Charge Protection IC Series with Built-in FET

Negative Voltage

Protection type

BD6046GUL

●Descriptions

BD6046GUL protects the devices from the abnormal input voltage at the USB port.

Addition to the conventinal charge protection IC, it prevents the negative voltage happened by the USB reverse

insertion without any additional compornents.

ROHM's original charge protection IC series enables to protect the abnormal input voltage from -30V to +30V.

●Features

1) Overvoltage Protection up to 28V

2) Negative Voltage Protection

3) Internal Low Ron (250mΩ) FET

4) Over voltage Lockout (OVLO)

5) Under voltage Lockout(UVLO)

6) Internal 2.5msec Startup Delay

7) Over Current Protect

8) Thermal Shut Down

9) Small package: VCSP50L2(2.5mm x 2.5mm, height=0.55mm)

●Applications

Mobile phones, MP3 players, Digital Still Camera, PDA, IC recorder, Electronic Dictionary, Handheld Game, Game

Controller, Camcorder, Bluetooth Headsets, etc

●Absolute maximum ratings (Ta=25℃)

No.09031EAT02

Parameter Symbol Rating Unit Conditions

Input supply voltage 1 Vmax1 -30~30 V IN

Input supply voltage 2 Vmax2 -0.3~7 V other

Power dissipation Pd 975 mW

Operating temperature range Topr -40~+85 ℃

Storage temperature range Tstr -55~+150 ℃

※ When using more than at Ta=25℃, it is reduced 7.8mW per 1℃.(ROHM specification board 50mm× 58mm mounting.)

●Recommended operating range (Ta=-40~+85℃)

Parameter Symbol Range Unit Usage

Input voltage range

※ This product is not especially designed to be protected from radioactivity.

Vin 2.2~28 V

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

1/7

2009.05 - Rev.A

BD6046GUL

Technical Note

●Electrical Characteristics

(Unless otherwise noted, Ta = 25C, IN=5V)

Parameter Symbol

Min. Typ. Max.

Rating

Unit Conditions

○Electrical

Input Voltage Range VIN - - 28 V

Supply Quiescent Current ICC 35 70 μA

Under Voltage Lockout UVLO 3.42 3.6 3.78 V IN=decreasing

Under Voltage Lockout Hysteresis UVLOh 50 100 150 mV IN=increasing

Over Voltage Lockout OVLO 6.5 6.7 6.9 V IN=increasing

Over Voltage Lockout Hysteresis OVLOh 50 100 150 mV IN=decreasing

Current limit ILM 1.2 - - A

Vin vs. Vout Res. RON - 250 300 mΩ

FLGB Output Low Voltage FLGBVO - - 400 mV SINK=1mA

FLGB Leakage Current FLGBleak - - 1 μA

○Timings (Flgb pull up resistance 100kΩ)

Start Up Delay Ton - 2.5 5 msec

Output Turn Off Time Toff - 2 10 μsec

Alert Delay Tovp - 1.5 10 μsec

* This product is not especially designed to be protected from radioactivity.

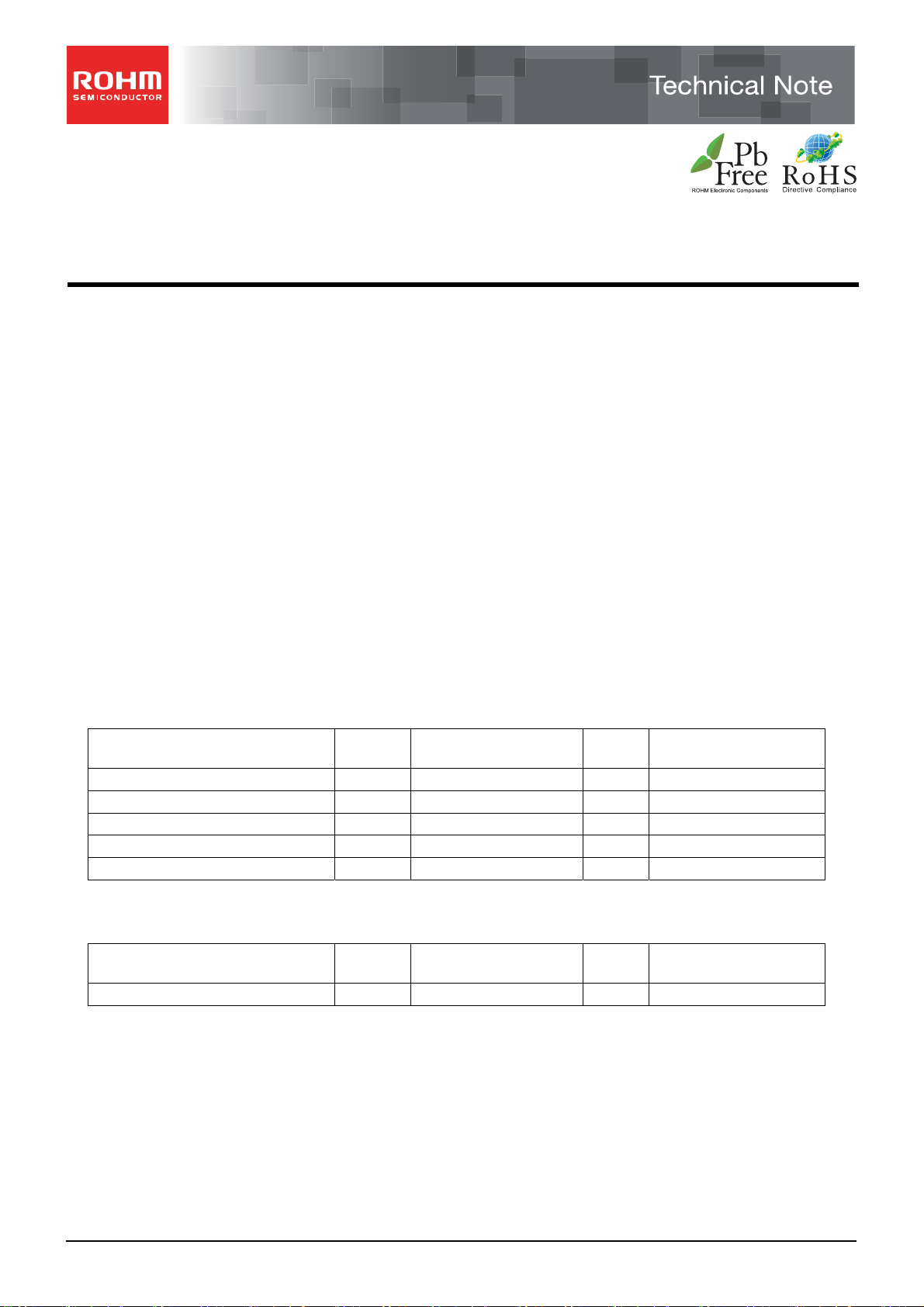

●Block Diagram

Travel

Adapter

IN

IN

IN

IN IN IN IN

OUT

OUT

OUT

CHARGER

OUT

FLGB

●PIN number / PIN name

A3, A4,B3, B4,C4, D3,D4 IN

NVP

GND

Gate

Driver

Initial

Delay

VREF

UVLO

OVLO

OCP

TSD

OSC

Initial

Delay

Timing

Generator

Fig. 1 Block Diagram

Pin number Pin name

A1, B1,C1, D1 OUT

D2 GND

A2 FLGB

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

2/7

2009.05 - Rev.A

BD6046GUL

A

A

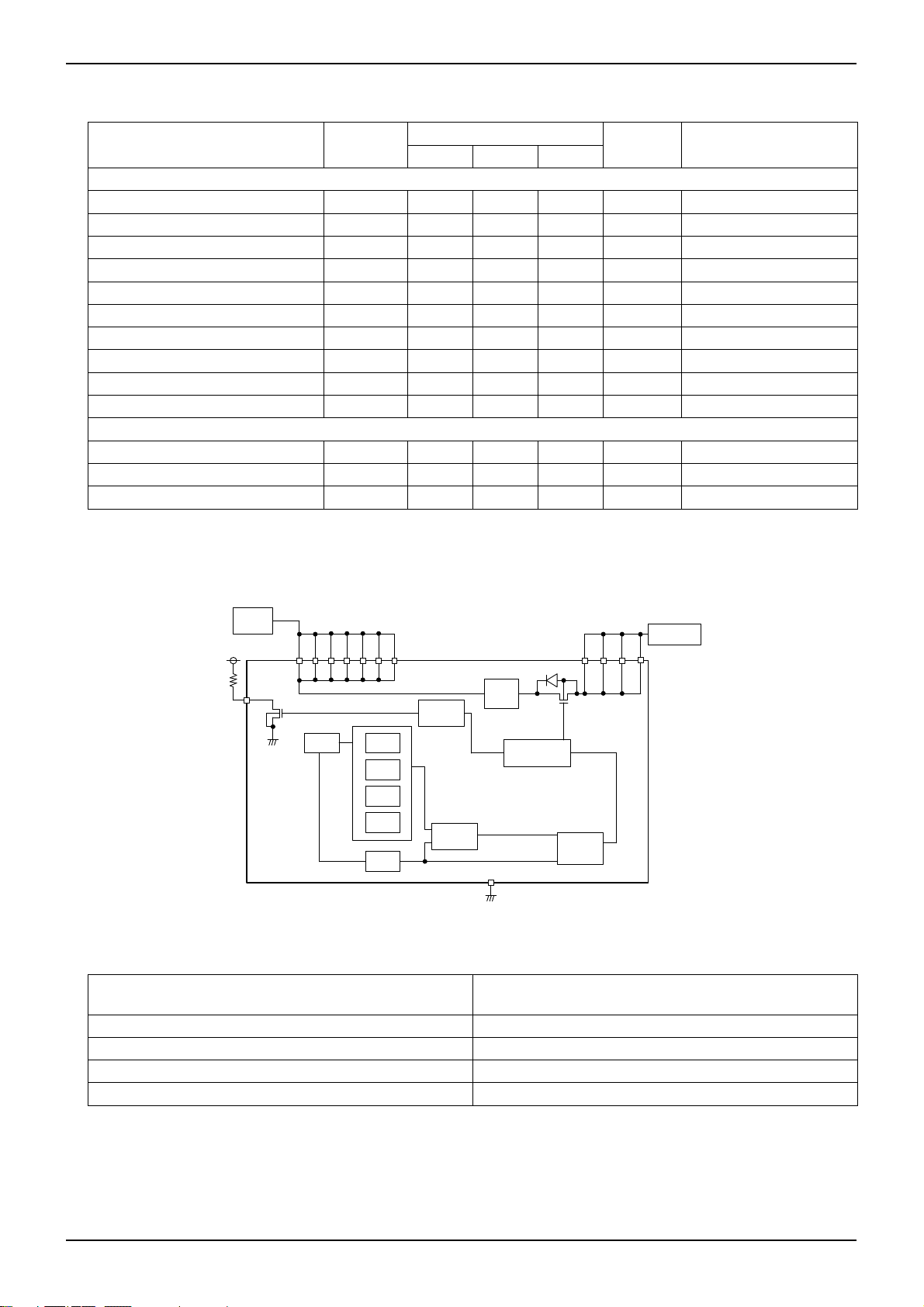

● Package Dimensions

●Ball Configuration

●PIN DESCRIPTIONS

OUT

OUT

B

C

OUT

OUT

D

1 2 3

BD6046

Top View

FLGB

index

GND

IN

IN

IN

Lot No.

Fig. 2 Package Dimensions (VCSP50L2)

Bottom View

IN

IN

IN

IN

4

Fig. 3 Ball Configuration

D

OUT

C

OUT

B

OUT

OUT

123

GND

index

FLGB

IN

IN

IN

Technical Note

IN

IN

IN

IN

4

PIN NAME FUNCTION

A3, A4, B3, B4, C4, D3, D4 IN

A1, B1, C1, D1 OUT Output Voltage Pin

A2 FLGB

D2 GND Ground Pin

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

Input voltage Pin. A 1・F low ESR capacitor,

or larger must be connected between this pin and GND

Open-drain output pin that turns low when any protection event occurs.

(overvoltage protection, thermal shut down)

3/7

2009.05 - Rev.A

BD6046GUL

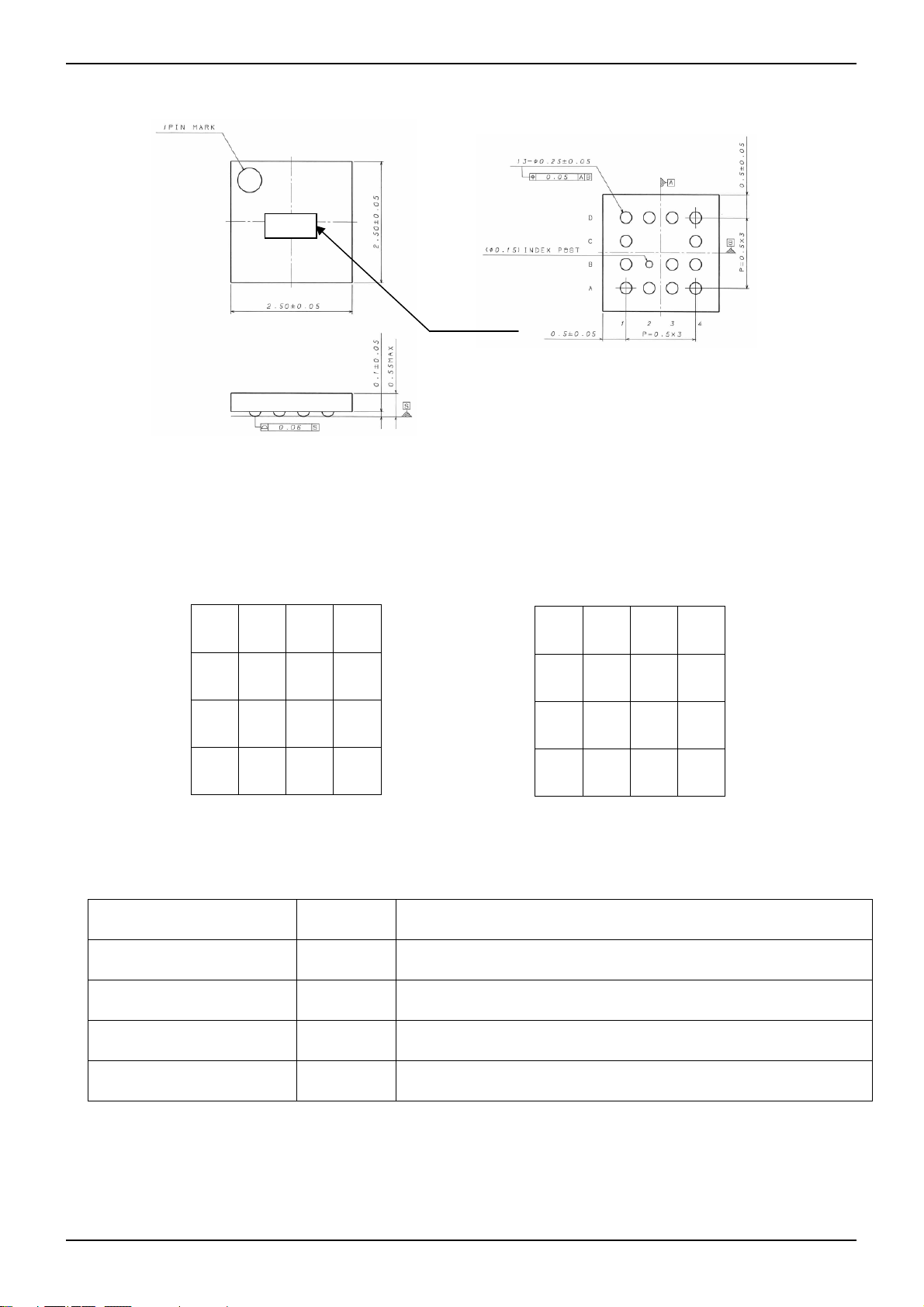

●Typical Application Circuit

Technical Note

OVP

CPU

FLGB

GND

PMIC

28V-OVP

OUT

CHGIN

IN

Charger

BATT

Fig. 4 Application Circuit

・Safety is high because it detects, and it protects it for an abnormal voltage up to 28V.

・It contributes to the miniaturization because all external is built into.

Cin

1.0uF

Travel

Adapter

Cout

4.7uF

Li-ion

1cell

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

4/7

2009.05 - Rev.A

BD6046GUL

c

●Timing Diagram

Technical Note

OVLO

IN

OUT

FLGB

OUT

FLGB

Fig. 5 Start up sequence

IN

2.0μ sec

(Toff)

1.5μ se

(Tovp)

Fig. 6 Shutdown by over voltage detection

15V

UVLO

2.5msec

(Ton)

OVLO

UVLO

IN

OUT

FLGB

5V

2.5msec

1μ sec

Fig. 7 Recovery from overvoltage protection

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

5/7

2009.05 - Rev.A

BD6046GUL

●Notes foer use

(1) Absolute maximum ratings

If applied voltage (VDD, VIN), operating temperature range (Topr), or other absolute maximum ratings are exceeded, there

is a risk of damage. Since it is not possible to identify short, open, or other damage modes, if special modes in which

absolute maximum ratings are exceeded are assumed, consider applying fuses or other physical safety measures.

(2) Recommended operating range

This is the range within which it is possible to obtain roughly the expected characteristics. For electrical characteristics, it

is those that are guaranteed under the conditions for each parameter. Even when these are within the recommended

operating range, voltage and temperature characteristics are indicated.

(3) Reverse connection of power supply connector

There is a risk of damaging the LSI by reverse connection of the power supply connector. For protection from reverse

connection, take measures such as externally placing a diode between the power supply and the power supply pin of the LSI.

(4) Power supply lines

In the design of the board pattern, make power supply and GND line wiring low impedance.

When doing so, although the digital power supply and analog power supply are the same potential, separate the digital

power supply pattern and analog power supply pattern to deter digital noise from entering the analog power supply due to

the common impedance of the wiring patterns. Similarly take pattern design into account for GND lines as well.

Furthermore, for all power supply pins of the LSI, in conjunction with inserting capacitors between power supply and GND

pins, when using electrolytic capacitors, determine constants upon adequately confirming that capacitance loss occurring

at low temperatures is not a problem for various characteristics of the capacitors used.

(5) GND voltage

Make the potential of a GND pin such that it will be the lowest potential even if operating below that. In addition, confirm

that there are no pins for which the potential becomes less than a GND by actually including transition phenomena.

(6) Shorts between pins and misinstallation

When installing in the set board, pay adequate attention to orientation and placement discrepancies of the LSI. If it is

installed erroneously, there is a risk of LSI damage. There also is a risk of damage if it is shorted by a foreign substance

getting between pins or between a pin and a power supply or GND.

(7) Operation in strong magnetic fields

Be careful when using the LSI in a strong magnetic field, since it may malfunction.

(8) nspection in set board

When inspecting the LSI in the set board, since there is a risk of stress to the LSI when capacitors are connected to low

impedance LSI pins, be sure to discharge for each process. Moreover, when getting it on and off of a jig in the inspection

process, always connect it after turning off the power supply, perform the inspection, and remove it after turning off the

power supply. Furthermore, as countermeasures against static electricity, use grounding in the assembly process and

take appropriate care in transport and storage.

(9) Input pins

Parasitic elements inevitably are formed on an LSI structure due to potential relationships. Because parasitic elements

operate, they give rise to interference with circuit operation and may be the cause of malfunctions as well as damage.

Accordingly, take care not to apply a lower voltage than GND to an input pin or use the LSI in other ways such that

parasitic elements operate. Moreover, do not apply a voltage to an input pin when the power supply voltage is not being

applied to the LSI. Furthermore, when the power supply voltage is being applied, make each input pin a voltage less than

the power supply voltage as well as within the guaranteed values of electrical characteristics.

(10) Ground wiring pattern

When there is a small signal GND and a large current GND, it is recommended that you separate the large current GND

pattern and small signal GND pattern and provide single point grounding at the reference point of the set so that voltage

variation due to resistance components of the pattern wiring and large currents do not cause the small signal GND voltage

to change. Take care that the GND wiring pattern of externally attached components also does not change.

(11) Externally attached capacitors

When using ceramic capacitors for externally attached capacitors, determine constants upon taking into account a

lowering of the rated capacitance due to DC bias and capacitance change due to factors such as temperature.

(12) Thermal shutdown circuit (TSD)

When the junction temperature reaches the defined value, the thermal shutdown circuit operates and turns a switch OFF.

The thermal shutdown circuit, which is aimed at isolating the LSI from thermal runaway as much as possible, is not aimed

at the protection or guarantee of the LSI.

LSI assuming its operation.

(13) Thermal design

Perform thermal design in which there are adequate margins by taking into account the permissible dissipation (Pd) in

actual states of use.

Therefore, do not continuously use the LSI with this circuit operating or use the

Technical Note

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

6/7

2009.05 - Rev.A

BD6046GUL

●Ordering part number

B D 6 0 4 6 G U L - E 2

Part No. Part No.

VCSP50L2

1PIN MARK

2.50±0.05

BD6046

(BD6046GUL)

13-φ0.25±0.05

0.05

(φ0.15)INDEX POST

2.50±0.05

0.5±0.05

0.1±0.05

0.06 S

BA

0.55MAX

S

A

D

C

B

A

3

2

1

P=0.5×3

0.5±0.05

B

P=0.5×3

4

(Unit : mm)

Package

GUL : VCSP50L2

<Tape and Reel information>

Embossed carrier tapeTape

Quantity

Direction

of feed

3000pcs

E2

The direction is the 1pin of product is at the upper left when you hold

()

reel on the left hand and you pull out the tape on the right hand

Reel

Technical Note

Packaging and forming specification

E2: Embossed tape and reel

1pin

Order quantity needs to be multiple of the minimum quantity.

∗

Direction of feed

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

7/7

2009.05 - Rev.A

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specied herein is subject to change for improvement without notice.

The content specied herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specied in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specied herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other par ties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

Notice

The Products specied in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, ofce-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specied in this document are not designed to be radiation tolerant.

While ROHM always makes ef forts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, re or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, re control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injur y (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specied herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

www.rohm.com

© 2009 ROHM Co., Ltd. All rights reserved.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

R0039

A

Loading...

Loading...