus resulting in a malfunction and then breakdown of the

input pin. Therefore, pay thorough attention not to handle the input pins, such as to apply to the input pins a voltage lower

than the ground respectively, so that any parasitic element will operate. Furthermore, do not apply a voltage to the input

pins when no power supply voltage is applied to the IC. In addition, even if the power supply voltage is applied, apply to

the input pins a voltage lower than the power supply voltage or within the guarante ed value of electrical characteristics.

(7) External capacitor

In order to use a ceramic capacitor as the external capacitor, determine the constant with consideration given to a

degradation in the nominal capacitance due to DC bias and changes in the capacitance due to temperature, etc.

(8) Thermal shutdown circuit (TSD)

This LSI builds in a thermal shutdown (TSD) circuit. When junction temperatures become detection temperature or higher,

the thermal shutdown circuit operates and turns a switch OFF. The thermal shutdown circuit, which is aimed at isolating

the LSI from thermal runaway as much as possible, is not aimed at the protection or guarantee of the LSI. Therefore, do

not continuously use the LSI with this circuit operat ing or use the LSI assuming its operation.

(9) Thermal design

Perform thermal design in which there are adequate margins by taking into account the permissible dissipation (Pd) in

actual states of use.

(10) LDO

Use each output of LDO by the independence. Don’t use under the condition that each output is short-circuited because it

has the possibility that an operation becomes unstable.

(11) About the pin for the test, the un-use pin

Prevent a problem from being in the pin for the test and the un-use pin under the state of actual use. Please refer to a

function manual and an application noteboo k . And, as for the pin that doesn't specially have an explanation, ask our

company person in charge.

(12) About the function description or application note or more.

The function manual and the application notebook are the design materials to design a set. So, the cont ents of t he

materials aren't always guaranteed. Please design application by having fully examinati on and evaluation include the

external elements.

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

34/35

2011.04 - Rev.

A

BD6081GU,BD6081GVW

●Ordering part number

B D 6 0 8 1 G U - E 2

Part No. Part No.

6081

VCSP85H3

(BD6081GU)

1PIN MARK

0.08

A

56 7

3.90± 0.1

1.0MAX

0.25±0.1

S

S

0.45±0.1

B

P=0.5× 6

(Unit : mm)

3.90±0.1

48-φ0.30±0.05

0.05

(φ0.15)INDEX POST

0.45±0.1

BA

G

F

E

D

C

B

A

1234

P=0.5× 6

SBGA063W060

1PIN MARK

6.0±0.1

0.1 S

P=0.65×7

63-φ0.33± 0.05

M

φ

0.08

0.65

ABS

H

G

F

E

D

C

B

A

6.0± 0.1

S

0.08

0.9MAX

0.725±0.1

A

B

0.65

51

3

762

4

P=0.65×7

8

0.725±0.1

(Unit : mm)

Package

GU : VCSP85H3

GVW : SBGA063W060

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

<Tape and Reel information>

Quantity

Direction

of feed

2500pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Embossed carrier tape (with dry pack)Tape

2000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

1pin

Packaging and forming specification

E2: Embossed tape and reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

Direction of feed

Technical Note

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

35/35

2011.04 - Rev.

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injur y (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any

of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Notice

www.rohm.com

© 2011 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R1120

A

Loading...

Loading...